Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1987 results about "Polypropylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene glycol or polypropylene oxide is the polymer of propylene glycol. Chemically it is a polyether, and, more generally speaking, it's a polyalkylene glycol (PAG). The term polypropylene glycol or PPG is reserved for low to medium range molar mass polymer when the nature of the end-group, which is usually a hydroxyl group, still matters. The term "oxide" is used for high molar mass polymer when end-groups no longer affect polymer properties. In 2003, 60% of the annual production of propylene oxide of 6.6×10⁶ tonnes was converted into the polymer.

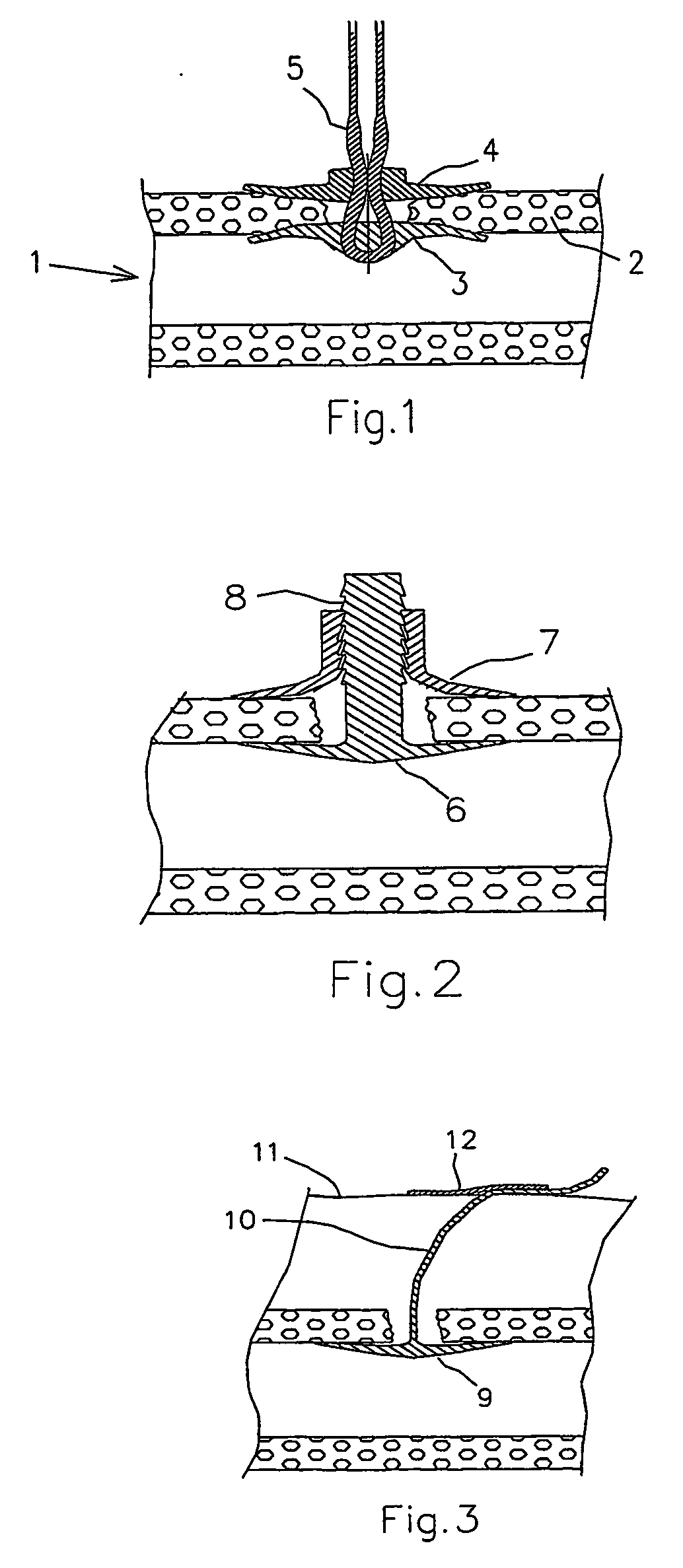

Dissolvable medical sealing device

ActiveUS20050169974A1Shorten the timeSuture equipmentsPharmaceutical delivery mechanismOrganismal ProcessPolyvinyl alcohol

The present invention provides a dissolvable medical sealing device (3, 4; 6, 7; 9) for closing a wound in vessel. A sealing device (3, 4, 6, 7, 9) according to the invention is made of a material that dissolves by means of physical processes, rather than by means of chemical or biological processes. Such a sealing device (3, 4; 6, 7; 9) can be made of polyethylene glycol, polypropylene glycol, copolymers containing ethylene glycol and propylene glycol, polyvinyl alcohol or polyvinyl pyrolidone, or any combinations thereof.

Owner:TERUMO MEDICAL CORP

Polypropylene glycol foamable vehicle and pharmaceutical compositions thereof

The present invention teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent water and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof. The present invention further teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent, and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Polypropylene glycol foamable vehicle and pharmaceutical compositions thereof

InactiveUS20080152596A1Easy to useCosmetic preparationsBiocidePolypropylene glycolSurface-active agents

The present invention teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent water and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.The present invention further teaches a foamable pharmaceutical carrier comprising polypropylene glycol (PPG) alkyl ether, a surface-active agent, and a liquefied hydrocarbon gas propellant; and pharmaceutical compositions thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

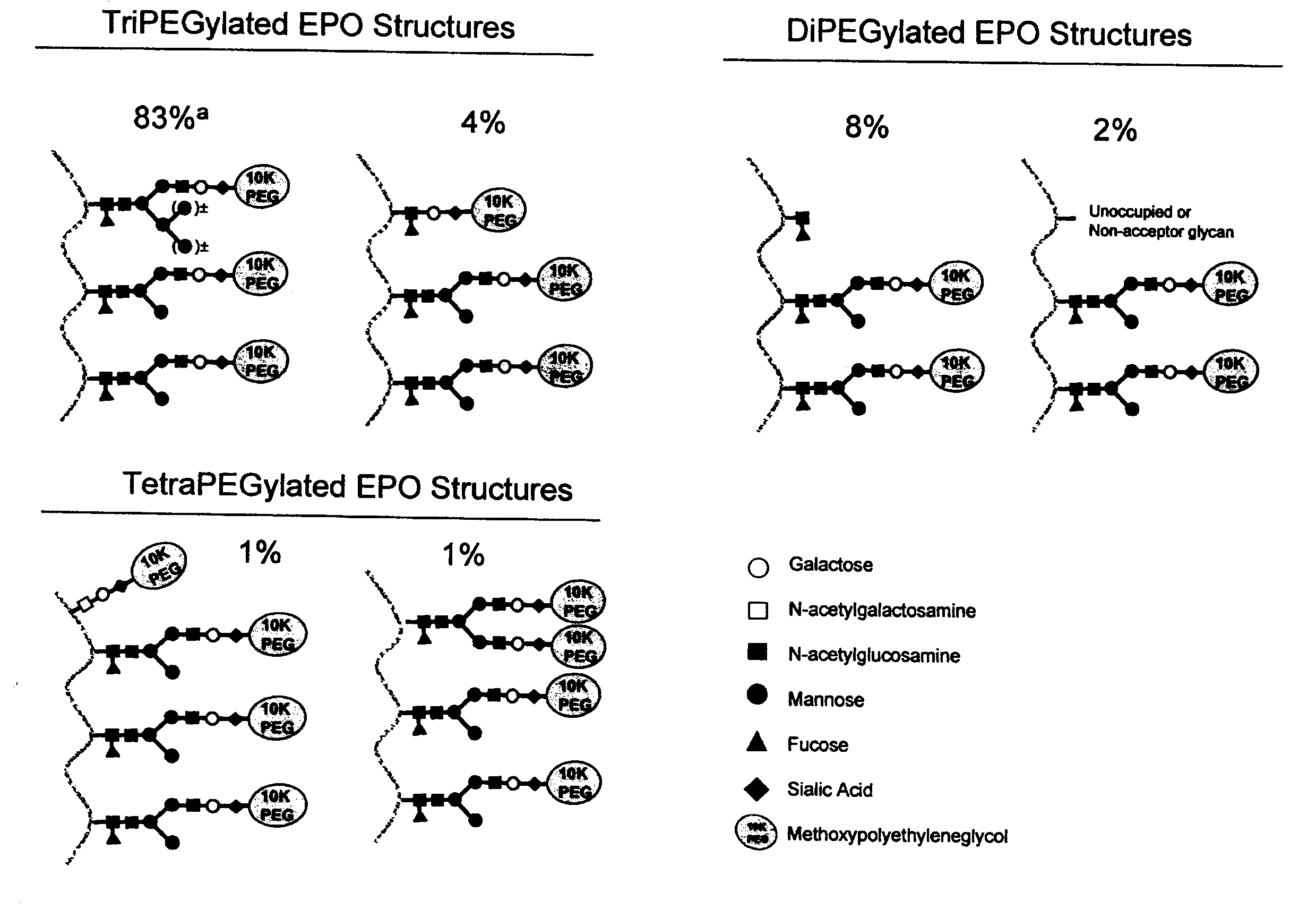

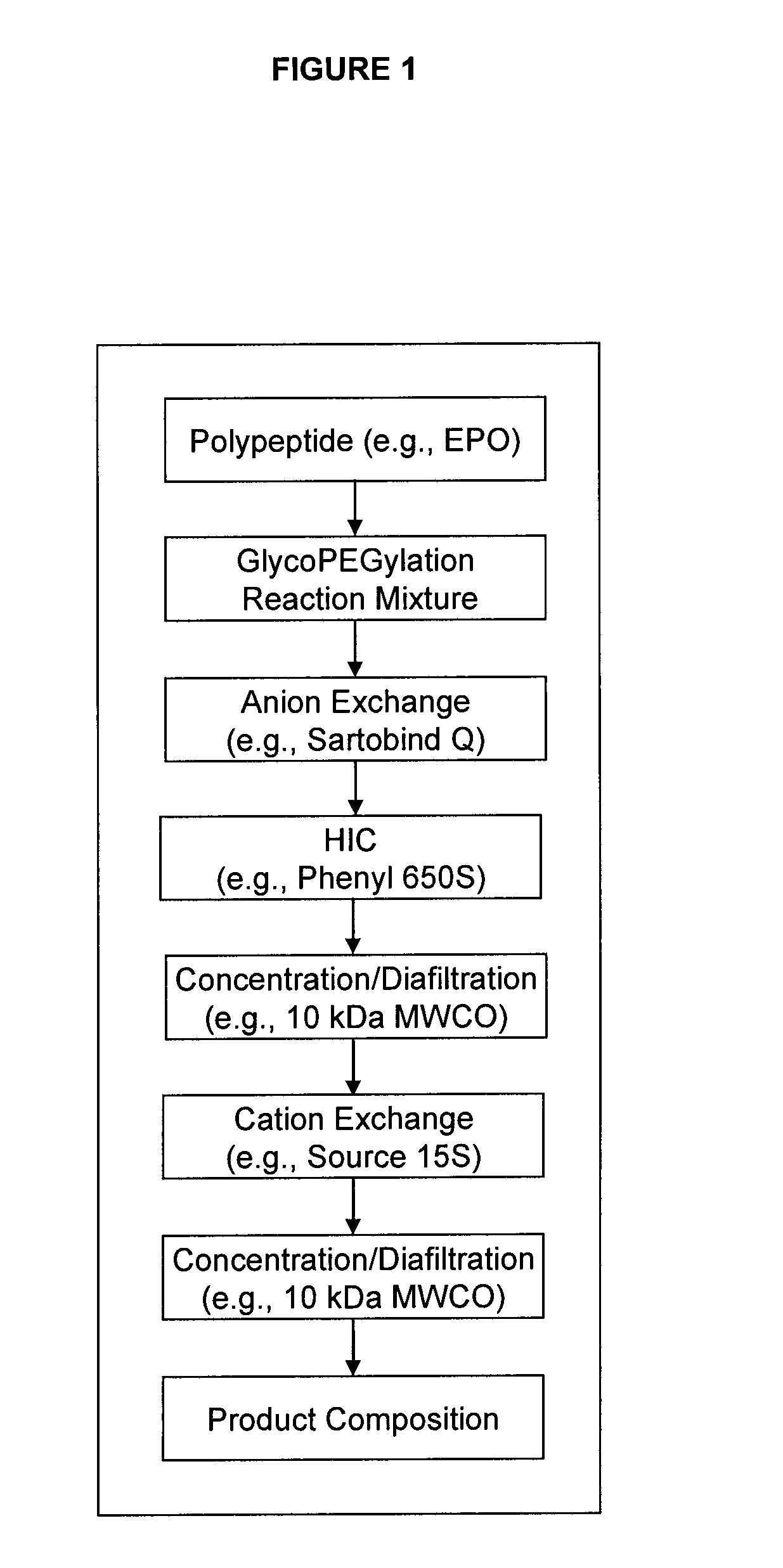

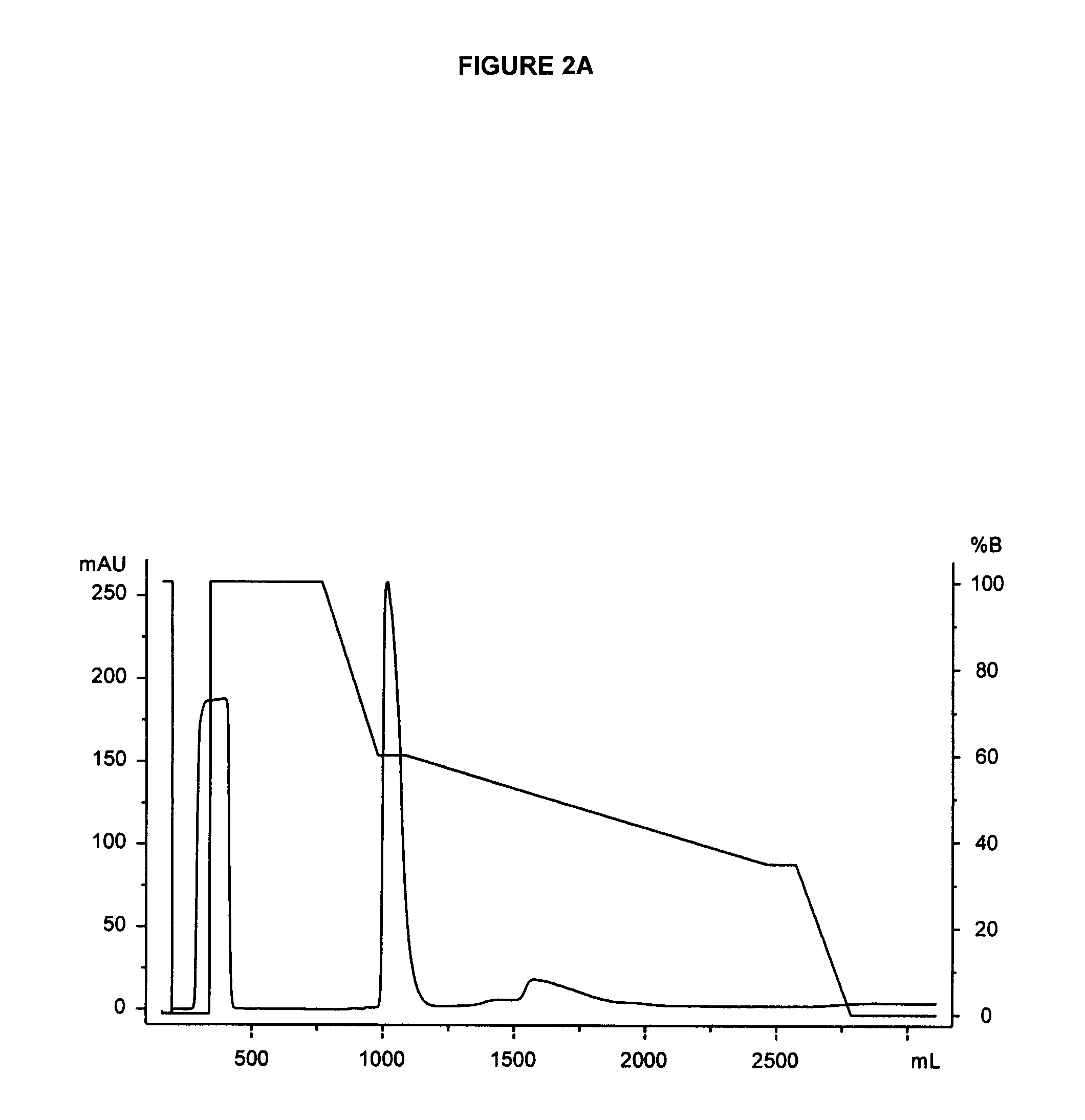

Methods for the purification of polypeptide conjugates

InactiveUS20100035299A1Peptide/protein ingredientsImmunoglobulinsPolymer sciencePolypropylene glycol

