Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

183results about How to "Improve friction and wear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

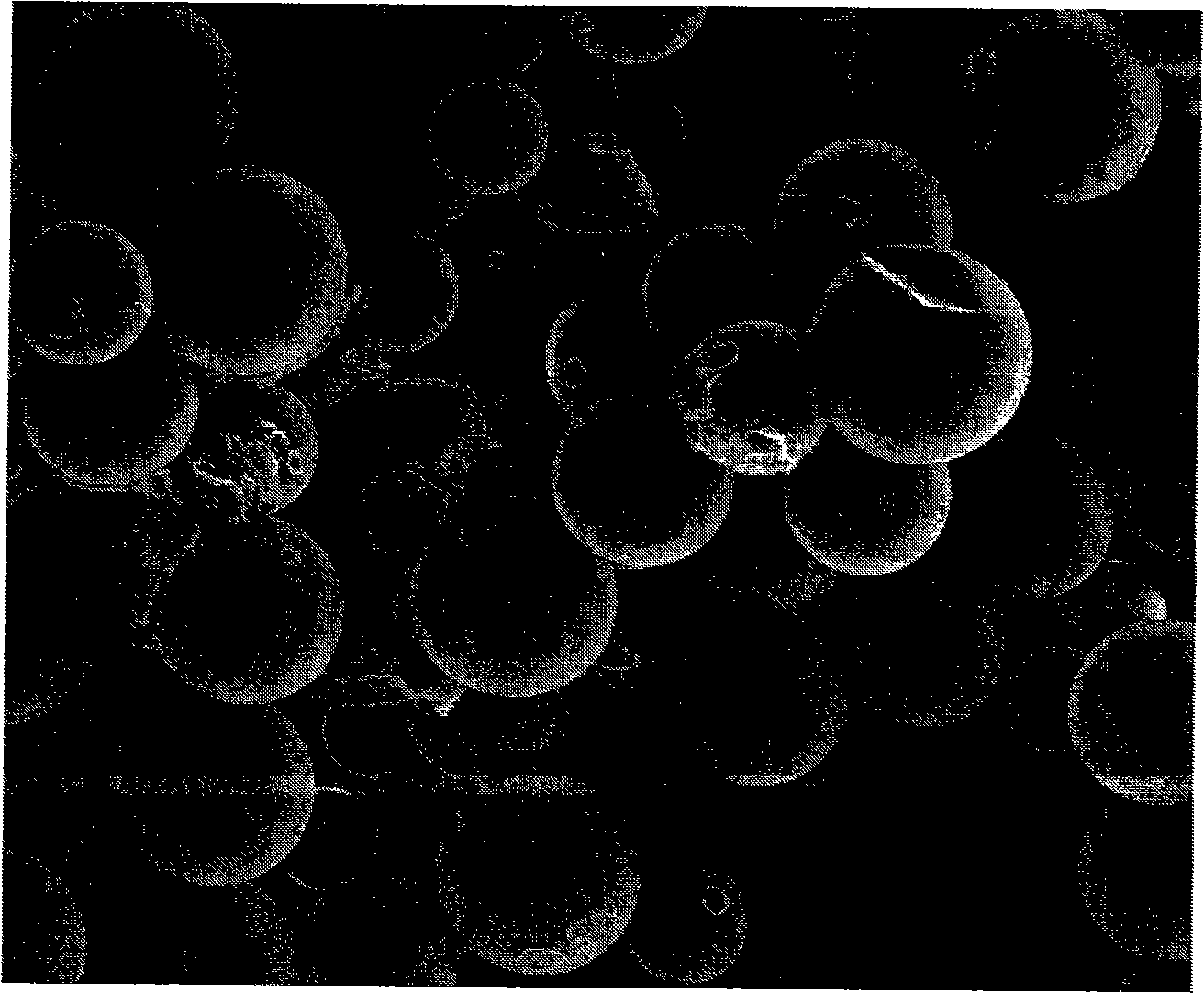

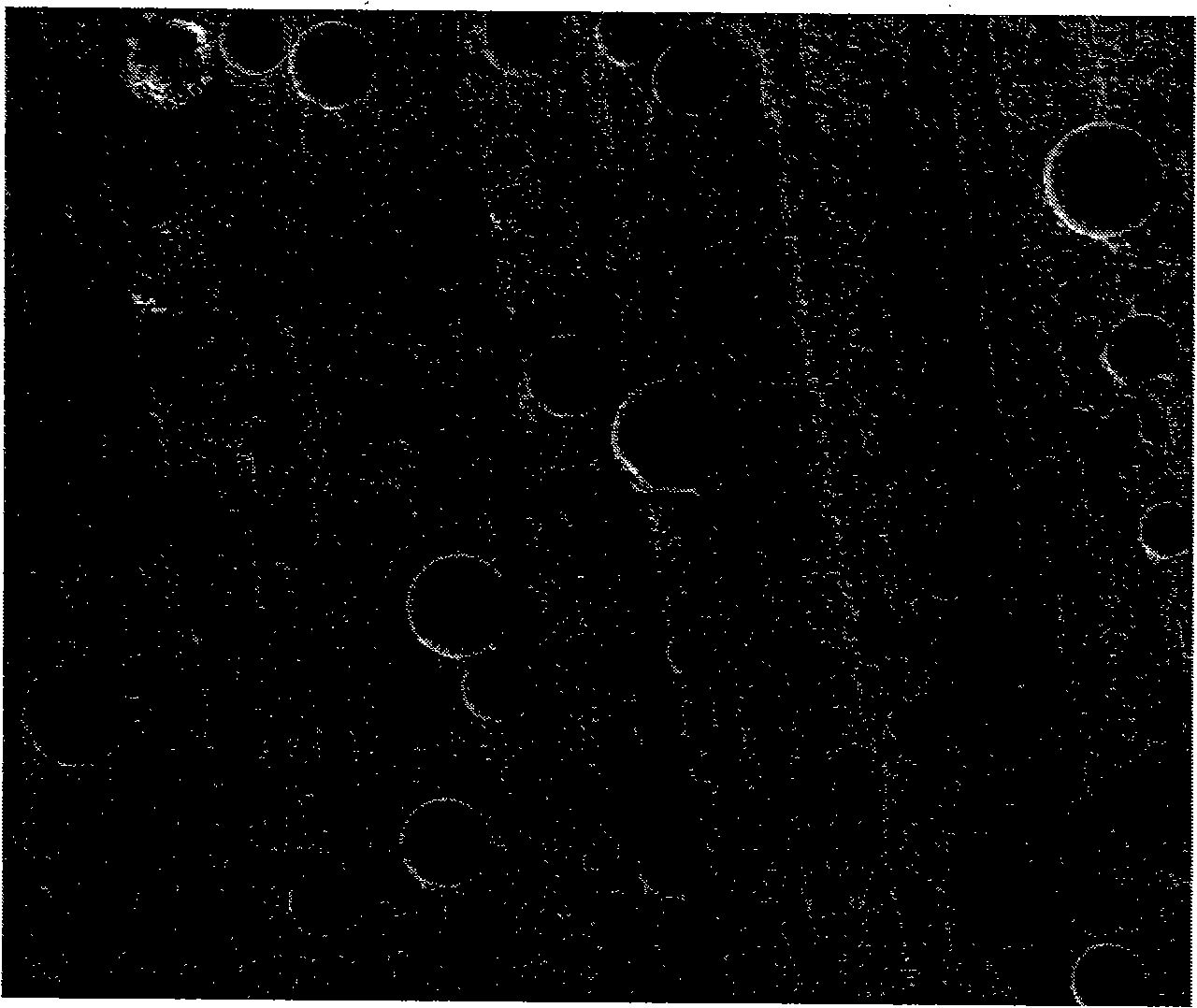

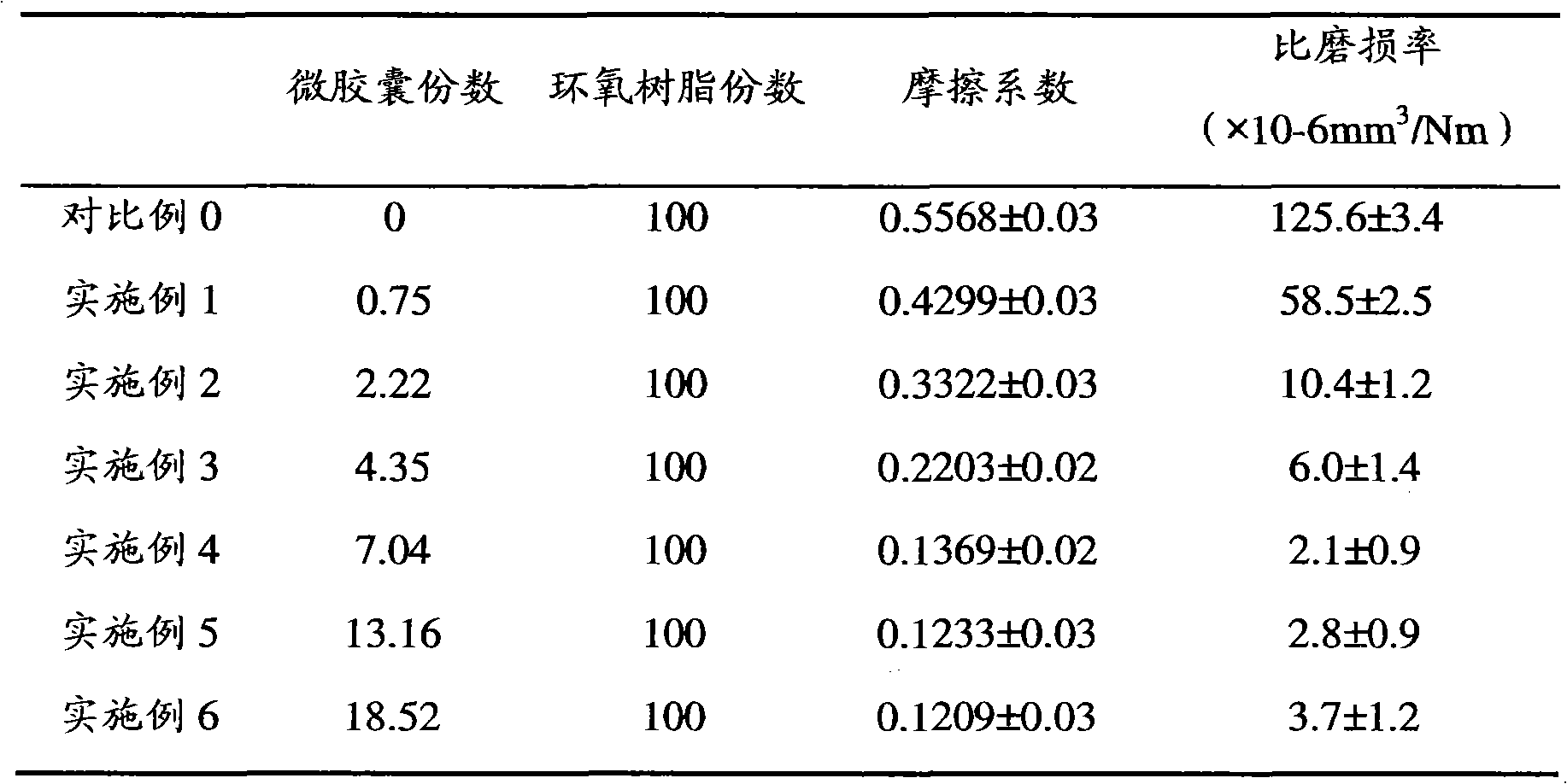

Self-lubricating type epoxide resin material and preparation thereof

InactiveCN101348600AImprove stabilityReduce pollutionMicroballoon preparationLubricant compositionFirming agentEpoxy resin composite

The invention discloses a self-lubricating type epoxy resin material and a preparation method thereof, belonging to the polymer material field. The self-lubricating type epoxy resin material comprises the following components in weight percentage: 60 to 80 percent of epoxy resin, 0.5 to 25 percent of lubricating oil microcapsules and 15 to 35 percent of curing agents. The preparation method for the self-lubricating type epoxy resin material comprises the following steps of well mixing the lubricating oil microcapsules, the epoxy resin with the curing agents and casting rapidly when to-be-mixed matter has gel phenomena, so as to obtain the self-lubricating type epoxy resin material. The invention also provides a lubricating oil microcapsule needed in the preparation of the epoxy resin material and a preparation method for the lubricating oil microcapsule. A technical proposal provided by the invention adds the lubricating oil microcapsules to the epoxy resin so as to prepare the epoxy resin compound material, which can remarkably improve the wear reducing-resisting performance of the epoxy resin material and has broad application prospects.

