Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182 results about "Polytetramethylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA INC

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA INC

Heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material

InactiveCN105694436AImprove wear resistanceImprove tear resistancePlastic/resin/waxes insulatorsPolymer scienceWear resistant

The invention discloses a heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material. The heat-resistant wear-resistant tear-resistant modified polyurethane rubber cable material is prepared from the following raw materials: modified polyurethane elastomer, neoprene, butyl rubber, ethylene propylene diene monomer, epoxy resin, ethyl acetate, polytetramethylene glycol, trimethylolpropane, polyethylene tetrahydrofuran ether glycol, hydroxyl-terminated polybutadiene, polycaprolactone glycol, MBOCA, hydroxyl-terminated butyl cyanide rubber, dibutyltin dilaurate, triethoxysilane, fumed silica, aluminum silicate, stearic acid, molybdenum disulfide, quartz powder, bentonite, zinc oxide, sulfur, accelerant M, anti-aging agent D, magnesium oxide, anti-aging agent 4040, hexanediol and chitosan. The modified polyurethane rubber cable material has excellent heat-resistant wear-resistant tear-resistant performance.

Owner:ANHUI DUJIANG CABLE GROUP

Size composition

InactiveUS20060237682A1Excellent hydrolysis and glycolysis stabilityImproved propertyFibre treatmentSynthetic resin layered productsPolycarbonateSize composition

The invention provides hydrolysis-stable size compositions based on polycarbonate polyols and polytetramethylene glycol polyols, their preparation and use.

Owner:BAYER MATERIALSCIENCE AG

Composition with long-acting moisturizing effect and preparation method thereof

ActiveCN107260626AStrong permeabilityPromote generationCosmetic preparationsToilet preparationsChemistryGlycerol

The invention relates to a composition with a long-acting moisturizing effect. The composition is characterized by being prepared from the following components in parts by mass: 0.5 to 2.5 parts of glue mixture, 1.0 to 3.0 parts of plant polysaccharide mixture, 0.1 to 1.0 part of collagen mixture, 0.1 to 1.0 part of amino acid mixture, 25 to 45 parts of PEG (Polyethylene Glycol) / PPG(Polypropylene Glycol) / polybutylene glycol-8 / 5- / 3 glycerin, 0.50 part of phenoxyethanol and the balance of deionized water, wherein the composition has the rotary viscosity of 800cp to 2,600cp after being subjected to high-pressure homogenization. The composition has the long-acting moisturizing effect.

Owner:PROYA COSMETICS

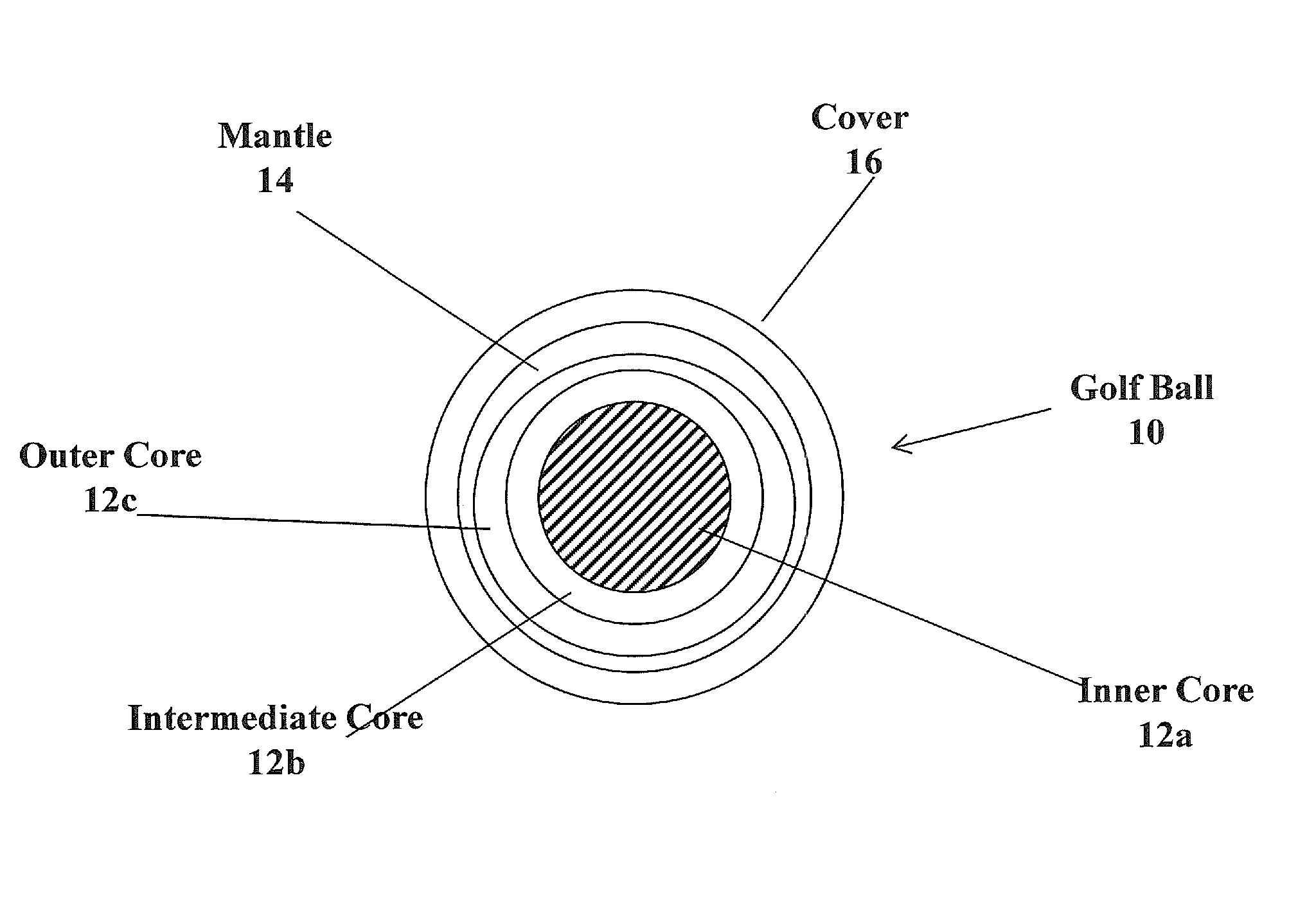

Thermoplastic polyester elastomer golf ball cores

ActiveUS9005052B1Increase elasticityMore ball distanceGolf ballsSolid ballsThermoplastic polyurethaneEngineering

A golf ball having a core layer comprising a thermoplastic polyester elastomer formed from a polytetramethylene glycol with a molecular weight greater than or equal to 1400 g / mol is disclosed herein. In one embodiment, an inner core sphere is the core layer and has a diameter ranging from 0.875 inch to 1.4 inches. The core comprises the inner core, an intermediate core and an outer core. The mantle component comprises an inner mantle and an outer mantle. The cover layer is preferably composed of a thermoplastic polyurethane.

Owner:CALLAWAY GOLF CO

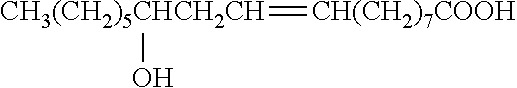

Two-part curable polyurethane foam resin composition, molded article using the same, and shoe sole

The two-part curable polyurethane foam resin composition uses little or no petroleum-derived raw materials but a plant-derived raw material so that the biomass ratio can be improved, the load on the environment can be reduced, and excellent physical characteristics can be exhibited. The two-part curable polyurethane foam resin composition includes a main agent that contains an isocyanate-terminated urethane prepolymer (A) and a curing agent that contains an isocyanate-reactive compound (B), water (C), and a catalyst (D), in which a polyol component used in (A) and (B) uses a castor oil polyol (b1) having 1.5 to 2.3 functional groups on average and a polyol (b2) prepared by addition polymerization of lactone to polytetramethylene glycol and / or polytetramethylene glycol (b3), the ratio (b1) / (b2) and / or (b3)=15 / 85 to 60 / 40 on a mass basis, and a content of the castor oil polyol (b1) is 10 to 45% by mass.

Owner:DAINIPPON INK & CHEM INC

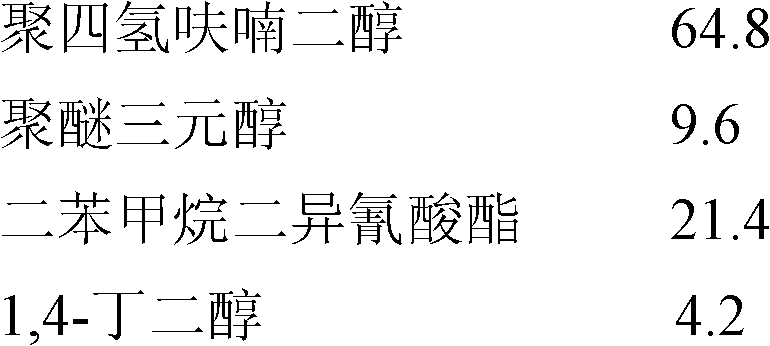

Preparation method of polyurethane elastomer for engineering tire treads

InactiveCN102643408AReduce resistanceHigh mechanical strengthSpecial tyresRolling resistance optimizationPolyurethane elastomerRolling resistance

The invention discloses a preparation method of polyurethane elastomer for engineering tire treads. The polyurethane elastomer is prepared from polytetramethylene glycol with the relative molecular weight of 2000, polyether triol EP-330N with the relative molecular weight of 4800, MDI (diphenylmethane diisocyanate), 1,4-butanediol and dibutyltin dilaurate. The polyurethane elastomer for the engineering tire treads prepared by the method has the advantages of no pollution, small wear, low rolling resistance and thermogenesis and excellent tearing resistance. Additionally, the tensile strength of the polyurethane elastomer reaches 31Mpa, the elongation at break of the polyurethane elastomer reaches 518%, the wear volume of the polyurethane elastomer reaches 0.0158cm3 (1.61km)-1, and the compression fatigue temperature rise of the polyurethane elastomer is only 9.2 DEG C.