The present invention provides processes for the manufacturing of polypeptide conjugates. In particular, the invention provides methods for the purification of polypeptide conjugates, which include at least one polymeric modifying groups, such as a poly(alkylene oxide) moiety. Exemplary poly(alkylene oxide) moieties include poly(ethylene glycol) (PEG) and poly(propylene glycol). In an exemplary process, hydrophobic interaction chromatography (HIC) is used to resolve different glycoforms of glycoPEGylated polypeptides.

Owner:NOVO NORDISK AS

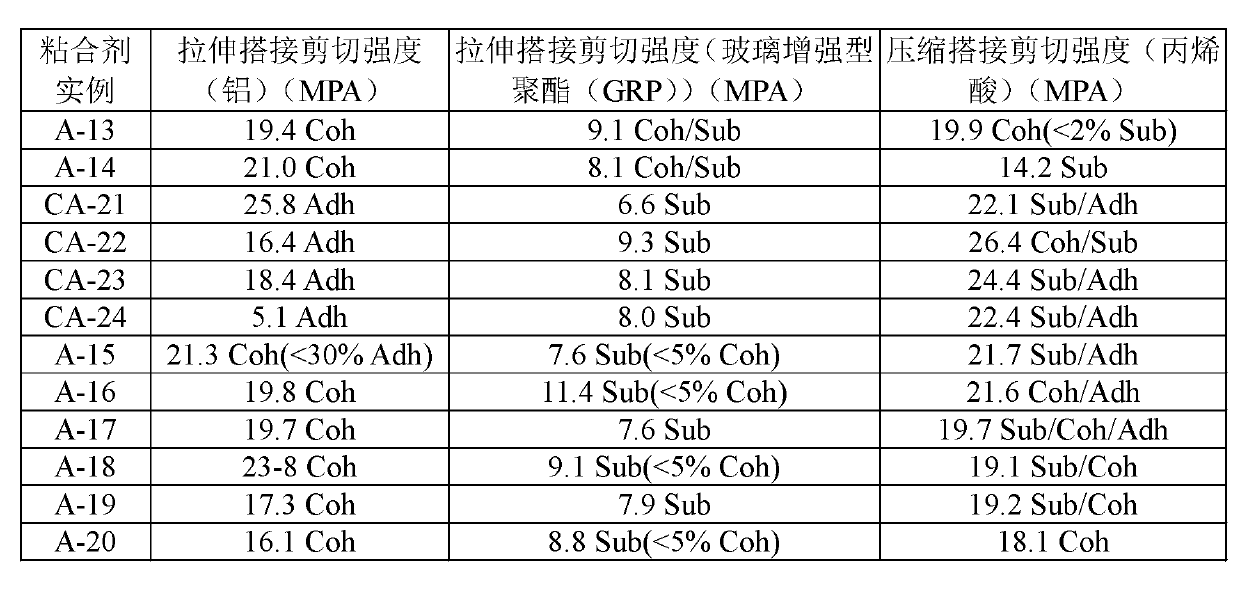

Polyurethane PSA

ActiveUS7160976B2Polyureas/polyurethane adhesivesSynthetic resin layered productsPolymer sciencePolypropylene glycol

Pressure-sensitive adhesive based on polyurethane, characterized in that the polyurethane is composed of the following starting materials which are reacted with one another in the stated proportions:a) at least one aliphatic or alicyclic diisocyanate having in each case an asymmetrical molecular structure,b) a combination of at least one polypropylene glycol diol and at least one polypropylene glycol triol,the ratio of the number of hydroxyl groups in the diol component to the number of hydroxyl groups in the triol component being between 0.7 and 9.0, preferably between 1.5 and 2.5,additionally the ratio of the number of isocyanate groups to the total number of hydroxyl groups being between 0.9 and 1.1, preferably between 0.95 and 1.05, and the diols and triols alternatively being selected and combined in each case as follows:diols having a molecular weight of less than or equal to 1000 are combined with triols whose molecular weight is greater than 1000, preferably greater than or equal to 3000,diols having a molecular weight of greater than 1000 are combined with triols whose molecular weight is less than 1000.

Owner:TESA SE

Degradable mulch film and preparation method thereof

InactiveCN102850626AFast degradationHigh strengthPlant protective coveringsPolyolefinPolymer science

The invention provides a degradable mulch film and a preparation method thereof, which belongs to the technical field of high polymer materials. The degradable mulch film comprises, by weight, 10 to 20 parts of polyethylene, 10 to 20 parts of polypropylene, 2 to 3 parts of polyvinyl alcohol, 1 to 2 parts of poly propylene carbonate, 3 to 5 parts of polylactic acid, 1 to 2 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), 4 to 6 parts of chitosan, 2 to 4 parts of methyl-polyolefin resin, 2 to 4 parts of polypropylene glycol, 0.5 part of nanometer titanium dioxide, 0.5 part of a photolysis agent, 5 to 15 parts of an inorganic filling material and 5 to 15 parts of starch. The degradable mulch film provided by the invention has the following advantages: 1, a fast degradation fast, and a fast degradation rate of more than 35% within 120 d; 2, high strength, transverse tensile strength of more than 16 MPa and vertical tensile strength of more than 17 MPa.

Owner:苏州市德莱尔建材科技有限公司

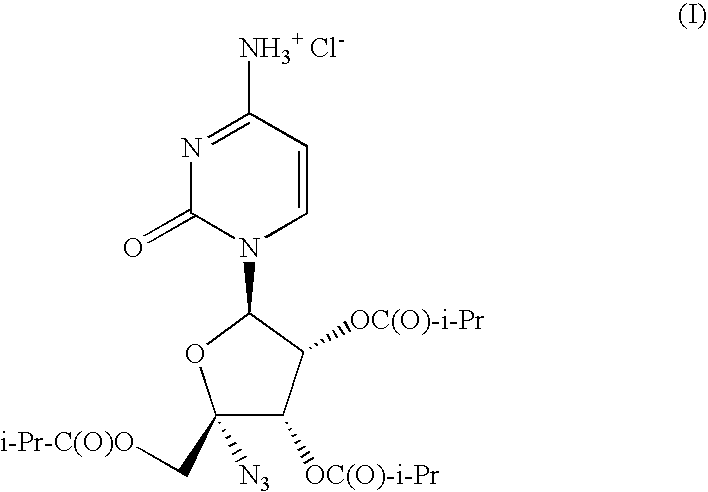

Pharmaceutical composition and process

The present invention relates to a pharmaceutical composition comprising a solid suspension prepared by hot melt extrusion of isobutyric acid (2R,3S,4R,5R)-5-(4-amino-2-oxo-2H-pyrimidin-1-yl)-2-azido-3,4-bis-iso-butyryloxy-tetrahydro-furan-2-ylmethyl ester; hydrochloride salt (I) and a polyethylene glycol (PEG) / polypropylene glycol (PPG) block copolymer.

