Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Coarse granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual desktop system and method for refreshing on-screen display of virtual desktop client

ActiveCN102566910AImprove experienceReduce transfer volumeTransmissionInput/output processes for data processingClient-sideData transmission

The invention provides a virtual desktop system and a method for refreshing on-screen display of a virtual desktop client. The virtual desktop system comprises a server and a client, the server comprises a server processing module, a server cache, a comparer and a transmitter, and the client comprises a receiver, a client cache, a client processing module, a display and a mobile detection module. The virtual desktop system and the method for refreshing on-screen display of the virtual desktop client are evidently advantageous in terms of mobile detection process and data transmission quantity reduction, mobile description instructions of pixel points / pixel blocks are used to indicate moving of existing on-screen display data of the client, retransmitting of existing pixels in the client cache through the network can be avoided, the process of updating single pixels in partial differential areas one by one is effectively substituted, the quantity of data to be transmitted is reduced, and consumption of network bandwidth can be effectively reduced while user experience is improved by using the method in the current network environment with the bandwidth limited.

Owner:GCI SCI & TECH

Rare earth ore beneficiation method

ActiveCN103962232ACoarse granularityReduce manufacturing costWet separationRare earthSmall footprint

The invention relates to a rare earth ore beneficiation method which is characterized in that grading is carried out after ore grinding is carried out on raw ore; reselection is carried out on coarse fractions to obtain gravity concentrates and tailings; magnetic separation is carried out on fine fractions to obtain strong-magnetic separation concentrates and tailings; reselection is respectively carried out on gravity concentrates and strong-magnetic separation concentrates which are different in fraction through a table to obtain table concentrates, table middlings and table tailings; the table concentrates and the table middlings which are different in fraction are mixed, and wet-type high-gradient magnetic separation is carried out to obtain magnetic separation rare earth ore concentrates and magnetic separation middlings; the magnetic separation middlings and the table tailings are mixed, closed-loop flotation including primary rough concentration, secondary scavenging and secondary fine selection is carried out after ore regrinding is carried out, the middlings are returned in proper sequence, and flotation rare earth ore concentrates and flotation tailings are obtained. The magnetic separation rare earth ore concentrates and the flotation rare earth ore concentrates are total rare earth ore concentrates, the REO grade is higher than 65%, and the total recovery rate ranges from 80% to 87%. The rare earth ore beneficiation method is high in grading efficiency, small in occupied area, continuous in production and low in cost, full-wet dust-free operation is achieved, and industrialization is easy to achieve. The rare earth ore beneficiation method is suitable for beneficiation of light rare earth ore existing in the bastnaesite or parisite mode.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

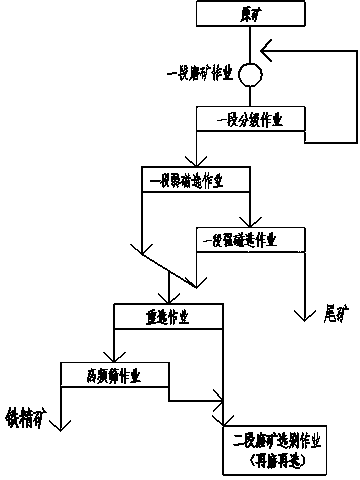

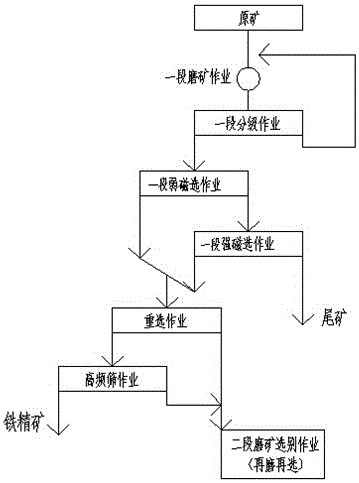

Magnetic ore rescreening process for mixed iron ore

ActiveCN104190522AReasonable workmanshipReliable technologyGrain treatmentsWet separationMonomerMaterials science

The invention discloses a magnetic ore rescreening process for mixed iron ore. The process comprises the following process steps: performing primary ore grinding, performing primary grading, performing primary low intensity magnetic separation, performing primary strong magnetic separation, rescreening, performing high frequency screening and performing secondary ore grinding and selecting. According to the invention, partial qualified iron ore concentrate and partial tailings are thrown out preferentially under the condition that the dissociation degree of useful mineral monomers is insufficient after the primary ore grinding operation, the amount of materials subjected to secondary regrinding and reselecting is reduced, and the aim of reducing the ore dressing cost is achieved.

Owner:ANHUI JINRISHENG MINING

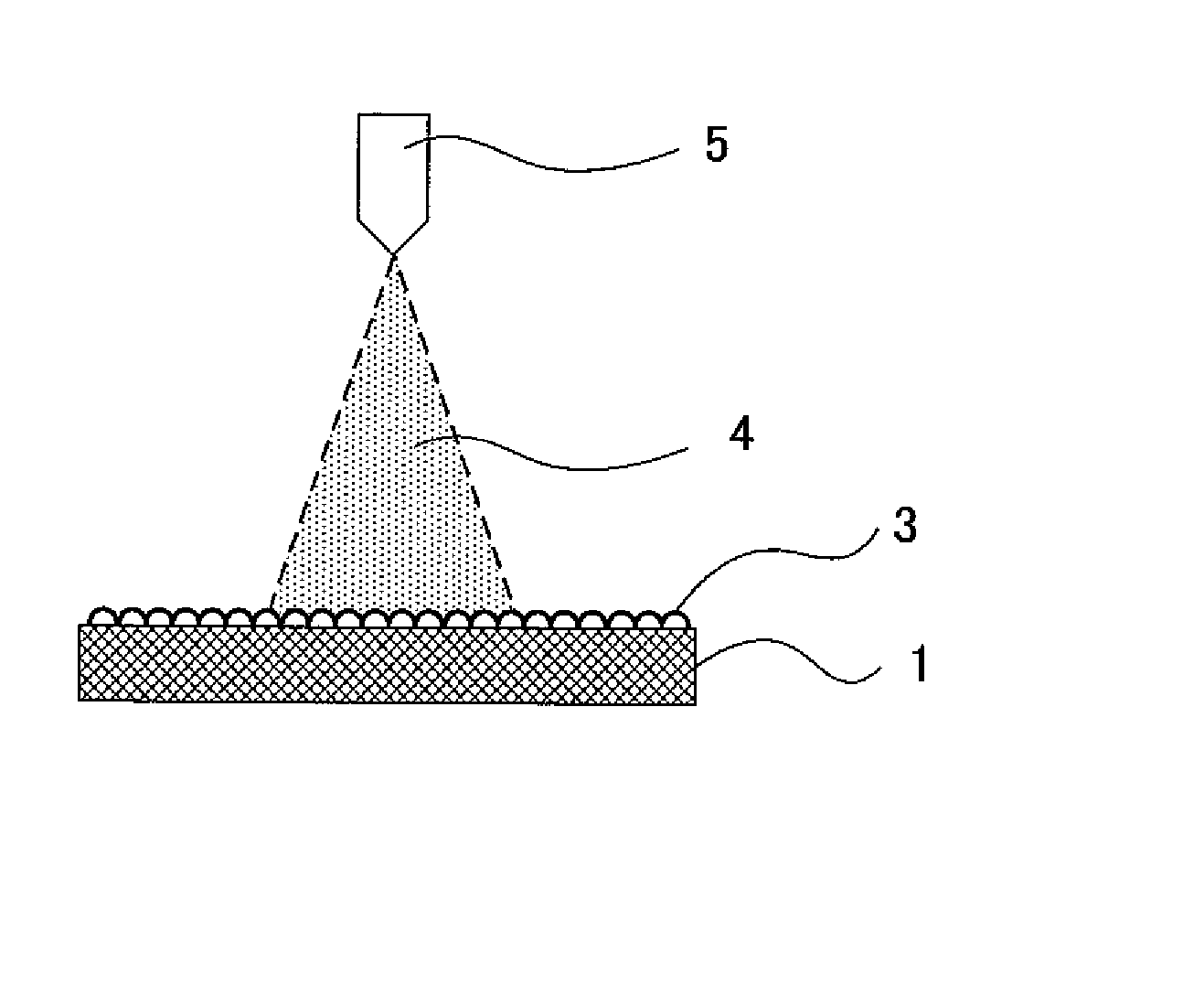

Method of Producing Metal Oxide Film

InactiveUS20080020133A1Poor propertyMaintain good propertiesFinal product manufactureSemiconductor/solid-state device manufacturingOxidizing agentMaterials science