Owner:BEIJING UNIV OF CHEM TECH +1

Rolling level thermoplastic polyurethane elastomer and preparation method thereof

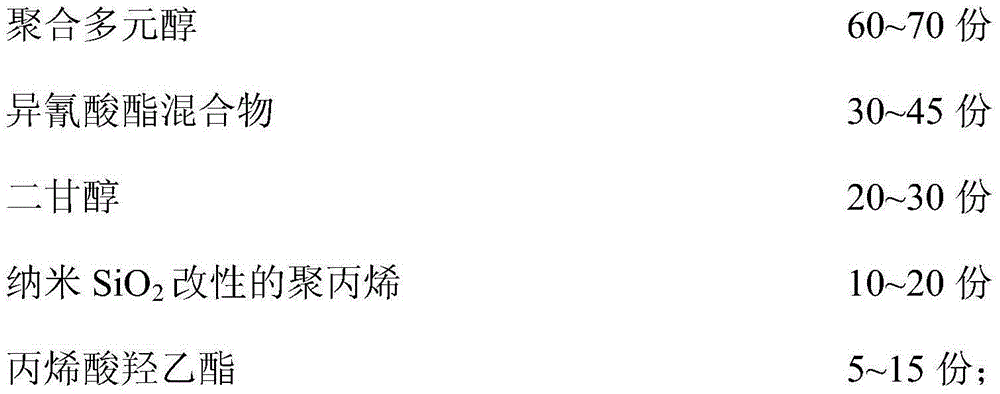

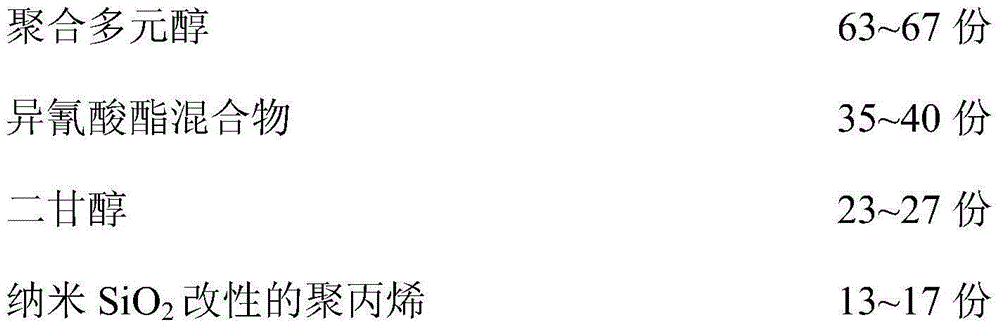

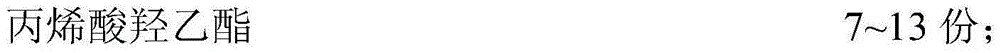

The invention provides a rolling level thermoplastic polyurethane elastomer and a preparation method thereof. The thermoplastic polyurethane elastomer is mainly prepared of the following components in parts by weight: polymeric glycol, isocyanate mixture, diethylene glycol, nano SiO2 modified polypropylene and hydroxyethyl acrylate, wherein the polymeric glycol is a polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol mixture; the isocyanate mixture is a toluene diisocynate and hexamethylene diisocyanate mixture. Under the synergistic effect of polytetramethylene glycol and adipic acid 1,4-butyl glycol ether glycol and the synergistic effect of toluene diisocynate and hexamethylene diisocyanate, the prepared rolling level thermoplastic polyurethane elastomer is high in processing performance and resilience performance due to nano SiO2 modified polypropylene and hydroxyethyl acrylate serving as a crosslinking agent; meanwhile, the phenomenon of roll bonding can be avoided in a working process.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Polyurethane prepolymer

ActiveCN102167794AEasy to handleResistant to hydrolysisOther chemical processesInsolesPolypropylene glycolLiquid state

The invention provides a polyurethane prepolymer with moisture curing, which is in a liquid state at a normal temperature and will not soak towards the inner substrate. The polyurethane prepolymer has good elastic force and moisture permeability. Solvent-free polyurethane prepolymer is formed in a manner that polyether polyalcohol, polyester polyalcohol and polyisocyanates undergo a reaction with the equivalence ration of NCO / OH being 1.1-3.0 to contain amine curing catalyst of 0.01-5mass%. The mass ratio between the polyether polyalcohol and the polyester polyalcohol is arranged from 95 / 5 to 75 / 25. The main component of the polyether polyalcohol is polytetramethylene glycol-polyethylene glycol copolymer or polypropylene glycol.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA INC

Waterproof noise-reduction multifunctional woven fabric and production method thereof

InactiveCN104652016AImprove spinnabilityImprove spinning qualityWoven fabricsMonocomponent polyesters artificial filamentFiberBenzoyl peroxide

The invention discloses a waterproof noise-reduction multifunctional woven fabric which is formed by weaving warp yarns and weft yarns by an air-jet loom, wherein the warp yarns and the weft yarns are prepared from the following raw materials in parts by weight: 30 to 36 parts of isotatic polypropylene, 10 to 14 parts of polyvinyl chloride, 20 to 24 parts of cowhair, 17 to 19 parts of alpinia fiber, 22 to 26 parts of kenaf fiber, 18 to 23 parts of cotton pulp, 7 to 9 parts of liquid paraffin, 8 to 10 parts of ethyl carbamate, 7 to 11 parts of polytetramethylene glycol, 1.1 to 2.5 parts of benzoyl peroxide, 2.1 to 3.2 parts of chitosan, 0.3 to 0.5 part of magnesium acetate, 2 to 4 parts of shell powder, 1 to 3 parts of rhizoma, 2 to 5 parts of mangnolia officinalis, 85 to 95 parts of 1-butyl-3-methyl imidazole acetate, 95 to 105 parts of 1-allyl-3-methyl imidazole chloride salt, a proper amount of water and 4 to 7 parts of assistant. The woven fabric has the advantages of warmth keeping, ventilation, wear resistance, antibacterial performance and the like.

Owner:章云

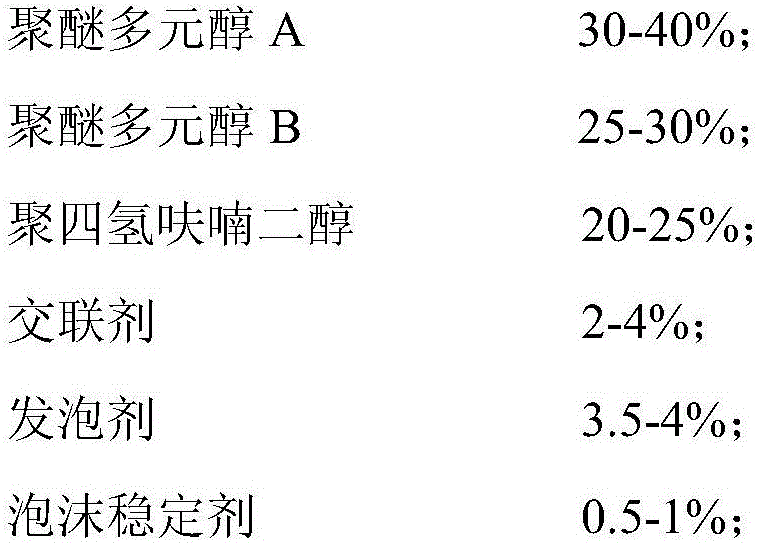

High-performance full-MDI polyurethane mixed component for automobile seats, and preparation method thereof

The invention belongs to the field of polymeric materials, and concretely relates to a high-performance full-MDI polyurethane mixed component for automobile seats, and a preparation method thereof. The mixed component is prepared through mixing a component A with a component B according to a weight ratio of 100:(65-70), wherein the component A is prepared from polyether polyol A, polyether polyol B, polytetramethylene glycol, a cross-linking agent, a foaming agent, a foam stabilizer, a pore forming agent and a catalyst; and the component B is prepared from polytetramethylene glycol, pure MDI, MDI-50 and crude MDI. The mixed component selects low-volatility and low-atomization reactive raw materials adopts high-molecular weight polyether as the cross-linking agent, and the high-performance material polytetramethylene glycol is introduced to the component A and the component B, so the produced automobile seats have the advantages of low density, good resilience, excellent mechanical performances, good sitting comfortableness, low smell, low content of VOCs, environmental protection and no pollution. The preparation method is simple, and is easy to implement.

