Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

153results about How to "Improved metallurgical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

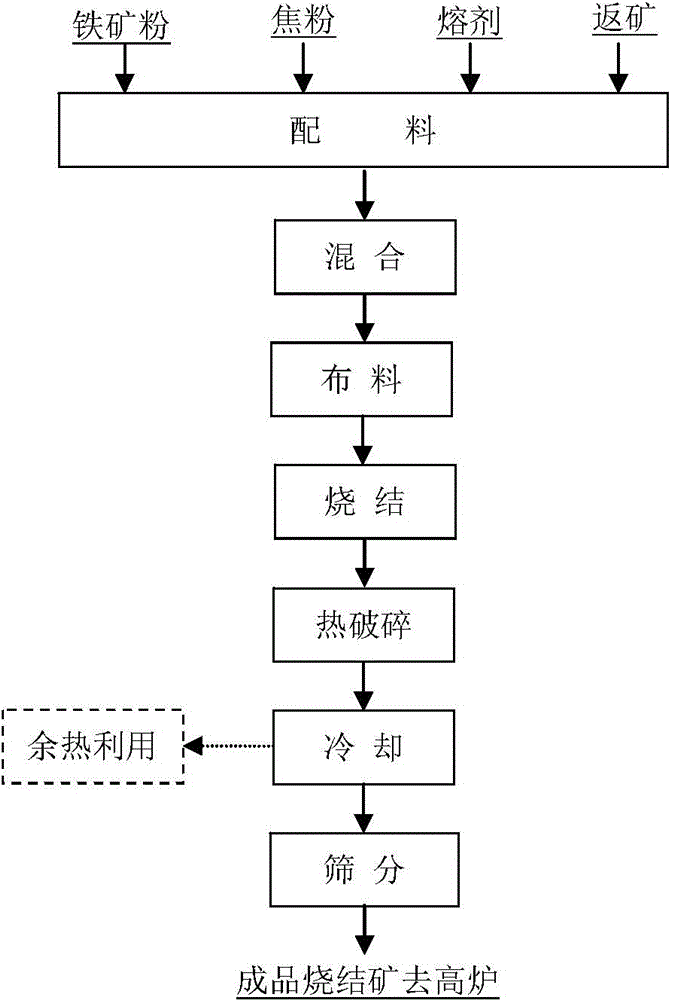

Sintering method for high-chromic vanadium-titanium ferroferrite

The invention discloses a sintering method of high-chromine typed V-Ti-bearing iron ore, which comprises the following steps: 1) allocating limestone and fined ferric ore to make grain; 2) adding water to wet; 3) putting wet and grained materials into sintering material in the mixer to ball; adding B2O3 in the composite material; 4) adding MgO in the composite material; 5) loading the composite material into sintering cup or sintering machine to sinter over 50 deg.c; increasing the content of calcium ferrite in the sintering ore by 5% and production by 4.2-5.0%.

Owner:PANZHIHUA IRON AND STEEL

Compound type binder used for pellet

The invention discloses a compound type binder used for pellet, which comprises the following raw materials in percentage by weight: 70-80% of clay powder, 10-20% of sodium humate, 3-6% of sodium carboxymethyl cellulose and 2-4% of sodium carbonate. The compound type binder used for the pellet of the invention is a pellet binder prepared by combining inorganic substance and organic substance, hasgood hydrophily and high viscosity, can be dissolved into water, replaces bentonite completely, has extremely low carry-in amount of detrimental impurity of the inorganic substance and does not influence the iron grade of the pellet; and when added into iron finemeal pellet for production, the invention does not change the original process and is an ideal and synergistic pellet binder.

Owner:王建忠

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

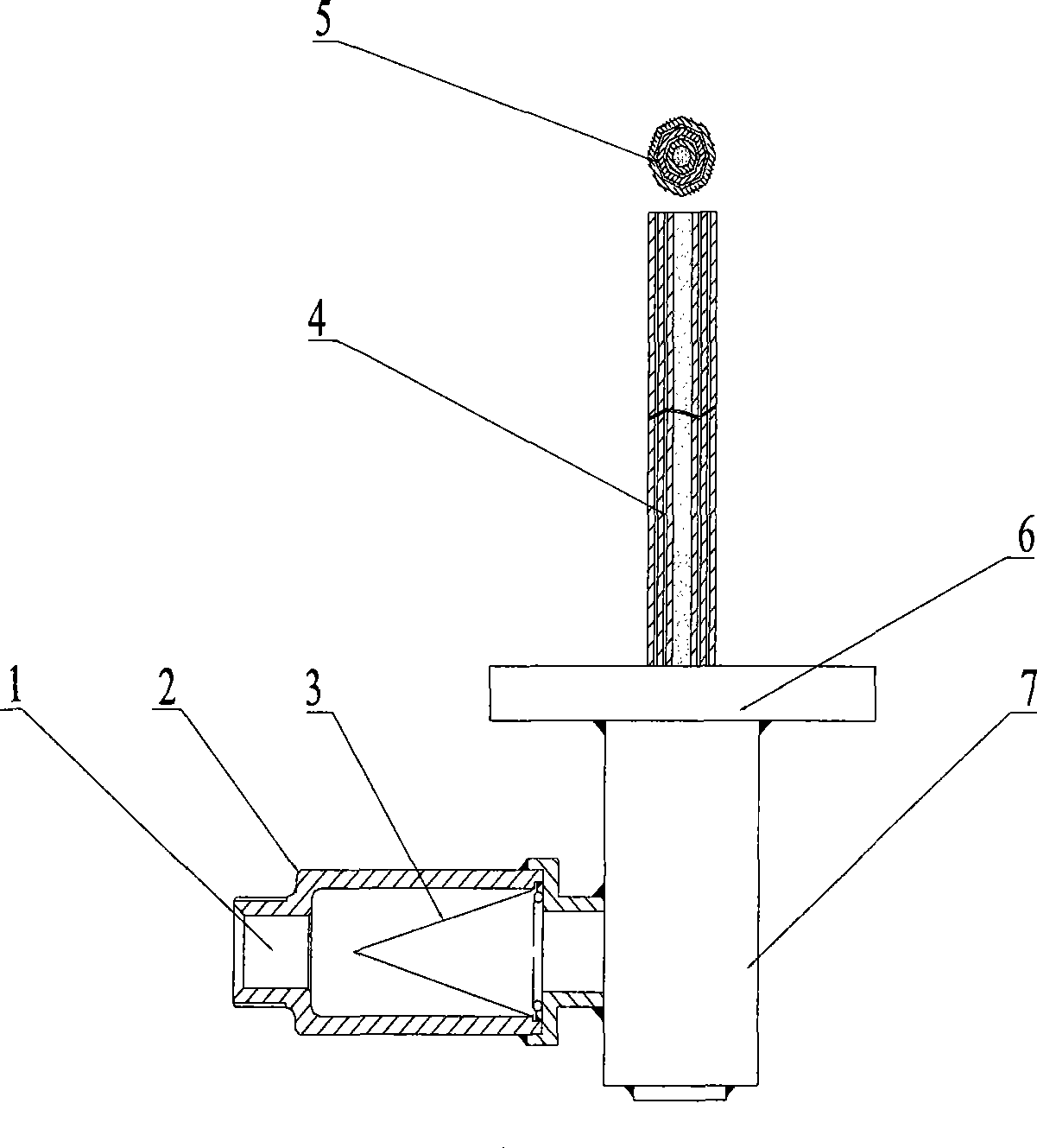

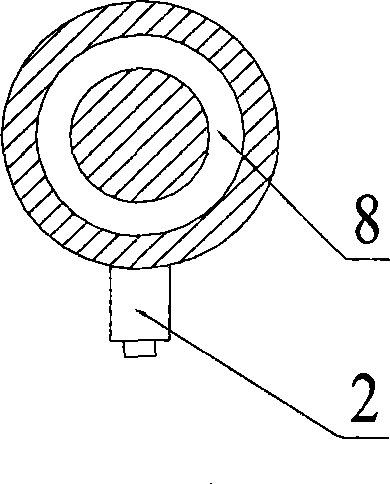

Multifunctional circular seam type gas supply element for steel melting

ActiveCN101487072AImprove furnace lifeSolve the worldwide metallurgical problem of low service lifeManufacturing convertersElectric furnaceWorking lifeAir separation

A steel-making multifunctional circular seam type air supply unit belongs to the steel-making technique field, and comprises a gas ejector pipe, a mounting flange, an air separation chamber and an air inlet chamber, wherein, the gas ejector pipe consists of 2 to 5 layers of pipes which are sheathed concentrically; the pipe in the innermost layer is called a central pipe; the seam width among circular seams among all the layers of the pipes is 0.2 to 3.0mm. A spot or a rib resurface-welded by stainless steel is used for ensuring the precise location of seam width and for preventing molten steel from moistening the interior wall of steel pipes, thus not easy to be jammed by pouring in. The gas ejector pipe is connected with the mounting flange which is connected with the air separation chamber used for distributing the air coming from the air inlet chamber to enter each circular seam of the gas ejector pipes to be sprayed out; and the air separation chamber is connected with the air inlet chamber. The steel-making multifunctional circular seam type air supply unit has the advantages of raising the furnace campaign to over 10000 with maximum over 30000 from 2000; and the complex blowing rate is 100 percent. The bottom blowing air supply unit is not replaced in the whole furnace campaign period, thus solving the problem of short working life of the combined blown converter, which is also a worldwide problem in metallurgy.

Owner:CENT IRON & STEEL RES INST

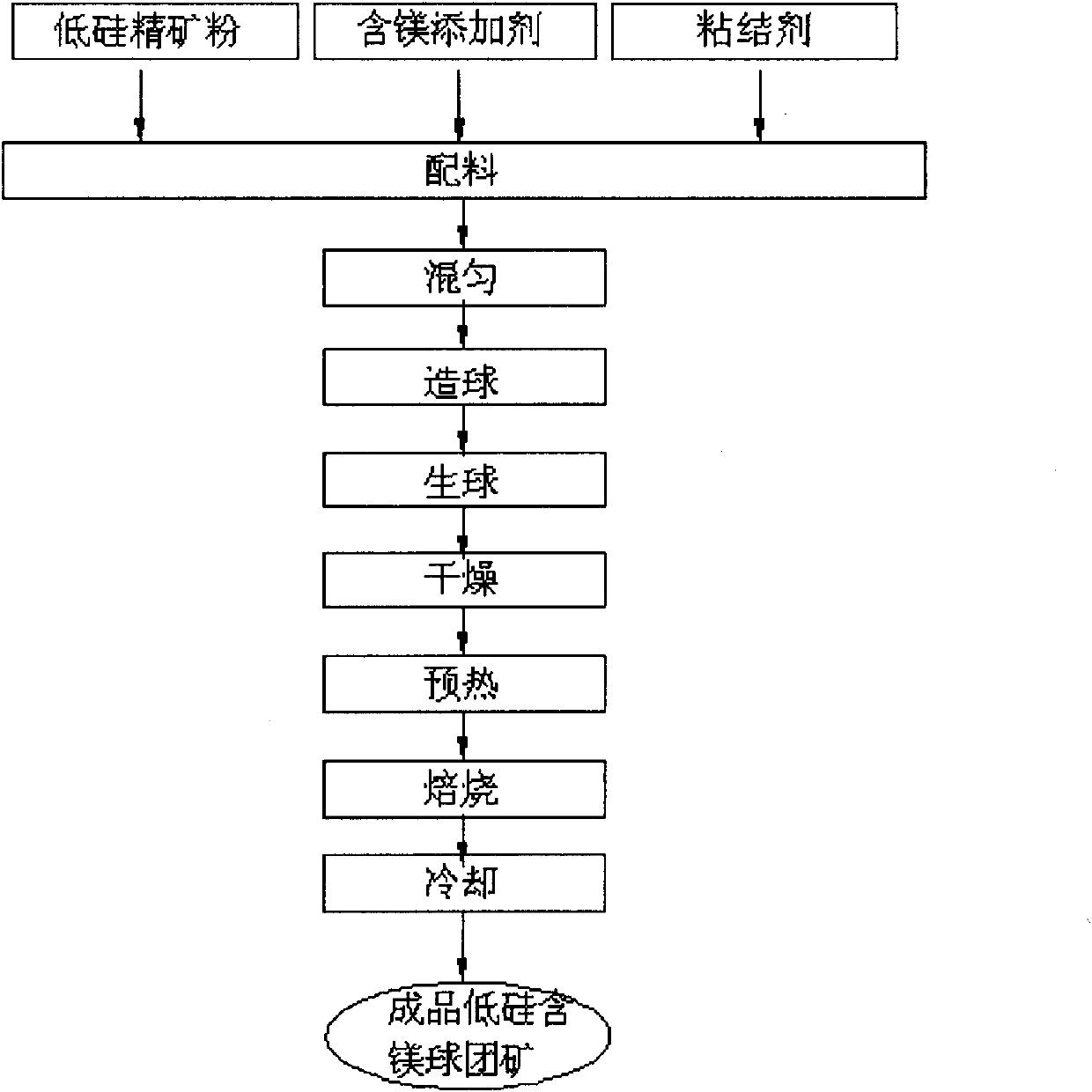

Low-silicon magnesium-containing pellets and production method thereof

ActiveCN101906533AImprove reducibilityGood droplet characteristicsBlast furnace detailsBLENDER/MIXERTO-18

The invention discloses low-silicon magnesium-containing pellets and a production method thereof. The method comprises the following steps of: proportioning 95 to 98.5 mass percent of low-silicon ore concentrate powder, 1 to 4 mass percent of magnesium-containing additive and 0.5 to 1.0 mass percent of binder, uniformly mixing the low-silicon ore concentrate powder, the magnesium-containing additive and the binder by using a blender mixer, adding an appropriate amount of water and controlling the water content of the mixture to be between 7.0 and 8.5 percent, wherein the magnesium-containing additive can be selected from magnesia powder, caustic calcined dolomite, dolomite, olivine and boric sludge and the binder can be selected from bentonite or a composite binder; pelletizing the mixture in a pan pelletizer, forming a mother pellet, adding materials and water gradually to allow the mother pellet to grow bigger and denser, screening green pellets of between 9 and 16 millimeters and performing a continuous roasting process consisting of drying, preheating, roasting and cooling; drying the pellets at the temperature of between 200 and 450 DEG C for 8 to 10 minutes, preheating the pellets at the temperature of between 700 and 1,050 DEG C for 10 to 15 minutes and roasting the preheated pellets at the high temperature of between 1,280 and 1,350 DEG C for 12 to 18 minutes; and cooling the roasted pellets to be less than 100 DEG C after roasting is finished so as to obtain the low-silicon magnesium-containing pellets serving as finished products.