A metal oxide film producing method which is an inexpensive wetting coating by use of a metal oxide film forming-solution, and which enables to yield an even and dense metal oxide film having a sufficient film thickness even on a substrate, such as one having complicated structural part or one comprising porous materials. The method of producing a metal oxide film, comprises: a first metal oxide film-forming step of bringing a substrate into contact with a first metal oxide film forming-solution that has a metal salt or a metal complex as a metal source and at least one of an oxidizing agent and a reducing agent dissolved, and forming a first metal oxide film on the substrate; and a second metal oxide film-forming step of heating the substrate having the first metal oxide film up to a metal oxide film forming-temperature or higher, bringing the resultant into contact with a second metal oxide film forming-solution that has a metal salt or a metal complex dissolved as a metal source, and yielding a second metal oxide film.

Owner:DAI NIPPON PRINTING CO LTD

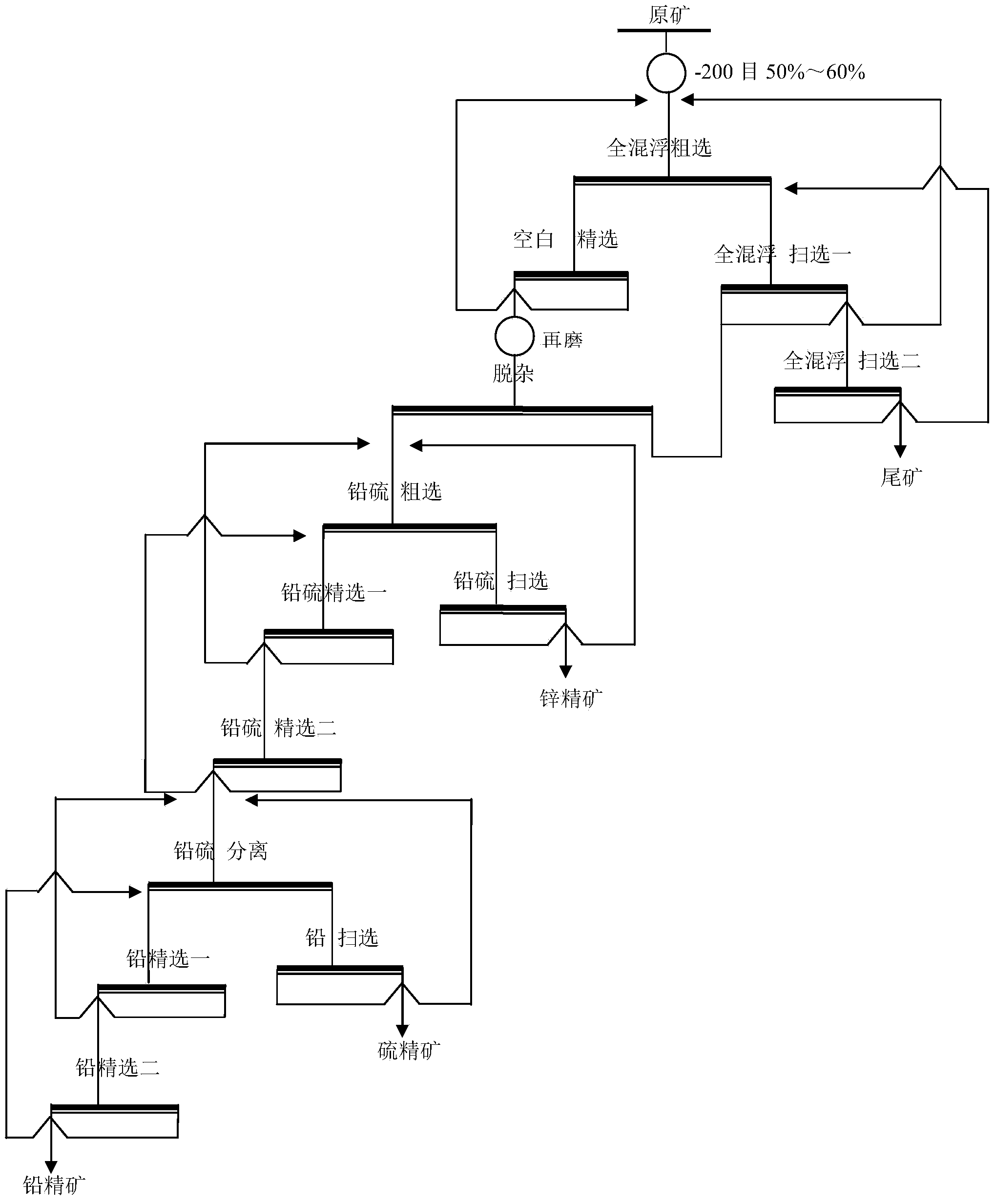

Method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation

ActiveCN104001626AReduce grinding energy consumptionImprove beneficiation efficiencyFlotationZincMaceral

The invention discloses a method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation. The method comprises the steps of firstly performing ore grinding on raw ores; then adding a combined flotation agent to perform complete-mixing rough flotation treatment on the raw ores subjected to the ore grinding; continuing to perform fine flotation on rough concentrates subjected to the rough flotation, and continuing to add the combined flotation agent to perform scavenging on tailings subjected to the rough flotation; re-grinding lead-zinc-sulfur mixed rough concentrates subjected to the fine flotation; adding the combined flotation agent into the grinded lead-zinc-sulfur mixed rough concentrates to perform impurity removal treatment, and performing scavenging on the tailings subjected to the impurity removal. On the basis of the method, lead-sulfur rough flotation, lead-sulfur fine flotation and lead-sulfur separation can be additionally performed to obtain lead concentrates, the tailings subjected to the flotation separation is subjected to lead scavenging, and finally sulfur concentrates are obtained. The method has the advantages of being simple and convenient to operate, reasonable in technological process, small in agent dosage, low in energy consumption, long in service life, good in separation effect and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

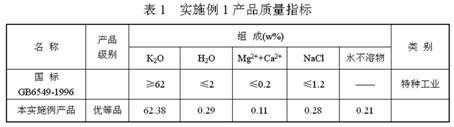

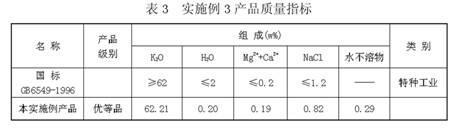

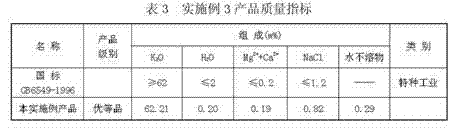

Process for extracting KCl coarse grains by carrying out flotation on solid sylvinite primary ores

The invention discloses a process for extracting KCl coarse grains by carrying out flotation on solid sylvinite primary ores, comprising the following steps; (1) crushing the solid sylvinite primary ores; (2) carrying out coarse grinding on the crushed sylvinite; (3) feeding the sylvinite material subject to coarse grinding into a flotation machine for primary rougher flotation and secondary refined flotation; and (4) filtering and drying concentrates obtained by the secondary refined flotation, thus obtaining the high-quality KCl bulky grain product. The product is purely white and transparent; the average grain size is 1mm-2mm; and the KCl grade is not less than 90% (by weight), thus exceeding the common industrial and agricultural high-class KCl product standards of class-II and class-III and reaching the special industrial KCl standard of national standard GB6549-1996I.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

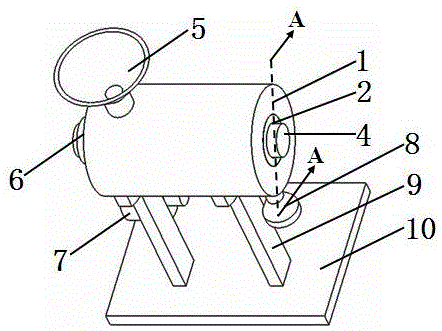

Process for mfg. ferrite rubber-plastic magnetic powder

ActiveCN1724461ACoarse granularityImprove performanceInorganic material magnetismMetallurgyFerrite powder

A process for preparing the magnetic ferrite powder used for rubber or plastic includes such steps as providing SrBa ferrite (SrO1-xBaOx) *nFe2O3 or Sr ferrite SrO*nFe2O3, proportionally mixing raw materials, grinding, adding assistant, pulverizing, granulating, sintering, pulverizing, tempering, water washing, baking, pulverizing and sieving.

