Plasma atomization method and apparatus for preparing pure titanium or titanium alloy powder

A kind of atomization equipment, titanium alloy technology, applied in the field of preparation of titanium or titanium alloy powder, can solve the problem that the powder has not been studied in depth, achieve no adhesion/agglomeration phenomenon, prevent agglomeration and adhesion, and reduce the quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] 1. Raw material preparation stage

[0074] The round pure titanium wire with a diameter of 8mm is selected as the raw material for powder making. Each batch of raw materials has a test material certificate, which meets the requirements of the American Society for Testing and Materials ASTM on chemical composition.

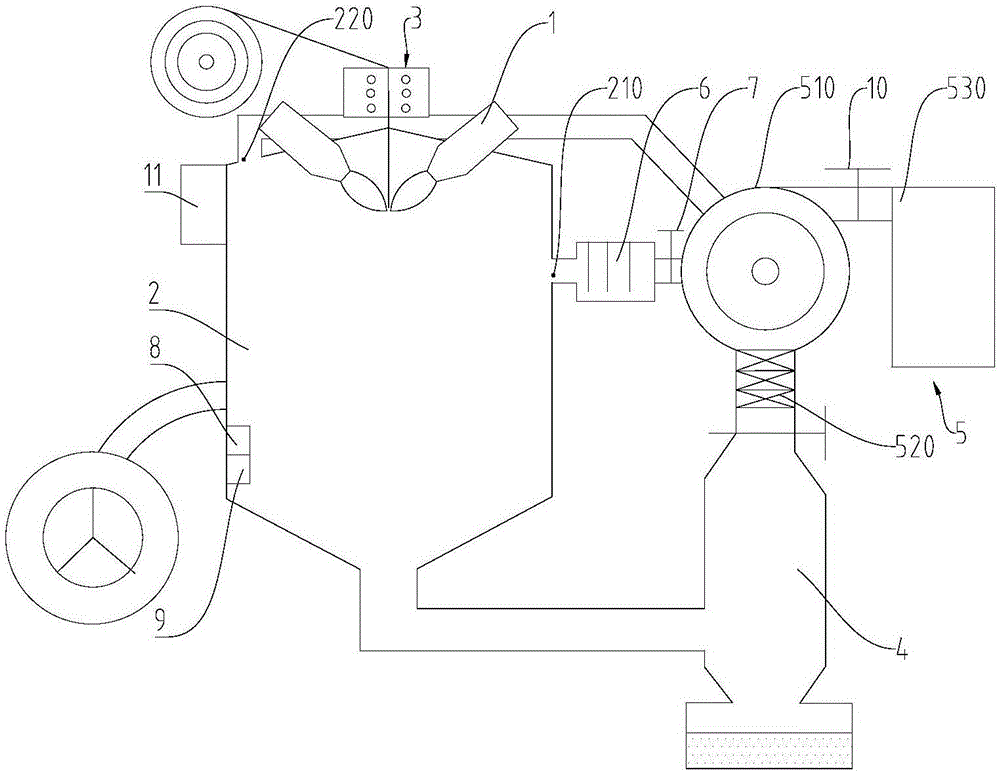

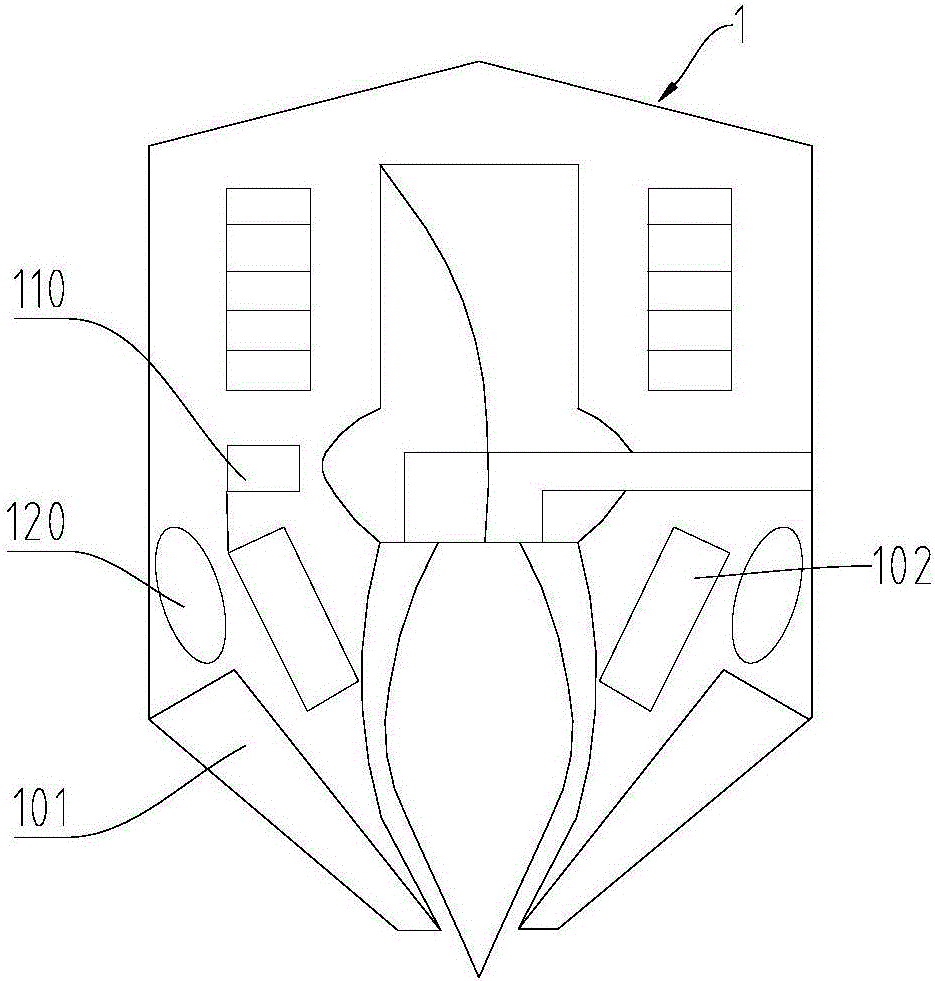

[0075] 2. Vacuumization and argon filling stage of atomization chamber 2

[0076] Before melting and atomization, use a vacuum device to remove the air in the atomization chamber 2, and after the inside reaches a vacuum of 40kPa, then fill it with argon to normal pressure, so that the initial oxygen and oxygen in the atomization chamber 2 The initial nitrogen content is less than 0.1%. The oxygen and nitrogen content detector 8 is used to detect the content