Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

990results about How to "Good quality and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

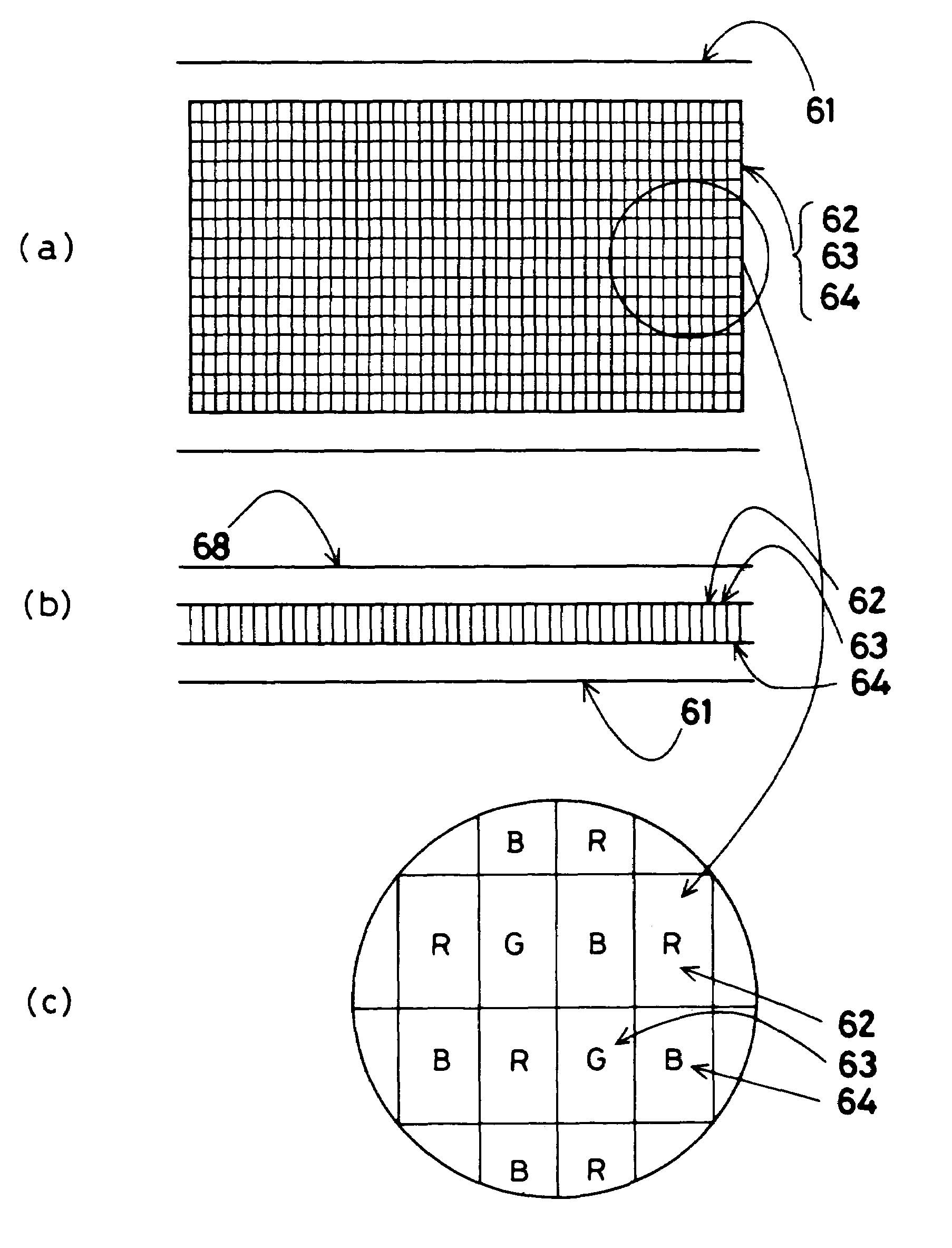

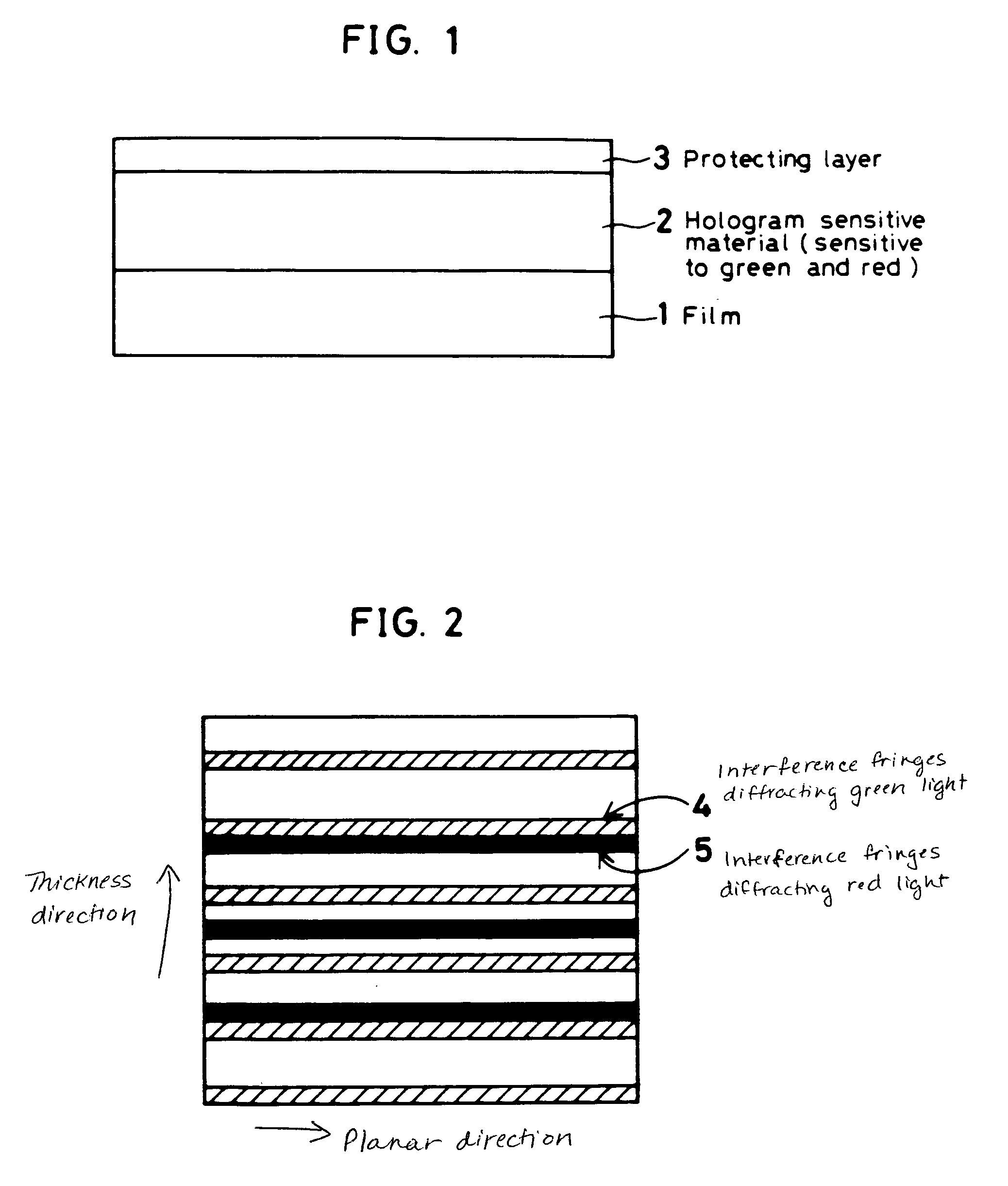

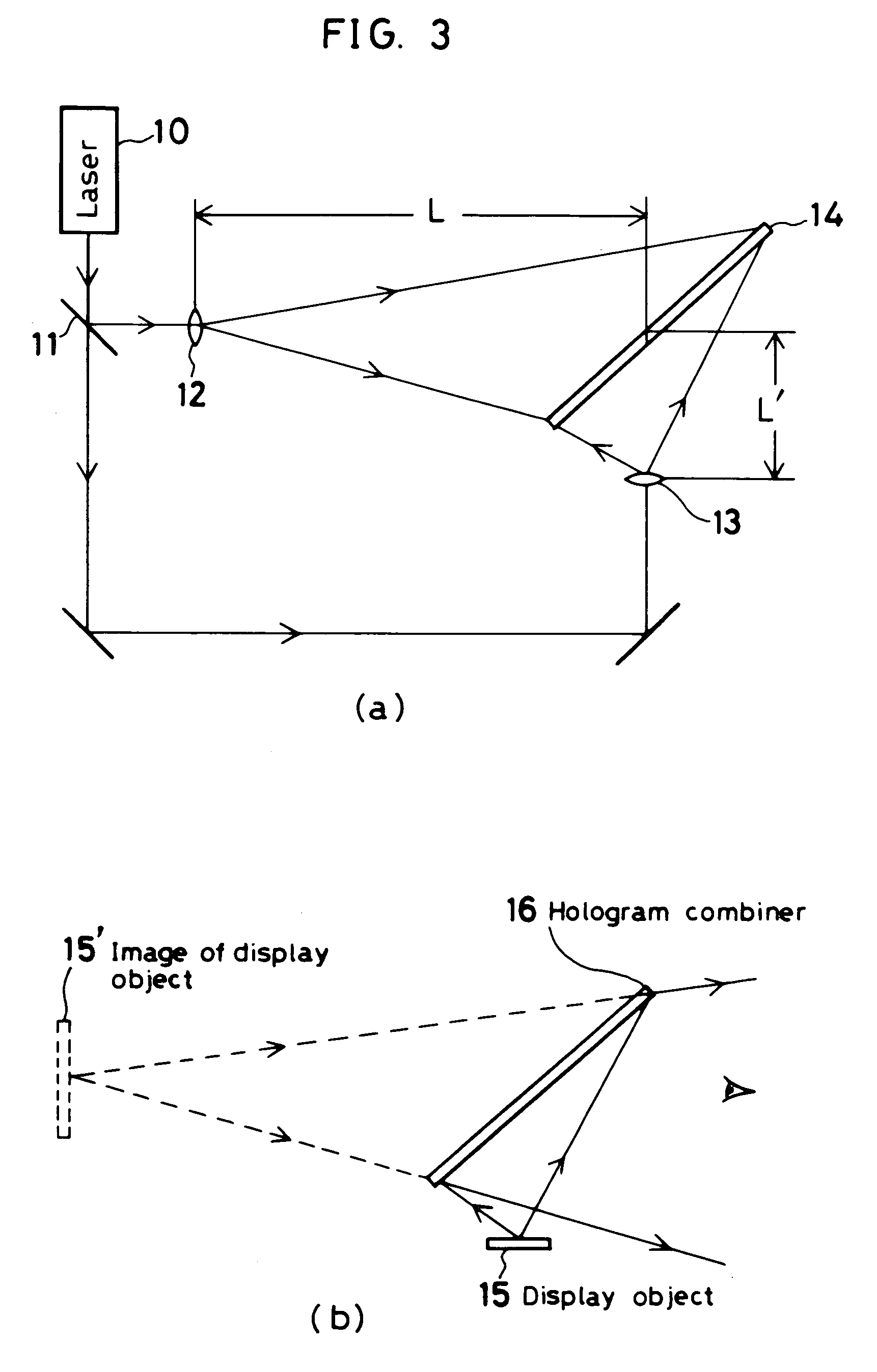

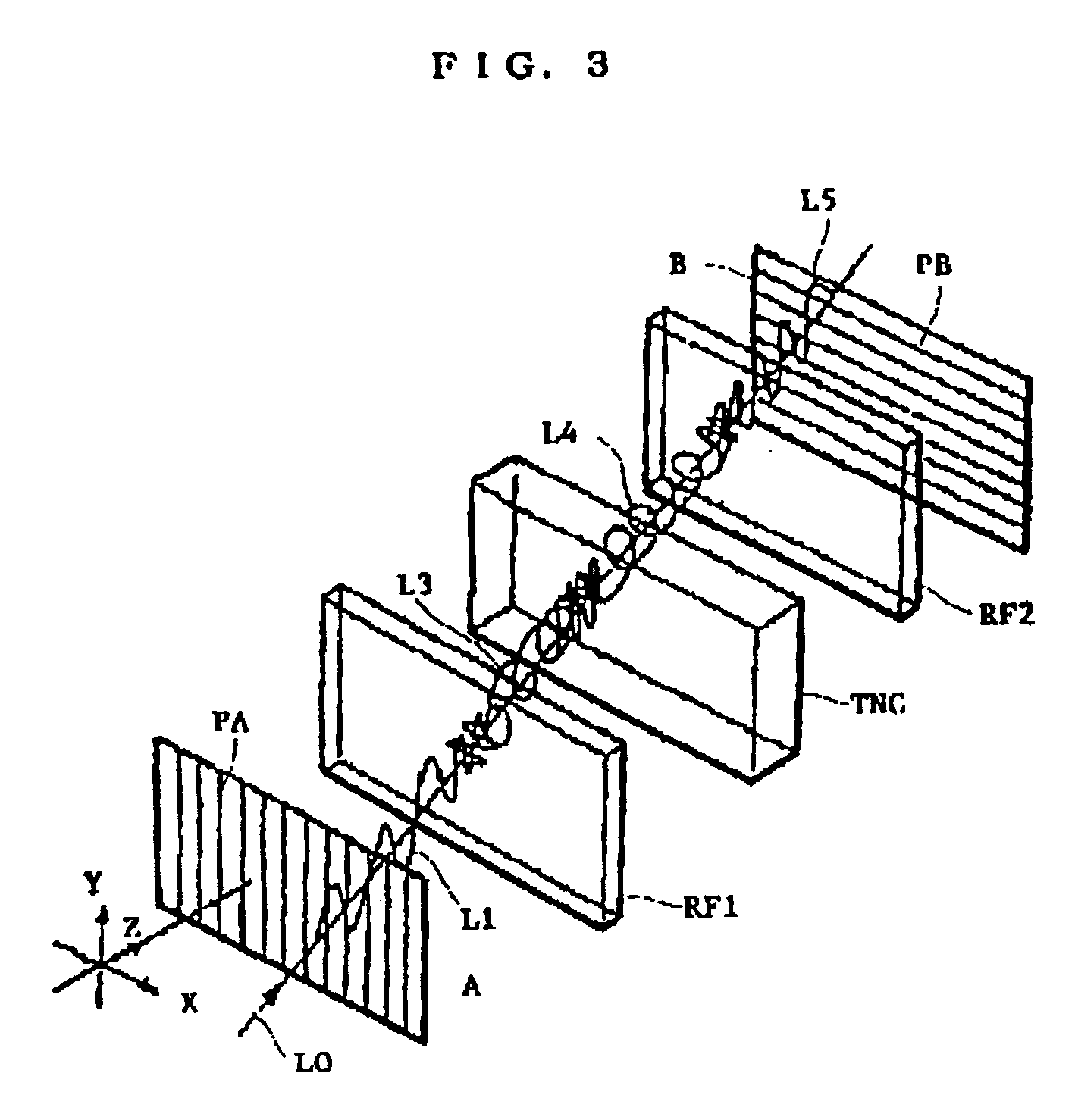

Hologram recording sheet, holographic optical element using said sheet, and its production process

