Preparation method for tungsten-copper-cobalt alloy powder

A cobalt alloy and tungsten-copper technology is applied in the field of preparation of tungsten-copper-cobalt alloy powder, which can solve the problems of easy segregation, and achieve the effects of easy segregation, easy operation and easy molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

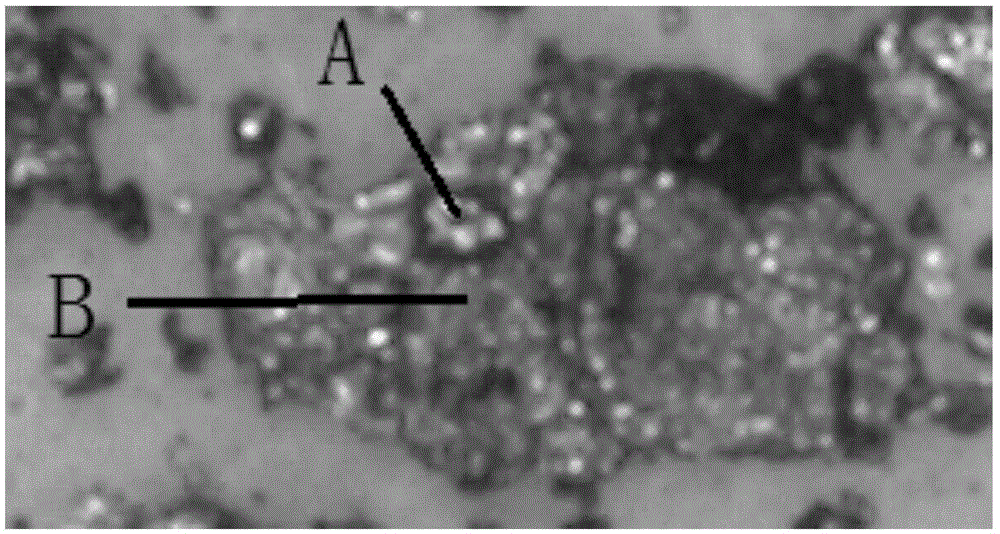

Image

Examples

Embodiment 1

[0028] 1) By weight percentage, weigh 80% crystalline tungsten powder, 16% atomized copper powder and 4% cobalt carbonyl powder, wherein, the mesh number of the crystalline tungsten powder is 400 mesh, and the mesh number of the cobalt carbonyl powder is 600 mesh, The mesh number of the atomized copper powder is 400 mesh, and the purity of the crystalline tungsten powder, carbonyl cobalt powder and atomized copper powder is greater than 99.5%;

[0029] 2) Add crystalline tungsten powder, atomized copper powder and cobalt carbonyl powder into w-20 double cone mixer and mix for 30min;

[0030] 3) Take out the material, carry out high temperature diffusion in the HYL-375-7Q steel belt reduction furnace under the protective gas or reducing atmosphere, the set temperature is 950 degrees Celsius, the diffusion time is 5h, and the cobalt powder is dissolved in copper and in copper. Diffusion in tungsten to realize alloy connection of copper and tungsten;

[0031] 4) After being rele...

Embodiment 2

[0036] 1) By weight percentage, weigh 60% crystalline tungsten powder, 37% atomized copper powder and 3% cobalt carbonyl powder, wherein, the mesh number of the crystalline tungsten powder is 500 mesh, and the mesh number of the cobalt carbonyl powder is 650 mesh, The mesh number of the atomized copper powder is 380 mesh, and the purity of the crystalline tungsten powder, carbonyl cobalt powder and atomized copper powder is greater than 99.5%;

[0037] 2) Add crystalline tungsten powder, atomized copper powder and cobalt carbonyl powder into w-20 double cone mixer and mix for 30min;

[0038] 3) Take out the material, carry out high temperature diffusion through HYL-375-7Q steel belt reduction furnace under protective gas or reducing atmosphere, set the temperature to 800 degrees Celsius, and the diffusion time is 4h, through cobalt powder in copper and in copper Diffusion in tungsten to realize alloy connection of copper and tungsten;

[0039] 4) After being released, crush a...

Embodiment 3

[0044] 1) By weight percentage, weigh 40% crystalline tungsten powder, 58% atomized copper powder and 2% cobalt carbonyl powder, wherein, the mesh number of the crystalline tungsten powder is 600 mesh, and the mesh number of the cobalt carbonyl powder is 600 mesh, The mesh number of the atomized copper powder is 400 mesh, and the purity of the crystalline tungsten powder, carbonyl cobalt powder and atomized copper powder is greater than 99.5%;

[0045] 2) Add crystalline tungsten powder, atomized copper powder and cobalt carbonyl powder into w-20 double cone mixer and mix for 30min;

[0046] 3) Take out the material, carry out high temperature diffusion in the HYL-375-7Q steel belt reduction furnace under protective gas or reducing atmosphere, set the temperature to 750 degrees Celsius, and the diffusion time is 3h, pass cobalt powder in copper and in copper Diffusion in tungsten to realize alloy connection of copper and tungsten;

[0047] 4) After being released from the fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com