Preparation method of spherical cobaltosic oxide

A technology of spherical cobalt tetroxide, which is applied in the field of preparation of spherical cobalt trioxide, can solve the problems of wide particle size distribution, irregular shape, single crystal, etc., and achieve the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

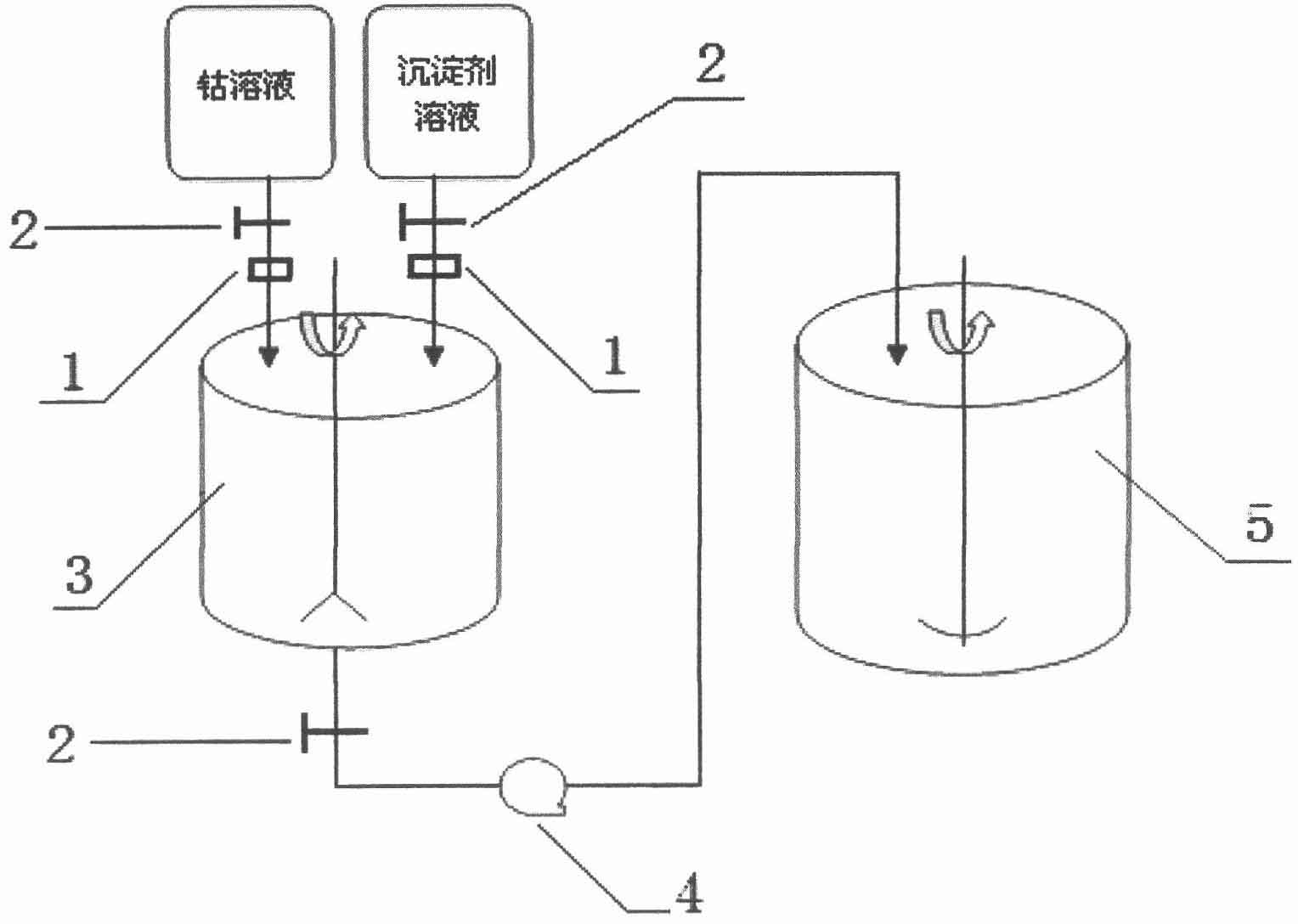

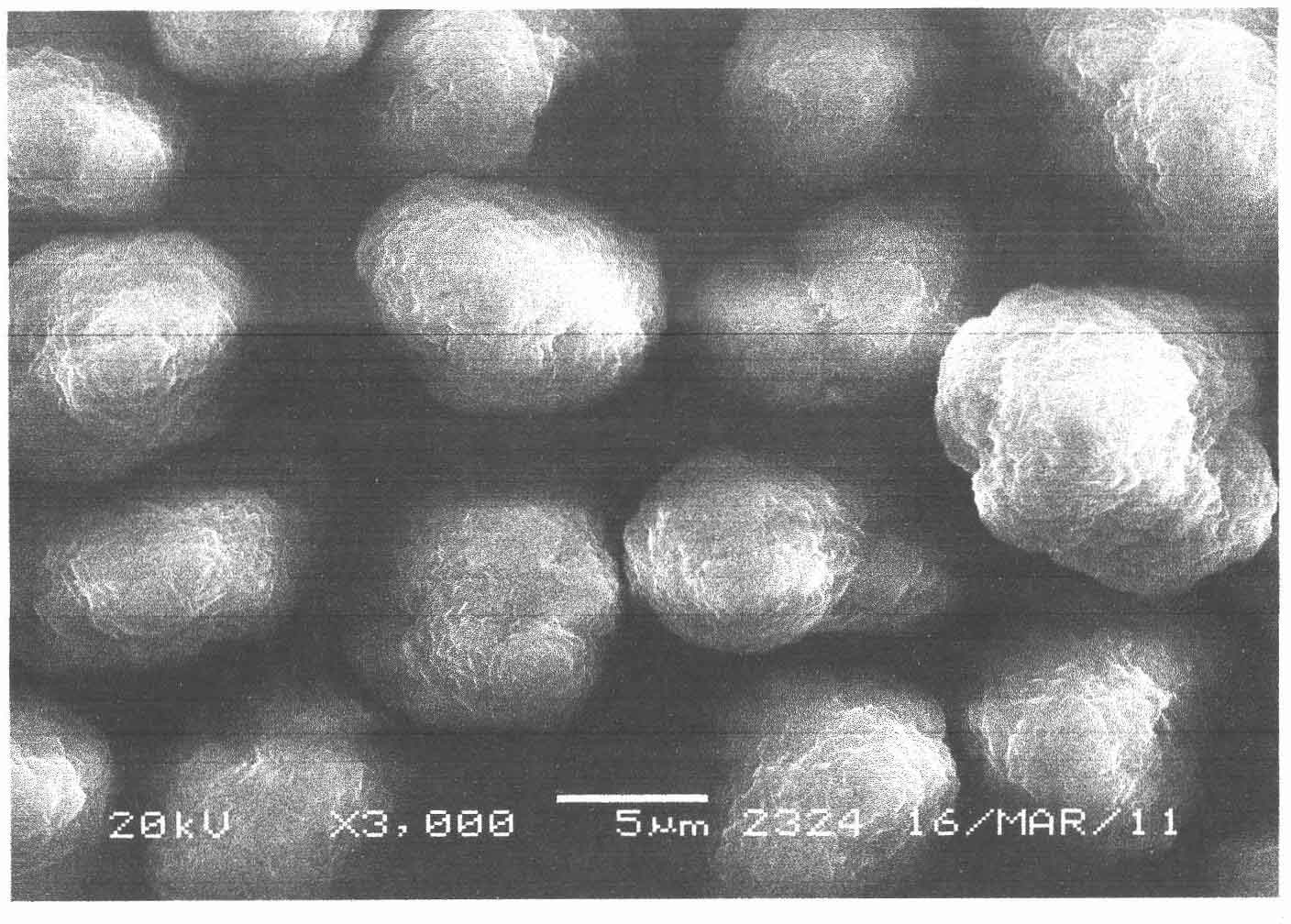

[0024] Reference attached figure 1 , to prepare a high-purity cobalt chloride solution, the solution contains about 90g / L of cobalt, and the pH value is controlled between 4.0-4.5. The concentration of preparing ammonium bicarbonate is 200g / L (containing ammonium bicarbonate concentration). Add about 500L of pure water into the 6m3 intermediate reaction tank in advance, control the stirring speed at 150r / min, and control the temperature at 60-65 degrees. Meter 1 flows into the intermediate reaction tank 3 in a divergent manner at the same time. After the heat preservation reaction for 1.5 minutes, the control reaction end point is pH=7.0, and other process parameters are carried out as required. After 1-5 days of continuous production, it is transferred into Aging kettle 5 aging 0.5-3h. Centrifuge, wash, wash with hot water above 50 degrees until the anion content detected in the washing water is within the acceptable range, and then dehydrate. Put the dehydrated cobalt car...

Embodiment 2

[0026] Reference attached figure 1 , prepare a high-purity cobalt sulfate solution, the solution contains about 80g / L of cobalt, and the pH value is controlled between 4.5-5.0. The concentration of preparing sodium carbonate solution is 150g / L (containing sodium carbonate concentration). Add about 500L of pure water into the 6m3 intermediate reaction tank in advance, control the stirring speed at 120r / min, and control the temperature at 25-30 degrees. The gauge 1 flows into the intermediate reaction tank 3 in a divergent manner. After the heat preservation reaction for 3.5 hours, the control reaction end point is pH=7.5, and other process parameters are carried out according to the requirements. Enter the aging kettle 5 and age for 0.5-3h. Centrifuge, wash, wash with hot water above 50 degrees until the anion content detected in the washing water is within the acceptable range, and then dehydrate. Put the dehydrated cobalt carbonate in a calciner, adjust the atmosphere in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com