InactiveUS7132200B1Simple processQuality improvementHolographic light sources/light beam propertiesPhotomechanical apparatusLength waveHolographic recording

The hologram recording sheet according to the invention is made up of a base film and hologram sensitive materials sensitive to different wavelength regions formed therein in a desired pattern, or a film and at least two hologram recording sensitive materials sensitive to different wavelength regions laminated on the film with a transparent plastic spacer layer located therebetween, thereby enabling the required diffraction light wavelengths to be recorded on the required sites without producing unnecessary interference fringes. At least two hologram recording sensitive materials sensitive to different wavelength regions are formed on different sites on a film in dotted or striped configuration, the size of which is up to 200 mm or at least twice as large as the thickness of the sensitive material layers, thereby enabling regions diffracting light of different wavelengths to be formed in the form of independent sets of interference fringes.

Owner:DAI NIPPON PRINTING CO LTD

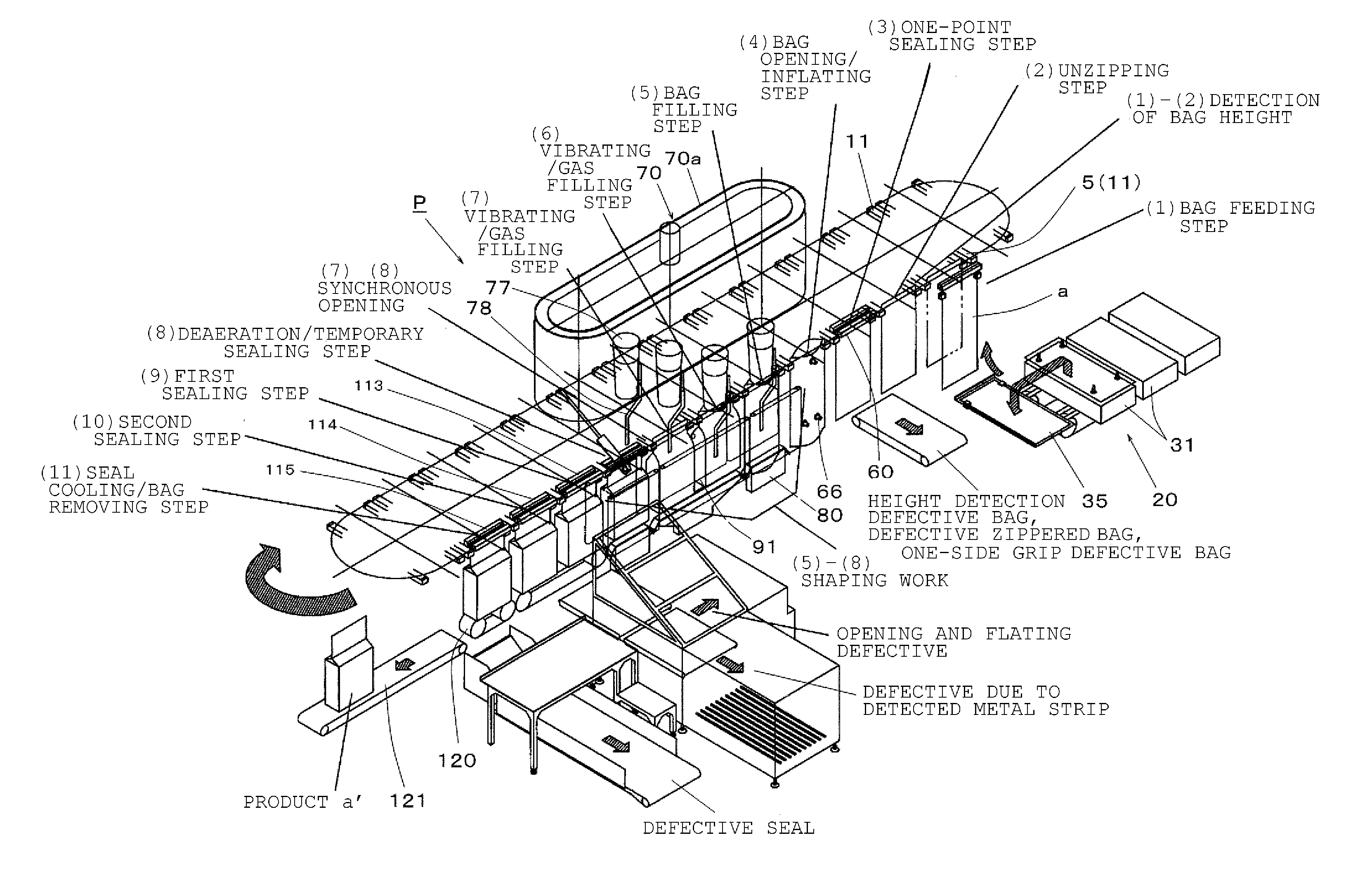

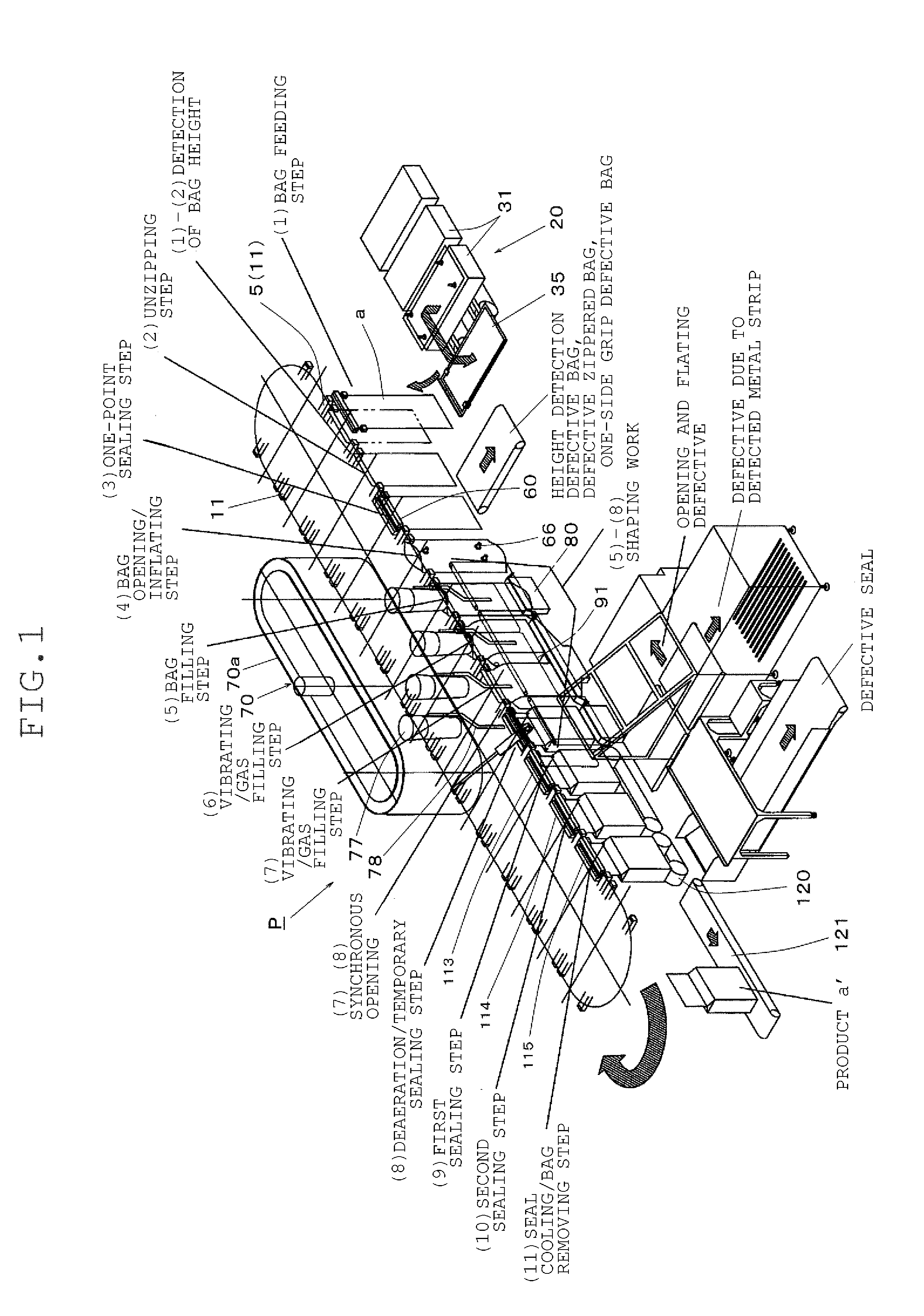

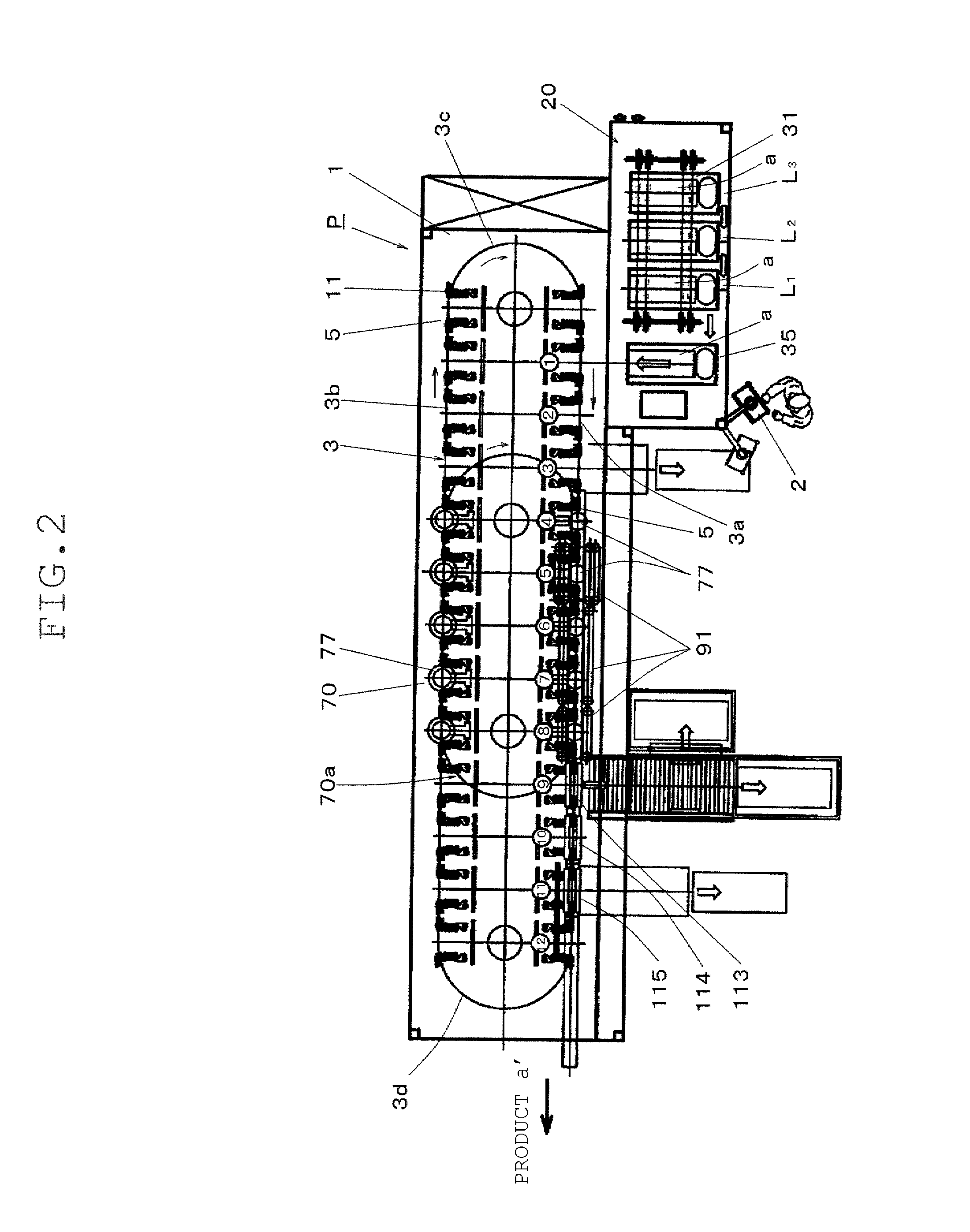

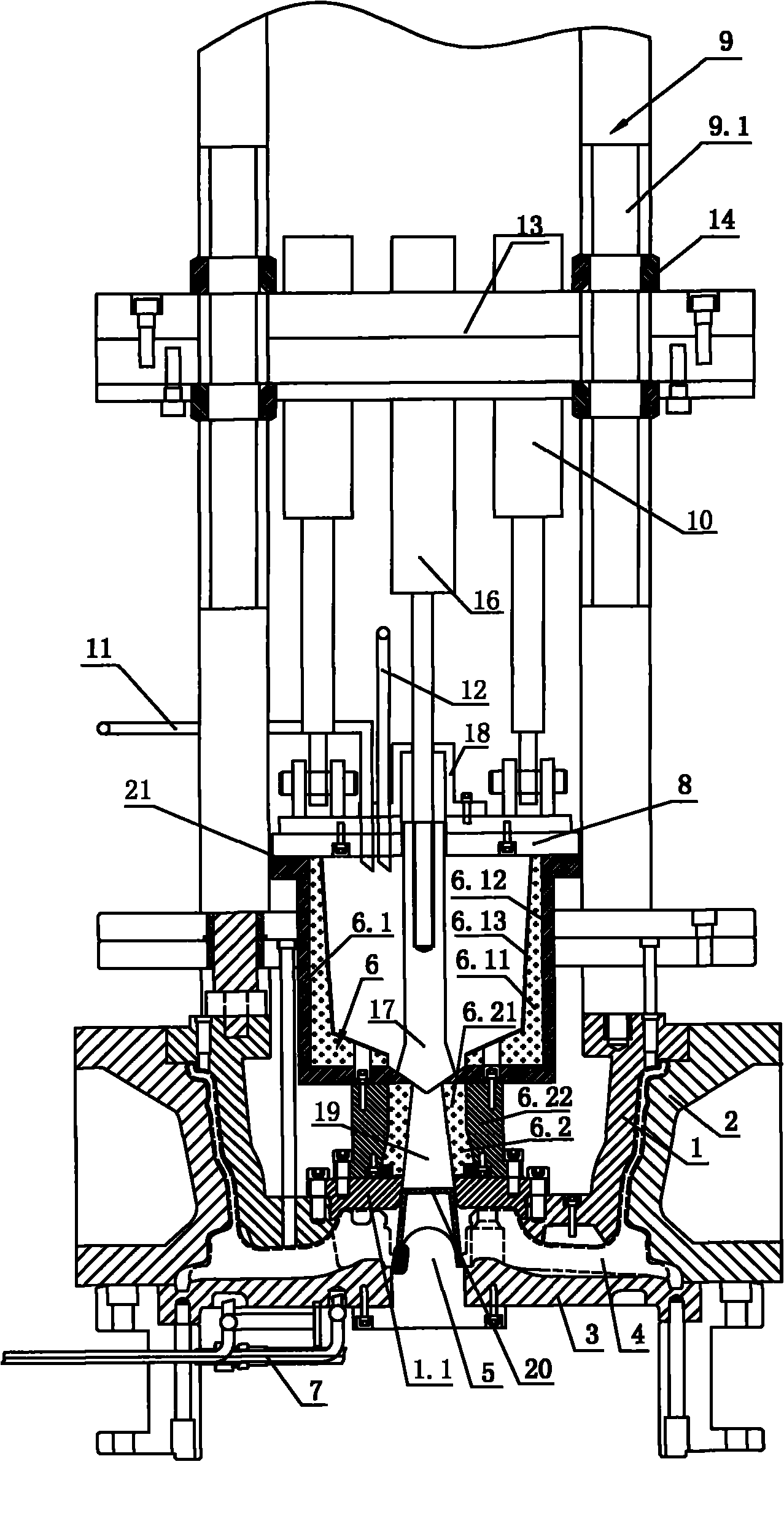

Gas-Filliing Packaging Method and Packaging Machine Therefor

InactiveUS20140331603A1Good quality and stabilityPackaging by pressurising/gasifyingWrapper twisting/gatheringPacking methodPackaging machine

A gas-filling packaging method using a track type gas-filling packaging machine includes a bag placing step in which a number of packaging bags set in a magazine in a stacked state are turned up one by one by a sucker and picking up and then passing the bag to a bag chuck, a bag opening / inflating step of opening the bag mouth and inflating the bottom of the bag by suckers, a bag filling step of lowering a synchronous funnel to be inserted into the bag and applying a receiving member of a bottom tapping unit to the bag, so that the bag is filled with a predetermined amount of article while the bottom is tapped, a deaeration / temporarily sealing step of inserting a deaeration nozzle into the bag to remove air in the bag and holding the bag mouth by a temporary heater.

Owner:GENERAL PACKER

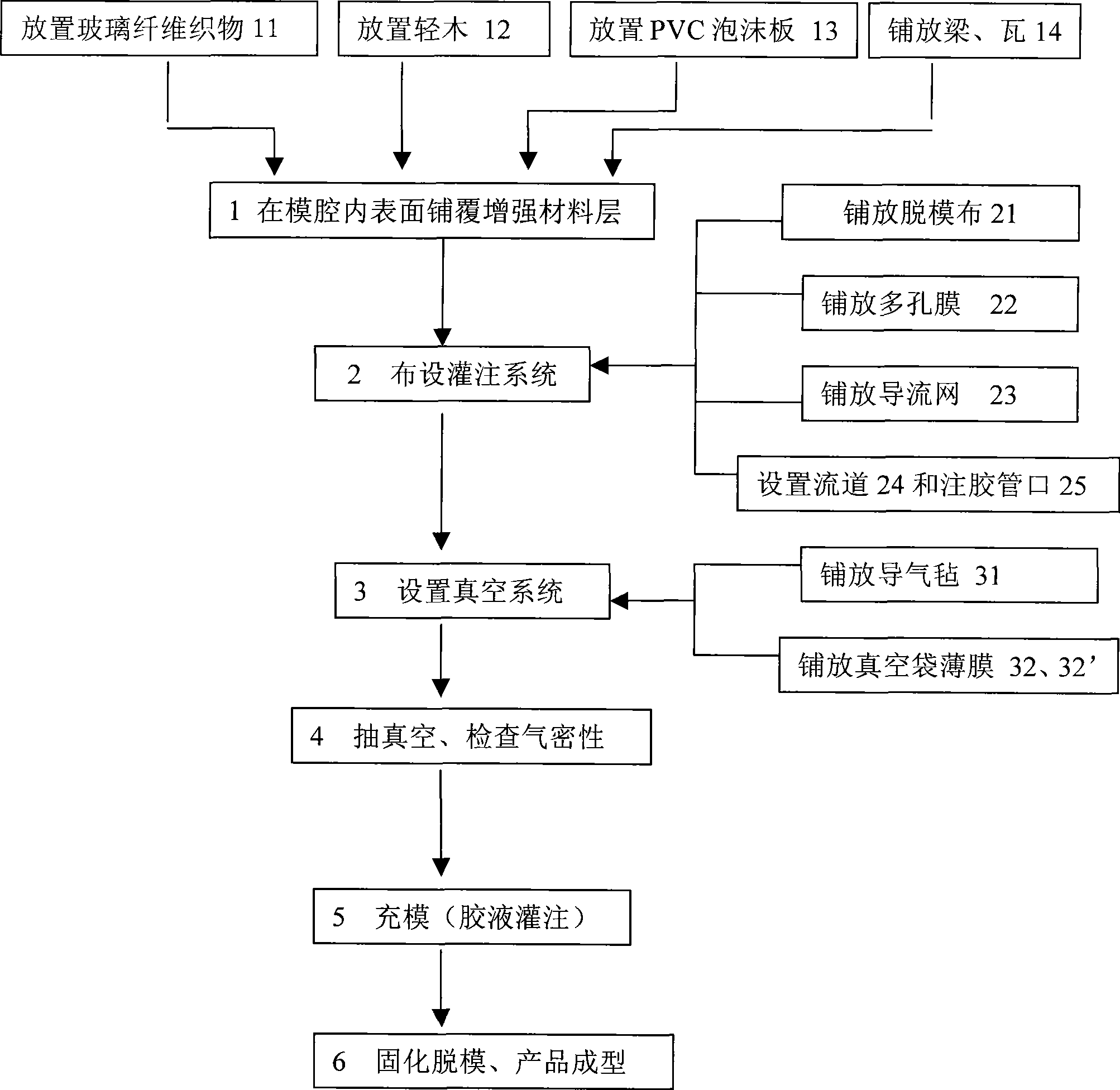

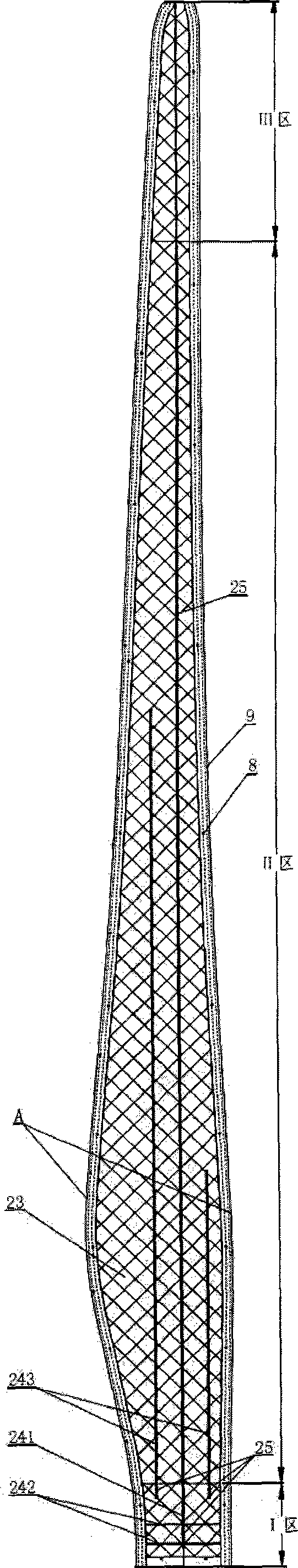

Megawatt level composite material wind electricity blade vacuum guiding and forming technique

ActiveCN101456256AHarm reductionImprove molding efficiencyFinal product manufactureDomestic articlesElectricityTurbine blade

