Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299 results about "Cobalt carbonyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt carbonate is a precursor to cobalt carbonyl and various cobalt salts. It is a component of dietary supplements since cobalt is an essential element. It is a precursor to blue pottery glazes, famously in the case of Delftware.

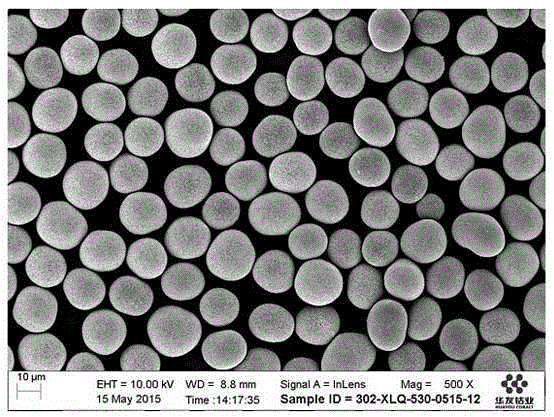

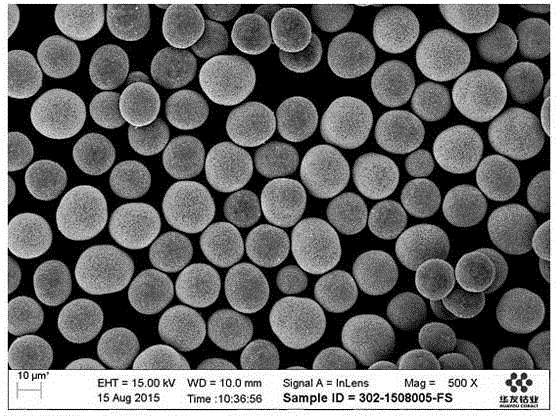

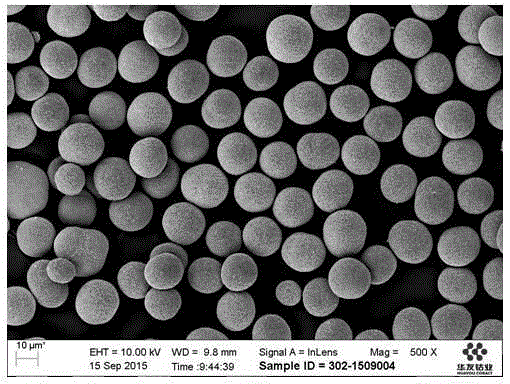

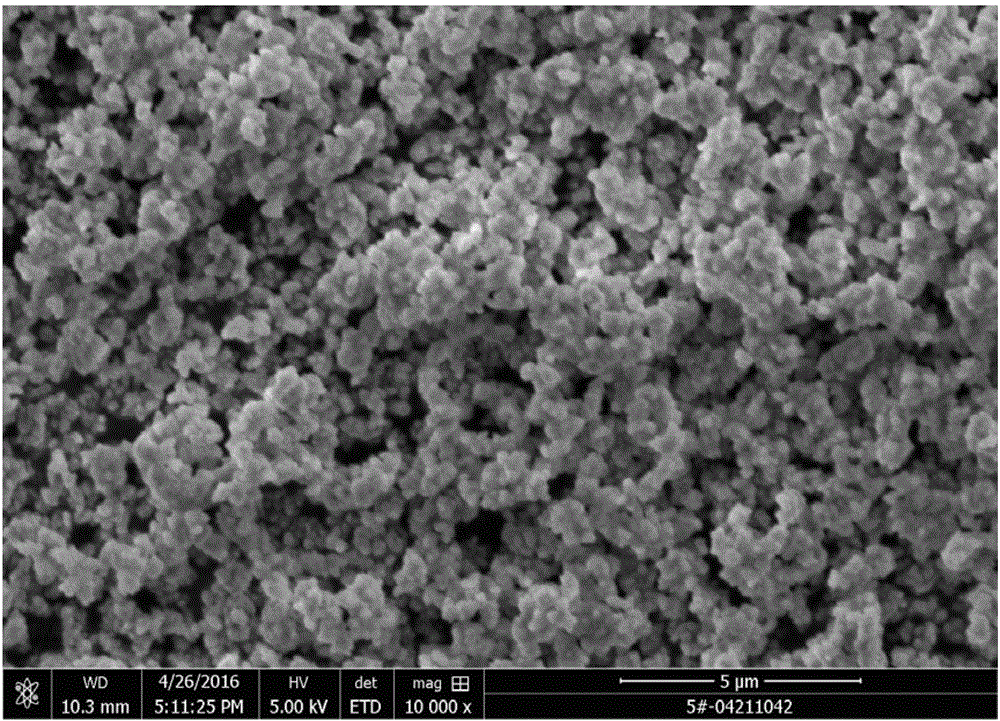

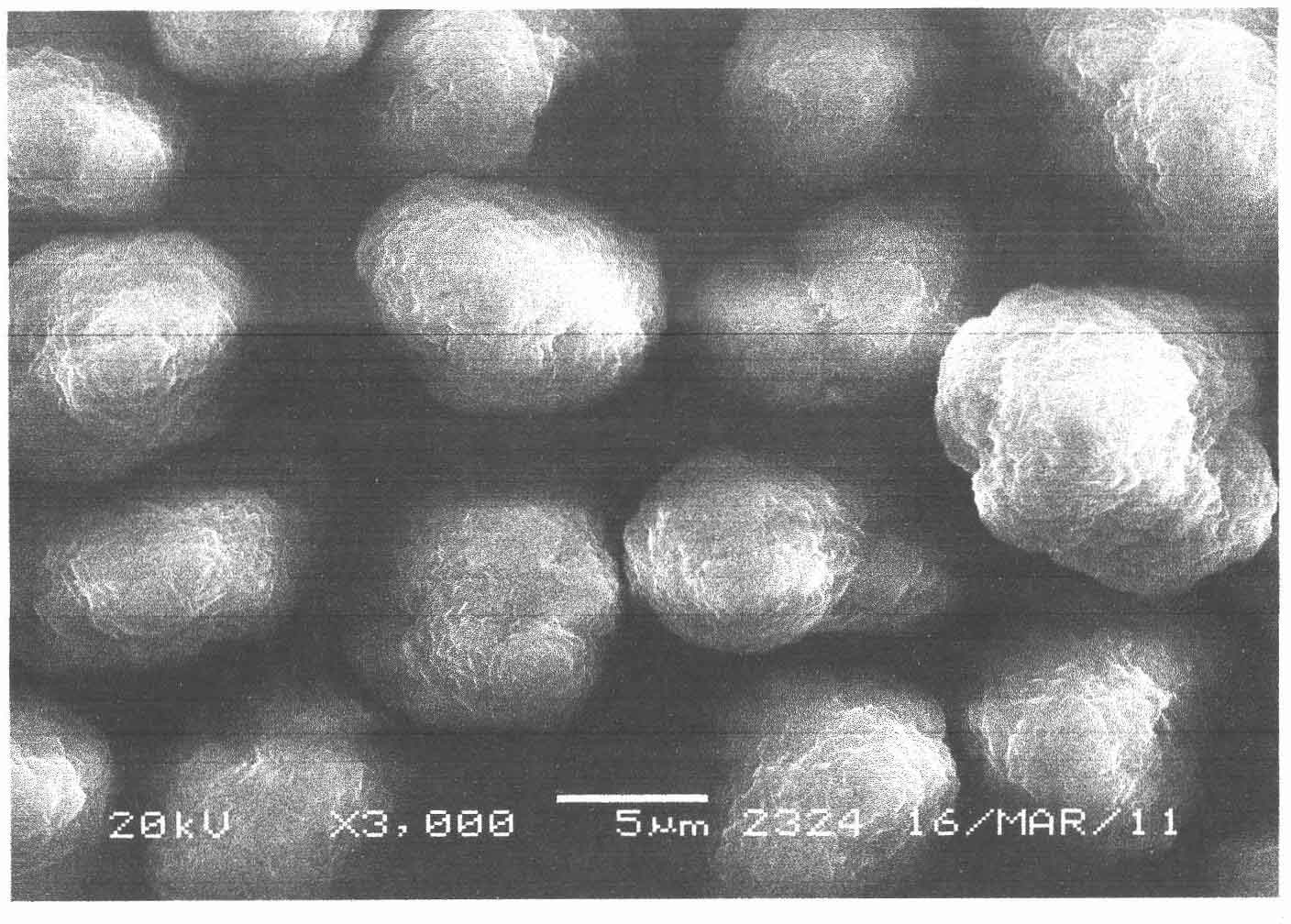

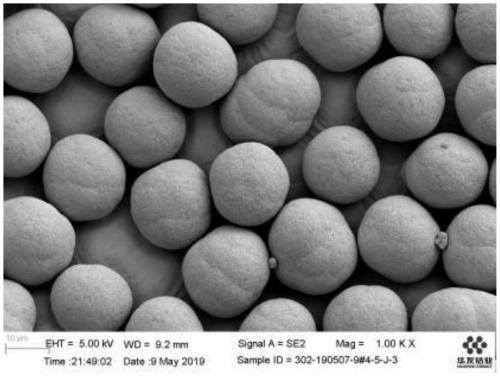

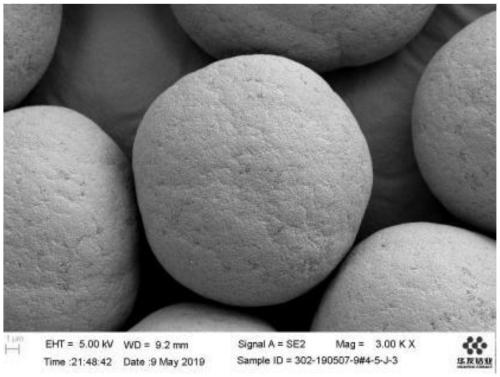

Preparation method of large-particle-size and high-density spherical cobalt oxide

The invention discloses a preparation method of large-particle-size and high-density spherical cobalt oxide. The preparation method aims at achieving the purposes that the median particle size D50 of the cobalt oxide is larger than or equal to 15 microns, particle size distribution is uniform, compacting density (TD) is larger than or equal to 2.2 g / cm<3>, and the large-particle-size and high-density spherical cobalt oxide can meet the development requirement of high-voltage lithium cobaltate. The preparation method of the cobalt oxide includes the cobalt carbonate synthesis stage and the spherical cobalt carbonate thermal decomposition stage. In the cobalt carbonate synthesis stage, a cobalt carbonate precursor prepared through many times of cyclic crystallization is compact and uniform in particle size distribution; due to the segmented thermal decomposition, cobalt carbonate is locally decomposed in the low-temperature pre-decomposing stage, a micro hole channel is formed, release of CO2 gas during subsequent decomposition is facilitated, and particles are prevented from crazing or being broken; in the high-temperature thermal decomposition stage, the particle surface is compact, and therefore the large-particle-size and high-density spherical cobalt oxide is prepared.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Superfine cobalt powder and its manufacturing technology

The present invention relates to one kind of superfine cobalt powder and its production process. The production process includes the following steps: setting cobalt carbonate or cobalt oxalate powder, grinding dispersant and hard alloy balls in certain weight proportion into high energy ball mill pot; vacuumizing the ball mill pot and introducing protective argon; sealing the ball mill pot, and ball milling at controlled rotation speed to obtain superfine cobalt carbonate or cobalt oxalate powder; and reducing the superfine cobalt carbonate or cobalt oxalate powder in hydrogen atmosphere to obtain superfine cobalt powder in oxygen content not more than 0.5 % and granularity smaller than 0.6 micron. The superfine cobalt powder is applied in producing high quality hard alloy, and has simple production process and low cost.

Owner:GEM CO LTD +1

Preparation method for lithium cobalt oxide anode material

ActiveCN103746114ALarge powder particlesEvenly distributedCell electrodesCobalt compoundsCobalt(II,III) oxideCobalt salt

A preparation method for a lithium cobalt oxide anode material relates to ananode material for lithium ion secondary batteries. The method comprises thefollowing steps: preparing a cobalt salt solution and a precipitator solution, precipitating a cobalt carbonate precursor by adopting a controlled crystallization process, and sintering cobalt carbonate to obtain cobaltosic oxide, wherein the cobalt carbonate precursor requires that the median diameter D50 ranges from 13-20 mum and the consistency is greater than or equal to 0.40 and smaller than or equal 0.50; mixing and then sintering the cobaltosic oxide, an additive and a lithium compound, milling and screening the product of sintering to obtain a lithium cobalt oxide semi-finished product; mixing thelithium compound and a coating element M, adding the mixture of the lithium compound and the coating element M and the lithium cobalt oxide semi-finished product into a ball mill for mixing, sintering the mixed materials, and milling and screening the product of sintering to obtain the lithium cobalt oxide anode material. The prepared lithium cobalt oxide product has the advantages that the size distribution of particles is uniform, and the product compaction densitycan be remarkably improved.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD +1