Owner:ROCHE PALO ALTO LLC

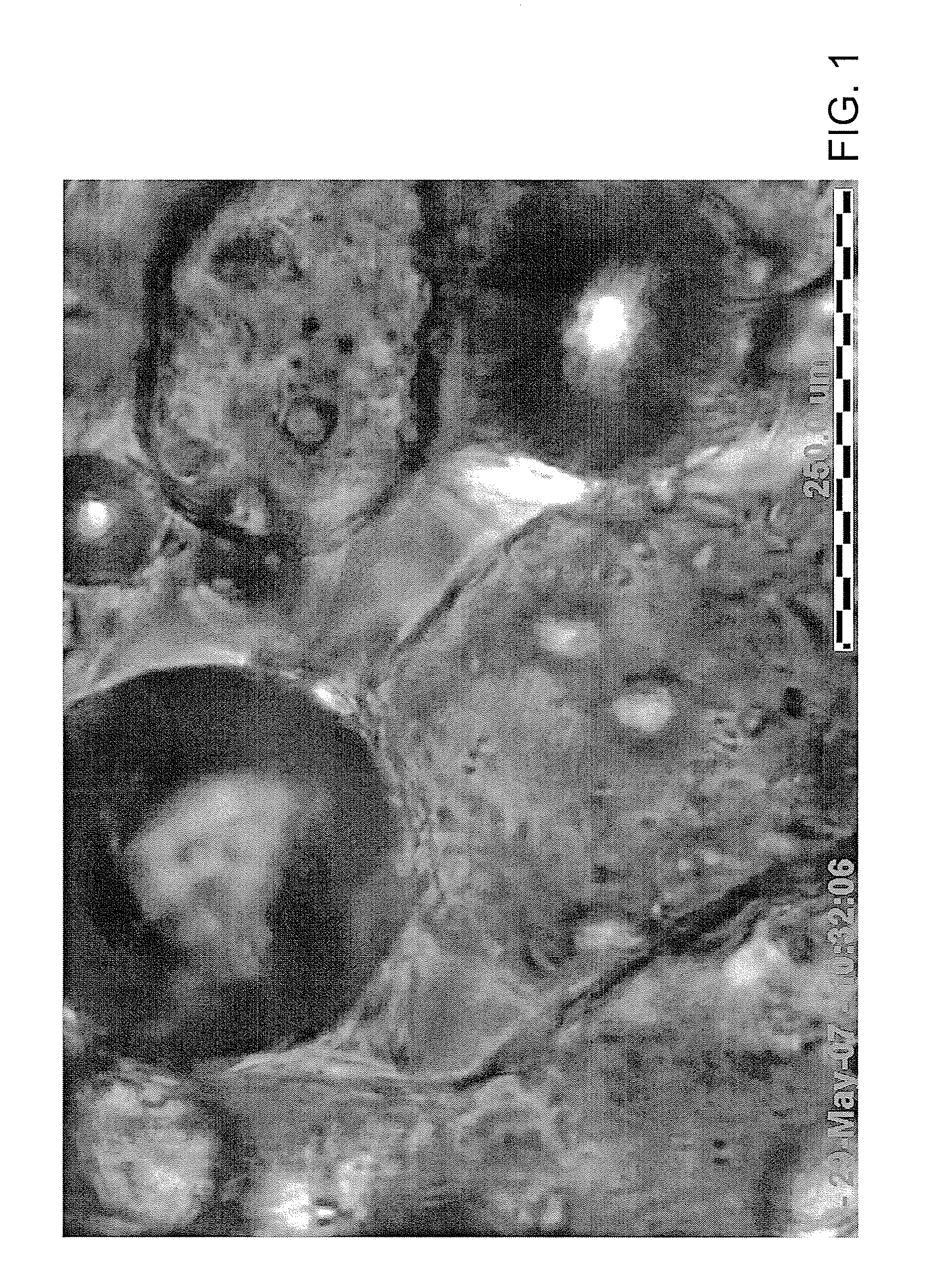

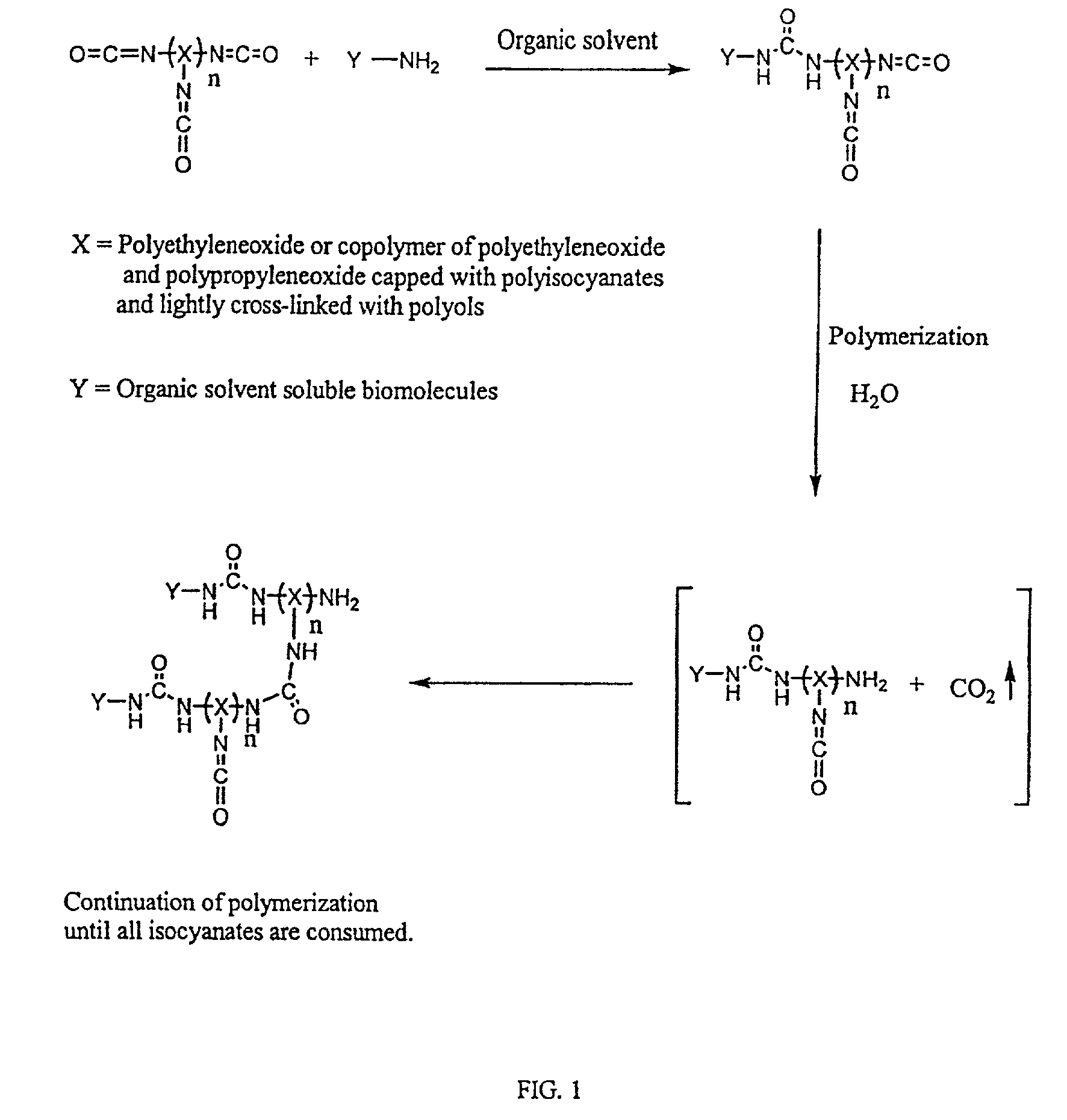

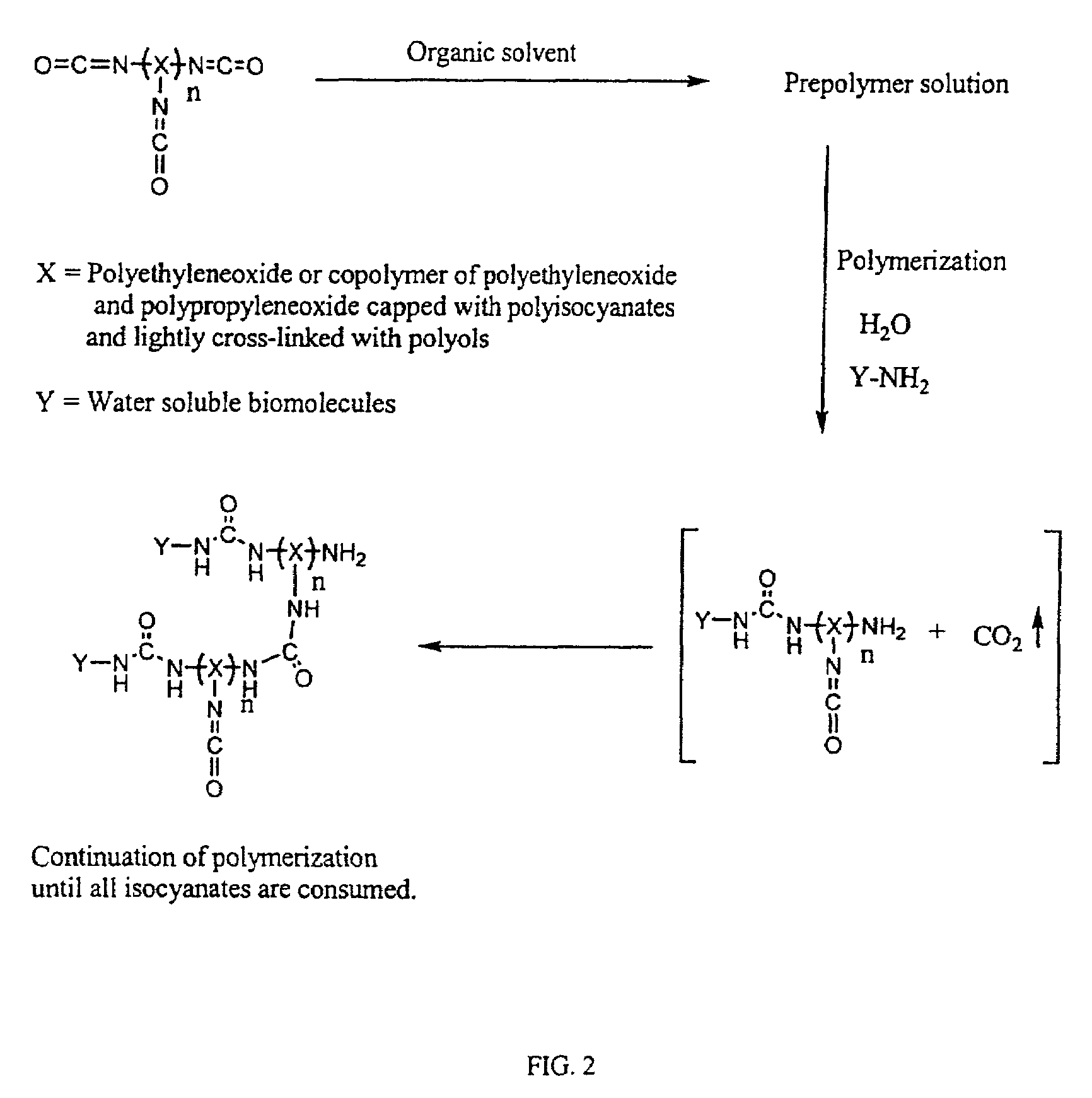

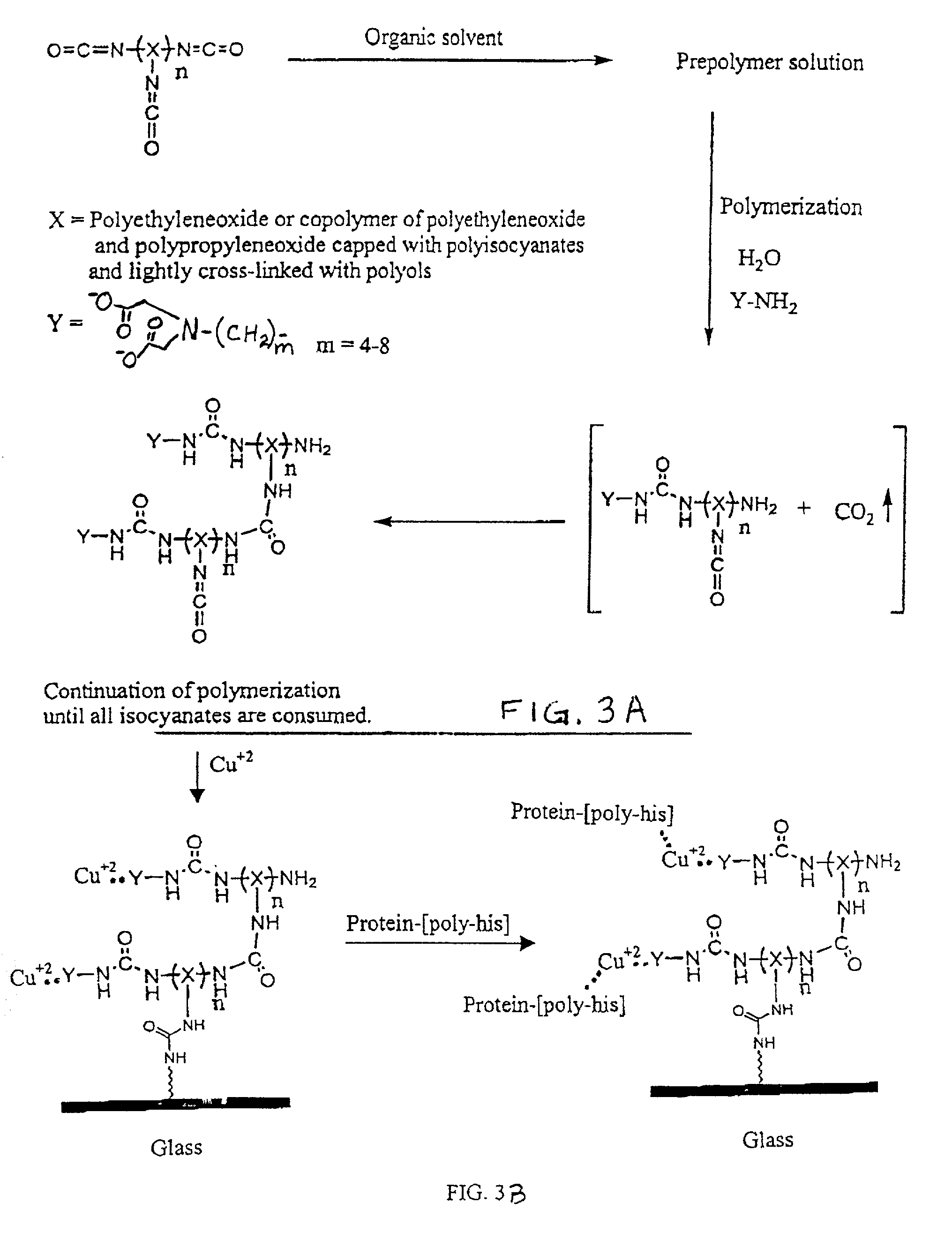

Three dimensional format biochips

InactiveUS7638464B2Rapid and simple and cost-effective methodHigh sensitivityBioreactor/fermenter combinationsPeptide librariesPolypropylene glycolSolid substrate

A biochip is formed with a plurality of optically clear hydrogel cells attached to the top surface of a solid substrate in the form of an array. Each of the cells is formed of a hydrogel of polyethylene glycol, polypropylene glycol or a copolymer thereof having reactive isocyanate groups. Binding entities are immobilized in these cells, which entities are effective to selectively hybridize to or sequester a target biomolecule. Different binding entities are immobilized in different cells in an array to create a biochip that can be used to assay for a number of target biomolecules.

Owner:BIOCEPT INC

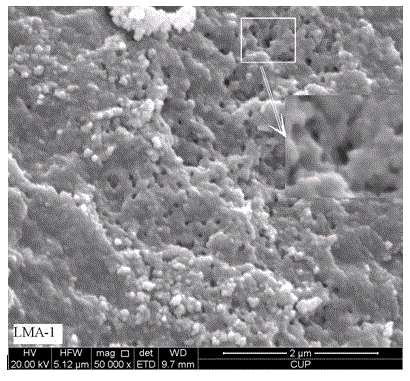

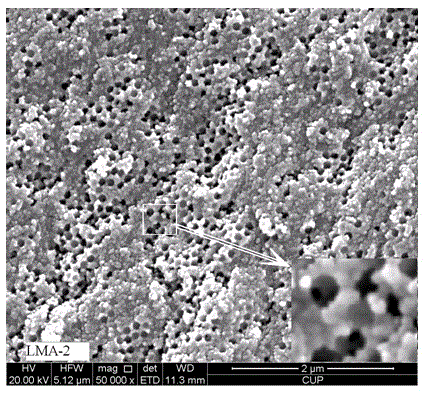

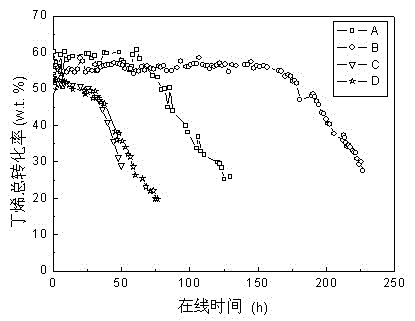

Alumina carrier with composite pore structure and preparation method thereof

ActiveCN102614934AExtend your lifeHigh selectivityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceMicrosphere

The invention discloses a preparation method of an alumina carrier with a composite pore structure, which comprises the steps of mixing and roasting an aluminum-contained compound and a composite template, wherein the composite template comprises a mesoporous template selected from at least one of a polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer, polyethylene glycol, dodecylamine, hexadecyl trimethyl ammonium bromide, lauric acid, stearic acid and fatty alcohol polyoxyethylene ether and a macroporous particulate template selected from polystyrene microspheres with the particle size of greater than 50nm, polymethyl methacrylate microspheres, biomaterial particles, asphalt particles or heavy oil residues; and the weight ratio of the mesoporous template to the macroporous particulate template to the aluminum-contained compound (by alumina) is 0.1-2:0.1-0.7:1. The invention also discloses the alumina carrier simultaneously having mesoporous tunnels and macroporous tunnels prepared through the method, wherein mesopores account for 40-90% of the total pore volume, and macropores account for 10-60% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP

Aqueous process for making a stable fluoropolymer dispersion

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers used in the invention are those that contain segments of polyethylene glycol, polypropylene glycol, and / or polytetamethylene glycol with repeating units of 3 to 100. The process and fluoropolymer produced contain no fluorinated surfactant.

