Preparation method of porous carbon-doped high-dispersion cobalt-phosphide-loaded material and application of porous carbon-doped high-dispersion cobalt-phosphide-loaded material in electro-catalysis hydrogen evolution

A cobalt phosphide and chemical doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of poor conductivity of metal phosphides, difficult to conduct electrons effectively, and need to be optimized and simplified. Conducive to environmental protection, ensuring long-term durability, high thermal and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

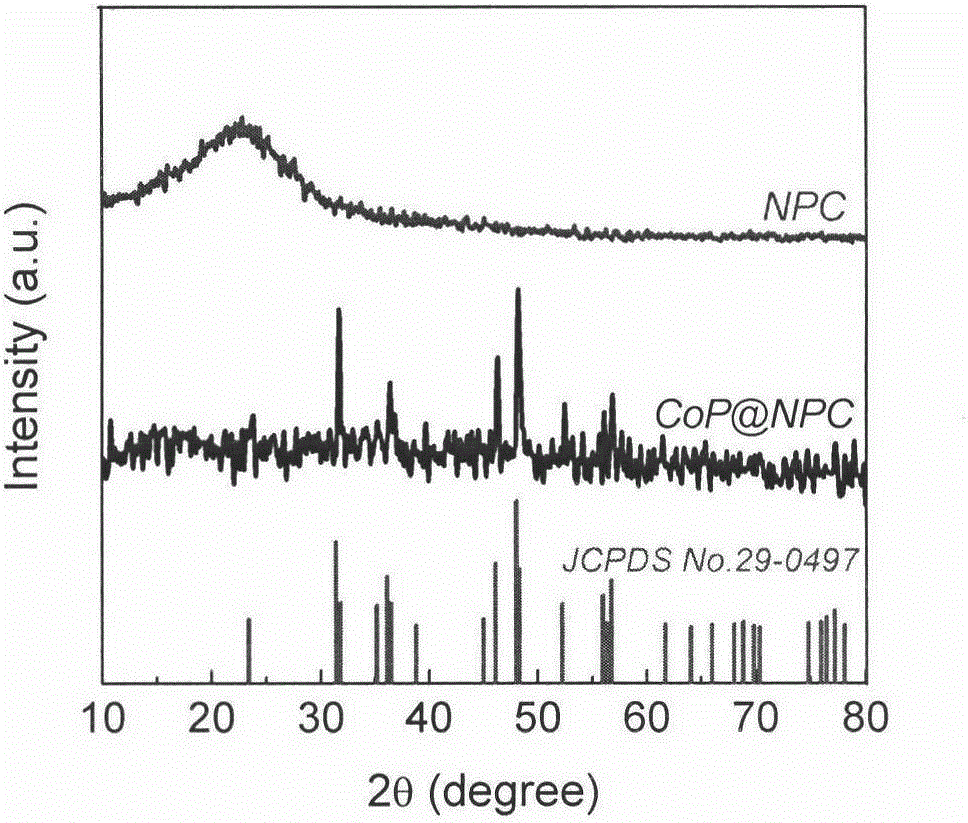

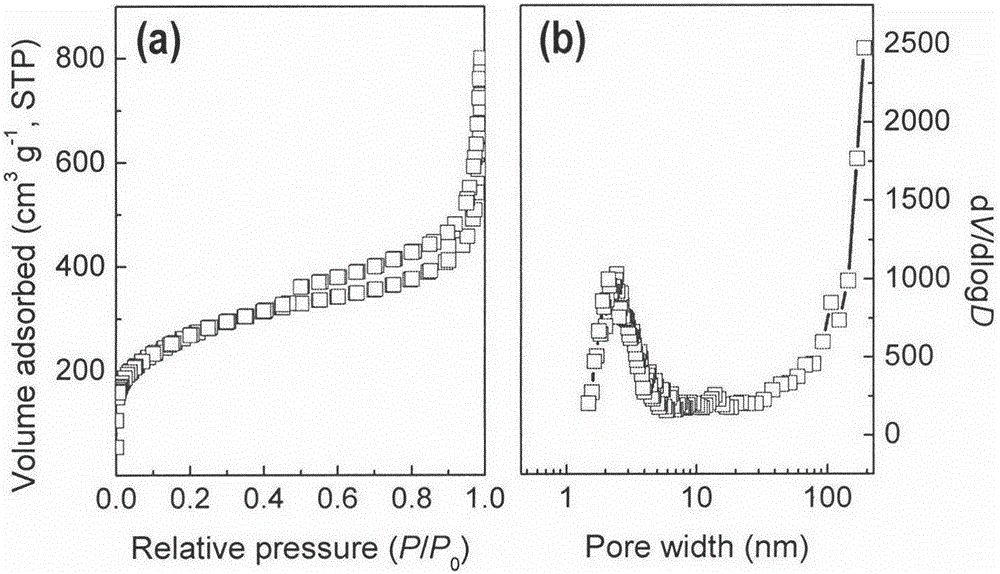

[0025] Under stirring at room temperature, 1.236 g of phosphonic acid HEDP was added into 100 ml of deionized water until clear, and then 1.01 g of melamine was slowly added. The temperature was raised to 105° C. to evaporate the solvent to dryness, and the resulting white solid product was continued to be treated at 80° C. under vacuum for 6 h. The product was under nitrogen protection, the nitrogen flow rate was 5ml / min, the temperature was programmed to 900°C for 3h, and the heating rate was 10°C / min, and it was naturally cooled to room temperature. The product was washed, further dried, and a sample was collected, which was recorded as NPC. The samples were characterized by XRD, nitrogen adsorption / desorption, SEM, TEM, XPS and Raman, etc., which confirmed that they were nitrogen-phosphorus co-doped carbon materials with mesoporous-macroporous structure. Among them, TEM and SEM show that the material has irregular macroporous channels. XRD and Raman spectra show that the ...

Embodiment 2

[0027] Under stirring at room temperature, 1.236 g of phosphonic acid HEDP was added into 100 ml of deionized water until clear, and then 1.01 g of melamine was slowly added. 0.012g of cobalt chloride hexahydrate was slowly added, the temperature was programmed to 105°C and the solvent was evaporated to dryness, and the obtained solid product was continued to be treated at 80°C under vacuum for 6h. The product was under the protection of nitrogen, the nitrogen flow rate was 50ml / min, the temperature was programmed to 900°C and kept for 3h, and the heating rate was 10°C / min, and it was naturally cooled to room temperature. The product was cross-washed with hydrochloric acid and water, further dried, and a sample was collected, which was designated as CoPNPC . The samples were characterized by XRD, nitrogen adsorption / desorption, SEM, TEM, XPS and Raman, etc., which confirmed that they were nitrogen-phosphorus co-doped carbon materials with mesoporous-macroporous structure and u...

Embodiment 3

[0029] In Example 1, 5 mg of the sample was taken as an electrocatalyst, ultrasonically dispersed in a mixed solution of 20 μl Nafion (Sigma-Aldrich), 0.2 ml isopropanol, and 0.8 ml deionized water, and ultrasonicated for 30 min. 10 μl of the dispersion solution was dropped onto a pre-polished glassy carbon (GC) electrode with a radius of 3 mm, and dried overnight at room temperature. Electrochemical tests were performed on a computer-controlled electrochemical workstation with a rotating rod. The scanning range of the disk electrode is 0 to -0.6V (vs reversible hydrogen electrode). Figure 5 The linear sweep polarization curves and Tafel curves of the synthesized catalysts are shown. The onset overpotential of electrochemical hydrogen evolution of NPC sample is 126mV, and the slope of Tafel curve is 148mV / dec.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com