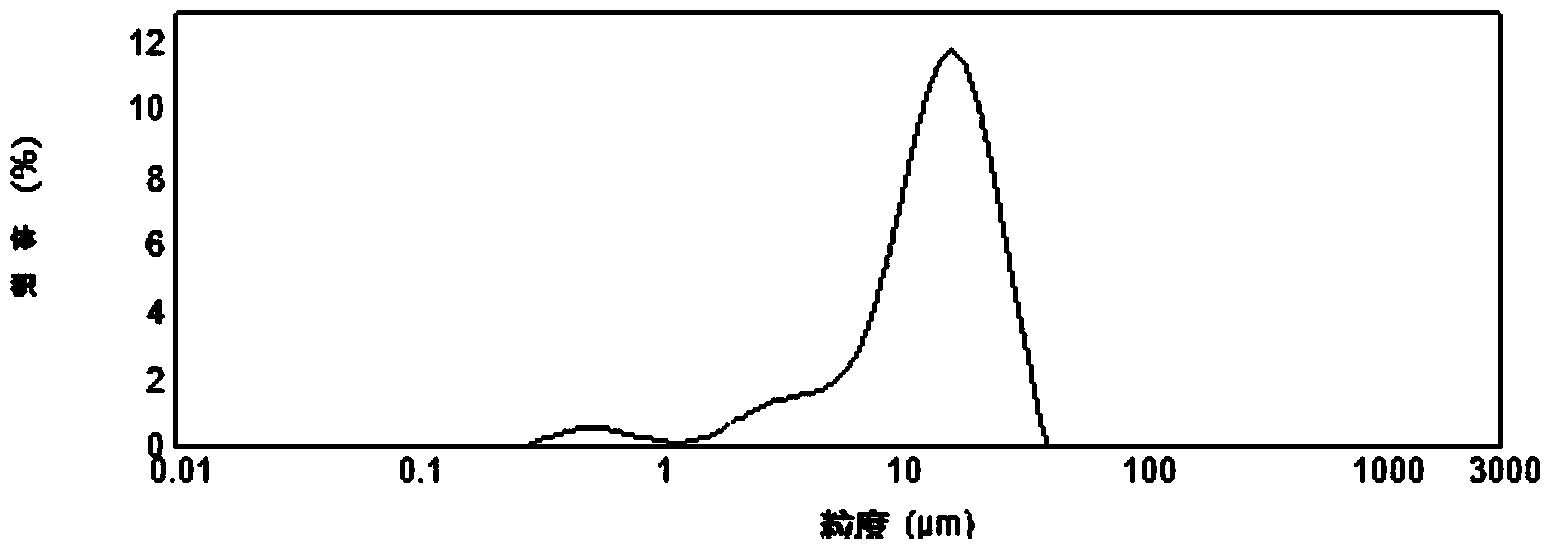

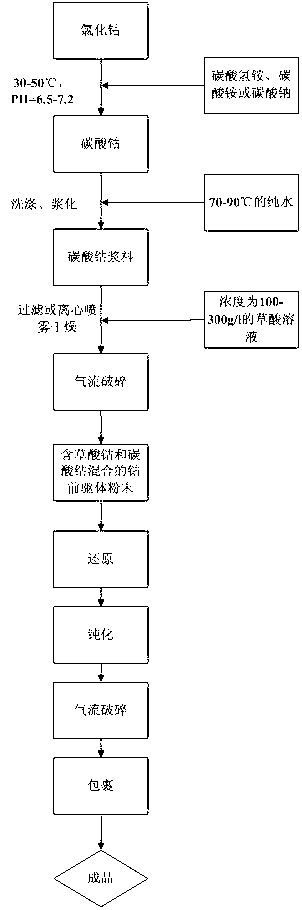

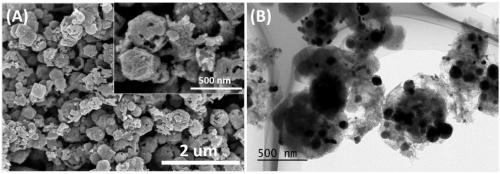

Preparation method of semi-micrometer cobalt powder

The invention provides a preparation method of semi-micrometer cobalt powder. The preparation method of the semi-micrometer cobalt powder is low in cost and simple and practical, and products by means of the preparation method are high in purity. The preparation method includes that cobalt carbonate sediments are produced through reaction of cobalt chloride and ammonium hydrogen carbonate, reaction of the cobalt carbonate sediments and oxalate solution is carried out, when the reaction is stopped, reaction products are directly crushed through drying and air flow by centrifugal spray drying equipment, and therefore precursor powder which is fine and even in particle size and sphere-like in particle shape and mixed by oxalate cobalt and cobalt carbonate. The precursor powder is reduced in a superfine powder hydrogen reduction furnace and then comes out of the furnace after reduction, and then the precursor powder is kept in nitrogen or carbon dioxide for 12-24 hours for passivating treatment. Afterwards, the precursor powder is crushed by the air flow, paraffin wax and oleic acid are added in the precursor powder, the precursor powder is packaged so as to prevent cobalt powder from oxidation, and finally superfine cobalt powder is obtained by vacuum package. The semi-micrometer cobalt powder obtained by means of the preparation method has the advantages of superfine cobalt powder and sphere-like cobalt powder, is fine in particle size, narrow in distribution, small and even in partical size and can be widely used in battery industries and hard alloy products like numerical blades, bar materials, holding-up hammers and drills.

Owner:GEM CO LTD

Zeolite y alkylation catalysts

ActiveUS20050203322A1Prolong lifeReduce inactivation rateOrganic active ingredientsMolecular sieve catalystsSulfonateAlkyl transfer

The present invention is directed to a zeolite Y catalyst having a controlled macropore structure. The present invention is also directed to a zeolite Y catalyst composite and a process for preparing the catalyst composite. The catalyst composite exhibits reduced deactivation rates during the alkylation process, thereby increasing the life of the catalyst. The present invention is also directed to processes for the preparation of carbonated, overbased aromatic sulfonates, which processes comprise alkylation, carbonation of aromatic hydrocarbons with one or more olefins.

Owner:CHEVRON ORONITE CO LLC +1

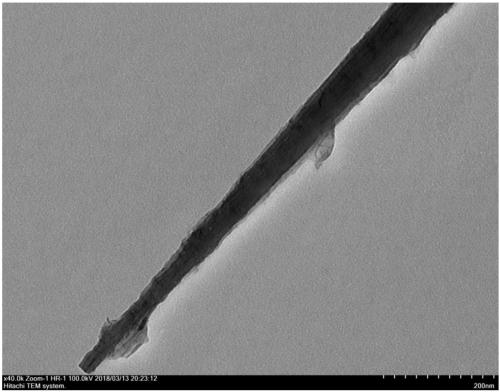

Nitrogen-doped porous carbon polyhedron@nanometer cobalt phosphide composite catalyst capable of efficiently activating persulfate and preparation method of composite catalyst

ActiveCN109603883AEfficient enrichmentEfficient degradationPhysical/chemical process catalystsWater contaminantsNanowirePorous carbon