Owner:SHOUGANG CORPORATION

Method for improving metallurgical property of vanadium-titanium blast furnace slag

InactiveCN102061346AImproved metallurgical propertiesImprove performanceBlast furnace detailsProcess efficiency improvementCast ironTitanium

The invention provides a method for improving metallurgical property of vanadium-titanium blast furnace slag, which comprises the following steps of: adding furnace materials containing vanadium, titanium, ferrum and ore in a blast furnace; regulating furnace temperature; and smelting, and then separating slag and ferrum, and adding fluorescence stones into the furnace material so that the weight percentage of CaF2 in the blast furnace slag is controlled within 0.5-5 percent. According to the method provided by the invention, the performance of a vanadium-titanium-containing iron ore concentrate blast furnace for smelting vanadium-containing cast iron furnace slag is improved, and meanwhile, the smelting furnace temperature fluctuation range of the vanadium-titanium-containing iron ore concentrate blast furnace is widened by using fluorescence stones so that the controlled range of the high furnace temperature is widened.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Preparation method for granulating fine-particle fuel for sintering of iron ore in advance

InactiveCN104313313AHigh strengthReduce return rate and solid fuel consumptionIron ore sinteringParticle material

The invention discloses a preparation method for granulating a fine-particle fuel for sintering of iron ore in advance and belongs to the technical field of preparation of a fuel for metallurgical production. By adoption of the preparation method, the content of micro-fine particle materials with the granularity being less than 0.5mm in the fuel for sintering of the iron ore can be effectively reduced. The preparation method comprises the following steps of: firstly sieving crushed fuel by adopting a sieving tool with the grading point being 0.5mm, collecting sieved fuel with the particle size being not more than 0.5mm to obtain the micro-particle fuel; then adding a binding agent with the mass ratio being 0.5%-2% into the micro-particle fuel collected in the step a, spraying water, and uniformly stirring to obtain a mixture of the binding agent and the micro-particle fuel; and then feeding the mixture prepared in the step b into a fine-particle making machine and preparing into fine-particle fuel with the particle size being not less than 0.5mm in advance so as to finish the preparation work of granulating the disposable micro-particle fuel into balls in advance.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

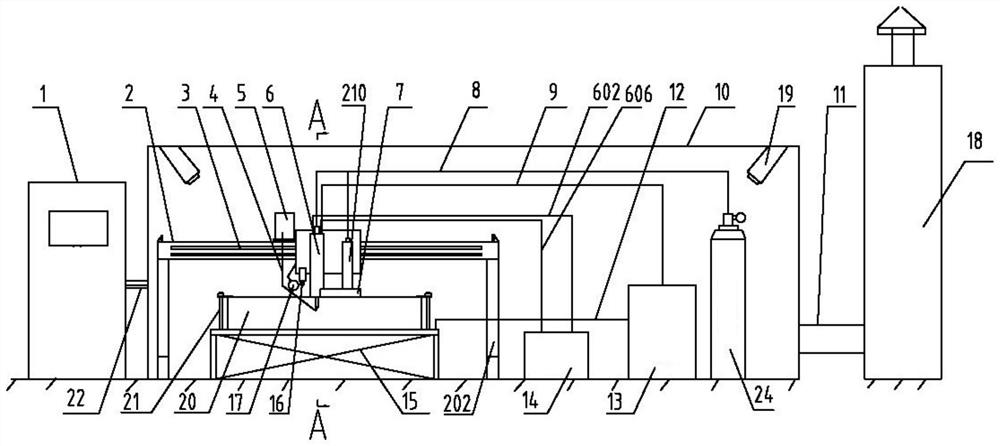

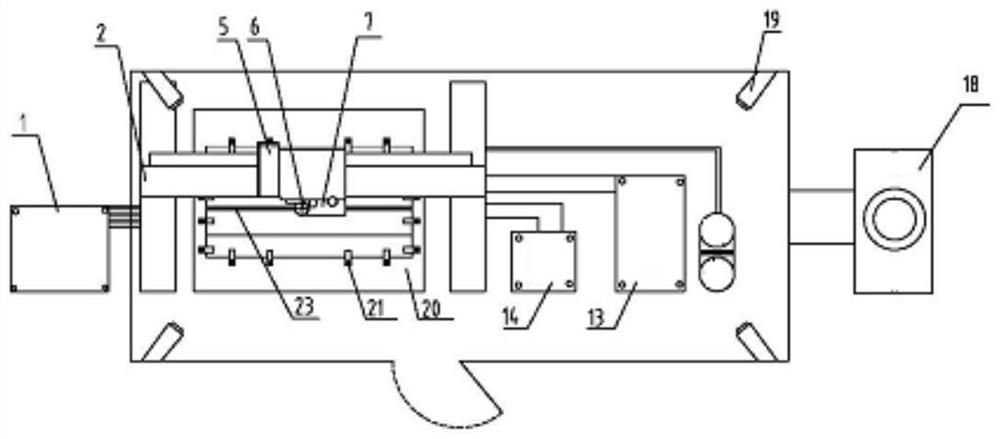

Smoke circulation type pre-reduction sintering technique and device

ActiveCN106282546AAchieve recyclingAchieve the goal of energy saving and emission reductionIncreasing energy efficiencyWaste heat treatmentSolventCoal

The invention provides a smoke circulation type pre-reduction sintering device and method. The pre-reduction sintering method comprises the steps that (1) pelletizing is conducted after iron fine powder and coal fuel are evenly mixed, so that carbon-burdened pellets are obtained; (2) iron ore powder, a solvent and coal fuel powder are proportioned, and then water is added into a primary mixing machine for mixing, so that a sintering mixture is obtained; (3) the carbon-burdened pellets, the sintering mixture and additional coal fuel fine powder are mixed in a secondary mixing machine, so that a pre-reduction sintering mixture is obtained, wherein the use amount ratio, by weight, of the sintering mixture to the carbon-burdened pellets to the additional coal fuel fine powder is (50-70):(28-48):(1-5); (4) the pre-reduction sintering mixture is arranged on a sintering trolley for conducting smoke circulation type pre-reduction sintering; and (5) pre-reduction sintered ore obtained after sintering is cooled under an anaerobic condition.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

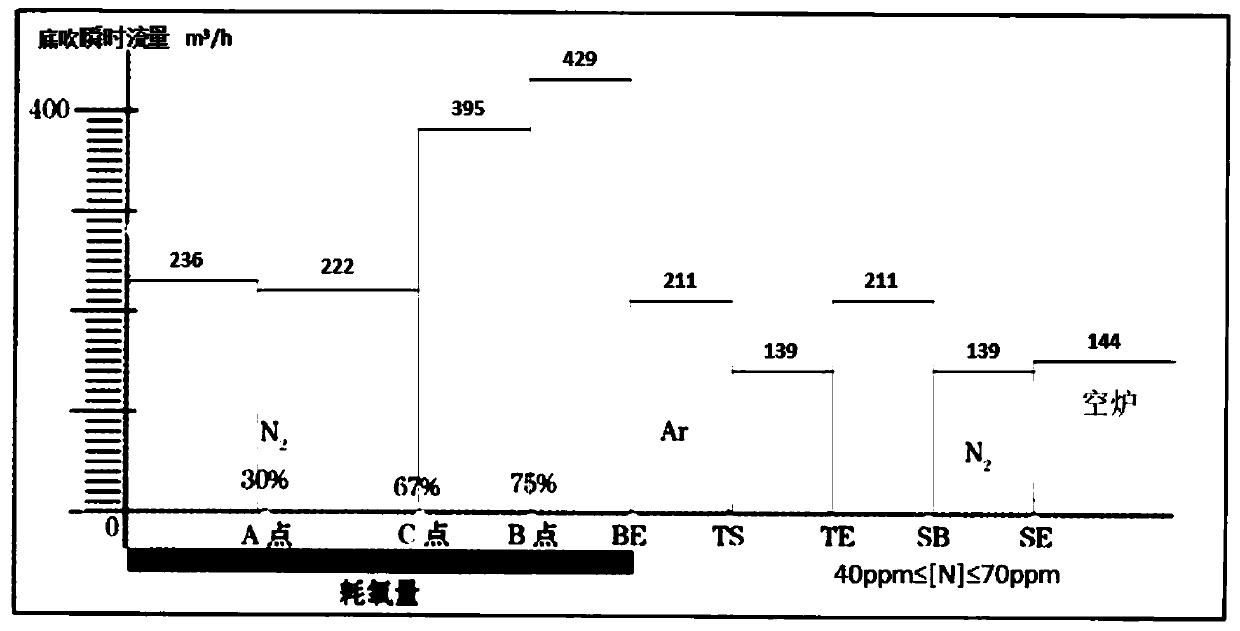

Method for making slag by replacing partial limestone with lime used for top and bottom combined blown converter

The invention provides a method for making slag by replacing partial limestone with lime used for a top and bottom combined blown converter. According to the invention, when the stainless is smelted by using the top and bottom combined blown converter, the partial limestone is used for replacing the lime, wherein, all the limestone is added at a time before blowing oxygen, the particle size of the limestone is between 5 and 20mm, and the addition of the limestone is 5-30kg / t of steel. The method for making slag by replacing the partial limestone with lime used for the top and bottom combined blown converter enables fast slagging, and is beneficial to converter dephosphorizing.

Owner:LAIWU IRON & STEEL GRP

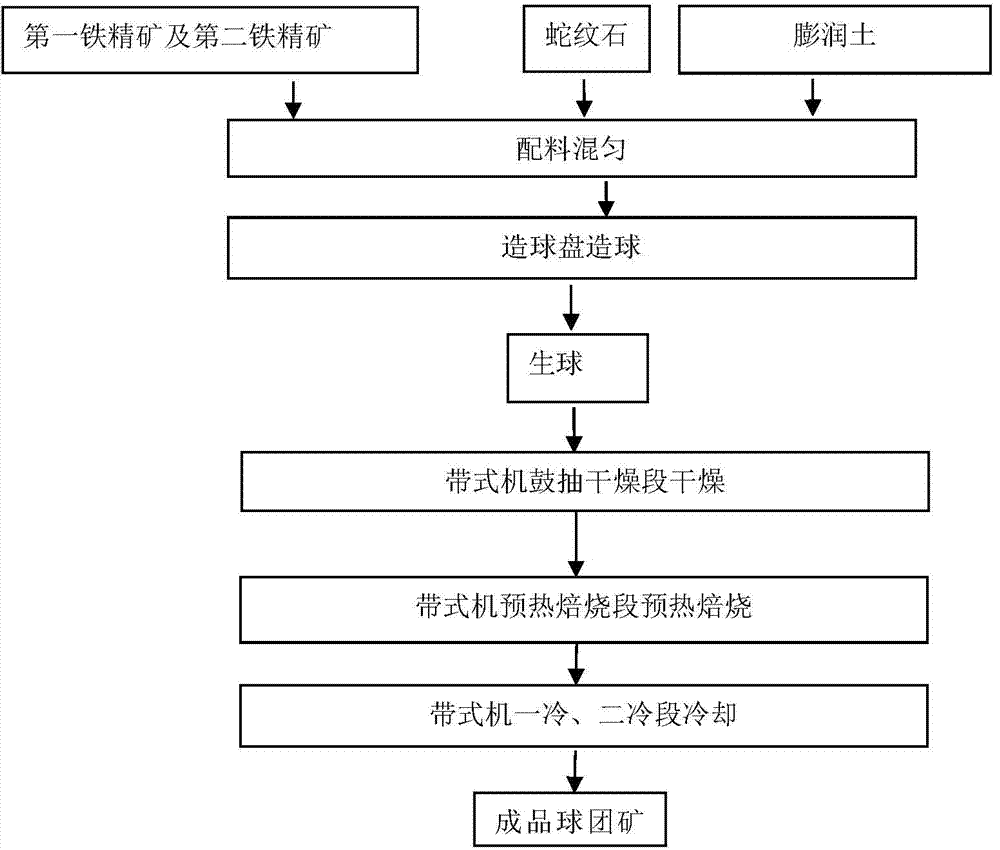

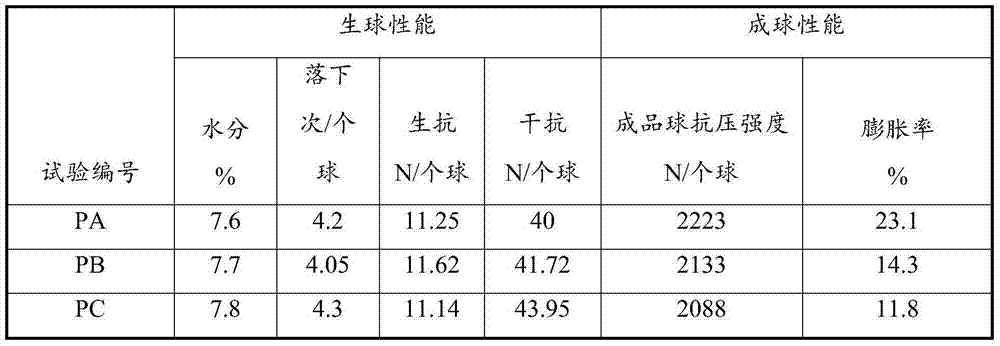

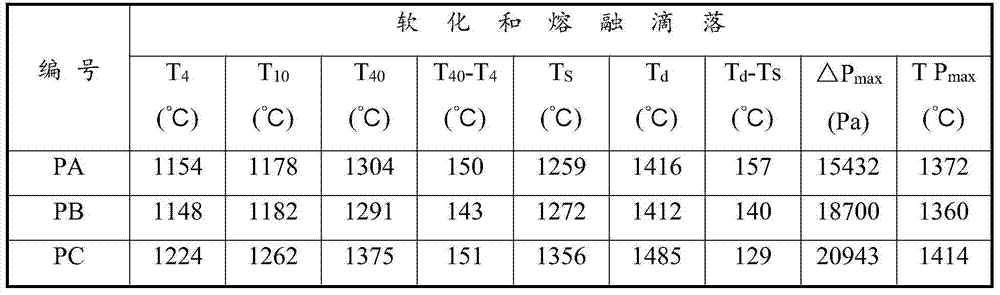

Raw material and method for producing magnesium pellets by using belt type machine

