Preparation method of polydopamine modified carbon fiber/mullite whisker reinforced resin-based friction material

A technology of mullite whisker and reinforced resin base, applied in the field of dry friction materials, can solve the problems of fiber surface damage, reduce the bonding strength of ceramic/fiber and resin interface, etc. The effect of thermal performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

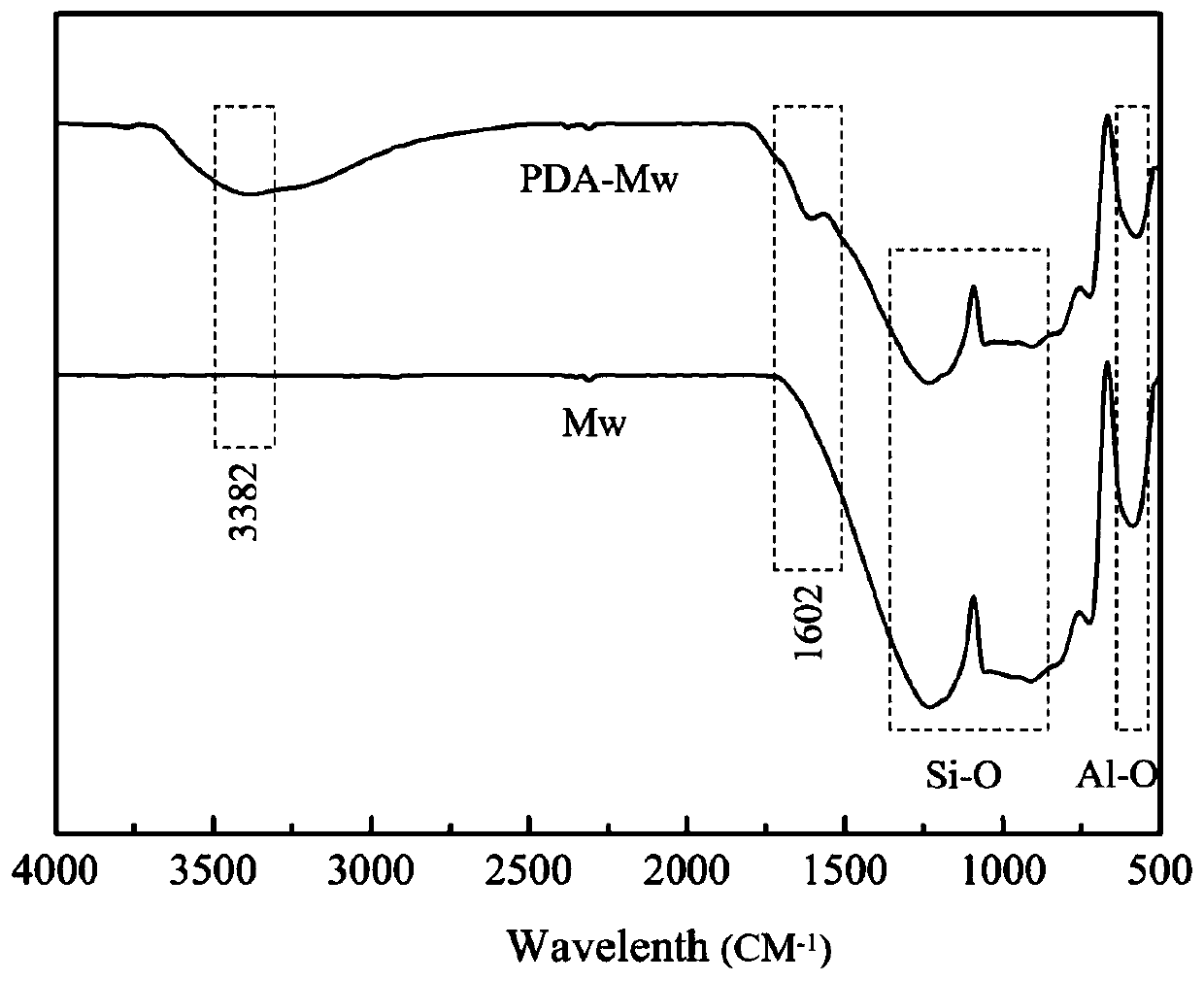

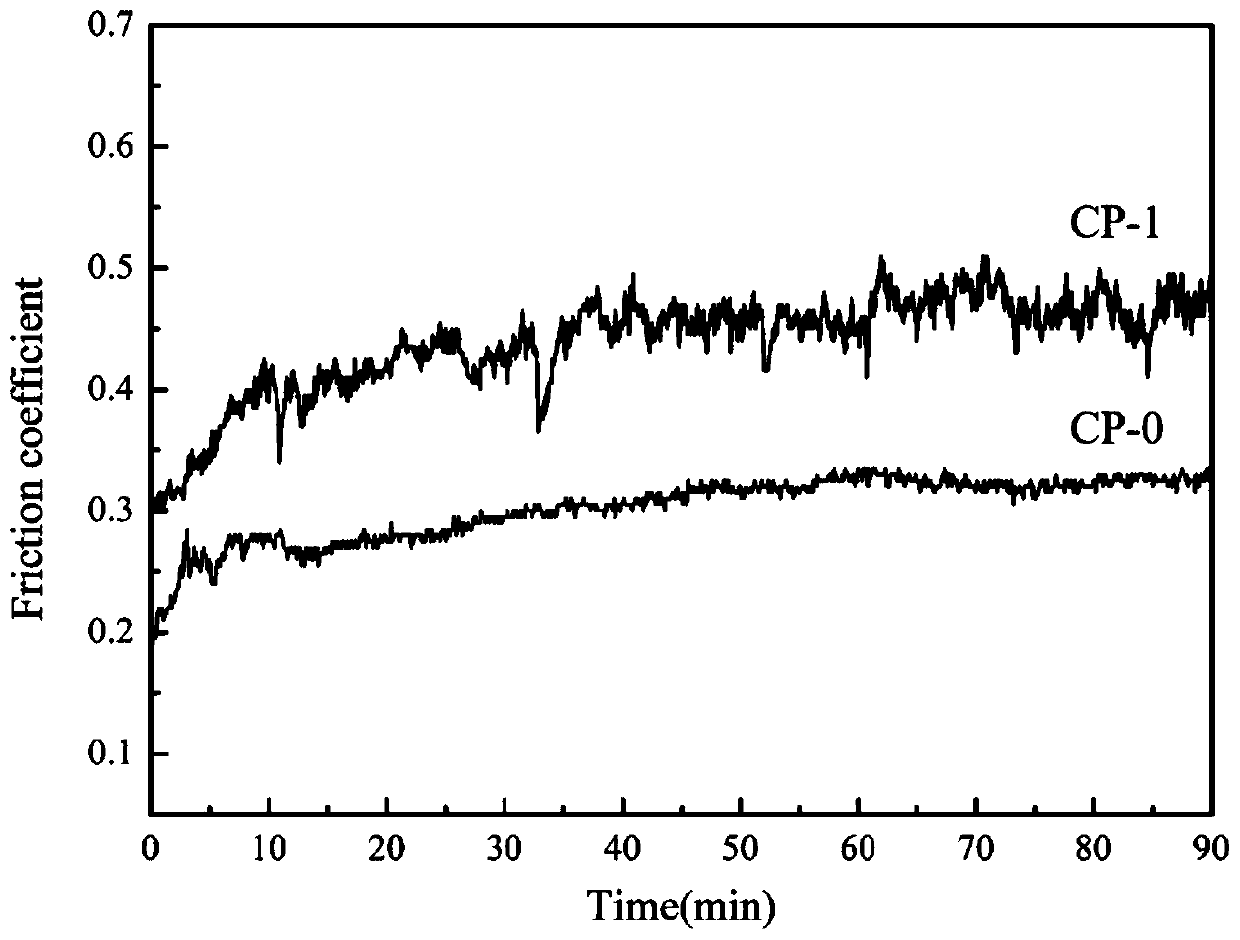

[0027] A method for preparing a polydopamine-modified carbon fiber / mullite whisker-reinforced resin-based friction material, comprising the following steps:

[0028] 1) The carbon fiber and mullite whiskers are degummed and cleaned respectively by using a mixed solution of acetone and ethanol, and the volume ratio of acetone and ethanol in the mixed solution of acetone and ethanol is 1:1;

[0029] 2) Dissolving Tris in ultrapure water and adjusting the pH of the solution to 8.5 to obtain a buffer solution with a concentration of 10-40 mM, adding dopamine to the buffer solution and stirring to obtain a concentration of 1-2.5 g / L Dopamine modification solution, the carbon fibers and mullite whiskers obtained in step 1) are added to the dopamine modification solution respectively for modification, the modification time is 24h, the temperature is room temperature, stir with a magnetic stirrer, and the stirring speed is 600r / min, the modified carbon fiber and the modified mullite ...

Embodiment 1

[0033] A method for preparing a polydopamine-modified carbon fiber / mullite whisker reinforced resin-based friction material, comprising the following steps:

[0034] 1) adopting acetone: a mixed solution with a volume ratio of ethanol of 1:1 to degumming carbon fiber and mullite whisker respectively and drying after cleaning with ultrapure water;