Owner:江门江益磁材有限公司

Process for preparing potassium chloride by using carnallite containing calcium sulfate

The invention provides a process for preparing potassium chloride by using carnallite containing calcium sulfate. The process comprises the following steps: applying old brine in slurry mixing of calcium sulfate-containing carnallite extracted in a salt pan by using a hydraulic mining or dry mining method, adding a collecting agent used for flotation of calcium sulfate during slurry mixing and carrying out primary reverse flotation on a material obtained after slurry mixing so as to collect calcium sulfate; then adding a collecting agent used for flotation of sodium chloride into the slurry which has undergone flotation of calcium sulfate and carrying out secondary reverse flotation to collect sodium chloride; and carrying out dehalogenation on a product in a tank obtained after flotation of sodium chloride, adding water to decompose a solid phase after dehalogenation and subjecting the decomposed solid phase to condensation, filtration, washing, centrifuge dewatering and drying so as to obtain the potassium chloride product. The production process provided by the invention is simple, is convenient to operate and has strong adaptability to the raw material carnallite; the potassium chloride product prepared by using the process in the invention has the advantages of good quality, coarse granularity, uneasy caking and convenient usage.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Method for producing extra-coarse tungsten powder

The invention belongs to the technical field of powder metallurgy, in particular provides a method for producing extra-coarse tungsten powder. The method is characterized in that intermediate products, namely sodium tungstate solution and ammonium tungstate solution, produced by smelting tungsten by virtue of a wet process are taken as raw materials, the sodium tungstate solution and the ammoniumtungstate solution are mixed in certain proportion, heating, steaming, concentrating and drying are carried out to obtain a precursor, fine tungsten powder return scrap is added into the precursor incertain proportion, hydrogen reduction is carried out in a tubular furnace, then sodium ion is removed by virtue of ultrasonic washing, industrial spirit is used for dehydration after filtering is carried out, finally vacuum drying and screening are carried out to obtain extra-coarse tungsten powder, and the screened fine tungsten powder return scrap is recycled. The method provided by the invention has simple process equipment, low reduction temperature, short reduction time, high production efficiency and low cost, the extra-coarse tungsten powder with the granularity of 60-150Mum can be prepared, crystals are complete and are approximately spherical and have good formability, and purity is high.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting vanadium by stone coal and sulfuric acid wet pile oxidation conversion at normal temperature and pressure

InactiveCN101476036ACoarse particle sizeSave investment in grindingProcess efficiency improvementCoalSulfuric acid

The invention provides a method of leaching vanadium by adding sulfuric acid to stone coal, wet-stacking, oxidizing and converting under the normal temperature and pressure. The method comprses the following steps: (1) dry-grinding bone coal into bone coal powder with a diameter of 1-5mm; (2) adding sulfuric acid and water with a mass ratio of bone coal powder :sulfuric acid :water of 100:10-25:5-12, stirring uniformly, wet-stacking under the normal temperature and pressure for 3-15 days with a stacking height equal to or larger than 2m, and the sulfuric acid is industrial sulfuric acid; (3) adding water according to a solid-liquid weight ratio of 1:0.7-1.5 under the normal temperature and pressure, stirring and leaching for 30-120 minutes, adjusting the PH value to 2-3, and filtering the final solution for deslagging to obtain a blue vanadic sulfate solution.The invention has characteristics of small investment, low energy-consumption, high coefficient of metal recovery, low producing cost and small environmental pollution.

Owner:谢桂文

Method for producing roll collars by recycling tungsten carbide from waste hard alloy roll collars

InactiveCN102784918ACoarse granularitySave resourcesRecycling and recovery technologiesAlcohol contentAlloy

The invention discloses a method for producing roll collars by recycling tungsten carbide from waste hard alloy roll collars. The method includes the steps: recycling coarse-grain tungsten carbide serving as a raw material from the waste hard alloy roll collars, mixing the coarse-grain tungsten carbide with other raw materials according to a formula of the roll collars, placing the mixture into a rotary mill, adding industrial alcohol which has alcohol content more than 95.5% and account for 13.8%-15.7% of the weight of the raw materials into the mixture, milling the mixture for 22 to 24 hours, screening, drying, blending rubber, pressing, removing rubber, pressurizing 6MPa at the temperature ranging from 1410 DEG C to 1460 DEG C in a vacuum pressurizing sintering furnace for longer than 70min, and uncovering the furnace with the temperature not higher than 100 DEG C to obtain the hard alloy roll collars. The method is physical, pollution-free and low in cost, and the recycled tungsten carbide is complete in shape and unchanged in alloy property.

Owner:蓬莱市超硬复合材料有限公司

Steel slag composition for removing divalent cadmium ion and its production method and uses

InactiveCN1994916AWide pH rangeStable removalWater/sewage treatment by sorptionSlagMaterials science

Owner:SHANGHAI NORMAL UNIVERSITY

Multi-functional composite additive for intensifying direct reduction of low-grade superfine hematite

The invention relates to a multi-functional composite additive for intensifying direct reduction of low-grade superfine hematite, which consists of the following components: iron oxides, calcium carbonate and sodium humate. The multi-functional composite additive has reasonable ratio of the components, can effectively improve the strength of low-grade iron ore and pellets and reductibility of the pellets, and promotes ferrite grains to grow; a reverse floatation direct reduction-magnetic separation process can be utilized to produce directly reduced iron powder for steelmaking at one step, the steel production flow is effectively shortened, energy is saved and consumption is reduced; and the multi-functional composite additive has wide component sources and low cost, is suitable for large-scale industrial production, and is particularly applied to the low-grade superfine hematite.

Owner:CENT SOUTH UNIV

Method for manufacturing strontium ferrite rubber plastic magnetic powder with low chlorine content

InactiveCN101830693AReduce chlorine contentReduce churnInorganic material magnetismLoss rateStrontium carbonate

The invention relates to method for manufacturing strontium ferrite rubber plastic magnetic powder with low chlorine content, comprising the steps of: (1) taking 50-76% of iron ore concentrate powder, 10-30% of iron oxide red, 12-16% of strontium carbonate, 0-2% of calcium carbonate and 2-6% of strontium chloride for evenly mixing, and preparing into 7-15mm small balls; (2) presintering the small balls at 1100-1260 DEG C, carrying out heat preservation for 1-4h, cooling to the room temperature, and grinding into coarse powder of 4-8 microns; (3) adding antichlor with the weight accounting for 1-20% of the total weight of the coarse powder, grinding into power of 2-3 microns, stirring and cleaning the powder by water for 10-20min, and standing still; after the powder precipitates, removing the water at the upper layer; and finally, drying the precipitate at 180-400 DEG C, sieving at 70-80 meshes, and obtaining the strontium ferrite rubber plastic magnetic powder. The method combines dechlorination and crushing into grinding working procedure, reduces the chlorine content to 178ppm, saves the water consumption, and has the characteristics of simplifying the technique, being coarse in magnetic powder granularity, good processing performance, high magnetic property and low loss rate of magnetic powder.