Owner:SHANDONG INOV POLYURETHANE

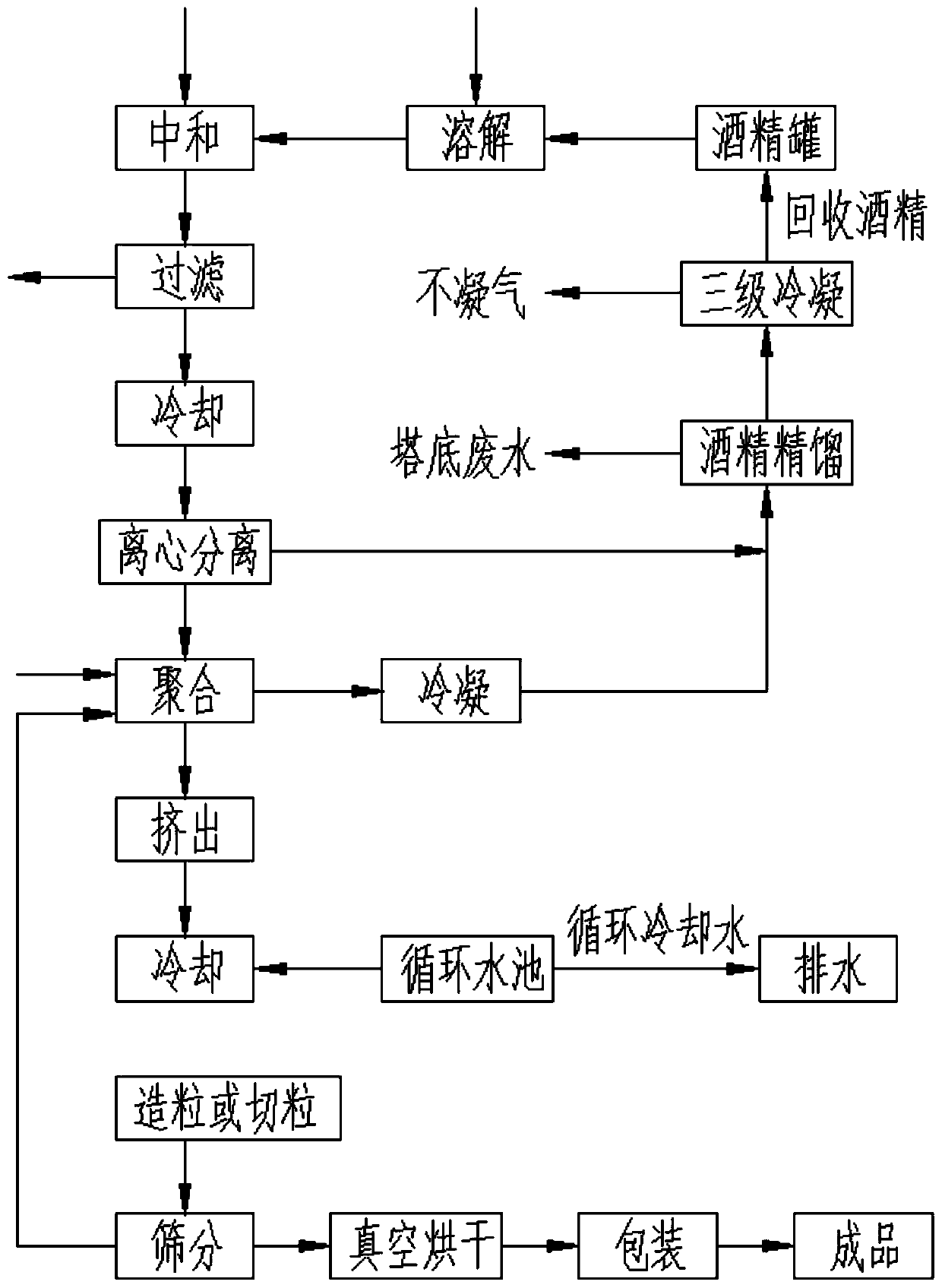

Bio-based polyalkylene glycol and preparation method thereof

The invention relates to bio-based polyalkylene glycol and a preparation method thereof. The product is a segmented copolymer which is prepared by using furfural derivative tetrahydrofuran and 2-methyltetrahydrofuran produced from wood fiber biomass as raw materials by a polymerization process, and has the structure shown in the specification. The preparation method comprises the following steps: adding tetrahydrofuran and an initiator in a mass ratio of 1:(2-10) into a reaction kettle in an inert gas atmosphere, and reacting at a temperature of 80-150 DEG C and a pressure of 0.2-0.5MPa for 4-15 hours to prepare a polytetramethylene glycol homopolymer; cooling the reaction kettle to normal temperature and normal pressure, adding 2-methyltetrahydrofuran into the reaction kettle, reacting at a temperature of 100-120 DEG C and a pressure of 0.4-1MPa for 2-8 hours to prepare the bio-based polyalkylene glycol, wherein the molar ratio of 2-methyltetrahydrofuran to tetrahydrofuran is 1:(1-10). The bio-based polyalkylene glycol has the advantages that the product by a process flow for producing bio-based PAG (polyalkylene glycol) from wood fiber biomass can achieve the performance index of fossil based PAG, and can completely replace an existing fossil based product.

Owner:俏东方生物燃料集团有限公司

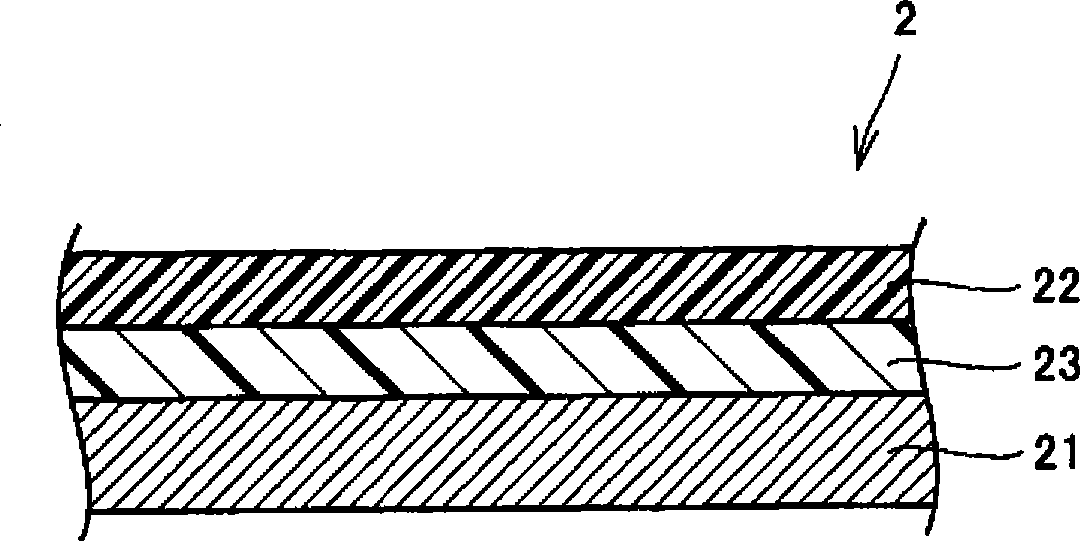

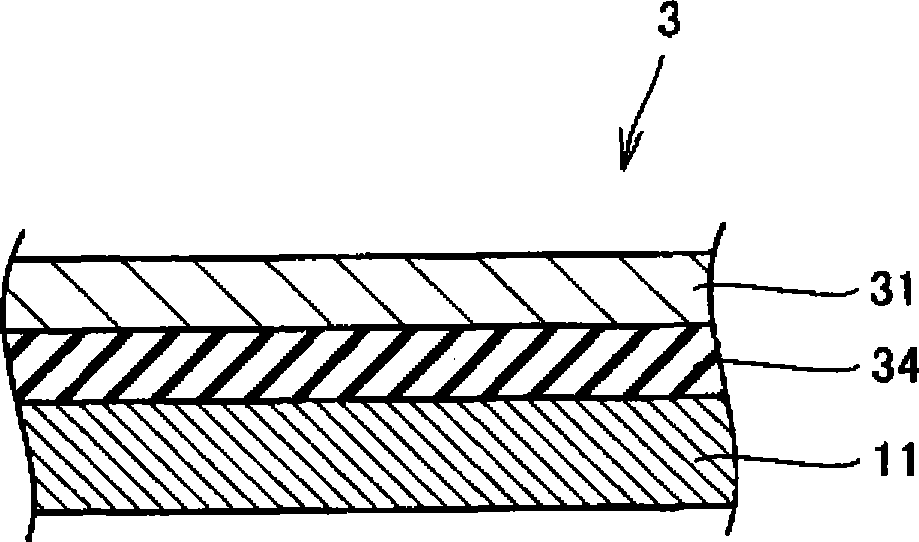

Resin tube

InactiveUS20050053742A1Synthetic resin layered productsMachines/enginesPolytetramethylene terephthalatePolybutylene

A resin tube has a multilayer resin structure. A first resin layer contains polybutylene naphthalate. Second and third resin layers are layers containing copolymer of polybutylene naphthalate and polytetramethylene glycol. The second resin layer is on an outer side of the first resin layer, and the third resin layer is on an inner side of the first resin layer. A fourth resin layer contains polybutyene terephthalate.

Owner:NISSAN MOTOR CO LTD +1

Polyurethane-polyurea coatings

InactiveUS20070166552A1Improve acceleration performancePrevents growthFibre treatmentSynthetic resin layered productsPolyolAlcohol

The present invention provides coating agents made up of the reaction product ofa) a polycarbonatediol component comprisinga1) a polytetramethylene glycol-based polycarbonatediol with a molecular weight of between 400 and 8000, anda2) optionally other polyols with a molecular weight of from 200 to 8000,b) 0.5-2.0 mol per mol of a) of a chain extender selected from the group consisting of a low-molecular weight aliphatic or cycloaliphatic diol, a low-molecular weight aliphatic or cycloaliphatic diamine, and hydrazine, andc) 1.5-3.0 mol per mol of a) of an aliphatic, cycloaliphatic or aromatic diisocyanate,dissolved ind) 40-90 percent by weight (based on the total formulation) of an organic solvent selected from the group consisting of linear or cyclic esters, ketones, alcohols, aromatic compounds and mixtures thereof.

