Pelletisation process for iron ore concentrate sintered mix

A technology for sintering mixtures and iron concentrates, which is applied in the field of metallurgy, can solve the problems of not being able to effectively improve the granulation performance of coarser iron concentrate mixtures, achieve improved particle size composition and granulation performance, promote production, and improve Effects of Strength and Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

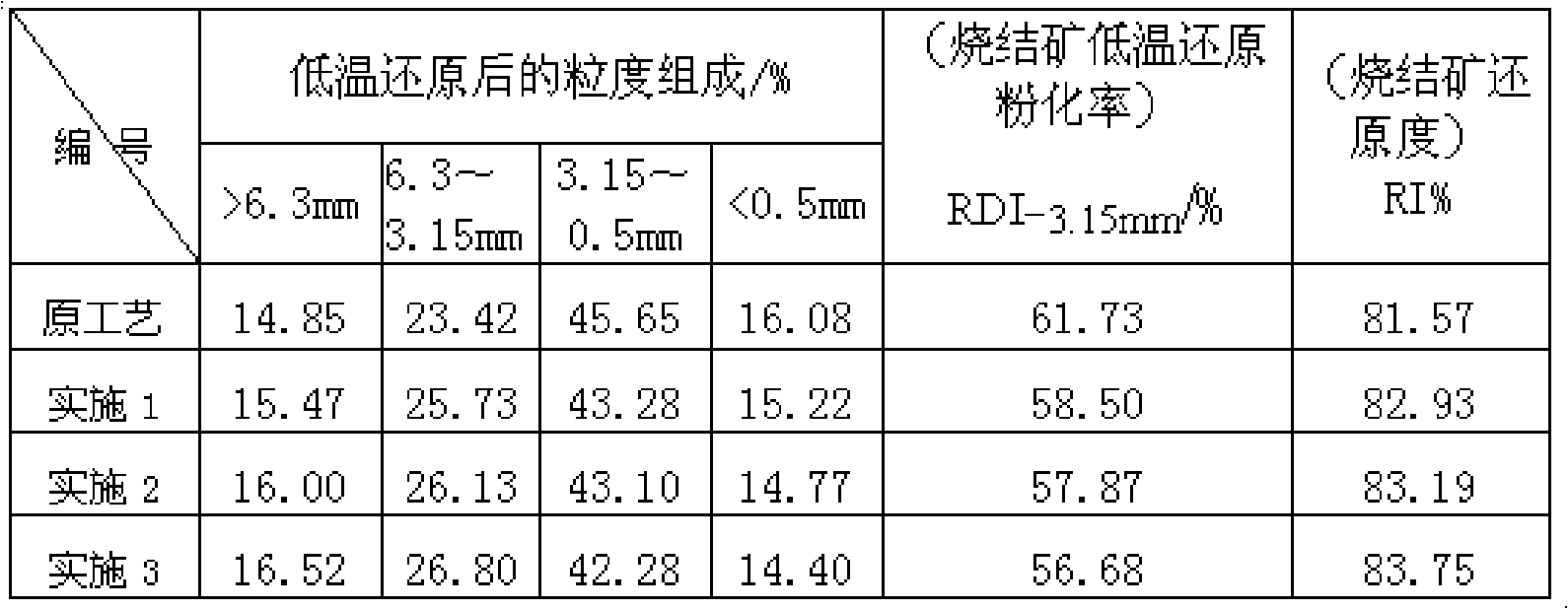

[0020] The amount of iron concentrate for primary granulation is 19.05kg, quicklime 2.55kg; the amount of imported ore powder for secondary granulation is 7.65kg, the amount of mixing powder is 8.9kg, the amount of sieving powder is 4.3kg, the amount of gas ash is 1.7kg, high brown powder The dosage is 3.4kg, the dosage of quicklime is 3.4kg, the dosage of limestone is 6.46kg, the dosage of coke powder is 3.9kg, the dosage of returning ore is 18kg, and the dosage of returning ore is wetted with water in advance. The results show that, compared with the original production process without this obvious method, the content of sintering mixture > 3mm particle size increases by 1.6 percentage points, < 0.5 mm powder decreases by 1.0 percentage points, the average particle size increases by 0.36 mm, and the sintering speed increases by 0.57 mm / min, the strength of the sinter drum increased by 0.26 percentage points, the yield increased by 1.95 percentage points, the output increased...

Embodiment 2

[0022] The amount of iron concentrate for primary granulation is 23.3kg, the amount of quicklime is 3.4kg; the amount of imported ore powder for secondary granulation is 7.0kg, the amount of mixing powder is 9.5kg, the amount of sieving powder is 4.75kg, the amount of gas ash is 1.5kg, and the amount of high brown powder The dosage is 3.6kg, the dosage of quicklime is 2.55kg, the dosage of limestone is 6.83kg, the dosage of coke powder is 4.1kg, the dosage of returning ore is 20kg, and the dosage of returning ore is wetted with water in advance. The results show that, compared with the original production process without this obvious, the sintering mixture > 3mm particle size content increased by 3.6 percentage points, < 0.5mm powder decreased by 1.4 percentage points, the average particle size increased by 0.67mm, and the sintering speed increased by 0.93mm / min, the strength of the sinter drum increased by 0.39 percentage points, the yield increased by 3.52 percentage points,...

Embodiment 3

[0024] The amount of iron concentrate for primary granulation is 27.5kg, quicklime 4.25kg; the amount of imported ore powder for secondary granulation is 7.38kg, the amount of mixing powder is 9.2kg, the amount of sieving powder is 4.6kg, the amount of gas ash is 1.6kg, high brown powder The dosage is 3.5kg, the dosage of quicklime is 1.7kg, the dosage of limestone is 5.2kg, the dosage of coke powder is 4.0kg, the dosage of returning ore is 20kg, and the dosage of returning ore is wetted with water in advance. The results show that, compared with the original production process without this obvious method, the content of the sintered mixture > 3mm particle size increased by 4.75%, the <0.5mm powder decreased by 2.2%, the average particle size increased by 0.83mm, and the sintering speed increased by 1.37mm / min, the strength of the sinter drum increased by 0.82 percentage points, the yield increased by 3.17 percentage points, the output increased by 3.21%, the pulverization rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com