Owner:MAGNETIC MATERIAL FACTORY MEIZHOU CITY GUANGDONG PROV

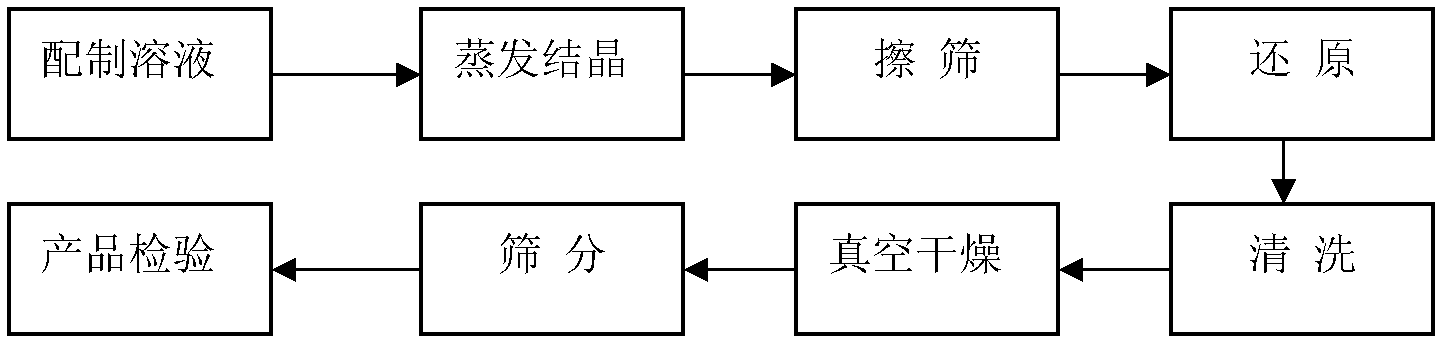

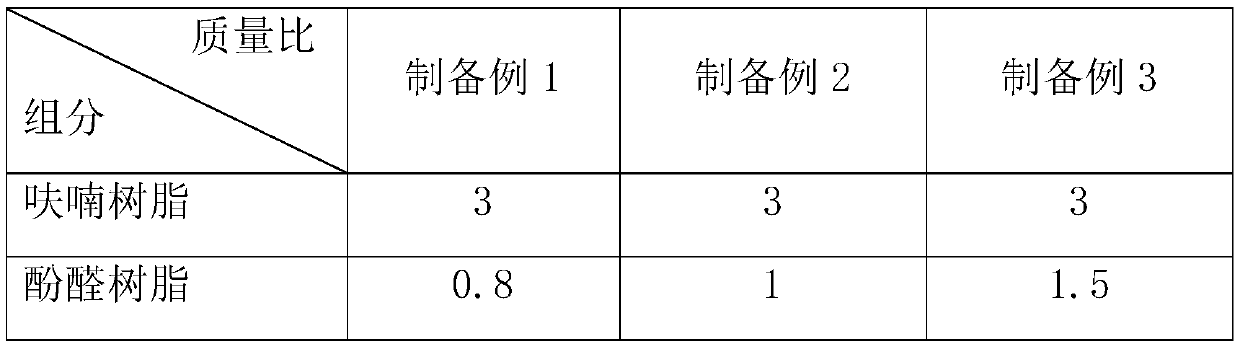

Regenerated resin sand for sand mold and preparation process thereof

InactiveCN110252939AAchieve purificationAchieve separationFoundry mouldsMould handling/dressing devicesFuranPolymer science

The invention discloses regenerated resin sand for a sand mold and a preparation process thereof. The regenerated resin sand comprises, by weight, 100-120 parts of raw sand, 80-100 parts of reclaimed sand, 3-6 parts of mixed resin and 0.5-1.5 parts of curing agents. The mixed resin comprises furan resin and phenolic resin with the mass ratio of 3: (0.8-1.5), the furan resin is low-nitrogen furfuryl alcohol resin, and the raw sand comprises round silica sand and polygonal silica sand with the mass ratio of 2:1. The preparation method of the reclaimed sand comprises the following steps of S301, crushing of old sand, S302, magnetic separation treatment, S303, roasting and purification, S304, crushing and sieving, and S305, washing and drying. The preparation process of the regenerated resin sand comprises the following steps of S601, preparing materials, S602, feeding and mixing, and S603 discharging sand. The regenerated resin sand is stable in process and capable of effectively recycling the old sand; and the sand mold prepared from the recycled resin sand has the advantages of being high in stability and capable of effectively inhibiting the occurrence of gas pores, sand holes and cracks.

Owner:启东宇杰雕塑有限公司

Method for preparing potassium chloride by using mixed potassic salt ores

ActiveCN103708504AQuality improvementCoarse granularityAlkali metal chloridesDecompositionGranularity

The invention provides a method for preparing potassium chloride by using mixed potassic salt ores. The method comprises the following step: firstly crushing the mixed potassic salt ores; then adding the mixed potassic salt ores into a decomposition crystallizer; adding fresh water and circulating saturated E-point liquid into the decomposition crystallizer at the same time, wherein the adding amount of the fresh water is 105%-120% of a theoretical calculating value and the adding amount of the circulating saturated liquid is 2.5-8 times as much as that the adding amount of raw ores; infiltrating a bottom flow of the decomposition crystallizer into grading work to be graded; carrying out ore grinding on a rough grain part and then carrying out flotation; directly carrying out the flotation on a fine grain part; in the flotation process, using the two parts to independently carry out the flotation; carrying out the flotation to obtain concentrate ores, and filtering, washing, dehydrating and drying to obtain a potassium chloride product. The product is good in quality, rough in granularity and relative low in processing cost; the adaptability to the raw ores is very strong; the potassium chloride product produced by the method can be used as an industrial product and can also be used as a farm-oriented potassium fertilizer, so that the application range of the product is widened; the potassium chloride product is rough in granularity and is easy to filter, centrifuge and dehydrate; when the potassium chloride product is dried, the energy consumption is low, so that the production cost of enterprises is reduced.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

A magnetic gravity screening process for mixed iron ore

ActiveCN104190522BReasonable workmanshipReliable technologyGrain treatmentsWet separationMaceralMaterials science

The invention discloses a magnetic ore rescreening process for mixed iron ore. The process comprises the following process steps: performing primary ore grinding, performing primary grading, performing primary low intensity magnetic separation, performing primary strong magnetic separation, rescreening, performing high frequency screening and performing secondary ore grinding and selecting. According to the invention, partial qualified iron ore concentrate and partial tailings are thrown out preferentially under the condition that the dissociation degree of useful mineral monomers is insufficient after the primary ore grinding operation, the amount of materials subjected to secondary regrinding and reselecting is reduced, and the aim of reducing the ore dressing cost is achieved.

Owner:ANHUI JINRISHENG MINING

Preparation method for tungsten copper nickel alloy powder

The invention discloses a preparation method for tungsten copper nickel alloy powder. Atomized copper powder and crystalline tungsten powder are selected and used as raw materials; carbonyl nickel powder is added to the atomized copper powder and the crystalline tungsten powder; mixed materials are put into a steel belt reduction furnace; high-temperature diffusion treatment is carried out at shielding gas or reducible atmosphere; alloy connection of the atomized copper powder and the crystalline tungsten powder is achieved through the diffusion of the carbonyl nickel powder in the atomized copper powder and the crystalline tungsten powder; the tungsten copper nickel alloy powder is obtained through crushing and screening of a crusher after the alloy connection. According to the preparation method for the tungsten copper nickel alloy powder, the prepared tungsten copper nickel alloy powder is even in composition, high in density, good in flowing property and easy to form; the problem of liable segregation in a traditional preparation method is solved; in addition, the preparation technology is simple and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

A kind of preparation method of tungsten-copper-cobalt alloy powder

The invention discloses a preparation method of tungsten-copper-cobalt alloy powder. The invention selects atomized copper powder and crystalline tungsten powder as raw materials, adds carbonyl cobalt powder into the atomized copper powder and crystalline tungsten powder, and places them in a steel strip reduction furnace. In the process, high-temperature diffusion treatment is carried out under protective gas or reducing atmosphere, through the diffusion of cobalt carbonyl powder in atomized copper powder and crystalline tungsten powder, the atomized copper powder and crystalline tungsten powder are connected by alloy, and then crushed by a crusher Sieve to obtain tungsten-copper-cobalt alloy powder. The tungsten-copper-cobalt alloy powder prepared by the preparation method of the present invention has uniform composition, high density, excellent fluidity and is easy to form, solves the problem of easy segregation in the traditional preparation method, and has a simple preparation process and is easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