The invention discloses a vacuum infusion forming process for a megawatt grade composite material wind turbine blade. The process comprises a step of spreading and cladding reinforced material layers in an upper mold cavity and a lower mold cavity of a mould of the blade respectively and a step of solidification, demoulding and product forming, and is characterized by comprises the following steps between the two steps: 1)distributing injection systems on the surfaces of the reinforced material layers; 2) distributing vacuum systems on the outer surface of the injection systems spread and covered with flow channels in the step 1); 3) checking the airtight performance of an vacuumizing opening; 4) mould filling ( filling rubber liquid); and 5), solidification, demoulding and product forming. The vacuum infusion process can complete mould filling in 1.5 hours, improves the forming efficiency of large blades, saves special equipment and achieves low production costs. Products formed by the process are uniform in quality distribution and good in process repeatability, and can reduce volatilization of harmful gases and environmental pollution and ensure heath of operators and are easy to promote and use compared with a hand lay up process and a wet spreading process.

Owner:SINOMATECH WIND POWER BLADE

Solvent casting process, polarizing plate protective film, optically functional film and polarizing plate

InactiveUS20030057595A1Good quality and stabilityHigh productivityDead plant preservationArtificial flowers and garlandsSolventSolid matter

A process for solvent casting which comprises, casting a dope from a casting die onto a casting support, drying the cast dope on the casting support to form film, stripping off the film from the casting support, and further drying the film, wherein the dope has a solid matter content of from 17 mass % to 30 mass %, and a mean drying rate between the casting of the dope and the stripping off is more than 300 mass % / minute and not more than 1000 mass % / minute is proposed. The process for solvent casting for producing a film comprising the steps of casting a dope from a casting die to a casting support, forming the film by drying the dope to some extent, stripping off the film from the casting support and further drying the film while conveying the film with carrying it at both side edges of the film by a tenter under a specified condition is also proposed. The high-speed solution film forming methods enable to produce the film having good quality with stable conveying and with stable drying especially in the conveying of the film by the tenter machine in the drying steps after stripping off from the casting support.

