Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250 results about "Size composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and composition for the sizing of paper with a mixture of a polyacid and a polybase

InactiveUS6171444B1Easy to produceHigh color fastnessNatural cellulose pulp/paperSpecial paperHueWater resistant

Compositions and methods are provided for the sizing of paper, to enhance the quality of images printed thereon. The novel sizing compositions contain as a sizing agent a mixture of a polyacid and a polybase. When applied to a paper substrate, such as in an internal or external sizing process, the sizing compositions result in a sized paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the sizing agent. Images printed on a paper substrate coated with the sizing compositions of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

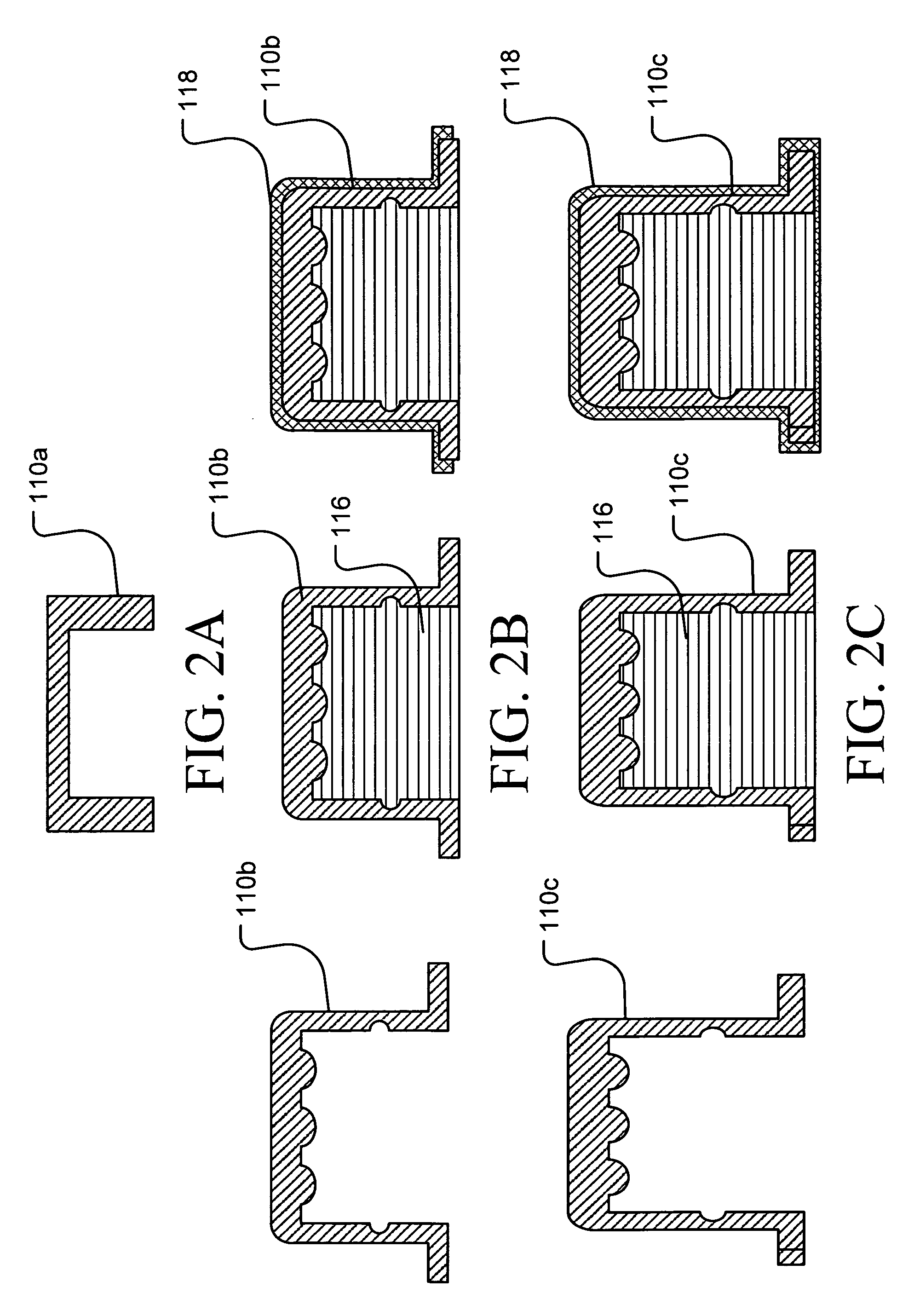

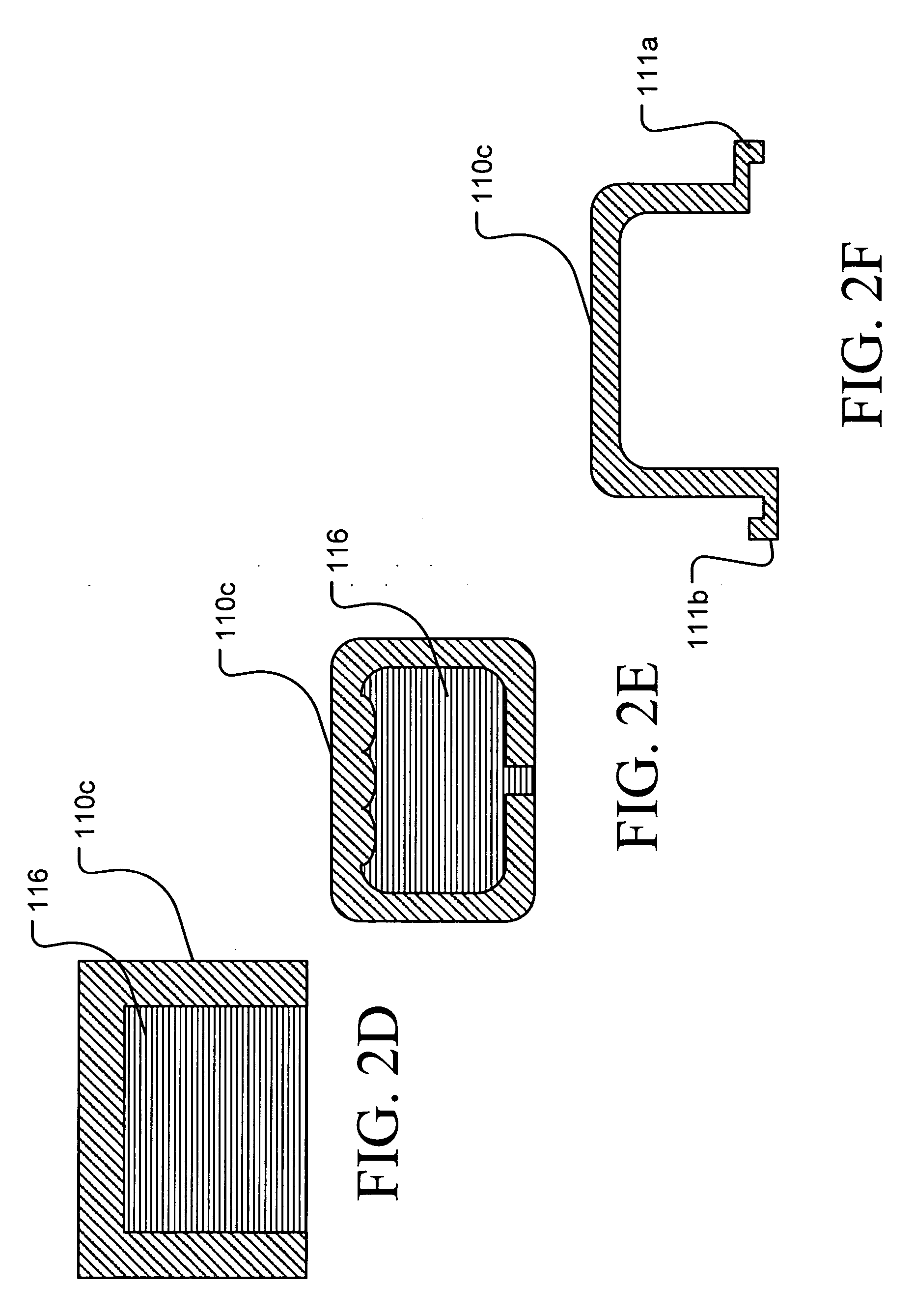

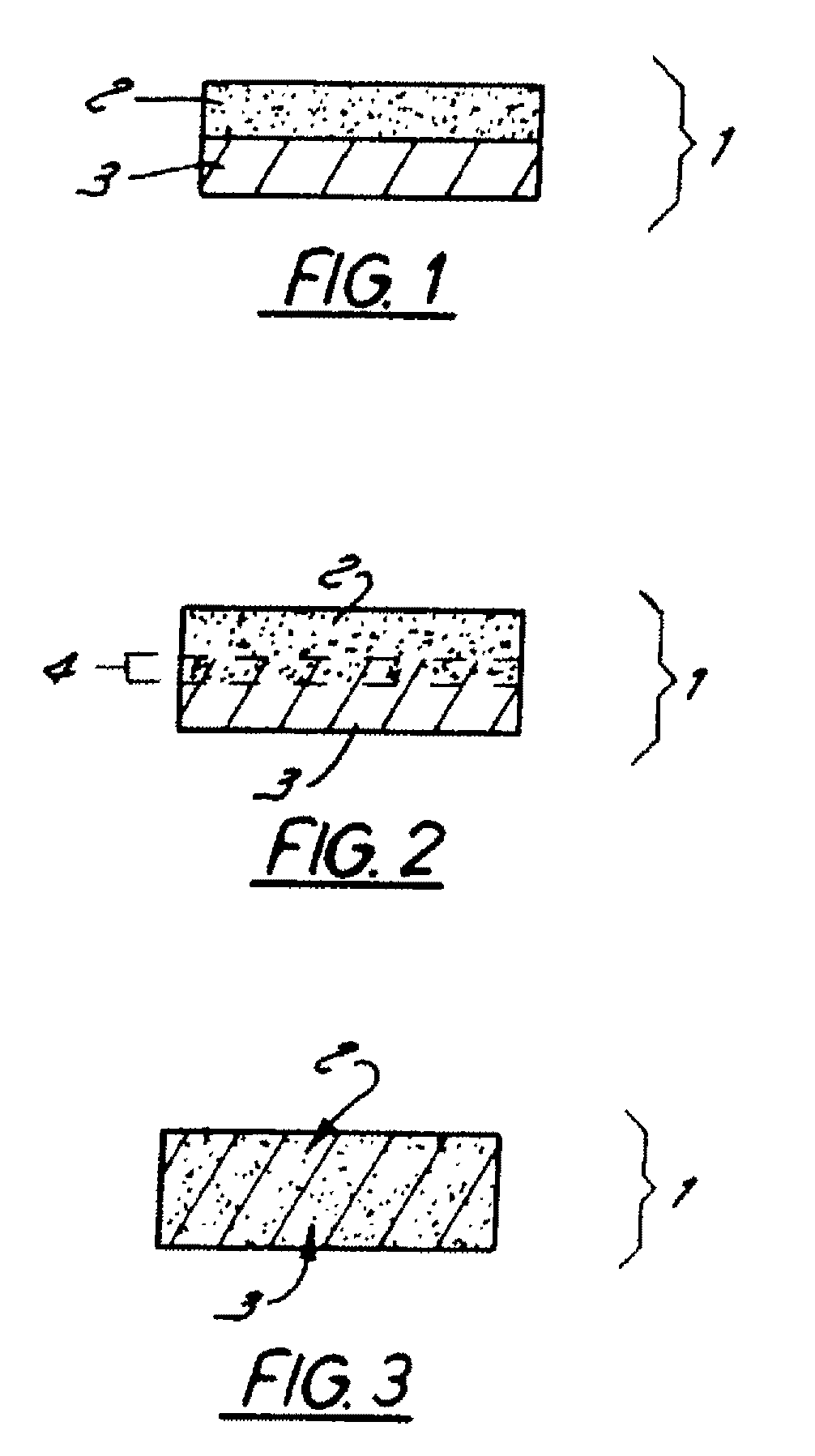

Modified fibers for use in the formation of thermoplastic fiber-reinforced composite articles and process