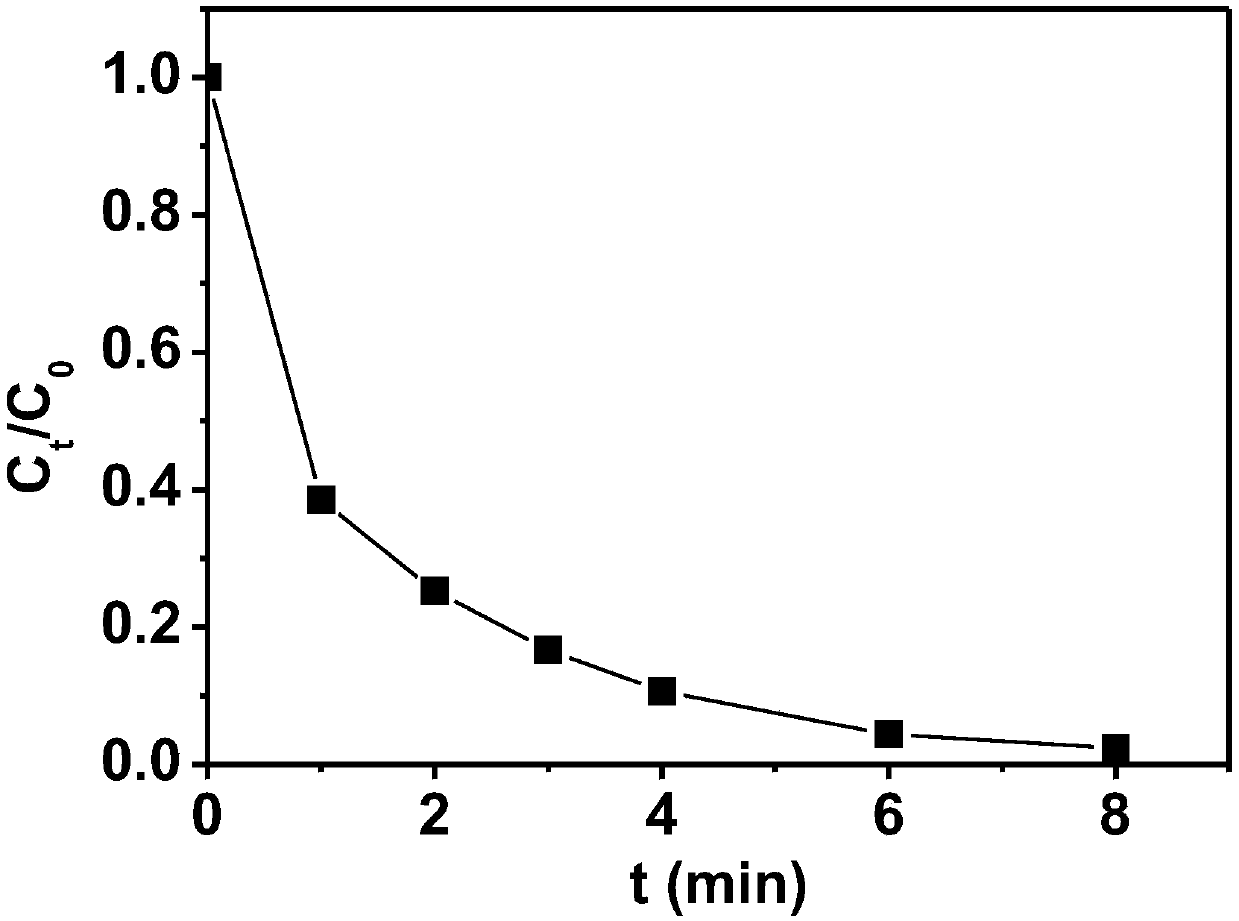

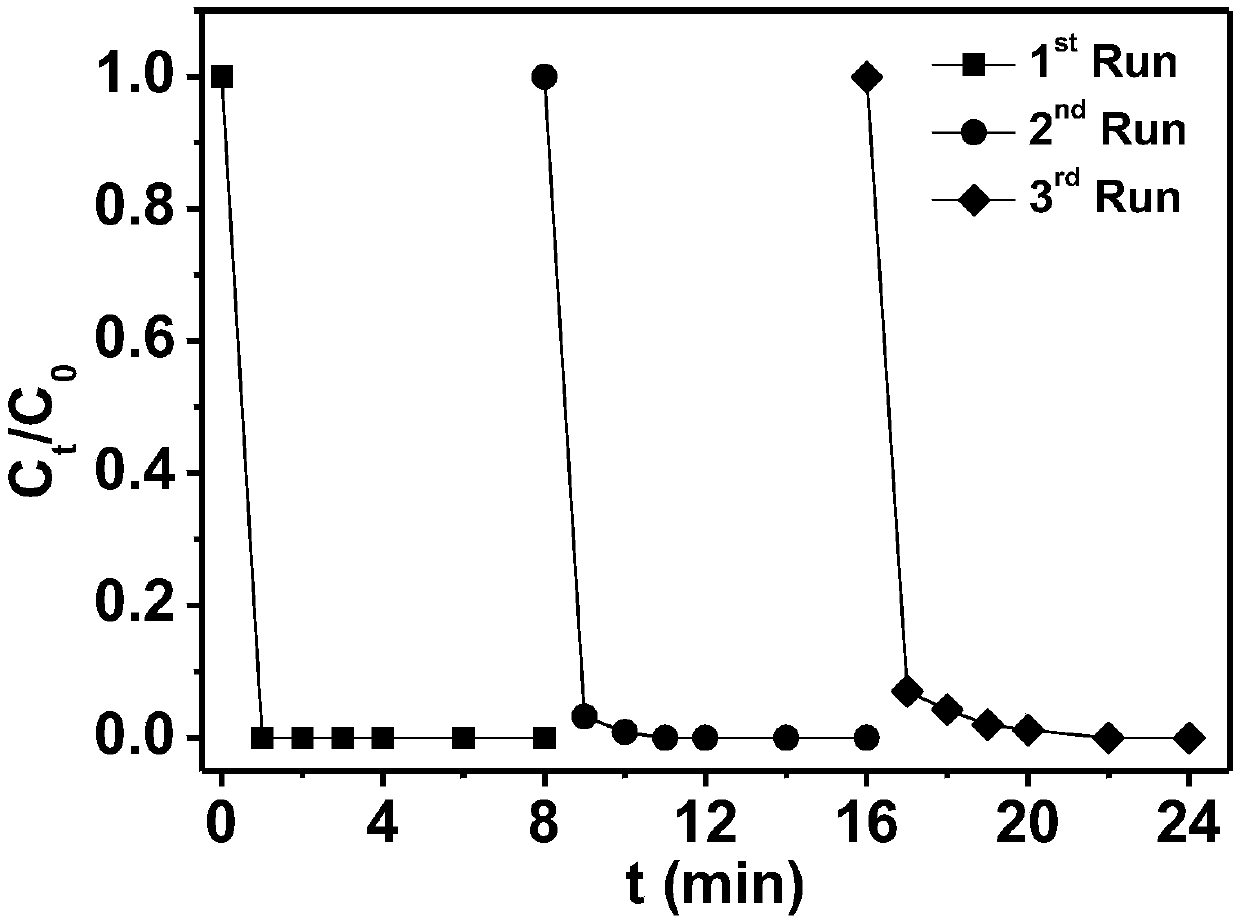

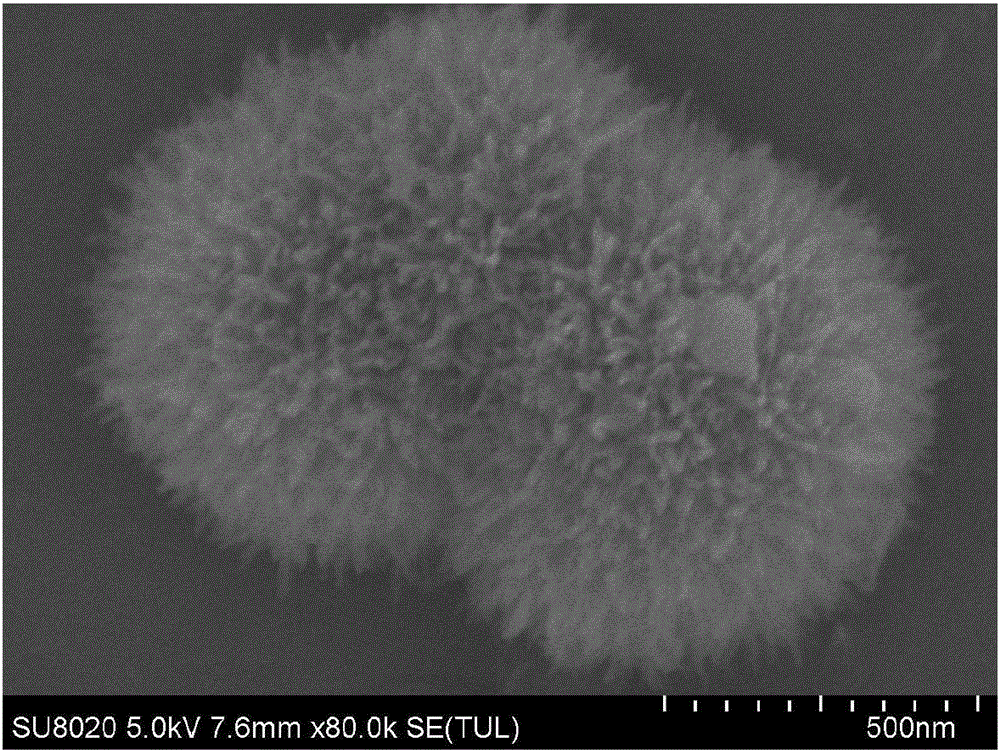

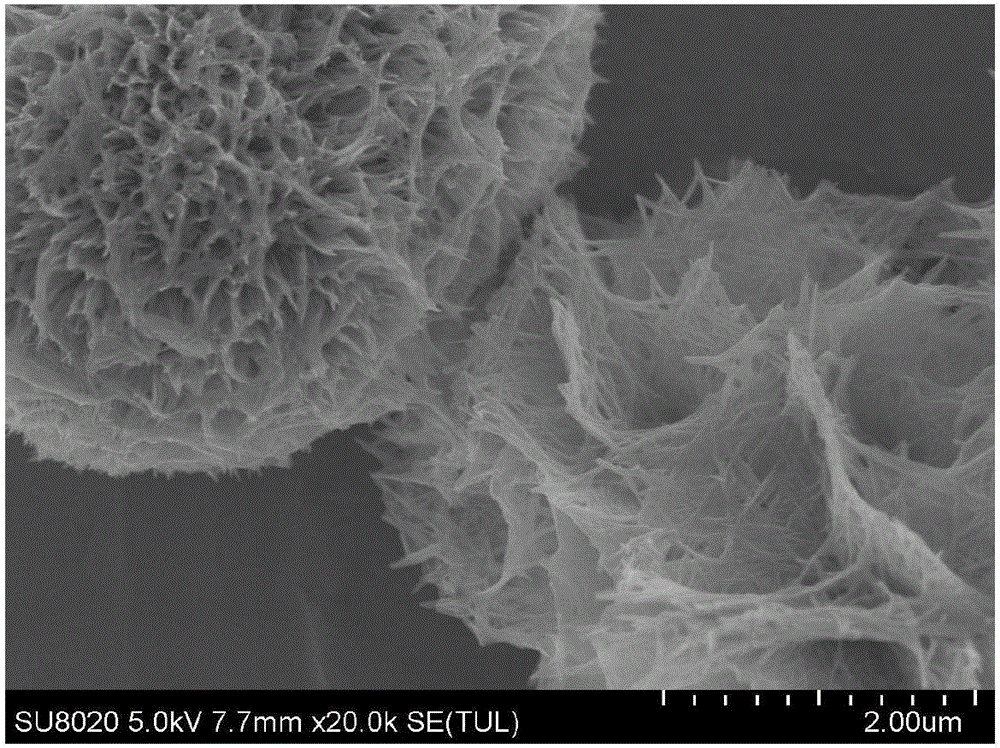

The invention belongs to the field of water pollution control, and particularly relates to a nitrogen-doped porous carbon polyhedron@nanometer cobalt phosphide composite catalyst capable of efficiently activating persulfate and a preparation method of the composite catalyst. The preparation method comprises the steps that basic cobaltous carbonate nanowires are prepared by using a hydrothermal method, the basic cobaltous carbonate nanowires are phosphorized to obtain cobalt phosphide nanowires, a metal-organic framework ZIF-8 grows around the cobalt phosphide nanowires by using a self-assemblymethod, and through high-temperature calcination, the nitrogen-doped porous carbon polyhedron@nanometer cobalt phosphide composite catalyst is obtained. Compared with an existing heterogeneous catalyst, the composite catalyst has nonmetal catalysis activity and metal catalysis activity and is high in persulfate activating efficiency, high in free radical production, wide in pH application range and capable of being recycled and widely used, obviously reducing the consumption of a catalyst and a oxidizing agent and shortening reaction time.

Owner:NANJING UNIV

Method for preparing supercapacitor electrode material basic nickel-cobalt carbonate through hydrothermal method

InactiveCN106587171AFully moistenedFull penetrationHybrid capacitor electrodesNickel carbonatesNickel saltHigh pressure

The invention discloses a method for preparing a supercapacitor electrode material basic nickel-cobalt carbonate through a hydrothermal method. The method comprises the following steps that metal nickel salt and / or metal cobalt salt and urea are weighed separately and mixed with deionized water, and stirring is performed so that solids can be dissolved to obtain a mixed solution; the mixed solution is poured into a high-pressure reactor, sealing is performed for performing a reaction for 10-16 h under the temperature of 80-110 DEG C, and a reaction product is obtained; the reaction product is separated, washed and dried to obtain basic nickel-cobalt carbonate. According to the method for preparing the supercapacitor electrode material basic nickel-cobalt carbonate through the hydrothermal method, on the basis of control over raw material compatibility and reaction conditions, the three-dimensional porous structure and morphology can be obtained, sufficient wetting and permeation of an electrolyte are promoted, the superficial area of active substances is sufficiently utilized, and the electrochemical performance is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

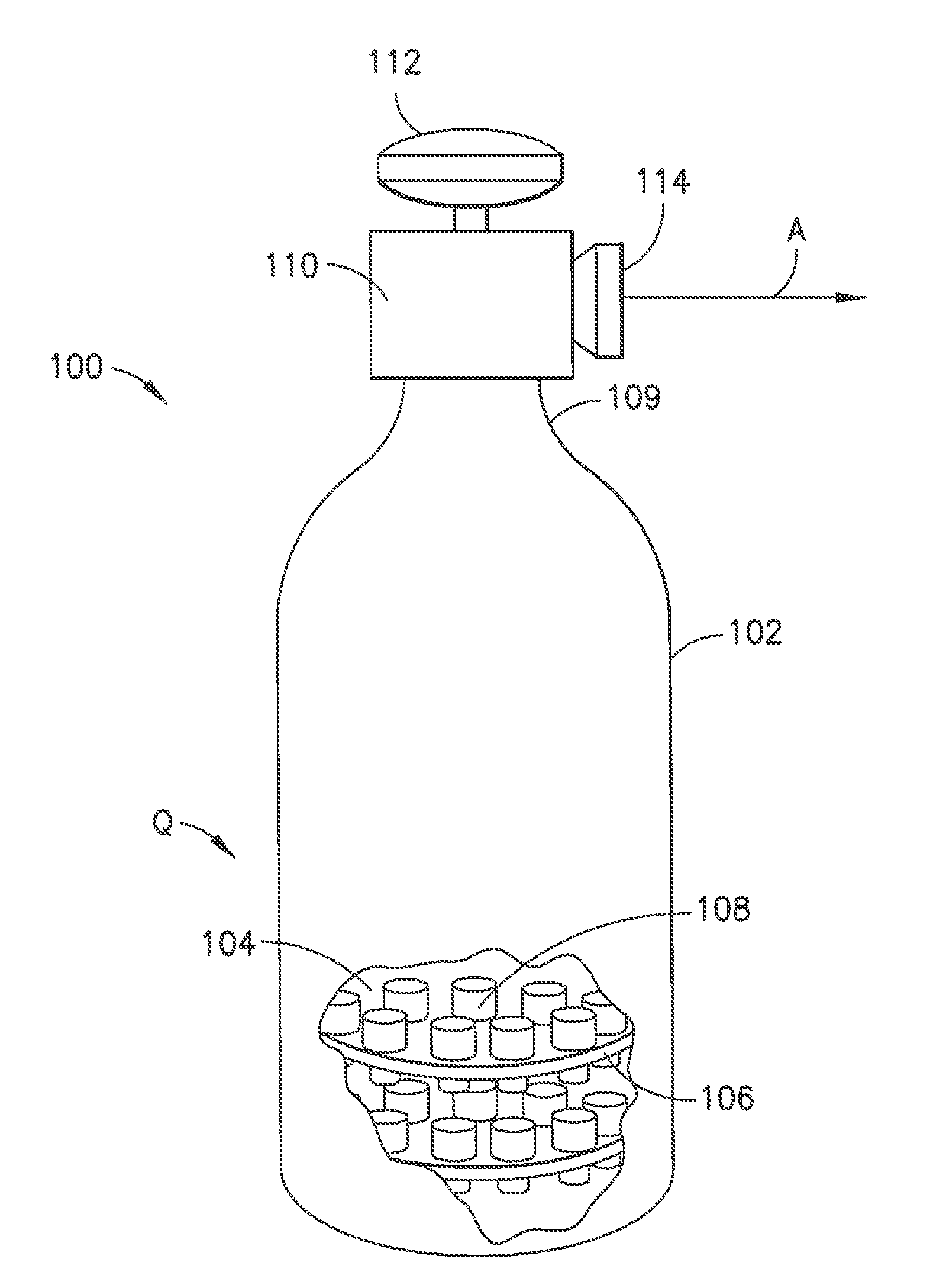

Optical method for additive manufacturing of complex metallic shapes using a gaseous medium

InactiveUS20130344258A1Additive manufacturing apparatusSolid state diffusion coatingThermal energyIodide

The present invention is a method for additive manufacturing in which a metal feedstock is converted to a carbonyl compound (or other gaseous media) and then optical heat patterns are used to direct the deposition of the contained metal into an arbitrary 3-D structure.The optical methods used to guide the metal deposit may include one or more laser beams acting independently or in concert, and / or other optical technologies to apply a pattern of thermal energy, including LCD, LED, LCoS, DLP, or even CRT projection technologies.The metals which may be deposited are limited to those which have compounds which are gaseous at moderate temperatures and which decompose (to a gas and the metal) upon the application of heat or specific chemical binding energies via optical means. Such compounds include (but are not limited to) nickel tetracarbonyl, iron pentacarbonyl, cobalt carbonyl, titanium iodide, and platinum chloro-carbonyl.