Owner:FUJIFILM HLDG CORP +1

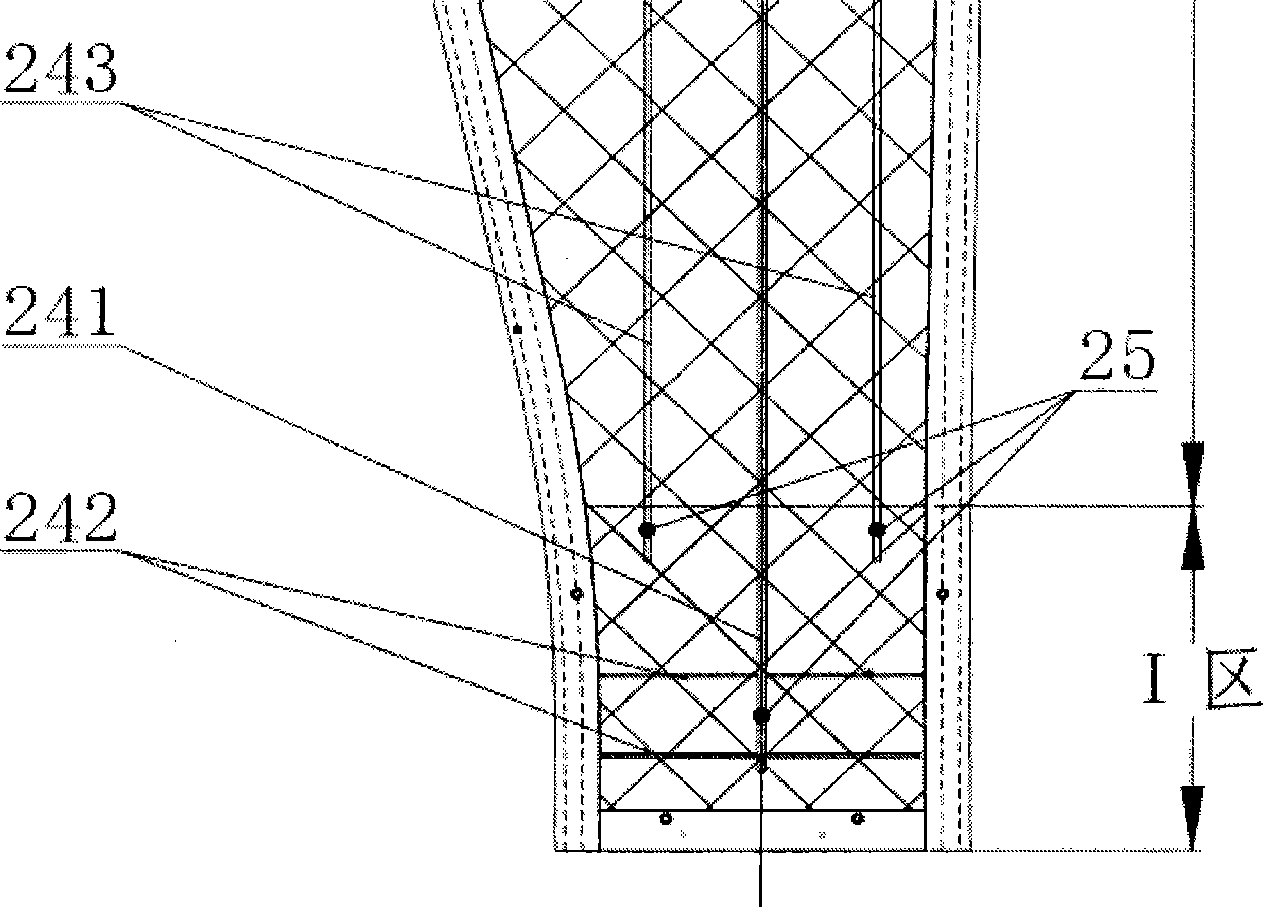

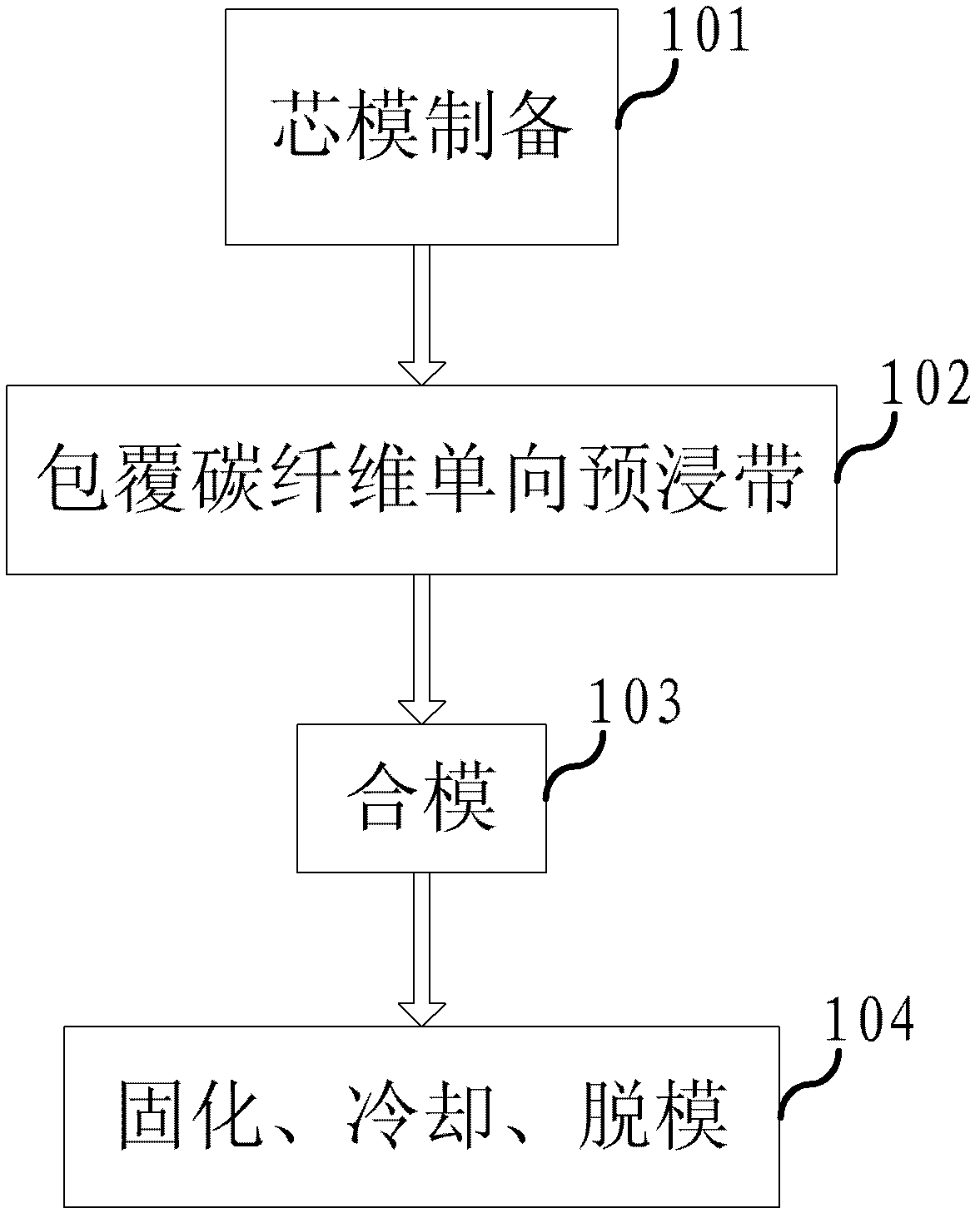

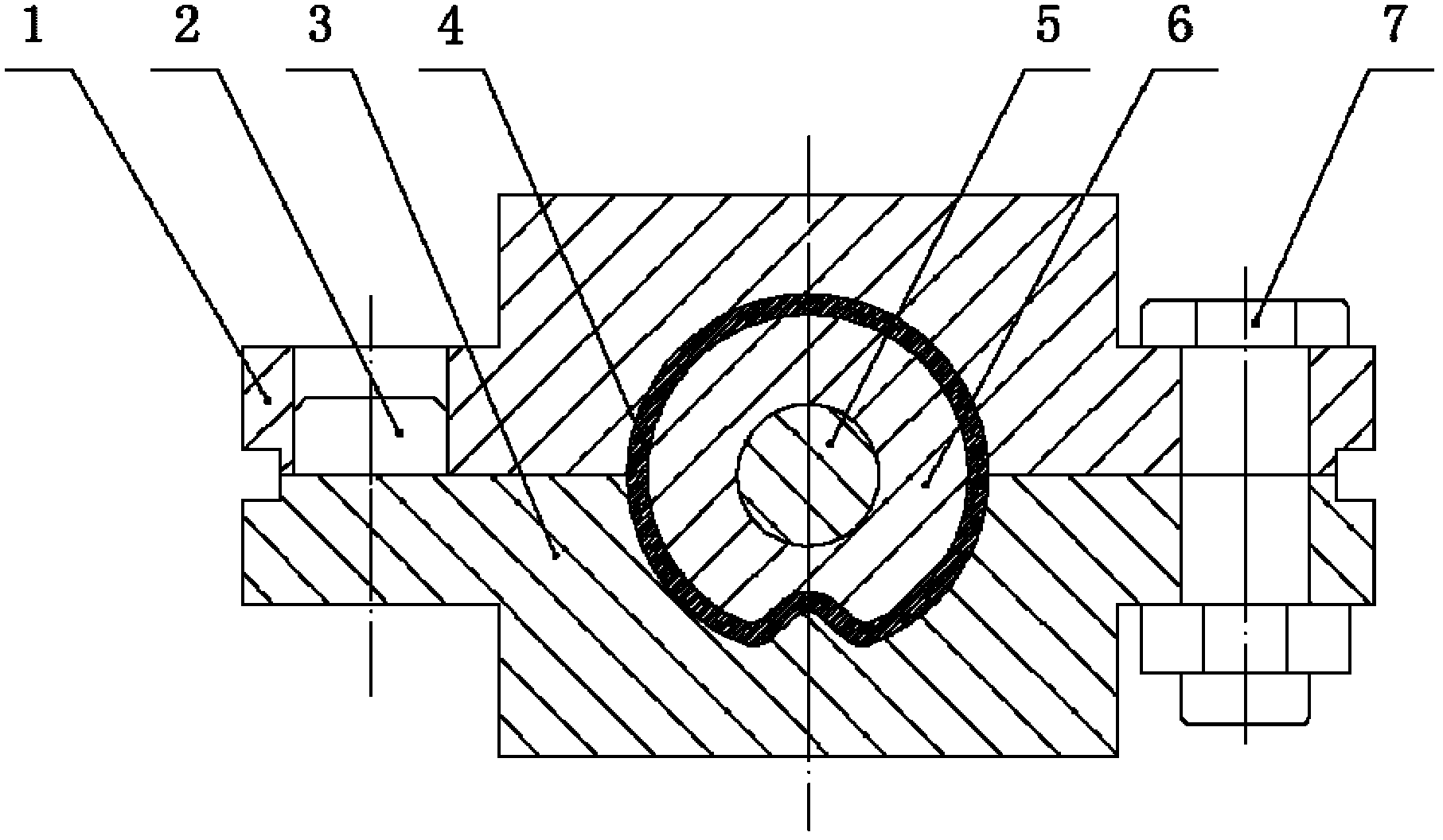

Method for forming carbon fiber pipe and die thereof

The invention discloses the technical field of carbon fiber composite materials, and discloses a method for forming a carbon fiber pipe. The method comprises the following steps of: preparing a core mould, namely preparing the core mould for wrapping carbon fiber one-way preimpregnation belts, wherein the core mould comprises a metal core rod and a rubber material wrapping the metal core rod; paving and coating the carbon fiber one-way preimpregnation belts, namely after coating a release agent on the surface of the core mould, paving and coating a plurality of layers of carbon fiber one-way preimpregnation belts according to different angles; closing the die, namely positioning the core mould in which the carbon fiber one-way preimpregnation belts are paved and coated and putting into a female die, closing the die, and fastening; and curing, cooling and demoulding, namely putting the die which is closed into a drying oven, curing, cooling with a furnace, and demoulding to form the required finished piece. The method for forming the carbon fiber pipe has the advantages of simple process, high production efficiency, low manufacturing cost, uniform wall thickness of the product, high quality and stability and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