InactiveUS20080160302A1Secure bondingImprove mechanical propertiesGlass making apparatusOptical articlesSize compositionNanometre

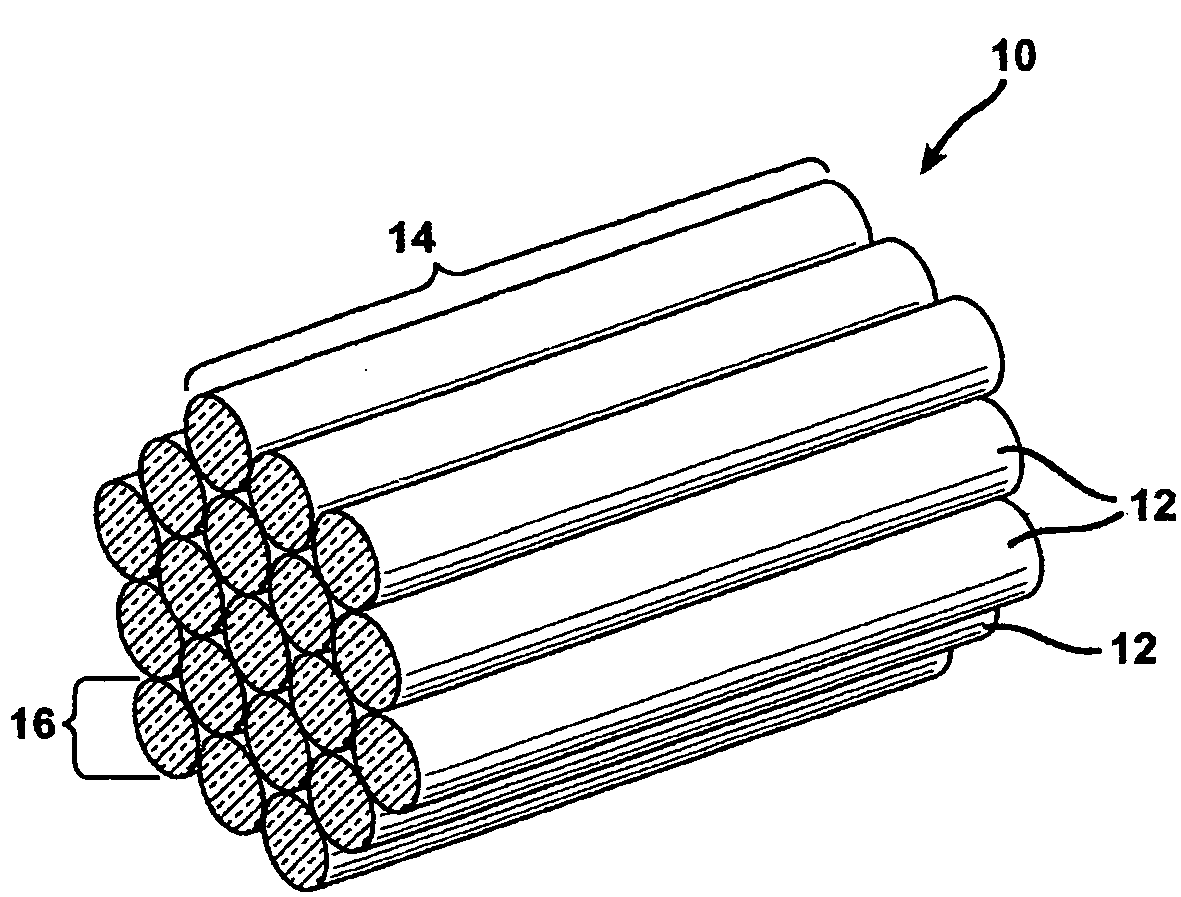

A surface-modified fibrous material is provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article. Good binding between the fibrous material and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The fibrous material may be provided in continuous or discontinuous form. In a preferred embodiment glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. The surface-roughened fibrous material is incorporated in a thermoplastic matrix as fibrous reinforcement with the application of heat whereby the thermoplastic matrix is rendered melt processable. In preferred embodiments injection or compression molding is utilized. Improved long-fiber thermoplastics also may be formed to advantage.

Owner:JOHNS MANVILLE CORP

Size composition for textile

A textile size composition is prepared from modified starch (20-90%) and specia nano material (0.05-5%) which is chosen any one of SiO2, TiO2, Al2O3 and ZrO2. Its advantages are high stability, shortdissolving time and high effect of benefiting weaving.

Owner:杭州科瀚盟新材料技术有限公司

Sizing for high performance glass fibers and composite materials incorporating same

ActiveUS20060204763A1Reduces amount of boronProcess environmental protectionOther chemical processesFibre treatmentEpoxySilanes

A sizing composition containing an epoxy film former, a urethane film former, a silane package that includes an aminosilane coupling agent and an epoxy silane coupling agent, a cationic lubricant, a non-ionic lubricant, an antistatic agent, and at least one acid is provided. The epoxy resin emulsion includes a low molecular weight liquid epoxy resin and one or more surfactants. The epoxy resin preferably has an epoxy equivalent weight from 185-192. The sizing composition may optionally contain a methacryloxy silane. The sizing composition may be used to size glass fibers used in filament winding applications to form reinforced composite articles with improved mechanical properties, wet tensile properties, improved resistance to cracking, and improved processing characteristics.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

Modified discontinuous glass fibers for use in the formation of thermoplastic fiber-reinforced composite articles

InactiveUS20080160286A1Secure bondingImprove mechanical propertiesMaterial nanotechnologyLayered productsFiber-reinforced compositeMechanical property

Surface-modified discontinuous glass fibers are provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article by injection or compression molding which displays enhanced mechanical properties, including improved tensile strength. Good binding between the discontinuous glass fibers and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. Improved color in the resulting injection or compression molded thermoplastic discontinuous glass fiber-reinforced composite articles is made possible in combination with enhanced mechanical properties.

Owner:ASRAR JAWED +1

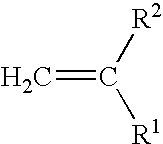

Size composition

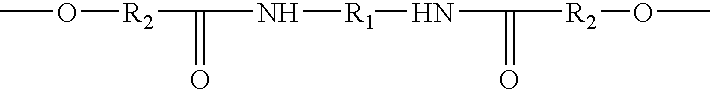

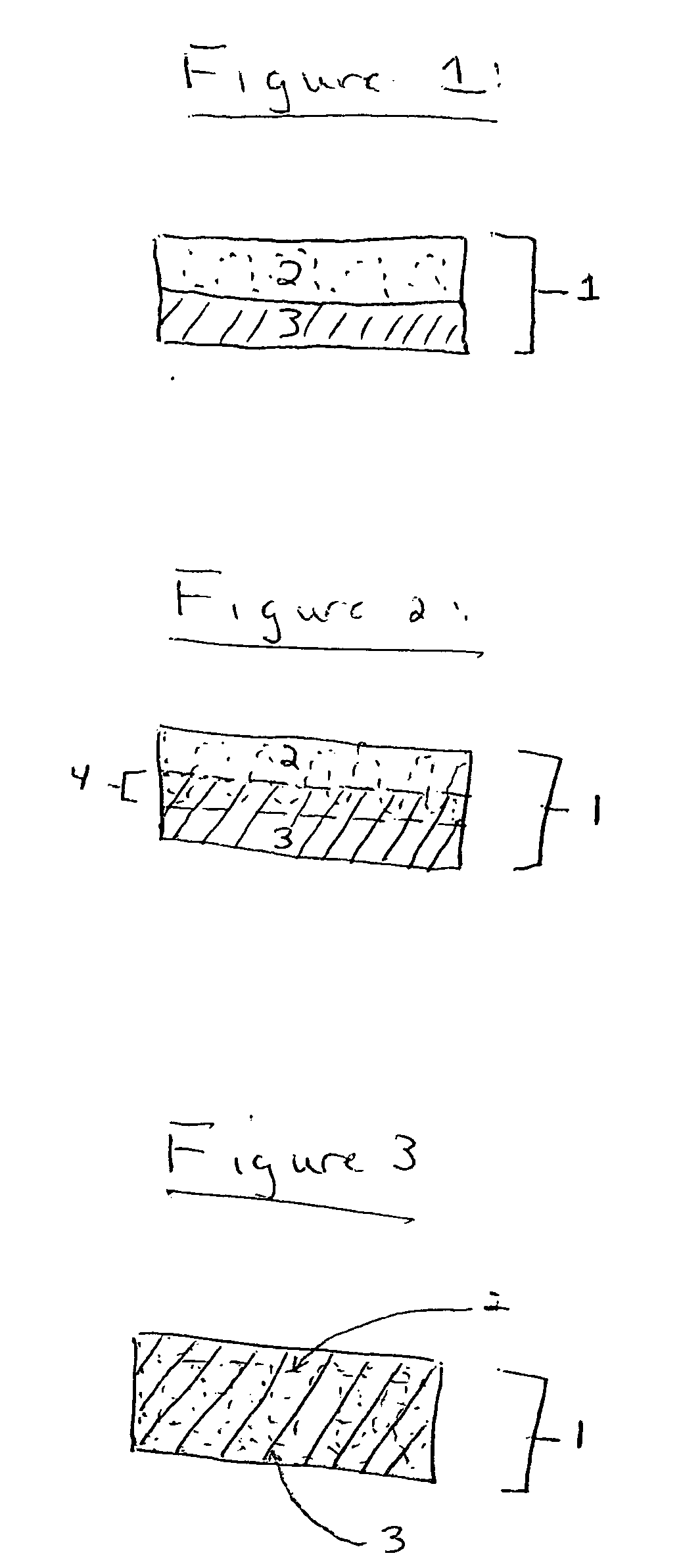

InactiveUS20080081870A1High impact strengthOvercome disadvantagesLiquid surface applicatorsCoatingsStructural unitPolymer chemistry

The invention relates to polyurethane-polyurea dispersions comprising structural units of formula (I) in which R1 is an aliphatic or cycloaliphatic radical having 2 to 18 C atoms and R2 is an aliphatic radical having 3 to 5 C atoms. Preparation of the polyurethane-polyurea dispersion and use as a size composition is also disclosed.