Owner:DEEP SPACE IND

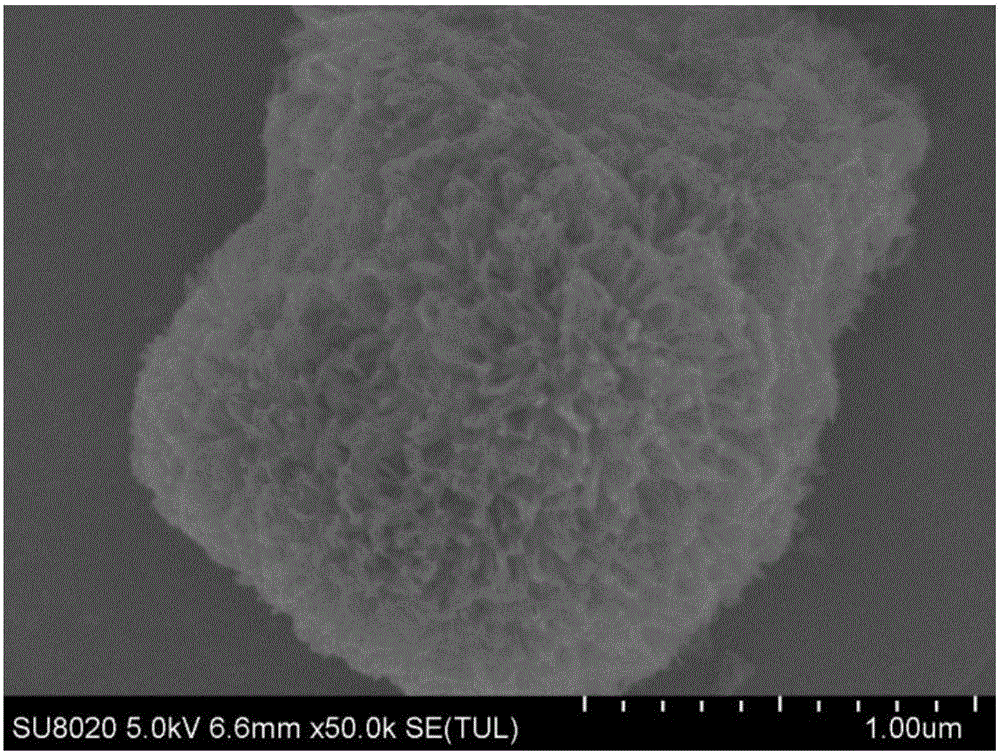

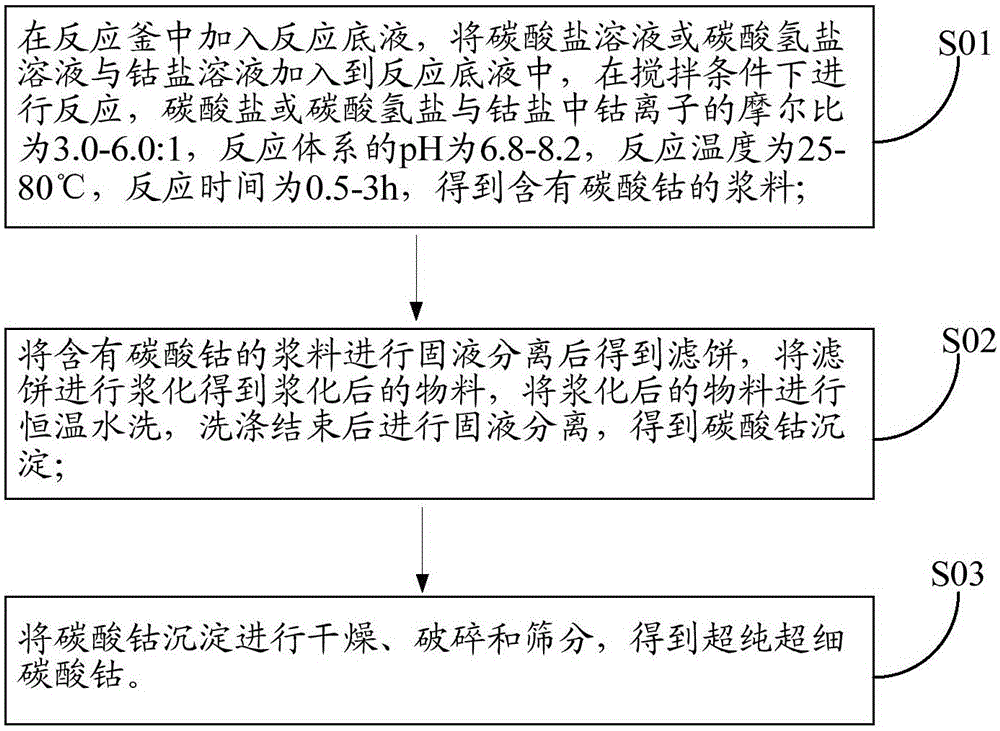

Preparation method for ultrapure ultrafine cobalt carbonate

InactiveCN106395916AReduce manufacturing costLow metal element impuritiesCobalt carbonatesCobalt saltReaction temperature

The invention provides a preparation method for ultrapure ultrafine cobalt carbonate. The preparation method comprises the following steps: (1) adding a base reaction solution into a reaction vessel, adding a carbonate solution or bicarbonate solution and a cobalt salt solution into the base reaction solution, and carrying out a reaction under stirring so as to obtain slurry containing cobalt carbonate, wherein a mol ratio of carbonate or bicarbonate to cobalt ions in the cobalt salt is (3.0-6.0): 1, the pH value of a reaction system is 6.8 to 8.2, reaction temperature is 25 to 80 DEG C and reaction time is 0.5 to 3 h; (2) subjecting the slurry containing cobalt carbonate to solid-liquid separation so as to obtain a filter cake, conveying the filter cake to a slurrying tank for slurrying so as to obtain a slurried material, conveying the slurried material to a washing tank for washing at a constant temperature and carrying out solid-liquid separation after completion of washing so as to obtain a cobalt carbonate precipitate; and (3) drying, crushing and sieving the cobalt carbonate precipitate so as to obtain ultrapure ultrafine cobalt carbonate. The preparation method provided by the invention is low in cost, simple in process flow and easy to operate.

Owner:JINGMEN GEM NEW MATERIAL +1

Preparation of organic cobalt salt adhesion promotion agent

ActiveCN101481591AHigh activityQuality improvementNon-macromolecular adhesive additivesCarboxylic acid salt preparationOrganic acidOrganic solvent

The invention discloses a method for preparing an organic cobalt salt adhesion promoter. The method comprises the following steps: cobalt solution, sodium hydroxide solution and sodium carbonate solution, which respectively have certain concentration, are respectively prepared; after the cobalt solution is heated, the sodium hydroxide solution is slowly added till the pH value of the reactant liquid reaches 7, and then the sodium carbonate solution is slowly added till the pH value of the reactant liquid reaches 9.5; the reaction liquid undergoes standing, and precipitates are rinsed with water; and the rinsed precipitate inorganic cobalt salt undergoes twice dehydration and then the reaction with weak organic acid in an organic solution so as to obtain the organic cobalt salt adhesion promoter product. The highly-active basic cobaltous carbonate powder produced according to the method has requirement-meeting indexes such as appearance, cobalt content, water content, trivalent cobalt content, impurity content, grain size, stacking density, and the like; and more importantly, the basic cobaltous carbonate powder has good reactive behavior. After the basic cobaltous carbonate powder undergoes neutralization reaction with the weak organic acid, the organic cobalt salt adhesion promoter product with high quality can be obtained.

Owner:JIANGSU KAOU CHEM

Polyvinyl-imidazole-supported cobalt carbonyl catalyst, preparation method and application of catalyst

InactiveCN107349962AImprove stabilityExcellent catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionEthylene oxideCobalt

The invention relates to a polyvinyl-imidazole-supported cobalt carbonyl catalyst, a preparation method and an application of the catalyst. The raw materials comprise a high-molecular compound containing imidazole groups and cobalt carbonyl, and the catalyst is used to catalyze an alkoxycarbonylation reaction of ethylene oxide to synthesize methyl 3-hydroxypropanoate. The method provided by the invention has the characteristics that the cobalt carbonyl which is used in the alkoxycarbonylation reaction of ethylene oxide is loaded on the PVI high-molecular compound containing imidazole groups through coordination, and the catalyst can be recycled and reused in the premise that the catalytic activity is not decreased. The polyvinyl-imidazole-supported cobalt carbonyl catalyst prepared by the method has the advantages of simple preparation method, high stability, easiness for separation recovery and cyclic utilization after the reaction, and stable catalytic performance after repeated use for multiple times.

Owner:南京大学扬州化学化工研究院

Method for preparing small-particle size large-bulk cobalt carbonate

The invention discloses a method for preparing small-particle size large-bulk cobalt carbonate. The method comprises the following steps: heating an ammonium carbonate base solution of certain concentration; respectively adding soluble cobalt salt and ammonium carbonate into the ammonium carbonate base solution according to certain velocities while stirring to react so as to obtain crystal slurry of cobalt carbonate after a certain time of the reaction; and by taking the crystal slurry of cobalt carbonate as a base solution, adding cobalt salt and ammonium carbonate to react for a certain time, thereby obtaining the target cobalt carbonate. The cobalt carbonate prepared by using the method has the characteristics of being small in particle size and large in bulk density.

Owner:JINGMEN GEM NEW MATERIAL

Catalyst for treating organic wastewater and preparation method thereof

InactiveCN102101053AHigh activityHigh removal rateMetal/metal-oxides/metal-hydroxide catalystsChemical oxygen demandRuthenium

The invention discloses a catalyst for treating organic wastewater and a preparation method thereof. The catalyst is a metal carbonyl loaded catalyst, a precursor of the catalyst is one or a combination of ruthenium carbonyl and cobalt carbonyl, a second component Ce or Fe is added at the same time, and a carrier of the catalyst is selected from one or a compound oxide of active carbon, gamma-Al2O3 and TiO2. The catalyst can be used for oxidizing and degrading different organic matters with various concentrations in water under a milder condition so as to greatly reduce COD (Chemical Oxygen Demand) in wastewater and improve the removal efficiency of the COD in the wastewater.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