Owner:BAYER MATERIALSCIENCE AG

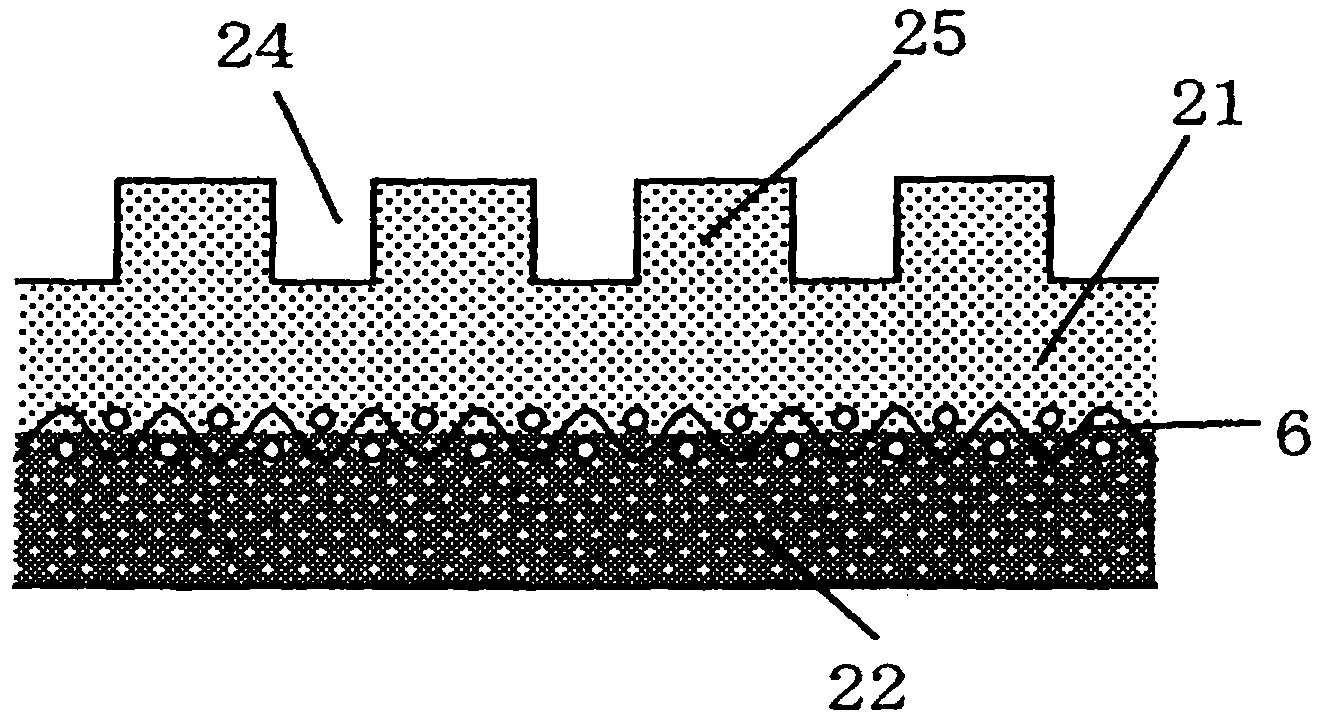

Shoe press belt for papermaking

ActiveCN101939483AExcellent mechanical propertiesIncreased durabilityPaper/cardboardPress sectionFiberCarbamate

A belt for papermaking shoe presses is provided which comprises a reinforcing fibrous base (6) and a polyurethane layer (2) united therewith, the reinforcing fibrous base (6) having been embedded in the polyurethane layer (2). The belt includes a polyurethane layer obtained by curing a mixture comprising: a urethane prepolymer obtained by reacting a polyisocyanate compound selected among p-phenylene diisocyanate, 4,4'-methylenebis(phenyl isocyanate), and tolylene diisocyanate with a polyol compound selected among polypropylene glycol, polytetramethylene glycol, and a polycarbonate diol; a hardener selected among an aliphatic diol compound, hydroquinone bis-ss-hydroxyethyl ether, and organic polyamine compound; and an aliphatic triol compound. Due to this layer, the shoe press belt for papermaking is excellent in wearing resistance and flexing fatigue resistance.

Owner:ICHIKAWA ELECTRIC CO LTD

Silyl-terminated polymers

Owner:DOW GLOBAL TECH LLC

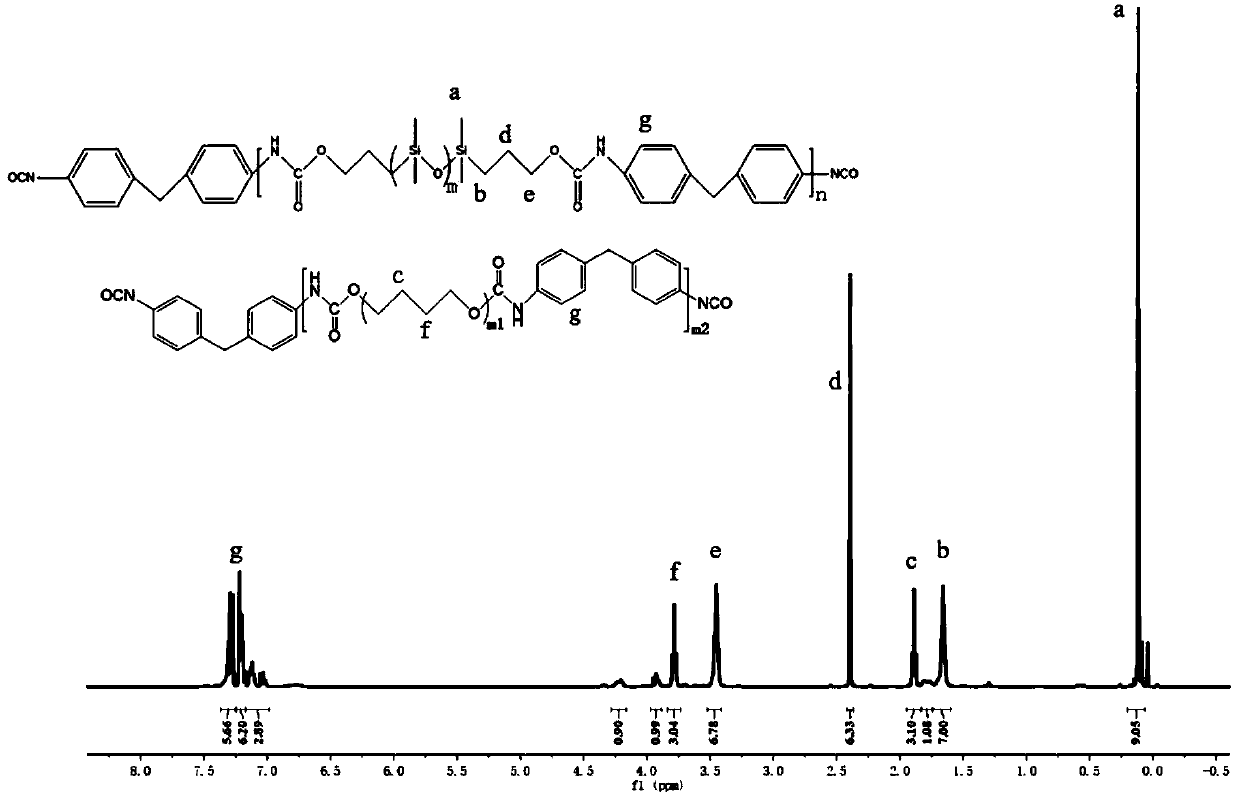

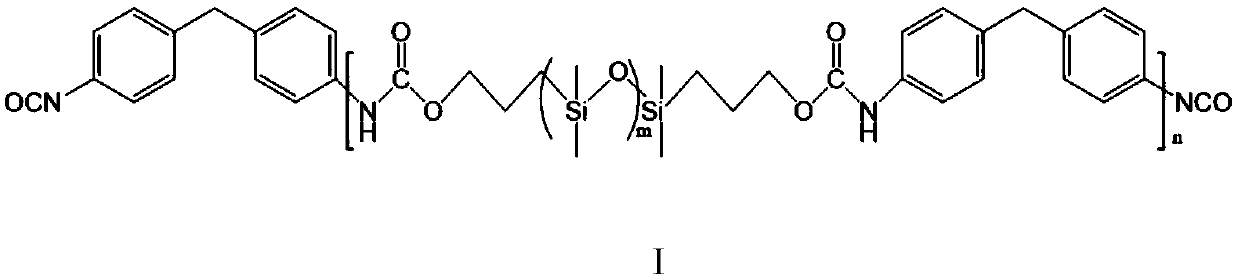

Polysiloxane polyether polyurethane elastomer with high mechanical property and preparation method of elastomer

ActiveCN109575233AGood mechanical propertiesHigh tensile strengthPolyurethane elastomerPolyether polyurethane

The invention provides a polysiloxane polyether polyurethane elastomer with a high mechanical property and a preparation method of the elastomer. Diphenylmethane diisocyanate, hydroxypropyl-terminatedpolysiloxane, diphenylmethane diisocyanate and polytetramethylene glycol serve as raw materials and are synthesized into two prepolymers, and then the two prepolymers are mixed and copolymerized by chain extension to prepare the polysiloxane polyether polyurethane elastomer with a specific molecular structure. The prepared polysiloxane polyether polyurethane elastomer with the specific molecularstructure has the excellent mechanical property, the tensile strength of the elastomer can reach 38Mpa, and the breaking elongation of the elastomer can reach 600% or more.

