Bladeless fan

A bladeless fan and base technology, applied in non-variable pumps, pump devices, machines/engines, etc., can solve problems such as uneven wind, high blade speed, difficult cleaning of blades and outer covers, and achieve remarkable results. The effect of large air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

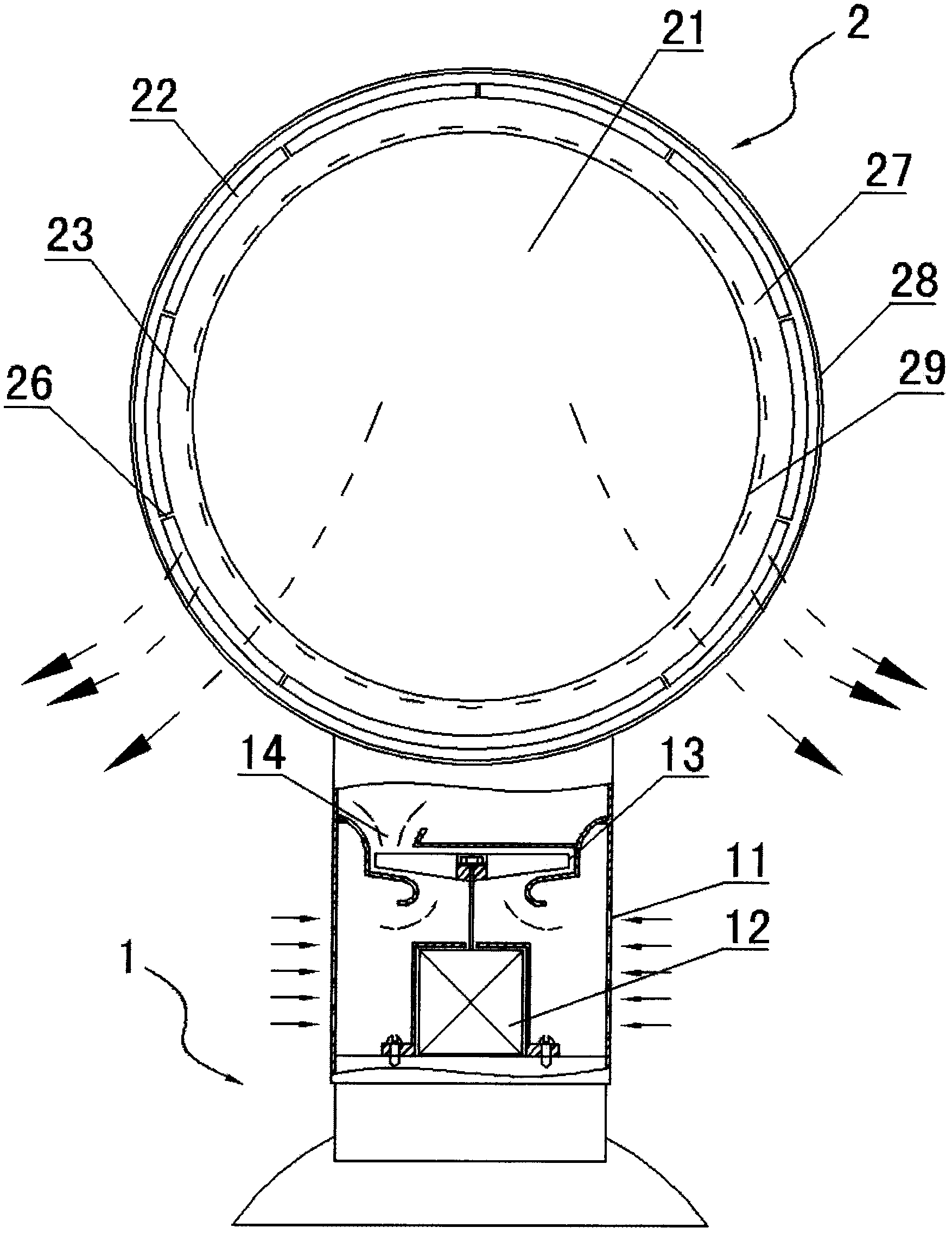

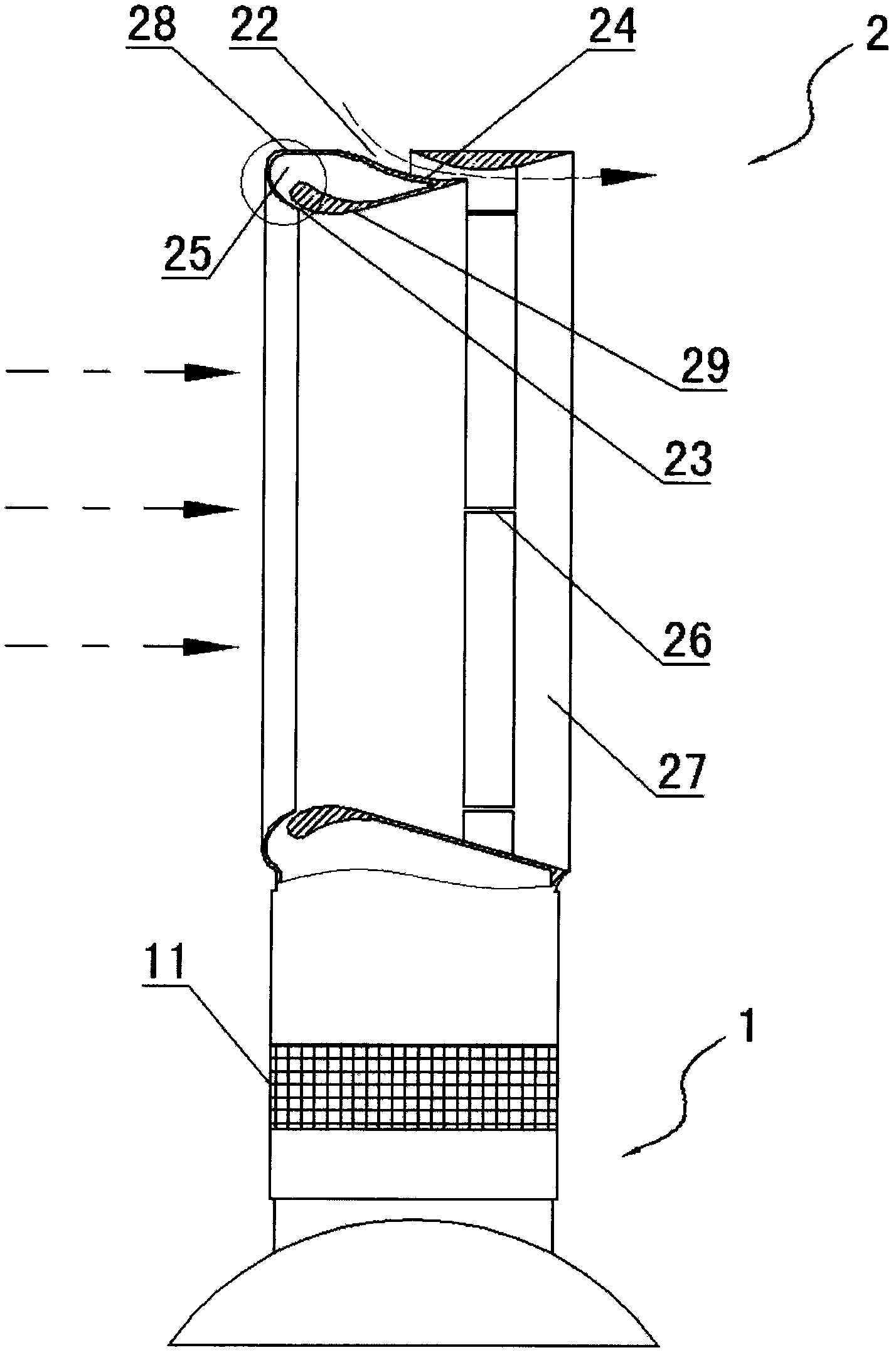

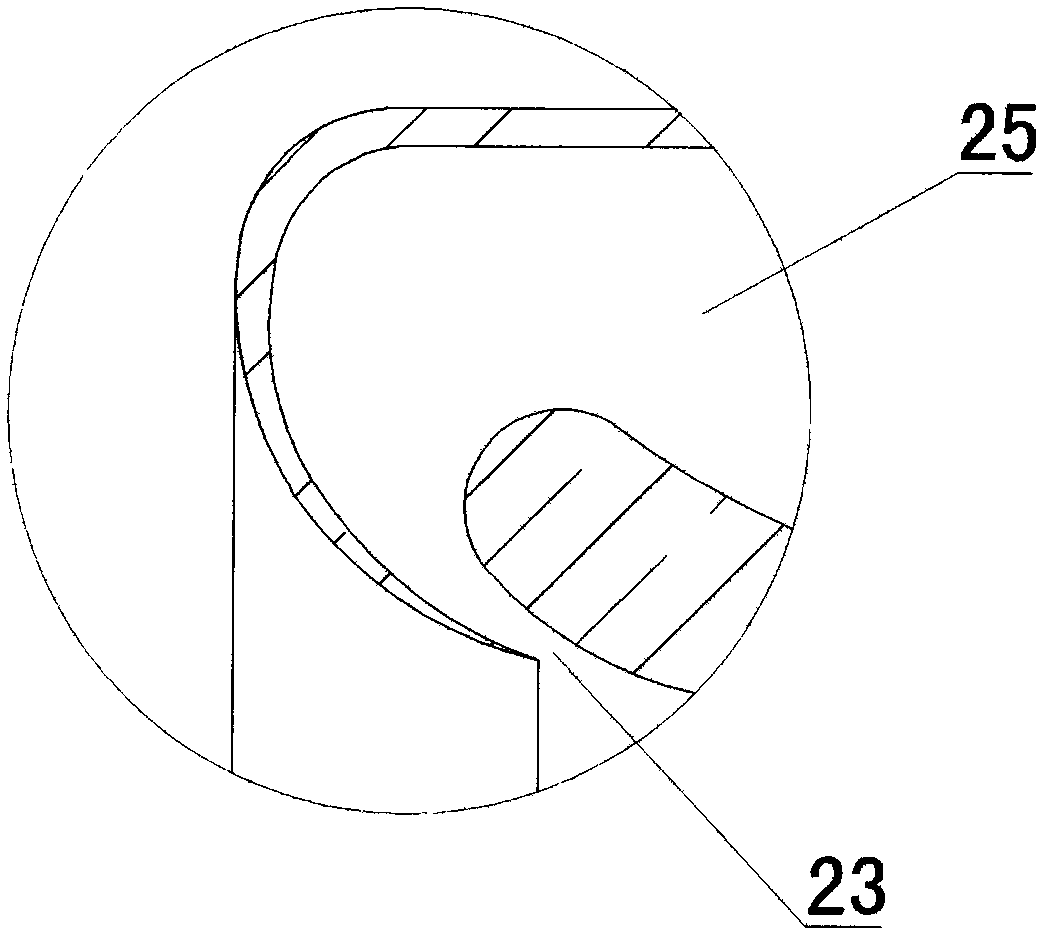

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the bladeless fan is composed of a base 1 and an airflow injection device 2 positioned above the base 1. An air inlet 11 is provided on the shell of the base 1. A motor 12 is arranged inside the base 1. The motor 12 Drive the rotating impeller 13, the air channel 14, the air flow injection device 2 is a hollow ring structure, the hollow part is the first air flow channel 21, and the air flow injection device 2 is provided with an annular second air flow channel 22 and an annular The exhaust port 23. The impeller 13 is arranged in the casing of the base 1 to help inhale and pressurize the air, and then blow the air into the air jet device 2 . The air jet device 2 is a hollow annular structure, and may also be square or elliptical, such as Figure 5 As shown, as long as the axis is symmetrical.

[0023] The air inlet of the second air flow channel 22 is located on the outer wall of the air jetting devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com