Owner:SUN YAT SEN UNIV

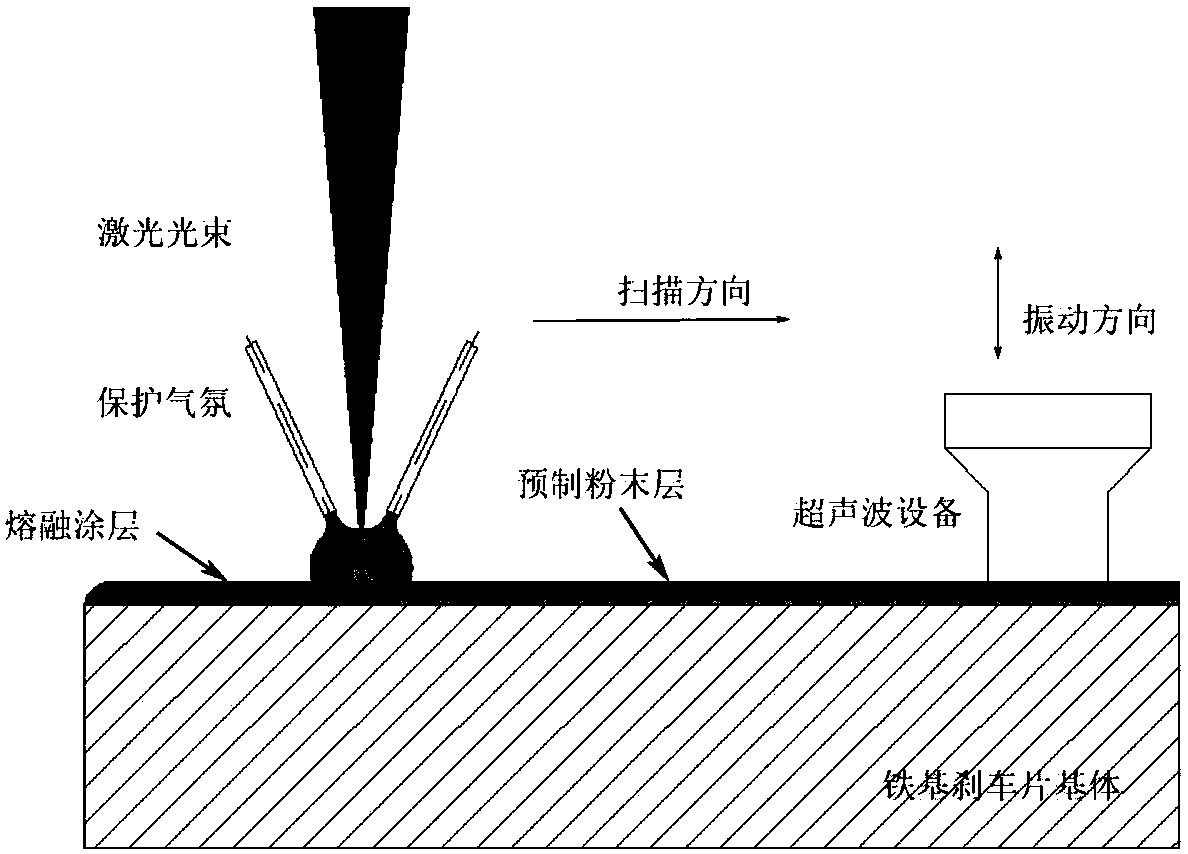

Composite coating material applied to semi-metal iron-based brake pads and preparation method for composite coating material

ActiveCN108127123AStable brakingImprove toughnessTransportation and packagingMetal-working apparatusWater vaporFerrosilicon

The invention discloses a composite coating material applied to semi-metal iron-based brake pads. The composite coating material is formed by nickel-chrome alloy powder, chromium carbide powder, ferrosilicon, ferrovanadium, aluminite powder and graphene being subjected to high temperature melting, water vapor mixing atomization, bonding batter-mixing brushing and laser melting. The raw materials comprise the ingredients of, in percentage by mass, 12-50% of nickel-chromium, 15-28% of chromium carbide, 6-10% of ferrosilicon, 5-8% of ferrovanadium, 20-40% of aluminum and 1-2% of graphene. By means of the composite coating material applied to the semi-metal iron-based brake pads and a preparation method for the composite coating material, a metal alloy powder coating formed on the surface of the semi-metal iron-based brake pads has good physical and mechanical performance and has good friction performance and thermal stability under high temperature conditions, and dust after friction is convenient to treat, furthermore, process parameters are easy to control in the preparation process, and the composite coating material applied to the semi-metal iron-based brake pads and the preparation method for the composite coating material are suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

Flexible-paper-base friction material

ActiveCN101024760AGood flexibilityImprove friction and wear performanceNon-fibrous pulp additionOther chemical processesFiberCarbon fibers

The invention discloses a soft paper based friction material that contains 3-7wt% flexibility reinforcement fiber, 5-20wt% carbon fiber, 4-25wt% other fiber, 2-20wt% flexibility adhesive, 20-44wt% friability adhesive, 10-25wt% frictional properties regulator, and 15-30wt% filling material. The invention has good flexibility, and improved frictional wear ability of the paper base friction material. The minimum bending radius of curvature is 6.0-6.8cm, and good mechanical strength and thermal endurance.

Owner:陕西航沣新材料有限公司

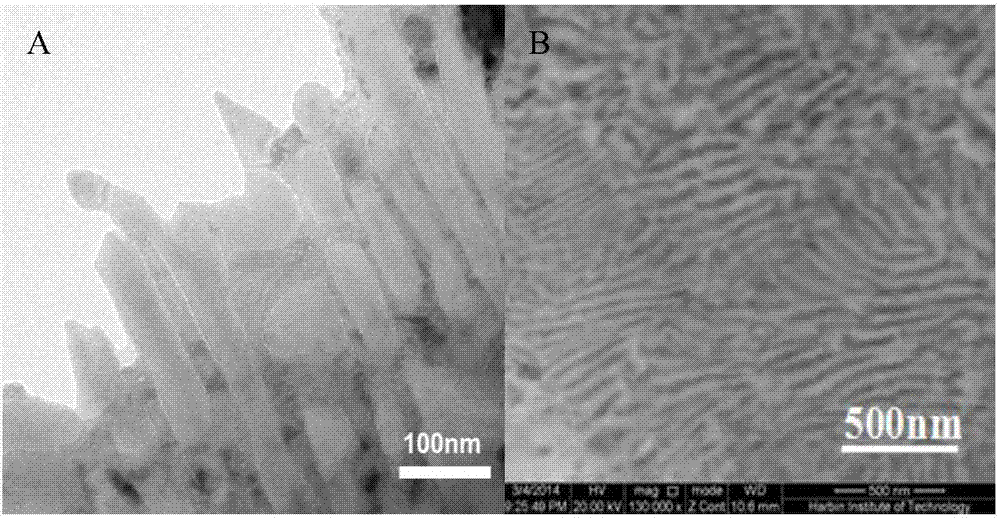

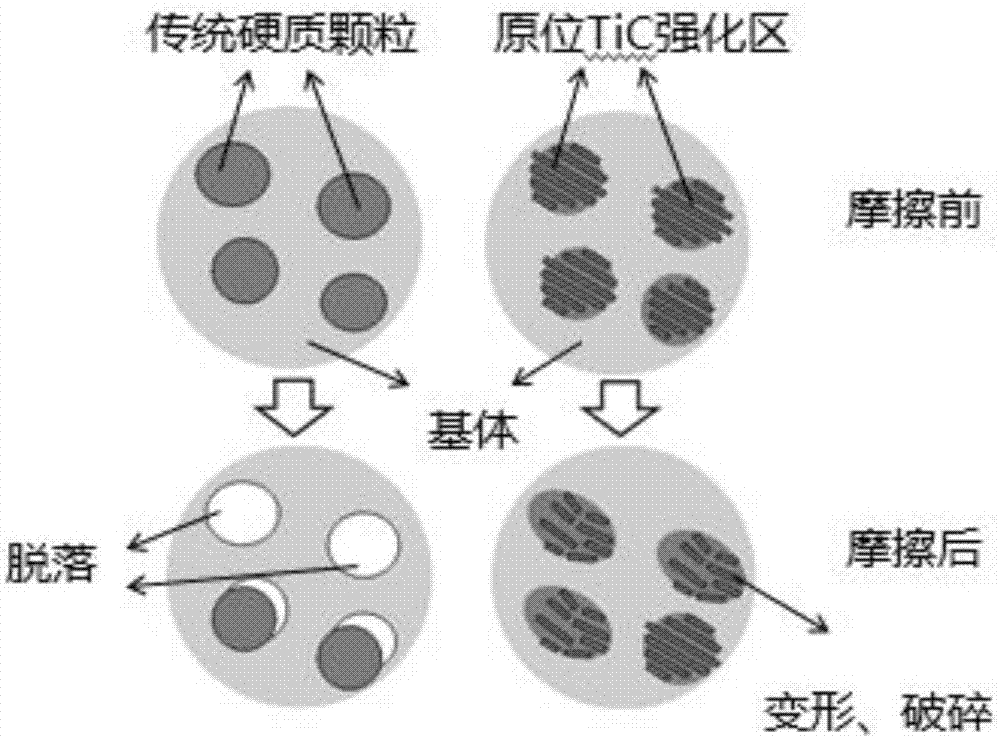

Brake pad material for high-speed railway passenger train and preparing method thereof

ActiveCN107460362ASolve the hardnessPoor ability to solve deformationTransportation and packagingMetal-working apparatusAdhesiveManganese

The invention discloses a brake pad material for a high-speed railway passenger train and a preparing method thereof and belongs to the technical field of powder metallurgy friction materials. The brake pad material is prepared by the following steps: after drying and sieving powdery raw materials, feeding the raw materials into a mixer, and spraying an adhesive; after mixing the materials, placing the materials in a steel mould, and carrying out pressing; and then, carrying out sintering at a reduction atmosphere, and then, carrying out heat treatment in a reduction atmosphere, wherein the powdery raw materials comprise copper powder, iron powder, Ti2AlC powder, chromium powder, nickel powder, manganese powder, silicon dioxide, graphite, boron nitride and molybdenum disulfate. The invention further provides the preparing method of the brake pad material. In the invention, in-situ TiC obtained through the Ti2AlC is used as a main friction component, the material of an in-situ nanometer TiC layered framework is prepared, the copper is accordingly used as a matrix, a small quantity of other metals is added, the content of lubricating components, such as the graphite, is regulated, and a novel material with a great brake effect and a low wear rate is finally obtained. The material is suitable for being used as the brake pad material for the high-speed railway passenger train.