of oxygen and nitrogen during the whole working process, so that the melting and atomization process can be carried out in a low oxygen and low nitrogen environment. When the oxygen and nitrogen content ...

Embodiment 2

[0090] A round Ti6Al4V wire with a diameter of 8 mm was selected as the powder-making raw material, and the titanium alloy powder was prepared by adopting the method in Example 1, only changing some parameters. Among them, the changed parameters are:

[0091] During the vacuuming and argon filling stages of the atomization chamber 2, the initial oxygen and nitrogen content is lower than 0.08%, and when the oxygen and nitrogen content exceeds 0.2%, it will automatically alarm and interrupt the working process.

[0092] In the stage of melting and atomization, the feeding speed of wire is 0.08m / s, the power of plasma torch is 40kW, and the jetting speed of hot gas flow at the torch port is 20L / min.

[0093] In the powder cooling stage, the air pressure at the air inlet 210 is 0.5Mpa, and the temperature of the cooling gas is maintained at 300-320°C.

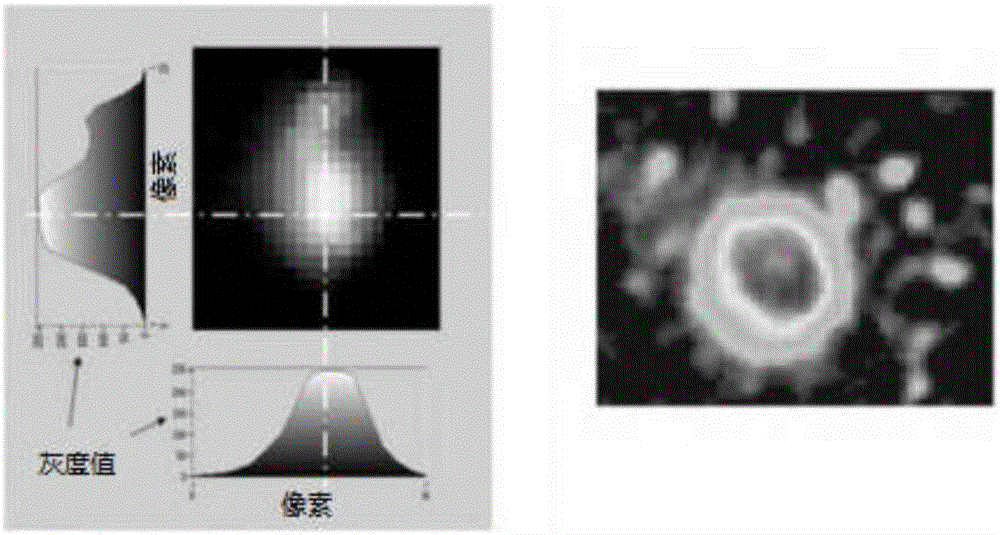

[0094] The Ti6Al4V alloy powder prepared as Figure 5 As shown, it is highly spherical, with uniform particles and few satellit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com