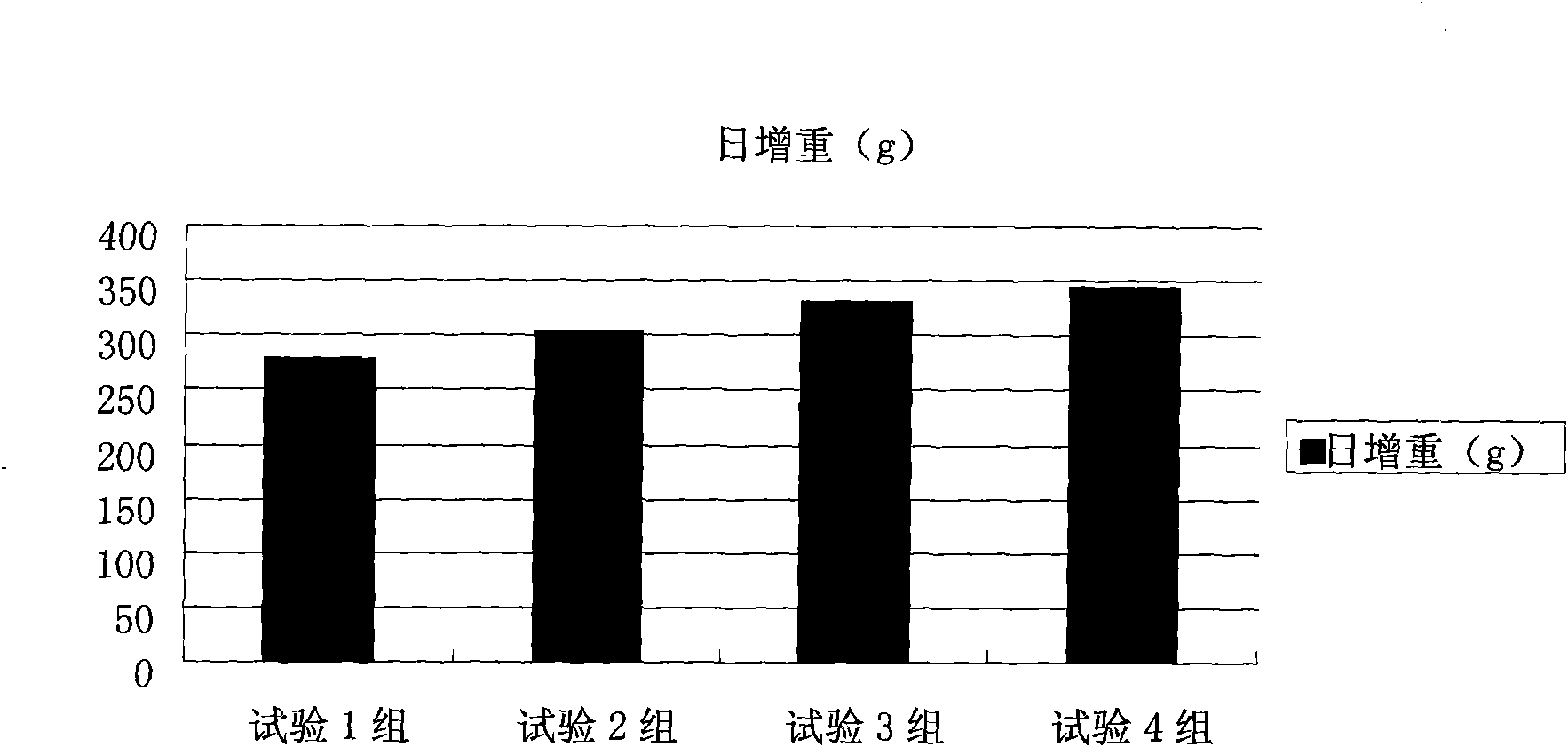

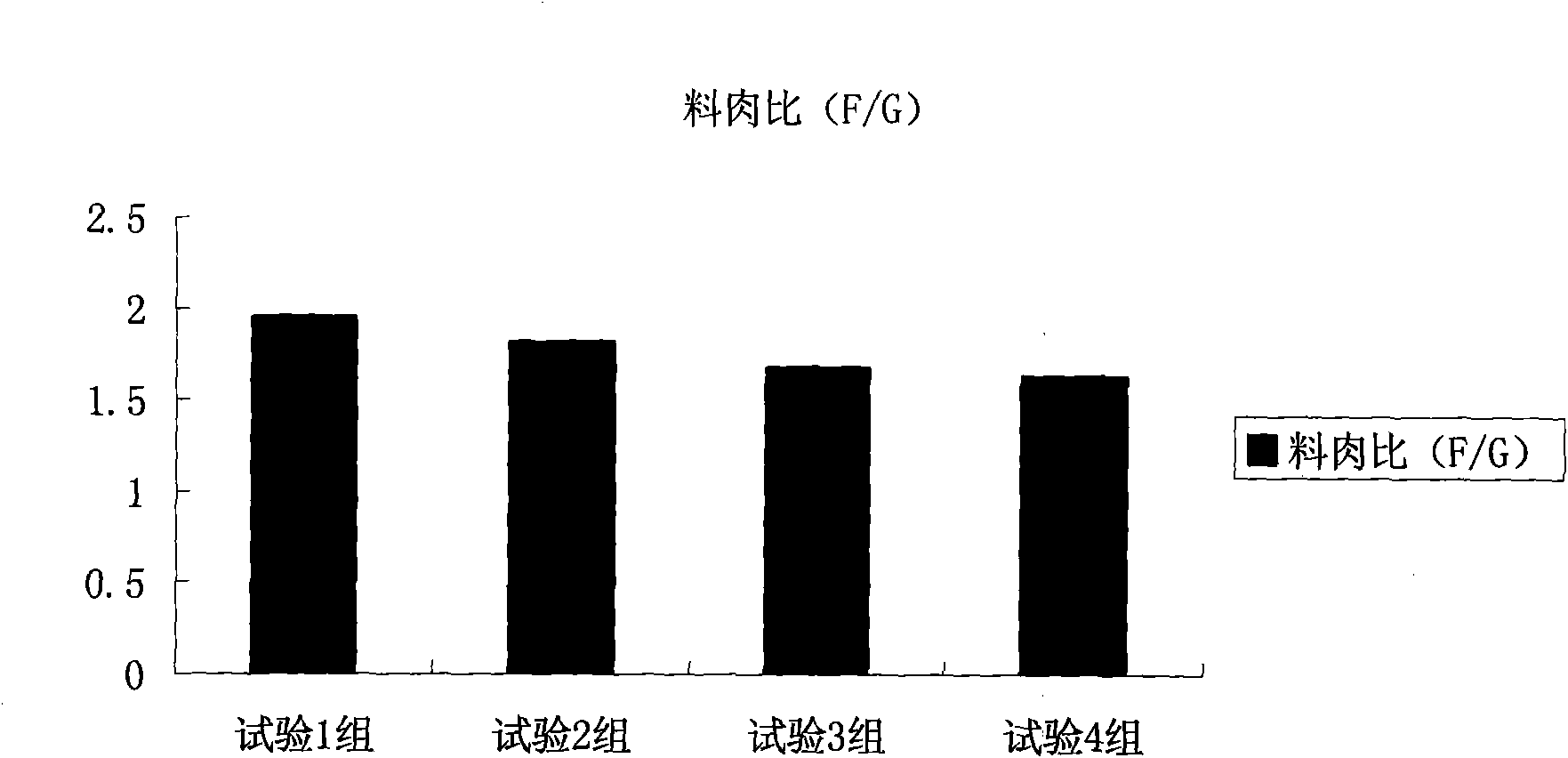

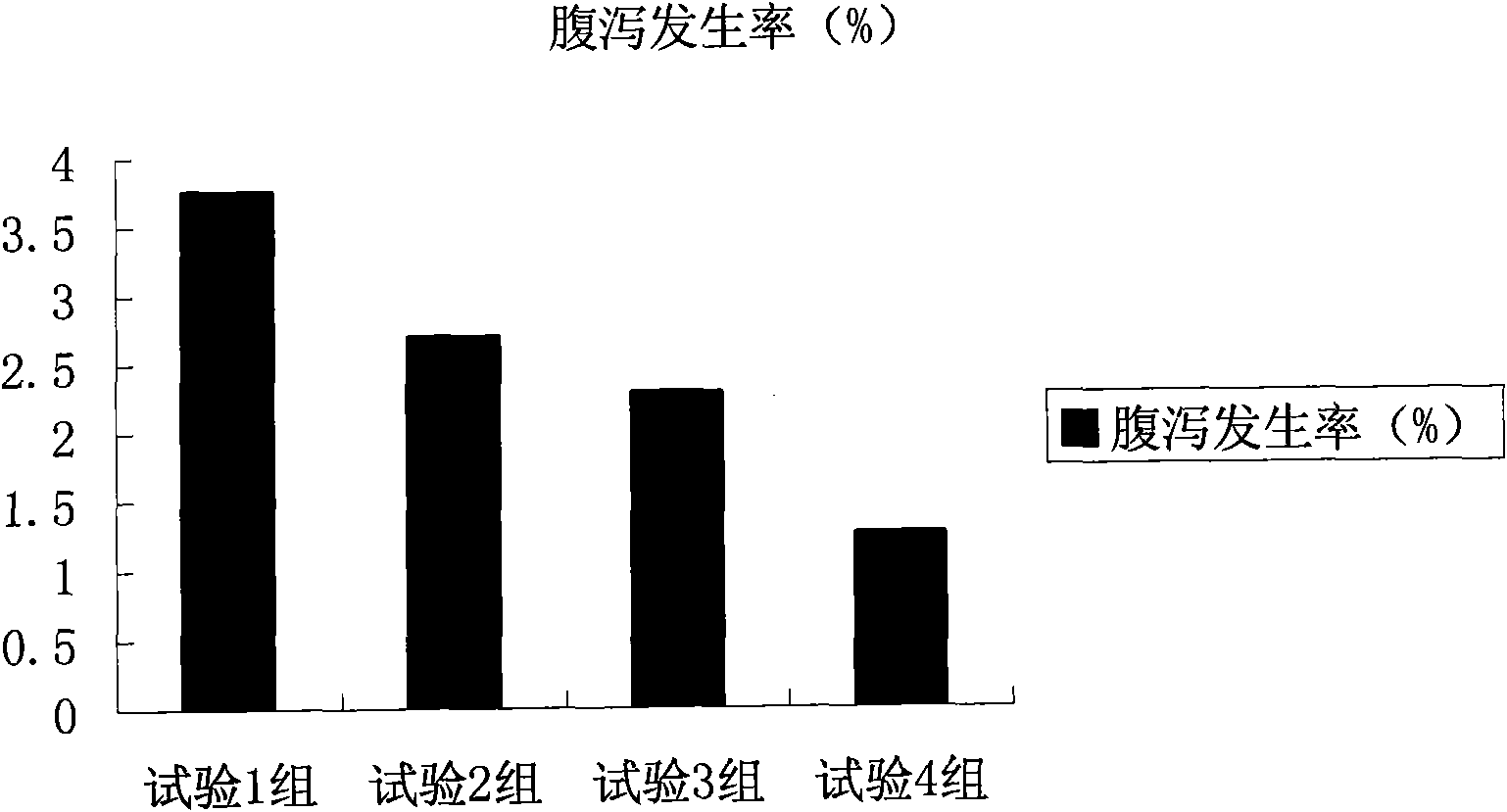

High efficiency livestock and poultry nutrition replenisher and preparation method thereof

ActiveCN101669578AAvoid direct contactImprove mixing uniformityAnimal feeding stuffAccessory food factorsSolubilityAnti stress

The invention provides a high efficiency livestock and poultry nutrition replenisher and a preparation method thereof, and the nutrition replenisher contains various vitamins, amino acids and electrolyte. Simultaneously, the multi-stage premixing process is adopted by the high efficiency livestock and poultry nutrition replenisher, so that the high mixing uniformity of ultra-trace elements can beensured; and furthermore, sanguinarine is introduced into drinking water nutrition replenisher and is processed by peridium treatment, and emulsification treatment is carried out on liposoluble vitamins, so that good water-solubility can be guaranteed. The high efficiency livestock and poultry nutrition replenisher has comprehensive nutrition, leads all nutrient components to be supplemented witheach other, can effectively prevent deficiency of the vitamins and the amino acids, maintains electrolyte balance, regulates the metabolism of organism, improves the feed conversion rate and the anti-stress capability, stimulates the immune function, reduces the occurrence of diseases, and has remarkable economic and social benefits as well as broad market prospect.

Owner:临沂福乐维生物科技有限公司

Earphone Microphone

InactiveUS20150023542A1Good quality and stabilityPick up clear soundMicrophonesLoudspeakersExternal Acoustic MeatusEngineering

Provided is an earphone microphone capable of outputting sound with good quality and picking up clear sound. The earphone microphone includes a speaker, a microphone, a main body case, and a seal member. The seal member seals between the main body case and user's external acoustic meatus when the earphone microphone is inserted in the external acoustic meatus. The main body case is provided with an acoustic space in which the speaker and the microphone are disposed, and a first opening and a second opening which are communicated with the acoustic space. When the earphone microphone is inserted in the external acoustic meatus, the first opening is communicated with the external acoustic meatus while the second opening is communicated with outside of the main body case other than the external acoustic meatus.

Owner:FUNAI ELECTRIC CO LTD

Integral forming method for thin-walled titanium alloy part with irregularly-shaped curved surface and die

InactiveCN102672435AOvercoming shape constraintsOvercome the processShaping toolsLaser beam welding apparatusTitanium alloyMetal

The invention belongs to the field of sheet metal and welding processing, and relates to an integral forming method for a thin-walled titanium alloy part with an irregularly-shaped curved surface. The integral forming method aims at overcoming the defects that the shape of parts processed through the prior art is limited or the procedure and the cost are higher, and effectively ensuring the precision forming of a thin-walled component with an irregular shape. The integral forming method comprises the steps as follows: a parting surface is determined; blanking is carried out; in the preforming step, a plate is bent from a flat into a circular arc through a bending die or a bending machine; welding is carried out; in the hot shaping step, a hot shaping die is put in the inner part of a part that is processed through the assembly welding under the ordinary temperature, and the part is supported tightly due to the dead weight of the die and is heated in a hot shaping machine; and in addition, a pressing machine applies pressure to the hot shaping die when the part is heated until material is softened, so as to enable the part to reach the needed size. The integral forming method comprehensively utilizes the advantages of various processes, can obtain the large-sized thin-walled titanium alloy part with the irregularly-shaped curved surface through only two weld joints, and achieves higher surface quality of the part.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Pullulan polysaccharide hollow hard capasule and its preparing method

InactiveCN101069677ASmall range of molecular weight variationProduct quality is easy to controlPharmaceutical non-active ingredientsCapsule deliveryPullulanHard Capsule

The present invention discloses a hollow hard capsule and its preparation method. It is made up by adopting prolanpolysaccharide as main body material and adding gelling agent, coagulant aids, surfactant and humectant through a certain preparation process. Said invention also provides the concrete steps of its preparation method.

Owner:广东强基药业有限公司

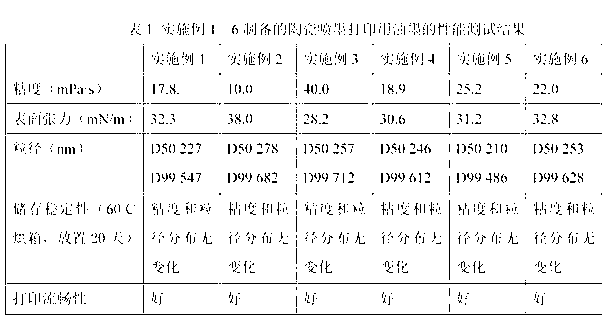

Ink for ceramic ink-jet printing and method for preparing same

ActiveCN102964920AGood quality and stabilitySimple manufacturing methodInksAcrylate esterDefoaming Agents

The invention discloses an ink for ceramic ink-jet printing and a method for preparing the same, wherein the ink comprises the following components by mass percent: 20-50% of ceramic pigment, 3-8% of resin, 2-10% of dispersant, 0.1-0.2% of flatting agent, 0.3-0.7% of defoamer, 0.08-0.12% of anti-settling agent and the balance of solvent; and the dispersant is a high-molecular-weight polyurethane type dispersant or a high-molecular-weight polyacrylate type dispersant. The ink for ceramic ink-jet printing provided by the invention is good in quality stability and thereby can be stored for a long time; the ink is excellent in ink-jet printing performance, low in ink viscosity and even in particle size distribution; the viscosity of the ink is between 10.0 and 40.0 mPa.s and is controllable; and the surface tension of the ink is 28-38 mN / m, while the average particle size is 200-300 nm and the maximum particle size is less than 800 nm. The method for preparing the ink for ceramic ink-jet printing provided by the invention is simple and efficient; and a one-step mill base grinding process and an ink performance regulation process are carried out, so that the production cost is greatly saved.

Owner:GUANGDONG DOWSTONE TECH

Rosin halogen-free scaling powder for lead-free soldering paste

InactiveCN1709638ASolve the serious problem of high temperature oxidationImprove liquidityWelding/cutting media/materialsSoldering mediaAcyl groupAlloy

The invention relates to a scaling powder, especially applying to the alloy's department such as SnAgCu, SnAgCuRE and SnAg and so on. The quality percent of the present invention is the activation dosage of the organic acid which consists of the duality acid, the three-member acid, the hydroxyl acid, the balminess acid in the fattiness race 4-30wt%,the changed capable colophony which is one or more mixed of the converged colophony, the hydrogen sulfide colophony and the divergent colophony 29-67wt%, the becoming electuary which is one or more mixed of the assembled glycol2000,the assembled glycol4000 and the assembled glycol6000 1-20wt%,the olefin as the tranquilization dosage 0.5-8wt%,the touched and altered dosage which one or more mixed of the hydrogen sulfide castor oil and the compound of the acyl and amine 1-8wt% and the remain is the impregnant of the high boiling point which is one or more mixed of the butyl dissolved fine dosage, the calorie certain alcohol of the cymene and the calorie certain alcohol of the second radicle. The invention doesn't contain the halogen and penetrate the copper mirror after welding. It has high insulated resistances, the excellent function of the assisting burning. Also it solves the problem of oxidation in the high temperature and the appropriate viscosity of the welding cream.