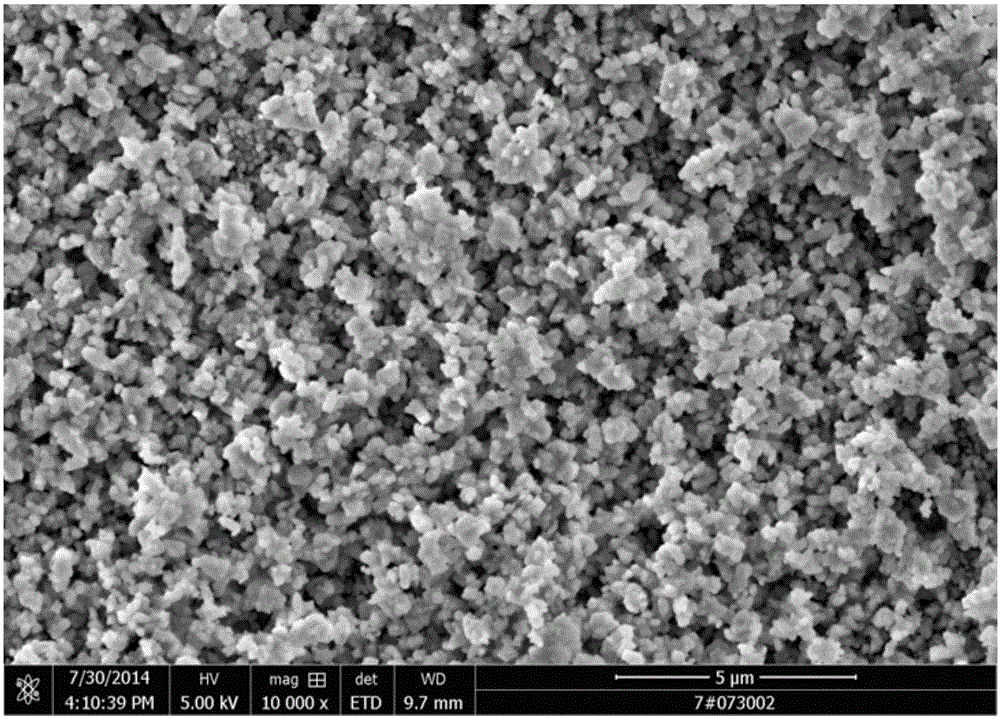

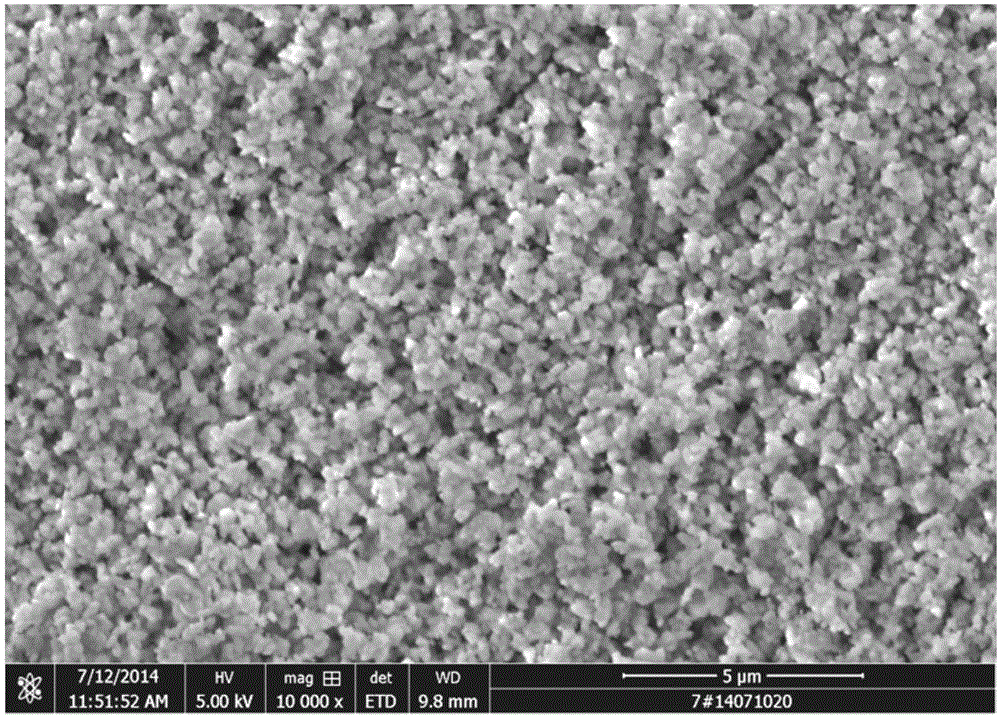

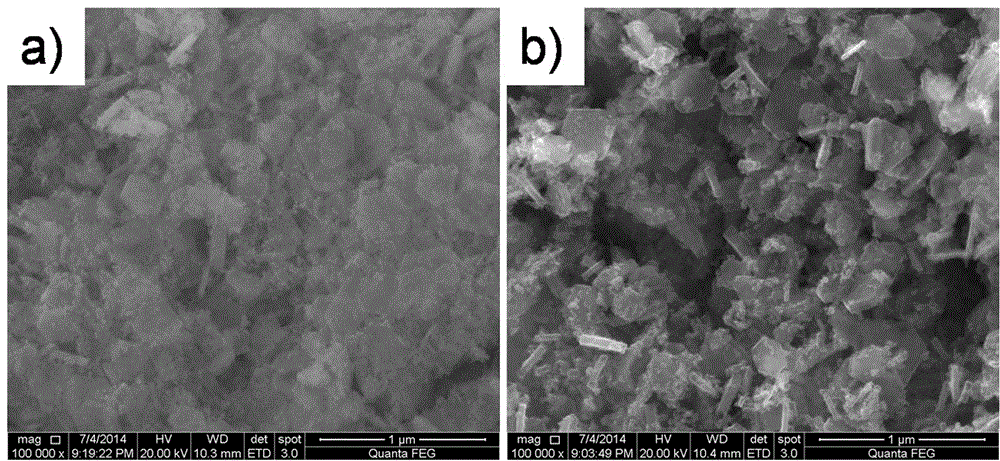

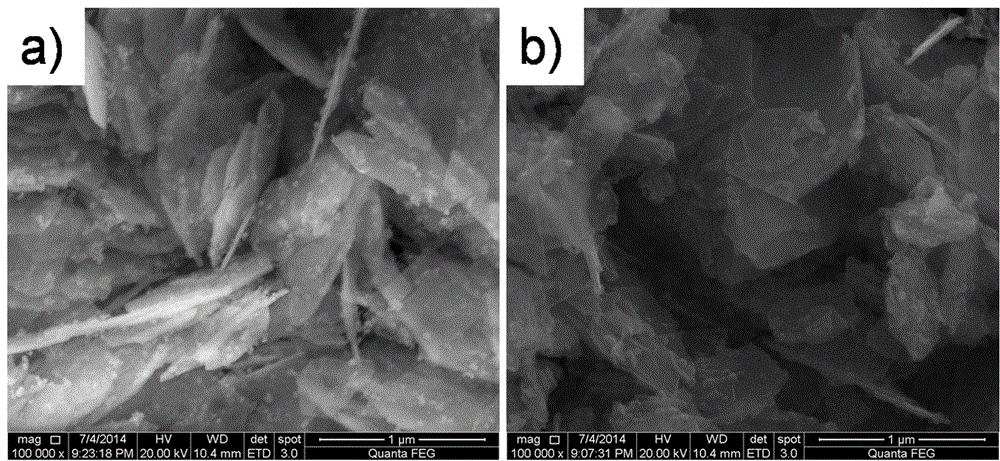

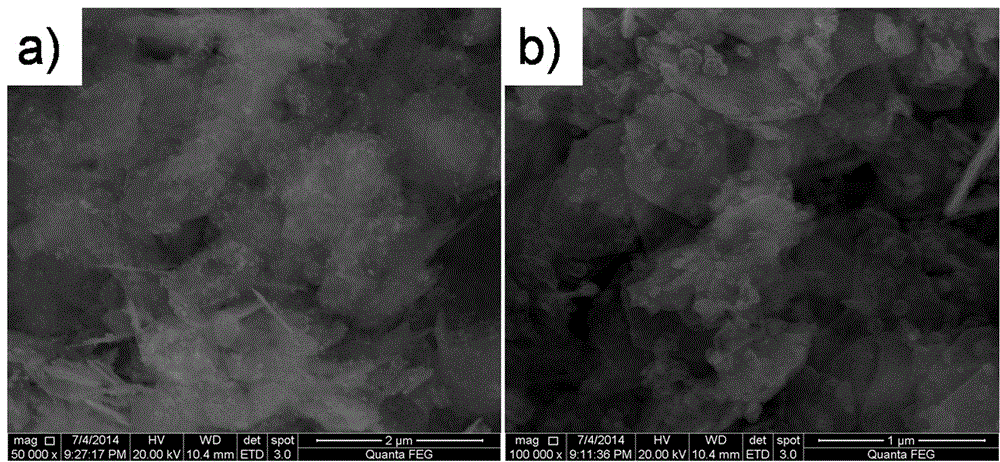

Cobalt carbonate preparation method and superfine cobalt powder preparation method

InactiveCN102910686ALow bulk densityUniform particle sizeNanotechnologyCobalt carbonatesApparent densityFiltration

The invention provides a cobalt carbonate preparation method and a superfine cobalt powder preparation method, which are applicable to the technical field of cobalt powder preparation. The cobalt carbonate preparation method comprises the following steps of: mixing a cobalt salt solution and soluble carbonate or soluble hydrocarbonate under a condition with temperature of 0-30 DEG C and pH value of 5.5-8.0; carrying out millipore filtration on an obtained mixture after reaction; collecting and washing filter residues; drying the washed filter residues under a negative pressure condition at 50-80 DEG C, so as to obtain a cobalt carbonate precursor; and carrying out airflow crushing and classification on the cobalt carbonate precursor, so as to obtain cobalt carbonate. The cobalt carbonate preparation method and the superfine cobalt powder preparation method, provided by the invention, have the advantages of mild technical condition, high production benefits, low apparent density of the obtained cobalt carbonate and uniform particle size and is suitable for industrial production.

Owner:GEM CO LTD +1

Preparation method of dye-sensitized solar battery cobalt-nickel sulfide counter electrode

InactiveCN105719836AHigh mechanical strengthNo sheddingLight-sensitive devicesPhotovoltaic energy generationNickel saltSlurry

The invention discloses a method for preparing a cobalt-nickel sulfide counter electrode. The steps include: first step, hydrothermally reacting cobalt salt, nickel salt and excess sodium hydroxide or sodium carbonate at 120-200°C to generate hydrogen Oxycobalt nickel or basic cobalt nickel carbonate; the second step, mix the hydroxide cobalt nickel or basic cobalt nickel carbonate with a certain concentration of sulfur source aqueous solution, and heat it at 140-230 ° C; the third step is to generate the sulfur Cobalt nickel is made into a slurry and coated on a conductive substrate, and dried at room temperature. The electrode prepared by the invention does not need to be sintered under vacuum or protective atmosphere, and the preparation process is simple; the prepared cobalt-nickel sulfide counter electrode has high mechanical strength and no shedding phenomenon; Better electrocatalytic activity; Dye-sensitized solar cells assembled with cobalt-nickel sulfide electrodes obtained higher photoelectric conversion efficiency than dye-sensitized solar cells assembled with pyrolyzed Pt electrodes.

Owner:CHINA THREE GORGES UNIV

Cobalt carbonate and cobaltosic oxide granularity controlled production process

InactiveCN109368709AHigh densityUniform shapeCobalt oxides/hydroxidesCobalt carbonatesCobalt(II,III) oxideProduct demand

The invention discloses a cobalt carbonate and cobaltosic oxide granularity controlled production process. The cobalt carbonate and cobaltosic oxide granularity controlled production process comprisesthe steps: firstly, a cobalt chloride solution and an ammonium bicarbonate solution are fed into a seed crystal reaction kettle to react under reaction conditions; feeding of cobalt chloride is increased in the later stage to obtain seed crystal cobalt carbonate; then the cobalt carbonate is distributed in a finished product reaction kettle to react, in the reaction process, the feeding quantityof the ammonium bicarbonate solution is adjusted, the alkaline environment is gradually lowered to the weak alkali environment, and the weak alkali environment is maintained; the feeding quantity of the cobalt chloride is increased every a period of time in the middle and later periods of a reaction, and finally, finished cobalt carbonate particle products with the required particle size are obtained; and cobalt carbonate particles are washed and dried, and then subjected to aerobic calcination in a rotary kiln, and cobaltosic oxide black powder is obtained. The produced cobalt carbonate particles are good in compactness and uniform in morphology and granularity, the specific surface area is adjusted according to product demands, the cobalt carbonate particles can be well controlled in therequired granularity, and calcined cobaltosic oxide is uniform in granularity, compact in particle, and also uniform in morphology.

Owner:JINGMEN GEM NEW MATERIAL +1

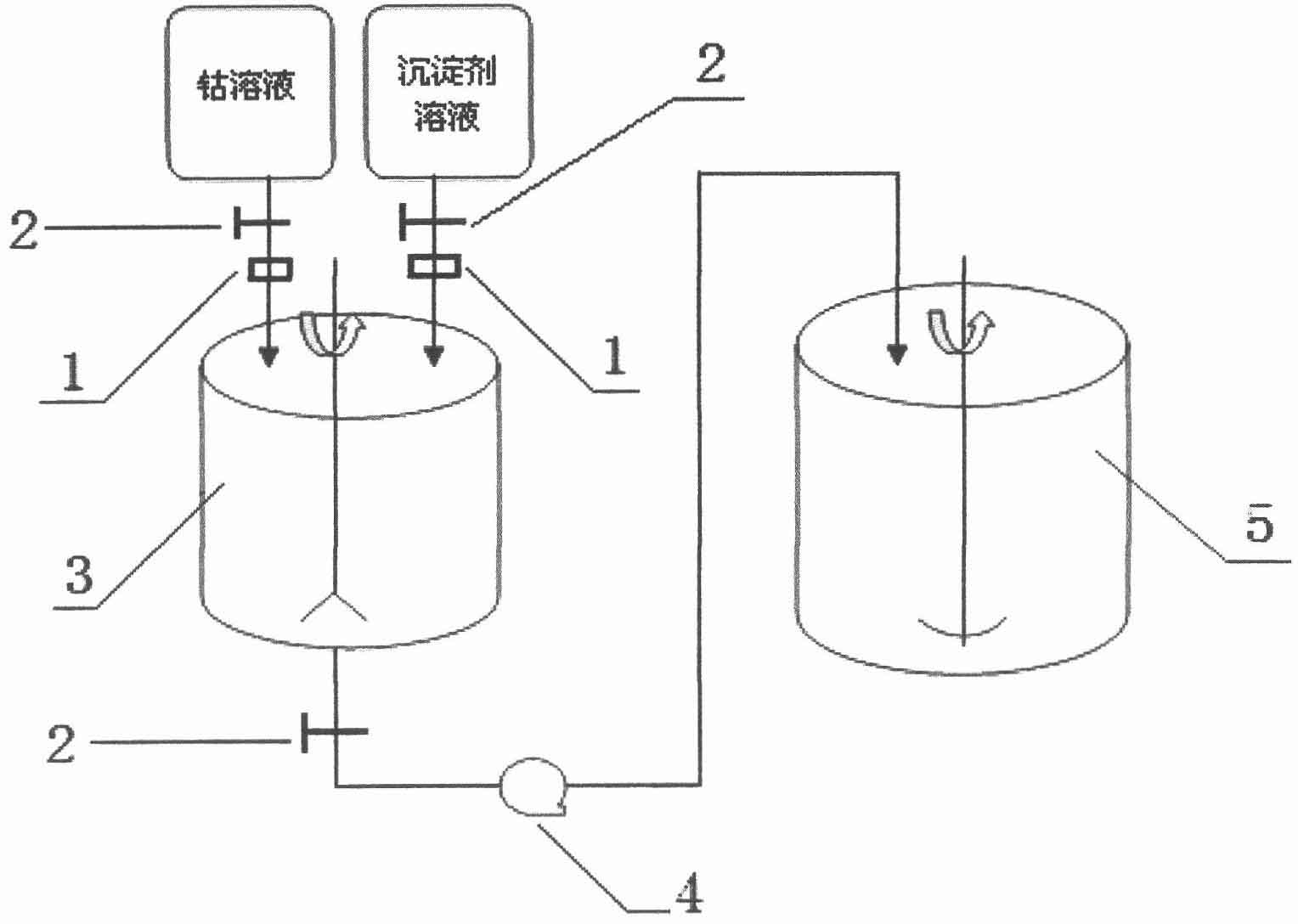

Preparation method of spherical cobaltosic oxide

InactiveCN102583584AUniform particle size distributionGranularity controllableCobalt oxides/hydroxidesCobalt(II,III) oxideReaction temperature

A preparation method of spherical cobaltosic oxide includes 1) preparing cobalt salt solution and enabling cobalt content in the cobalt salt solution to be 40-180g / L, 2) preparing precipitator solution, enabling density of the precipitator solution to be 60-300g / L and enabling solution temperature to be 20-70 DEG C, 3) combining cobalt carbonate, naturally combining two strands of cobalt salt and precipitator solution flows and enabling the flows to flow into a middle reaction tank and enabling reaction temperature to be 20-70 DEG C and reaction time to be 0.5-1h; 4) conducting centrifugal washing and dehydrating; and 5) burning the mixture into a product, placing dehydrated cobalt carbonate into a burning furnace, conducting burning for 4-10h under the temperature from 400 DEG C to 900 DEG C to obtain pure-phase cobaltosic oxide. The preparation method adopts two-strand natural flow combining mode to control crystallization and burning conditions, and the prepared cobaltosic oxide is the pure-phase cobaltosic oxide. The product is spherical in microcosmic appearance, even in size distribution, controllable in size and capable of meeting requirements of markets for diversification of product size and appearance.

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

Method for continuously preparing large-particle-size spherical cobalt carbonate

The invention discloses a method for continuously preparing large-particle-size spherical cobalt carbonate. All the cobalt carbonate production methods in China at present adopt an intermitted technique which has the characteristics of aggregated particle, poor dispersity and poor flowability. The method comprises the following steps: by using pure water as bottom liquor, adding a parallel flow of an excessive 10-30% precipitant solution and a soluble cobalt salt-activator mixed solution into a reaction kettle while controlling the pH value at 6.5-7.5, the temperature at 30-90 DEG C and the stirring speed at 200-100 rpm; starting continuous feeding and continuous output when achieving the overflow port; and filtering the reaction product, washing and drying to obtain the large-particle-size spherical cobalt carbonate. The particle size of the cobalt carbonate product forms standard normal distribution; the cobalt carbonate product has the advantages of uniform particle and favorable flowability; and D50 is 15-30mm.