The invention discloses a raw material and method for producing magnesium pellets by using a belt type machine. The method comprises the steps of sufficiently mixing an iron-containing raw material, serpentine and bentonite in an intensive mixer to obtain a mixture, wherein the serpentine accounts for 1.0-2.5% of the mixture, and the bentonite accounts for 2% of the mixture; pelletizing the mixture in a pelletizing pan to obtain green pellets; drying the green pellets on a forced air drying zone and an induced-draft drying zone of the belt type machine, preheating the green pellets on a preheating zone, roasting the green pellets on a roasting zone, recrystallizing the green pellets on a soaking zone, and cooling the green pellets on a first cooling zone and a second cooling zone to finally obtain the magnesium oxidized pellets. According to the method, the serpentine is used as a magnesium additive for producing the magnesium pellets, and the metallurgical performances of the pellets with special baiyenebo iron concentrate ratio can be remarkably improved by virtue of a technical measure that the serpentine is added.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

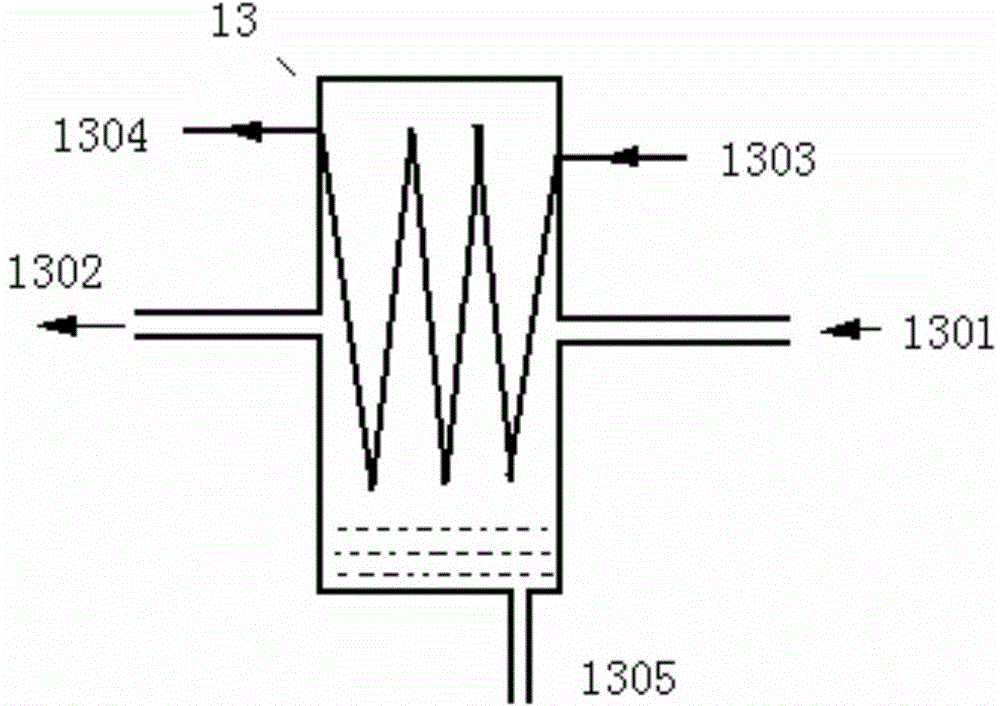

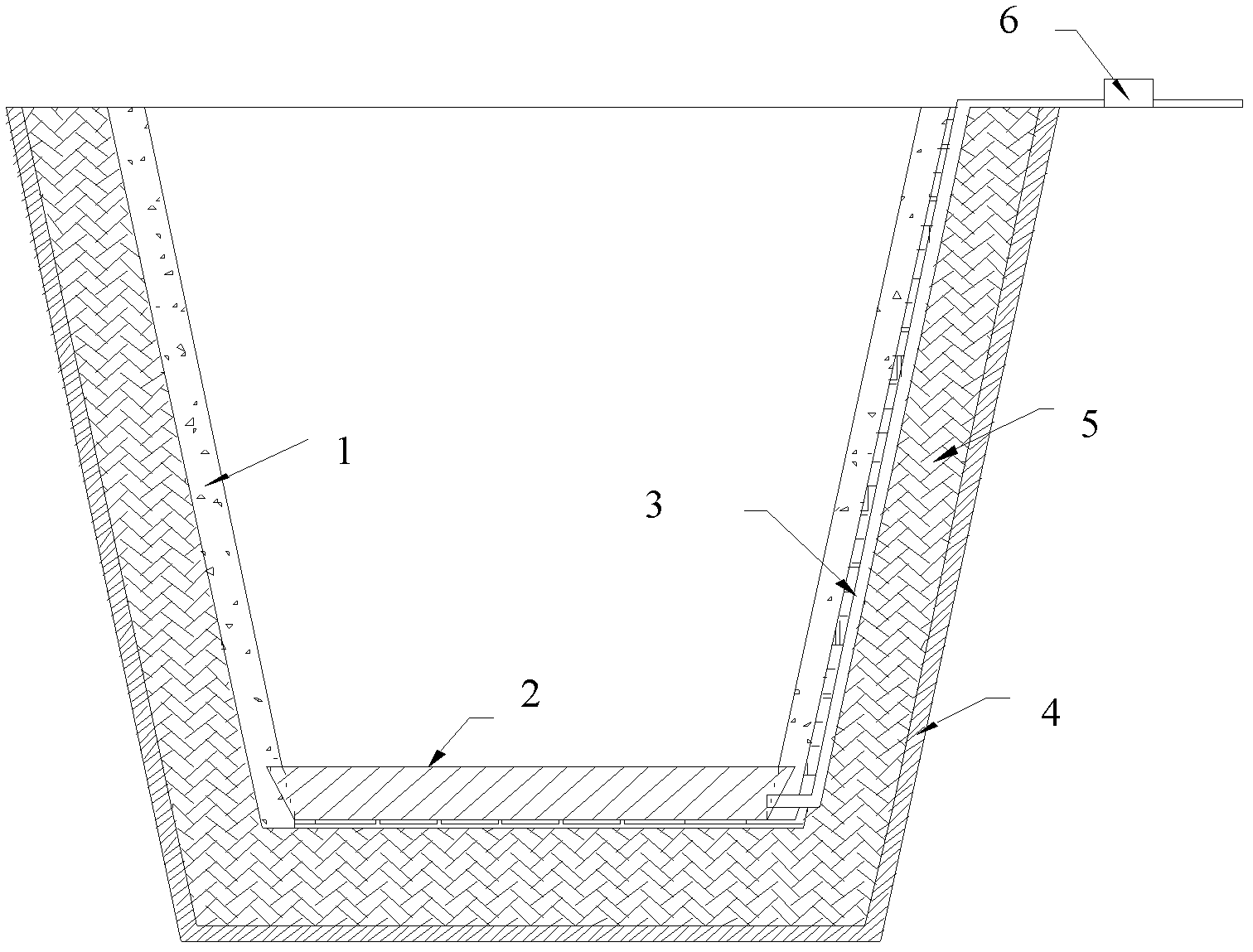

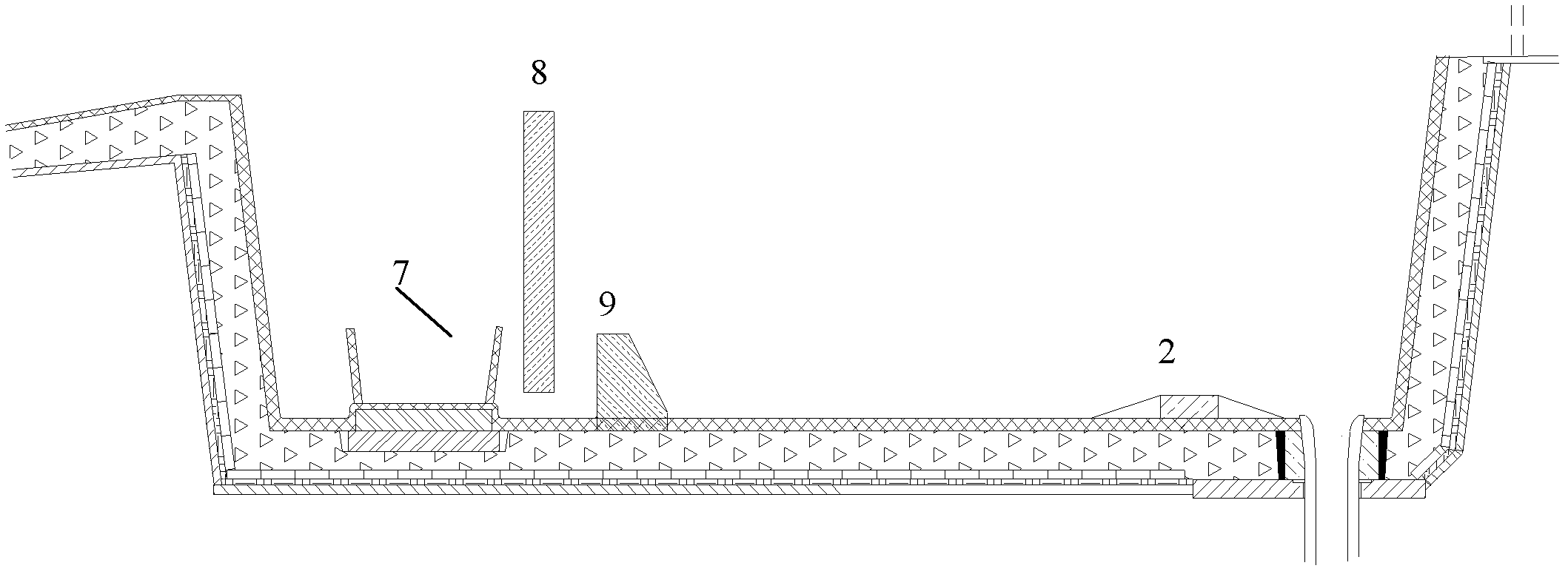

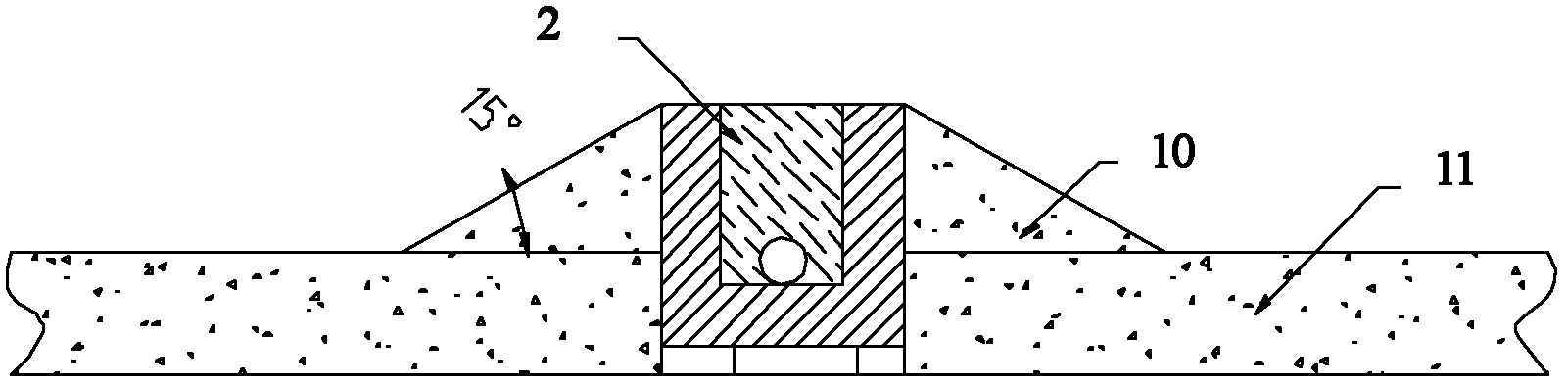

Pouring basket with molten steel purity stably improved under low argon consumption and metallurgical method thereof

The invention provides a pouring basket with molten steel purity stably improved under low argon consumption. Through the arrangement of a barrier wall, a gas-curtain brick and a short dam and position points thereof, the purity of molten steel for the metallurgy of the pouring basket can be effectively improved. The invention also provides a metallurgical method of the pouring basket. The method comprises the following steps of: in a pouring process, when the weight of the molten steel of the pouring basket reaches 12 tons, trigging an automatic argon regulating system, wherein the regulating goal is an argon flow from 50 L / min to 150 L / min and an argon pressure from 0.05 Mpa to 0.25 Mpa. With the pouring basket and the metallurgical method provided by the invention, the molten steel purity of the pouring basket can be stably improved under the situation of low argon consumption; and total oxygen content is lower than 30 ppm, which is superior to the prior art.