Owner:哈尔滨新干线轨道交通科技有限公司

VN/TiN-powder-containing high-chromium cast iron and preparation method thereof, and wear-resistant part

ActiveCN102212740AChange growth morphologyControl growth directionImpeller wheelsRotor bladesWear resistantNanoparticle

The invention discloses a VN / TiN-powder-containing high-chromium cast iron and a preparation method thereof, and a wear-resistant part. The technical scheme is as follows: the VN / TiN-powder-containing high-chromium cast iron is characterized in that the purity of the VN powder is 99.5%, and the purity of the TiN powder is 99.3%; the VN powder accounts for 2-4 wt% of the high-chromium cast iron, and the TiN powder accounts for 2-4 wt% of the high-chromium cast iron; and the high-chromium cast iron also comprises 3.1-3.9% of C, 18-22% of Cr, 0.5-1.0% of Si, 0.6-1.6% of Mo, 0.6-1.2% of Mn, 0.1-0.4% of Ni, 0.04-0.09% of V, 0.011-0.031% of S, 0.018-0.030% of P and the balance of iron as base material. The VN / TiN powder can be used as a high-chromium cast iron molten metal base and a nucleation core for solidifying carbides, thereby enhancing the wear resistance of the castings; the VN / TiN powder is utilized to reinforce the high-chromium cast iron material, so that wear-resistant shot blasting device blades made of the high-impact-resistant frictional-wear-resistant high-chromium cast iron can be formed; and since the VN / TiN powder is added by an in-furnace addition method, the nanoparticles are added to perform a strengthening effect, and argon gas added into the furnace protects the molten metal.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Preparation method of composite material and composite material

The invention relates to a preparation method of a composite material and the composite material. The preparation method of the composite materials comprises the following steps: a, adding 0.1-5 parts by mass of mono-layer graphene oxide to 500 parts by mass of a solvent, sufficiently dispersing and carrying out ultrasonic treatment; b, adding 95-99.9 parts by mass of UHMWPE to the solution obtained in the step a, magnetically stirring and stripping ultrasonically; c, carrying out drying treatment; d, grinding and crushing; e, prepressing by using a press vulcanizer, holding the temperature, carrying out compression moulding treatment to obtain a plate, and cooling; and f, irradiating the plate for 5-9d by using an electron beam or radioactive source cobalt with the irradiation dose being 50-150kGy, thus finishing the preparation. The composite material comprises 0.1-5 parts by mass of mono-layer graphene oxide and 95-99.9 parts by mass of UHMWPE. According to the preparation method of the composite material and the composite material, the mechanical property of UHMWPE is improved and the hardness, the tensile property and friction and wear properties are improved.

Owner:JIANGNAN UNIV

High chromium cast iron containing SiC powder, preparation method thereof and wear resistant casting

ActiveCN102220541AChange growth morphologyControl growth directionImpeller wheelsRotor bladesGranularityWear resistant

The invention discloses a high chromium cast iron containing SiC powder, a preparation method thereof and a wear resistant casting manufacturing method utilizing the same. A technical scheme is that a high chromium cast iron containing SiC powder is characterized in that the SiC powder is 99.9% SiC and with an average granularity of 20-40 nm, and accounts for 3-6% of a gross weight of the high chromium cast iron. The high chromium cast iron also comprises 3.1-3.9% of C, 18-22% of Cr, 0.5-1.0% of Si, 0.6-1.6% of Mo, 0.6-1.2% of Mn, 0.1-0.4% of Ni, 0.04-0.09% of V, 0.011-0.031% of S, and 0.018-0.030% of P. The beneficial effects are that :1) wear resistance of the casting id substantially raised by the SiC powder; 2) the SiC powder is used to enhance the high chromium cast iron material to form a high impact-resistant, friction-resistant, wearing- resistant high chromium cast iron wear-resistant blast blade. Therefore, the SiC nano powder can not only change growth morphology of high chromium cast iron crystal and growthform of a martensite to substantially enhance material hardness, but also improve material friction and wearing performance at a high temperature to obviously play a role of friction and wearing resistance at a high temperature.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

High performance nano-composite aluminum oxide based self-lubricating cutter material and preparation method thereof

InactiveCN103011784AImprove mechanical propertiesImprove friction and wear performanceTitanium carbideMaterials science

The invention relates to a high performance nano-composite aluminum oxide based self-lubricating cutter material and a preparation method thereof. The high performance nano-composite aluminum oxide based self-lubricating cutter material comprises the raw materials in percent by volume as follows: 25-55% of titanium carbide, 5-15% of nano calcium fluoride, 0.5-1.5% of magnesium oxide, and the balance of aluminum oxide. The preparation method comprises the steps: first, preparing nano calcium fluoride into a dispersing liquid; then, adding MgO, Al2O3 and TiC, mixing, dispersing, ball-grinding, drying and sieving to obtain powder; and sintering by a vacuum hot-press approach. According to the invention, nanosolid lubricant CaF3 is successfully guided into a ceramic matrix crystalline grain, so that the bending strength and hardness of the self-lubricating ceramic cutter material are improved, and the breaking tenacity is improved. The self-lubricating cutter material is low in cost of material, simple in process, small in device investment, and industrialization is easy to realize.

Owner:QILU UNIV OF TECH

Silane coupling agent modified friction material and friction plate made of friction material

InactiveCN104356590ALiquidInfiltratingOther chemical processesFriction liningUltimate tensile strengthShear strength

The invention discloses a silane coupling agent modified friction material and a friction plate made of the friction material. The friction material comprises components in a frictional material formula and a processed silane coupling agent. A method for preparing the friction material comprises steps as follows: raw materials are prepared according to the friction material formula, the components of the friction material are uniformly mixed through a mixing process, and the processed silane coupling agent is sprayed into mixing equipment through the mixing process. The silane coupling agent modified friction material and the friction plate made of the friction material have the benefits as follows: the problem about compatibility of raw materials in a friction product is solved, then one friction product is provided, the friction product improves impact strength and inner shearing strength while the friction coefficient and performance are not damaged under the same condition, the wearing is reduced, and the friction plate made of the friction material can be applied to the harsh working condition.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

Production method of powder metallurgy high-silicon aluminum alloy compressor piston

ActiveCN105522156AThe proportion of material composition is scientific and reasonableSimple preparation processTurbinesOther manufacturing equipments/toolsImpurityPiston

The invention relates to a production method of a powder metallurgy high-silicon aluminum alloy compressor piston. Materials comprise 14-32% of silicon, 0-5.0% of copper, 0.8-2.0% of magnesium, iron not more than 0.3%, other impurities not more than 2.0% and the balance of aluminum; according to alloy components of the piston, pure aluminum powder and aluminum alloy powder are taken for batching; 0.8-2.0% of organic wax bonding agent or lubricating agent is added for mixing; and then, the piston is machined through a series of steps of formation, dewaxing, sintering, heat treatment, shaping, machining, burr brushing, vacuum resin dipping, cleaning, curing and oxidation. The production method is simple in preparation process and reasonable in batching, has the characteristics of low machining quantity and high material utilization, is reasonable in material component ratio of the piston, reduces the production cost, and improves the production efficiency; primary silicons in a microscope structure of the molded piston are fine particles uniformly distributed; and the total strength and the frictional wear performance of the piston can be effectively improved.

Owner:NBTM NEW MATERIALS GRP

Wear-resisting heat-conducting polyurethane bearing as well as preparation method and application thereof

The invention belongs to the field of light-weight wear-resisting materials and discloses a wear-resisting heat-conducting polyurethane bearing as well as an preparation method and an application thereof. The preparation method of the wear-resisting heat-conducting polyurethane bearing comprises the following steps of: soaking a fiber into a copolymer, dispersing ultrasonically, adding a polyurethane prepolymer, a curing agent and a heat-conducting filler, mixing the materials, degassing in vacuum, pouring the degassed mixture into a preheating mold, heating to cure, cooling, and demolding to obtain the wear-resisting heat-conducting polyurethane bearing. The wear-resisting heat-conducting polyurethane bearing prepared by adopting the preparation method has the advantages of light weight, wear resistance (relative volume wear loss of 150mm<3>), good heat conductivity of 4W / m*K, high strength (high modulus of compression of 520Mpa, and notched impact strength of 120J / m), low cost, long service life and the like, is simple in forming process, is suitable for industrial production and can be widely applied to clean-energy power generation equipment.

Owner:JINAN UNIVERSITY

Potassium hexatitanate/sodium hexatitanate whisker composite ceramic frication material and preparation method thereof

The invention relates to a composite ceramic fiction material of potassium hexatitanate / sodium hexatitanate whisker belonging to the material technical field, wherein the composite ceramic fiction material comprises 5-20 parts of organic resin, 1-10 parts of rubber powder, 10-40 parts of potassium hexatitanate and sodium hexatitanate whisker, 0-5 parts of aramid fiber, 10-20 parts of graphite and 20-40 parts of filler. The composite ceramic fiction material of the invention doesn't contain asbestos without harming the human body and polluting the environment, which has superiorities in eliminating braking noise and heat degeneracy, improving using life of the product, overcoming adhesive occlusion among friction couples and the like.

Owner:SHANDONG UNIV

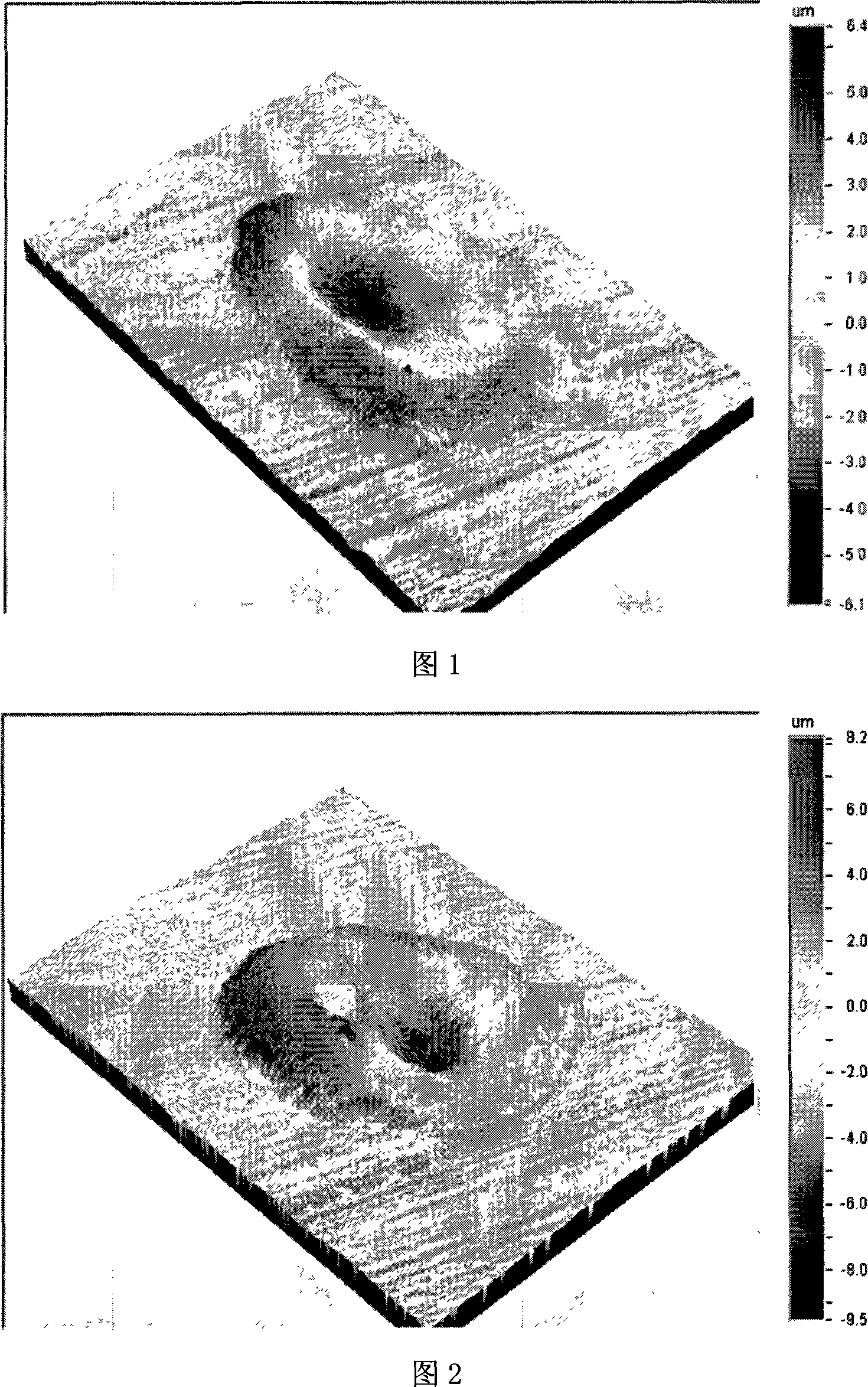

Roller surface laser texturing and micro-alloying composite processing method

InactiveCN101117712AHigh hardnessImprove friction and wear performanceMetallic material coating processesLaser beam welding apparatusWear resistantSurface roughness

The present invention relates to a composite processing method of laser texturing and micro-alloying of roller surface in the technical field of material processing. The method, more specifically, comprises spraying a film containing alloy micro-powder on the roller surface. The alloy micro-powder containing film can increase the laser energy adsorption ability of the roller basal surface and can melt, through laser heating, into the base material to form a new alloy material. Under the effect of laser beams, the film fuses with the base body and forms textured pits. Compared with the prior laser texturing method, the present invention has the advantages that the roller surface is micro-alloyed simultaneously when laser-textured, deepening the textured pits, increasing the boss height and the border definition, improving the hardness and the wear-resistant performances of the roller surface and prolonging the service life of the roller in the premise of guaranteeing the textured surface roughness..