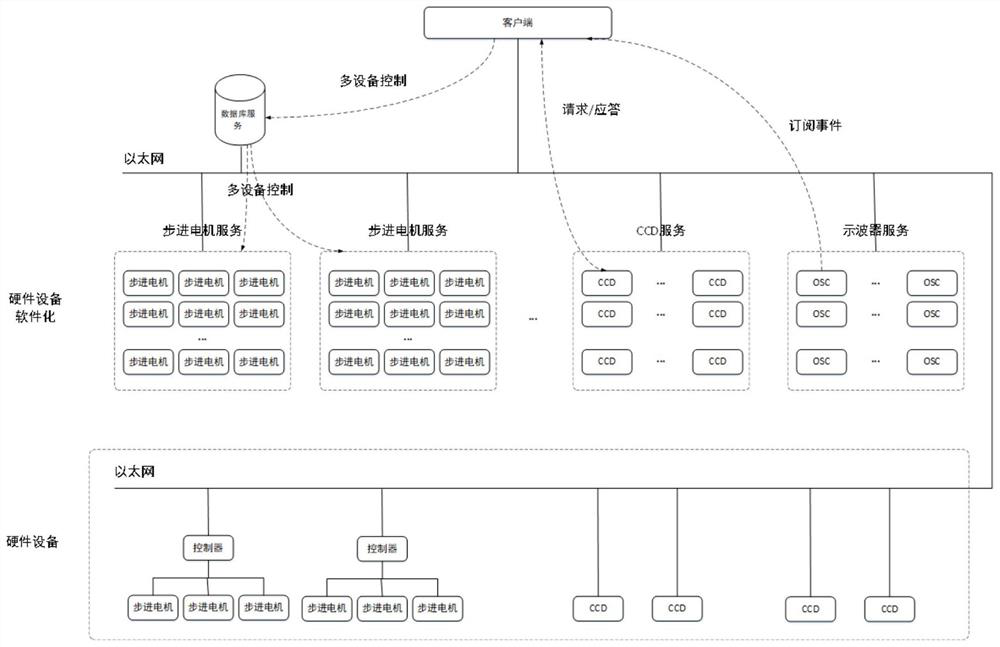

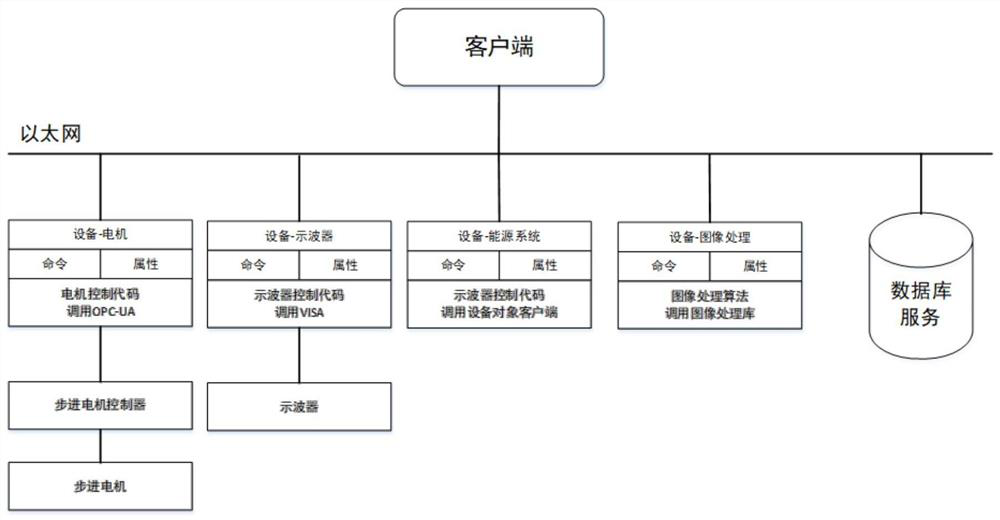

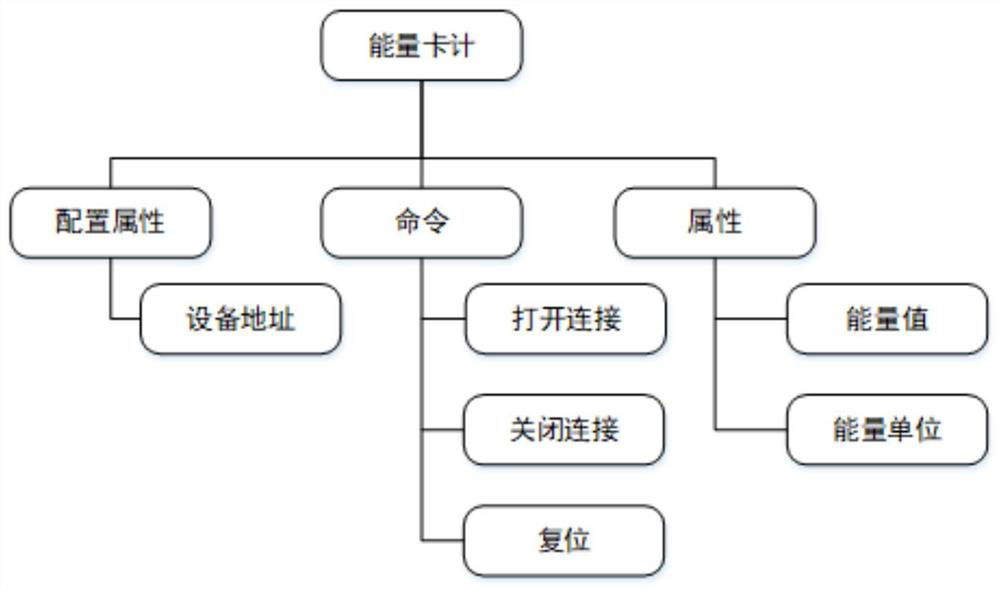

Large-scale heterogeneous equipment integrated control method based on message middleware

ActiveCN111651332AFast integrationMeet the needs of fast controlElectric testing/monitoringHardware monitoringControl systemDatabase services

The invention discloses a large-scale heterogeneous equipment integrated control method based on message middleware. The method comprises the following steps of: abstracting all controlled objects inlarge-scale heterogeneous equipment into an equipment consistency access model which is provided with a uniform interface and is irrelevant in position; configuring the control system adopting the access model to comprise a server for providing equipment service, a database for providing database service and a client, and achieving the command and attribute read-write functions of multiple piecesof equipment through a publish / subscribe mechanism of the message-oriented middleware. The consistency access model and the control system matching the consistency access model are arranged, so that when the method is scientifically arranged in the control system, rapid integration and group monitoring of large-scale heterogeneous equipment can be conveniently and flexibly realized, and good coupling, expandability and maintainability are achieved, so that the requirement of long-period operation of the device is met.

Owner:COMP APPL RES INST CHINA ACAD OF ENG PHYSICS

Preparation method for tungsten-copper-cobalt alloy powder

The invention discloses a preparation method for tungsten-copper-cobalt alloy powder. The preparation method comprises the following steps: selecting atomized copper powder and crystalline tungsten powder as raw materials; adding cobalt carbonyl powder into the atomized copper powder and the crystalline tungsten powder to obtain a mixture; putting the mixture into a steel belt reducing furnace to carry out high-temperature diffusion treatment under protective gas or a reducing atmosphere; diffusing the cobalt carbonyl powder in the atomized copper powder and the crystalline tungsten powder, thereby realizing alloy connection between the atomized copper powder and the crystalline tungsten powder; and crushing and screening the mixture by a crusher to obtain the tungsten-copper-cobalt alloy powder. The tungsten-copper-cobalt alloy powder prepared by the preparation method disclosed by the invention is uniform in component, high in compactness, excellent in flowing property and easy to form; the liable segregation problem in a conventional preparation method is solved; and the preparation method is simple and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

Process for extracting KCl coarse grains by carrying out flotation on solid sylvinite primary ores