Owner:BAOSHAN IRON & STEEL CO LTD

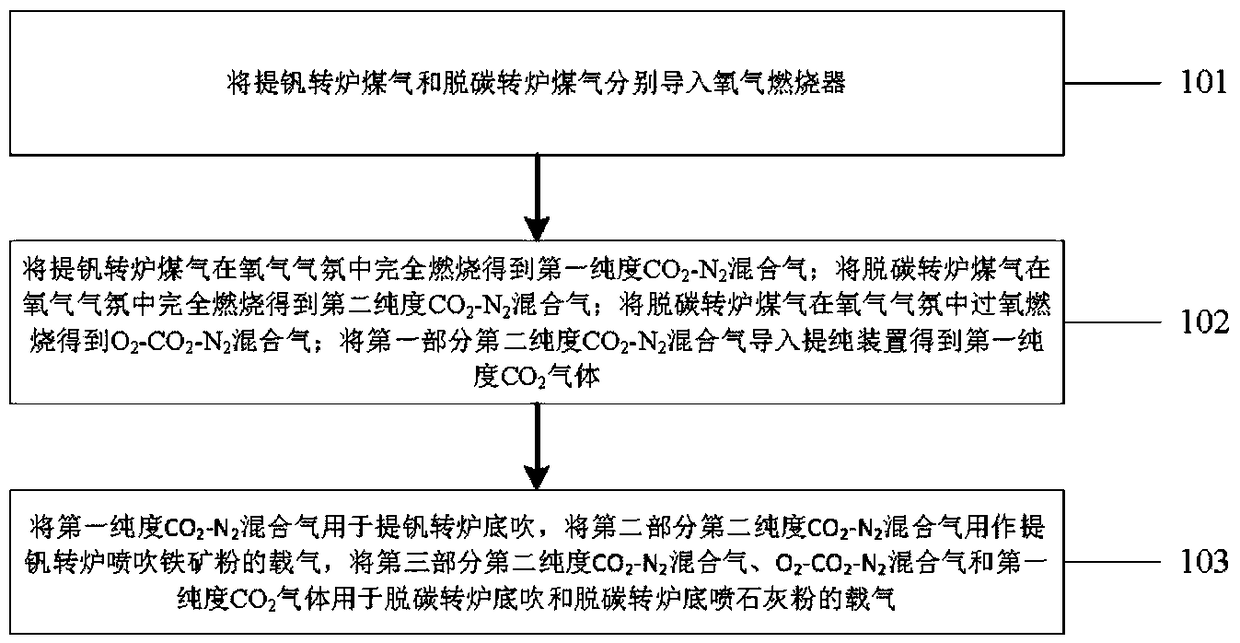

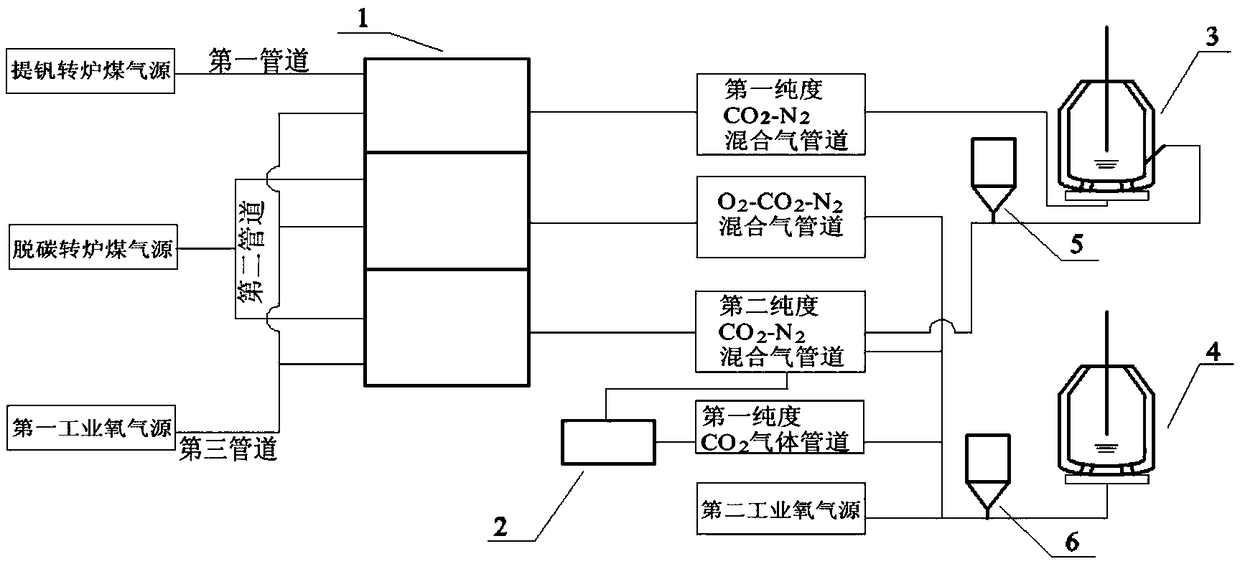

Efficient and long-service-life blowing method and system of vanadium extraction-decarburization dual converter

ActiveCN109234490ALower acquisition costsImprove efficiencyGas treatmentOxide/hydroxide preparationSteelmakingCombustor

The invention discloses an efficient and long-service-life blowing method and system of a vanadium extraction-decarburization dual converter and belongs to the technical field of vanadium-containing liquid iron steelmaking. The efficient and long-service-life blowing method comprises the following steps: conducting vanadium extraction converter coal gas and decarburization converter coal gas intoan oxygen combustor; obtaining CO2-N2 mixed gas with first purity through the vanadium extraction converter coal gas; obtaining CO2-N2 mixed gas with second purity through the decarburization converter coal gas; btaining O2-CO2-N2 mixed gas through decarburization converter coal gas; obtaining CO2 gas with first purity through CO2-N2 with the second purity; carrying out vanadium extraction converter bottom blowing by utilizing the CO2-N2 mixed gas with the first purity; taking the CO2-N2 mixed gas with the second purity as iron ore powder carrier gas of vanadium extraction converter blowing; O2-CO2-N2 mixed gas and the CO2-N2 mixed gas with the first purity are used as lime powder carrier gas of the vanadium extraction converter bottom blowing and decarburization converter bottom spraying.By adopting the efficient and long-service-life blowing method, the vanadium oxidization rate of a vanadium extraction converter is improved and the dephosphorization effect of a decarburization converter is improved; the service life of the vanadium extraction converter and the decarburization converter is prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of blast furnace sludge pre-reduced pellet

ActiveCN103451421AImproved metallurgical propertiesLow firing temperatureBlast furnace detailsSludgeDolomite

The invention provides a preparation method of a blast furnace sludge pre-reduced pellet. The blast furnace sludge pre-reduced pellet is prepared from the following raw materials in percentage by mass: 10-30% of blast furnace sludge, 3.5-10% of SiC powder, 60-85% of iron ore concentrate and 1.2-1.5% of bentonite. The preparation method comprises the following steps: uniformly mixing 20-30% of the total dosage of the bentonite with the blast furnace sludge and the SiC powder, respectively, and uniformly mixing the iron ore concentrate with 70-80% of the total dosage of the bentonite to prepare a mixture; in a pellet preparation process, firstly, preparing the mixture of the blast furnace sludge, the SiC powder and the bentonite to a pellet core; then, adding the mixture of the iron ore concentrate and the bentonite to continue the pellet preparation process; and wrapping a layer of dolomite accounting for 0.5-1.5% of the total mass of the raw materials on the formed pellet, and preparing the pre-reduced pellet according to a conventional production process. By adopting the preparation method provided by the invention, a large amount of blast furnace waste can be consumed, the roasting temperature of the pellet is reduced, the utilization proportion of non-magnetite concentrate is increased, and the finished product pellet is non-adhesive, good in metallurgical performance and beneficial to improving the blast furnace efficiency and reducing the coke ratio of a blast furnace.

Owner:ANGANG STEEL CO LTD

Ore proportioning and sintering method

The invention relates to an ore proportioning and sintering method used for sintering a mixing iron ore material comprising high-silicon low-aluminum iron ore powder and high-aluminum low-silicon iron ore powder, wherein the high-silicon low-aluminum iron ore powder comprises the following components in percentage by weight: 45-55 percent of TFe, 10-20 percent of SiO2 and less than 1.0 percent of Al2O3; the high-aluminum low-silicon iron ore powder comprises the following components in percentage by weight: 60-70 percent of TFe, less than 5 percent of SiO2 and 2.0-4.0 percent of Al2O3, and Al2O3 / SiO2 is 0.1-0.35; in the mixing iron ore material, the proportion of the high-silicon low-aluminum iron ore powder and the high-aluminum low-silicon iron ore powder is larger than 0 and not larger than 50 percent, and the grade of the iron of a sintering ore is 50-60 percent, the SiO2 occupies 5.0-9.0 percent, and the alkalinity is 1.2-2.5 percent. The method can reduce the cost of steel, increase the utilization efficiency of the two kinds of ore powder, improve the metallurgical property of the sintering ores and improve the breathability of a material layer in the process of sintering.