Owner:ZHEJIANG HUAYOU COBALT

Method for preparing optical activity 3-hydroxycarboxylate

InactiveCN101143823AHigh selectivityEasy to operatePreparation by carbon monoxide or formate reactionEpoxyAlcohol

The invention discloses a method in which carbonylation reaction is carried out between an epoxy compound and carbon monoxide and alcohol in order to prepare optically active 3-hydroxy carboxylic ester. The method uses the chiral epoxy compound, the monohydric alcohol and the carbon monoxide as reactants, cobalt carbonyl as main reactive catalyzer and a heterocyclic compound containing nitrogen as cocatalyst to synthesize the optically active 3-hydroxy carboxylic ester under the controlled operational conditions of reaction pressure between 3.0 MPa and 10.0 MPa, reaction temperature between 50 DEG C and 150 DEG C and reaction time between 1 and 8 hours. Under the relatively mild conditions, the invention can realize high conversion rate of chiral epoxy dimethylmethane and high selectivity of 3-hydroxy carboxylic ester, and therefore the invention is a high-efficiency, economical, environment-friendly and conveniently operated catalyzer system.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

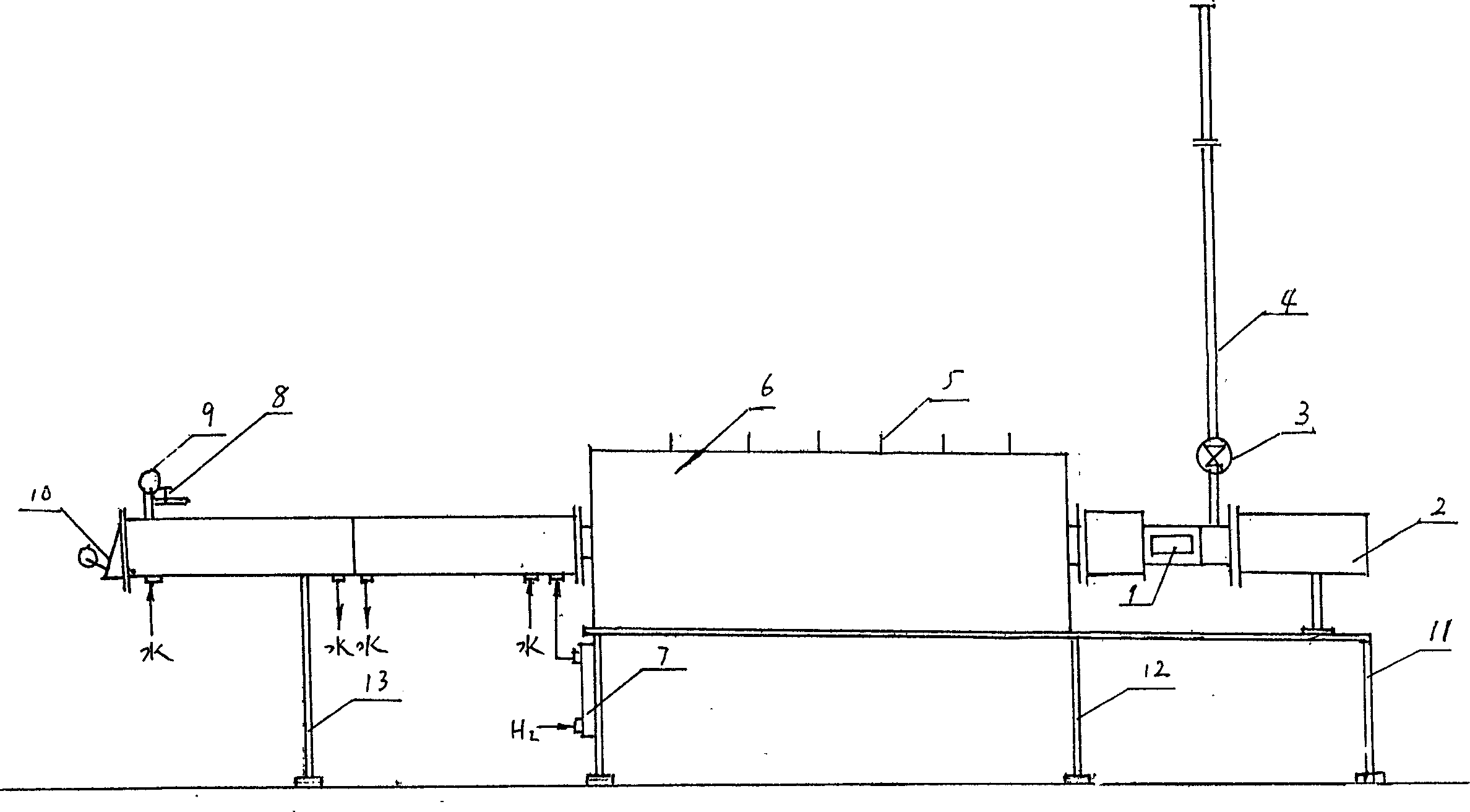

Preparation method and equipment for nano-grade superfine cobalt powder

The invention discloses a nanometer super fine cobalt powder preparing method and device, which comprises the following steps: (1)solution strength of CoCl2 is 70-120g / l; NH4 HCO3 liquor is saturation density; the reaction temperature is at 25-50deg, c; pH=7.2-7.5; adding in reactor speed of CoCl2 is 20-100L / min; NH4 HCO3 fat solution is 60-400L / min; the ageing time is 0.5-2.0 hour;(2) the nanometer super fine cobalt powder thermal reduction can use hydrogen to deacidize or heat decomposition in high-temperature electric resistance furnace at 300-500deg C. The intermediate section and front end of feed head of high-temperature electric resistance furnace jamb installs exhaust stabilivolt guide and mechanical pulling-boat-machine; the furnace body heating device installs independently in 5 to 8 sections; the oven tail installs two to three sections of double layer hydrocooling device and checking-valve and micromanometer. The invention has short process, which reduces the cost.

Owner:湖南鼎伦新材料有限公司

Doped large-particle cobalt carbonate and preparation method thereof

ActiveCN113307308AHigh tap densityNarrow particle size distributionCobalt carbonatesCrystallinityCobalt

The invention relates to doped large-particle cobalt carbonate and a preparation method thereof. The large-particle cobalt carbonate is doped with metal elements, primary particles are conical in morphology and form spherical secondary particles, and the particle size distribution range of the secondary particles is that (D90-D10) / D50 is larger than or equal to 0.3 and smaller than or equal to 0.5; and the preparation method comprises the following steps: nucleation, concentration, growth in a seed crystal kettle, and growth of the seed crystal in different kettles. The doped large-particle cobalt carbonate is high in crystallinity, beneficial to uniform distribution of doped element aluminum, high in tap density, narrow in particle size distribution and beneficial to reduction of aluminum segregation of small particles; and according to the preparation method, the D50 rising speed and the solid content rising speed are strictly controlled, uniform growth of cobalt carbonate particles is guaranteed by adjusting the flow and the rotating speed in different solid content intervals, the concentration process greatly saves the standing waiting time, the efficiency is high, and the obtained product is good in performance and has a wide market prospect.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Method for preparing alkaline cobalt carbonate under hyper-gravity hydrothermal condition

InactiveCN102145924AReaction is easy to controlEasy to industrializeNanotechnologyCobalt carbonatesOrganosolvReaction temperature

The invention relates to a method for preparing alkaline cobalt carbonate under hyper-gravity hydrothermal condition. The method comprises the following specific steps of: adding a certain amount of cobalt salt into deionized water to obtain a metal salt solution with the concentration between 0.1 mol / L and 2 mol / L; dissolving a corresponding chemical reagent which can produce CO3<2-> at the reaction temperature between 50 DEG C and 250 DEG C; adding a certain amount of organic solvent which has higher density in comparison with water and is insoluble in water or a water-soluble high molecular compound with density higher than that of water into the prepared solution, wherein the volume ratio of the organic solvent or the water-soluble high molecular compound to an aqueous solution is 1:1-1:100; filling the mixed solution into a reaction kettle, sealing, fixing the reaction kettle on a fixing bracket in a hearth and undergoing a hydrothermal reaction at certain temperature in the presence of hyper-gravity, wherein the reaction temperature is between 50 DEG C and 250 DEG C, the reaction time is between 0.1 hour and 5 hours, and relative centrifugal force is between 500 / g and 10,000 / g; and filtering, cleaning repeatedly and drying in vacuum to obtain a needed material. By adopting the method, a substrate-free alkaline cobalt carbonate membrane can be directly prepared; and equipment is simple, the reaction is easy to control, and industrialization is easy to realize.

Owner:TONGJI UNIV

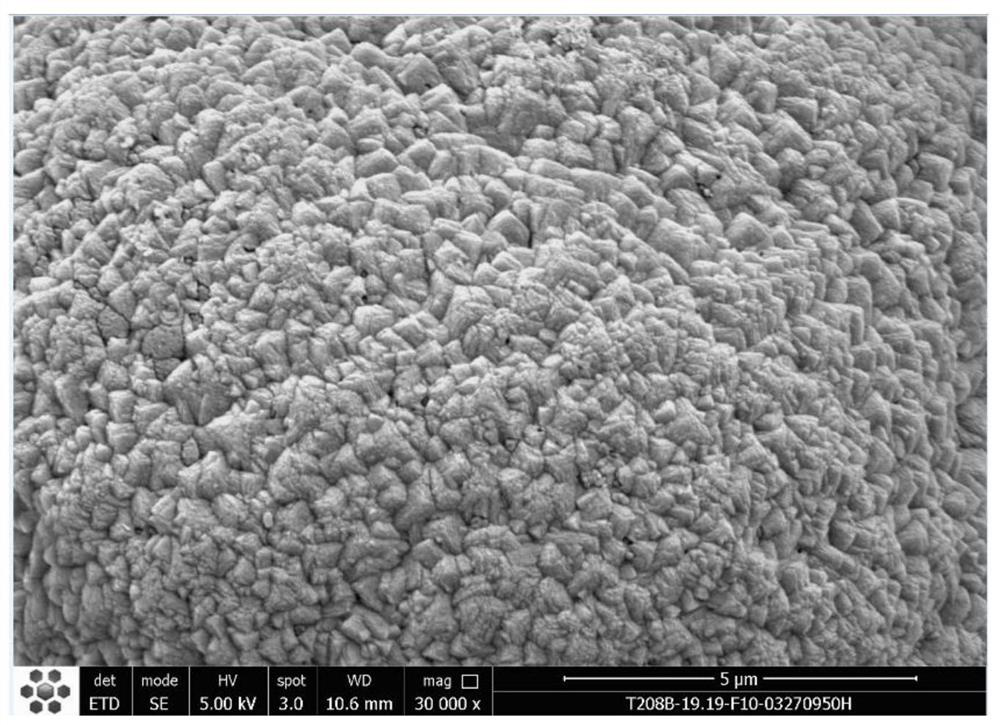

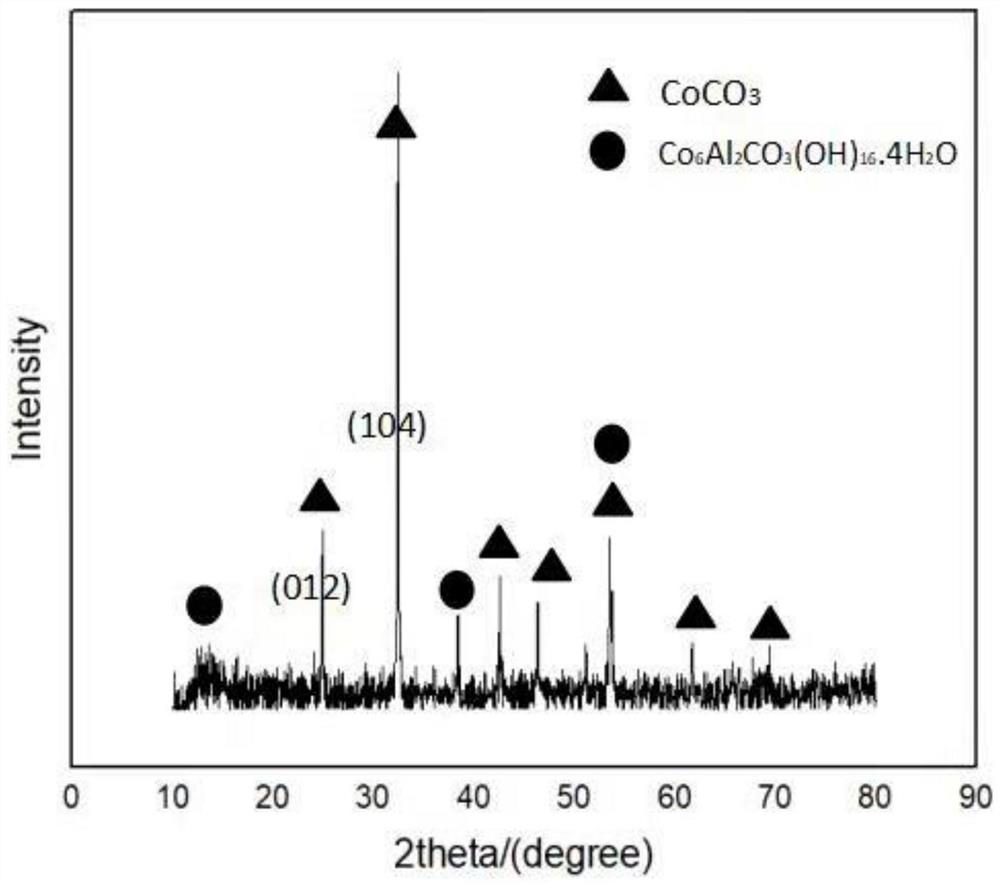

Nano basic aluminum cobalt carbonate/cobalt carbonate composite spherical precursor

ActiveCN111082007AGood dispersionGood sphericityMaterial nanotechnologySecondary cellsAluminum CarbonatePhysical chemistry

The invention relates to the technical field of precursors of lithium cobalt oxide serving as a positive electrode material of a lithium ion battery, and particularly relates to an aluminum cobalt carbonate / cobalt carbonate composite spherical precursor and a preparation method thereof. The nano basic aluminum cobalt carbonate / cobalt carbonate composite spherical precursor is composite material formed by taking spherical cobalt carbonate as a main body material and uniformly distributing nano basic aluminum cobalt carbonate crystal particles in a bulk phase of the main body material, the expression of the composite material is (1-x)[CoCO3].x [Co6Al2CO3(OH)16.4H2O], and x is greater than or equal to 0.001 and less than or equal to 0.04. The product obtained by the invention has better aluminum distribution uniformity, is applied to the preparation of lithium cobalt oxide (LCO), is easier to uniformly dope Al into LCO crystal lattices, and has excellent high-voltage cycle performance.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