Owner:BAYER MATERIALSCIENCE AG

Wet-laid chopped strand fiber mat for roofing mat

A sizing composition for reinforcement fibers that includes one or more film forming agents, a silane coupling agent package, and at least one lubricant surfactant is provided. Optional components such as rheology modifiers, fillers, biocides, and pH modifiers may also be included. Preferred film forming polymers are amide-based polymers. Additionally, the sizing composition is free of polyvinyl alcohol. The absence of polyvinyl alcohol in the size composition reduces or eliminates the production of precipitates from white water in wet-laid processes. The size composition is applied to reinforcement fibers and formed into chopped strand, wet-laid mats that can be used for a variety of purposes, including roofing products. Chopped strand mats formed from fibers sized with the inventive sizing composition maintains or improves the dry tear and tensile strengths compared to chopped strand mats made from fibers sized with a commercial sizing composition that does not contain polyvinyl alcohol.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

Fibers treated with polymerization compounds and fiber reinforced composites made therefrom

InactiveUS20110045275A1Group 4/14 element organic compoundsMolecular sieve catalystsFiber-reinforced compositePolymer chemistry

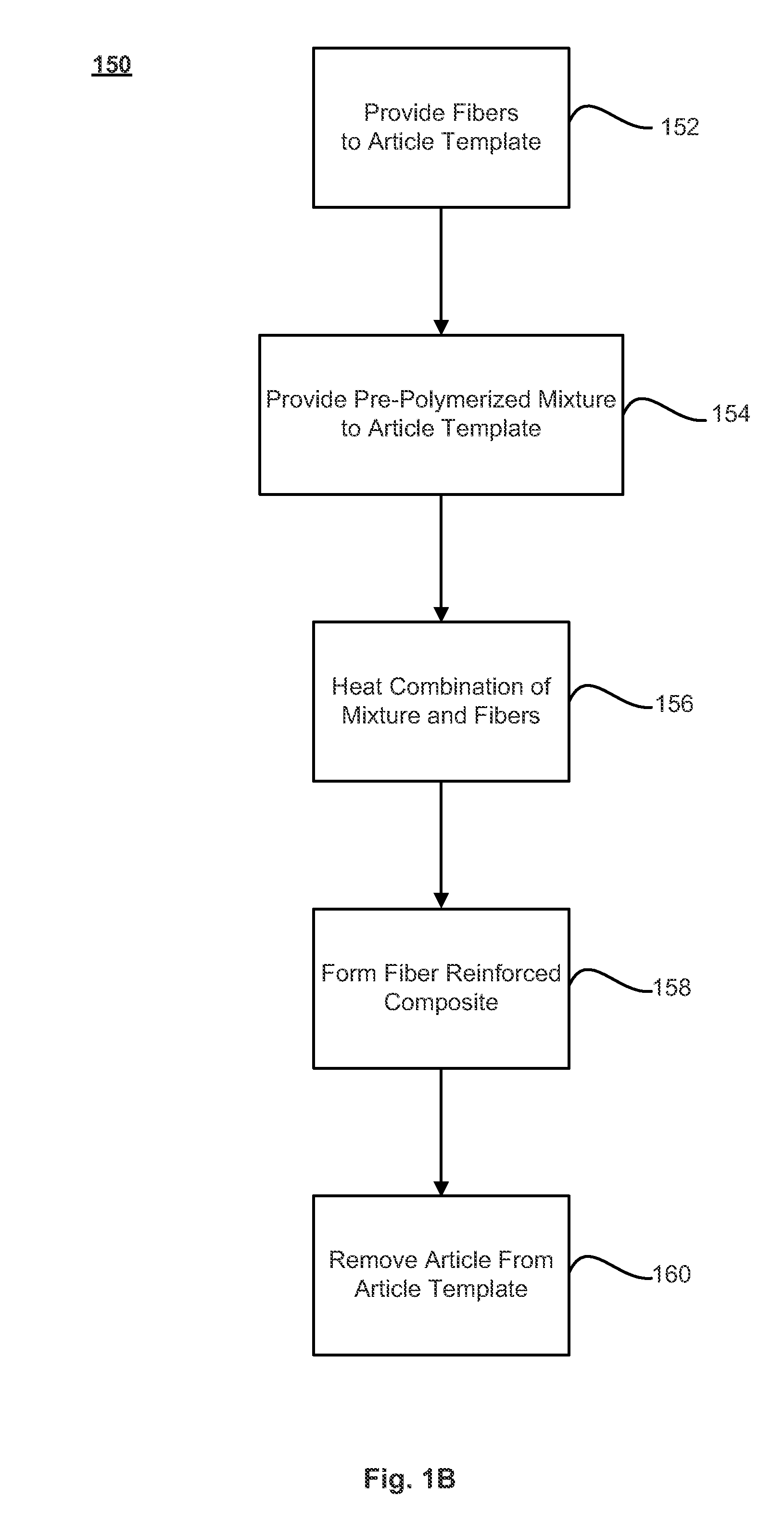

Methods of making fiber reinforced composite articles are described. The methods may include treating fibers with a sizing composition that includes a polymerization compound, and introducing the treated fibers to a pre-polymerized composition. The combination of the treated fibers and pre-polymerized composition may then undergo a temperature adjustment to a polymerization temperature at which the pre-polymerized composition polymerizes into a plastic around the fibers to form the fiber-reinforced composite article. Techniques for introducing the treated fibers to the pre-polymerized composition may include pultrusion, filament winding, reactive injection molding (RIM), structural reactive injection molding (SRIM), resin transfer molding (RTM), vacuum-assisted resin transfer molding (VARTM), long fiber injection (LFI), sheet molding compound (SMC) molding, bulk molding compound (BMC) molding, a spray-up application, and / or a hand lay-up application, among other techniques.

Owner:TADEPALLI RAJAPPA +3

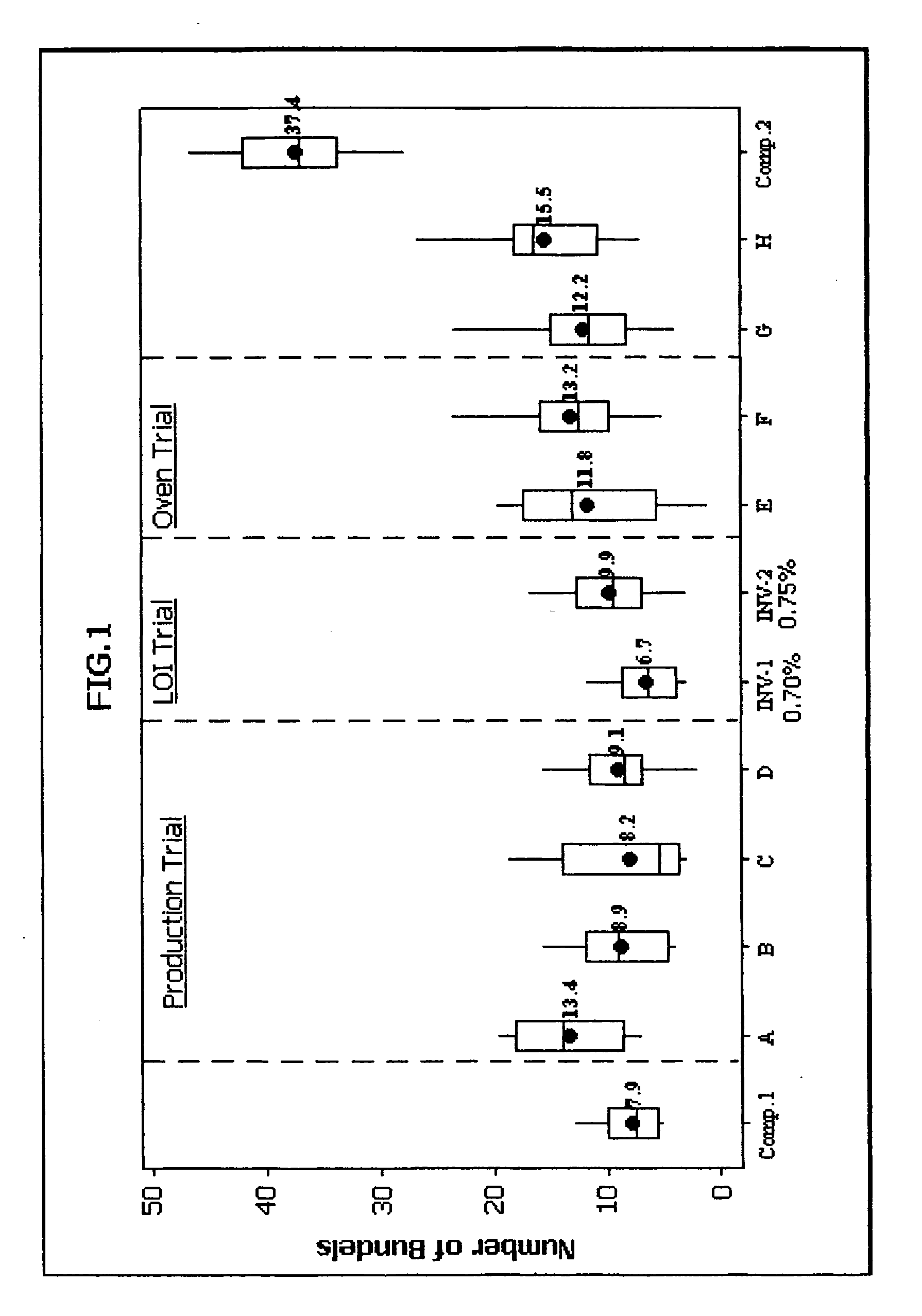

Sizing composition for glass fibers

InactiveUS20080160281A1Improve productivityReduce manufacturing costGlass making apparatusGlass/slag layered productsProduction rateGlass fiber

A sizing composition that permits in-line chopping and drying of reinforcement fibers for reinforcing thermoset resins is provided. The size composition includes at least one coupling agent and one or more blocked polyurethane film forming agents. The blocking agent preferably de-blocks at a temperature that permits simultaneous or nearly simultaneous de-blocking and curing of the polyurethane film former. The sized fiber strands may be chopped to form chopped strand segments and dried in a fluidized bed oven, such as a Cratec® drying oven, in-line. The chopped fiber strands may then be used in a bulk molding compound and molded into a reinforced composite article. Chopping the glass fibers in-line lowers the manufacturing costs for products produced from the sized fiber bundles. Further, because the reinforcement fibers can be chopped and dried at a much faster rate with the inventive size composition compared to conventional off-line chopping processes, productivity is increased.