Owner:BEIJING ZHONGDIAN HUAFANG TECH +1

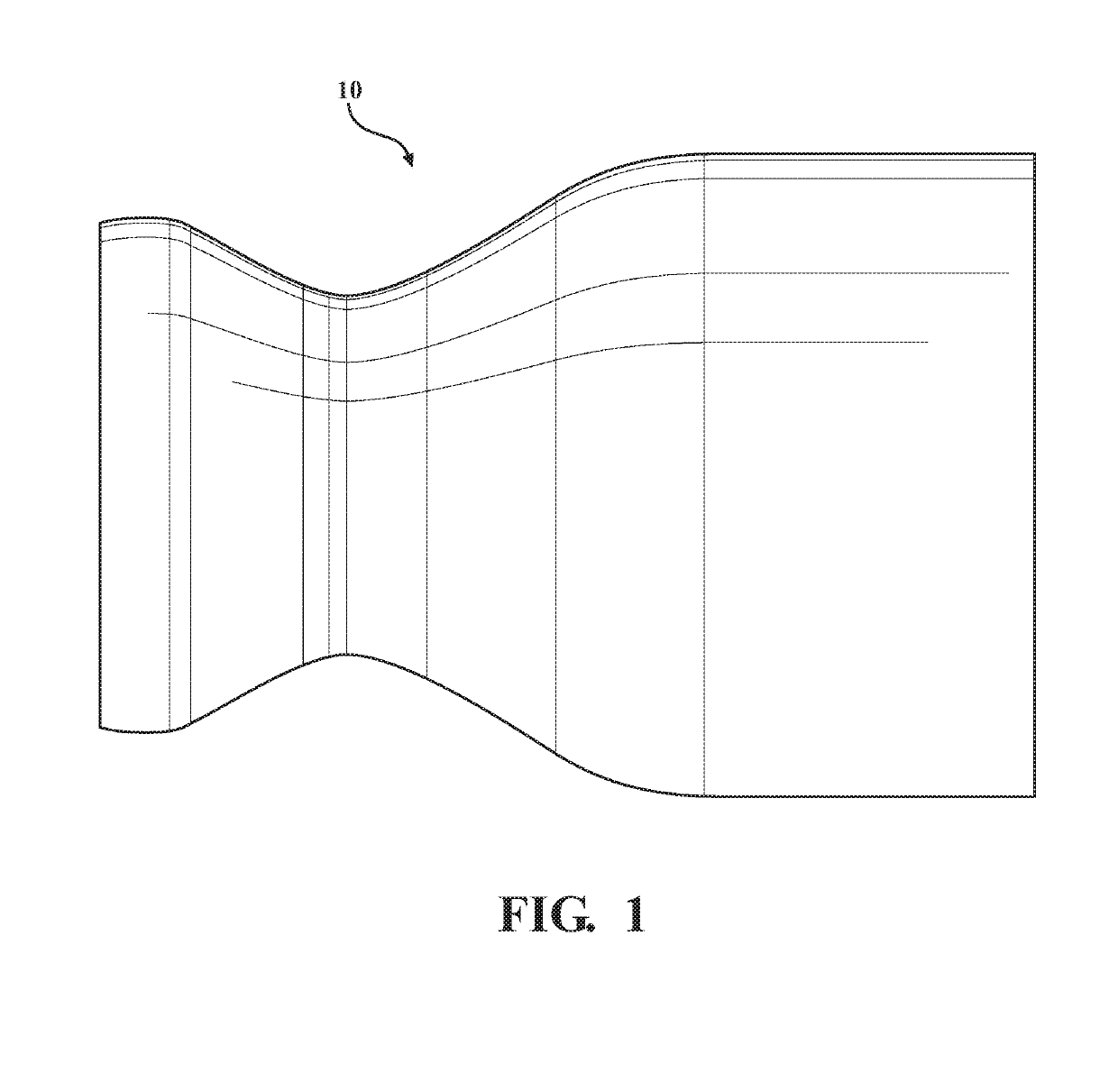

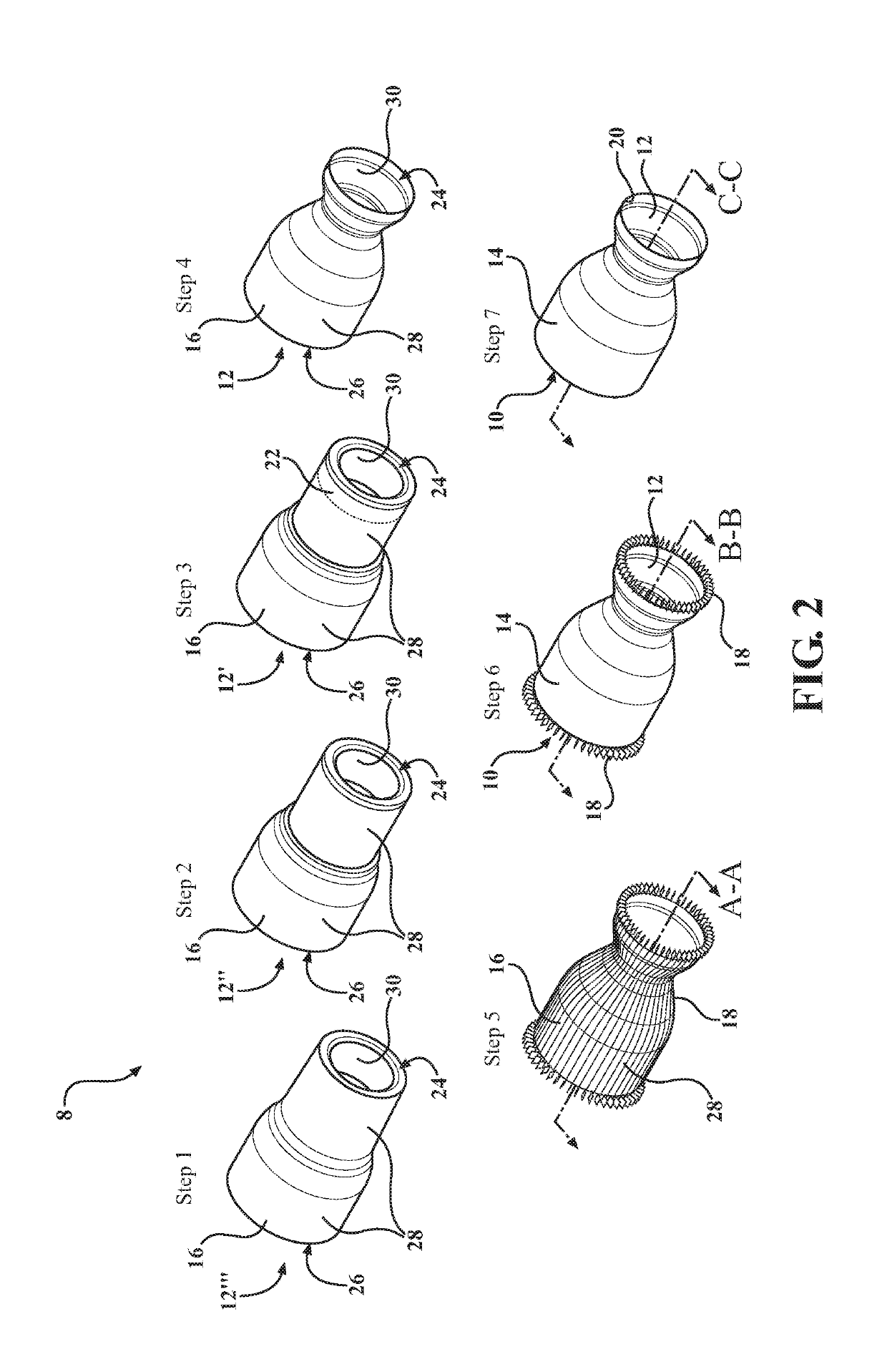

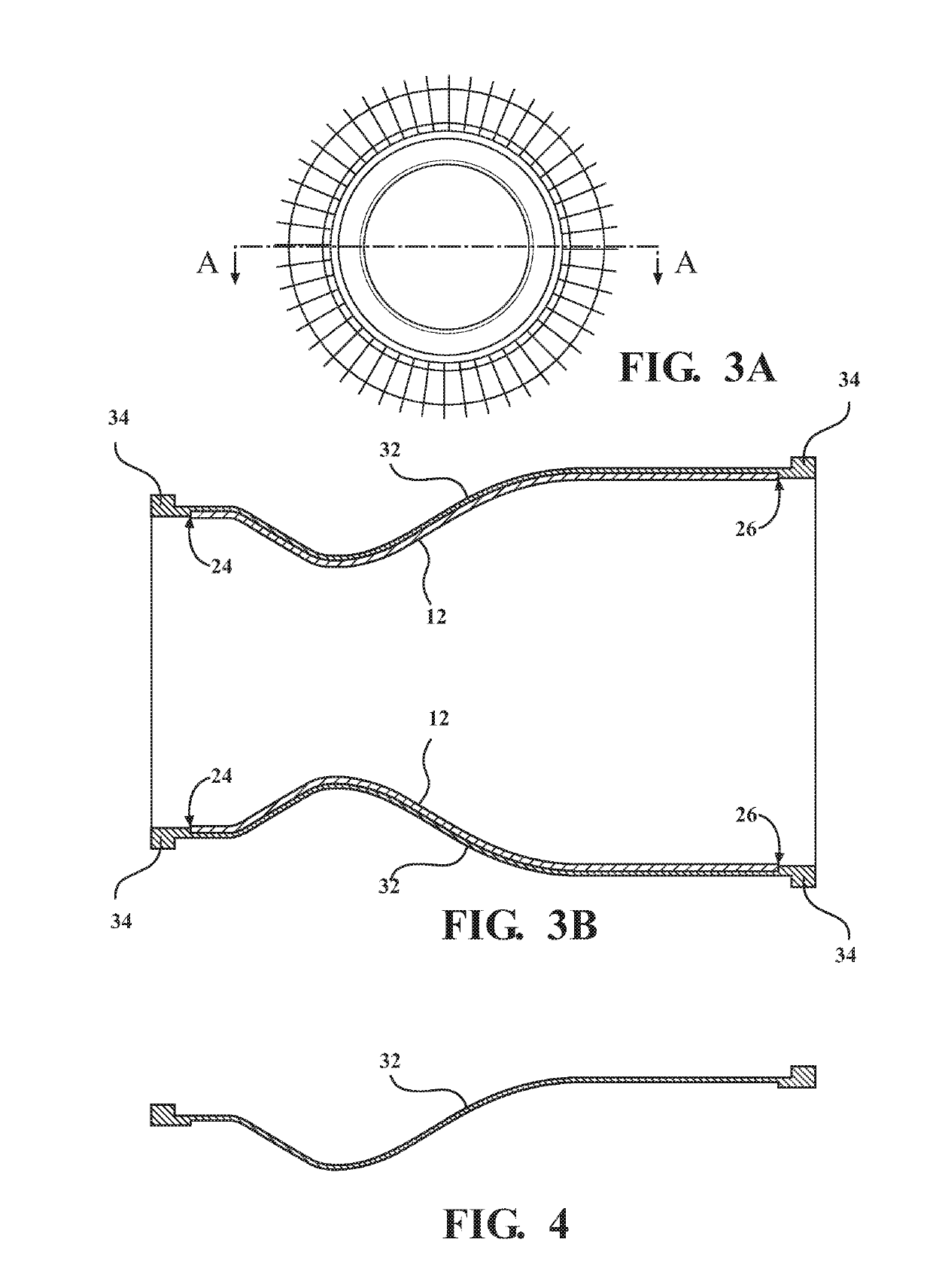

Method Of Producing A Component With Additive Manufacturing

InactiveUS20190283136A1Efficient productionImprove mechanical propertiesAdditive manufacturing apparatusFoundry mouldsMetallurgyExoskeleton

A method of producing a component is disclosed. The method first comprises the steps of providing a base structure having a surface, providing an exoskeleton, and positioning the exoskeleton about the surface of the base structure. Once the exoskeleton is positioned, the method further comprises the steps of depositing metallic material on the surface of the base structure having the exoskeleton thereabout with an additive manufacturing process to form an additive structure, and removing the exoskeleton to form one or more cavities within the component and complete production thereof

Owner:WELDALOY PROD CO

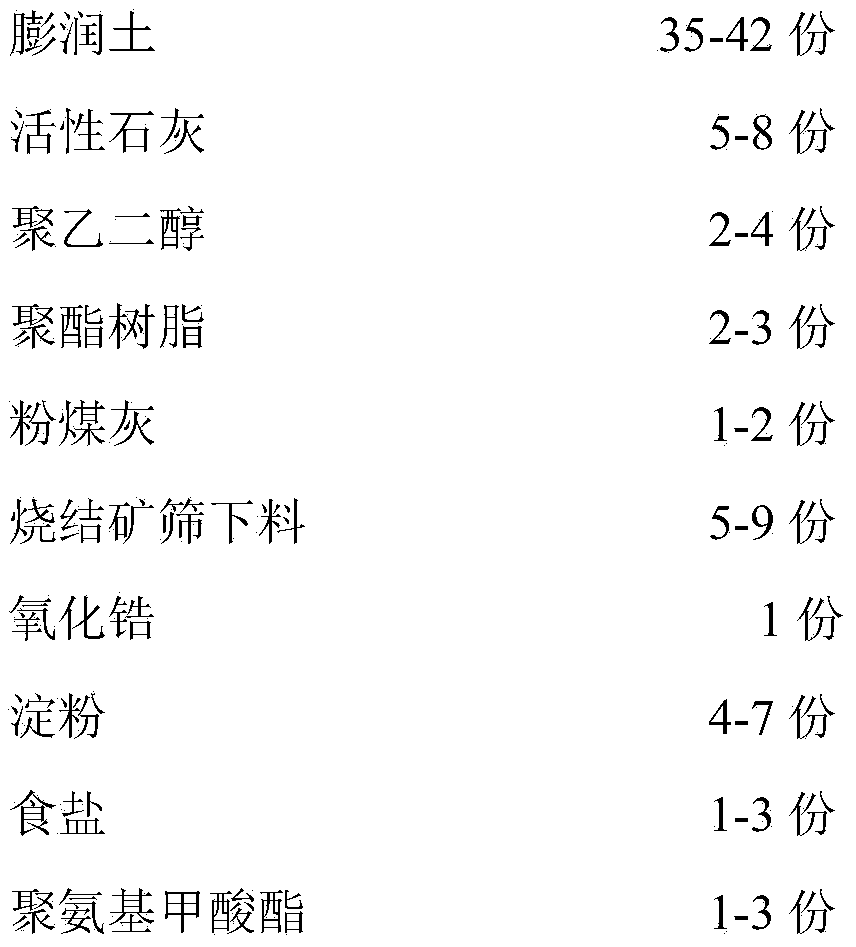

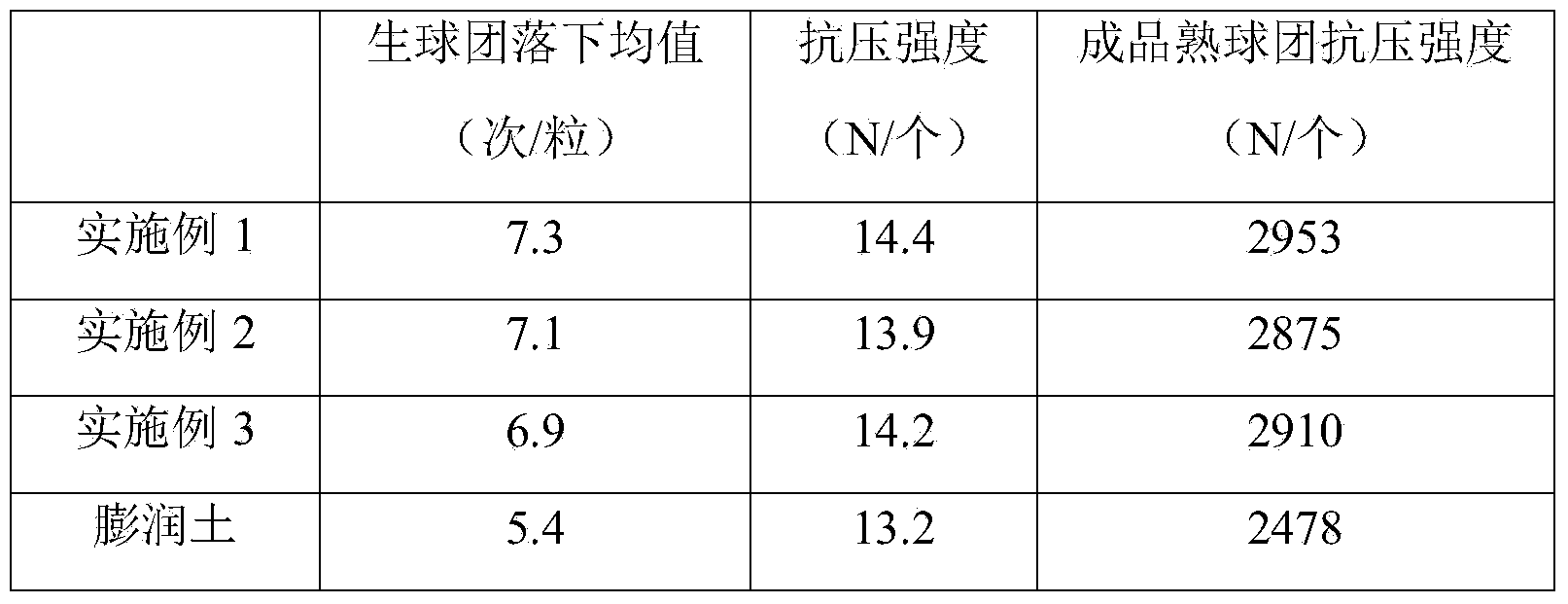

Preparation method of pellet binder with high performance

The invention discloses a preparation method of a pellet binder with high performance, and belongs to the technical field of a metallurgy pellet binder. The method comprises the following steps: weighing 35-42 parts of bentonite, 5-8 parts of active lime, 2-4 parts of polyethylene glycol and 2-3 parts of polyester resin according to the mass ratio, evenly mixing to obtain a mixture A; weighing 1-2 parts of coal ash, 5-9 parts of agglomerate sieve residue and 1 part of zirconium oxide according to the mass ratio, evenly mixing with the mixture A, so as to obtain a mixture B; weighing 4-7 parts of starch, 1-3 parts of salt, 1-3 parts of polyurethane and 2-4 parts of phenolic resin according to the mass ratio, and evenly mixing to obtain a mixture C; evenly mixing the mixture B with the mixture C, so as to obtain the binder. By adopting the preparation method of the pellet binder with high performance, wastes of iron and steel enterprises are recycled, the burnt rate is low, the metallurgical performance of the pellet is improved, the grade of the charged ore is improved, the slag quantity of ironmaking and smelting by a blast furnace is reduced, and the fuel consumption is reduced. Therefore, the method has good economic benefits.