Owner:BEIJING UNIV OF TECH

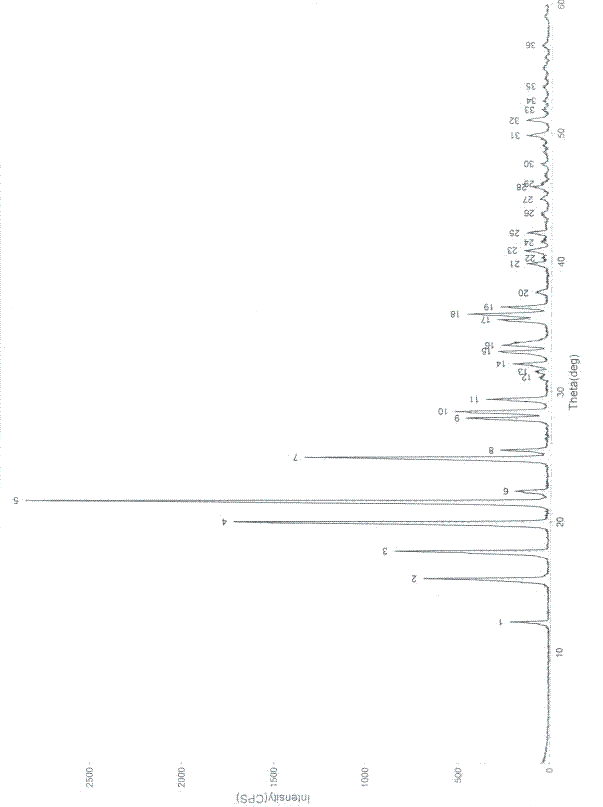

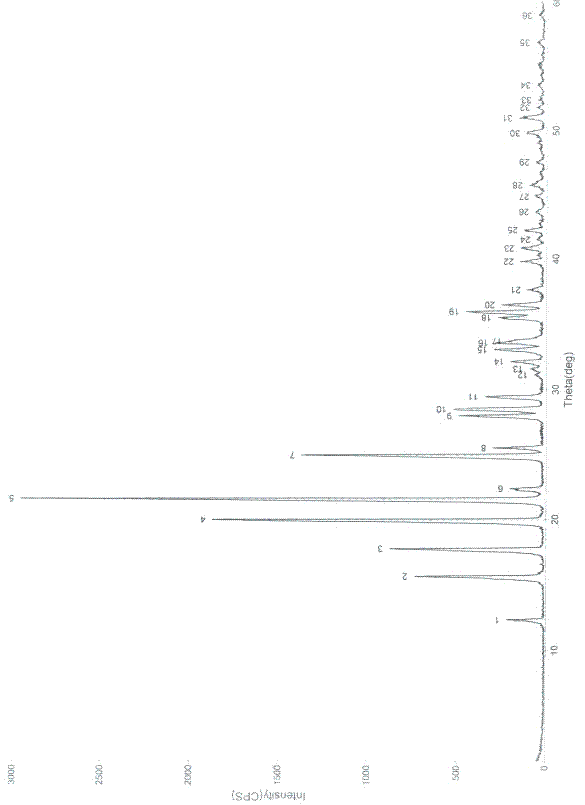

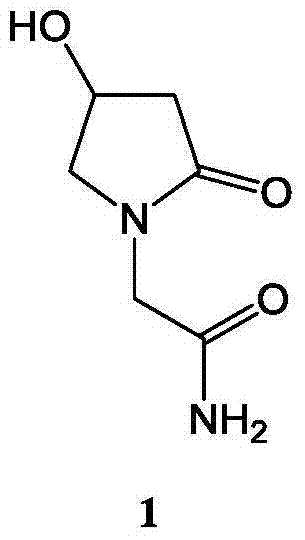

Oxiracetam capsule and preparation method thereof

ActiveCN103494790AHigh purityLow impurity contentOrganic active ingredientsNervous disorderMedicinal chemistryImpurity

The invention relates to an oral capsule preparation of oxiracetam and a preparation method thereof. The oxiracetam capsule contains 80.0-85.5% by weight of oxiracetam, 9.7-15.2% by weight of xylitol and 4.8% by weight of an emollient, wherein the oxiracetam is in a crystal form. The oxiracetam in the crystal form is a good crystal with excellent mobility. Compared with the crystal form provided in the prior art, the oxiracetam in the crystal form has higher purity, less impurity, better quality stabilizer and better crystal form stability. The quality stability of the disclosed oxiracetam capsule is improved remarkably, the preparation process is simple, and the production cost is lowered.

Owner:CSPC OUYI PHARM CO LTD

Hand held shower head with filter replacing pre-alarm assembly

InactiveUS7468127B2Quality improvementDrawback can be obviatedServomotor componentsWater/sewage treatment by magnetic/electric fieldsDisplay devicePropeller

A hand held shower head with a filter replacing pre-alarm assembly includes a propeller wheel with a magnetically induced signal emitter and a correspondingly placed signal receptor, as well as a digital display connected to the signal receptor. Upon a total accumulated quantity of water flow through a filter positioned within a hand held portion, a pre-alarm signal is generated, and upon reaching a critical point, a buzzer is activated to remind the user to replace the filter to ensure a quality filtered water.

Owner:HSU CHAO FOU

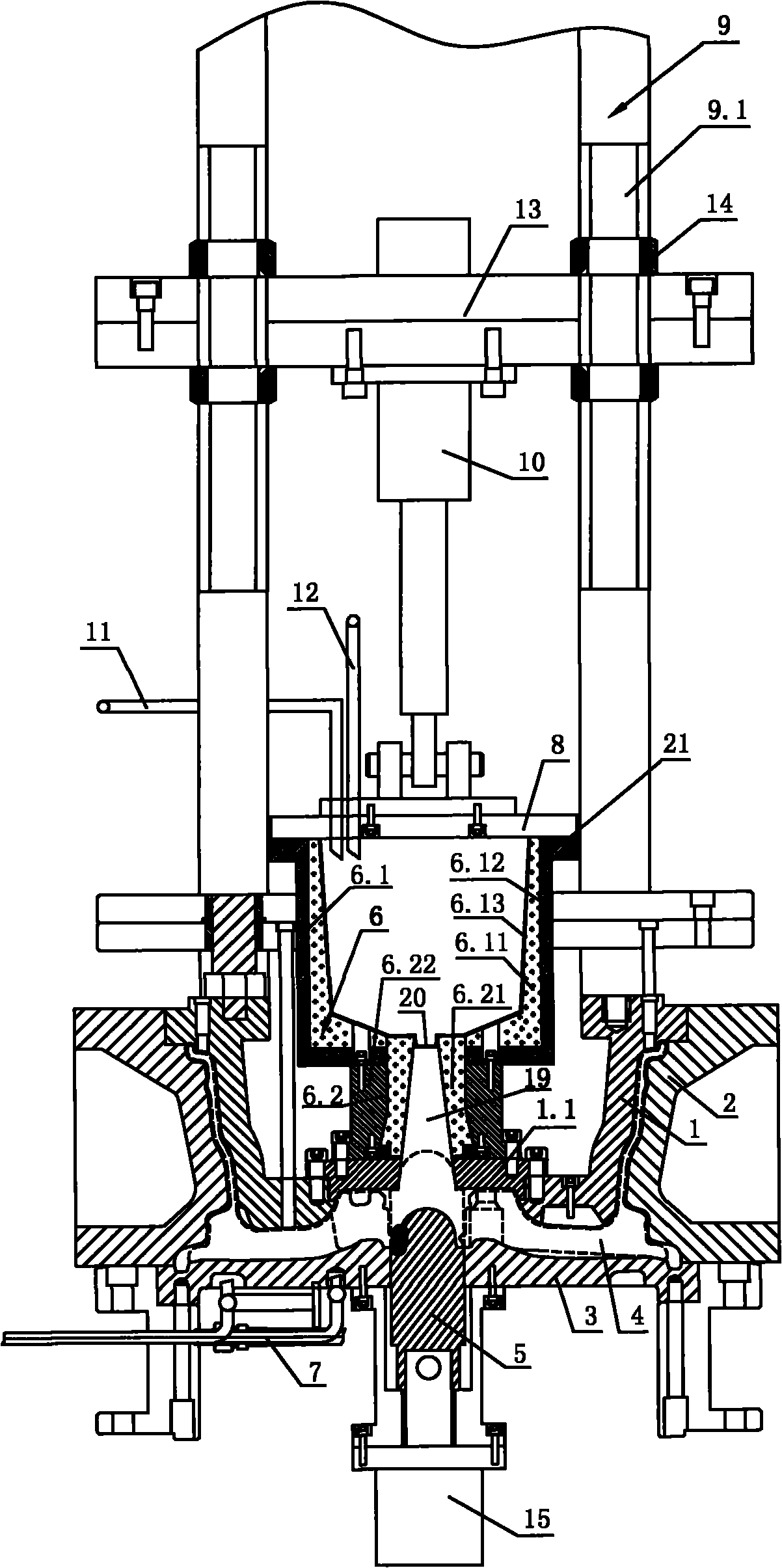

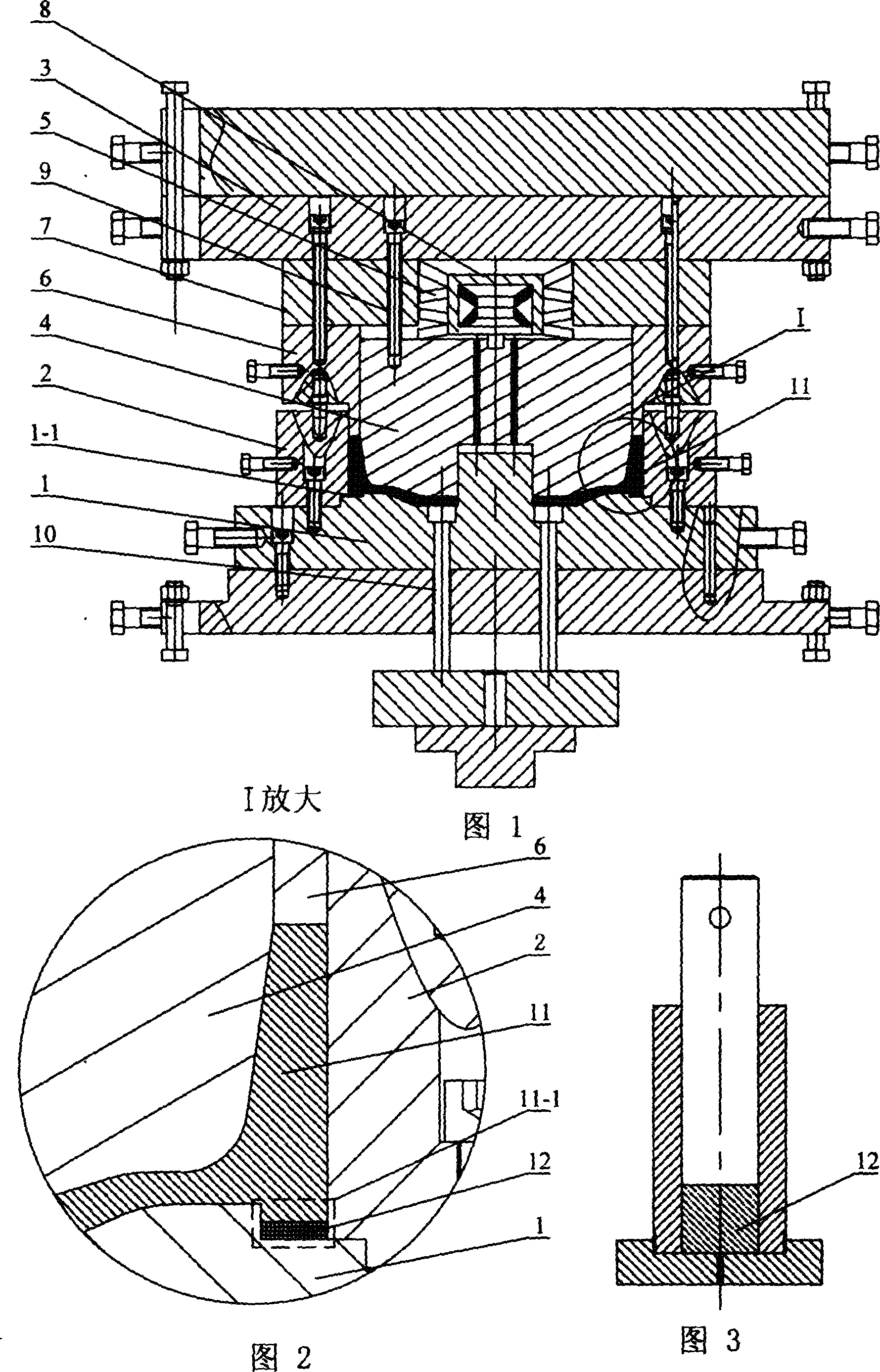

Aluminum alloy wheel gravity casting die and casting method thereof

InactiveCN102029383ARiser lessHigh weight yieldMolten metal conveying equipmentsMetallurgyAlloy wheel

The invention discloses an aluminum alloy wheel gravity casting die and a casting method thereof. The aluminum alloy wheel gravity casting die comprises a cooling device, a top die, a side die, a bottom die and a die cavity formed by the top die, the side die and the bottom die; the bottom die is provided with a sprue spreader; the aluminum alloy wheel gravity casting die also comprises a heat insulation cup communicated with the die cavity and capable of storing molten aluminum, a pressing device capable of enabling the molten aluminum stored in the heat insulation cup to be continuously injected into the die cavity, and a plugging device capable of stopping the molten aluminum stored in the heat insulation cup from flowing into the die cavity under the action of gravity; the heat insulation cup is arranged on a rack of a gravity casting machine, and the plugging device is arranged on the bottom die or the rack of the gravity casting machine; and the casting method for the aluminum alloy wheel gravity casting die comprises molten aluminum injection, pressing, continuous casting, filling, feeding, crystallization and solidification. The cast aluminum alloy wheel has the advantages of a few dead heads, high weight and yield, and good quality stability.