Owner:OCV INTELLECTUAL CAPITAL LLC

Use of alkenyl succinic anhydride compounds derived from symmetrical olefins in internal sizing for paper production

A method of sizing paper for use in applications which require resistance to liquids comprising incorporating in the paper a size composition comprising one or more alkenyl succinic anhydride (ASA) compounds prepared from the reaction of maleic anhydride and one or more substantially symmetrical C20-C28 internal olefins.

Owner:ECOLAB USA INC

Sizing compositions for fibers utilizing low VOC silanes

A low VOC sizing composition includes a liquid carrier containing a silane which, upon hydrolysis, produces substantially no significant amount of volatile organic compound and / or the silicon-containing hydrolyzate of the silane. The sizing composition can optionally include one or more of film forming agents, anti-static agents, lubricants, surfactants, emulsifying agents, wetting agents, peroxide, starch, oil, plasticizer, wax, acids or bases.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Sized reinforcements, and materials reinforced with such reinforcements

InactiveUS6846855B2Enhanced short-termEnhanced long-term composite strengthPlastic/resin/waxes insulatorsFibre treatmentSize compositionEmulsion

A sizing composition and method for manufacturing such, which is suitable for use in manufacturing fiber-reinforced composites which have desirable properties such as high strength, high resistance to water and chemical degradation, and improved coloring. This is achieved in part by good adhesion of the sizing composition to the reinforcing fibers and the polymer matrix. The sizing composition includes an emulsion having a grafted polyolefin, two or more saturated fatty acids, and one or more silane coupling agents. When reinforcing fiber materials sized according to the invention are used in a molding process, the resulting composites are observed to show minimal discoloration.

Owner:OCV INTELLECTUAL CAPITAL LLC

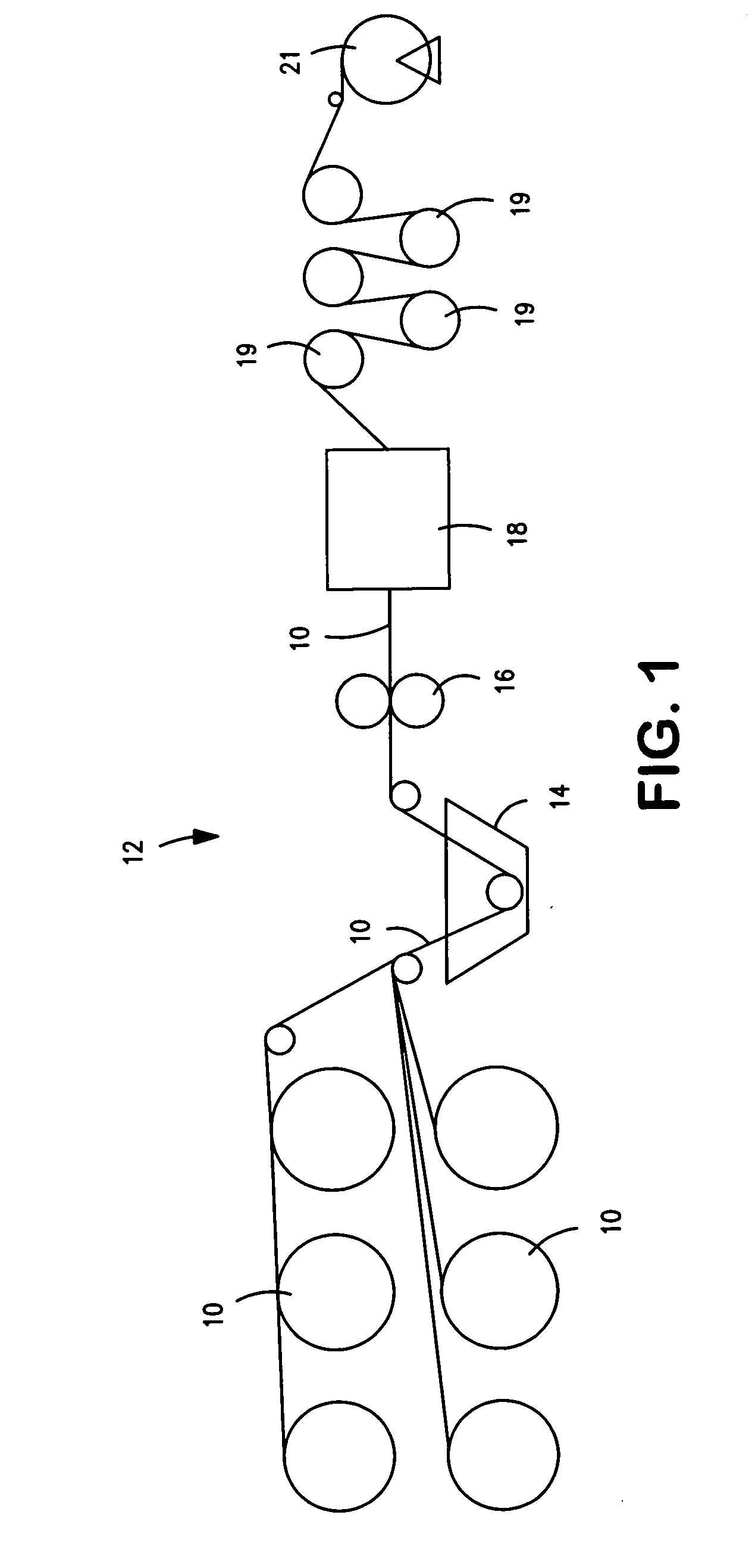

Papers for liquid electrophotographic printing and method for making same

InactiveUS7828935B2Low viscosityImprove performanceNatural cellulose pulp/paperSpecial paperCellulose fiberCalipers

The specification discloses papers suitable for liquid electrophotographic printing (“LEP”) and a method for making such papers. According to the method, a papermaking furnish containing cellulosic fibers is formed into a fibrous web on a papermaking machine and at least partially dried. The web is then treated with a sizing composition comprising starch, an acrylic acid polymer, an organic material having an HLB value of from about 2 to about 14 such as a polyglycerol ester, and water. The treated web is dried and calendered to a final desired caliper. Since the sizing composition is an aqueous mixture, it may be applied to the web on-line during production of the paper on the papermaking machine, thereby avoiding the expense and inconvenience of conventional off-line methods used to make existing LEP papers. The resulting paper exhibits at least 80% and preferably above 90% toner adhesion as measured by the tape pull tests used for the assessment of papers printed by LEP.

Owner:GLOBAL HLDG II INC

Reverse/direct flotation technology of collophanite

The invention discloses a reverse / direct flotation technology of collophanite. The technology comprises the following steps of: performing ore reduction, ore grinding and size mixing on the silicon calcium type collophanite; adding a carbonate gangue mineral flotation regulator and fatty-acid soap respectively to perform size mixing; performing reverse flotation on the material after the size mixing, wherein the product in the tank is reverse flotation concentrate; dehydrating the reverse flotation concentrate and adding sodium carbonate so as to adjust the pH value to 8-10; performing closed-loop ore grinding and grading on the base flow; enabling the grading overflow to enter a direct flotation stirring tank, and adding water glass and fatty acid soap into the tank respectively to perform size mixing; performing direct flotation on the material subjected to the size mixing, wherein the direct flotation foam product is direct flotation concentrate; and performing concentration, filtration and drying to obtain the finished product of phosphate concentrate. After dehydration (reagent removal), the technology disclosed by the invention can be used for remarkably reducing the amount of sodium carbonate for neutralizing acid water; the sodium carbonate has a dispersion and grinding aid function, and the over-grinding of the material of direct flotation can be reduced; and the fresh surface and proper size composition generated by the ore grinding are favorable for improving the sorted behavior of the direct flotation and improving the sorting efficiency.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