Owner:吴雪健

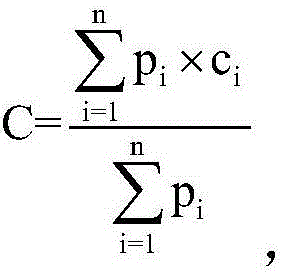

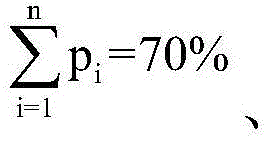

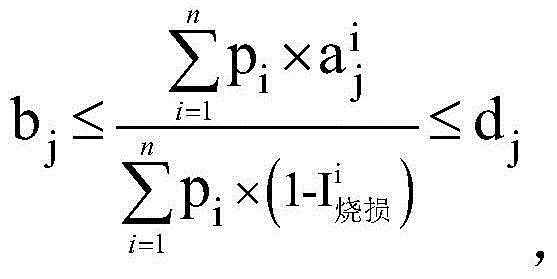

Burdening optimization method for sintering

InactiveCN103911507AImproved metallurgical propertiesCost efficientUltimate tensile strengthMaterials science

The invention discloses a burdening optimization method for sintering. Through adjustment of the using amount of each sintering raw material, sintered ore with high quality can be produced, wherein the yield, the dropping strength, the tumbler strength, the abrasion resistance index, the reducibility, the low-temperature reduction disintegration property, and the like of the sintered ore meet requirements of sintering and iron making production.

Owner:CHONGQING UNIV +1

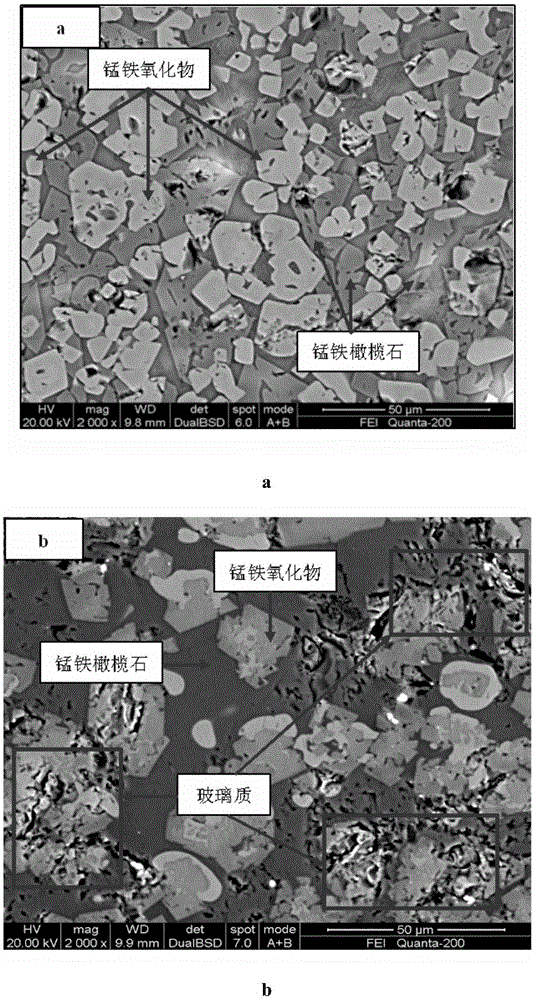

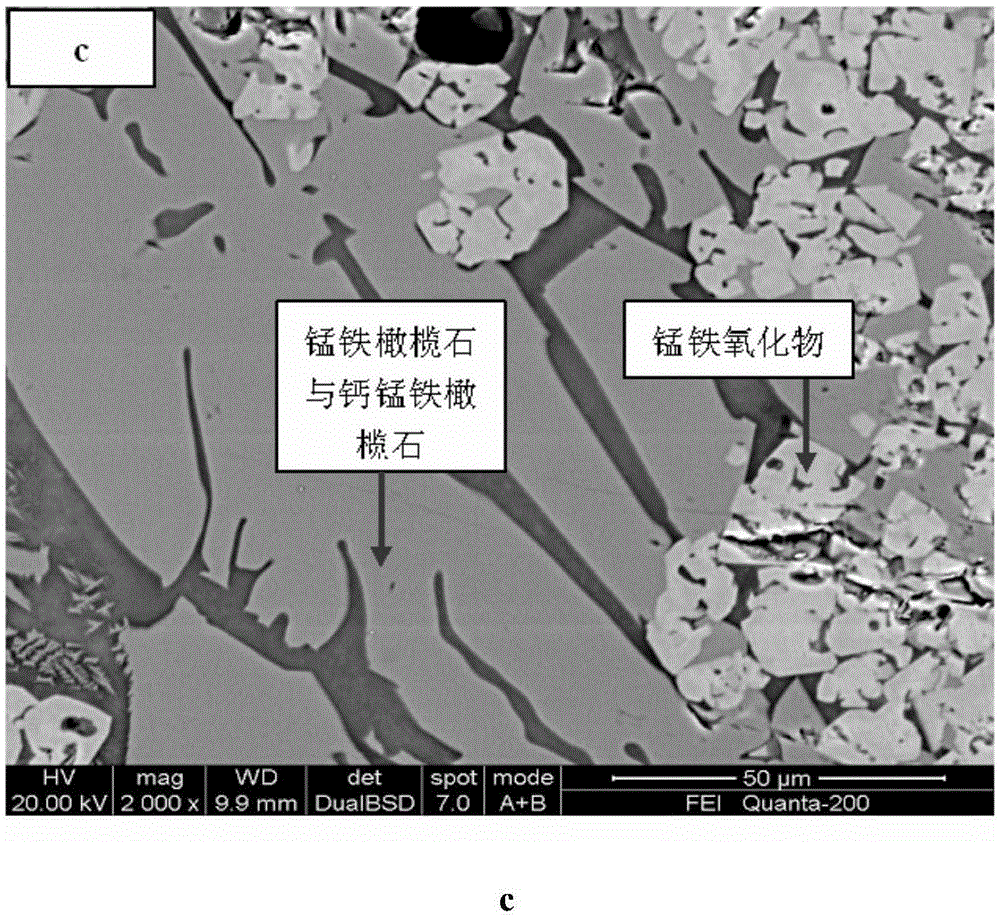

Method for manufacturing high-iron manganese ore composite sintering ores

ActiveCN105331805AEffective regulation of microstructureHigh strengthMass ratioMaterial distribution

The invention provides a method for manufacturing high-iron manganese ore composite sintering ores. The method includes the following steps that firstly, after raw materials including high-iron manganese ore concentrates, finely-ground coke powder, bentonite and a fusing agent are evenly mixed, and a pellet material is made, wherein according to the mass ratio of all the raw materials, the ternary basicity of the pellet material satisfies the inequation of 0<(CaO+MgO) / SiO2<=0.4; secondly, the raw materials including high-iron manganese ore powder, the fusing agent and the coke powder are evenly mixed, and granules are made, wherein according to the mass ratio of all the raw materials, the ternary basicity of the granules satisfies the inequation of 1.6<=(CaO+MgO) / SiO2<=2.4; and thirdly, the pellet material obtained in the first step and the granules obtained in the second step are evenly mixed, material distribution, ignition, sintering and cooling are sequentially conducted, and the composite sintering ores with the basicity ranging from 0.4 to 1.6 are obtained. The method can be suitable for manufacturing of the sintering ores through various raw materials, and the manufactured ferromanganese sintering ores have good strength and metallurgical performance.

Owner:CENT SOUTH UNIV

Desulfurating agent for out-of-furnace treatment and preparation method thereof

InactiveCN101649371ASimple processHandling conditions are easy to implementEnergy consumptionAluminium oxide

The invention relates to a desulfurating agent for out-of-furnace treatment and a preparation method thereof. The technical scheme is achieved as follows: putting waste residues of out-of-furnace treatment in water with a temperature of 80-374 DEG C according to a solid-to-liquid ratio of 1:(2-8), stirring the waste residues for 2-60 minutes and then filtering and drying the waste residues; then uniformly mixing 30-80 weight percent of the treated waste residues of the out-of-furnace treatment and 20-70 weight percent of additive and then packaging or respectively packaging. The waste residuesof the out-of-furnace treatment comprise the following chemical components by weight: 30-65 percent of CaO, 8-35 percent of SiO2, 2-30 percent of Al2O3, 0.2-3.5 percent of S and the balance of MgO, CaF2, MnO, FeO, P and other impurities. The additive is uniformly mixed and packaged or respectively packaged according to the following components by weight: 70-100 percent of lime, 0-30 percent of one of bauxite, aluminum oxide and fluorite and 1-10 percent of one of aluminum ball and calcium carbide. The invention has the characteristics of simple process, low energy consumption and low cost; and the prepared desulfurating agent for the out-of-furnace treatment has good metallurgical property and strong desulfurating capacity.

Owner:WUHAN UNIV OF SCI & TECH

Narrow gap tungsten electrode argon arc welding technology method for thick plate

ActiveCN111618402APlay a binding rolePlay a buffer roleWelding accessoriesLaser rangingAC - Alternating current

The invention relates to a narrow gap tungsten electrode argon arc welding technology method for a thick plate, belongs to the technical field of narrow gap welding, utilizes narrow gap tungsten electrode argon arc welding equipment, and adopts a non-axisymmetric tungsten electrode rotation way to carry out the automatic welding of an ultra-thick plate (0-300 mm) and a narrow gap (4-10 mm). The narrow gap tungsten electrode argon arc welding technology method comprises the following steps of: (1) arranging a groove, and carrying out groove processing; (2) clamping the narrow gap tungsten electrode argon arc welding equipment; (3) installing the tungsten electrode, and carrying out equipment programing; (4) positioning: moving the tip of the welding gun tungsten electrode to the bottom of the center of a welding line, enabling a gas hood to be covered above the welding line, and then, through laser distance measurement, carrying out second positioning; (5) carrying out welding line backing weld: in a welding process, carrying out arc pressure and laser tracking to guarantee that the tungsten electrode is centered, utilizing an alternating current pulse hot filament TIG (Tungsten Inert Gas Welding) technology, and regulating welding current and pulse frequency to accurately control the heat input of the welding line; (6) carrying out layered filling weld; and (7) carrying out cosmetic weld. Compared with common tungsten electrode argon arc welding, the narrow gap tungsten electrode argon arc welding technology method disclosed by the invention greatly increases weldable platethickness and improves production efficiency and production quality.

Owner:SHANDONG UNIV +1

Method for iron ore powder agglomeration

The invention discloses a method for iron ore powder agglomeration. The method aims at improving the iron grade of iron ore, reducing energy consumption and reducing environmental pollution. The method includes the steps that iron ore powder, limestone powder, magnesium cement and pore-forming agents are proportioned for iron ore powder briquettes; primary mixing is carried out, and the small-granularity iron ore powder, the limestone powder, the magnesium cement and the pore-forming agents are put in a mixer; secondary mixing is carried out, the primary mixture and the remaining large-granularity iron ore powder are put into the mixer to be mixed evenly to obtain a uniform mixture; the uniform mixture is placed in a cuboid-shaped mold to be pressed into an iron briquette raw material; the iron briquette raw material is roasted; and crushing and screening are carried out. According to the method, the magnesium cement serves as a binder and a MgO additive, the pore-forming agents are added to the mixture, the cold press molding technology is adopted for pressing multi-pore iron briquettes, and therefore the iron ore powder agglomeration efficiency is improved, the metallurgical performance of the iron briquettes is improved, the production technology process is simplified, the quantity of the binder used in sintering and palletizing is reduced, iron ore resources are expanded, and the bulk density of the iron briquettes and the production efficiency of a blast furnace are improved.