Owner:SHANDONG UNIV

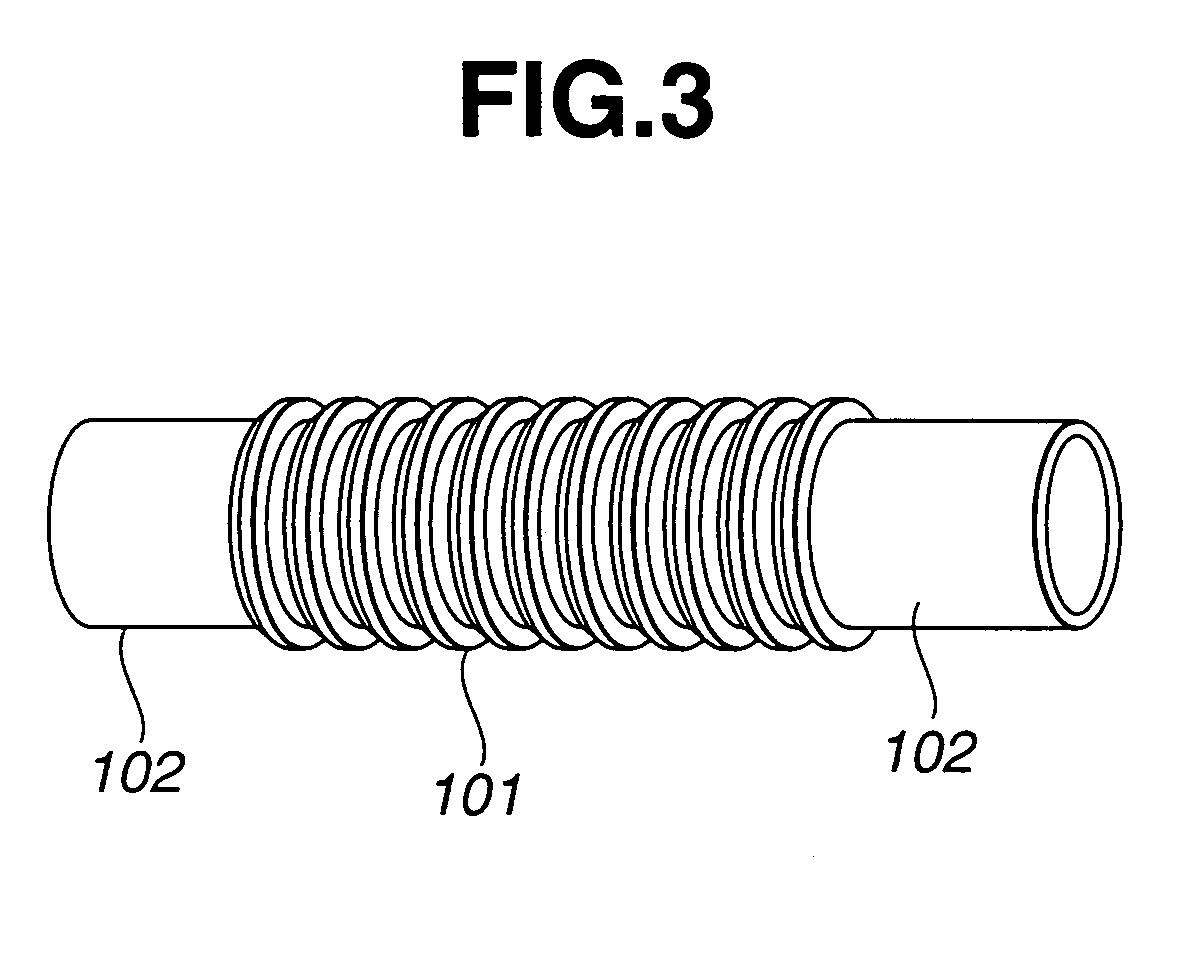

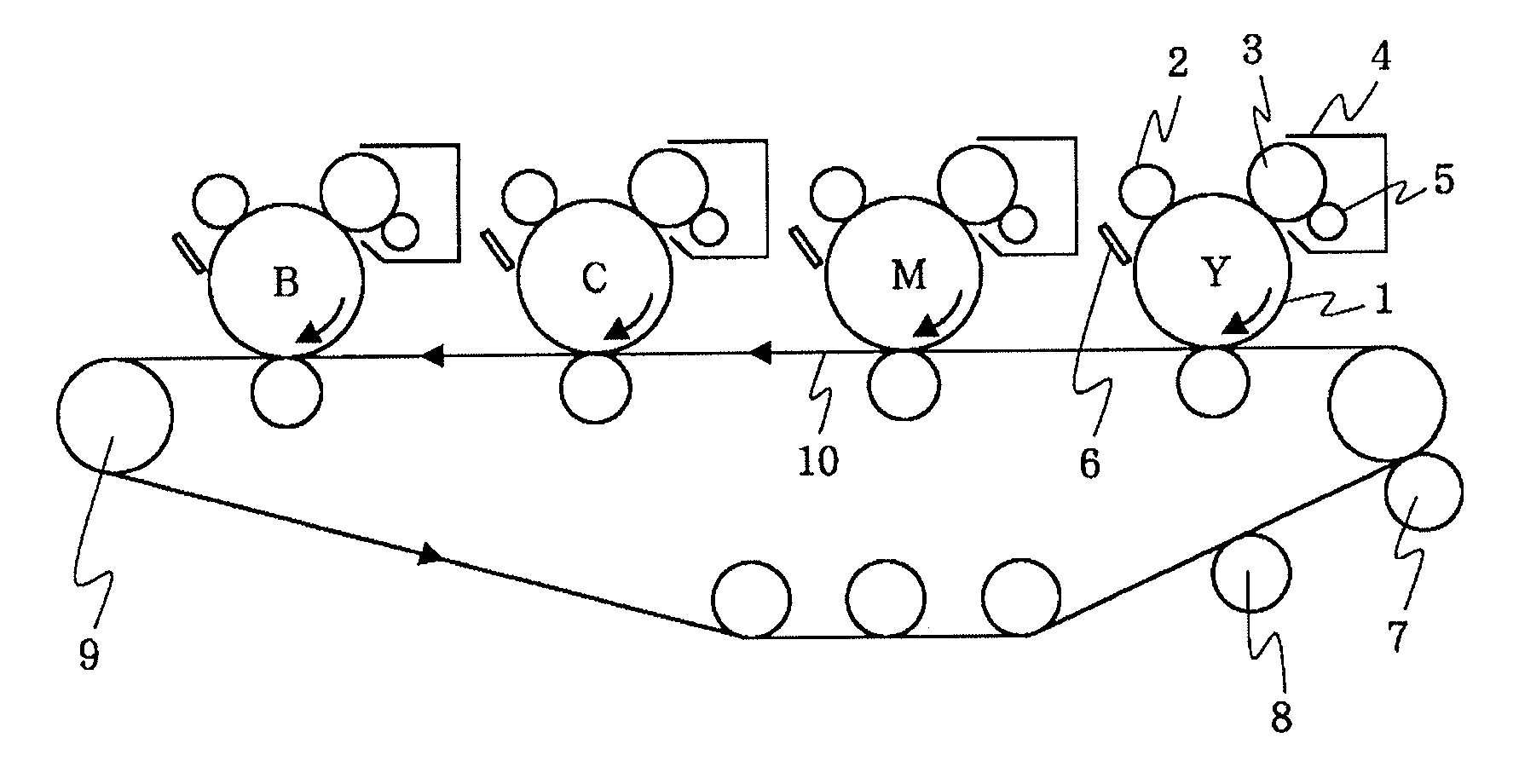

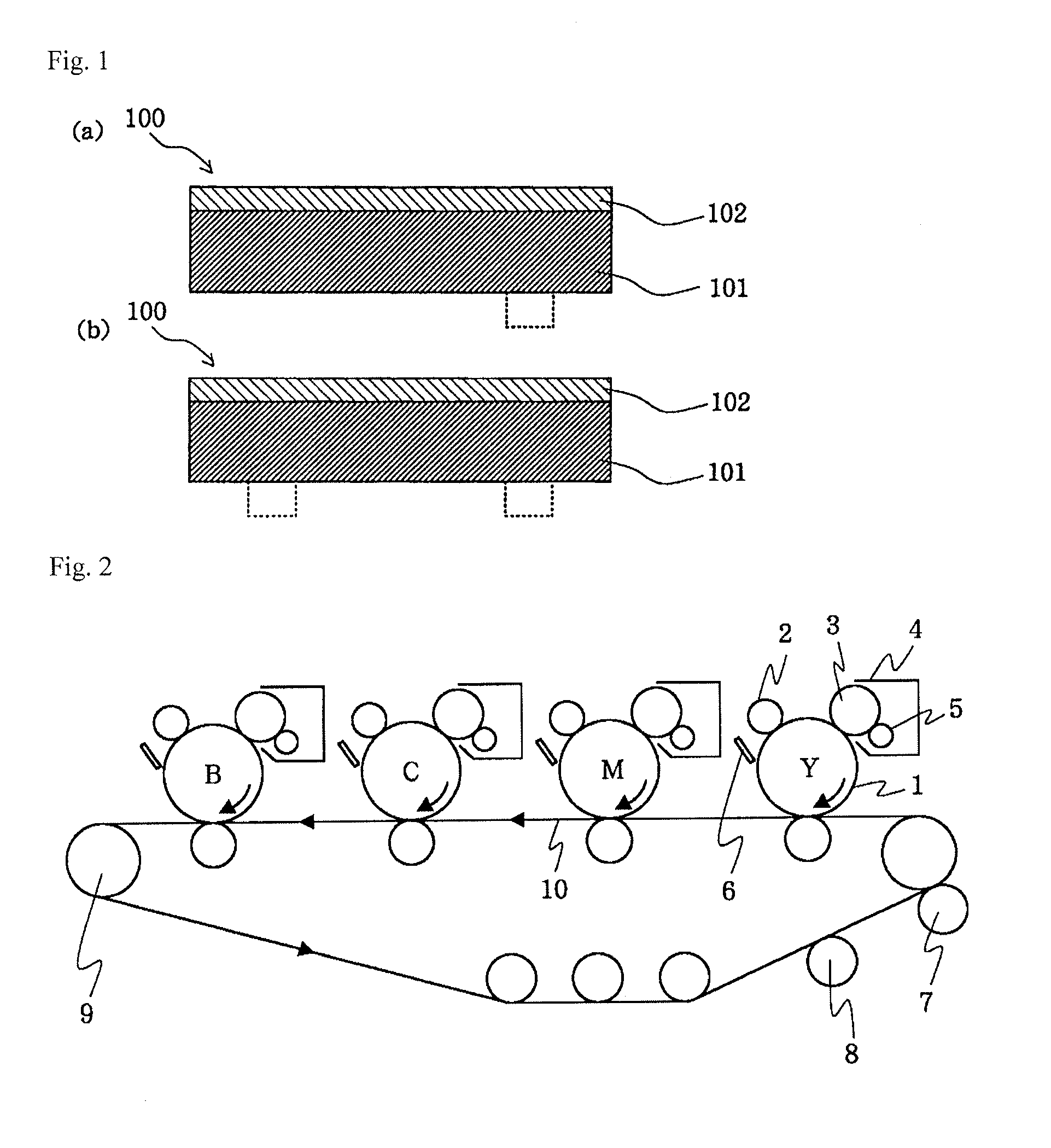

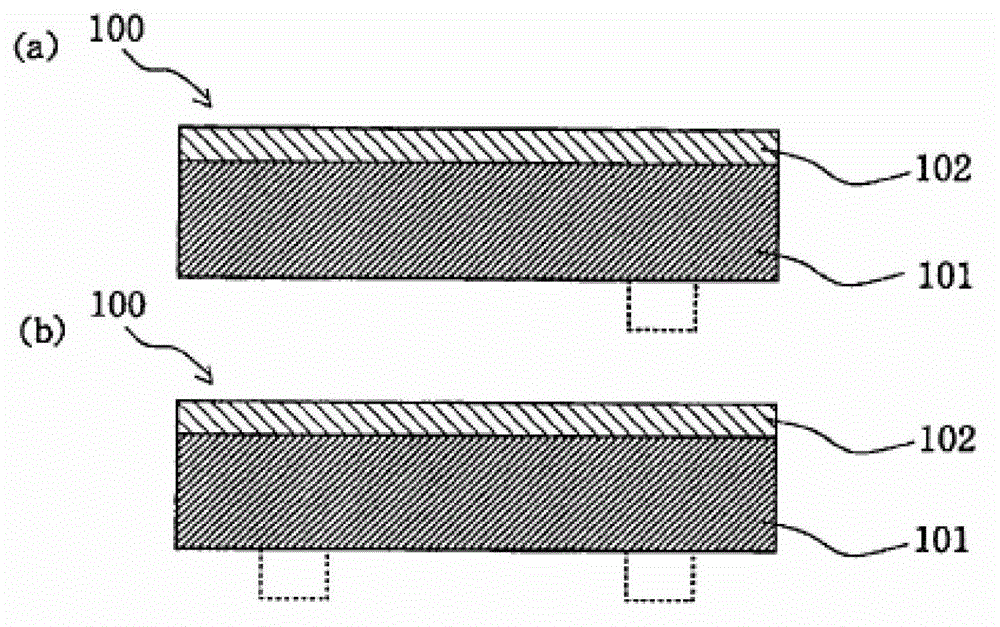

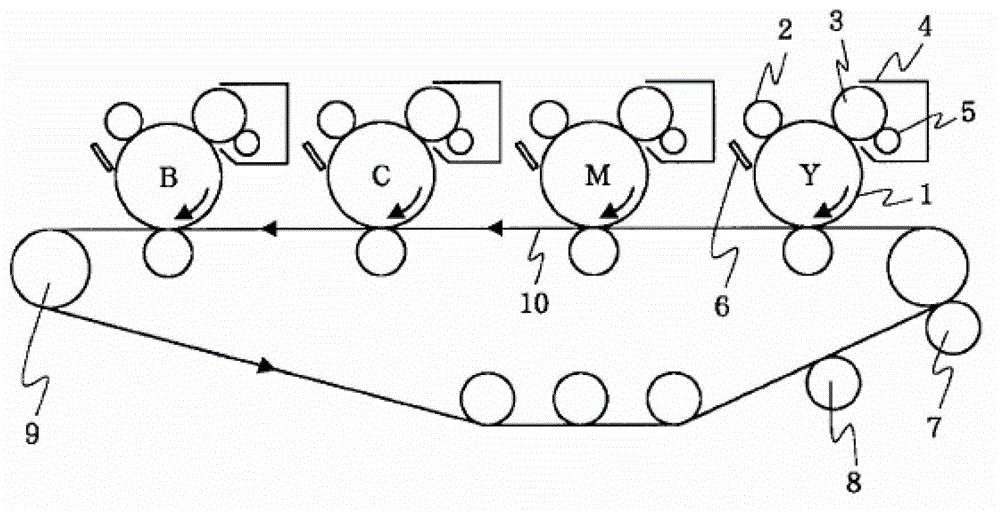

Electroconductive endless belt

InactiveUS20120301190A1Good image uniformityLow costElectrographic process apparatus1,4-ButanediolUV curing

Provided is an electroconductive endless belt by which a good image with uniformity and without local unevenness can be obtained at a lower cost.Provided is an electroconductive endless belt 100, which is used for an image forming apparatus, in the shape of an endless belt having a laminated structure provided with at least a base layer 101 and a cured resin layer 102 in the mentioned order from the inside. The base layer 101 contains a thermoplastic resin, the cured resin layer 102 contains an ultraviolet curable resin; an ionic conductive agent; at least one of 1,4-butanediol acrylate and a polytetramethylene glycol acrylate; and a polymer having an ethylene oxide, and the content of the ionic conductive agent is 0.5 to 5 parts by mass with respect to the total content 100 parts by mass of an ultraviolet curable resin; at least one of 1,4-butanediol acrylate and polytetramethylene glycol acrylate; and a polymer having an ethylene oxide.