Owner:SHANGHAI JIAO TONG UNIV

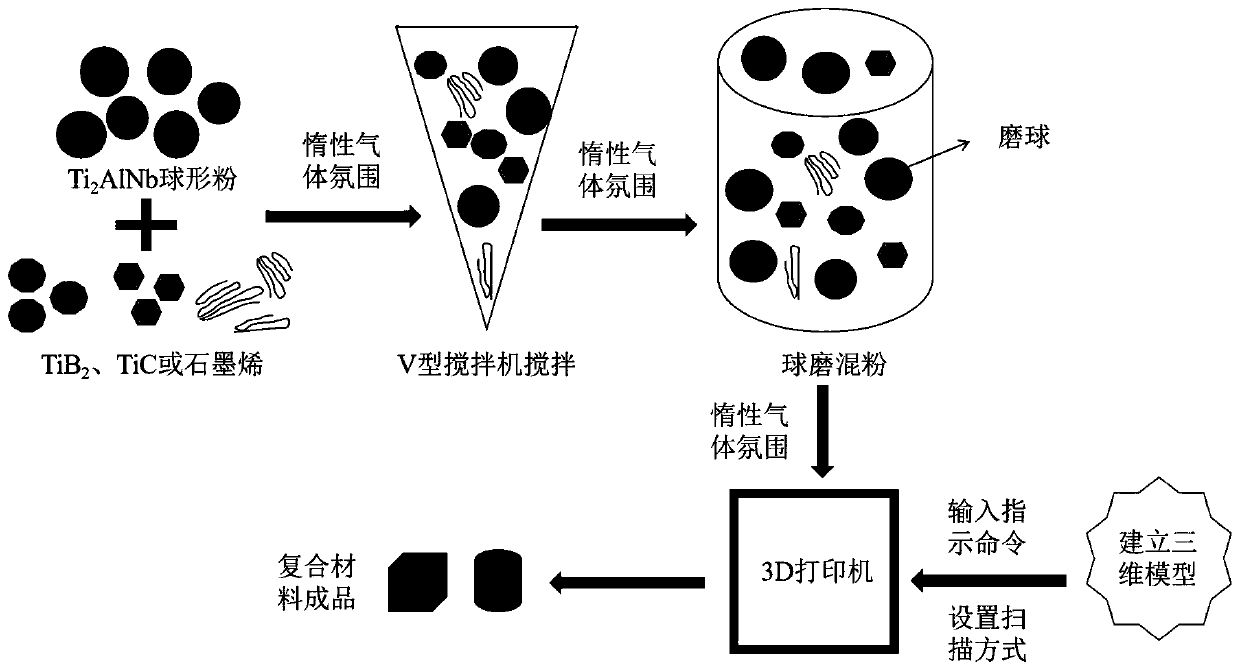

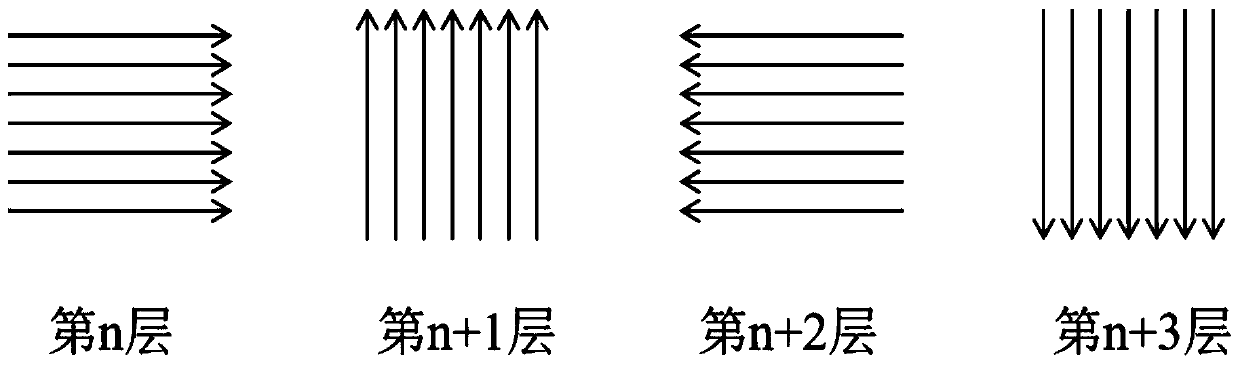

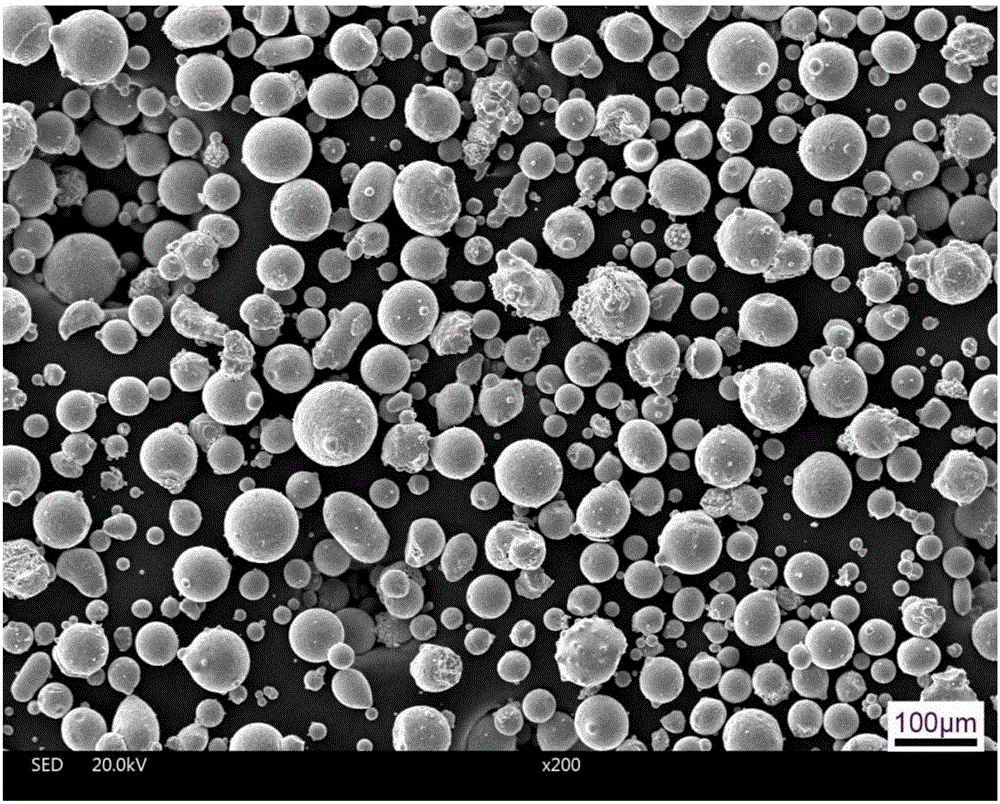

3D printing reinforcement/Ti2AlNb base composite material and preparation method thereof

ActiveCN109865836AEvenly dispersedScattered tightlyAdditive manufacturing apparatusIncreasing energy efficiencyHardnessGraphene

The invention discloses a 3D printing reinforcement / Ti2AlNb base composite material and a preparation method thereof, and belongs to the field of metal material manufacturing. The preparation method comprises the following steps: (1) Ti2AlNb spherical prealloy powder is used as a basal body; and TiB2, graphene or TiC powder is used as reinforced particles; (2) the selected powder is mixed for mechanical stirring; (3) the pre-stirred powder is mixed through dry ball milling; (4) a three-dimensional pattern of a needed sample is designed by using a computer; and drawing procedures are input intoa 3D printer; and (5) the ball-milled mixed powder is scanned layer by layer according to preset procedures to finally prepare the needed composite material. The process is simple; all the componentsare excellent in stability; a reinforcing phase is tightly combined with the basal body, and a second phase generated in the laser melting process achieves a pinning effect in metal; and the reinforcing phase and the second phase are coacted to achieve a refined crystalline strengthening effect, so that the defects of the material after 3D printing can be eliminated. The composite material is small in average grain size, and prominently optimizes the hardness and the friction and wear performances of the material.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

M50-Ag-TiC self-lubricating composite material and preparation method thereof

ActiveCN106825546AReduce coefficient of frictionReduce wear rateAdditive manufacturing apparatusTransportation and packagingLubricationMaterials science

The invention relates to an M50-Ag-TiC self-lubricating composite material. An aerial main shaft bearing material, namely M50 steel, is used as a base material, and Ag and TiC are respectively used as a lubrication phase and a reinforcement phase, wherein the mass of the lubrication phase is (8.0-10.0) wt% of that of the base material; the mass of the reinforcement phase is (4.0-6.0) wt% of that of the base material. The composite material is prepared from M50 spherical powder containing Ag and TiC by adopting 3D printing. The M50-Ag-TiC self-lubricating composite material disclosed by the invention is low in friction coefficient and wear rate, so that the tribological property of M50 bearing steel can be effectively improved; a preparation method is simple and convenient, and process parameters are easy to control during preparation; and complicated mechanical parts can be manufactured, so that the M50-Ag-TiC self-lubricating composite material has important significance in industrialized application of self-lubricating materials.

Owner:江苏双正机械有限公司

Synchronous ring for synchronizer and method for manufacturing synchronous ring

ActiveCN102588460AImprove friction and wear performanceImprove reliabilityMechanical actuated clutchesCeramic shaping apparatusEngineeringToughness

The invention discloses a synchronous ring for a synchronizer and a method for manufacturing the synchronous ring. The synchronous ring comprises a synchronous ring base, and a friction plate is arranged in the synchronous ring base and consists of a flexible base layer and a friction layer which are compounded. A combined structure consisting of the flexible base layer and the friction layer replaces an existing machined friction layer structure, a hard friction material without elasticity and toughness is improved to form a bendable adhesive friction material without being machined, and a friction abrasion performance and reliability of the synchronous ring are improved. In addition, an oil drainage groove is directly pressed on the friction layer, process is simplified, and cost is lowered. Besides, the platy friction plate can be cut into various shapes according to actual needs, the process is simple, machining is omitted, materials are saved, and the synchronous ring is applicable to synchronizers.