Owner:UNIV OF SCI & TECH LIAONING

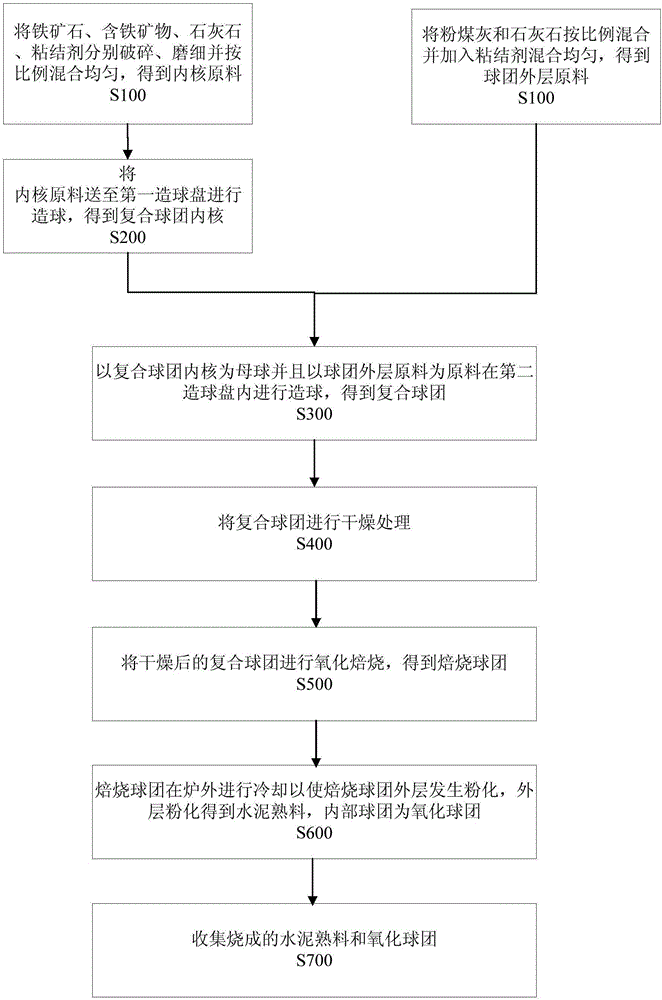

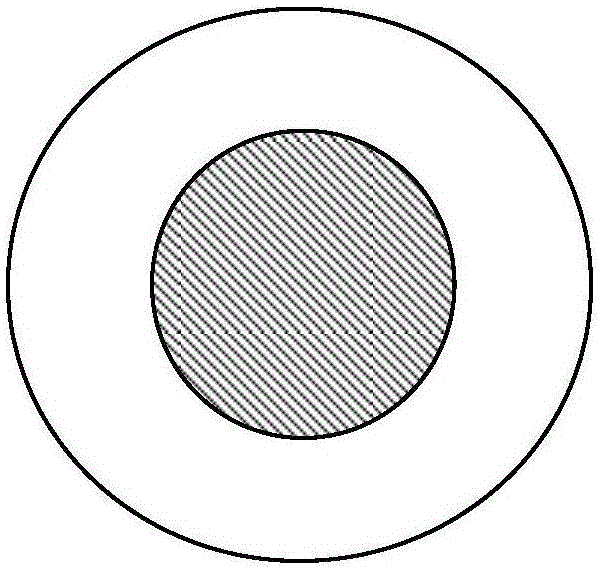

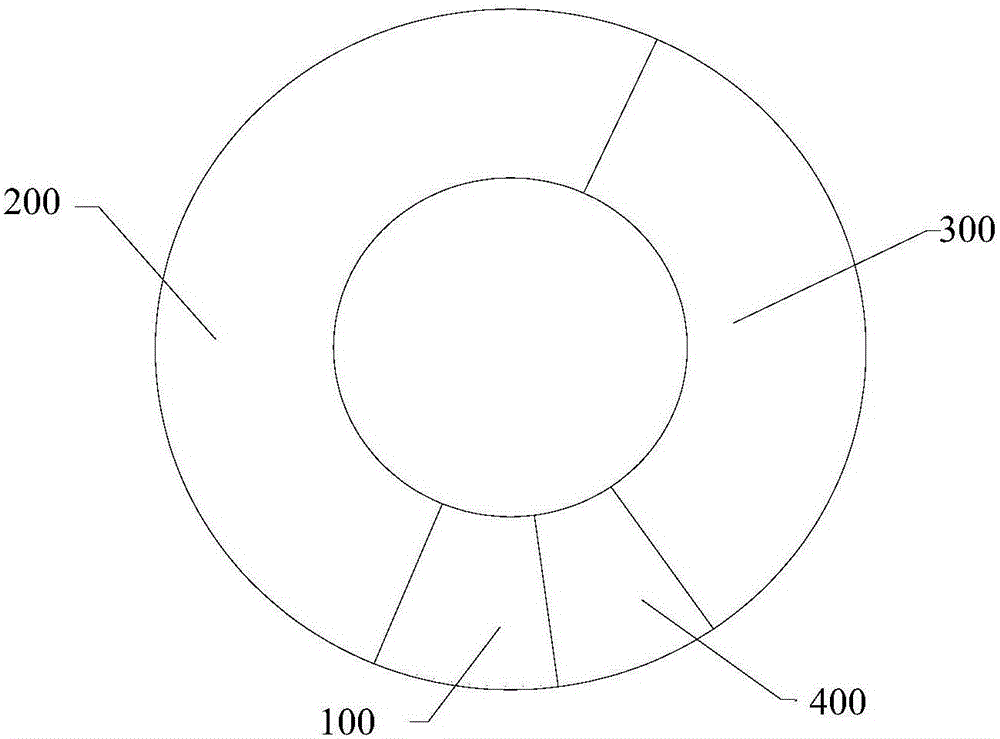

Method for producing cement clinker and oxide pellets

ActiveCN106636627AIncrease productivityGood metallurgical performanceClinker productionOxideAdhesive

The invention discloses a method for producing cement clinker and oxide pellets. The method comprises the following steps: (1) respectively crushing and grinding iron ores, iron-bearing minerals, limestone and adhesive, uniformly mixing according to a proportion to obtain an inner core raw material, mixing pulverized fuel ash and limestone according to a proportion, adding adhesive, and uniformly mixing to obtain an outer layer raw material of pellets; (2) pelletizing the inner core raw material to obtain pellet inner cores; (3) pelletizing by using the pellet inner core as female parent pellets and the outer layer raw material of pellets as a raw material to obtain compound pellets; (4) drying the compound pellets; (5) roasting the dried compound pellets in the air to obtain roasted pellets; (6) cooling the roasted pellets out of a furnace to pulverize the outer layer of the roasted pellets, namely pulverizing the outer layer to obtain cement clinker, and obtaining inner pellets as oxidized pellets; and (7) collecting the roasted cement clinker and oxidized pellet ore. The method can be used for simultaneously producing cement clinker and oxidized pellet ore, so that the production efficiency is improved, and energy conservation and emission reduction can be achieved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Multi-functional composite additive for intensifying direct reduction of low-grade superfine hematite

The invention relates to a multi-functional composite additive for intensifying direct reduction of low-grade superfine hematite, which consists of the following components: iron oxides, calcium carbonate and sodium humate. The multi-functional composite additive has reasonable ratio of the components, can effectively improve the strength of low-grade iron ore and pellets and reductibility of the pellets, and promotes ferrite grains to grow; a reverse floatation direct reduction-magnetic separation process can be utilized to produce directly reduced iron powder for steelmaking at one step, the steel production flow is effectively shortened, energy is saved and consumption is reduced; and the multi-functional composite additive has wide component sources and low cost, is suitable for large-scale industrial production, and is particularly applied to the low-grade superfine hematite.

Owner:CENT SOUTH UNIV

Method for preparing sintered ore

InactiveCN101177731AReduce particle fraction contentReasonable particle size compositionAdhesiveMaterials science

The invention pertains to the metallurgy technical field, in particular to a method of a sintered ore, which aims at solving the technical problem that sintered coke powder is easy to be over crushed, resulting in the proportion of -0.5mm granule being over high and then influencing the sintered effect. The method comprises the steps of crushing the coke powder, making balls with burden and mixture, burden distribution sinter, etc. The invention is characterized in that the coke powder after being crushed is added with adhesive to make the granule and then make the balls with the burden and the mixture. Since the method of the invention is adopted, the coke powder -0.5 mm granule proportion is decreased by 10 percent -21 percent, thus improving the sintered process; the calcium ferrite content in the sintered ore is increased by over 2 percent, the drum strength in the sintered ore is improved by 1.0 percent-1.62 percent, the rate of finished products is improved by 1.35 percent-3.26 percent, the yield is increased by 2.7 percent-5.4 percent, and the metallurgical property of the sintered ore is also promoted. The technology is simple and practicable, and the on-site technology process can be conveniently modified with strong feasibility.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Novel binder for metallurgical pellets

The invention belongs to metallurgical raw materials and pretreatment technology, and in particular relates to a novel binder for metallurgical pellets. The novel binder for the metallurgical pellets consists of the following components in part by weight: 100 parts of natural calcium-based bentonite, 2 to 5 parts of sodium carbonate and 1.1 to 2.0 parts of sodium cellulose, wherein the natural calcium-based bentonite is natural calcium-based bentonite with montmorillonite content of more than 54 percent. The preparation method comprises the following steps of: adding 2 to 5 weight parts of sodium carbonate into 100 weight parts of natural calcium-based bentonite for sodium treatment, drying until the moisture content is below 12 percent, performing ore grinding until the ore with granularity of less than 43 microns is over 90 percent, adding 1.1 to 2.0 weight parts of sodium cellulose, and stirring and uniformly mixing to prepare the novel binder for the metallurgical pellets. The pellet forming property of green pellets can be effectively improved, the cracking temperature of the green pellets is improved, the metallurgical property of pellet ore is improved, and the binder has the effects of increasing the yield and reducing the consumption for the production of the pellet ore.

Owner:ANSTEEL GRP MINING CO LTD

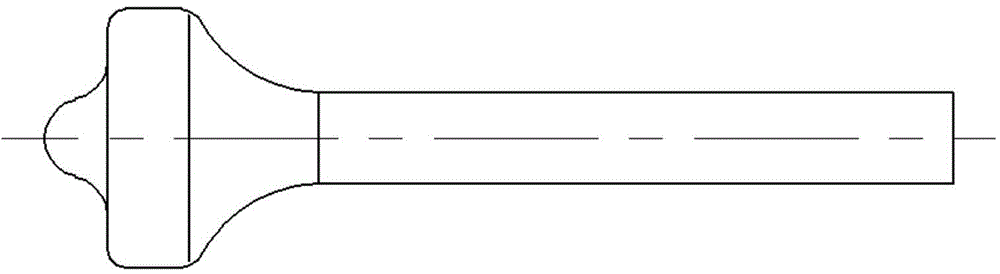

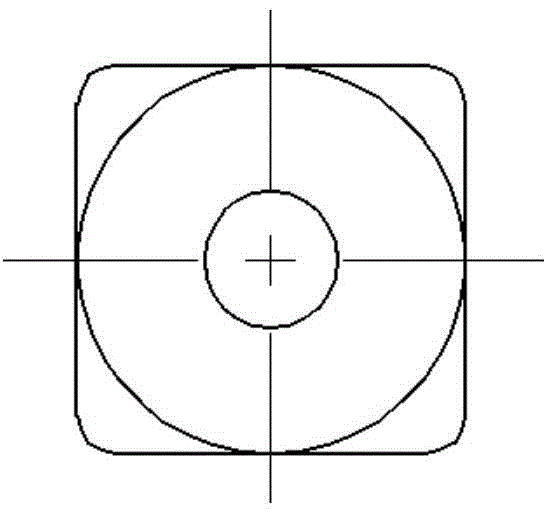

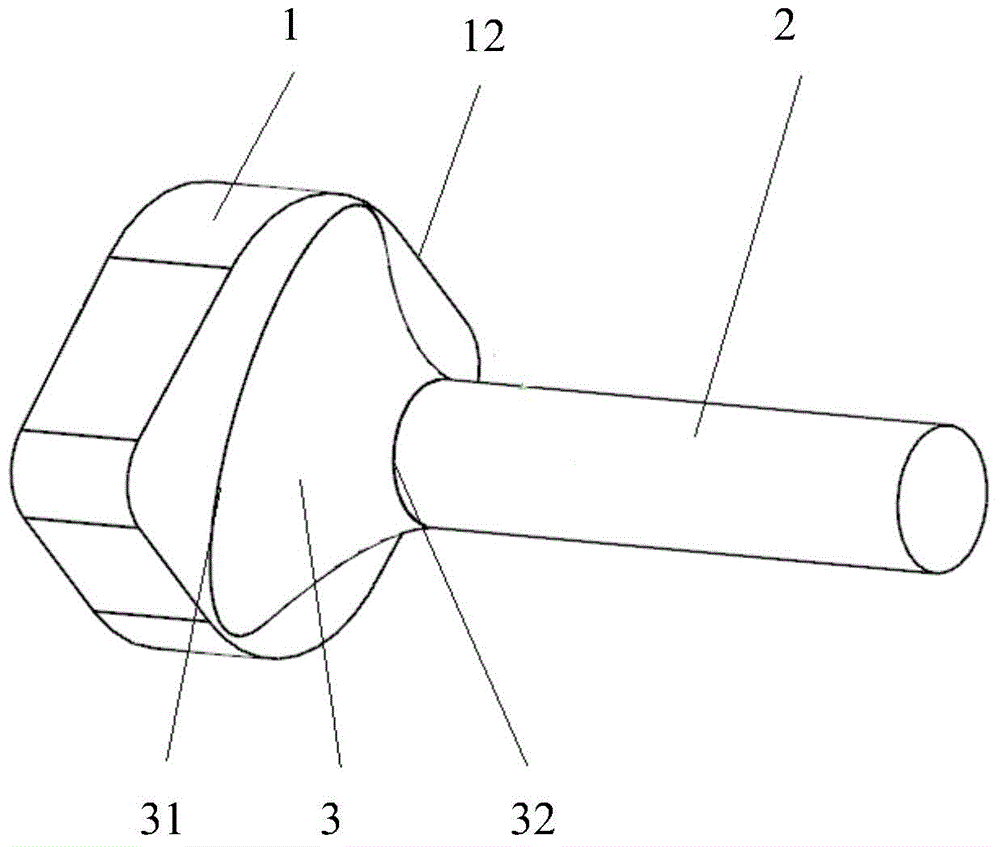

Cast blade upset head blanking forming piece

The invention belongs to precision forging, and provides a cast blade upset head blanking forming piece. The cast blade upset head blanking forming piece comprises a head part and a rod part. The front end of the head part is hemispheric, and the hemispheric front end of the head part is connected to a body of the head part in a transitional mode. The body of the head part is rectangular, the four corners of the rectangular body are rounded, and the rounding radius of one set of opposite corners is three to five times that of the other set of opposite corners. The body of the head part is backwards connected with the rod part through a turning connection area. The first cross section, connected with the body of the head part, of the turning connection area is oval, the long axis direction of the oval first cross section is consistent to the intake and exhaust edge of a blade, and the two ends of the long axis direction of the first cross beam reach the edge of the body of the head part. The second cross section, connected with the rod part, of the turning connection area is the same as the cross section of the rod part. The cross section of the turning connection area is gradually formed from the first cross section to the second cross section in a transitional mode from front to back. The area of the cross section of the rod part is equal to the area of the cross section of a pre-forging piece, and the rod part is longer than a blade body of the pre-forging piece.