The invention discloses a process for extracting KCl coarse grains by carrying out flotation on solid sylvinite primary ores, comprising the following steps; (1) crushing the solid sylvinite primary ores; (2) carrying out coarse grinding on the crushed sylvinite; (3) feeding the sylvinite material subject to coarse grinding into a flotation machine for primary rougher flotation and secondary refined flotation; and (4) filtering and drying concentrates obtained by the secondary refined flotation, thus obtaining the high-quality KCl bulky grain product. The product is purely white and transparent; the average grain size is 1mm-2mm; and the KCl grade is not less than 90% (by weight), thus exceeding the common industrial and agricultural high-class KCl product standards of class-II and class-III and reaching the special industrial KCl standard of national standard GB6549-1996I.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

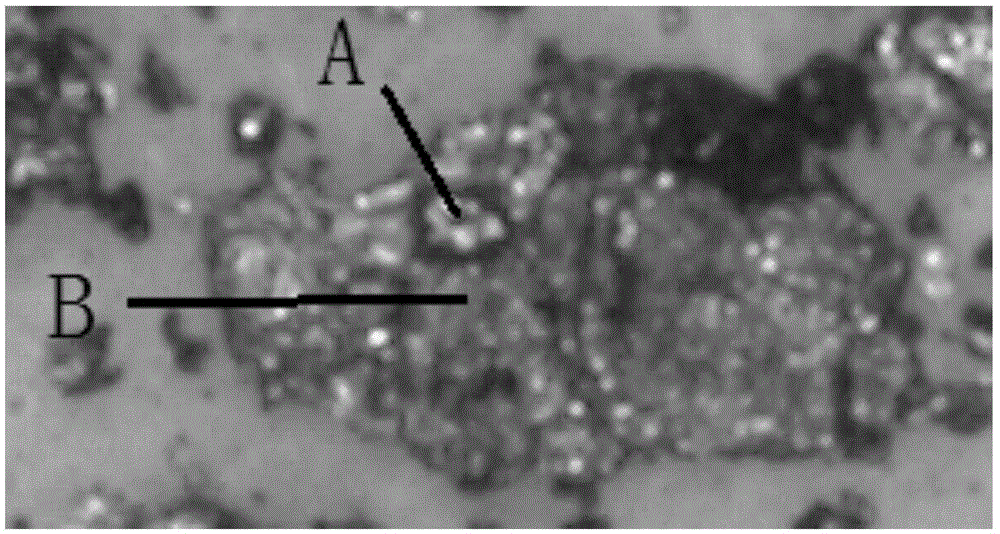

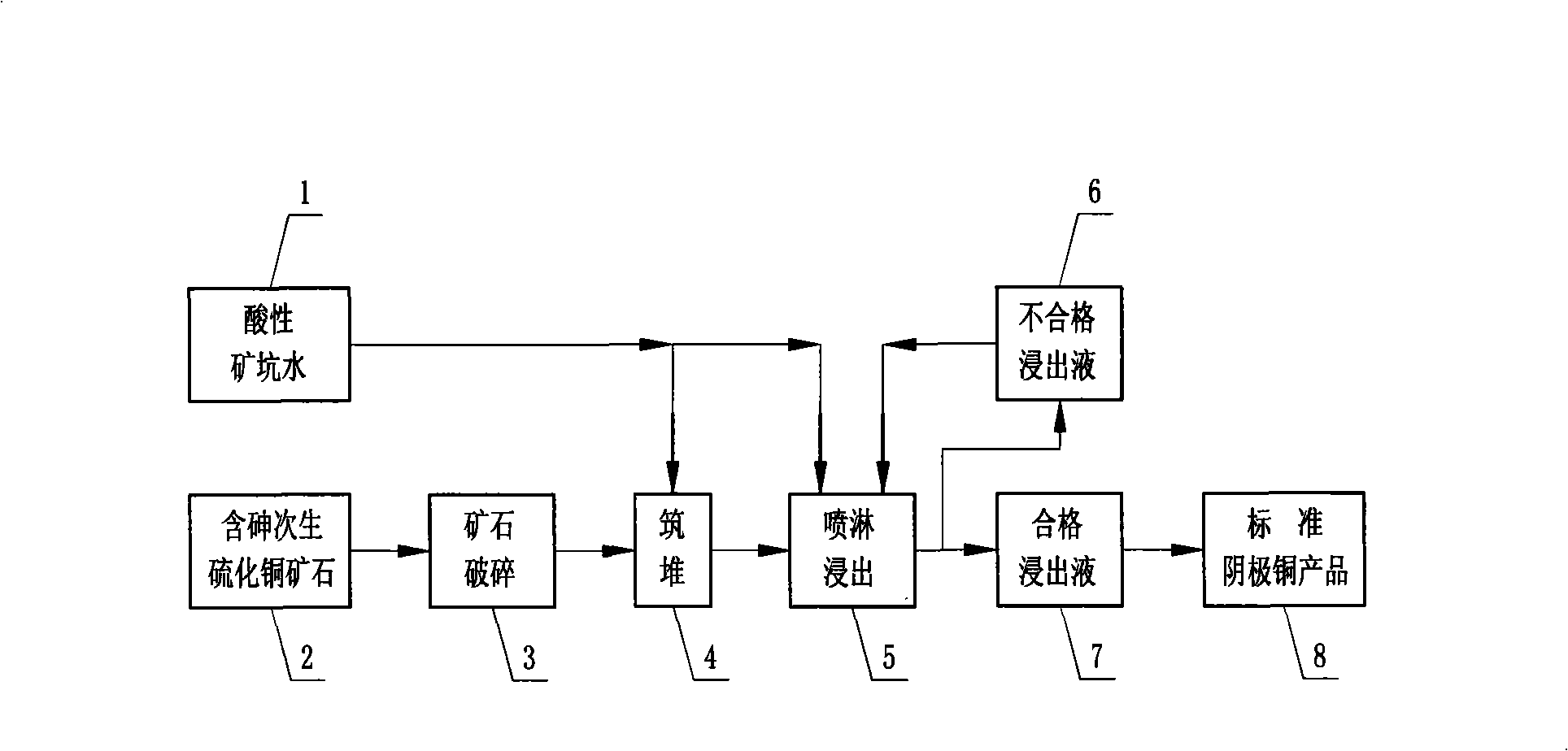

Earth's surface biological dump leaching process for secondary copper sulfide ore with higher arsenic content

InactiveCN101403037AConvenient sourceSimple and fast energy consumptionProcess efficiency improvementThiobacillus ferrooxidansDump leaching

The invention discloses a dump leaching technique of ground organism of secondary copper sulphide ore with high content of arsenic. The technique comprises the following steps: the secondary copper sulphide ore with high content of arsenic is crushed to 10 to 30mm, and acid mine water of mineral-leaching microorganism with thiobacillus ferrooxidans and thiobacillus thiooxidans is used for leaching the secondary copper sulphide ore with high content of arsenic; while most of the arsenic in the ore is still in leaching residue and a small part of the arsenic is in the leachate, faffinated and electrodeposition liquid; but closed cycle in the production has no effect on the extraction and electrodeposition and standard cathode copper product, thus avoiding the hazard of the arsenic to the environment. The technique has short process, little investment, low cost and energy consumption, no pollution and high rate of recovery, can process the copper ore with high content of arsenic which can not be processed by the traditional smelting technique, and also can process the secondary copper sulphide ore with high content of arsenic and similar secondary copper sulphide ore with high content of arsenic so as to expand the utilization range of resources.

Owner:CHINA NERIN ENG

Modified iron tailing sand, preparation and application of sand

PendingCN109663563AWide variety of sourcesLow priceOther chemical processesWater contaminantsAntibiotic freePhysical chemistry

The invention discloses modified iron tailing sand which is prepared by mixing and then modifying raw materials including, by weight, 2-5 parts of antibiotic mushroom dregs or biogas residues and 3-8parts of iron tailing sand. The modified iron tailing sand is stable in adsorption performance and less affected by pH (potential of hydrogen) values and temperature. Compared with unmodified iron tailing sand, the modified iron tailing sand has the advantages that heavy metal ion and phosphorus adsorption performance is greatly improved, and waste can be turned into wealth while antibiotic residues in the antibiotic mushroom dregs are removed. The invention further provides preparation of the modified iron tailing sand and an application of the modified iron tailing sand. In order to acquirethe modified iron tailing sand with excellent performance and high porosity and without antibiotic residues, a proper preparation process is provided. By the aid of procedures such as granulation, themodified iron tailing sand is further applicable to river sediment pollution control, and the decontamination effect of the modified iron tailing sand is further improved.