Owner:SHIYAN TONGCHUANG DRIVE TECH CO LTD

Method for preparing carbon fiber fabrics friction material used for wet clutch and application thereof

InactiveCN102343679ABest friction and wear resistanceAvoid shear damageFriction liningFiberCarbon felt

The invention relates a method for preparing a carbon fiber fabrics friction material used for a wet clutch and an application thereof, which comprises the following steps: 1), 3D braiding carbon felt or carbon fiber and puncturing to carbon fiber fabrics as a preform; 2), dipping the preform into a soaker, wherein the soaker comprises high temperature resistance brake sheet phenol resin containing a rubbing agent with one or more from SiO2, ZrO2, boron iron, manganese iron and chromium iron, controlling the concentration of the dipped perform at 1.68g / cm<3>-2g / cm<3> by controlling the dipping pressure or controlling the addition of high temperature resistance brake sheet phenol resin; 3), pressurizing and thermocuring the dipped preform which is impregnated cloth; 4) punching the processed impregnated cloth into a required shape, coating a binder on one surface of the impregnated cloth and performing a heat bonding with a support steel back. The method for preparing the carbon fiber fabrics friction material used for the wet clutch and the application are capable of raising the friction and wear performance of the wet carbon fiber fabrics and conveying large torsional moment. According to the invention, the obtained friction material still has good friction and wear performance even if the friction material is thinned.

Owner:CENT SOUTH UNIV

Preparation method of composite material and composite material

InactiveCN104356481AImprove mechanical propertiesHigh hardnessGrapheneAnhydrous ethanolMonolayer graphene

The invention relates to a preparation method of a composite material and the composite material. The preparation method comprises the following steps in parts by weight: a, adding 0.3-0.5 part of monolayer graphene oxide into 79 parts of anhydrous ethanol and ultrasonically stripping after magnetic stirring; b, adding 100 parts of UHMWPE (ultrahigh molecular weight polyethylene) into a solution and ultrasonically stripping after magnetic stirring; c, drying; d, grinding and smashing the dried substance; e, pre-pressing for 10-20 minutes at the pressure of 5-10MPa by using a press vulcanizer; f, electrically heating and airing; and g, sulfidizing and cooling. The composite material prepared by the method comprises 0.3-0.5 part by weight of monolayer graphene oxide and 100 parts by weight of UHMWPE. According to the preparation method of the composite material and the composite material, the mechanical property of UHMWPE is improved and the hardness, the tensile property and the friction and wear properties of the composite material are improved.

Owner:JIANGNAN UNIV

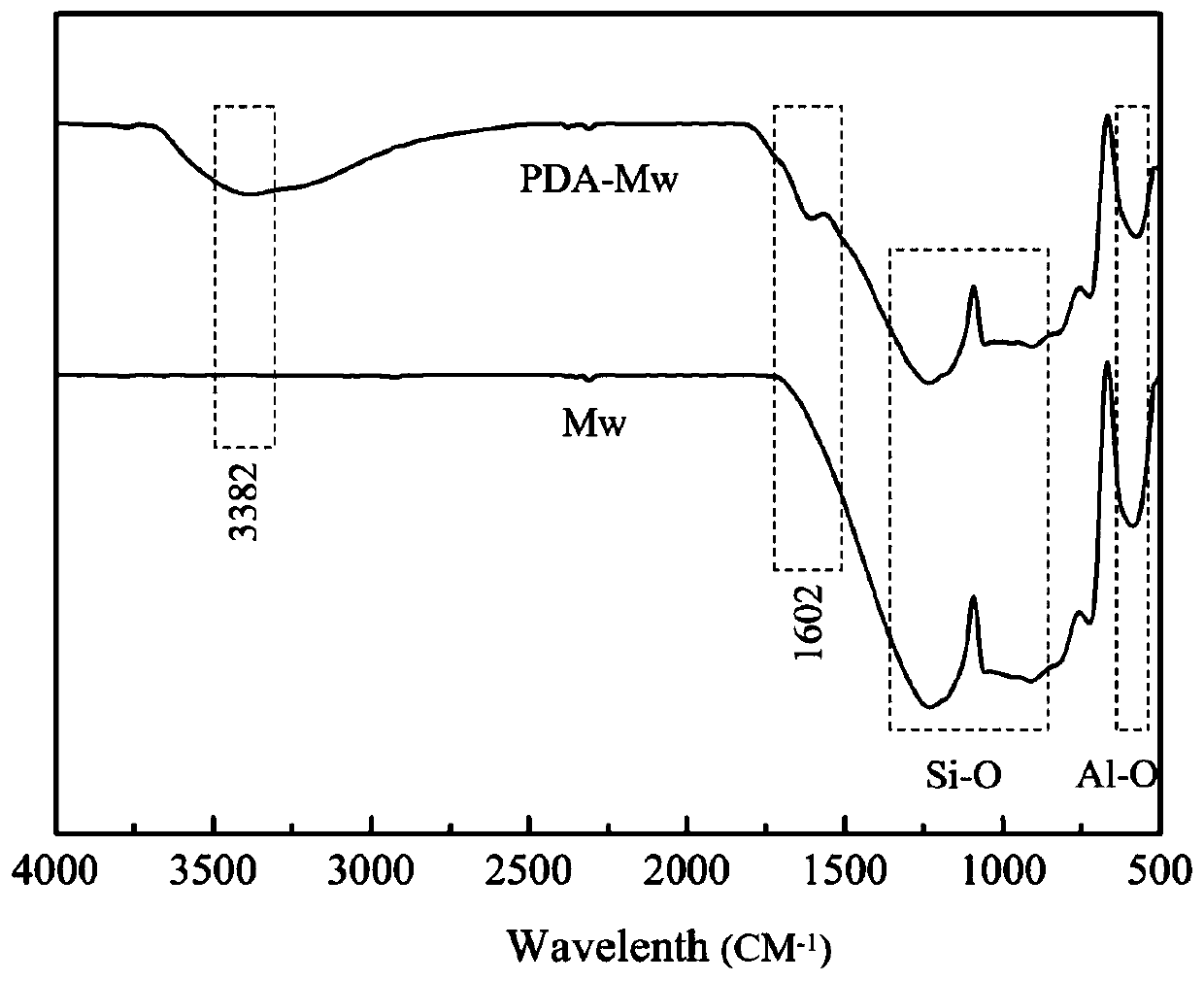

Preparation method of polydopamine modified carbon fiber/mullite whisker reinforced resin-based friction material

The invention discloses a preparation method of a polydopamine modified carbon fiber / mullite whisker reinforced resin-based friction material. The carbon fibers and the mullite whiskers are subjectedto degumming treatment by acetone / ethanol solution separately, and then are added into a prepared dopamine solution, wherein nano-scale polydopamine particles are deposited on the surface through self-oxidation polymerization of dopamine; and the modified mullite whiskers and carbon fibers and modified phenolic resin are mixed, and then are subjected to hot pressing to prepare the resin-based friction material. The friction coefficient of the prepared resin-based friction material is obviously improved, the wear amount is reduced by 53%, the bending strength is improved by 81.2%, and the heatresistance can be improved by 25%. According to the data, the polydopamine surface deposition modification method can effectively enhance the interface bonding strength of resin and the carbon fiber / mullite whisker, so that the resin coating the surface of carbon fiber / mullite whisker does not fall off easily, the friction abrasion performance, the mechanical property and the heat resistance of the friction material are further improved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing bearing retainer by using carbon fiber composite material

The invention relates to a method for preparing a bearing retainer by using a carbon fiber composite material. The method is characterized in that: a bearing retainer is prepared from 10 to 20 percent of carbon fiber, 10 to 20 percent of polytetrafluoroethylene, 10 to 20 percent of graphite, and 40 to 70 percent of poly(ether-ether-ketone) through the processes such as material preparation, raw material pretreatment, mould design, mould temperature, forming temperature, injection pressure, holding pressure and time. The bearing retainer has the advantages of: 1, uniform color, no pore, 38 percent of crystallinity of the materials, and the optimum state of the products; and 2, high hydrolysis resistance, low water absorption, and superhigh performance of chemical attack resistance and radiation resistance. Therefore, the comprehensive performance of the bearing retainer material can be improved, and the continuously-improved requirements of the national high-tech engineering on the bearing are met.

Owner:大连三木得科技有限公司

Carbon fiber containing ceramic particles

InactiveUS20090148699A1Increase frictionImprove wear propertyCarbon fibresCeramic layered productsCarbon compositesCarbon fibers

Small ceramic particles (e.g., of TiC) are incorporated into fibers. The ceramic particles enhance the friction and / or wear properties of a carbon-carbon composite article made with the impregnated or coated fibers. The impregnated fibers can be, e.g., polyacrylonitrile (PAN) fibers, pitch fibers, and other such fibers as are commonly employed in the manufacture of C—C friction materials. The impregnated fibers can be used to make woven, nonwoven, or random fiber preforms or in other known preform types. Preferred products are brake discs and other components of braking systems. The particles may be included in the fibers by mixing them with the resin employed to make the fibers and / or by applying them to the surfaces of the fibers in a binder.

Owner:HONEYWELL INT INC

High-performance engine inlet valve and preparing method thereof

InactiveCN105296858AImprove high temperature performanceImprove antioxidant capacityMachines/enginesLift valveInlet valveUltimate tensile strength

The invention discloses an engine inlet valve and a preparing method thereof. The inlet valve is prepared from, by weight percentage, 0.32% to 0.40% of C, 0.17% to 0.37% of Si, 2.5% to 3.5% of Mo, 0.50% to 0.80% of Mn, 0.80% to 1.10% of Cr, 0.50% to 1.0% of W, smaller than or equal to 0.013% of Ni, smaller than or equal to 0.015% of P, smaller than or equal to 0.015% of S, smaller than or equal to 0.010% of Cu and the balance Fe. The inlet valve is manufactured through the processes including surface nanocrystallization, low-temperature nitriding, tungsten and zirconium alloy bead welding and the like. The inlet valve is large in surface strength, high in hardness, good in abrasion resistance and long in service life.

Owner:杨秋香

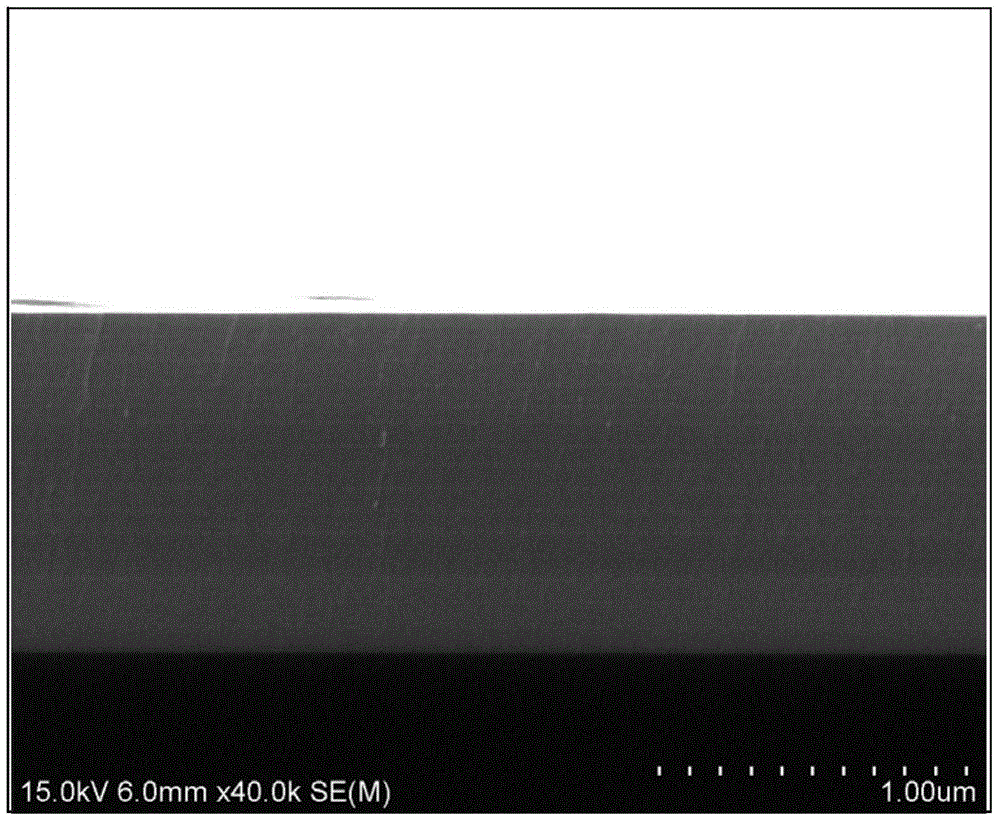

Multilayer multielement high temperature resistant diamond-like nano composite thin film material