Owner:AECC AVIATION POWER CO LTD

Bottom-blowing flow dynamic control method of top-bottom combined blowing converter

InactiveCN110157848ARealize dynamic controlSolve fixed problemsSteel manufacturing process aspectsIncreasing energy efficiencyEngineeringOxygen content

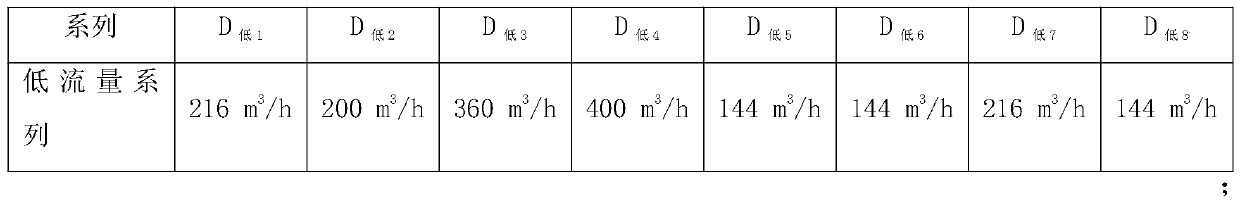

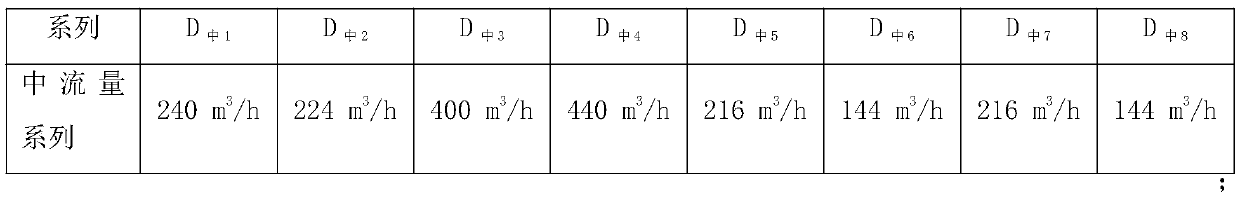

The invention provides a bottom-blowing flow dynamic control method of a top-bottom combined blowing converter. Firstly, three flow series composed of a high-flow series, a medium-flow series and a low-flow series are added based on three bottom-blowing air supply modes, three bottom blowing air supply modes and three flow series are permuted and combined into nine basic bottom-blowing curves, wherein the time coordinate axes of the basic bottom-blowing curves are provided with eight time intervals; in addition, the measured carbon content [C], the oxygen content [O], a molten pool liquid level a, and an end point temperature T of the converter blowing end point of the previous furnace as well as the furnace age of a next furnace to be blown are taken as variable parameters to be substituted into a formula, then the nine basic bottom blowing curves are dynamically corrected through formula calculation, thus the bottom blowing instantaneous flow after dynamic correction is the bottom blowing instantaneous flow of the actual blowing of the next furnace. According to the bottom-blowing flow dynamic control method of the top-bottom combined blowing converter, the problem that the bottom blowing flow is fixed is solved, the dynamic control of the bottom blowing flow is realized, thus reducing the carbon oxygen product at the blowing end point and improving the metallurgical effect of the bottom blowing as well as the quality of the molten steel.

Owner:山东钢铁集团有限公司

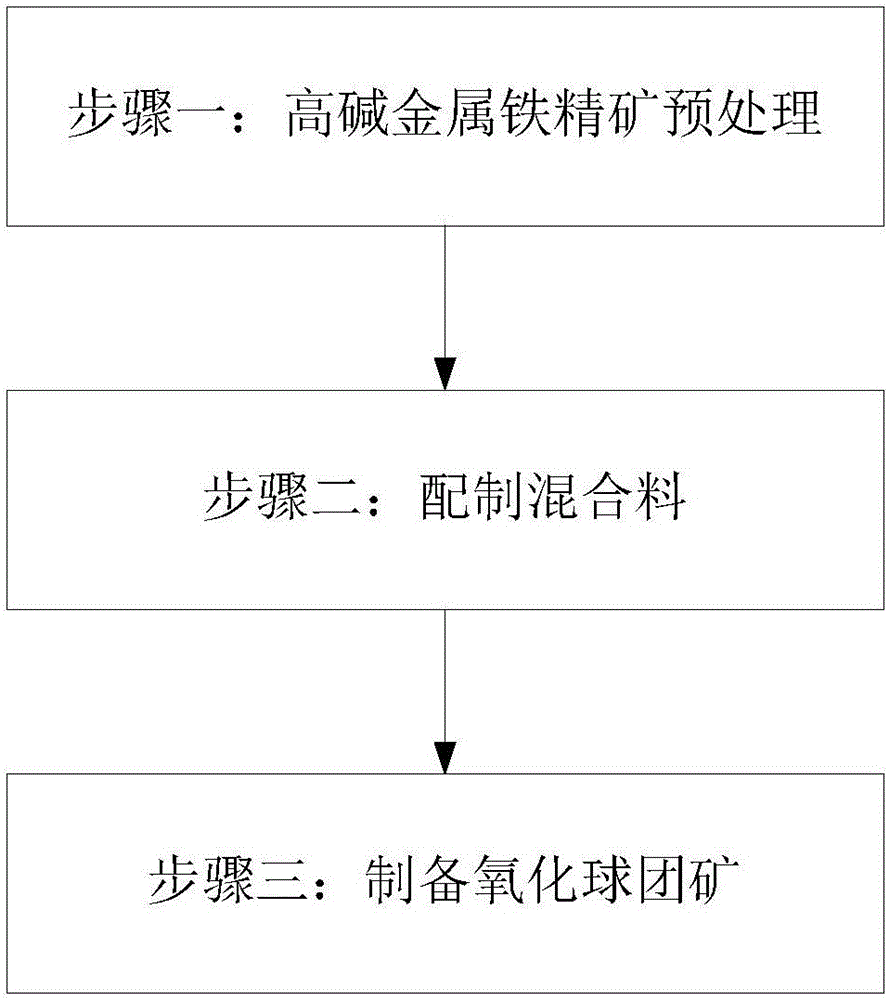

Production method of oxide pellets

The invention discloses a production method of oxide pellets. The production method comprises the following steps that firstly, high alkali metal iron ore concentrate pretreatment is conducted, specifically, high alkali metal iron ore concentrate is subjected to high pressure roller grinding pretreatment; secondly, a mixture is prepared, specifically, a high alkali metal iron ore concentrate pretreated material obtained in the first step and a low alkali metal iron ore concentrate are mixed into mixed concentrate, then bentonite and a magnesium addition agent are added into the mixed concentrate, and a mixture is obtained; and thirdly, the oxide pellets are prepared, specifically, the mixture obtained in the step two is subjected to water adding pelletizing through a pelletizing device, and green pellets are subjected to drying, preheating and roasting to obtain the finished oxide pellets. The oxide pellets produced through the provided method is low in expansion rate, good in metallurgical performance, and the finished pellet performance can meet the requirement of production of blast furnace with the particle size being 3000 or more.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

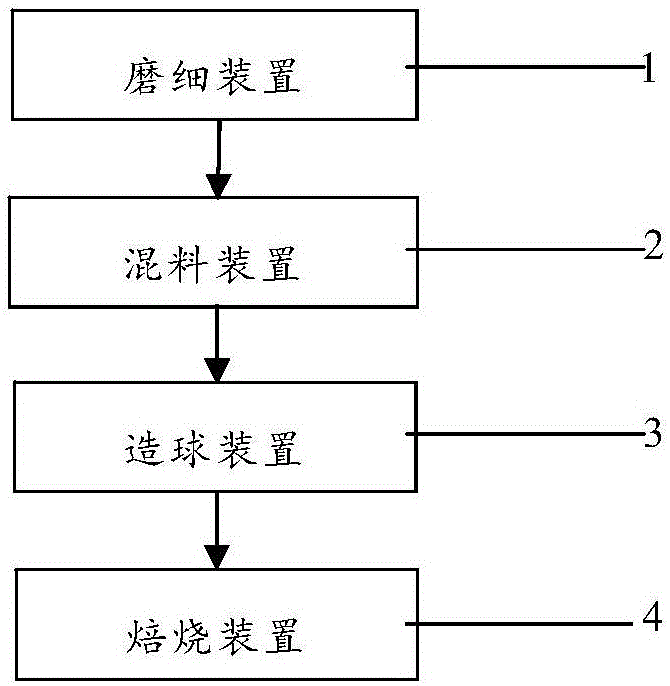

Method and system for reducing reduction degradation of vanadium-titanium magnet pellets

The invention discloses a method and system for reducing reduction degradation of vanadium-titanium magnet pellets. The method for reducing reduction degradation of the vanadium-titanium magnet pellets includes the following steps that firstly, vanadium-titanium magnetite is ground to be fine, and vanadium-titanium magnetite powder is obtained; secondly, the vanadium-titanium magnetite powder is mixed with bentonite, and a mixture is obtained; thirdly, the mixture is pelletized, and green pellets are obtained, wherein a boric acid water solution is added in the pelletizing process to serve as water for pellet pelletizing; and fourthly, the green pellets are roasted, and the vanadium-titanium magnet pellets are obtained. The invention further discloses a system implementing the method, and the system includes a fine grinding device, a material mixing device, a pelletizing device and a roasting device. According to the method and the device, in the pelletizing process, the boric acid water solution is evenly sprayed into the green pellets, the reduction degradation rate of the vanadium-titanium magnet pellets is effectively reduced, and the metallurgical performance in the pellet smelting reduction process is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

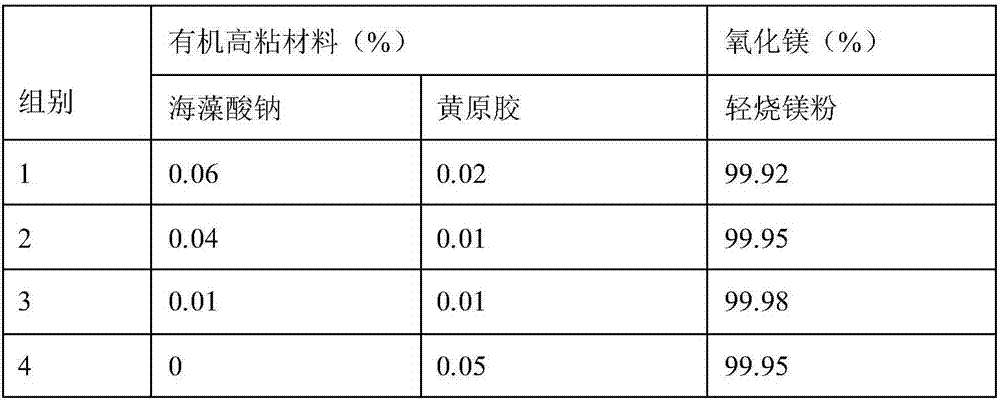

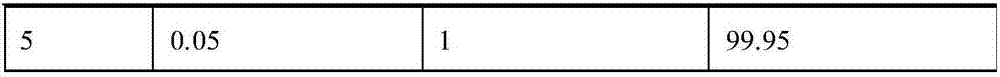

Magnesium-based pellet ore organic binding agent and preparation and using method thereof

The purpose of the present invention is to solve the defects of the pellet binder in the prior art and the problem that the sinter is affected by MgO, and provide a magnesium-based pellet organic binder and its preparation and use methods, which belong to the metallurgical Technical field of binder for sintering. The binder is composed of 0.02%-0.08% of organic high-viscosity material and 99.92-99.98% of magnesium oxide powder. The organic high-viscosity material is one or both of sodium alginate and xanthan gum, and the magnesium oxide powder is lightly burned magnesium Powder, the particle size is less than 0.044mm. The present invention uses magnesium material instead of bentonite, which can improve the quality of pellets, increase the strength and bursting temperature of green pellets, and improve the compressive strength of finished balls and the grade of total iron; at the same time, by adding MgO to pellets, it can not only improve the quality of pellets Excellent metallurgical properties, and can also reduce the MgO content in sinter, so that the quality of sinter and pellets can be improved together.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com