Owner:BRIDGESTONE CORP

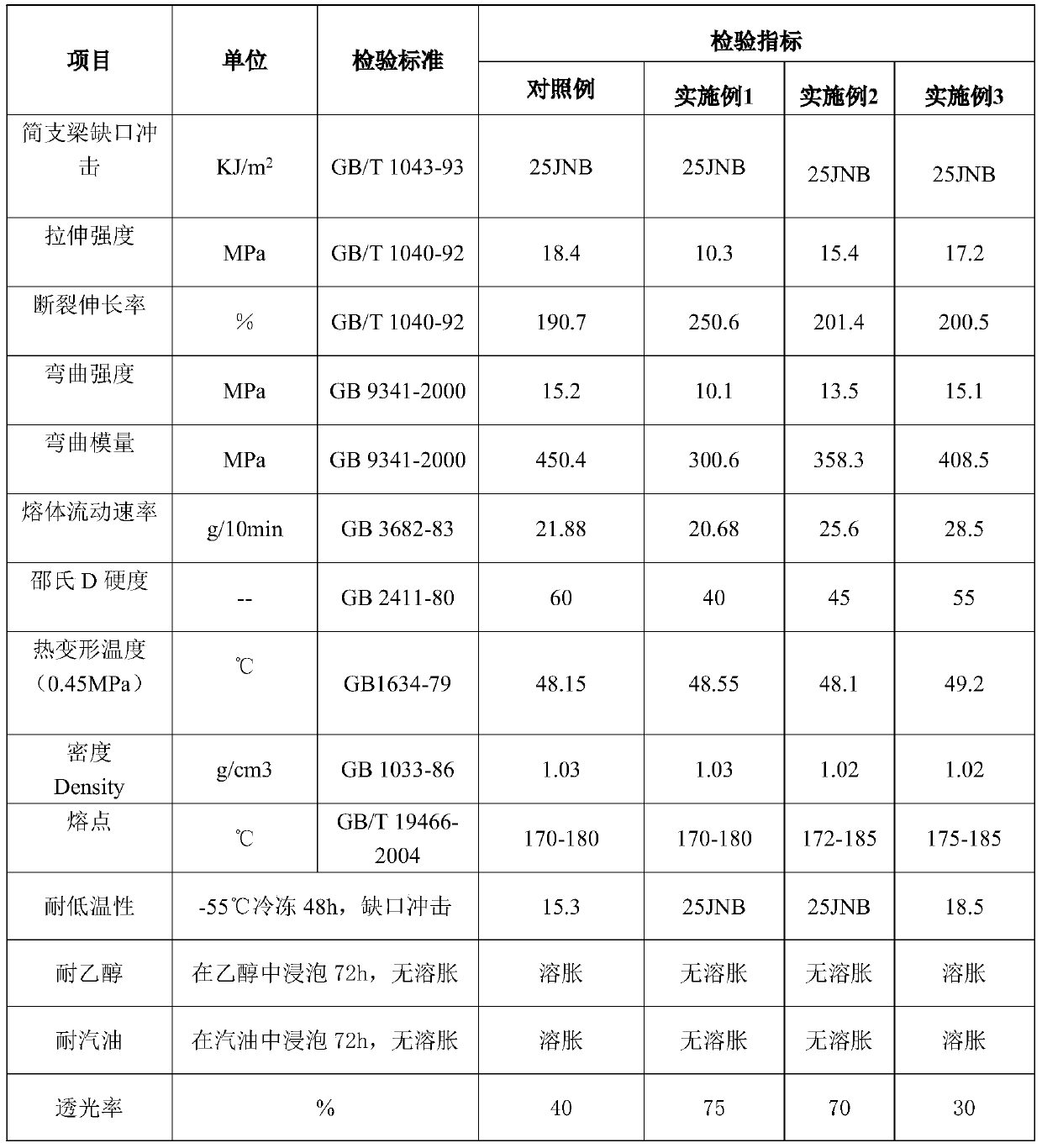

Nylon elastomer material and preparation method thereof

The invention relates to a nylon elastomer material and a preparation method thereof. The nylon elastomer material is composed of the following components in parts by mass, wherein the mass ratio of anylon 1012 salt monomer to a softener to an end-capping reagent is 100:(10-30):(0.1-0.5), and the softener is any one or a combination of more of polybutylene glycol, dimer acid, polyester and polyether; long-carbon-chain decamethylene diamine and aliphatic dodecanedioic acid are used as main raw materials for synthesizing the nylon 1012 salt monomer; the characteristics of good flexibility and high benzene ring rigidity of long-carbon-chain nylon are combined; the nylon matrix resin has relatively good flexibility and crystallinity; the temperature resistance, the alcohol resistance and theoil resistance are good; copolymerization is carried out under a proper reaction condition by using the softener; meanwhile, the active stable polymerization of end groups is eliminated by the end-capping reagent, and the thermal stability, the oxidation resistance and the catalytic activity are improved by the aid of the auxiliaries, so that on one hand, the hardness of nylon is reduced, and thematerial feels soft, and on the other hand, the material can be conveniently used for manufacturing foaming base materials of sneaker soles, is lighter and can be widely used.

Owner:建湖县兴隆尼龙有限公司

Make-up removal wet tissue with moisturizing function and preparation method thereof

The invention relates to a make-up removal wet tissue with a moisturizing function and a preparation method thereof. According to the invention, the PEG modified grease, such as, PEG-6 octanoic acid / tricaprin, PEG-20 glyceryl isostearate and polytetramethylene glycol-3 PEG / PPG-8 / 5 glyceride, are matched with a water-soluble humectant, polyhydric alcohol and corrosion remover, the natural active ingredients, such as pullulan, dipotassium glycyrrhizinate, aloe vera juice, dendrobium stem extract and purple coneflower extract, are specially added, and a spunlace non-woven fabric at certain gram weight and spinning ratio is adopted for preparing the make-up removal wet tissue with the moisturizing function. The make-up removal wet tissue has an excellent make-up removal capacity; the skin feels no burden when the wet tissue is used; after the use, the skin is moistened and cool; through the evaluation for the excellent make-up removal capacity, moisturizing capacity and stability of the formula product and the marketed similar products, a result proves that the make-up removal wet tissue provided by the invention has an ideal moisturizing effect and a cleaning capacity better than that of the marketed make-up removal products.

Owner:YUNNAN BAIYAO GROUP

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA FRANCE SA

Preservative-free centella lyophilized mask and preparation method thereof

InactiveCN110051585AImprove securityImprove water retentionCosmetic preparationsToilet preparationsSide effectGlycerol

The invention discloses a preservative-free centella lyophilized mask and a preparation method thereof. The mask comprises lyophilized powder comprising the following components: 0.5-10 parts of centella leaf extract, 0.1-5 parts of hydroxyethyl urea, 0.5-5 parts of PEG / PPG / polytetramethylene glycol-8 / 5 / 3 / glycerin, 0.1-5 parts of glycerin, 0.1-5 parts of sodium hyaluronate, 0.5-5 parts of naturalthickener and 5-60 parts of water. The lyophilized mask can deeply clean the skin, shrink pores, contains no chemical additives such as preservatives, hormones and antibacterial agents and has no adverse stimulation and side effects on the skin. The lyophilized mask can effectively increase the water retention of the skin, protect the skin from external stimulation, protect the skin from harm andrestore the water and oil balance of the skin, so that the skin is healthy and achieves an ideal state.

Owner:深圳津梁生活科技有限公司 +1

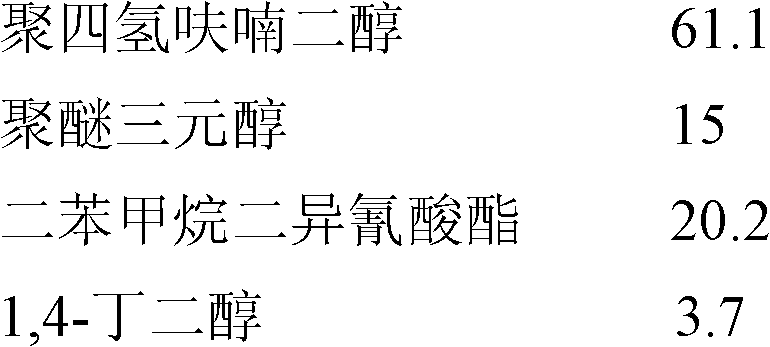

Cross-linked anti-fatigue and anti-wear polyurethane rubber

The invention discloses a method for preparing cross-linked anti-fatigue and anti-wear polyurethane rubber. The cross-linked anti-fatigue and anti-wear polyurethane rubber comprises the following components in percentage by mass: 65-70% of polytetramethylene glycol, 6-10% of cyclic polypropylene oxide ether triatomic alcohol, 14-20% of toluene diisocyanate, 5-8% of 1,5-naphthalene diisocyanate, 1-3% of di-o-chlorodiphenylamine methane, 0.5-1.5% of trimethylolpropane, 0-0.5% of carbon black and 1-2% of molybdenum disulfide. The rubber has the advantages of high wear resistance, good resilience, good low-temperature resistance, high tensile strength, predominant hydrolysis resistance, good adhesion to metal, shock resistance and relatively good anti-fatigue performance.

Owner:JIANGSU GUANGDING PIPE IND TECH CO LTD

Electroconductive endless belt

Owner:BRIDGESTONE CORP

Fluorinated polytetramethylene glycol (PTMG) with diepoxide endgroups as magnetic lubricants

A surface agent includes two end portions and a middle portion disposed between the end portions. The end portions include a terminal section and a midsection. The terminal section includes at least one surface active functional group. The midsection includes at least one perfluoroethyl ether unit. The middle portion includes at least one perfluorobutyl ether unit.

Owner:WESTERN DIGITAL TECH INC

Aqueous process for making fluoropolymers

A novel aqueous polymerization process for making fluoropolymer dispersions is disclosed in which non-ionic non-fluorinated emulsifier is used to produce fluoropolymer emulsions. The emulsifiers contain blocks of polyethylene glycol, polypropylene glycol and / or polytetramethylene glycol. The process and fluoropolymer produced contain no fluorinated surfactant. The fluoropolymers have excellent resistance to discoloration.