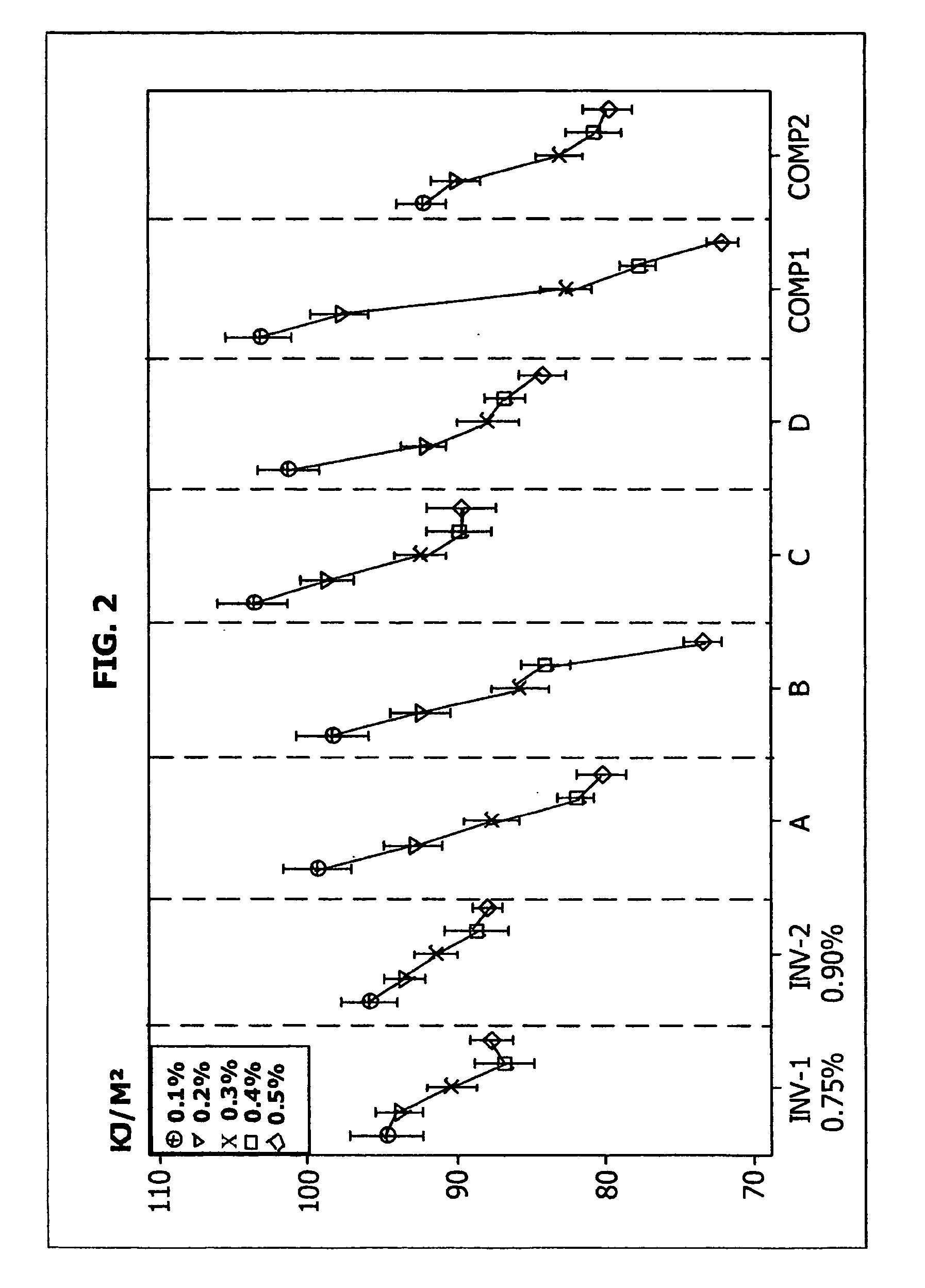

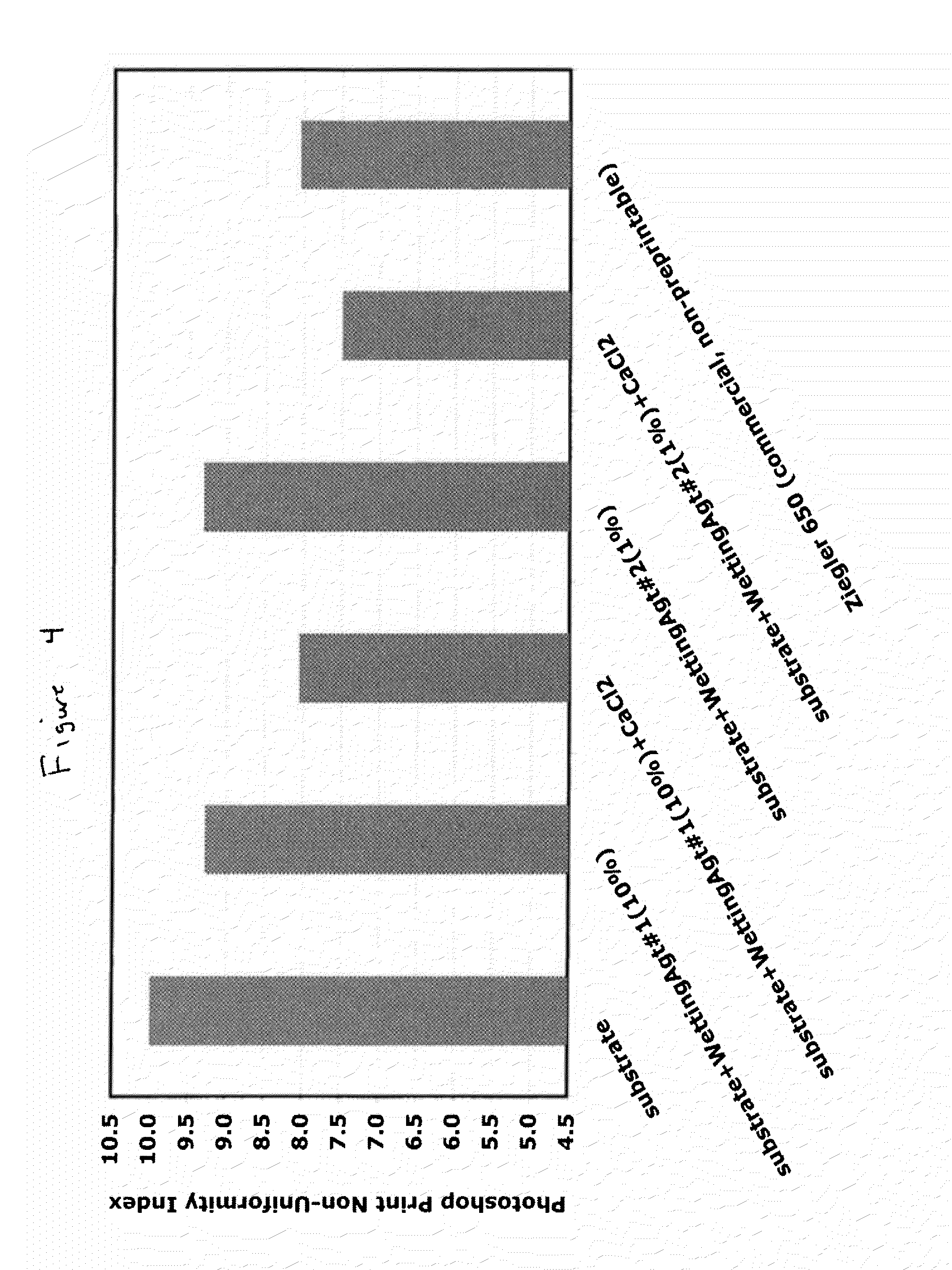

Paper substrate having enhanced print density

ActiveUS20070125267A1Natural cellulose pulp/paperSpecial paperVolumetric Mass DensityPulp and paper industry

The present invention relates to a sizing composition that, when applied to paper substrate, creates a substrate, preferably suitable for inkjet printing, having increased print density, print sharpness, low HST, and / or image dry time, the substrate preferably having high brightness and reduced color-to-color bleed as well. In addition, the present invention relates to a method of reducing the HST of a paper substrate by applying the sizing composition to at least one surface thereof. Further, the application relates to methods of making and using the sizing composition, as well as methods of making and using the paper containing the sizing composition.

Owner:GLOBAL HLDG II INC

Sizing compositions and glass fiber reinforced thermoplastic composites

InactiveUS20080241533A1Group 4/14 element organic compoundsNon-fibrous pulp additionGlass fiberCarboxylic acid

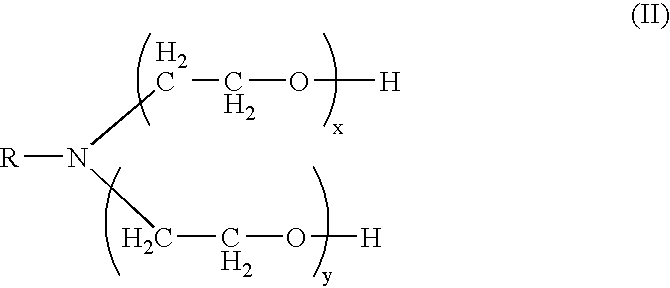

The present invention relates to sizing compositions, glass fibers at least partially coated with sizing compositions, and glass fiber reinforced composite materials. In one embodiment, a sizing composition comprises at least one maleic anhydride copolymer, at least one coupling agent, and a reaction product of an alkoxylated amine and a polycarboxylic acid, which is further reacted with an epoxy compound.

Owner:PPG IND OHIO INC

Water jet woven air bag fabric made from sized yarns

InactiveUS20070184733A1Improve various propertyHigh tear strengthEnvelopes/bags making machineryLayered productsEngineeringWeft yarn

An air bag material and a process for making the material are disclosed. The air bag material is formed from a water jet woven fabric containing warp yarns and weft yarns. In accordance with the present disclosure, the warp yarns are treated with a size composition prior to being woven into the fabric. The size composition improves the runnability of the yarns. Of particular advantage, the size composition does not need to be removed after the fabric is produced. In fact, leaving the size composition on the fabric has been found to significantly increase the tear strength of the fabric.

Owner:SAFETY COMPONENTS FABRIC TECH

Sizing composition and glass fiber reinforced thermoplastic resin

InactiveUS20050136237A1High strengthFibre treatmentSynthetic resin layered productsGlass fiberPolyamide

The present invention is directed to sizing compositions for glass fibers and glass fiber reinforced thermoplastic resins. The sizing composition comprises a maleic anhydride copolymer. Thermoplastic polyamide resin articles reinforced with glass fibers at least partially coated with a residue of the sizing composition can demonstrate a surprising improvement in strength of the reinforced polyamide resin when lubricated with a fatty acid metal salt and in the hydrolysis resistance when exposed to boiling water / ethylene glycol medium.