Owner:何丙军 +1

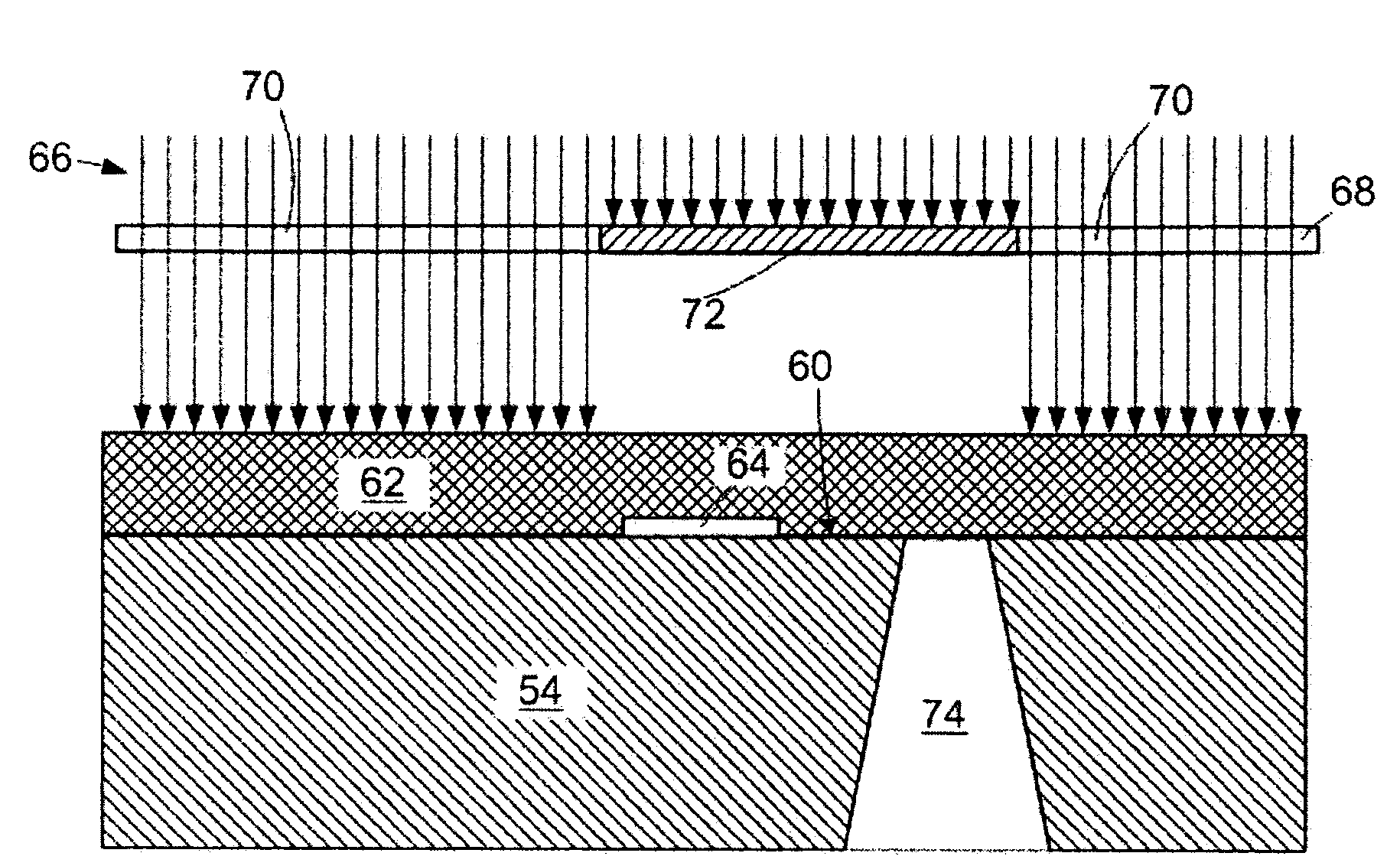

Dry film protoresist for a micro-fluid ejection head and method therefor

InactiveUS20090186293A1Low costImprove reliabilityPhotosensitive materialsSemiconductor/solid-state device manufacturingEngineeringPhotoresist

A method for making a dry film photoresist layer for a micro-fluid ejection head and a micro-fluid ejection head made by the method. The method includes applying a photoimageable liquid to a moving web of release material to provide a photoimageable layer on the release material using a slot die coater. The layer on the release material has a coating thickness ranging from about 8 to about 25 microns with a thickness variation of no more than about one micron. The photoimageable layer on the web is dried to provide a dry film photoresist layer. A protective web is then applied to the dry film photoresist layer.

Owner:LEXMARK INT INC

Methods for making micro-fluid ejection head structures

InactiveUS20070070122A1Easy to optimizeSmall sizeRadiation applicationsPhotomechanical apparatusActuatorBiomedical engineering

Methods of making micro-fluid ejection head structures. One of the methods includes providing a substrate having a plurality fluid ejection actuators on a device surface thereof. The device surface of the substrate also has a thick film layer comprising at least one of fluid flow channels and fluid ejection chambers therein. A removable anti-reflective material is applied to at least one or more exposed portions of the device surface of the substrate. A nozzle layer is applied adjacent to the thick film layer. The nozzle layer is imaged to provide a plurality of nozzles in the nozzle layer, and the non-reflective material is removed from the exposed portions of the device surface of the substrate.

Owner:FUNAI ELECTRIC CO LTD

High-efficiency flocculant

InactiveCN103253752AExtensive sources of raw materialsReduce manufacturing costWater/sewage treatment by flocculation/precipitationChemistryPerlite

The invention discloses a high-efficiency flocculant which is composed of the following components in parts by weight: 15-25 parts of polyaluminum silicate sulfate-aluminum potassium sulfate mixture, 5-10 parts of ferric citrate, 3-5 parts of potassium ferrate, 2-5 parts of polyferric chloride phosphate, 5-10 parts of polyferric phosphate, 5-10 parts of polyaluminum chloride, 10-15 parts of soluble coating and 3-5 parts of flocculant activating component. The flocculant activating component is selected from one or combination of expanded perlite micropowder and fly ash micropowder, wherein the weight ratio of the expanded perlite micropowder to the fly ash micropowder is 3:2-5:3. The flocculant disclosed by the invention has the advantages of wide raw material sources, low production cost, low material input, favorable flocculation activating effect and low flocculation processing cost.

Owner:CHUZHOU YOULIN TECH DEV

Matte glaze ink for ceramic jet printing and preparation method thereof

The present invention discloses a matte glaze ink for ceramic jet printing and preparation method thereof, wherein the ink comprises, based on the mass percentage, 30-50% of matte glaze, 3-8% of resin, 2-10% of dispersant, 0.1-0.2% of leveling agent, 0.3-0.6% of defoaming agent, 0.08-0.12% of anti-settling agent and the balance for the solvent, wherein the matte glaze includes raw materials of the following components of SiO2, Al2O3, K2O, Na2O, CaO, MgO, ZnO and BaO. Matte glaze ink prepared by the invention has low viscosity, uniform distribution of particle diameter with maximum particle diameter of less than 1Mum and good printing performance. Fired glaze owns gentle matte finish.

Owner:FOSHAN DOWSTONG TECH

Ceramic ink with sinking effect and preparation method thereof

The invention discloses ceramic ink with a sinking effect and a preparation method thereof. The ceramic ink comprises sinking glaze and an organic composition; the organic composition comprises resin, a disperse agent, a defoamer and a solvent; the sinking glaze comprises V2O5, Bi2O3, Ba2CO3, ZnO, SiO2, Al2O3, K2O and Na2O. The ceramic ink with the sinking effect is low in viscosity, controllable, uniform in particle size distribution and excellent in quality stability and ink-jet printing performance, and can show concave-convex vivid texture and strong third dimension of a ceramic tile in a more sufficient and visual manner when being matched with pigment ink for ceramic ink-jet printing to further improve the decorative effect and the added value of the ceramic tile. According to the ceramic ink with the sinking effect, the preparation method is simple and efficient, the controllability is excellent, and the industrial mass production is applicable.

Owner:FOSHAN DOWSTONG TECH

Solvent casting process, polarizing plate protective film, optically functional film and polarizing plate

InactiveUS20050110186A1Good quality and stabilityImprove productivityFlat articlesCoatingsTectorial membraneSolvent

A process for solvent casting including, casting a dope from a casting die onto a casting support, drying the cast dope on the casting support to form film, stripping off the film from the casting support, and further drying the film, wherein the dope has a solid matter content of from 17 mass % to 30 mass %, and a mean drying rate between the casting of the dope and the stripping off is more than 300 mass % / minute and not more than 1000 mass % / minute. Also, a process for solvent casting including the steps of casting a dope from a casting die to a casting support, forming the film by drying the dope to some extent, stripping off the film from the casting support and further drying the film while conveying the film with carrying it at both side edges of the film by a tenter under specified conditions.

Owner:FUJIFILM CORP

Method for producing fabrics by weaving terylene and natural fibers or regenerated fiber yarns

InactiveCN101691675AReduce manufacturing costGood quality and stabilityDyeing processWoven fabricsNatural fiberSizing

The invention relates to a method for producing fabrics by weaving terylene and natural fibers or regenerated fiber yarns, comprising the following technique process: step one: selecting terylene as a raw material of warp, selecting natural fiber yarn or regenerated yarn as a raw material of weft, dyeing the warp by dispersedye, and manufacturing into a tube; step two: winding the warp after warping and sizing or warp rebeaming on a driving shaft, drafting, weaving with the weft into grey cloth, and directly using grey yarn for weaving, wherein the weft is not dyed when the grey cloth is weaved; and step three: dyeing or bleaching the woven grey cloth, adopting beck dyeing, jig dyeing or pad dyeing. The fabrics woven by the method in the invention are strong in pattern stereoscopic impression, more in variety variations, high in production efficiency and low in cost.

Owner:华明浩

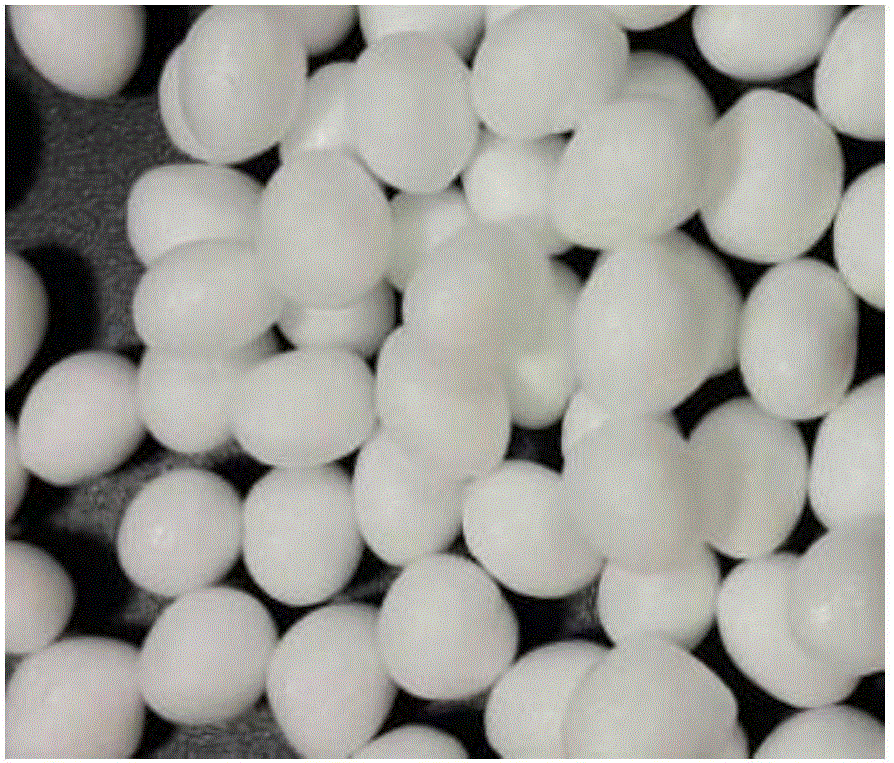

Foamed type TPU (thermoplastic polyurethane elastomer) material and preparation method thereof

The invention relates to a foamed type TPU (thermoplastic polyurethane elastomer) material and a preparation method thereof. The preparation method comprises the following steps: polymer polyol, diisocyanate and a chain extender are taken and poured into a casting machine to be mixed uniformly, then a mixture I is added to a first reactive extrusion machine for a polymerization reaction, and a TPU polymer melt is obtained; a physical foaming agent is injected into the tail end of a screw of the first reactive extrusion machine, the TPU polymer melt is mixed preliminarily with the physical foaming agent, and a mixture II is obtained; the mixture II is added to a second reactive extrusion machine, and the physical foaming agent and the TPU polymer melt are mixed uniformly to form a homogeneous system; the homogeneous system passes through a neck ring mold of the second reactive extrusion machine and then is subjected to underwater palletizing, and foamed thermoplastic polyurethane particles are obtained; the foamed thermoplastic polyurethane particles are dehydrated and dried, and the foamed type TPU material is obtained. The foamed type TPU material has stable foaming density, the batch-to-batch product quality is stable, central control monitoring is performed at any time, and the yield is increased.