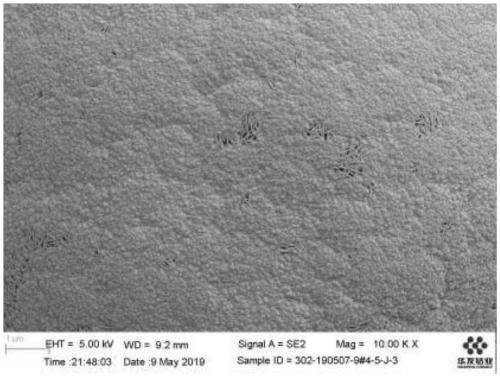

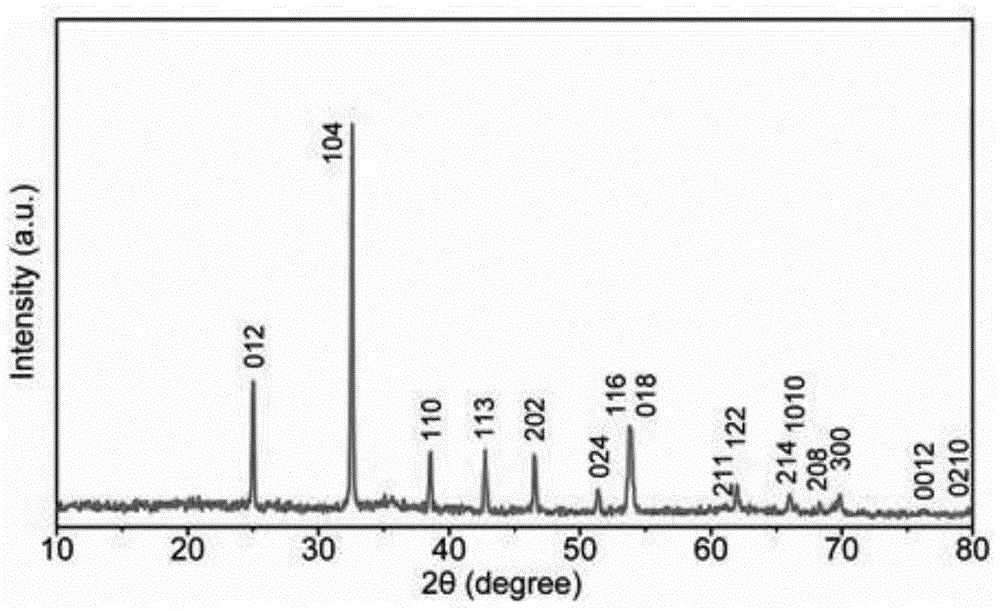

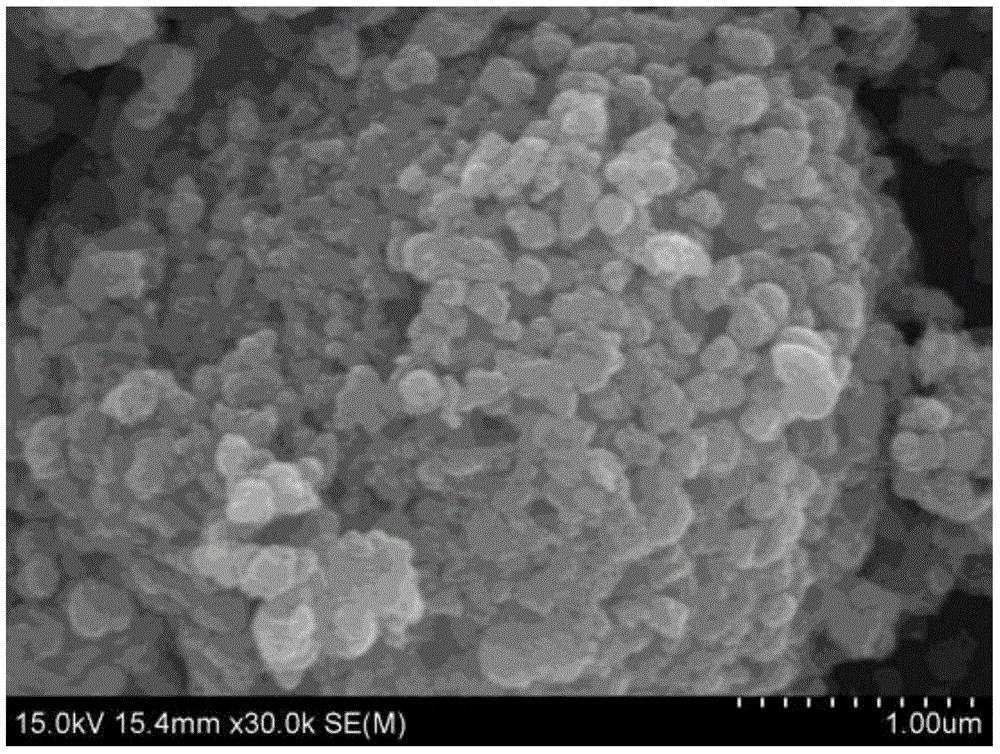

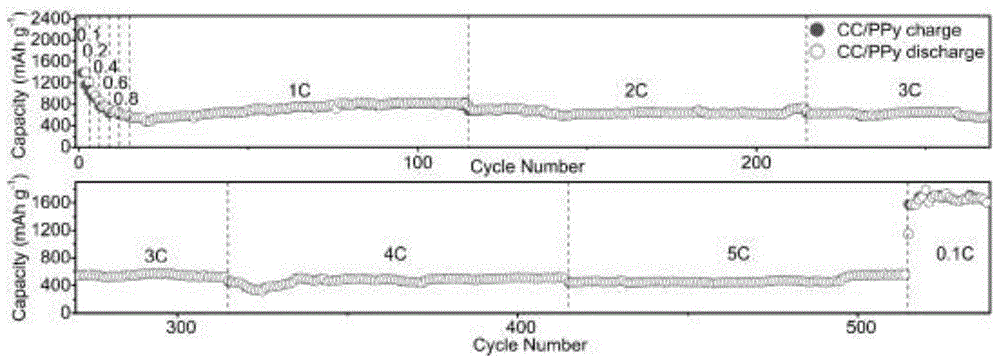

Cobalt carbonate-polypyrrole composite anode material used for power lithium ion battery and preparation method thereof

InactiveCN104157838AImprove cycle stabilityExcellent rate performanceCell electrodesSecondary cellsMicro nanoCobalt

The invention discloses a cobalt carbonate-polypyrrole composite anode material used for a power lithium ion battery and a preparation method thereof. The material is in a micro-nano-scale spheroid core-shell structure in which an exterior is a cobalt carbonate core which is coated by polypyrrole. The composite anode material is 3-5 [mu]m in particle sizes. The cobalt carbonate core is assembled by nanometer rods with widths being 20-50 nm. A thickness of a polypyrrole coating layer is 0.3-1 [mu]m. The polypyrrole coating layer is formed, in an aggregation manner, from polypyrrole nanometer particles with particle sizes being 50-100 nm. The preparation method includes following steps: dispersing CoCO3 powder into water in which a surfactant is dissolved to prepare a suspension; adding a pyrrole monomer to the suspension with mixing uniformly; adding ferric chloride to carry out a polymerization reaction; performing a filtering process and collecting a cobalt carbonate-polypyrrole precipitate after the reaction being finished; and performing a washing process and a drying process to obtain the cobalt carbonate-polypyrrole composite anode material. The composite anode material has excellent circulation stability, an excellent rate capability and a very strong capacity recovering capability. In addition, the preparation method is simple and is easy to carry out in large-scale production.

Owner:SHANDONG UNIV

Method for preparing small-particle-size cobalt carbonate

The invention discloses a method for preparing small-particle-size cobalt carbonate, which comprises the following steps: preparing solution A with a cobalt slat concentration of 0.1 to 10M and an additive concentration of 0.05 to 5M by dissolving an industrial cobalt salt and an additive in deionized water; preparing solution B with a precipitator concentration of 0.1 to 10M and a complexing agent concentration of 0.05 to 5M by dissolving an industrial precipitator and a complexing agent in deionized water; filling deionized water which accounts for 1 / 10 to 3 / 10 of the volume of the reactor into the reactor, filling the solution A and the solution B into the reactor according to a volume ratio of 1:1 to 1:5 to perform a precipitation reaction, controlling the pH value to be 6 to 10, and reacting for 4 to 10 hours; and overflowing the precipitator formed by the reaction into a washing and filtering device, washing the precipitator till the pH value of the washing water is between 6.5 and 7.5, filtering, and drying the filter cake in an oven at 80 to 120 DEG C for 2 to 10 hours to obtain small-particle-size cobalt carbonate powder. In the invention, the small-particle-size cobalt carbonate powder prepared by a controlled synthesis process has high flowability, small particle size, uniform particle size distribution, and large specific surface area and makes the realization of industrial production easy.

Owner:JIANGSU FANGZHOU NEW ENERGY

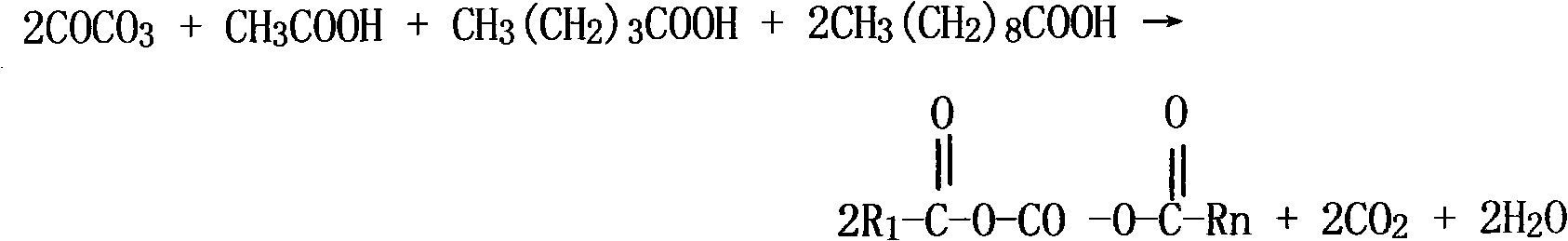

Preparation technique of cobalt decanoate by hybrid reaction of cobaltous carbonate and organic acid

InactiveCN101348426APrevent rustBalance pHCarboxylic acid salt preparationFiltrationOrganic synthesis

A preparation process for preparing organic cobalt salt compound mainly comprising cobalt neocaprate through the hybrid reaction between cobalt carbonate and organic acid belongs to the organic synthesis technical field. Taking cobalt carbonate as a raw material, the preparation process is characterized in that the process is carried out in turn according to the following steps that (1) taking cobalt carbonate, glacial acetic acid, neodecanoic acid and neopentanoic acid as raw materials, reaction is carried out inside a normal pressure sealed reactor for more than or equal to 3 hours with the temperature controlled between 90 and 100 DEG C; (2) abietic acid is added in the reaction system so as to carry out reaction at a temperature of between 160 and 168 DEG C for more than or equal to 1 hour, thereby displacing glacial acetic acid; then, cobalt neocaprate is generated through excluding displaced glacial acetic acid and water by means of vacuum reaction and filtration; and (3) activated calcium carbonate is added in the reaction system at a temperature of between 160 and 168 DEG C so as to prepare a finished product. Through replacing common cobalt hydroxide by cobalt carbonate to carry out reaction with organic acid, and adding abietic acid tackifier and activated calcium carbonate with amphoteric compound in neodecanoic acid, the preparation process effectively balances the pH degree in the system, thereby effectively preventing the product from metallic corrosion and increasing adhesion level.

Owner:逯大成

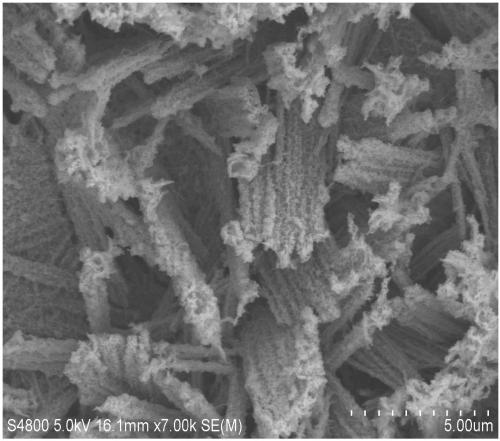

One-dimensional basic cobalt carbonate@two-dimensional CoSe/NF heterostructure composite material and preparation method and application thereof

ActiveCN109174146AImprove electrocatalytic activityEasy to operatePhysical/chemical process catalystsElectrodesNanowireSolvent

The invention discloses a one-dimensional basic cobalt carbonate@two-dimensional CoSe / NF heterostructure composite material and a preparation method and an application thereof. The preparation methodcomprises the following step: carrying out a solvothermal reaction on a basic cobalt carbonate nanowire Co(CO3)0.5(OH).0.11H2O, a selenium source and a cobalt source in a solvent to prepare the one-dimensional basic cobalt carbonate@two-dimensional CoSe / NF heterostructure composite material, wherein the basic cobalt carbonate nanowire is loaded to foam nickel NF. The heterostructure composite material has excellent electrocatalytic and cyclic performance, so that the heterostructure composite material can be applied to electrocatalytic hydrolysis. Meanwhile, the preparation method has the advantages of being simple in process and low in price.