Owner:ARKEMA INC

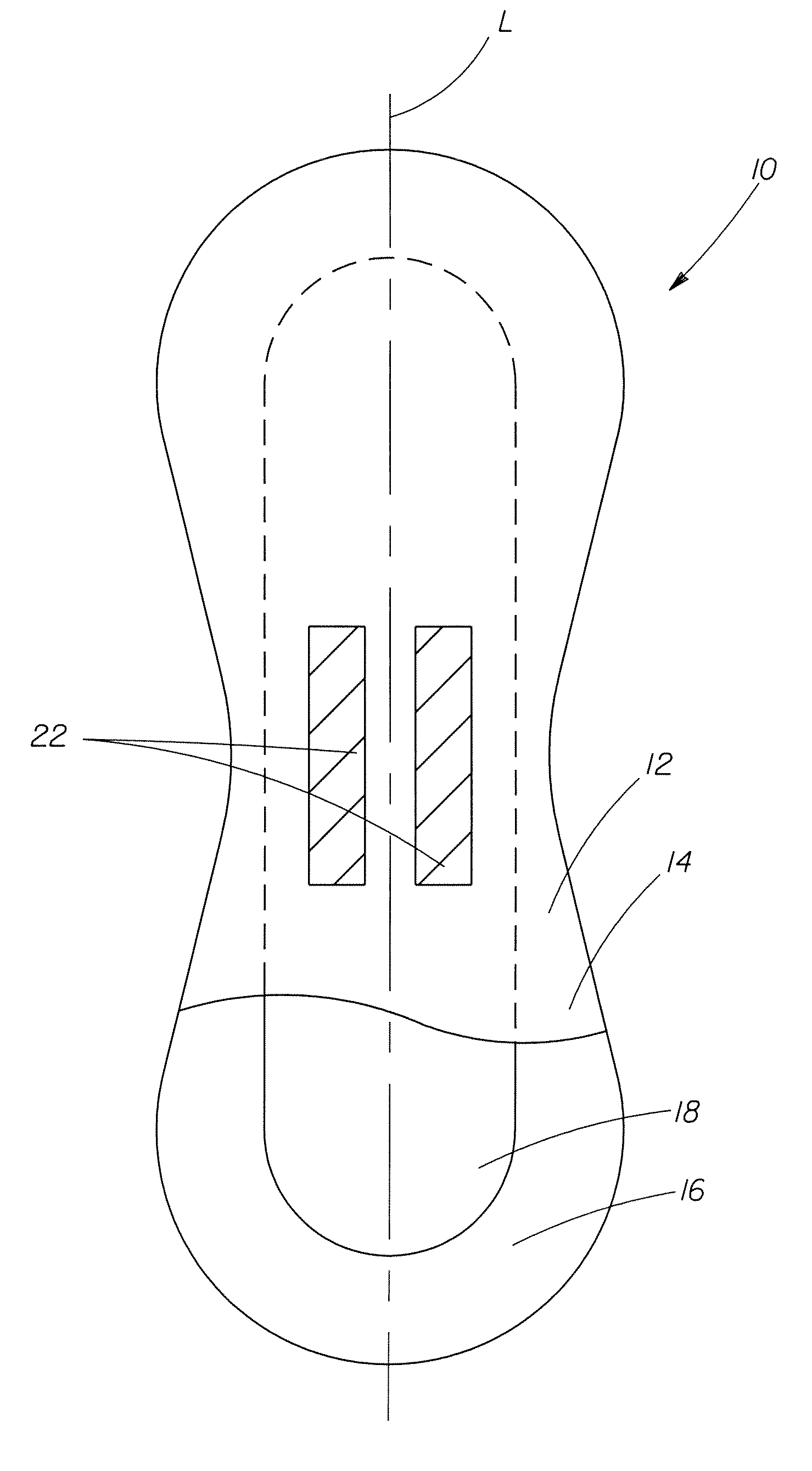

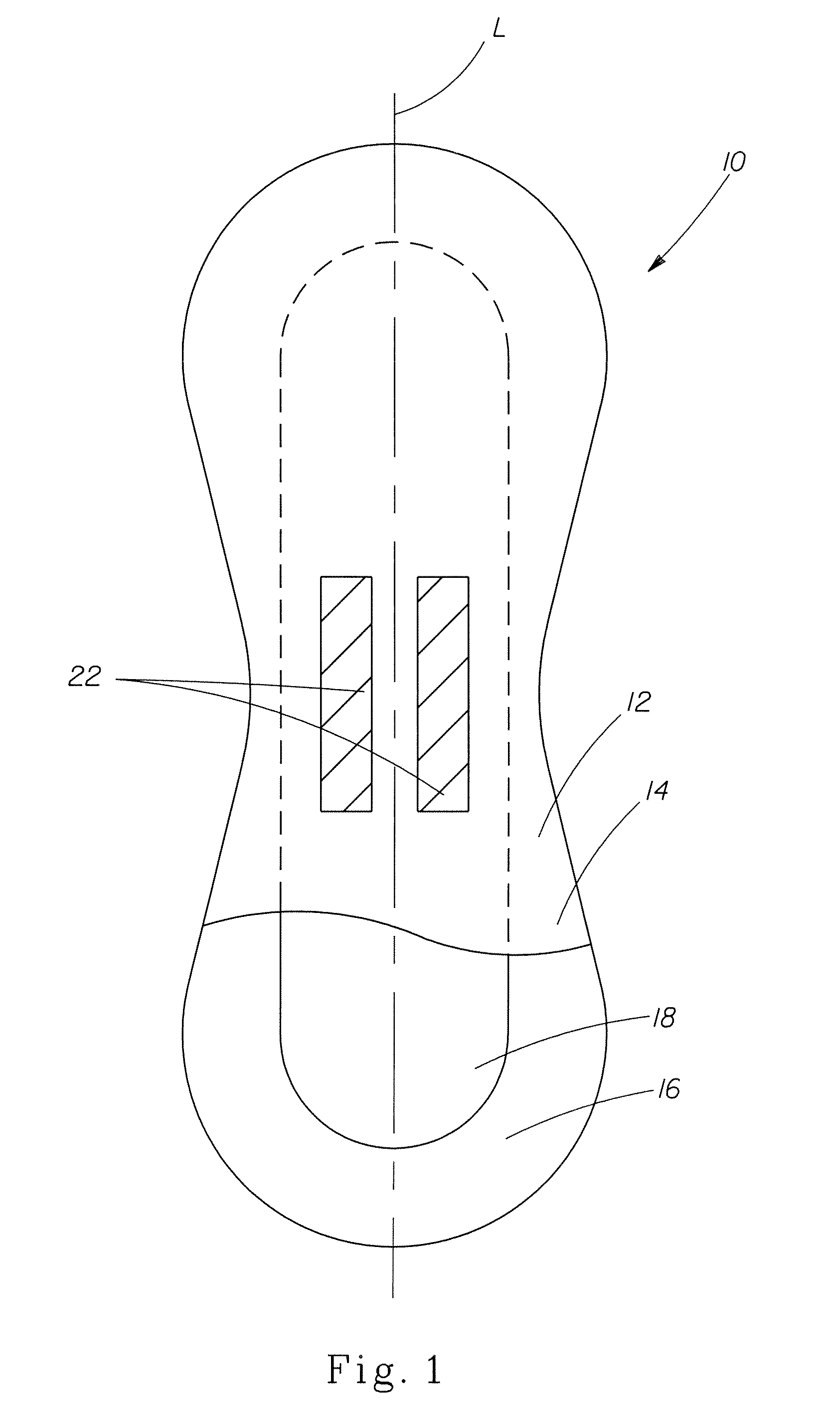

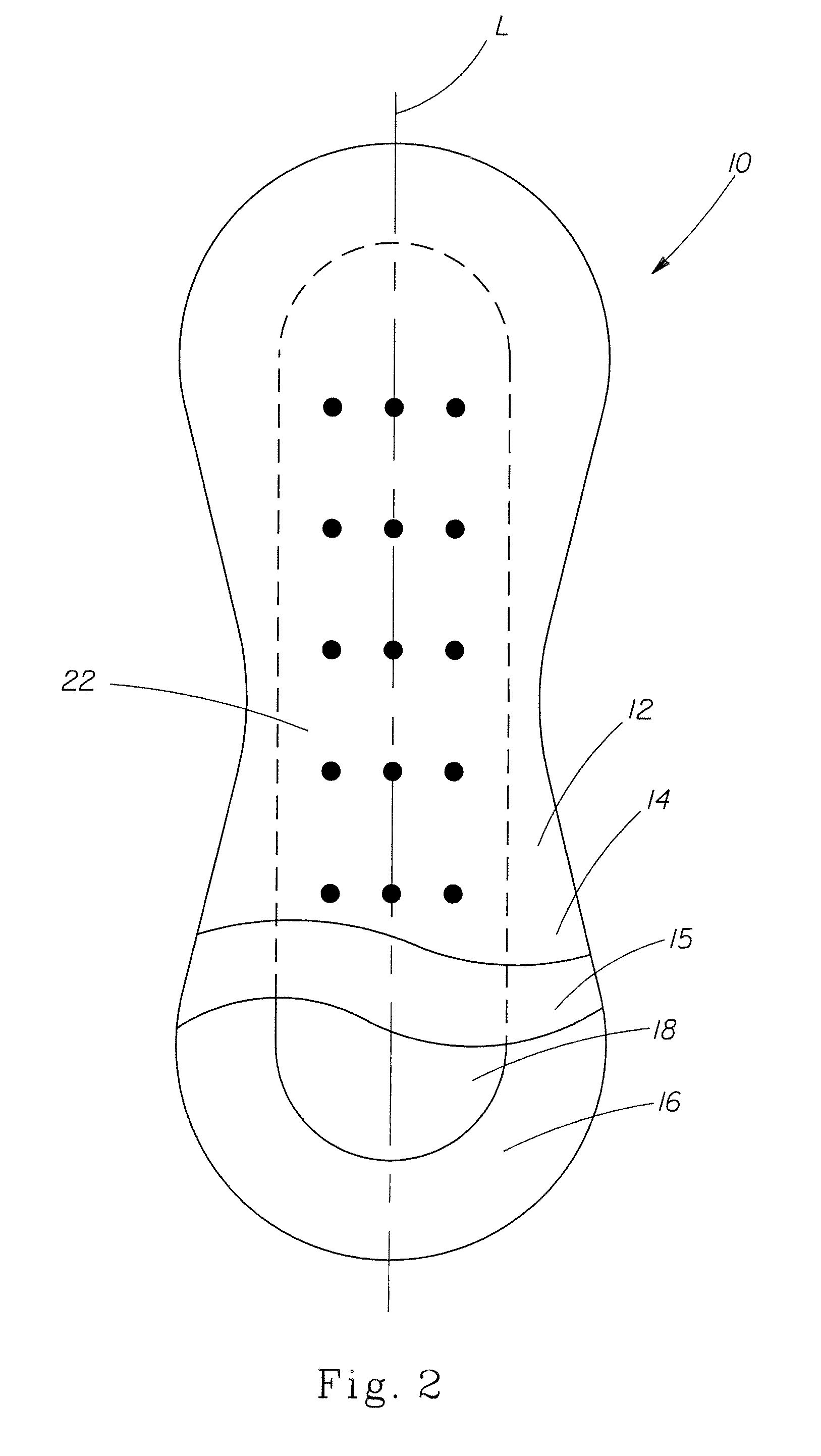

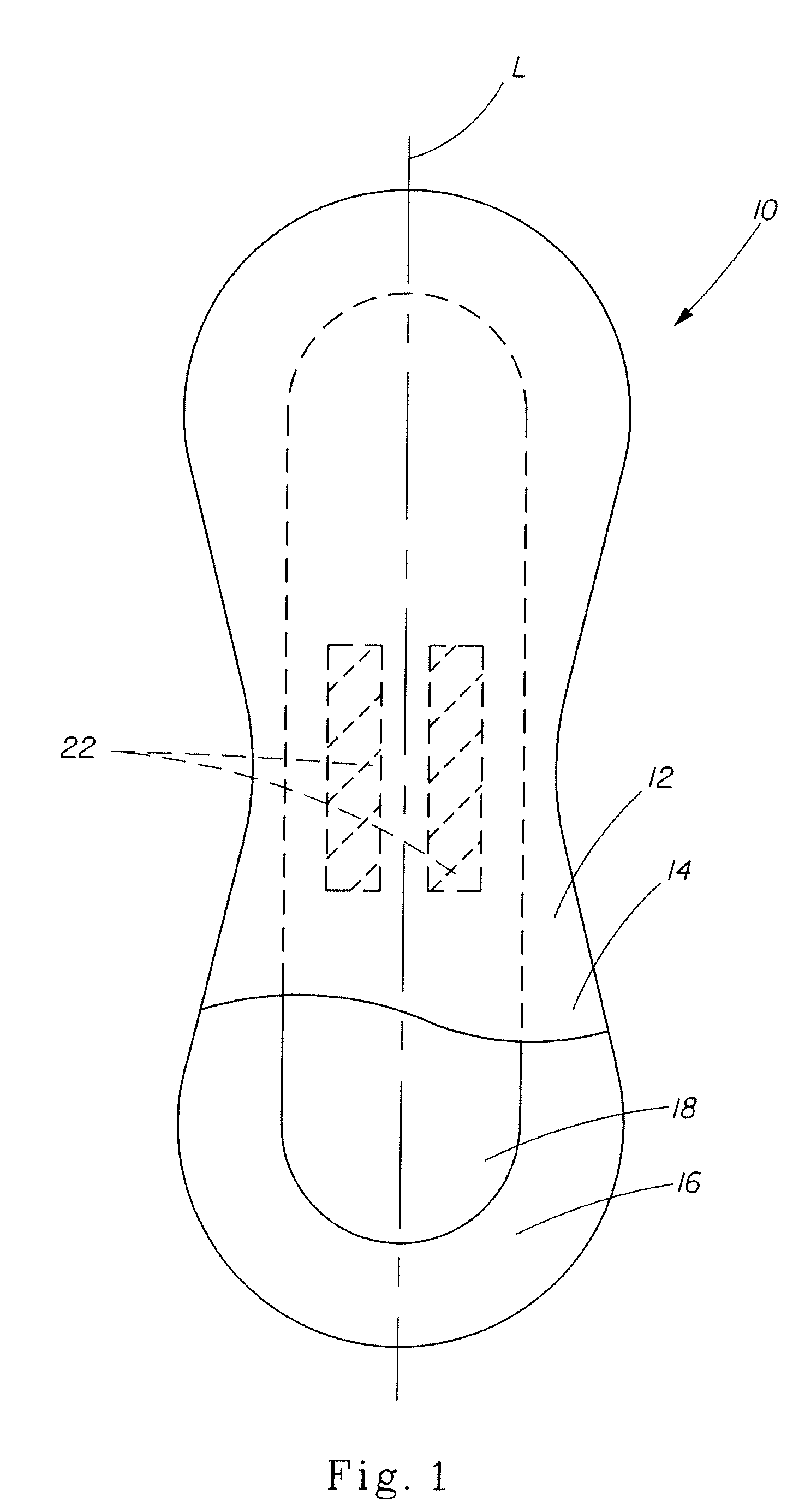

Absorbent article with lotion comprising a polypropylene glycol material

InactiveUS20090221978A1Less stainingImprove continuous fluid acquisitionSanitary towelsBaby linensPolypropylene glycolEngineering

An absorbent article, such as a catamenial device, comprises a liquid pervious topsheet, the topsheet having an inner surface oriented toward the interior of the absorbent article and an outer surface oriented toward the skin of the wearer when the absorbent article is being worn. The absorbent article includes a backsheet joined to the topsheet, the backsheet having an inner surface oriented toward the interior of the absorbent article and an outer surface oriented toward the garment of the wearer when the absorbent article is being worn. The absorbent article includes an absorbent core disposed between the topsheet and the backsheet, the absorbent core having an inner surface oriented toward the skin of the wearer when the absorbent article is being worn and an outer surface oriented toward the garment of the wearer when the absorbent article is being worn. The absorbent article includes a lotion composition applied to at least a portion of the outer surface of the topsheet, wherein the lotion composition comprises a polypropylene glycol material.

Owner:THE PROCTER & GAMBLE COMPANY

Hair cosmetic composition

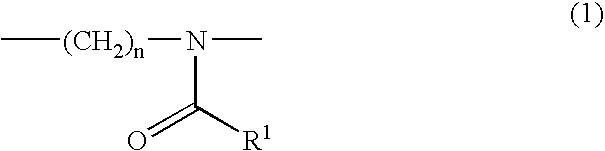

Provided are a leave-on hair cosmetic composition, containing the following components (A), (B) and (C): (A) an organic dicarboxylic acid or salt thereof, (B) an organic solvent selected from aromatic alcohols, N-alkylpyrrolidones, alkylene carbonates, polypropylene glycols having a number average molecular weight of from 100 to 1000, lactones and cyclic ketones, and (C) an organopolysiloxane having an organopolysiloxane segment and a poly(N-acylalkyleneimine) segment having a recurring unit represented by the following formula (1): (wherein, R1:H, C1-22 alkyl, cycloalkyl, aralkyl or aryl, and n: 2 or 3), wherein the latter segment has been bonded to at least one silicon atom of the former segment via a hetero-atom-containing alkylene group; having the organopolysiloxane segment and the poly(N-acylalkyleneimine)segment at a weight ratio of from 98 / 2 to 40 / 60; and having a weight average molecular weight of from 50,000 to 500,000; and a hair treating method with the composition. The hair cosmetic composition of the invention can essentially improve the hair quality, give excellent luster, manageability, setting property to the hair, and also give excellent flexible hair feel and elasticity.