Owner:BIOLOGY INST OF HEBEI ACAD OF SCI

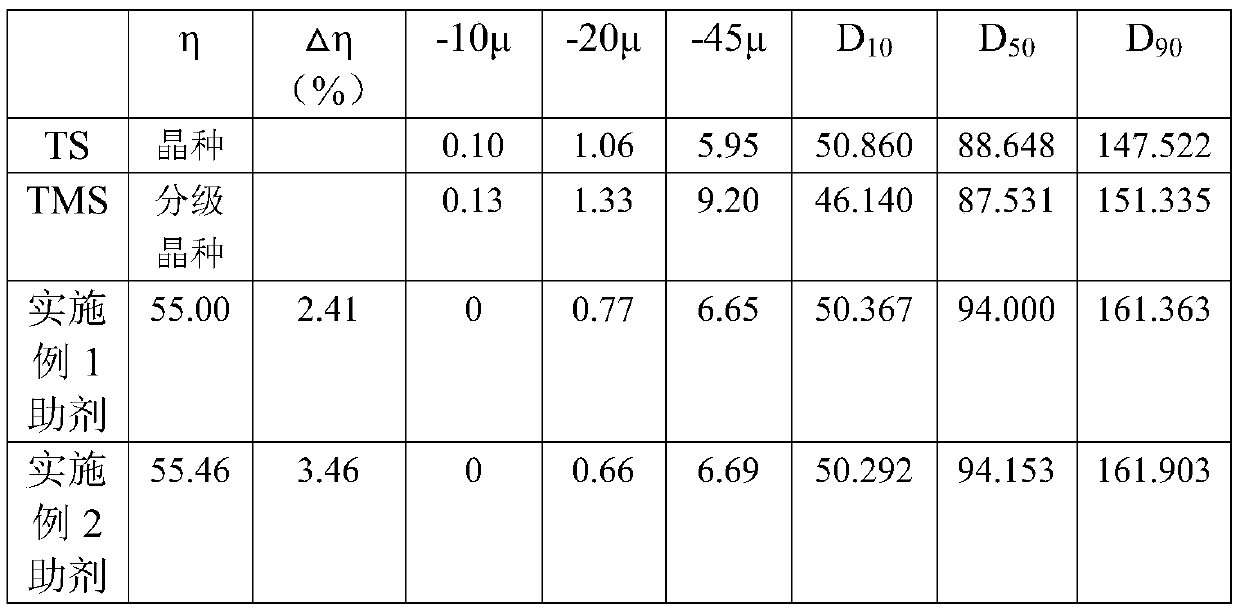

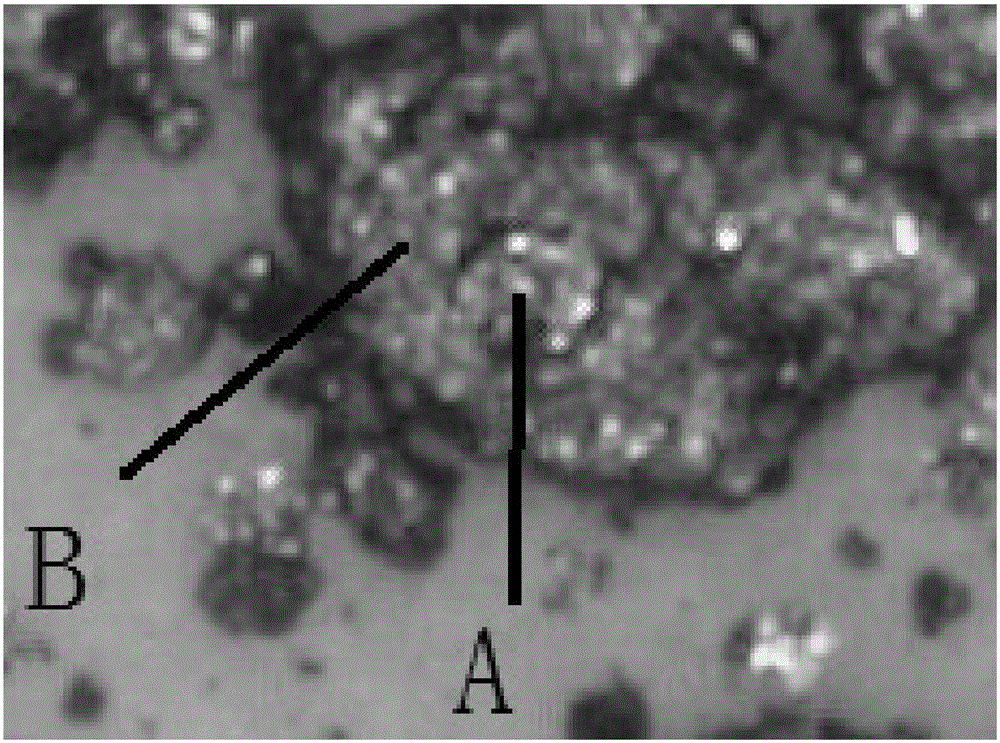

Decomposition crystallization aid for producing aluminum oxide

ActiveCN109761253AGood dispersionReduce dosageAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSolubilitySodium stearate

The invention relates to the technical field of production of aluminum oxide and specifically discloses a decomposition crystallization aid for producing aluminum oxide. The decomposition crystallization aid is composed of a component I, a component II and a component III, wherein the component I is selected from any one or several of methanol, ethanol, propanol, glycerol, polyethylene glycol, polypropylene glycol and polyvinyl alcohol; the component II is selected from any one or several of sodium stearate, sodium oleate and sodium humate; and the component III is selected from any one or several of diethanol amine, triethanolamine and polyacrylamide. The decomposition crystallization aid provided by the invention has good water solubility and alkali solubility, and is good in dispersionperformance in a sodium aluminate solution and low in usage amount. It is proved, by a test, that the decomposition crystallization aid involved in the invention is applied to decomposition of the sodium aluminate solution in production of the aluminum oxide and is capable of improving the decomposition rate of the sodium aluminate solution; the particle size of decomposed products is obviously increased; the roasted aluminum oxide is high in strength; and the problems that the particle size is increased and the decomposition rate is increased in a decomposition process of the sodium aluminatesolution can be effectively solved.

Owner:湖南绿脉环保科技股份有限公司

Preparation method of tungsten-copper-tin alloy powder

The invention discloses a preparation method of tungsten-copper-tin alloy powder. The preparation method comprises the steps that atomized copper powder and crystalline tungsten powder are taken as the raw materials; tin power is added to the atomized copper powder and the crystalline tungsten powder; the mixed powder is placed in a steel band reduction furnace, and is subjected to high temperature diffusion treatment in a shielding gas or reducing gas atmosphere; and through the diffusion of the tin power in the atomized copper powder and the crystalline tungsten powder, alloy connection between the atomized copper powder and the crystalline tungsten powder is realized; and through breaking and screening of a crusher, the tungsten-copper-tin alloy powder is obtained. The tungsten-copper-tin alloy powder prepared by preparation method is uniform in component, high in density, excellent in flowing property and easy to form; the problem that the possibility of segregation in the traditional preparation method is high is solved; and the preparation method is simple in preparation technology and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