Owner:ANHUI NORMAL UNIV

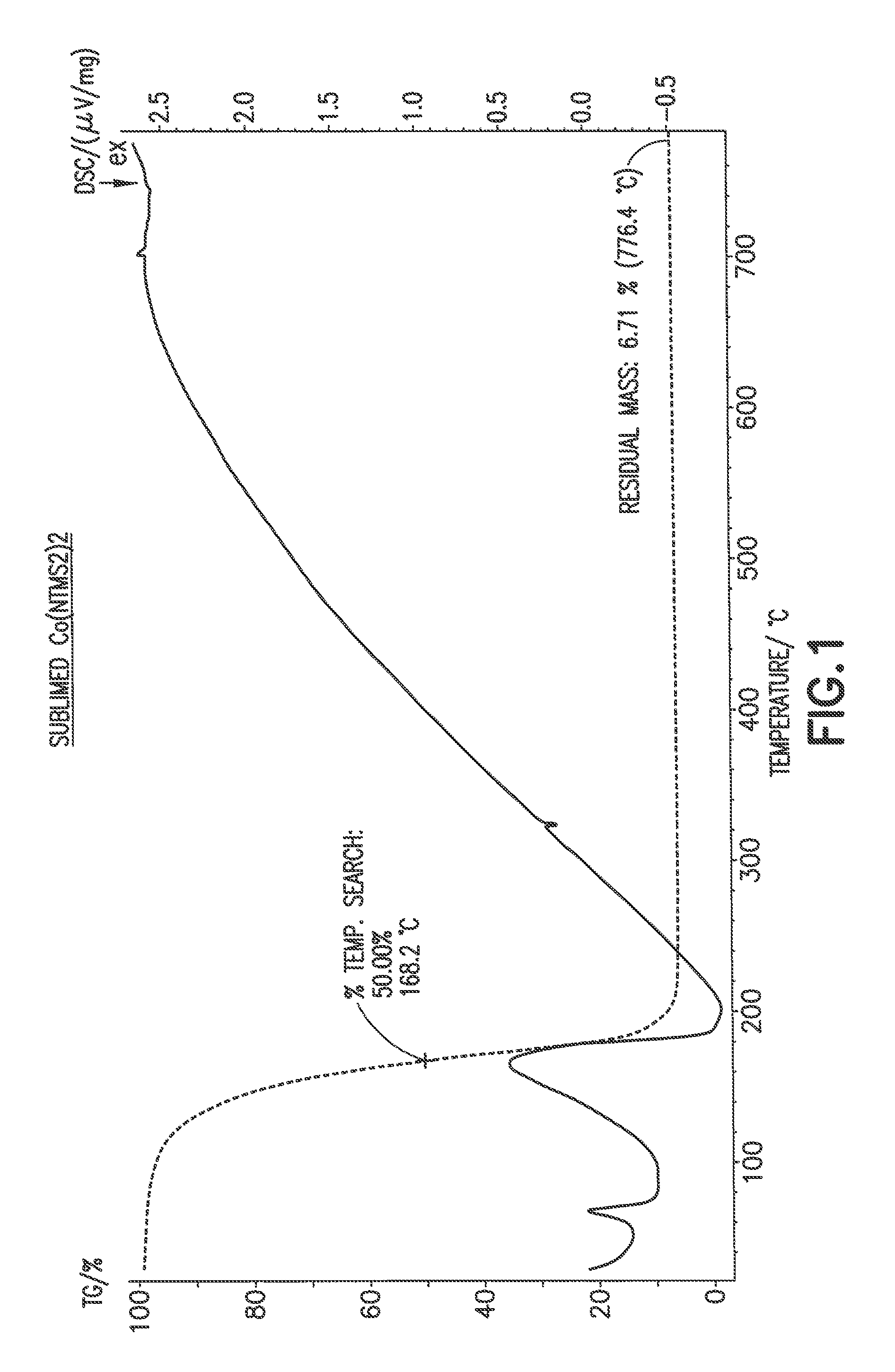

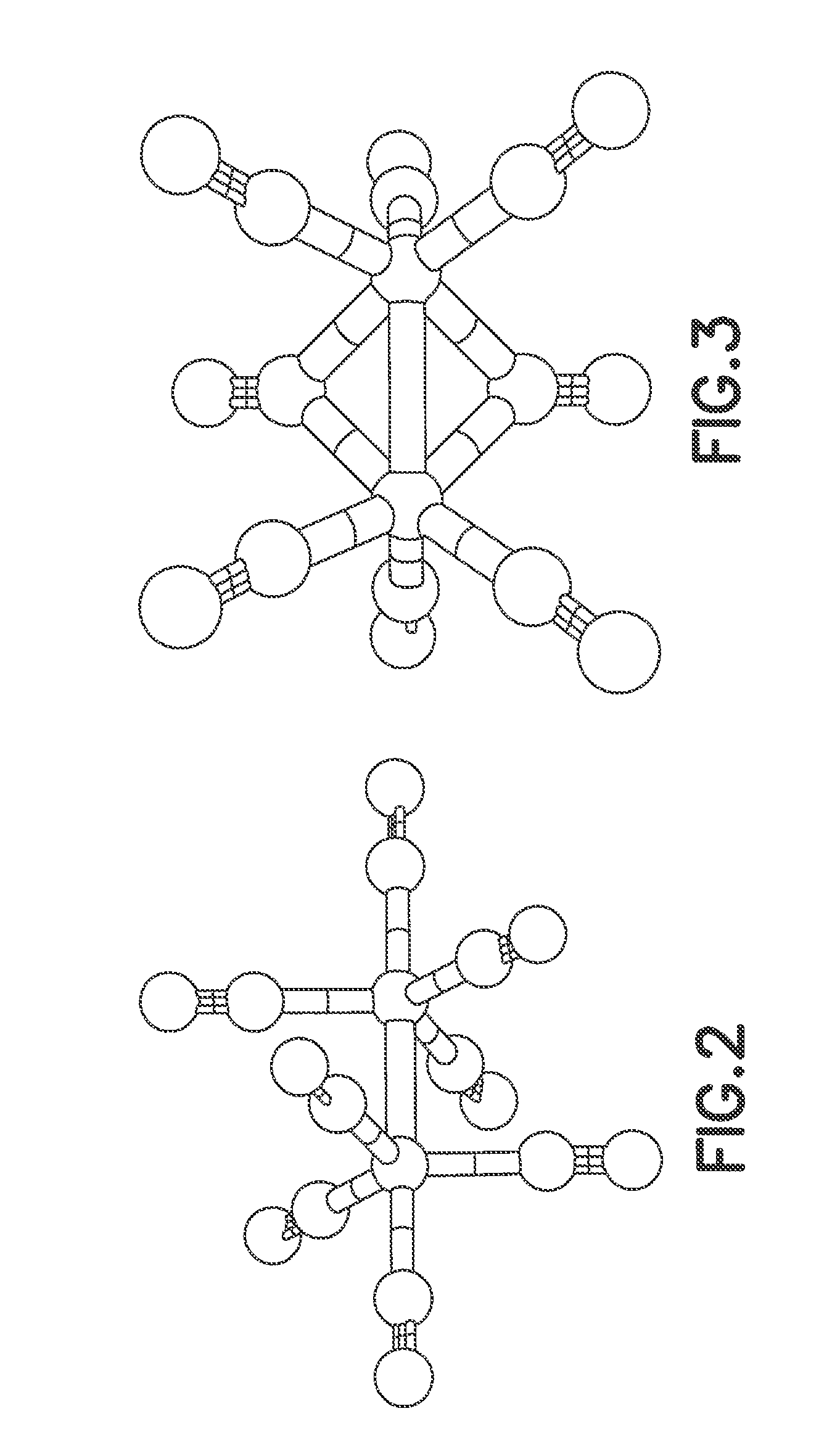

Cobalt precursors for low temperature ald or CVD of cobalt-based thin films

ActiveUS20150246941A1Silicon organic compoundsCobalt organic compoundsDeposition processChemical vapor deposition

Cobalt silylamide and cobalt carbonyl precursors are described, which are usefully employed in vapor deposition processes, such as chemical vapor deposition and atomic layer deposition, to deposit cobalt and to form high purity cobalt-containing films at temperatures below 400° C. These precursors and processes can be utilized in the manufacture of integrated circuitry and production of devices such as microprocessors, and logic and memory chips.

Owner:ENTEGRIS INC

Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof

InactiveCN101463001ASimple processEasy industrial operationOrganic chemistryBulk chemical productionTert-Butyloxycarbonyl protecting groupStructural formula

The invention relates to an octahydro cyclopentenopyridine (c) carboxylic acid derivative and a preparing method thereof, providing basis for designing and preparing compounds with different biological activities. A chemical structural formula is shown in the fight formula, wherein, R1 is one of alkoxy, bydroxy and amine. R2 and R3 are one of bydroxy, fluorine and hydrogen. N protecting group is tertbutyloxycarbonyl, benzyloxycarbonyl or benzyl. The compounds are optically pure. Starting from natural methionine ester or hydrochloride thereof, the compound of (S)-2-((benzyloxycarbonyl)(propargyl)-amine)butane-3-carboxylic ester (5) is obtained through substitution, oxidation and elimination. After reactions of cobalt carbonyl catalytic cyclization, and the like, (S)-2-benzyloxycarbonyl-5-octahydro cyclopentenopyridine (c)-1- carboxylic ester is obtained. Series of deritative compounds are obtained through reduction of carbonyl, fluorination, chiral separation, hydrolysis and condensation.

Owner:上海药明康德新药开发有限公司

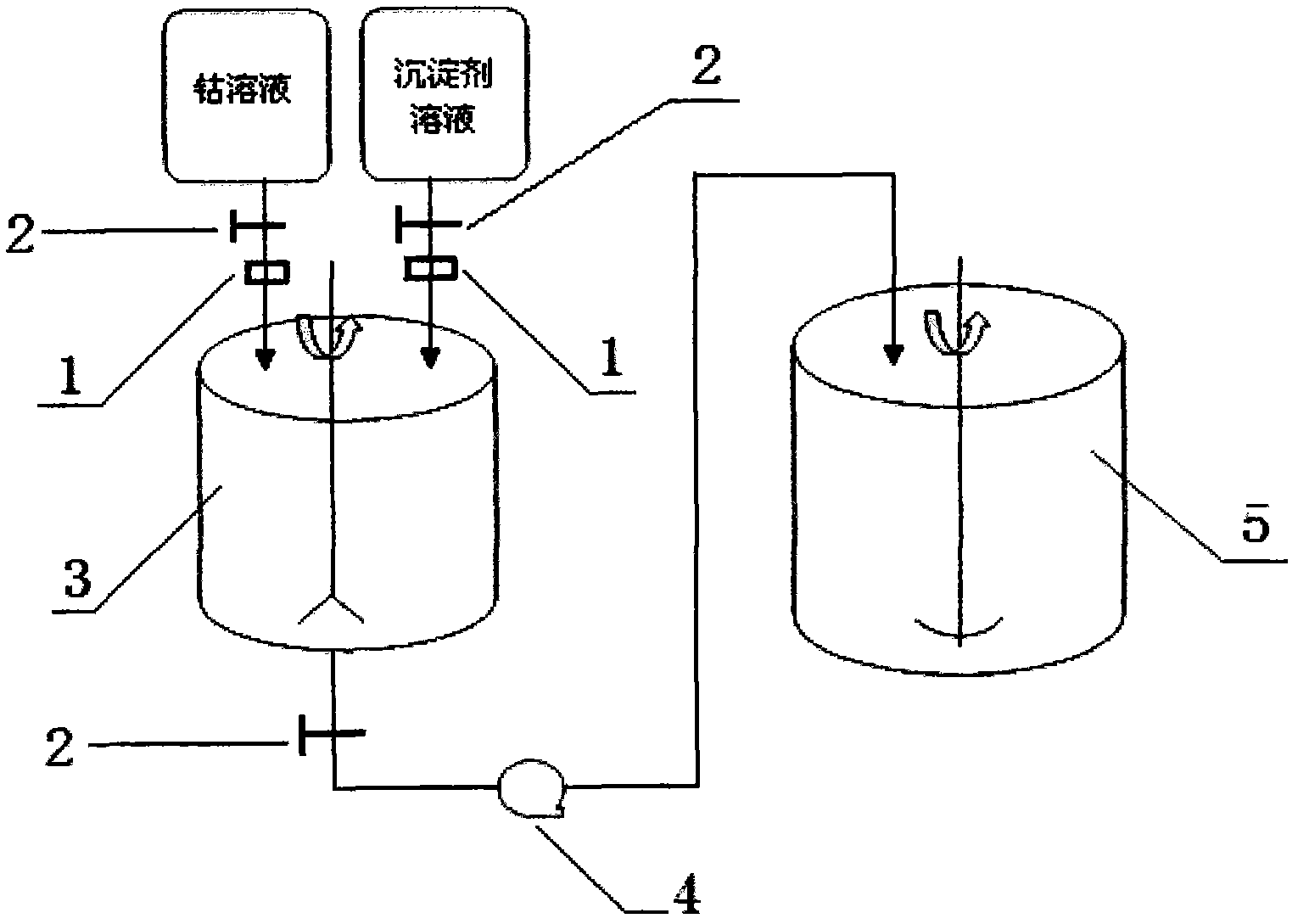

Production equipment and technique for ultramicro powder of cobalt carbonate

The present invention discloses a production equipment of ultramicrofine cobaltous carbonate powder and its production process. Said production equipment includes cobalt salt header tank, precipitating agent header tank, reactor under two header tanks, stirrer placed in the reactor, sieve-plate fixed on the stirring shaft, material-discharging hole positioned in the lower end of the reactor and ageing tank, and the top of the above-mentioned every header tank is equipped with a material inlet, and its lower portion has a material liquor outlet. Besides, said invention also provides the concrete technological condition for producing ultramicrofine cobaltous carbonate powder.

Owner:湖南鼎伦新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/28c5abf4-a2cd-42d3-bc98-d2d1badcb37c/A200710094607C00021.PNG)

![Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/28c5abf4-a2cd-42d3-bc98-d2d1badcb37c/A200710094607C00022.PNG)

![Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof Octahydro cyclopenteno [c] pyrroletetrazole derivative and preparation thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/28c5abf4-a2cd-42d3-bc98-d2d1badcb37c/A200710094607C00031.PNG)