Owner:PPG IND OHIO INC

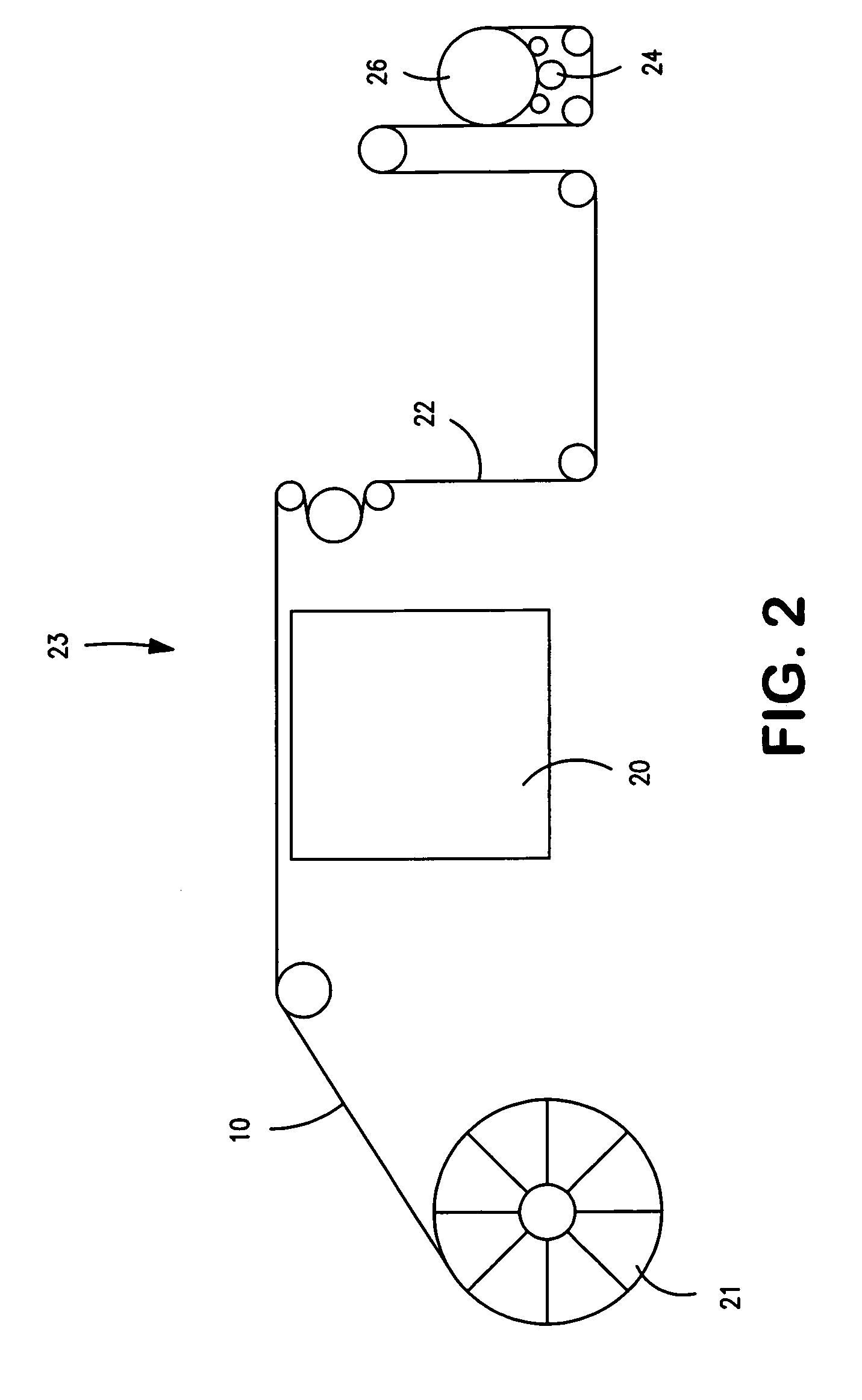

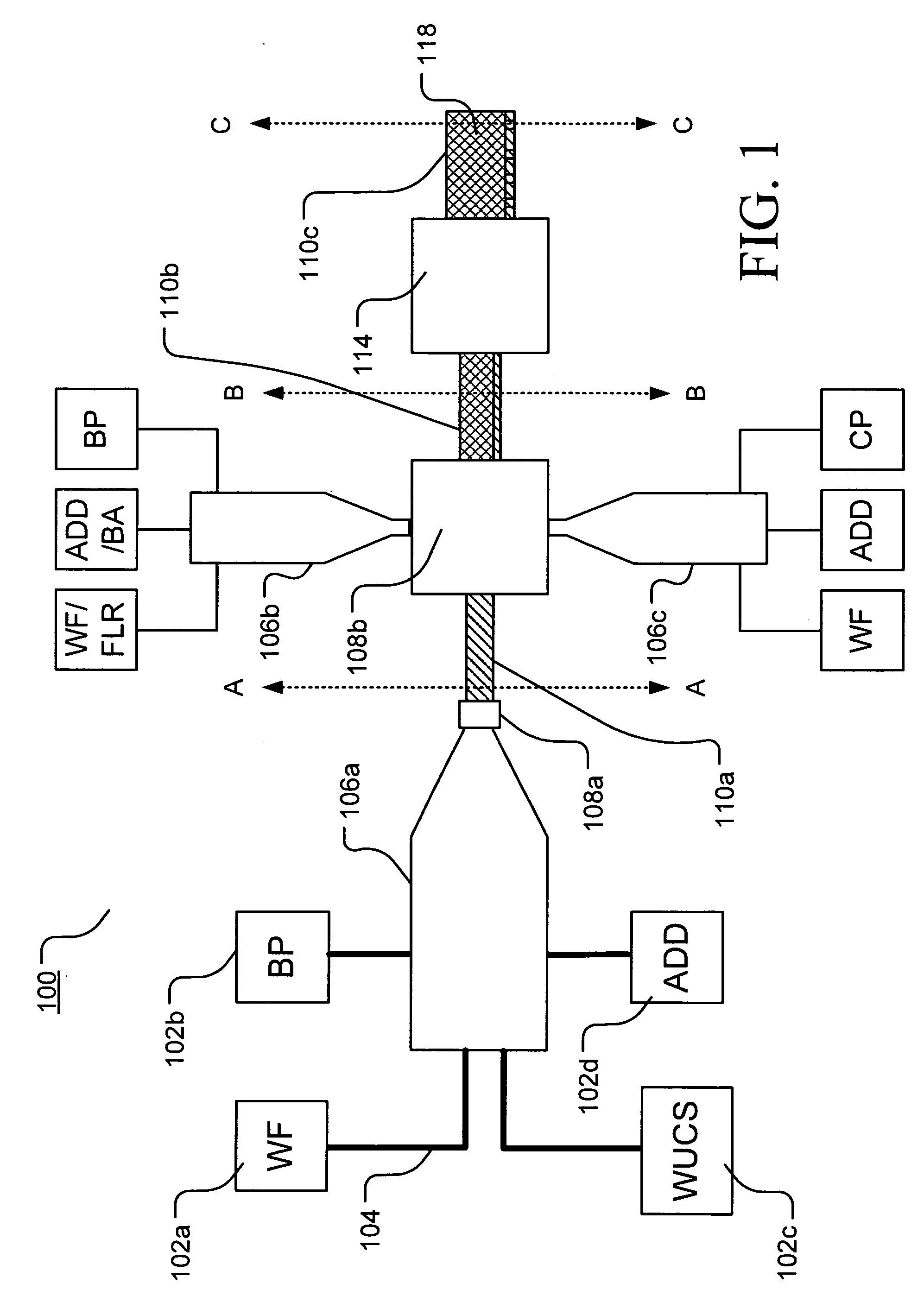

Tri-excluded WUCS glass fiber reinforced plastic composite articles and methods for making such articles

InactiveUS20070148429A1Improve performanceSimple interfaceNon-woven fabricsCoatingsGlass fiberPolymer science

Disclosed are a series of composite polymer composite structures formed by the coextrusion of at least two distinct polymeric components. A first polymeric component includes a structural composition and a second polymeric component includes a coating composition. The primary structural frame formed from the structural composition includes at least one longitudinal recess. These recesses may be filled with a third polymeric composition that may include wood byproducts and / or a blowing agent. The first polymeric component may include reinforcing fibers at least partially coated with a size composition that includes a film forming agent, a lubricant, one or more additives, and first and second coupling agents. The additives may be chosen to achieve selective or desired properties in the end product. The inclusion of additives to the reinforcing fiber enhances the fiber reinforcements and enables the production of reinforced composite articles having a desired combination of size, strength, appearance, and / or functionality.