InactiveCN103866234AImprove thermal stabilityPrevent graphitizationVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses a multilayer multielement high temperature resistant diamond-like nano composite thin film material comprising a carbon steel substrate, a stainless steel substrate or a hard alloy substrate, a substrate bonding layer, an intermediate transition layer and a surface functional layer, the substrate bonding layer is a metal Ti bonding layer, the intermediate transition layer is a silicon carbide layer, and the surface functional layer is a Si doped diamond-like carbon film. Compared to general diamond-like thin film materials, the use temperature of the multilayer multielement high temperature resistant diamond-like nano composite thin film material is increased by 150 DEG C, and the wear resistance and service life of the multilayer multielement high temperature resistant diamond-like nano composite thin film material are increased.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Powder metallurgy iron copper-based oiliness antifriction material containing rare earth oxides and preparing method

The invention provides a powder metallurgy iron copper-based oiliness antifriction material containing rare earth oxides and a preparing method. The oiliness antifriction material comprises, by mass, 67.0%-71.0% of Fe, 27.2%-32.1% of Cu, 0.6% of Sn, 0.3%-1.2% of CeO2, 0.7% of zinc stearate and the balance unavoidable impurities. The oil content of the oiliness antifriction material is 17%-22% by volume. Powder which is uniformly mixed undergoes pressing, sintering, finishing, oil immersion and other work procedures, and the powder metallurgy iron copper-based oiliness antifriction material containing the rare earth oxides is obtained. Compared with a base material, when the antifriction material contains 0.6% of CeO2 by mass, the mechanical performance including crushing strength and hardness is improved in a certain degree, the antifriction performance is greatly improved, and the friction loss is nearly reduced by 40%. The oiliness antifriction material has the advantages that the wear-resistant performance of the material is greatly improved due to the CeO2 in proper amount, service life of the material is prolonged, the copper content is high, the friction coefficient is low, the anti-corrosion performance is excellent, the raw material is mixed powder of iron powder and copper powder, price is low, and the material contains no lead and meets requirements of environment protection.

Owner:SOUTHEAST UNIV

Connecting member for mounting of spring supports and hangers and manufacturing method of connecting member

ActiveCN104879572AReduce porosityReduce tensionPipe supportsFoundry mouldsRare-earth elementUltimate tensile strength

The invention discloses a connecting member for mounting of spring supports and hangers. The connecting member comprises a base and supporting frames, the supporting frames are symmetrically arranged on the base, the supporting frames and the base form a U-shaped groove, a threaded hole is formed in each supporting frame, the base is of a cuboid structure, a fixing hole is formed in each of four corners of the base, a zinc layer is plated on the surface of each supporting frame, the base and the supporting frames are made by a same material, and the material is composed of Cr, Mo, C, Co, Mn, P, S, Ni, Ti, W, V, Cu, Si, Nb, Ta, N, Mg, rare earth element and the rest Fe and unavoidable impurities. The invention further discloses a manufacturing method of the connecting member. The manufacturing method is simple and easy to implement, pollution-free in manufacturing process and low in manufacturing cost, and the connecting member manufactured by the method is resistant to corrosion and wear, high in strength and tenacity and long in service life.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

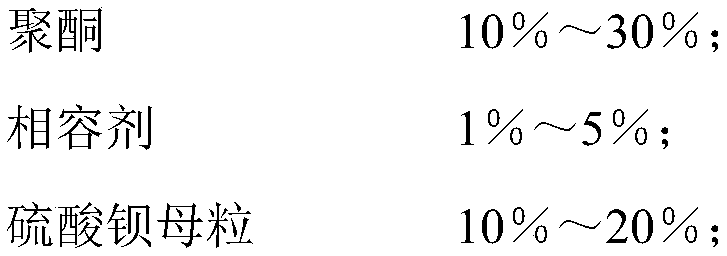

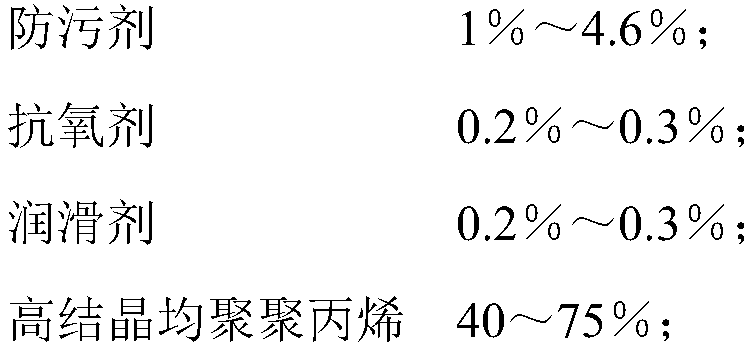

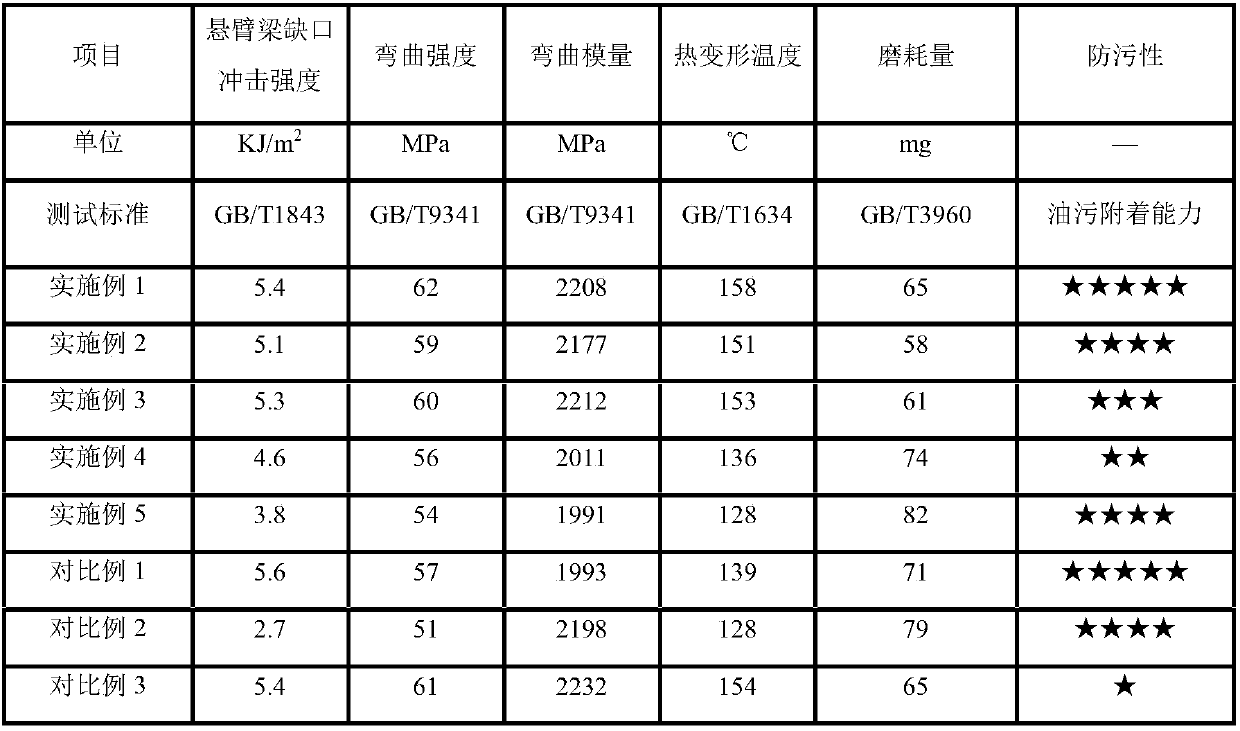

Pollution-resistance high-temperature-resistance polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer composite material modification, and particularly relates to a pollution-resistance high-temperature-resistance polypropylene material and a preparation method thereof. The polypropylene material is characterized in that high-crystallization homopolymer polypropylene is taken as a basic component, polyketone resin is added to improve the wearresistance and mechanical performance of the material, barium sulfate masterbatch is taken as a filling agent to reduce dust pollution, a compatibilizer is added to improve the bonding force betweenraw materials to improve the mechanical performance of the material, organic group modified ultrahigh molecular weight polyorganosiloxane is taken as an antifouling agent to improve the water and oilresistance and the wear resistance of the material, and the anti-ageing performance of the material is improved by adopting an antioxidant. The material has the advantages of easy processing, high glossiness, high wearing resistance, pollution resistance, easy dyeing, excellent physical mechanical performance and the like, the demands by household electrical appliance products and kitchen electrical appliances on housing materials thereof in severe environments can be completely met, and the material can be widely applied to the production of plastic spare parts which need to slide or rotate in the fields of machinery, building materials, sports and the like.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