Owner:ARKEMA INC

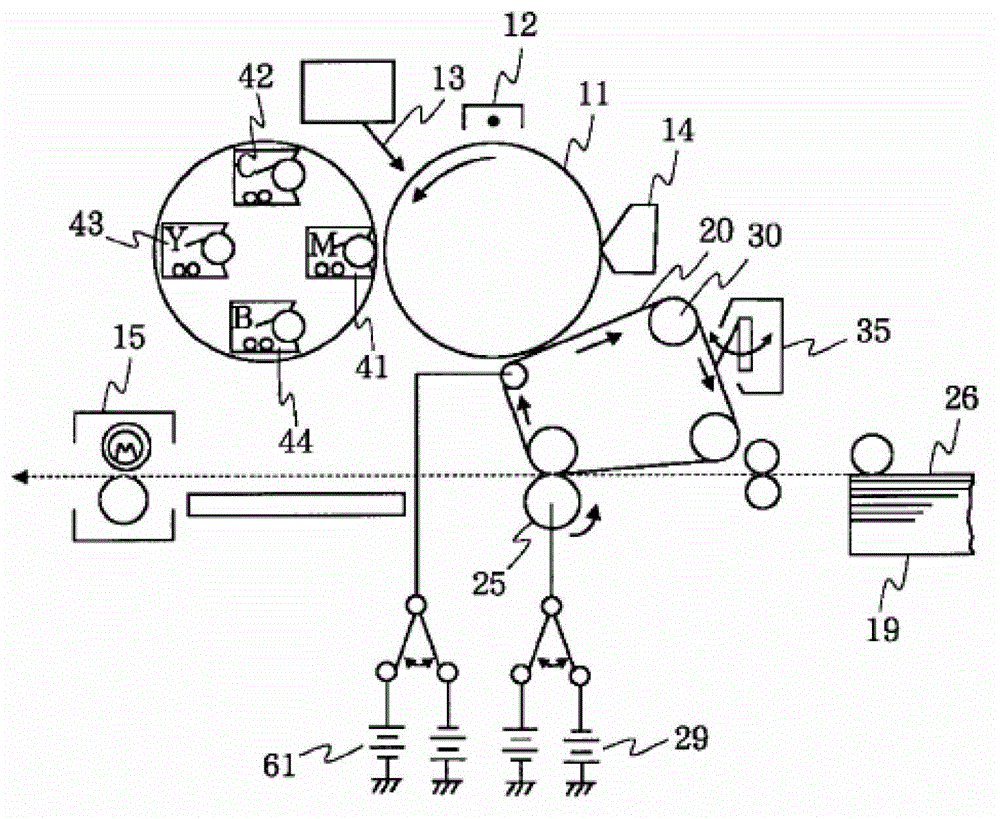

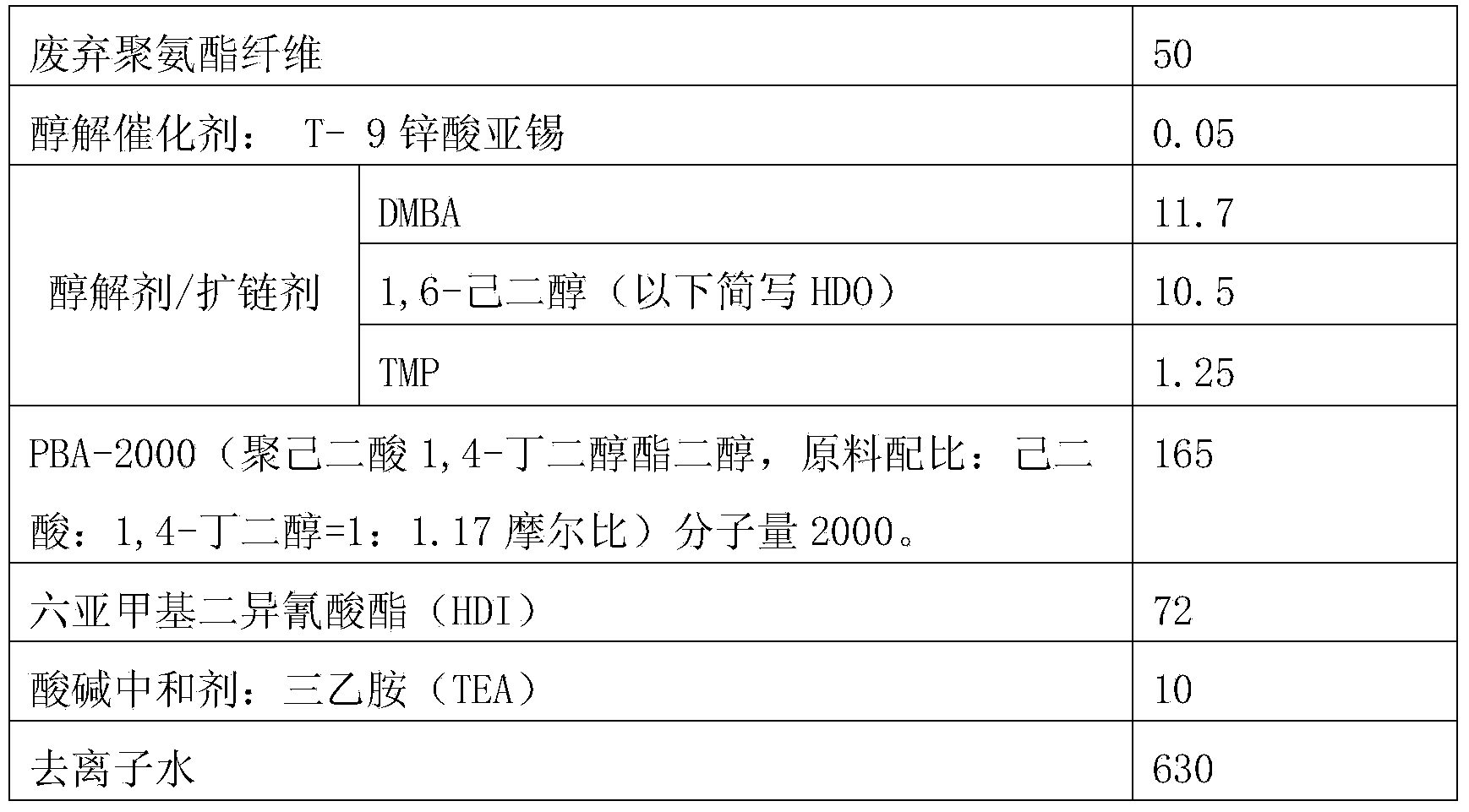

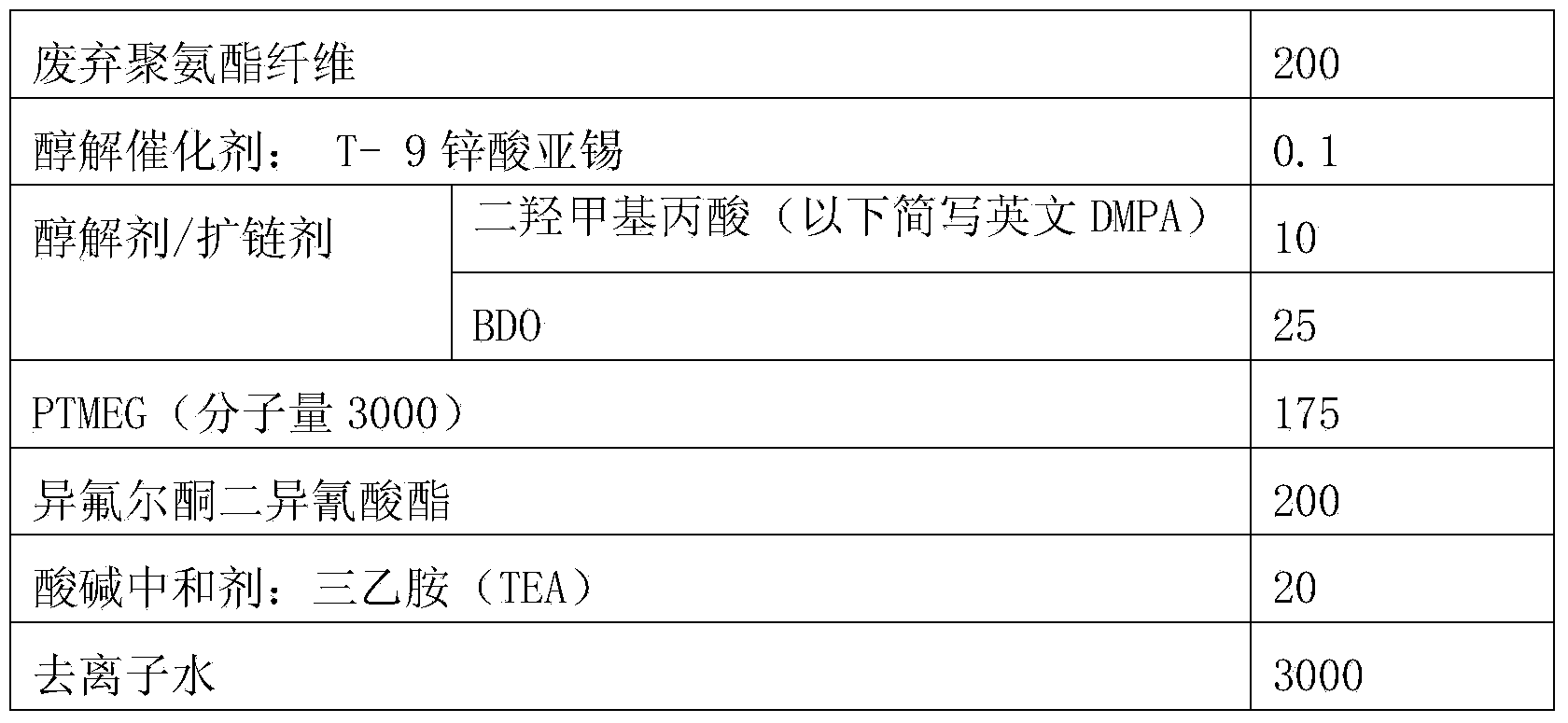

Preparation method of aqueous polyurethane emulsion and aqueous polyurethane emulsion prepared thereby

InactiveCN103641974AReduce manufacturing costPromote technological developmentPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsFiberPolyol

The invention provides an aqueous polyurethane emulsion preparation method. The preparation method comprises the following steps: subjecting waste polyurethane fibers to an alcoholysis treatment so as to obtain a mixture of hydroxyl terminated polyurethane with a molecular weight of 5000 to 10000 and polyol, and directly subjecting the mixture to processes of pre-polymerization, chain propagation, and emulsification so as to one-step obtain aqueous polyurethane emulsion; wherein the waste polyurethane fiber is preferably selected from waste polyether type polyurethane fiber and / or polycarbonate type polyurethane fiber generated by dry spinning or wet spinning; more preferably, the waste polyurethane fiber is selected from waste polytetramethylene glycol type polyurethane fiber and / or polycarbonate diol type polyurethane fiber whose soft section ratio is 85% or more; and most preferably, the waste polyurethane fiber is waste polytetramethylene glycol type polyurethane fiber whose soft section ratio is 85% or more. The preparation method provided a more reasonable reutilization method with a more additional value for waste high-grade polyurethane fibers.

Owner:高松文

Leather-like sheet

ActiveCN101443513AImprove surface qualitySoft touchTextiles and paperThin material handlingMeth-Polyol

Disclosed is a leather-like sheet (1) having at least a base layer (11) and a skin layer (12). The skin layer (12) is composed of a crosslinked product of a polyurethane hot melt composition which contains 100 parts by mass of a urethane prepolymer (A), 5-40 parts by mass of a coloring agent (B) containing a polyol as a vehicle, 5-50 parts by mass of a polyfunctional (meth)acrylate (C), and 0.5-5 parts by mass of a photopolymerization initiator (D). The urethane prepolymer (A) is obtained by reaction 5-50% of the total number of isocyanate groups contained in an isocyanate group-containing urethane prepolymer, which is obtained by reacting apolyol (a1) containing not less than 40% by mass of a polytetramethylene glycol and a polyisocyanate (a2), with a hydroxy group-containing (meth)acrylate. The leather-like sheet (1) has excellent surface quality, while securing excellent flexibility and bending resistance.

Owner:DIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com