Owner:KAO CORP

Gel laundry detergent composition

InactiveUS7297674B2Improve clarityHigh transparencySoap detergents with organic compounding agentsNon-ionic surface-active compoundsActive agentPolypropylene glycol

The present invention provides a shear thinning, transparent gel laundry detergent composition, comprising a surfactant system containing surfactant material selected from an anionic surfactant, a nonionic surfactant or a mixture thereof, and from 0.1 to 10% by weight of a clarity improving agent being a glycol dialkyl ether selected froma mono-or polyethylene glycol dialkyl ether having the formula(CpH2p+1)O—(CH2CH2O)n—(CqH2q+1), (I)a mono- or polypropylene glycol dialkyl ether having the formula(CpH2p+1)O—(CH2CH (CH3)O)n—(CqH2q+1), (II) and mixtures thereof,wherein p and q independently are integers in the range of from 1 to 5, and n is an integer in the range of from 1 to 50, preferably 1 to 10. It has been found that this gel laundry composition is highly transparent, such that particles can be suspended therein for improving visual appearance.

Owner:HENKEL IP & HOLDING GMBH

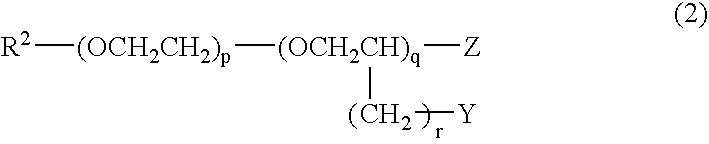

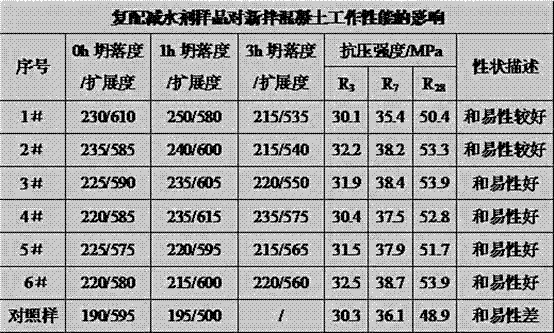

High slump retaining type polycarboxylic acid water reducing agent with sustained-release effect and preparation method thereof

The invention relates to a high slump retaining type polycarboxylic acid water reducing agent with a sustained-release effect and a preparation method thereof. The preparation method is characterized by comprising the following steps of: preserving 5-30 mol% of monomer A, 30-60 mol% of monomer B, 20-55 mol% of monomer C at 60-80 DEG C for 1-3 h under the effect of an initiator, a chain transfer agent and a polymerization inhibitor; copolymerizing the monomers to obtain a polymer with molecular weight of 30000-100000; and then adding alkali to neutralize the polymer, wherein the total amount of the monomers A, B and C is 100 mol%; the monomer C comprises a slump retaining auxiliary 1 and a slump retaining auxiliary 2 according to a mol ratio of 1:20-13:20; the monomer A is isopentene alcohol polyoxyethylene ether, allyl polyethylene glycol, 1-methyl-2-allyl polyethylene glycol or allyl poly diglycidyl ether with polymerization degree n of 20-60; and the monomer B is acrylic acid or methacrylic acid. The high slump retaining type polycarboxylic acid water reducing agent with the sustained-release effect, provided by the invention, has the advantages of excellent slump retaining property, substantially no loss for slump degree within 3 h and wide applicability.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

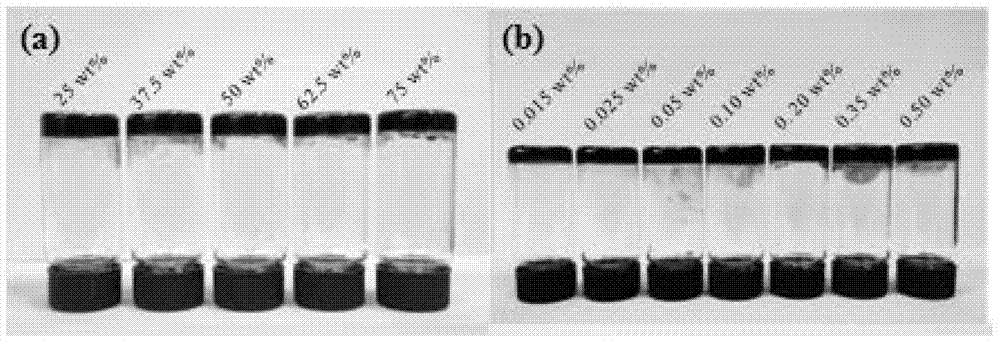

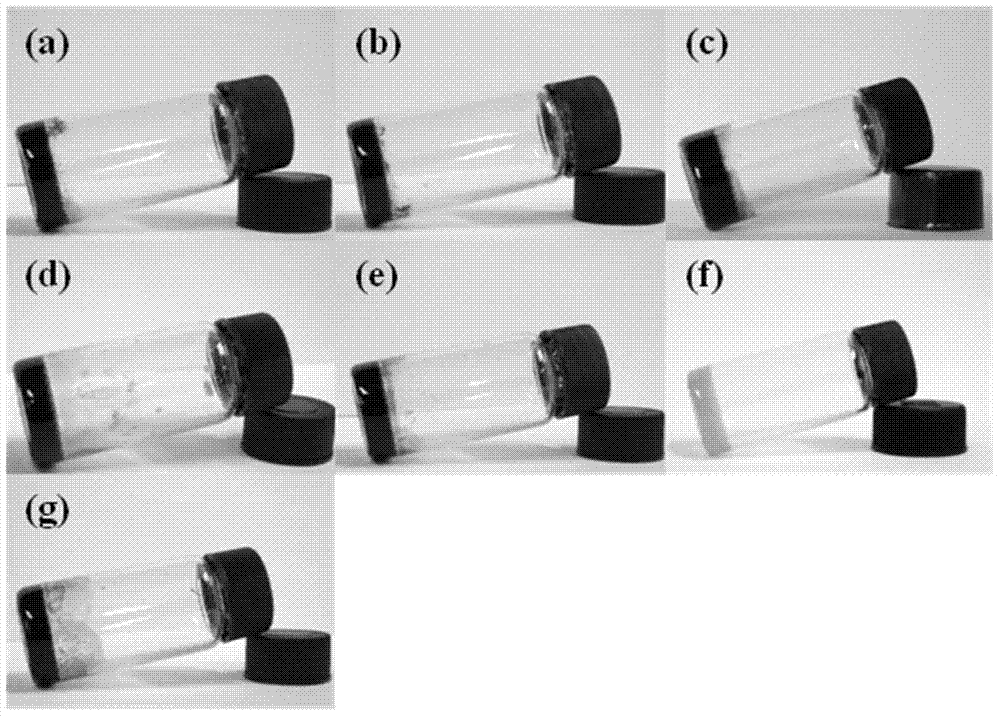

Multi-component super-molecular hydrogel and preparation method thereof

ActiveCN103242656AAchieve multi-functionalityUniversalNon-macromolecular adhesive additivesPhotometryCross-linkPolyvinyl alcohol

The invention discloses multi-component super-molecular hydrogel and a preparation method of the multi-component super-molecular hydrogel. The hydrogel is formed by a component containing a strong hydrogen bond, a component containing a weak hydrogen bond and water, wherein the component containing the strong hydrogen bond is one or more of a carbon oxide nano tube, graphene oxide, a carboxylated ferroferric oxide nano particle, a carboxylated silver nano particle, a carboxylated quantum dot, polyacrylic acid, polypropylene glycol, polyvinyl alcohol, polyurethane, polyamide and poly(p-styrene) sodium sulfonate; and the component containing the weak hydrogen bond is a small-molecular compound or a high-molecular compound. A lot of cross-linking force of the hydrogel disclosed by the invention comes from the weak hydrogen bond so that the hydrogel is very sensitive to the stimulation of an external environment; when chemical components are proper, gel-sol conversion can be carried out under the effects of temperature rising, near-infrared light illumination and acids; and the conversion is reversible, namely the gel-sol conversion can be carried out under the effects of temperature reduction, removing of a near-infrared light source and alkalis.

Owner:PEKING UNIV

Stable, low viscosity cosmetic compositions

InactiveUS20080305056A1Reduce viscosityLong-term storage stabilityCosmetic preparationsToilet preparationsAmmonium compoundsPolypropylene glycol

The invention relates to a cosmetic composition for application to the skin, having:a) 0.05 to 0.5% by weight of a quaternized polysaccharide, 0.05 to 5.0% by weight of a polyethylene glycol derivative or polypropylene glycol derivative and / or 0.05 to 3% by weight of a polymeric quaternized ammonium compound (“polyquaternium”),b) 10 to 40% by weight of oils and / or oil-like constituents, andc) 0.2 to 15% by weight of an ester quat and / or of a dialkyl quat.

Owner:EVONIK GOLDSCHMIDT GMBH

Polyurethane-polypeptide graft copolymer and preparation method thereof

The invention relates to a polyurethane-polypeptide graft copolymer and a preparation method thereof. The graft copolymer is a comb-shaped polymer, wherein the molecular weight of polyurethane is 10,000 to 100,000; and the molecular weight of the polypeptide chain segment is 500 to 5,000. The preparation method comprises the following steps of: 1) synthesis of polyurethane provided with lateral carboxyl on the molecular chain: adding diisocyanate, polypropylene glycol, polyethylene glycol, dibutyltin dilaurate catalyst and dimethyl formamide solvent into a dry reaction bottle, performing stirring reaction under inert atmosphere, adding dimethylolpropionic acid dissolved in dimethyl formamide to react, adding butanediol to react, finally adding butanol to react, and obtaining a target product; and 2) synthesis of the polyurethane-polypeptide graft copolymer: putting the polyurethane provided with lateral carboxyl on the molecular chain, a solvent and a condensation agent into a dry reactor, adding polypeptide homopolymer into the reactor, and performing stirring reaction under the inert atmosphere to obtain a target product with pH response.

Owner:SHANDONG UNIV OF TECH

Absorbent article with lotion comprising a polypropylene glycol material

An absorbent article, such as a catamenial device, comprises a liquid pervious topsheet, the topsheet having an inner surface oriented toward the interior of the absorbent article and an outer surface oriented toward the skin of the wearer when the absorbent article is being worn. The absorbent article includes a backsheet joined to the topsheet, the backsheet having an inner surface oriented toward the interior of the absorbent article and an outer surface oriented toward the garment of the wearer when the absorbent article is being worn. The absorbent article includes an absorbent core disposed between the topsheet and the backsheet, the absorbent core having an inner surface oriented toward the skin of the wearer when the absorbent article is being worn and an outer surface oriented toward the garment of the wearer when the absorbent article is being worn. The absorbent article includes a lotion composition applied to at least a portion of the inner surface of the topsheet, the inner surface of the backsheet, and / or a substrate or surface thereof disposed between the inner surface of the topsheet and the inner surface of the backsheet, wherein the lotion composition comprises a polypropylene glycol material.