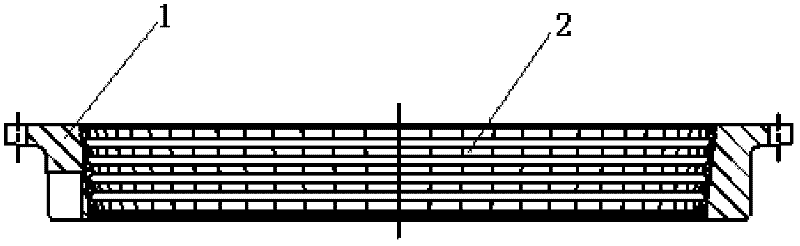

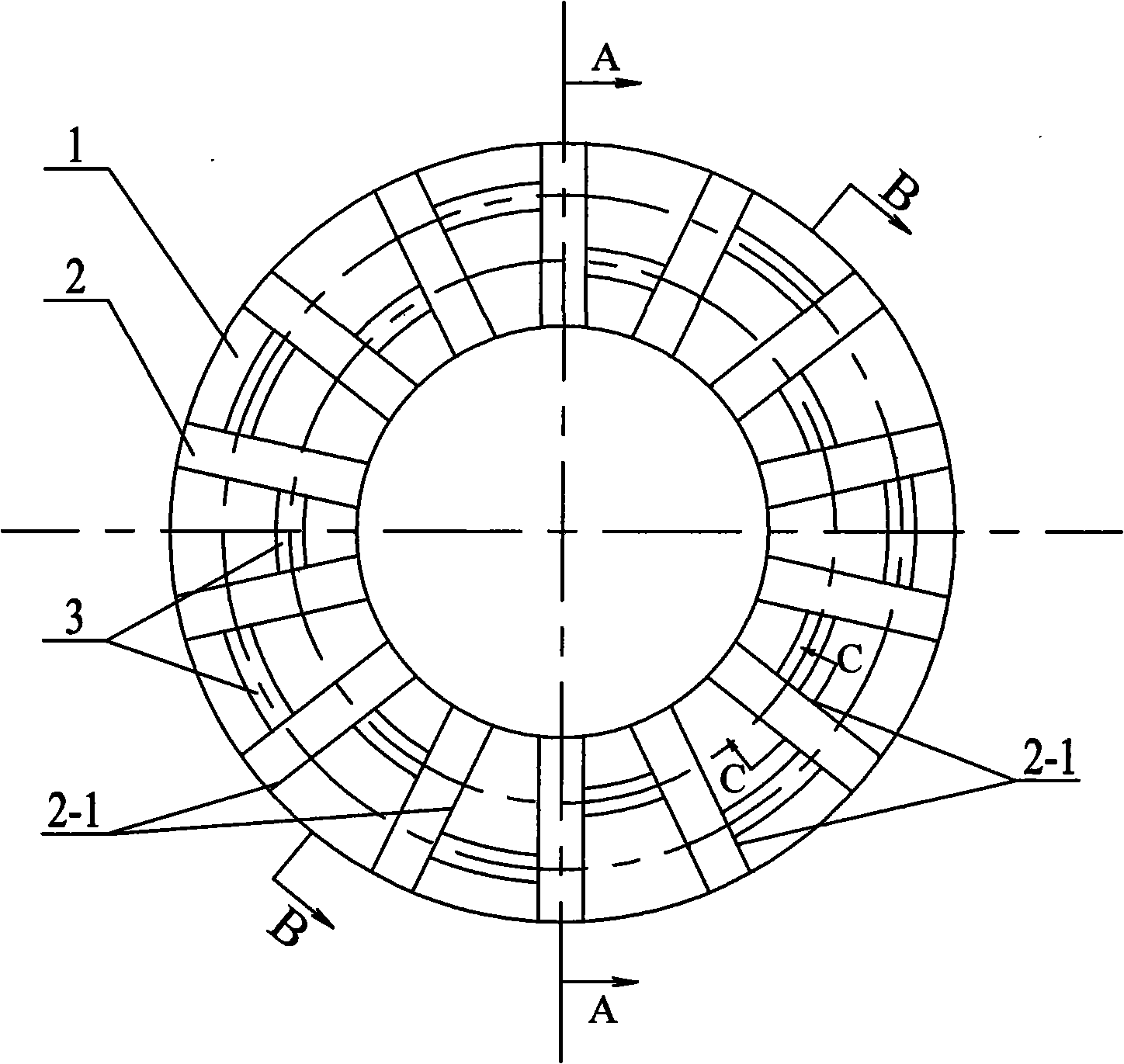

Water lubricating thrust bearing possessing annular groove

InactiveCN101285500AImprove machine efficiencyImprove machine reliabilityBearing componentsSliding contact bearingsSocial benefitsEconomic benefits

The invention discloses a water lubrication thrust bearing wit a ring grooves, relating to a thrust bearing. The invention solves the problems of bad performance of frictional wear, easy wear and cracking to a grinding disc, small bearing area, low bearing capacity, short service life, difficult fluid hydrodynamic lubrication, unreliable work process, complicated structure, large axial size, complicated processing process and high cost and so on of the prior thrust bearing. A friction surface (1) of the thrust bearing is provided with aequilate water grooves (2) along the radial direction, sector massive bearing surfaces is formed on the friction surface (1), and the sector massive bearing surfaces are provided with ring grooves (3). The water lubrication thrust bearing with the ring grooves has the advantages of high bearing capacity, long service life, easy fluid hydrodynamic lubrication, stable and reliable work process, simple structure, small axial size, simple processing process and low cost and so on. Practical application of the water lubrication thrust bearing with the ring grooves can improve whole device efficiency and reliability of water environment work machinery to a large extent, which brings better economic benefit and social benefit, and has better development potential and market prospect.

Owner:HARBIN INST OF TECH

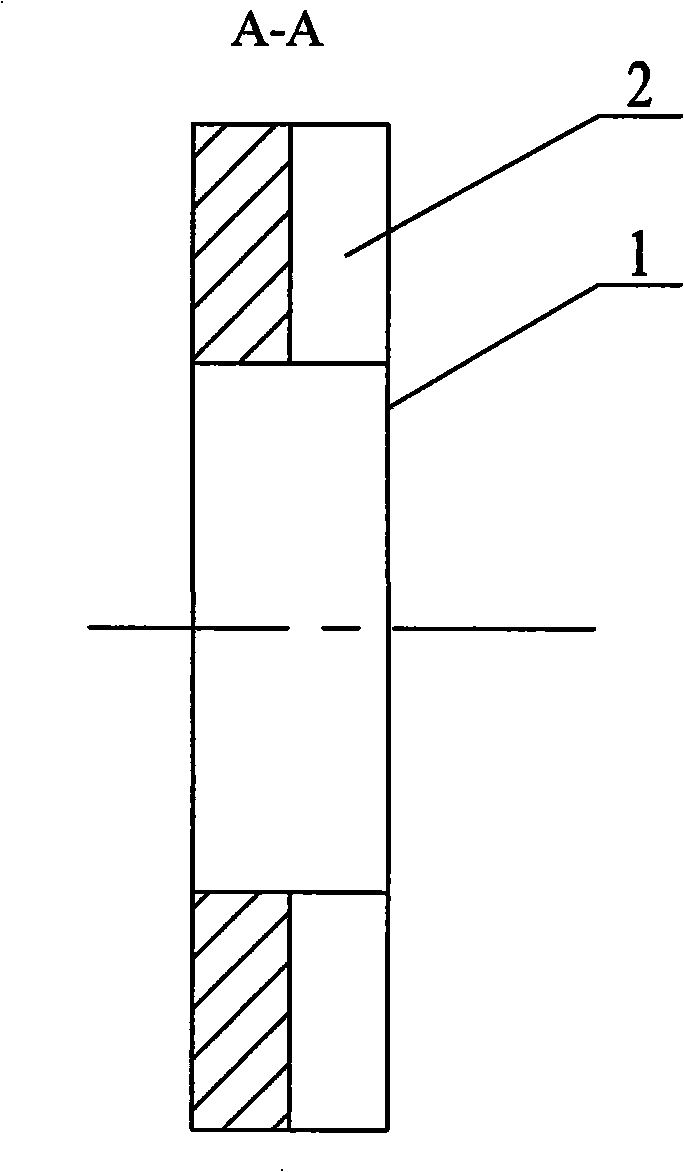

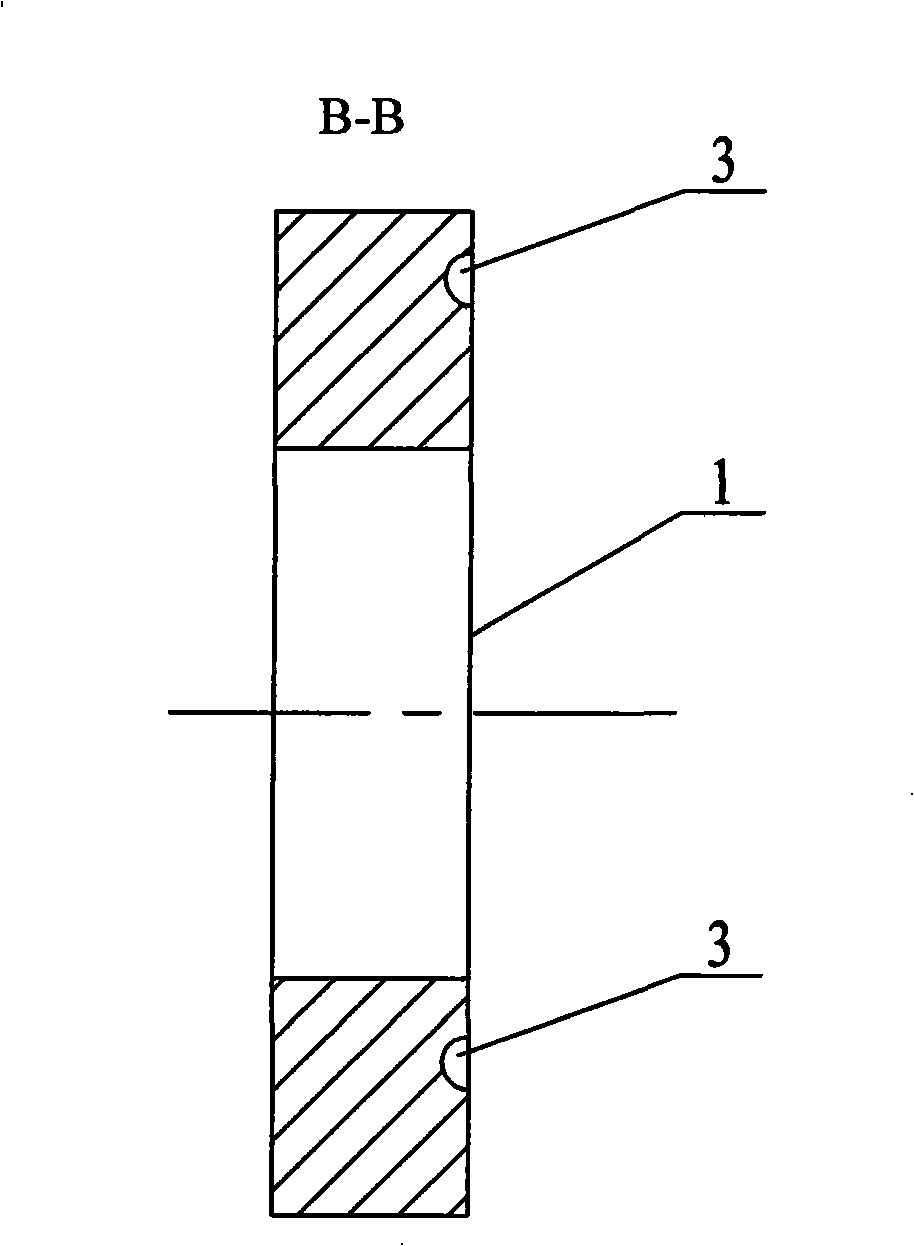

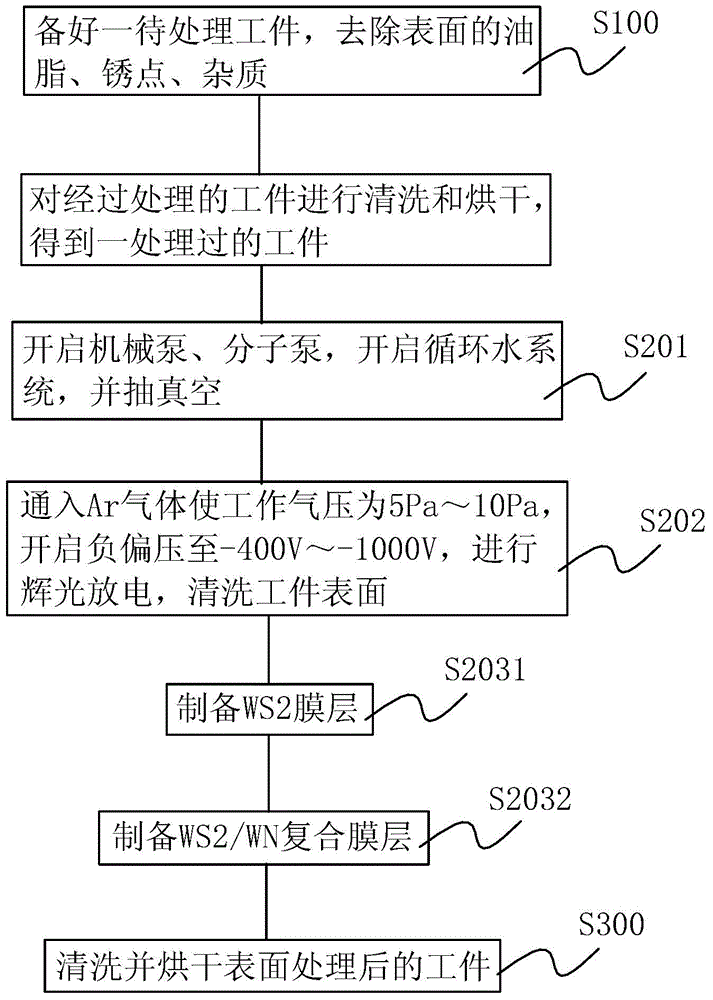

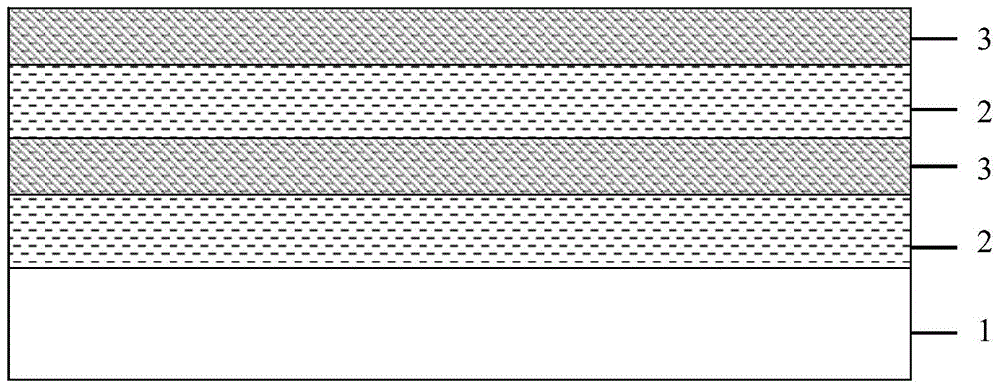

Method for preparing multiphase coupled WS2/WN solid lubrication film

ActiveCN104962860ASimple structureImprove friction and wear performanceVacuum evaporation coatingSputtering coatingVacuum pumpingComposite film

