Underwater cleaner

A technology of cleaners and passages, applied in ship cleaning devices, ship construction, ships, etc., can solve the problems of vortex, high fluid loss, invisible filling degree, etc., and achieve the effect of high flow rate and high suction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

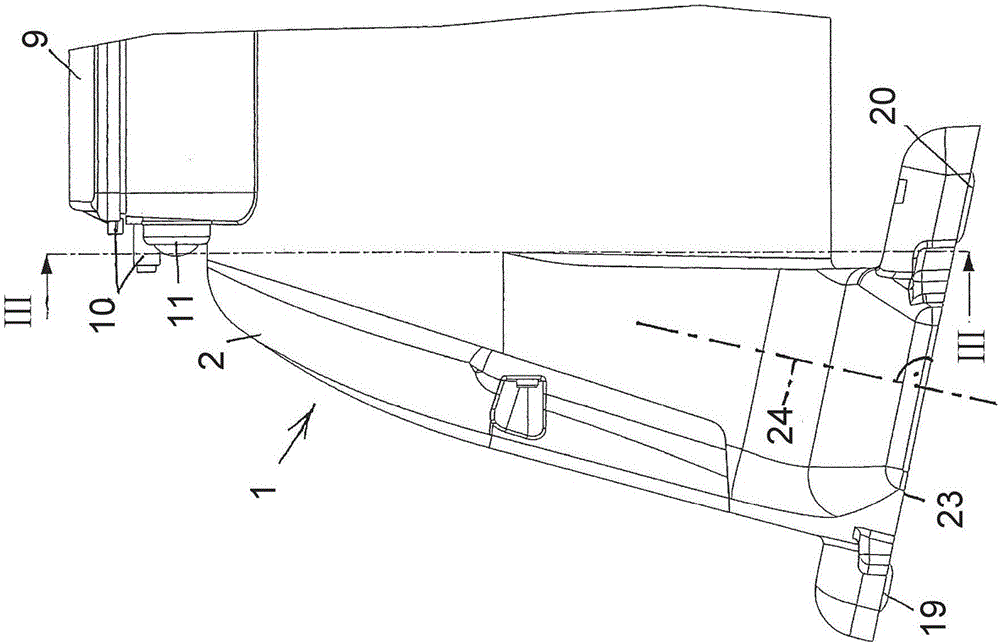

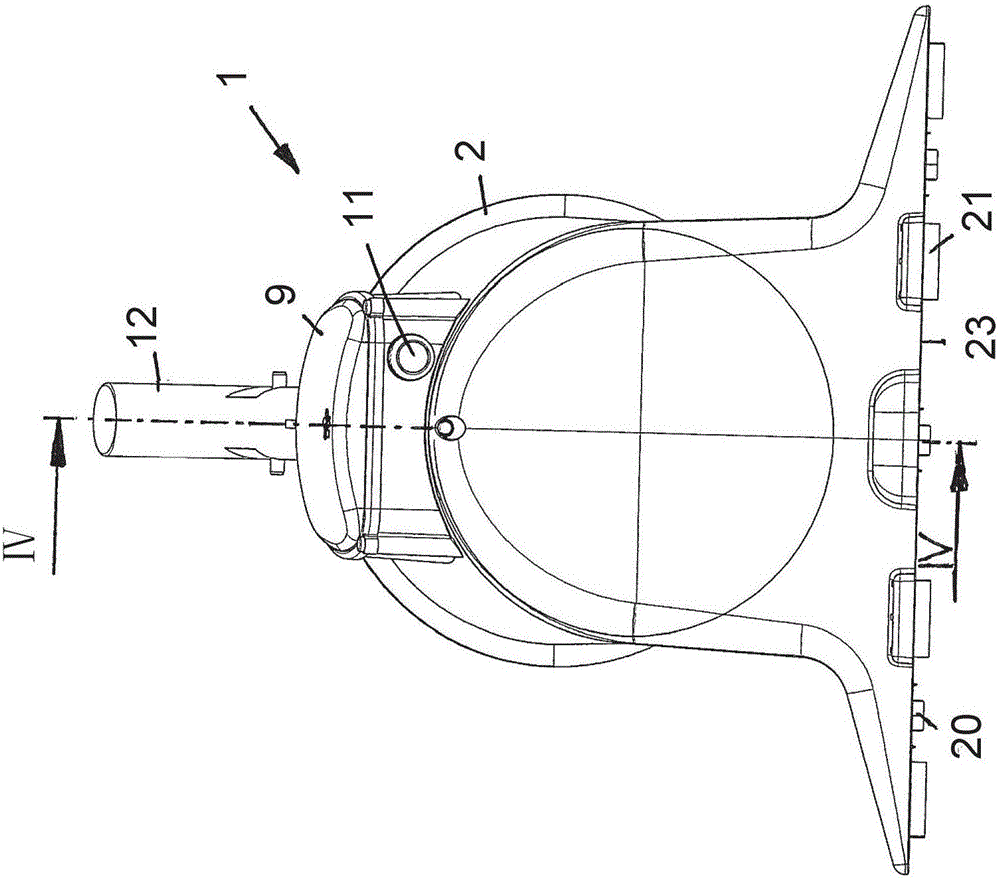

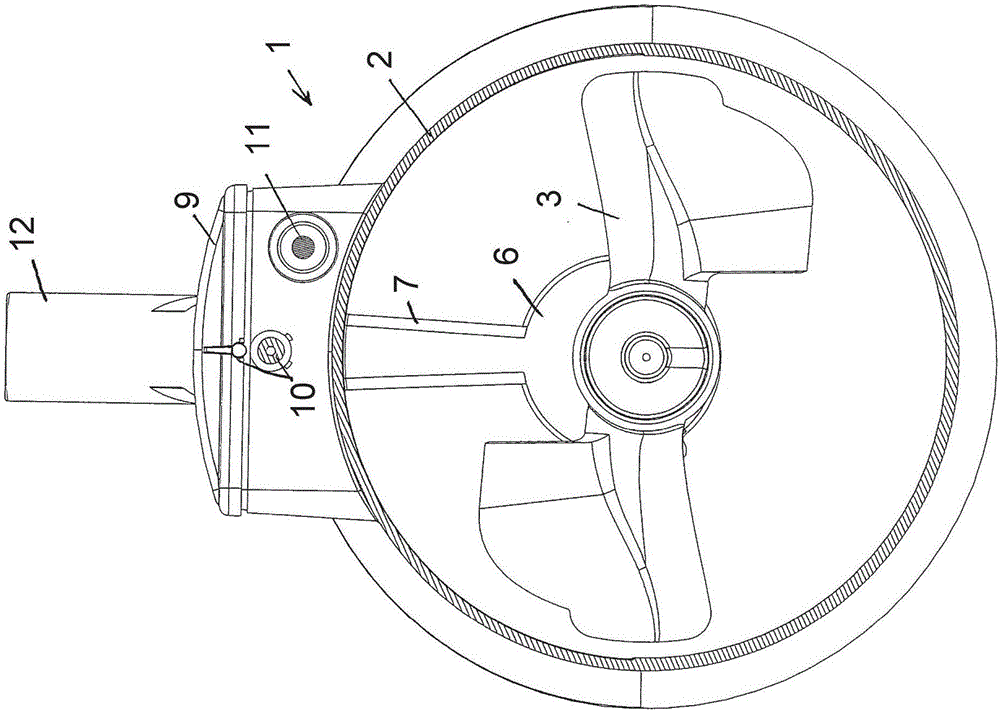

[0026] The underwater cleaner 1 for swimming pools shown in the figures comprises, for example, a housing 2 in which an impeller 3 with an electric motor 4 and a gear 5 operates as a pump. The impeller 3 is driven by a motor 4 via a gear 5 . The motor 4 and the gear 5 as well as the mountings for the impeller 3 are housed in the pump housing 6 . The pump housing 6 is connected to the housing 2 via a suspension 7 . A rechargeable battery 8 is arranged, for example, above the suspension 7 , on the upper side of the housing 2 . The battery 8 is arranged in a waterproof manner, sealed within the housing 2 by a battery housing cover 9 . A closure 10 for the battery housing cover 9 is attached to the housing 2 . In order to house the electrical connection between the electric motor 4 and the battery 8 inside said suspension, the suspension 7 is hollow. Located on the outside of the housing 2 and adjacent to the closure 10 is a switch 11 via which the power supply to the motor 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com