Owner:THE PROCTER & GAMBLE COMPANY

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA INC

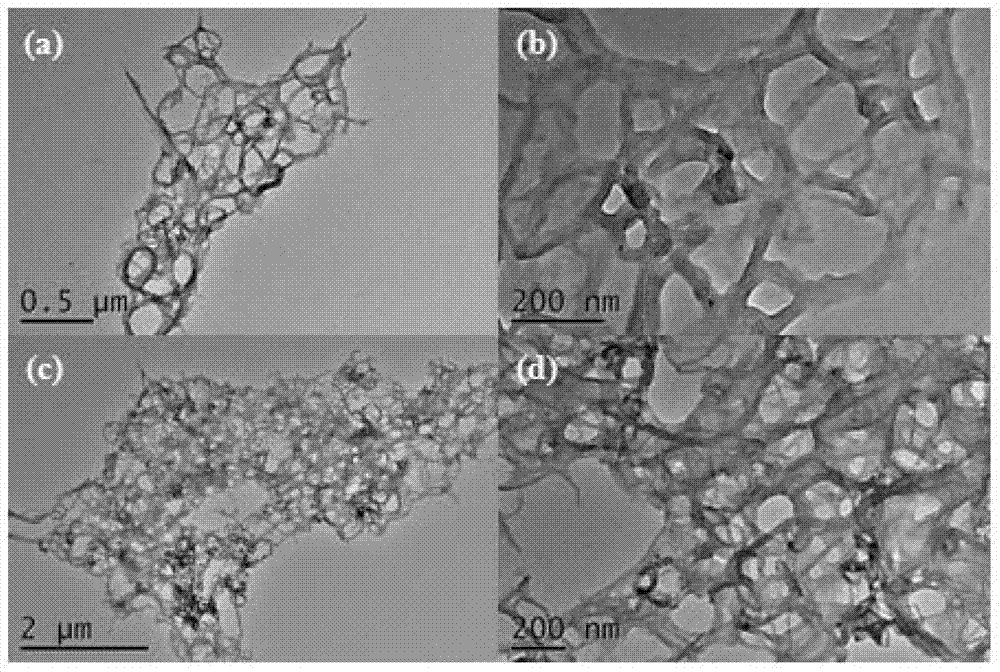

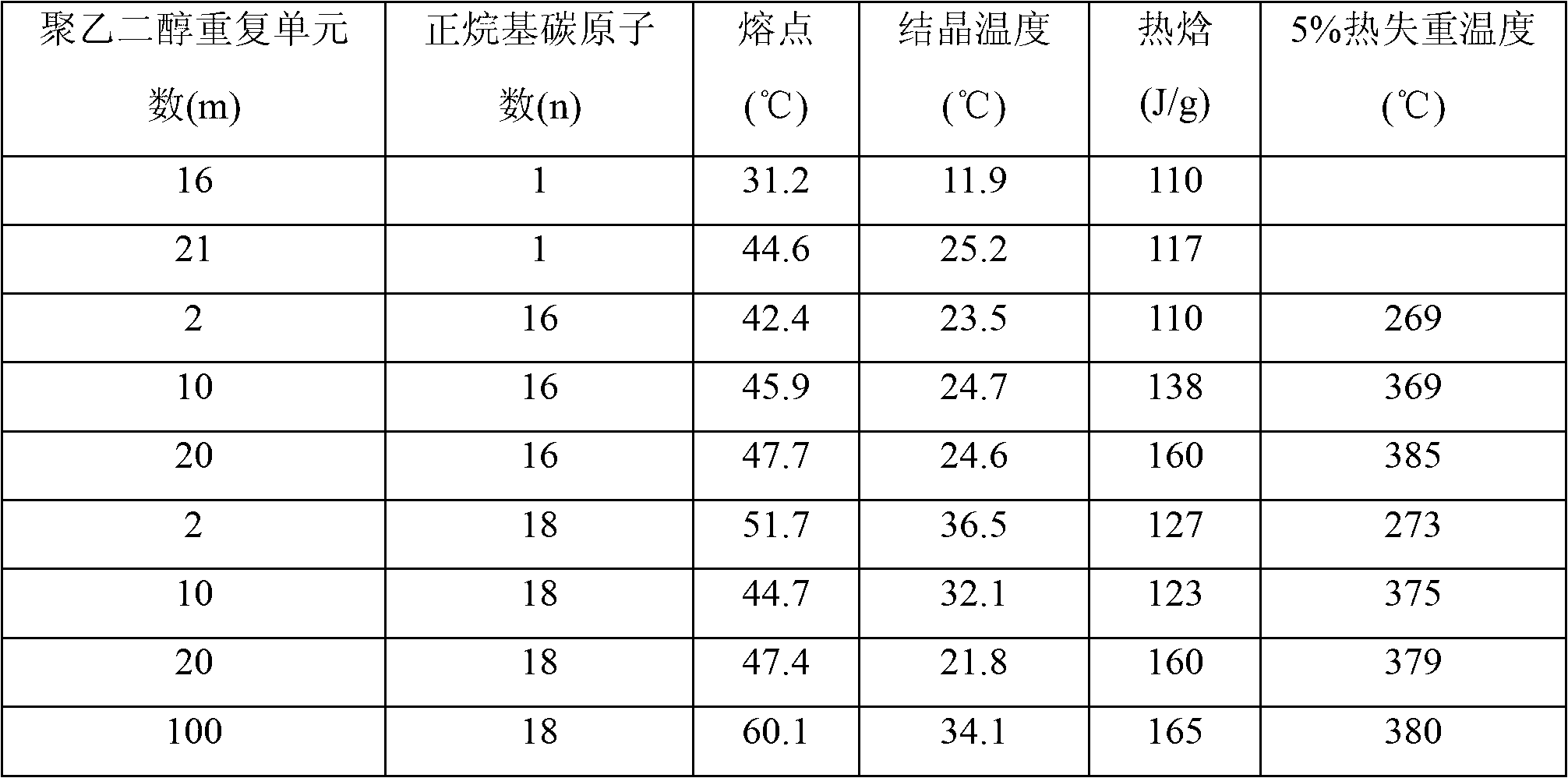

Heat accumulating temperature regulating fiber and method for preparing same

ActiveCN102704037AGive full play to the heat storage and temperature adjustment functionVarious formsFilament forming substance formingElectro-spinningFiberPolypropylene glycol

The invention discloses a heat accumulating temperature regulating fiber and a method for preparing the same. The fiber takes a polymer phase-change material as component A and a fiber-forming polymer as component B, wherein the mass fraction of the component A in the fiber counts 20-60%, while the mass fraction of the component B in the fiber counts 80-40%; the fiber is produced by using a method comprising the steps of melting composite spinning, solution composite spinning or electrostatic solution composite spinning; the fiber has a composite structure and the cross section of the fiber is shaped as an island or concentric circles, wherein the polymer phase-change material is polypropylene glycol-n-alkyl ether; the number m of glycol repetition units is 1-100; the number n of carbon atoms in alkyl is 11-30; and the heat absorption / dissipation temperature of the fiber is 11.9-53.8 DEG C, while the heat accumulation quantity is 18-55 J / g and 5% thermal gravimetric temperature is above 203 DEG C. The method for preparing the fiber employs the constitution and the structure of the heat accumulating temperature regulating fiber provided by the invention and prepares the fiber by using the method of the melting composite spinning, the solution composite spinning or the electrostatic solution composite spinning.

Owner:陕西析睿凯莱材料科技有限公司

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymers is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers used in the invention are those that contain segments of polyethylene glycol and / or polypropylene glycol with repeating units of 3 to 100.