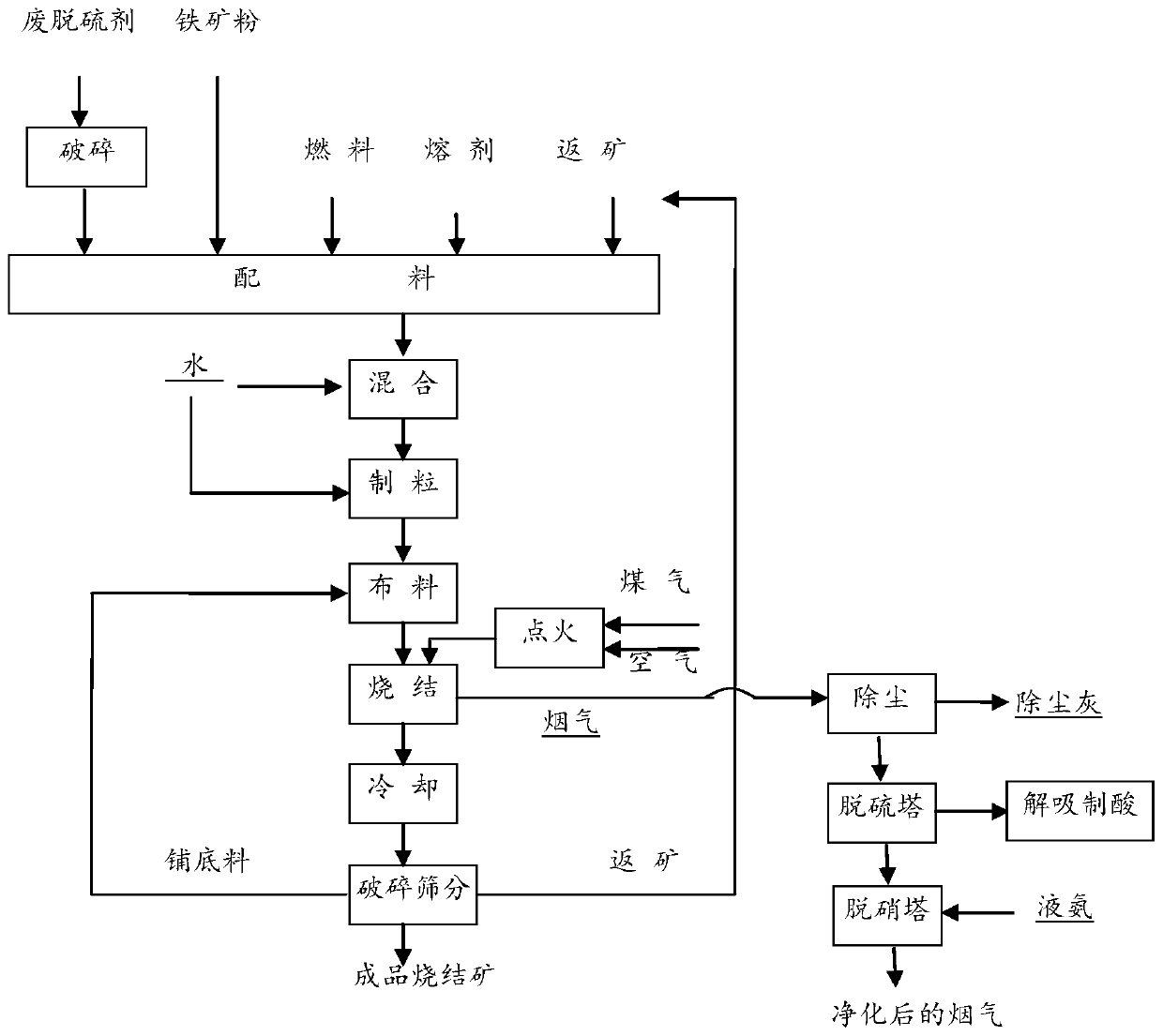

A kind of treatment method of waste desulfurization agent

ActiveCN108796215BEmission reductionReduce processing costsGas treatmentDispersed particle separationSulfurFlue gas

Owner:CENT SOUTH UNIV

Method and system for producing sandy aluminum oxide through three-section seed decomposition

The invention relates to a method for producing sandy aluminum oxide through three-section seed decomposition in a process of producing aluminum oxide with a Bayer process or in a Bayer process part of a combined process. The method for producing the sandy aluminum oxide through three-section seed decomposition comprises the steps of: mixing fine fluid with seeds; feeding into a first-section decomposition groove; discharging; performing first-stage cooling; feeding into a second-section decomposition groove; forming a necessary gravity fractionation layer in the decomposition groove by controlling proper stirring intensity; and drawing out coarse particles from the bottom of the groove and taking the coarse particles as aluminum hydroxide products; performing second-stage cooling on overflow containing fine particles at the upper part; feeding into a third-section decomposition groove; separating the underflow; performing seed filtering and washing processes; mixing the filtered seeds with the fine fluid; returning to the first-section decomposition groove; and performing an oxalate removing process on a seed washing solution after the seeds are washed. According to the method and system provided by the invention, by adoption of the three-section decomposition technology, the positions of the products to be output and the seeds are respectively arranged in the first-section and third-section decomposition grooves, so that the aims of obtaining high-quality aluminum hydroxide product, realizing high yield and flexible process control and facilitating the removal of oxalate are achieved.

Owner:中铝国际技术发展有限公司

Method for extracting vanadium by stone coal and sulfuric acid wet pile oxidation conversion at normal temperature and pressure

The invention provides a method of leaching vanadium by adding sulfuric acid to stone coal, wet-stacking, oxidizing and converting under the normal temperature and pressure. The method comprses the following steps: (1) dry-grinding bone coal into bone coal powder with a diameter of 1-5mm; (2) adding sulfuric acid and water with a mass ratio of bone coal powder :sulfuric acid :water of 100:10-25:5-12, stirring uniformly, wet-stacking under the normal temperature and pressure for 3-15 days with a stacking height equal to or larger than 2m, and the sulfuric acid is industrial sulfuric acid; (3) adding water according to a solid-liquid weight ratio of 1:0.7-1.5 under the normal temperature and pressure, stirring and leaching for 30-120 minutes, adjusting the PH value to 2-3, and filtering thefinal solution for deslagging to obtain a blue vanadic sulfate solution.The invention has characteristics of small investment, low energy-consumption, high coefficient of metal recovery, low producing cost and small environmental pollution.

Owner:谢桂文

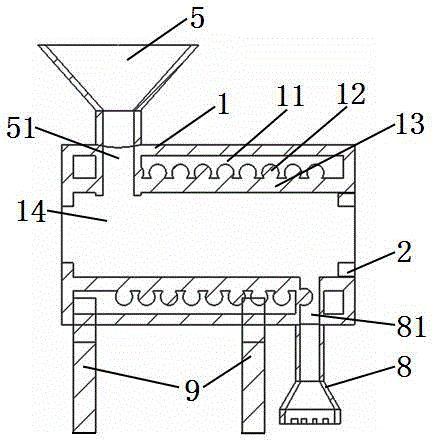

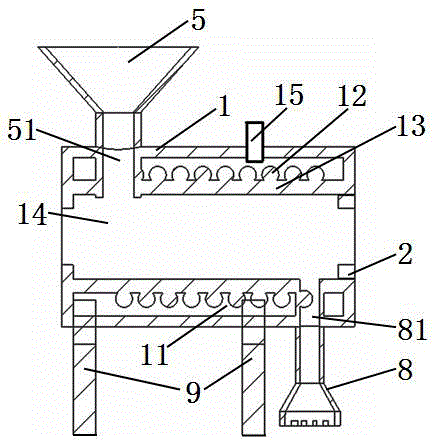

Low-stickiness food noodle maker

The invention belongs to the field of food machines and relates to a low-viscosity food noodle maker. The low-viscosity food noodle maker is characterized by comprising a shell, a front bearing seat, a rear bearing seat, a screw rod, a feeding device, a motor, a transmission device, a discharging and noodle-forming device, a bracket and a base, wherein the left end, a groove, a first screw section, a finely grinding section, a second screw section and the right end are sequentially arranged on the screw rod from left to right; the first screw section and the second screw section are same in screw pitch; or the pitch of the first screw section is greater than the pitch of the second screw section; moreover, the first screw section and the second screw section are same in screw direction; the finely grinding section is a cylindrical body; and a plurality of protruded cylindrical convex bodies are arranged on the surface of the cylinder. The low-viscosity food noodle maker has the main beneficial effects that the low-viscosity food noodle maker is simple in structure, easy to operate, small in size and relatively low in power consumption; the made noodle is smooth and good in taste, so that the low-viscosity food noodle maker is suitable for manufacturing noodles from low-viscosity and viscous materials.

Owner:内蒙古仟成生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com