Silane coupling agent modified friction material and friction plate made of friction material

A technology of silane coupling agent and silane coupling agent, applied in the field of friction plates, can solve the problems of poor compatibility between organic raw materials and inorganic raw materials, damage to the health of workers, and affect the performance of finished products, so as to improve market competitiveness , cost control, mechanical performance and friction and wear performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

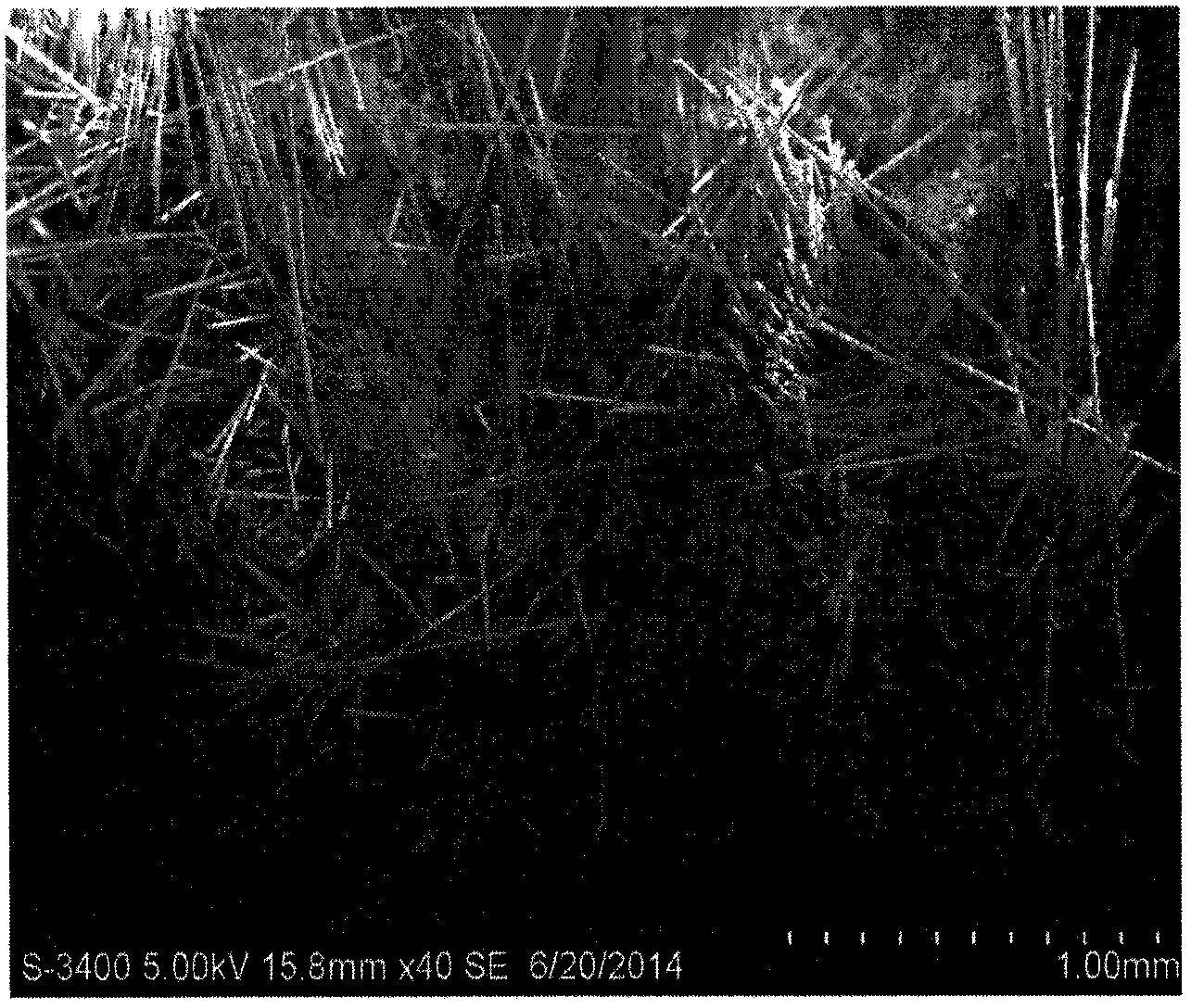

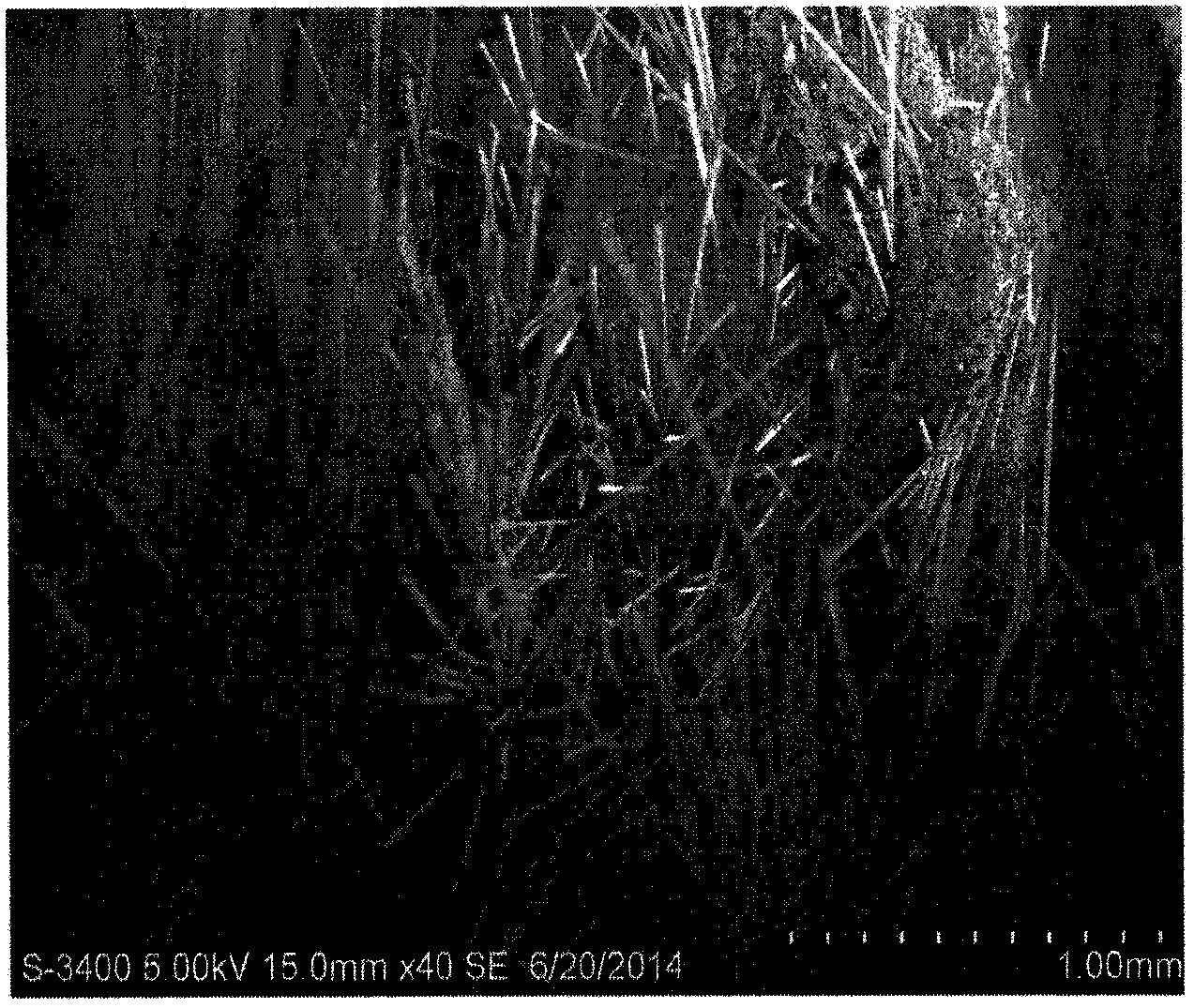

Image

Examples

Embodiment 1

[0033] The invention provides a friction material modified by a silane coupling agent and a drum friction plate made of the friction material, which can be prepared by the following method:

[0034] 1) Put the friction material mixture in a heat-curing mold, cure it under a pressure of 16 MPa for 8 minutes, and get the finished product after drilling. In this embodiment, the friction article is a friction plate.

[0035] In this embodiment, the formula (parts by weight) of the friction material mixture is: 6 parts of phenolic resin, 5 parts of glass fiber, 4 parts of nitrile rubber powder, 4 parts of polyacrylonitrile fiber, 10 parts of rock wool, sulfuric acid 34.5 parts of barium, 13 parts of calcium carbonate, 2 parts of calcium fluoride, 3 parts of alumina, 3 parts of synthetic graphite, 5 parts of coke powder, 10 parts of calcium hydroxide, 0.5 parts of plant cellulose, 0.03 parts of treated silane coupling agent share;

[0036] Wherein the silane coupling agent treatme...

Embodiment 2

[0045] The invention provides a friction material modified by a silane coupling agent and a drum friction plate made of the friction material, which can be prepared by the following method:

[0046] 1) Put the friction material mixture in a heat-curing mold, cure it under a pressure of 16 MPa for 8 minutes, and get the finished product after drilling. In this embodiment, the friction article is a friction plate.

[0047] In this embodiment, the formula (parts by weight) of the friction material mixture is: 5 parts of phenolic resin, 6 parts of glass fiber, 5 parts of nitrile rubber powder, 3 parts of polyacrylonitrile fiber, 10 parts of rock wool, sulfuric acid 34.5 parts of barium, 13 parts of calcium carbonate, 2 parts of calcium fluoride, 3 parts of alumina, 3 parts of synthetic graphite, 5 parts of coke powder, 10 parts of calcium hydroxide, 0.5 parts of plant cellulose, 0.05 parts of treated silane coupling agent share;

[0048] Wherein the silane coupling agent treatme...

Embodiment 3

[0056] The invention provides a friction material modified by a silane coupling agent and a drum friction plate made of the friction material, which can be prepared by the following method:

[0057] 1) Put the friction material mixture in a heat-curing mold, cure it under a pressure of 16 MPa for 8 minutes, and get the finished product after drilling. In this embodiment, the friction article is a friction plate.

[0058] In this embodiment, the formula (parts by weight) of the friction material mixture is: 7 parts of phenolic resin, 4 parts of glass fiber, 4 parts of nitrile rubber powder, 3 parts of polyacrylonitrile fiber, 10 parts of rock wool, sulfuric acid 35.5 parts of barium, 13 parts of calcium carbonate, 2 parts of calcium fluoride, 3 parts of alumina, 3 parts of synthetic graphite, 5 parts of coke powder, 10 parts of calcium hydroxide, 0.5 parts of plant cellulose, 0.03 parts of treated silane coupling agent share;

[0059] Wherein the silane coupling agent treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com