Owner:ARKEMA INC

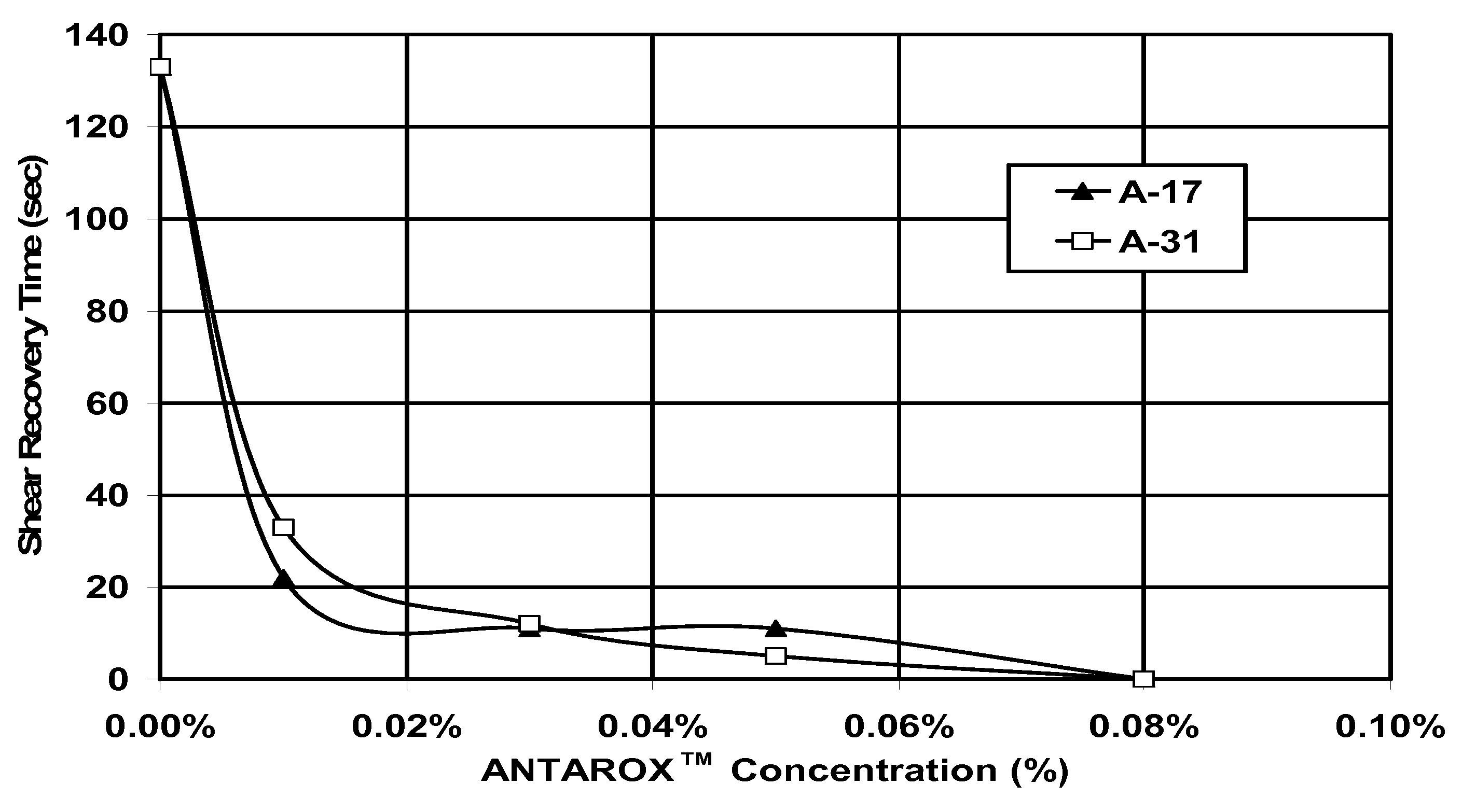

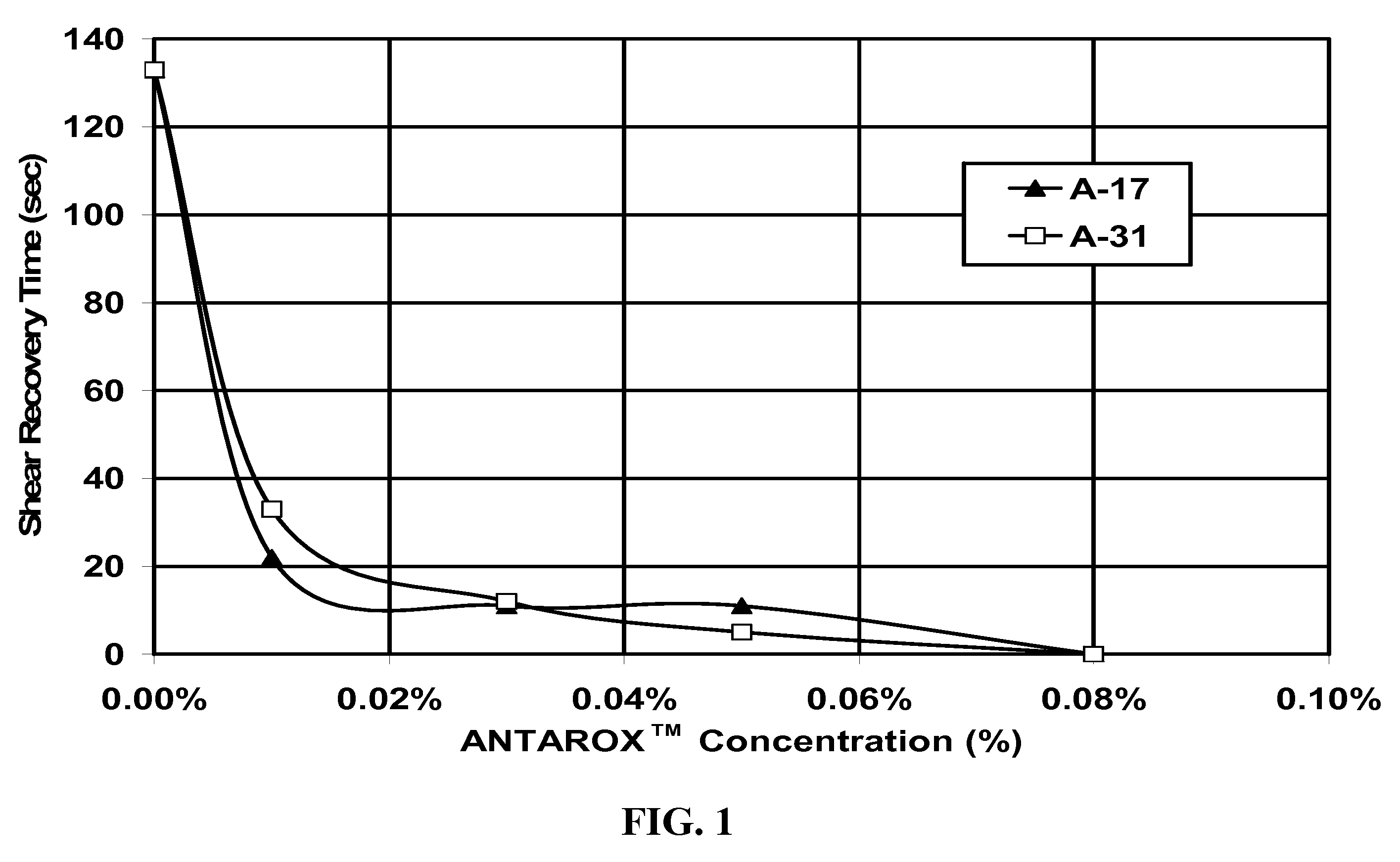

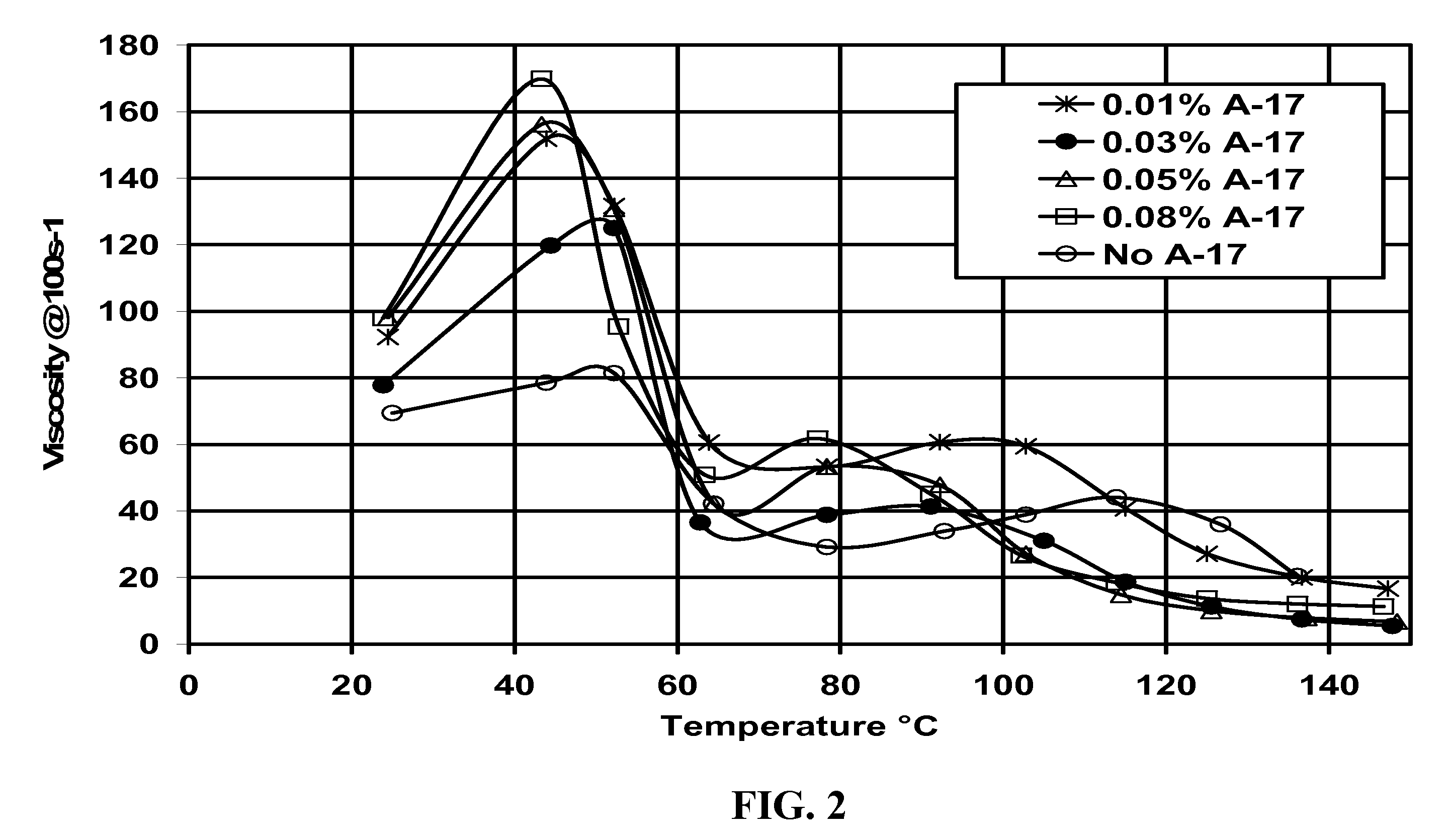

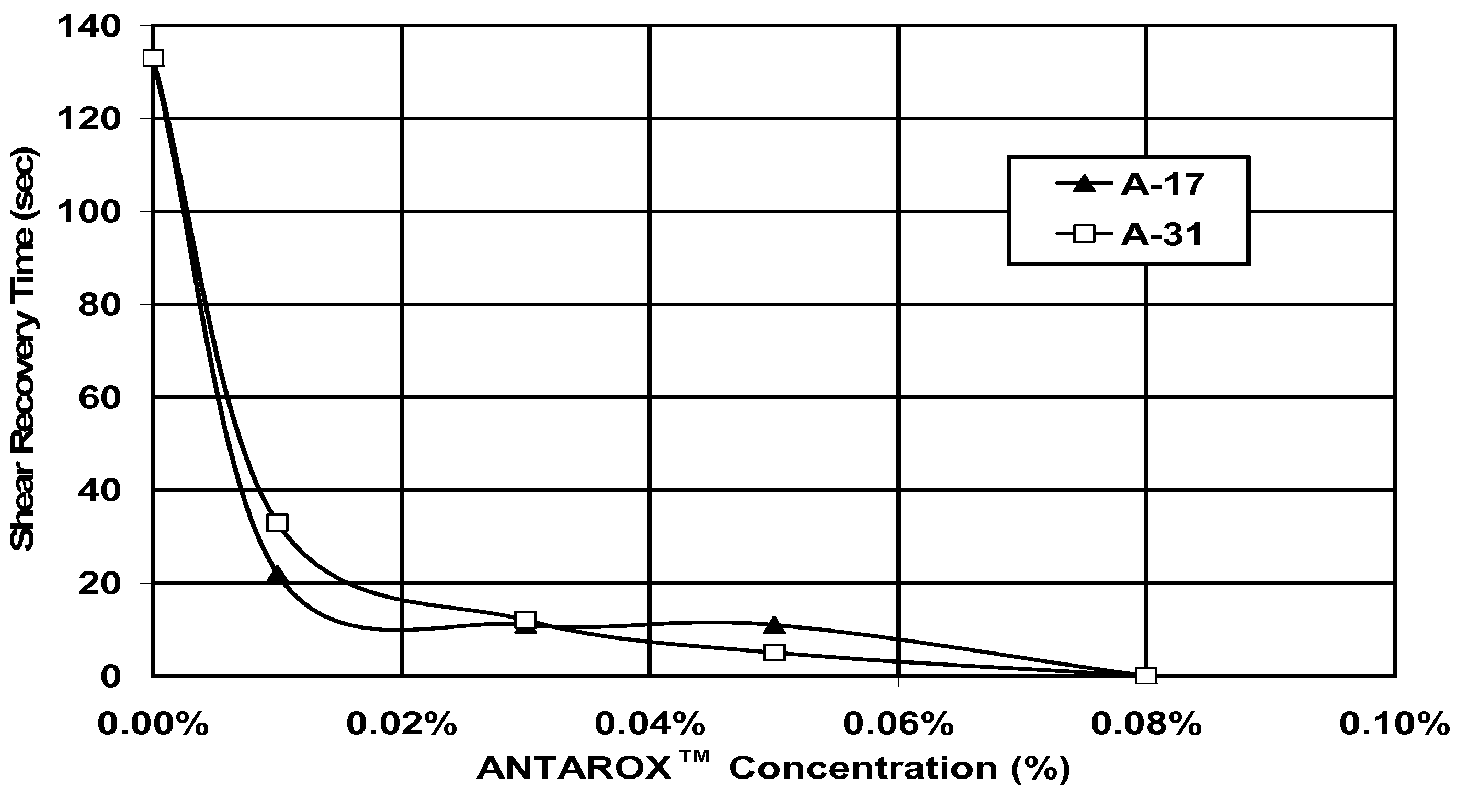

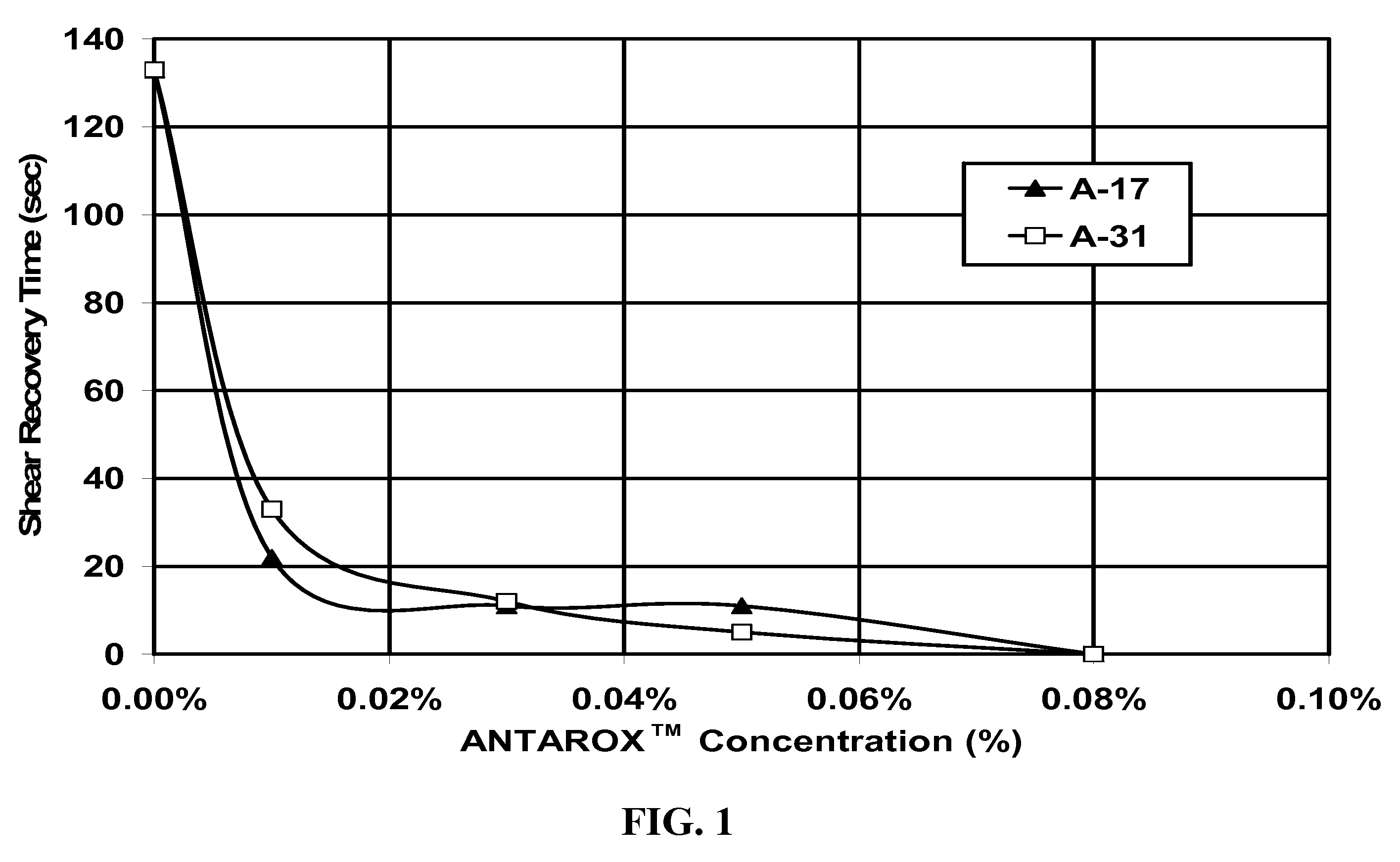

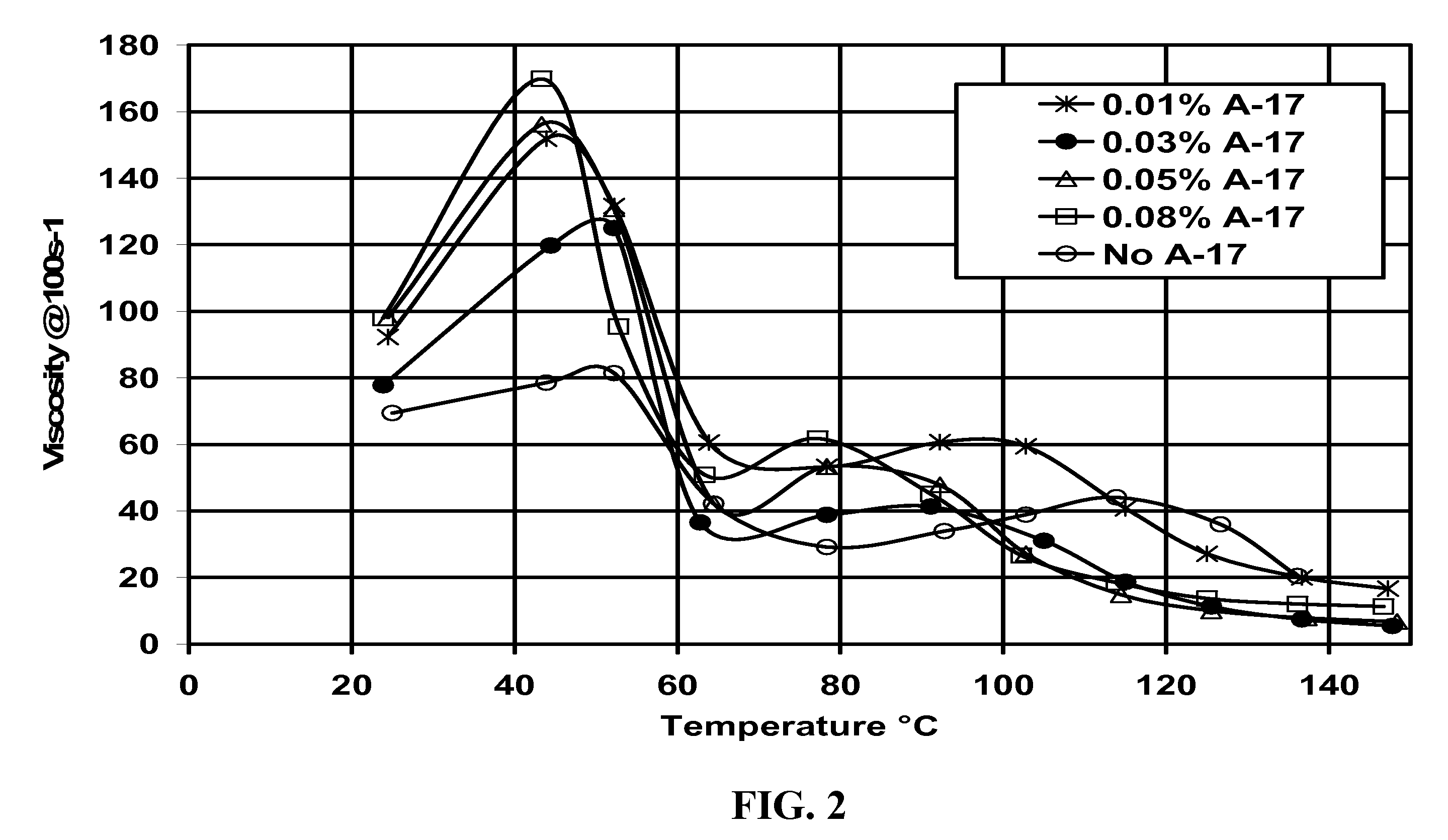

Rheology Modifiers

InactiveUS20060185842A1Increase ratingsIncrease shear rateCleaning apparatusFluid removalPolymer scienceBetaine

A method for increasing the rate of shear rehealing of fluids made with cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of a polymeric rheology enhancer selected from polypropylene glycols and block copolymers of polypropylene glycol and polyethylene glycol. For applications in which rapid shear rehealing is required, the rheology enhancer allows fluids to be made and used at lower viscoelastic surfactant concentrations. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

High brightness coating compositions and related products

InactiveUS7608338B2Improve adhesionImprove antistatic performanceSynthetic resin layered productsPaper/cardboard layered productsPorosityPolystyrene

The invention provides a coating composition that provides high brightness, high gloss and superior print quality. The coated product comprises a substrate coated on at least one side with a coating composition comprising a pigment component and a binder component that is made of mixture of two binder resins. Both binder resins are capable of film forming. The first binder resin provides coating gloss and adhesion properties and the second binder resin enhances coating porosity, adhesion, and anti-static properties. The first binder resin that is used at 60-95% by weight of the total binder resin blend is selected from the group consisting of vinyl acetate acrylate, styrene acrylate and styrene butadiene acrylic copolymers. The second binder resin that is used at 5-40% by weight of the total binder resin blend is selected from the group consisting of anion type polystyrene derivatives, polyethylene glycol and polypropylene glycol.

Owner:INT PAPER CO

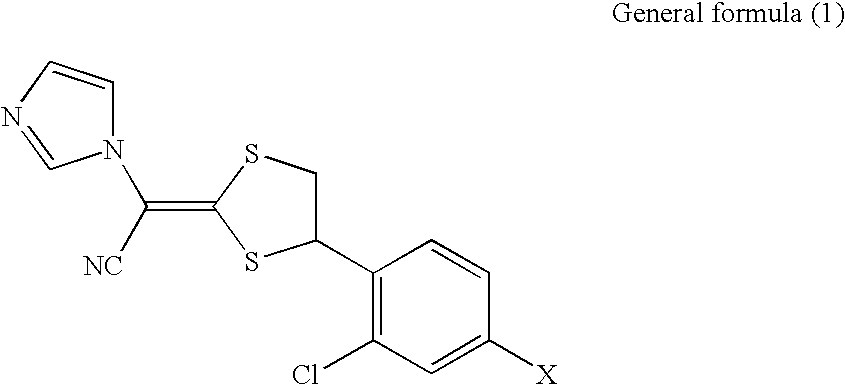

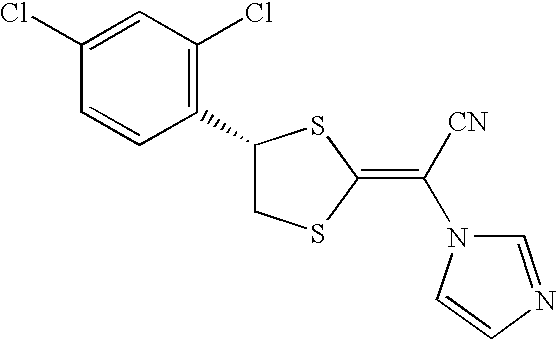

Antifungal composition

Disclosed is a pharmaceutical composition for antifungal use, comprising: 1) one or more compounds selected from compounds represented by the general formula (1) below and physiologically acceptable salts thereof; 2) one or more compounds selected from polypropylene glycol, diesters of dibasic acids, triacetin, 2-ethyl-1,3-hexanediol, lauromacrogol, and polyoxyethylene-polyoxypropylene glycol; and 3) one or more compounds selected from glucono-δ-lactone, propylene glycol, glycerin, and lactic acid. General formula (1) (In the formula, X represents a halogen or hydrogen).wherein X represents a halogen or hydrogen.