Owner:MIRACLL CHEM

Model and method for liquid state formation of aluminium hub disc for special vehicle

InactiveCN1887474AImprove performanceMeet the needs of local wear resistanceExtrusion diesForging/hammering/pressing machinesLiquid stateWear resistant

The present invention relates to material forming technology, and is especially mold and method for liquid state formation of aluminum hub disc for special vehicle. The mold includes a lower mold, a female mold casing, an upper mold, an inner male mold and an outer male mold. The corresponding forming process includes the steps of: making wear resistant reinforcing body, setting the reinforcing body inside the mold, pouring aluminum alloy liquid, and extruding. The mold has simple structure, the forming process is simple and high in efficiency, and the product has high performance.

Owner:HARBIN INST OF TECH

White glaze printing ink for ceramic ink-jet printing and preparation method thereof

The invention discloses a white glaze printing ink for ceramic ink-jet printing and preparation method thereof, wherein the printing ink comprises, based on the mass percentage, 30-60% of white ceramic glaze, 3-10% of dispersant, 2-8% of resin, 0.1-0.2% of leveling agent, 0.3-0.7% of antifoaming agent, 0.08-0.12% of anti-settling agent, and the balance for the solvent. Wherein the white glaze includes, based on the mass percentage, 40 - 55% of SiO2, 38 - 15% of Al2O, 4 - 8% of (K2O + Na2O), 6 - 10% of (CaO + MgO), 3 -8% of ZrSiO4, 6 - 10% of B2O3, 6- 8% of ZnO, and 9 - 12% of CeO2. The viscosity of the printing ink prepared by the invention is low, and the distribution of particle size is uniform, and the viscosity is between 10.0 - 30.0mPa.s and adjustable, and the surface tension is 28 - 35mN / m, and the average particle diameter is 200 -400nm, and the maximum particle size less than 900 nm. The ceramic white glaze printing ink prepared by the invention has advantages of good quality stability, long-time preservation, and good performance of ink-jet printing, and realizes the preparation of white glaze printing ink for ceramic jet-printing.

Owner:FOSHAN DOWSTONG TECH

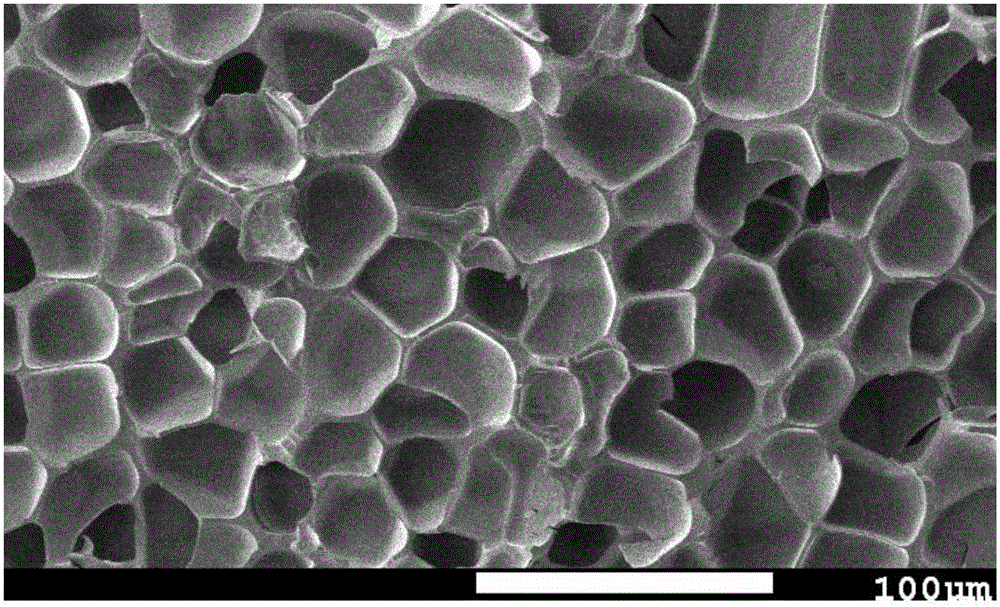

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

Aromatic candle with skin care effect and preparation method thereof

The invention relates to an aromatic candle with a skin care effect and a preparation method thereof. The aromatic candle is characterized by comprising the following raw materials in part by weight: 150 to 300 parts of partially hydrogenated glyceride, 100 to 300 parts of triglyceride, and 1 to 8 parts of natural essential oil. The preparation method comprises the following steps: mixing the raw materials; heating the mixture to a temperature of between 50 and 100 DEG C; stirring the mixture evenly; pouring an emulsion after mixing into a candle forming die; and cooling the formed emulsion and then demoulding the formed candle to obtain a finished product of the aromatic candle with the skin care effect. Because the aromatic candle is added with the essential oil which has the skin care effect, the wax oil after a candle is burnt has the skin care effect by daubing the wax oil on a skin.

Owner:NINGBO KWUNGS WISDOM ART & DESIGN

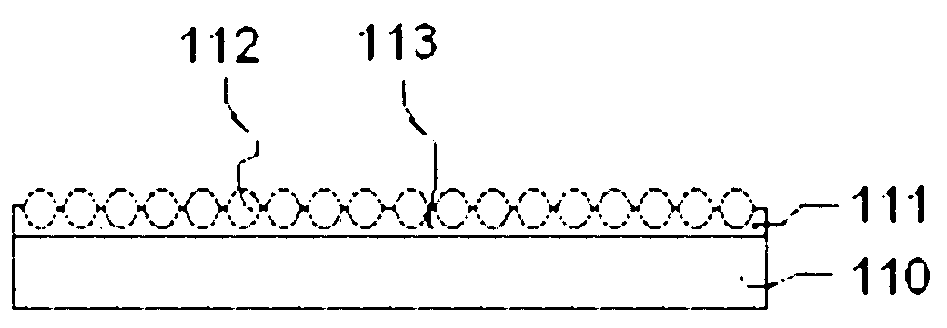

Optical diffusion film and backlight module using same

InactiveCN101979914ASimple processSuitable for industrial productionPoint-like light sourceLight fasteningsDiffusionLiquid-crystal display

The invention discloses an optical diffusion film. An optical diffusion layer is coated on one surface of a transparent base film, optical diffusion particles are uniformly distributed in the optical diffusion layer, the optical diffusion particles are transparent polymer spherical particles with diameters of 5 to 50 microns, and the particle diameter distribution of the transparent polymer spherical particles is monodisperse; and the optical diffusion film can effectively improve the optical uniformity. The invention also discloses a backlight module using the optical diffusion film. The backlight module can avoid using a high-cost prism sheet or a brightness enhancement film assembly, and can greatly improve the brightness of a liquid crystal display and save the manufacturing cost of the liquid crystal display.

Owner:浙江池河科技有限公司

Trimetazidine dihydrochloride sustained-release tablet and preparation method thereof

InactiveCN102885795AThe solution is not easy to cleanSimple preparation stepsOrganic active ingredientsPharmaceutical non-active ingredientsTrimetazidine DihydrochlorideSustained Release Tablet

The invention discloses a trimetazidine dihydrochloride sustained-release tablet and a preparation method thereof. The trimetazidine dihydrochloride sustained-release tablet comprises the following constituents in percentage by mass: 5-60% of trimetazidine dihydrochloride, 10-25% of sustained-release framework material, 1-8% of adhesive, 20-80% of filler, 0.1-5% of glidant and 0.2-3% of lubricant. According to the trimetazidine dihydrochloride sustained-release tablet, medicine can be slowly and uniformly released by adding the sustained-release framework material, so as to achieve regulation and control for a release speed, reduce the peak-valley ratio of the medicine, improve the efficacy, reduce the toxic and side effects of the medicine, reduce daily medicine-taking times and enhance the compliance of the patient on the medicine. The preparation method of the trimetazidine dihydrochloride sustained-release tablet disclosed by the invention is simple in process, does not need specially process production equipment, and is low in cost and good for batch amplification and industrialized production for products.

Owner:AC PHARMA CO LTD

Pulullan polysaccharide empty hard capsule and preparation method thereof

InactiveCN101579326AReduce moisture contentSmall range of molecular weight variationPharmaceutical non-active ingredientsCapsule deliveryPlasticizerHard Capsule

The invention discloses a polullan polysaccharide empty hard capsule and a preparation method thereof. The preparation method comprises the following steps: mainly adopting polullan polysaccharide, gel agent, plasticizer, emulsifying agent, latent solvent, water, and the like as raw materials; stirring and dissolving the raw materials in a heating-stirring tank which is vacuumized, heating to form glue, filtering, conveying glue solution into a capsule making machine for making a capsule and finally obtaining the polullan polysaccharide empty hard capsule. The empty hard capsule has the advantages of good quality stability, uneasy friability, stable breakdown index, difficult hydrolysis, no misty and yellowing appearance on the surface while in long-term deposition and can hold solids, oily liquid, semisolids and pasty materials; especially, as the water content of the capsule is lower than that of a gelatine capsule, the capsule is more suitable for being filled with moisture-absorption medicines and aldehydes-containing medicines and has wide market prospect and practical value.

Owner:金斐嘉

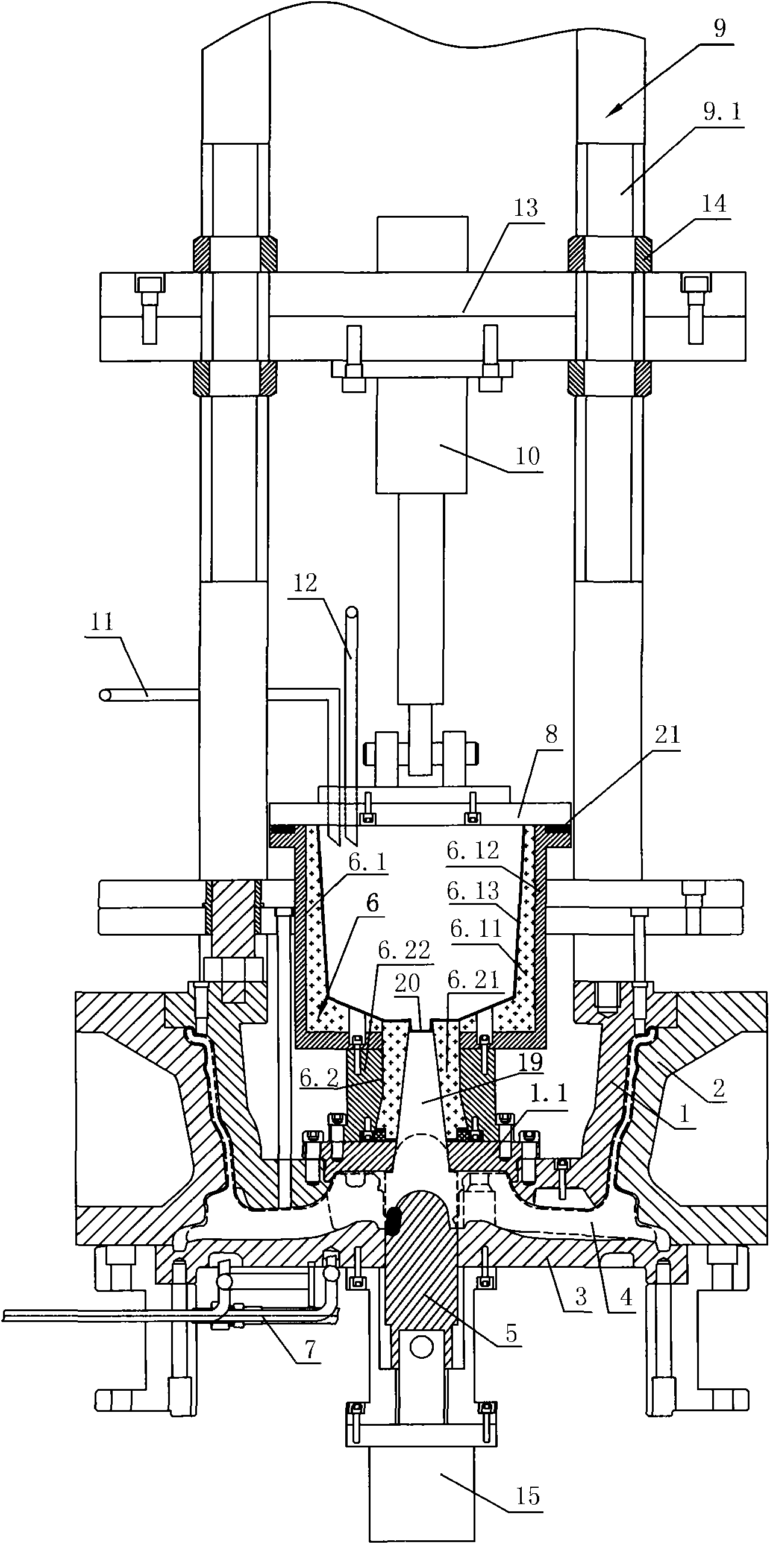

Electric motor stator assembly machine

InactiveCN102394538AGood quality and stabilityReduce labor intensityManufacturing stator/rotor bodiesElectric machineEngineering

The invention discloses an electric motor stator assembly machine. The assembly machine comprises a hydraulic machine tool, wherein a top plate is fixed on the nose of the hydraulic machine tool; the workbench of the hydraulic machine tool is provided with an L-shaped roll-over stand; the roll-over stand is provided with a bearing plate and a base backup plate; one side of the bearing plate and one side of the base backup plate are in right angular connection; the joint of the bearing plate and the base backup plate is rotatably connected with one side of the workbench; and a jacking device is connected below the bearing plate. According to the invention, an operator sleeves the stator assembly of the electric motor at the opening of a motor casing, and the stator assembly is pressed into the motor casing through the hydraulic machine tool when particular operation is carried out; and compared with the traditional manual operation, the labor intensity of the operator is greatly alleviated and the production efficiency is substantially improved. Meanwhile, as the stator assembly is pressed into the motor casing by the hydraulic machine tool, the stress of the stator assembly is uniform, and no impact is applied on the stator assembly, thereby ensuring that the assembling quality stability of the stator assembly is relative good.

Owner:浙江优力仕电驱动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com