Model and method for liquid state formation of aluminium hub disc for special vehicle

A special vehicle, liquid die forging technology, applied in metal extrusion dies, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problem that the performance requirements of the wheel cannot be guaranteed, the high-quality wheel cannot be processed, and the forging is difficult to form. and other problems, to achieve the effect of good parts performance, low cost and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

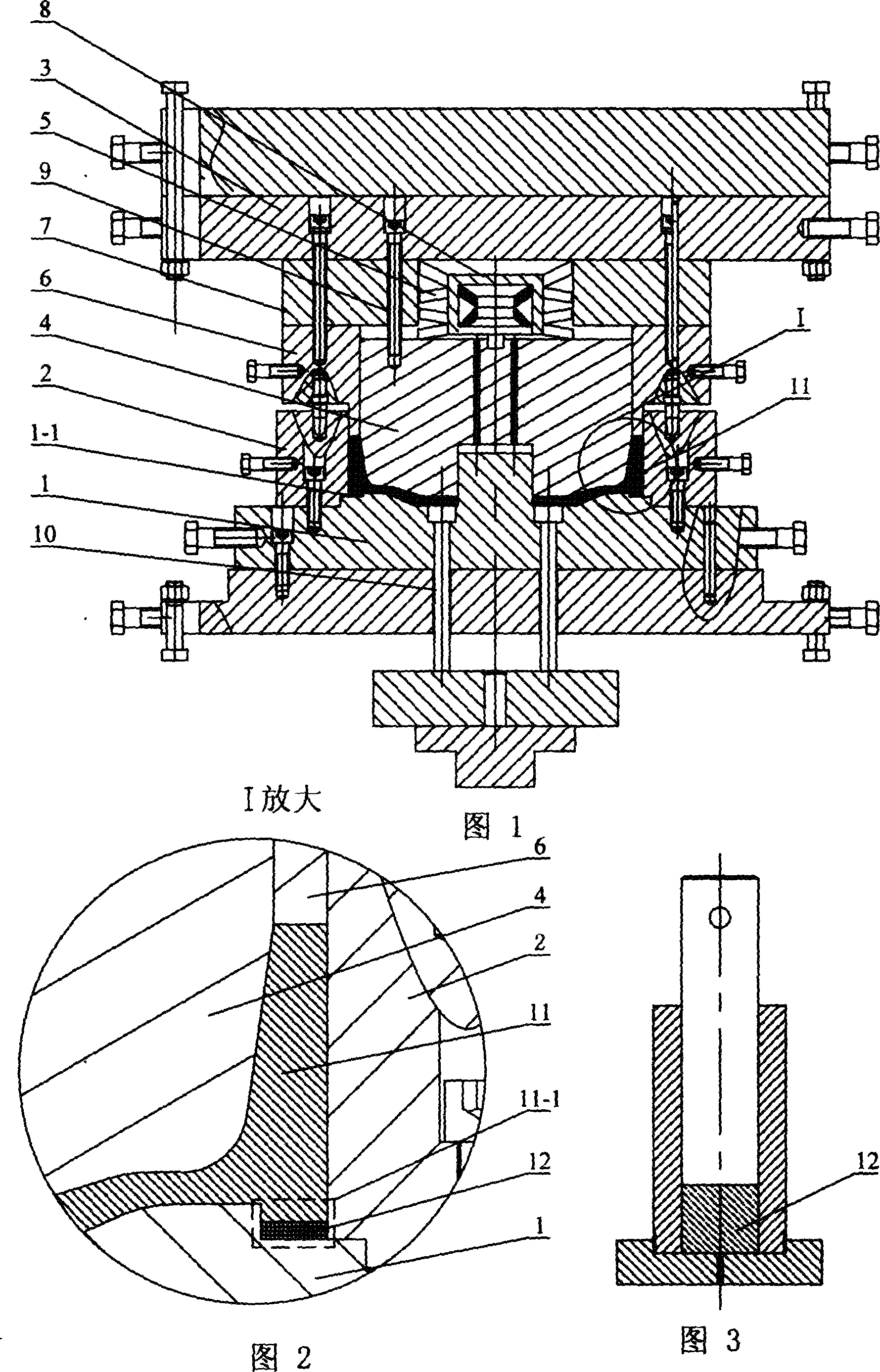

[0009] Specific Embodiment 1: The die used in the liquid die forging of the special vehicle aluminum wheel described in this embodiment, referring to Fig. 1 is provided with a wear-resistant ring groove 1-1, and a ejector pin 10 is provided in the lower die 1, and the ejector rod 10 runs through the lower die 1 longitudinally, and the upper surface of the ejector rod 10 is flush with the upper surface of the lower die 1 , it also includes an upper template 3 and an inner punch 4 arranged below the upper template 3, the inner punch 4 is connected with the upper template 3 through a spring 5, and an outer punch 6 is set outside the inner punch 4, The upper end of the outer punch 6 is affixed to the upper template 3 through the backing plate 7, and the distance between the lower end of the outer punch 6 and the lower end of the inner punch 4 is higher than the straight wall portion of the wheel to be formed. The spring 5 is a disc spring, a guide post 8 is arranged between the up...

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that due to the effect of disc spring 5 described in specific embodiment one, "the distance ratio between the lower end of the outer punch 6 and the lower end of the inner punch 4 In "height of the straight wall part of the wheel to be formed", the size of the raised part is numerically equal to the ratio of the height of the straight wall of the wheel to be formed to the thickness of the bottom, and the unit is mm. Its function is: at first a press is set above the upper template 3, and the combined punch (inner punch 4 and outer punch 6) is driven downward by the press. When the combined punch goes down and initially pressurizes, it relies on the inner punch to fill the space closed by the lower die 1, the outer casing of the die 2 and the inner punch 4; The load-bearing pressure of the type spring 5 makes the spring compressed, and the inner punch 4 stops; the outer punch 6...

specific Embodiment approach 3

[0013] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the reinforcing body 12 is made of Al 2 o 3sf Short fiber and SiC p Granules are prepared from raw materials, and the specific preparation process is as follows:

[0014] a. Prepare the glue solution according to the following ingredients and volume ratio: distilled water: silica sol: polyvinyl alcohol: glycerin = 100:3:1:3, mix well;

[0015] b. Join Al 2 o 3sf fiber, stir well;

[0016] c. Then add SiC p , stir evenly;

[0017] Wherein, the gel solution prepared in step a accounts for Al 2 o 3sf Fiber and SiC p 10 to 15 times the total mass, the Al 2 o 3sf Fiber and SiC p The mass ratio between is 1:2~2:1, the Al 2 o 3sf Fiber is made of (wt%) Al 2 o 3 72.3% and SiO 2 27.7% blended;

[0018] d. Seep water after stirring, then pressurize and shape; it can be poured into a mold with the structure shown in Figure 3 for water seepage. After the surface water seeps out, pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com