[0035] 2) Tris was dissolved in ultrapure water to prepare a 10 mM buffer solution, and the pH of the solution was adjusted to 8.5. Dopamine is added to the buffer solution and stirred to obtain a 1g / L dopamine modified solution, the carbon fibers and mullite whiskers obtained in step 1) are added to the dopamine modified solution respectively, and a magnetic stirrer is used at room temperature to Stir at a speed of 600r / min, wash and filter the modified carbon fibers and mullite whiskers, and dry at 60°C to obtain modified carbon fibers and modified mullite whiskers;

[0036] 3) Mix the modified carbon fiber and the modified mulli...

Embodiment 2

[0038] A method for preparing a polydopamine-modified carbon fiber / mullite whisker reinforced resin-based friction material, comprising the following steps:

[0039] 1) adopting acetone: a mixed solution with a volume ratio of ethanol of 1:1 to degumming carbon fiber and mullite whisker respectively and drying after cleaning with ultrapure water;

[0040] 2) Dissolving Tris in ultrapure water to prepare a 20 mM buffer solution, and adjusting the pH of the solution to 8.5. Dopamine is added to the buffer solution and stirred to obtain a 1g / L dopamine modified solution, the carbon fibers and mullite whiskers obtained in step 1) are added to the dopamine modified solution respectively, and a magnetic stirrer is used at room temperature to Stir at a speed of 600r / min, wash and filter the modified carbon fibers and mullite whiskers, and dry at 60°C to obtain modified carbon fibers and modified mullite whiskers;

[0041] 3) Mix the modified carbon fiber and the modified mullite whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com