Owner:OCV INTELLECTUAL CAPITAL LLC

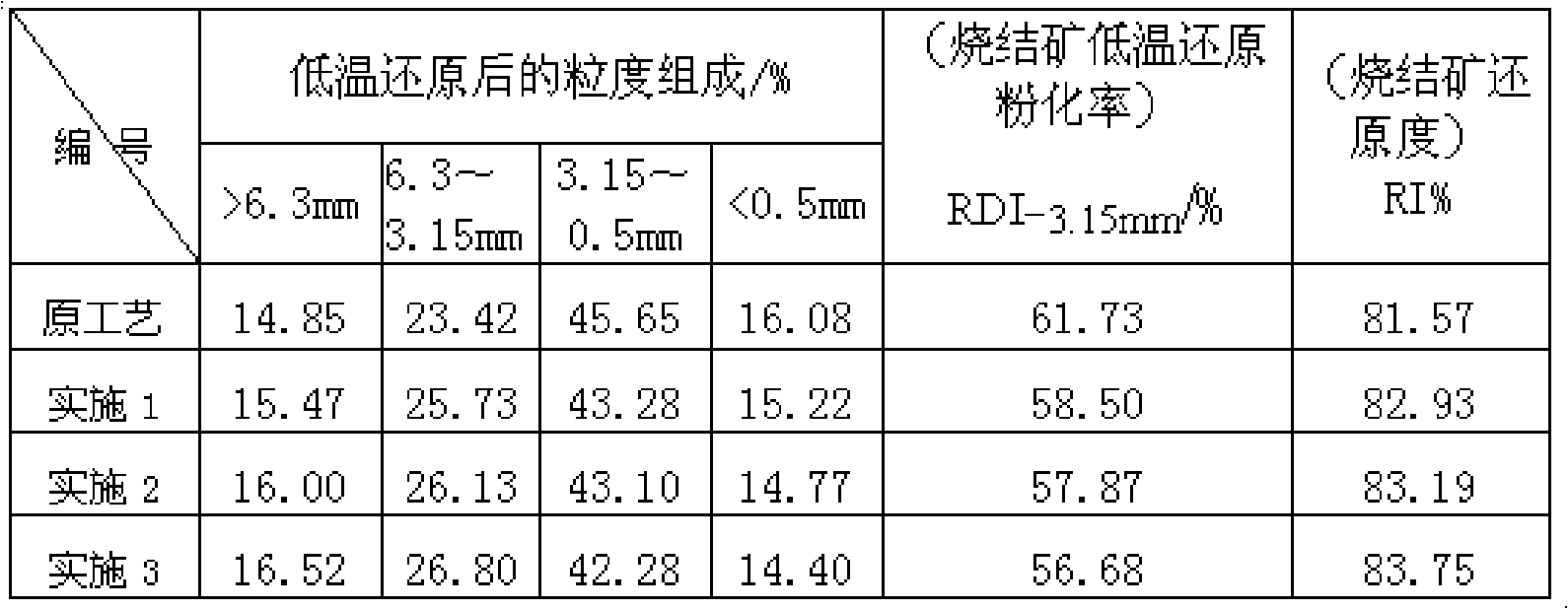

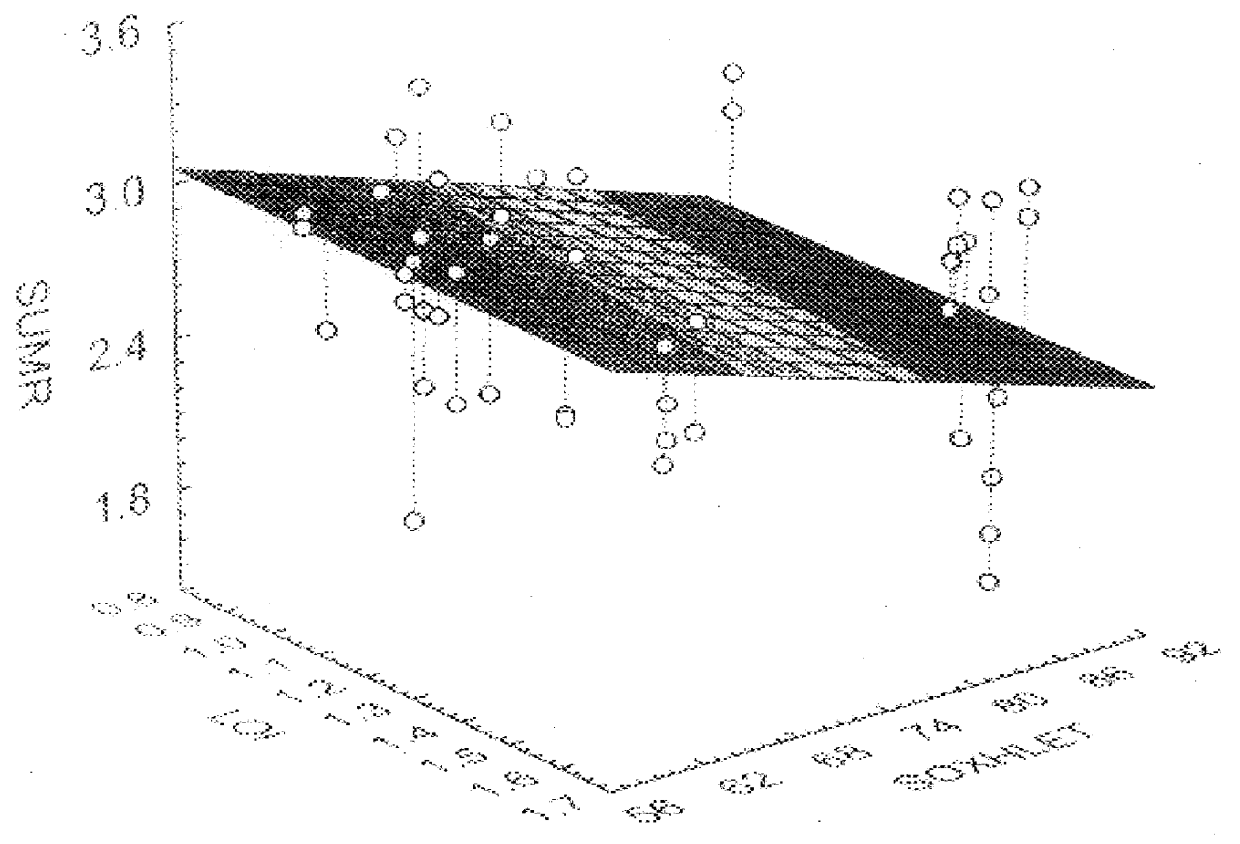

Pelletisation process for iron ore concentrate sintered mix

The invention relates to a granulating method of iron ore concentrate sintering mixture, and belongs to the metallurgical field. The method solves the technical problem that the granulating method of the iron ore concentrate sintering mixture is provided, wherein, the granulating method can increase the quality of sintering minerals. The granulating method of the iron ore concentrate sintering mixture adopts a secondary granulating method for granulating. The granulating method of the iron ore concentrate sintering mixture improves the grain-size composition and the granulation property of the sintering mixture, and increases the ventilation property and the sintering speed of a sinter bed, thereby increasing the sinter output; the granulation of the iron ore concentrate is strengthened, the intensity of the granulating pellets is increased, and the increase of the sinter strength is facilitated; partial high basicity of the iron ore concentrate is formed during the pre-granulating produces, the generation of partial calcium ferrite is promoted, the total content of the calcium ferrite and silicate, the mineral compositions and structure of sintering ore is facilitated to be improved, and the intensity and the finished product rate of the sintering ore are increased; the metallurgical property of the sintering ore is improved, the technical and economic index of blast furnace smelting is increased, and the wide application prospect is realized.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

High solubility size composition for fibers

InactiveUS6025073AImprove featuresIncreases filler loadingLayered productsPretreated surfacesPolyesterFiber

A high solubility size composition is provided which may be applied to glass fibers useful for reinforcing polymeric materials. The size composition includes: a first film former comprising a polyether-based or polyester-based thermoplastic polyurethane derived from a saturated, non-crosslinkable polyether or polyester; a second film former comprising at least one ingredient selected from i) a vinyl acetate glycidyl methacrylate copolymer and ii) a mixture of a vinyl acetate glycidyl methacrylate copolymer and a vinyl acetate homopolymer; a silane coupling agent; and water. Using glass fibers coated with the high solubility size composition allows the advantageous production of low-pigmented or non-pigmented molded parts having enhanced surface appearance and color uniformity.

Owner:OCV INTELLECTUAL CAPITAL LLC +1

Environmentally-friendly size composition for tyre surface of tyre and preparation method thereof

ActiveCN102408589AEnsure safetyHigh viscositySpecial tyresRolling resistance optimizationHazardous substanceStearic acid

The invention discloses an environmentally-friendly size composition for a tyre surface of a tyre and a preparation method thereof. The environmentally-friendly size composition comprises natural rubber, butadiene styrene rubber, butadiene rubber, carbon black, zinc oxide, stearic acid, an antiager, C5 resin, insoluble sulfur, environmentally-friendly arene oil, an accelerator and a homogenizing agent and various other components. The environmentally-friendly size can be prepared by the steps of plastifying and mixing the raw materials and the like. The environmentally-friendly size composition for the tyre surface of a tyre and size obtained by using the preparation method have better breaking strength, tensile strength and hardness, meet environmentally-friendly requirement and are prepared from environmentally-friendly raw materials which do not contain harmful substances, wherein arene oil, C5 resin, insoluble sulfur, carbon black and the like belong to the environmentally-friendly materials; and through adopting the environmentally-friendly raw materials coordinated with reasonable composition design, the environment pollution hidden danger caused in the production and use processes is greatly reduced, and the product has wider safety, economy and adaptability.

Owner:SICHUAN YUANXING RUBBER

Sizing composition and glass fiber reinforced thermoplastic resin

The present invention is directed to sizing compositions for glass fibers and glass fiber reinforced thermoplastic resins. The sizing composition comprises a maleic anhydride copolymer. Thermoplastic polyamide resin articles reinforced with glass fibers at least partially coated with a residue of the sizing composition can demonstrate a surprising improvement in strength of the reinforced polyamide resin when lubricated with a fatty acid metal salt and in the hydrolysis resistance when exposed to boiling water / ethylene glycol medium.

Owner:PPG IND OHIO INC

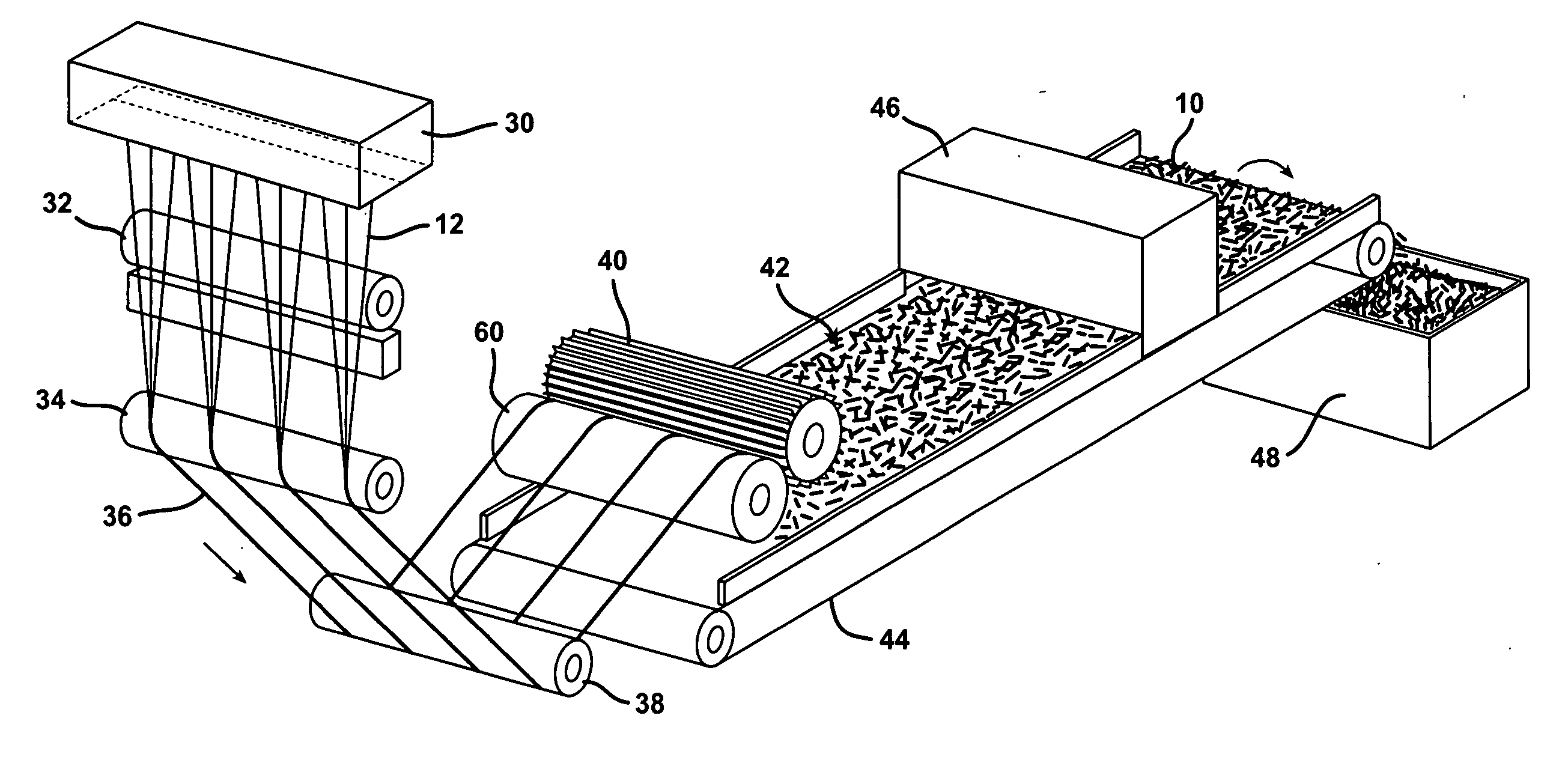

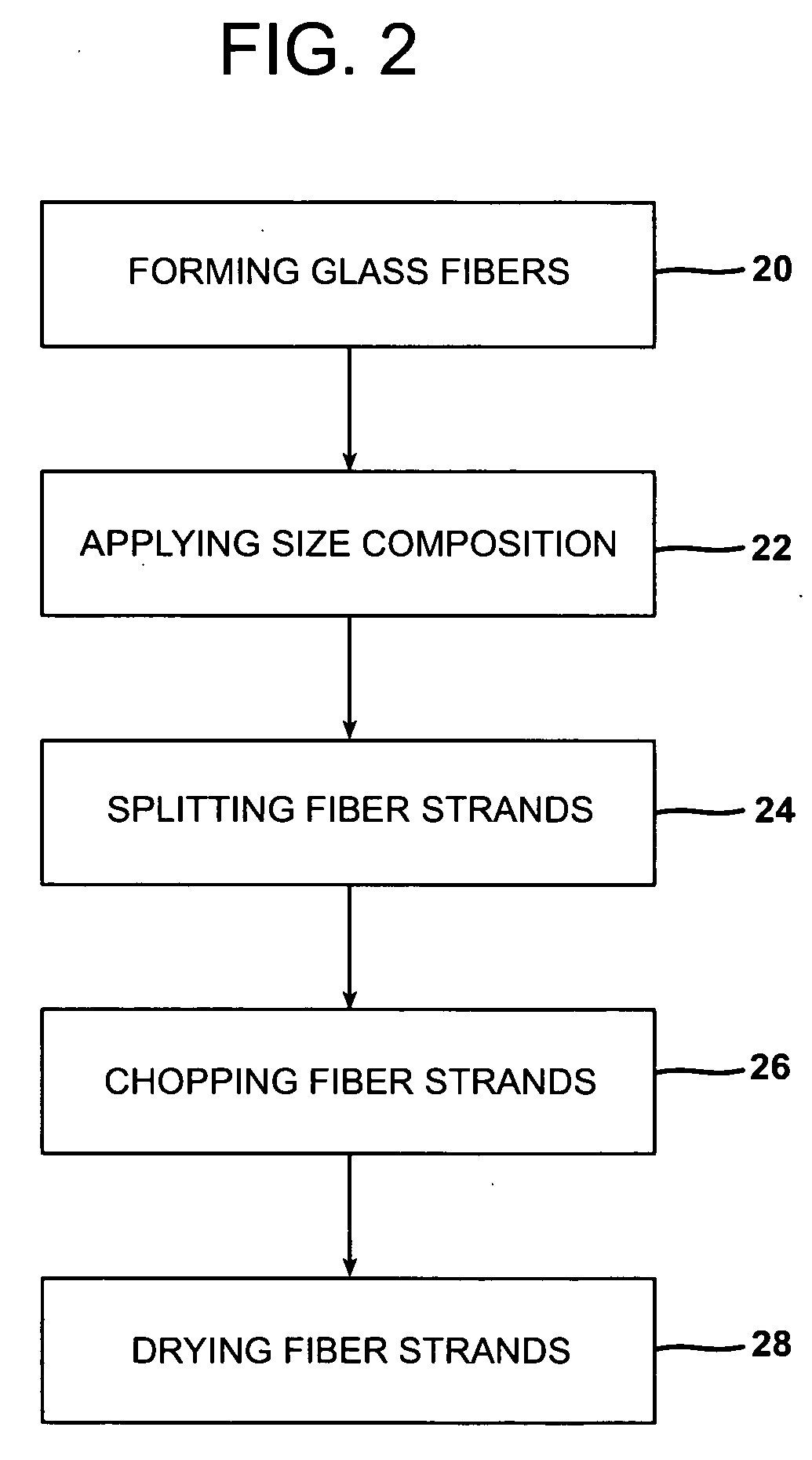

Compression and injection molding applications utilizing glass fiber bundles

InactiveUS20070057404A1High speedImprove throughputDrying solid materials with heatWood working apparatusFiberGlass fiber

