Waterborne polyurethane epoxy resin modified emulsified asphalt

A water-based polyurethane and epoxy resin technology, applied in the direction of on-site coagulation pavement, building components, building insulation materials, etc., can solve the problems of inferior asphalt, low flexibility, brittle cracking, etc., and achieve high cohesion. , Good flexibility, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of water-based epoxy resin curing agent

[0032] Diethylenetriamine and polypropylene glycol diglycidyl ether are in a molar ratio of 4:1, put diethylenetriamine into a four-necked flask with stirring and reflux condensation, add a small amount of sodium hydroxide, heat to 70°C, and slowly add polypropylene glycol After adding diglycidyl ether, continue to react under stirring for 3 hours, then distill off excess diethylenetriamine under reduced pressure, add hydrochloric acid and water to neutralize to pH 8.0, solid content 50%.

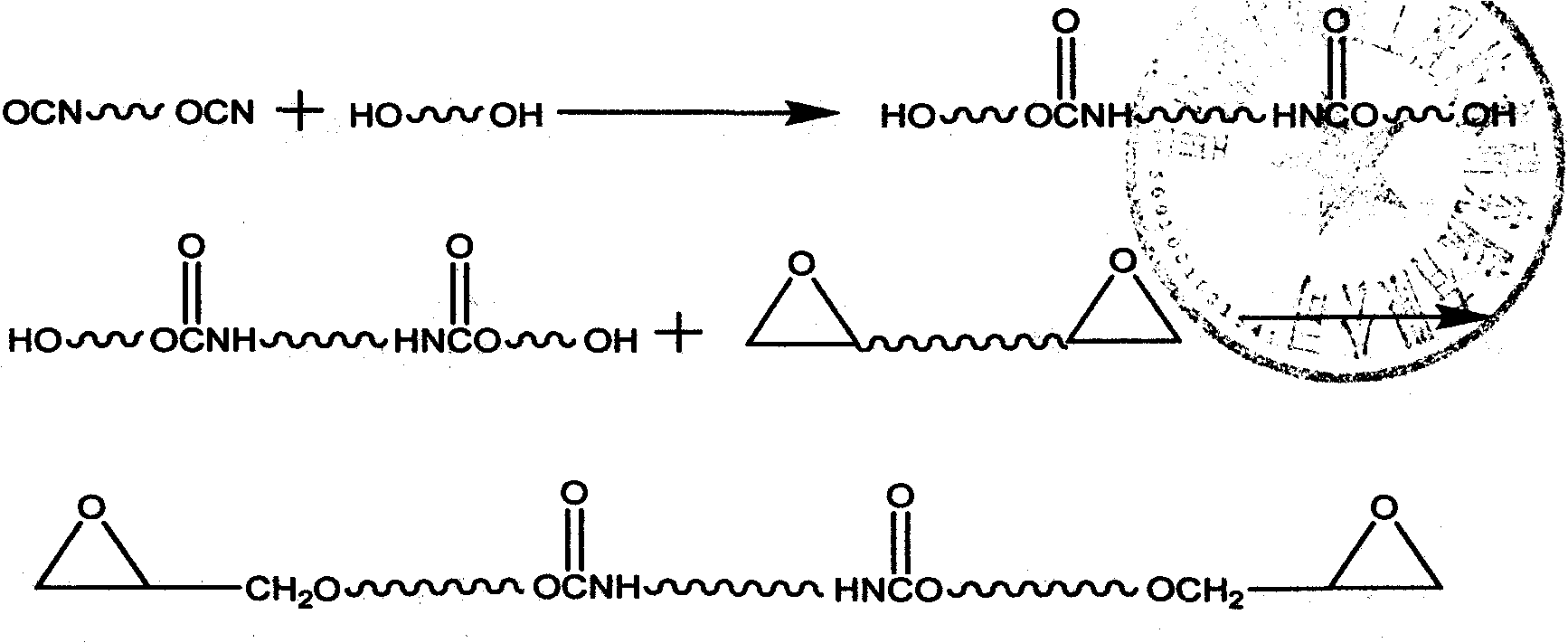

[0033] 2. Preparation of Waterborne Polyurethane Epoxy Resin

[0034] 2.1 Preparation of polyurethane epoxy resin

[0035] Put polyethylene glycol 80 into a dry four-necked flask with stirring and reflux condensation, heat to 80°C, vacuumize to remove moisture, fill with nitrogen for protection, slowly add hexamethylene diisocyanate, and continue to react under stirring after the addition is complete 4 hours.

[0036] Add ep...

Embodiment 2

[0047] 1. Preparation of water-based epoxy resin curing agent

[0048] Triethylenetetramine and polypropylene glycol diglycidyl ether are in a molar ratio of 4:1, put triethylenetetramine into a four-necked flask with stirring and reflux condensation, add an appropriate amount of sodium hydroxide, heat to 70 °C, and slowly add polypropylene glycol After adding diglycidyl ether, continue to react under stirring for 3 hours, then distill off excess triethylenetetramine under reduced pressure, add hydrochloric acid and water to neutralize to pH 2.0, solid content 50%.

[0049] 2. Preparation of Waterborne Polyurethane Epoxy Resin

[0050] 2.1 Preparation of polyurethane epoxy resin

[0051] Put polyethylene glycol 200 into a dry four-neck flask with stirring and reflux condensation, heat to 80°C, vacuumize to remove moisture, fill with nitrogen for protection, slowly add toluene diisocyanate, and continue to react under stirring for 4 hours after the addition is complete.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com