Owner:POLA PHARMA +1

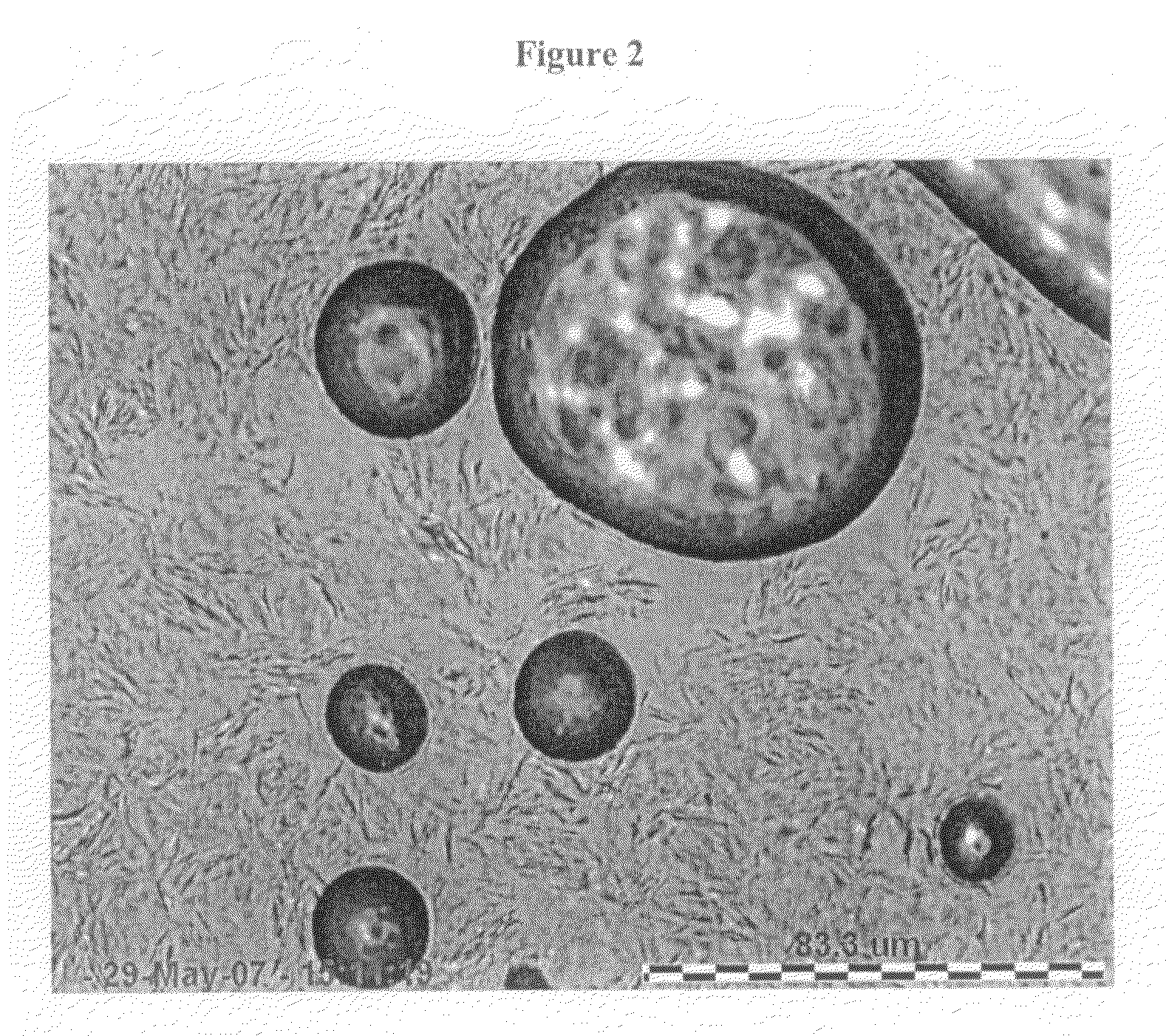

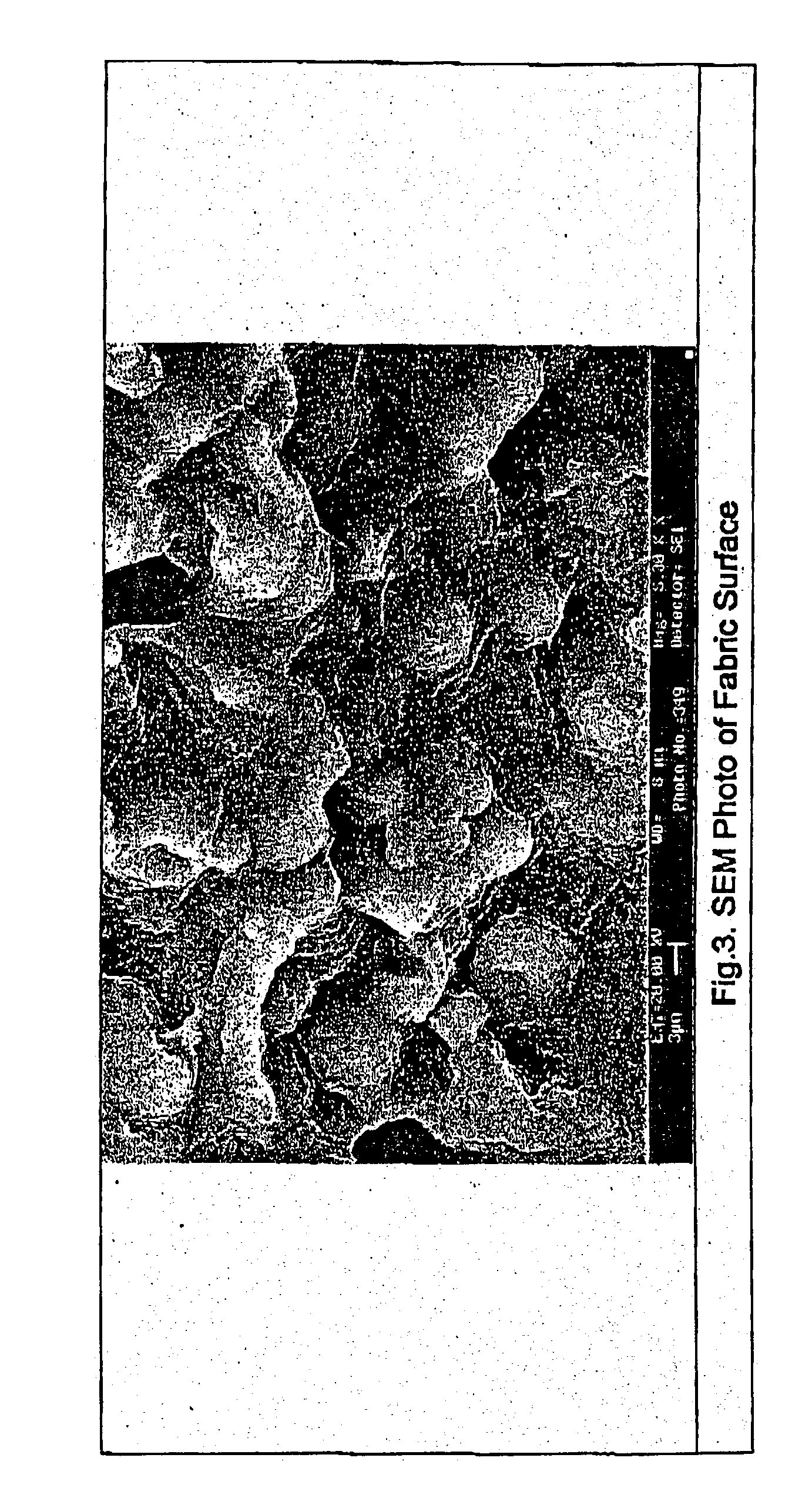

Method for encapsulating phase transitional paraffin compounds using melamine-formaldehyde and microcapsule resulting therefrom

A process for the microencapsulation of phase transitional paraffin compounds is described. Polypropylene glycols with the average molecule weight over 400 were used as the surface tension modifiers for emulsifying the paraffin compounds. Polyisocyanates capable of being dissolved in the phase change materials were employed to promote the deposition of melamine, partially methylolated melamine and the precondensate of melamine-formaldehyde onto the hydrophobic droplets for the microencapsulation. The prepared emulsion of microencapsulated phase change materials was successfully coated on textile fabrics and the coated products showed improved thermal regulation function.

Owner:NANO SPORTS TECH

Methacrylate-based adhesive compositions

An adhesive composition, especially suitable for a two- part adhesive system curable via free radical polymerisation comprises; (A) (meth) acrylate ester monomer; (B) chlorinated elastomeric polymer; (C) core-shell impact modifier; and (D) urethane (meth) acrylate oligomer. Example adhesive compositions include urethane (meth) acrylate oligomer (D) derived from (i) a di- or higher isocyanate having at least two isocyanate groups which differ in reactivity; (ii) a chain-extending reagent which has at least two groups selected from hydroxyl and / or amino groups, each capable of reaction with an isocyanate group of (i); (iii) a hydroxymethacrylate component or hydroxyacrylate component. Also urethane (meth) acrylate oligomers, suitable for use in adhesive compositions, and derived from: (i) a diisocyanate having two isocyanate groups which differ in reactivity; (ii) a chain-extending reagent which is a polyether polyol selected from ethoxylated and propoxylated derivatives of tri- and tetra- functional polyols; and (iii) a hydroxyl (meth) acrylate selected from polyethylene glycol (meth) acrylate and polypropylene glycol (meth) acrylate, are disclosed.

Owner:SCOTT BADER CO LTD

High-dispersity acidic copper plating additive as well as preparation method and application thereof

InactiveCN105734623AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of highly dispersive all-bright acidic copper plating of printed circuit boards, in particular to a highly dispersive acidic copper plating additive and its preparation method and application. A highly dispersed acidic copper plating additive: at least one divalent sulfide main brightener, at least one polyethylene glycol or polypropylene glycol or both block copolymer polymer inhibitors, at least one alkyl quaternary ammonium salt Type cationic surfactant, 5‑50ml / L sulfuric acid, 0.1‑4ml / L formaldehyde. Its preparation method is to slowly add a specified amount of concentrated sulfuric acid into water, stir evenly and cool to room temperature, then sequentially add the inhibitor, surfactant, main brightener and formaldehyde into the sulfuric acid aqueous solution, stir until completely dissolved Concentrate to the final volume to obtain the highly dispersed acidic copper plating additive of the present invention. The high-dispersion acidic copper plating additive of the invention is especially suitable for electroplating through-holes with high thickness-to-diameter ratio of printed circuit boards, and can obviously improve the dispersion ability of the plating solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

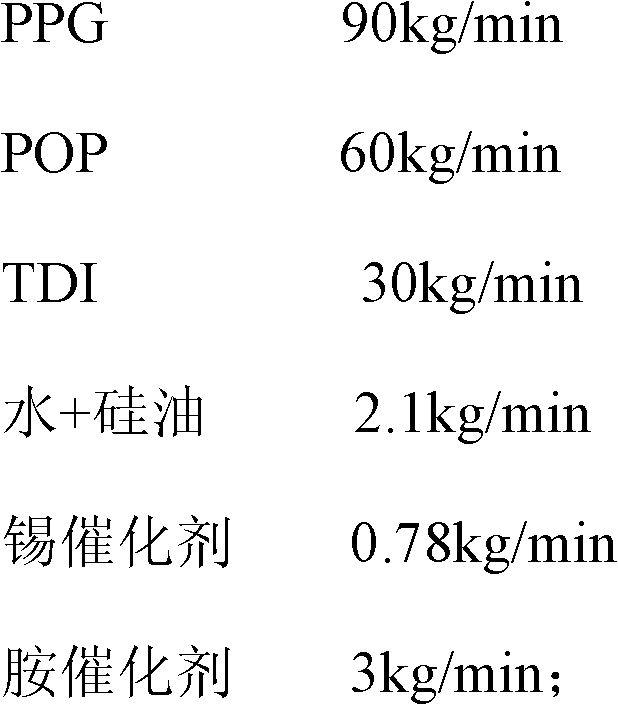

Flexible polyurethane foam and production process

The invention discloses flexible polyurethane foam and a production process for preparing the flexible polyurethane foam. A mixture of polyether, isocyanate, water, a catalyst and foam stabilizer is formed by reacting by means of one-step continuous foaming process, wherein the polyether consists of PPG (polypropylene glycol) and POP (polyether polyol), and the proportion of 2,4-TDI (toluene diisocyanate) to 2,6-TDI, which are isomers of TDI of isocyanate, ranges from 75-85:15-25. High-density foam with apparent density up to 80kg / m3 is produced by means of the one-step continuous foaming process and has the advantages of high production capacity and fine cell-opening performance as compared with molding foam. The foam produced by the process has high density up to 80kg / m3 under the condition of continuous production as compared with common block foam, so that the cell diameter of the foam is thick, and the foam is high in elasticity and bearing capacity.

Owner:ZHEJIANG CHUANYANG SPONGE

Ultraviolet-curing resin composition, paint, ink, adhesive, sealing agent and primer

InactiveUS7763692B2Improve adhesionReduce the burden onOther chemical processesInksPolymer scienceMeth-

An ultraviolet-curing resin composition of (a) 5 to 35 parts by mass of a chlorinated polyolefin with a chlorine content of 15 to 40 mass %, (b) 15 to 60 parts by mass of an alicyclic hydrocarbon mono(meth)acrylate, and (c) 5 to 80 parts by mass of a polypropylene glycol di(meth)acrylate; and, per 100 parts by mass of the total amount of components (a), (b) and (c), (d) 0 to 1100 parts by mass of an aliphatic hydrocarbon di(meth)acrylate and (e) 0 to 600 parts by mass of a polyfunctional monomer having 3 to 6 (meth)acryloyl groups in its molecule; and, per 100 parts by mass of the total amount of components (b), (c), (d) and (e), (f) 1 to 15 parts by mass of a photoinitiator; andthe composition as an active ingredient in paints, inks, adhesives, sealing agents and primers.

Owner:OSAKA RES INST OF IND SCI & TECH +1

Rheology modifiers

InactiveUS7387987B2High viscosityIncrease ratingsCleaning apparatusFluid removalPolymer scienceBetaine

A method for increasing the rate of shear rehealing of fluids made with cationic, zwitterionic, and amphoteric viscoelastic surfactant fluid systems by adding an effective amount of a polymeric rheology enhancer selected from polypropylene glycols and block copolymers of polypropylene glycol and polyethylene glycol. For applications in which rapid shear rehealing is required, the rheology enhancer allows fluids to be made and used at lower viscoelastic surfactant concentrations. Preferred surfactants are betaines and quaternary amines. The fluids are useful in oilfield treatments, for example fracturing and gravel packing.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com