Dried bundles of chopped glass fibers that may be used in compression and injection molding applications is provided. The chopped glass fiber bundles are formed of individual glass fibers positioned in a substantial parallel orientation. The dried chopped glass fiber bundles may be prepared by applying a size composition to attenuated glass fibers, splitting the fibers to obtain a desired bundle tex, chopping the wet glass bundles to a discrete length, and drying the wet glass bundles in a dielectric oven. Alternatively, the dried chopped glass bundles may be prepared by sizing attenuated glass fibers, passing the sized fibers through a heat transfer chamber where air heated by a bushing is drawn into the heat transfer chamber to dry the glass fiber bundles, splitting the dried, sized glass fiber bundles to obtain a desired bundle tex, and chopping the dried bundles of glass fibers.

Owner:OCV INTELLECTUAL CAPITAL LLC

Two-part sizing composition for reinforcement fibers

InactiveUS20070072989A1Reduce subsequent chemical corrosionReduce interfilament abrasionSynthetic resin layered productsSpecial tyresFiberFilm-forming agent

A two-part sizing formulation that imparts improved strength of reinforced composites including a size composition and a binder composition is provided. The size composition may include one or more coupling agents and one or more film forming agents. The binder composition includes a blocked isocyanate and a copolymer formed of a maleic anhydride and at least one other monomer copolymerizable therewith. In a preferred embodiment, the binder composition includes an ethylene-maleic acid copolymer formed by the hydrolysis of an ethylene-maleic anhydride copolymer. In an alternate embodiment, the size composition includes a coupling agent, a lubricant, and a wetting agent. The size composition may be applied to a reinforcing fiber material before the binder size material is applied. The two-part size composition may be applied to a reinforcing fiber which may then be densified or compacted to form a densified reinforcing fiber product, such as a pellet.

Owner:OWENS CORNING FIBERGLAS TECH II

Sandrock oil field all-rock mineral simulated rock core production method

InactiveCN101122549AWith characteristicsEasy to preparePreparing sample for investigationThroatCelsius Degree

The invention relates to a manufacturing method of a sandstone oilfield whole rock mineral simulated core. The manufacturing method is as follows. Firstly, required mineral raw materials are weighted quantitatively according to the component content, the size composition and the physical parameters of the sandstone oilfield blocks, and the is evenly mixed and sieved. Then, prepared cementing agent and the well mixed mineral raw materials are proportionally prepared, and are fully well mixed and sieved. Under the conditions of 6MPa-22MPa manufacturing pressure and 5min-10min manufacturing time, the solid-liquid mixture after sieving is made into simulated core through a fixing die forming method. The simulated core is dried under the temperature-changing with time-fixing conditions. The drying temperature with consumed time is from 40 degrees Celsius with 8 hours, 80 degrees Celsius with 16 hours, 120 degrees Celsius with 8 hours, 160 degrees Celsius with 16 hours to 200 degrees Celsius with 8 hours. The method is simple, safe and easy to be operated. The manufactured simulated core is equipped with not only the pore throat characteristics and seepage properties of a natural core, but also the sensitive properties of the natural core.

Owner:DAQING OILFIELD CO LTD

Paper surface sizing composition, sized paper, and method for sizing paper

InactiveUS20080173420A1Natural cellulose pulp/paperStarch dervative coatingsPulp and paper industryDrying time

Embodiments of the present invention provide a paper surface sizing composition, a paper web coated on one or more sides or surfaces with a paper surface sizing composition, and a method for treating one or more sides of the paper web with a paper surface sizing composition to impart benefits relating to one or more of the following properties: (1) brightness; (2) opacity; (3) paper smoothness; (4) print quality; (5) optionally ink dry time (e.g., for ink jet printing where the sizing composition has option); and (6) optionally minimizing or eliminating edge welding (e.g., for paper webs used in, for example, form printing).

Owner:INT PAPER CO

Paper substrate containing a wetting agent and having improved printability

The present invention relates to a sizing composition that, when applied to paper substrate, creates a substrate, preferably suitable for inkjet printing, having increased print density, and print mottle, as well as print sharpness, low HST, and / or image dry time, the substrate preferably having high brightness and reduced color-to-color bleed as well. In addition, the present invention relates to a method of reducing the HST of a paper substrate by applying the sizing composition to at least one surface thereof. Further, the application relates to methods of making and using the sizing composition, as well as methods of making and using the paper containing the sizing composition.

Owner:GLOBAL HLDG II INC

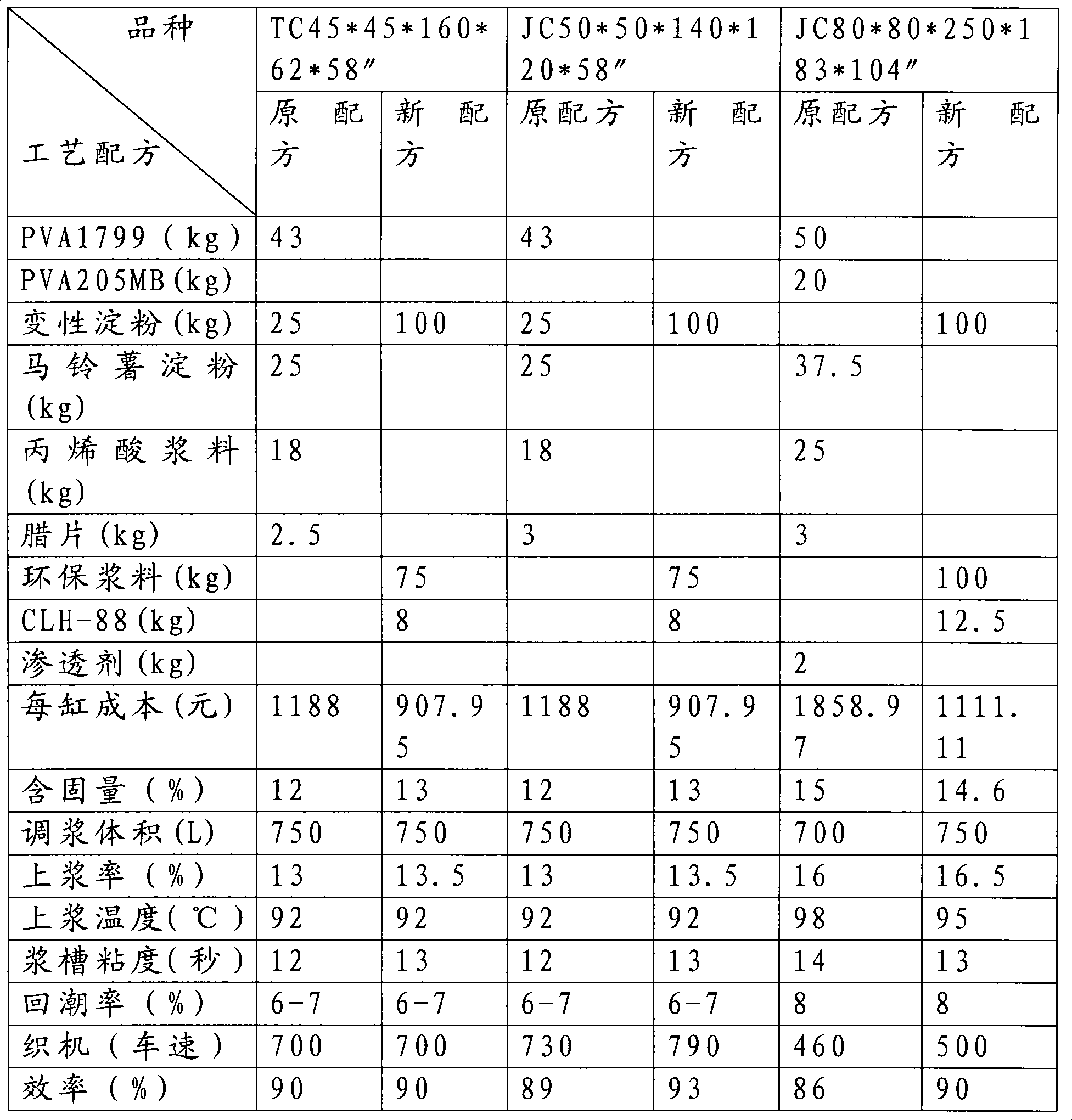

Textile slurry composition replacing for polyvinyl alcohol and preparing method thereof

The invention provides an environment-friendly textile size composition which has simple process and convenient use, and substitutes for polyvinyl alcohol, and a preparation method thereof, which aim at the current status that the sizing of the prior textile fiber warp can not be independent from PVA size and the disadvantages of the prior size. The size composition is prepared by mixing an ultrafine particle inorganic material which accounts for 1 to 10 percent of the total weight, polyacrylic acid size which accounts for 10 to 40 percent of the total weight, and water for the balance. The size composition is matched with modified starch size, can fully substitute for the PVA size during the sizing process of yarns such as pure cotton, polyester cotton, hemp, artificial cotton, and tenel, and meet the manufacturing requirement of high-difficulty varieties.

Owner:青岛常力恒工贸有限公司

Modified fibers for use in the formation of thermoplastic fiber-reinforced composite articles and process

ActiveUS20130040108A1Secure bondingImprove mechanical propertiesMaterial nanotechnologyPretreated surfacesRough surfaceGlass fiber

A surface-modified fibrous material is provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article. Good binding between the fibrous material and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The fibrous material may be provided in continuous or discontinuous form. In a preferred embodiment glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. The surface-roughened fibrous material is incorporated in a thermoplastic matrix as fibrous reinforcement with the application of heat whereby the thermoplastic matrix is rendered melt processable. In preferred embodiments injection or compression molding is utilized. Improved long-fiber thermoplastics also may be formed to advantage.

Owner:JOHNS MANVILLE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com