The invention discloses a method for preparing a multiphase coupled WS2 / WN solid lubrication film. The multiphase coupled WS2 / WN solid lubrication film is formed on the surface of a metal material base body in a magnetron sputtering method. The method for preparing the multiphase coupled WS2 / WN solid lubrication film includes the steps that the metal material base body to be processed is preprocessed; the metal material base body is put into a vacuum room, and vacuum pumping is conducted; a low-energy ion source is used for conducting ion bombardment cleaning on the metal material base body; a magnetron sputtering device is used for conducting surface modification on the metal material base body, Ar gas and N2 gas are used as magnetron sputtering and reacting gases, WS2 serves as the target material, a WS2 film layer is deposited on the surface of the metal material base body firstly, then a WS2 / WN film composite film layer is deposited, the operation of depositing a WS2 film layer and the operation of depositing a WS2 / WN composite film layer are cycled in turns, and 1-10 WS2 film layers are deposited and 1-10 WS2 / WN composite film layers are deposited; the metal material base body is put into an acetone solution to be cleaned and then dried, and the dried metal material base body is sealed and stored in a vacuum mode.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

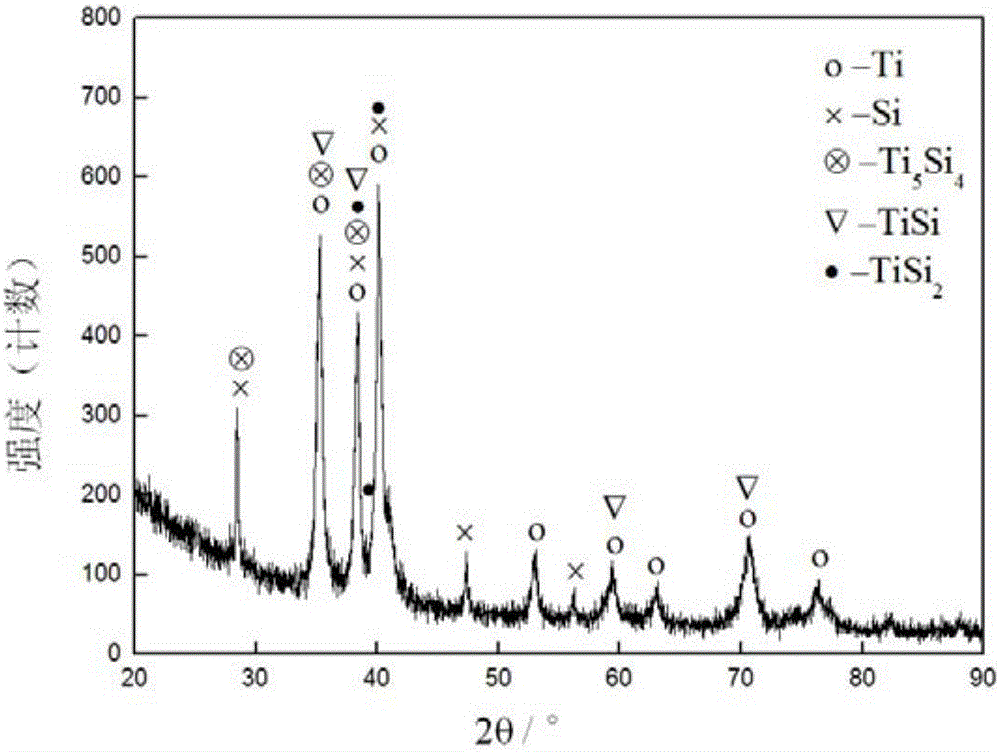

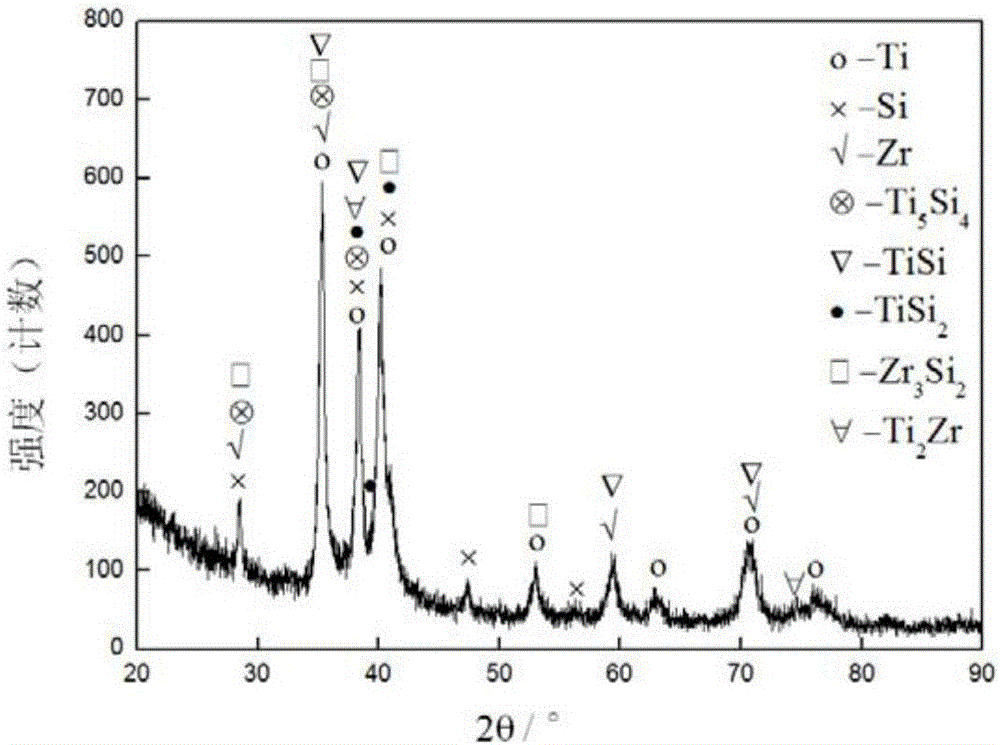

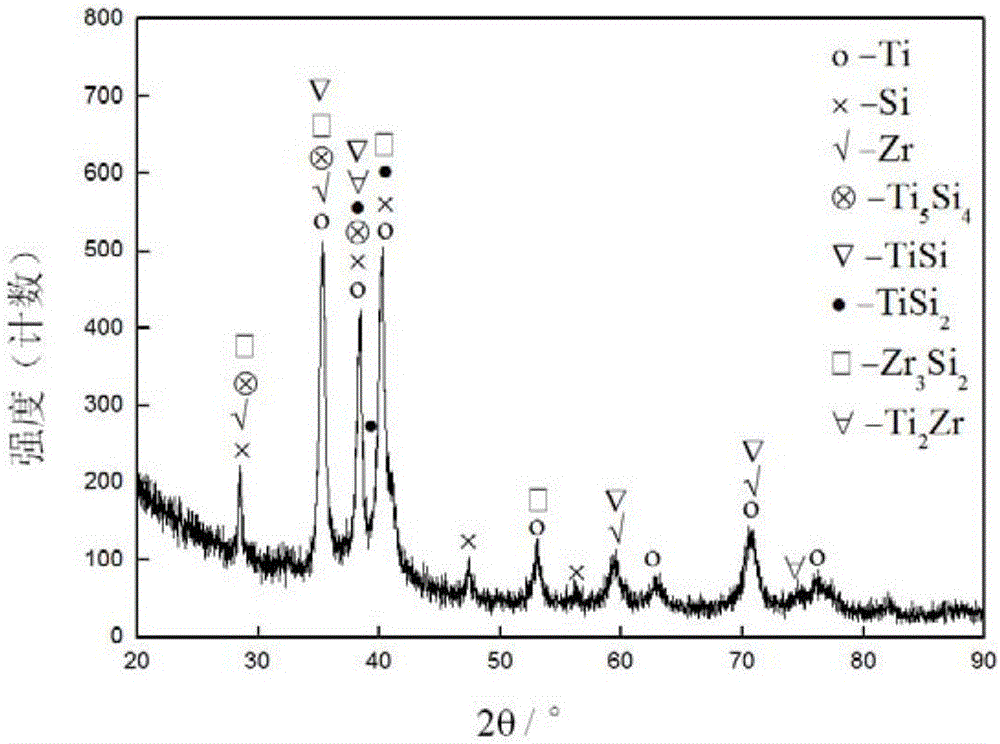

Zr alloying Ti-8Si alloy and preparing method thereof

The invention relates to a Zr alloying Ti-8Si alloy and a preparing method thereof. The Zr alloying Ti-8Si alloy is characterized in that preparation raw materials comprise Ti powder, Si powder and Zr powder. The preparing method includes the steps that firstly, the Ti powder, the Si powder and the Zr powder are evenly mixed to be subject to high energy ball milling, and partial alloying is carried out on the raw materials; secondly, powder obtained after ball milling is screened and dried; thirdly, the dried powder is prepared into press cakes through compression molding forming; and finally, vacuum pressureless sintering is carried out so that sufficient alloying can be achieved. According to the Zr alloying Ti-8Si alloy and the preparing method, the Ti-8Si-xZr alloy face is uniform in component, the compactness, the inoxidizability, the abrasive resistance and the like are improved to a certain degree, and the Zr alloying Ti-8Si alloy and the preparing method have a wide application prospect in the fields of aerospace, traffic and weaponry.

Owner:JIANGSU UNIV

Method utilizing powder metallurgy friction reducing materials to manufacture gears

InactiveCN110004373AHigh oil contentHigh hardnessTransportation and packagingMetal-working apparatusCeriumTin

The invention discloses a method utilizing powder metallurgy friction reducing materials to manufacture gears. Surface layer materials including graphite, molybdenum, titanium, copper, cerium dioxide,zinc stearate, tin and iron are uniformly mixed by a ratio. Base body materials including nickel, molybdenum, titanium, graphite, a lubricating agent, a sintering aid and iron powder are uniformly mixed after being previously dispersed. Then, the surface layer materials and the base body materials which are mixed together are sequentially put in the same mould, and a green is pressed at 60-120DEGC under the pressure of 500-600Mpa. Low-temperature pre-sintering and high-temperature sintering are carried out under the protection of hydrogen and argon. Then, oil immersion is carried out, and afinished product is finally obtained. The finished product comprises a surface layer and a base body layer, the base body layer is high in density, high in strength and high in hardness, has high carrying capability and is used for carrying, the surface layer is a porous layer and provides a lubricating function, and at the same time, TiC particles produced on the surface layer ensure the strengthand hardness of the surface layer.

Owner:益阳市再超粉末冶金有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com