Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136results about How to "Uniform mass distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

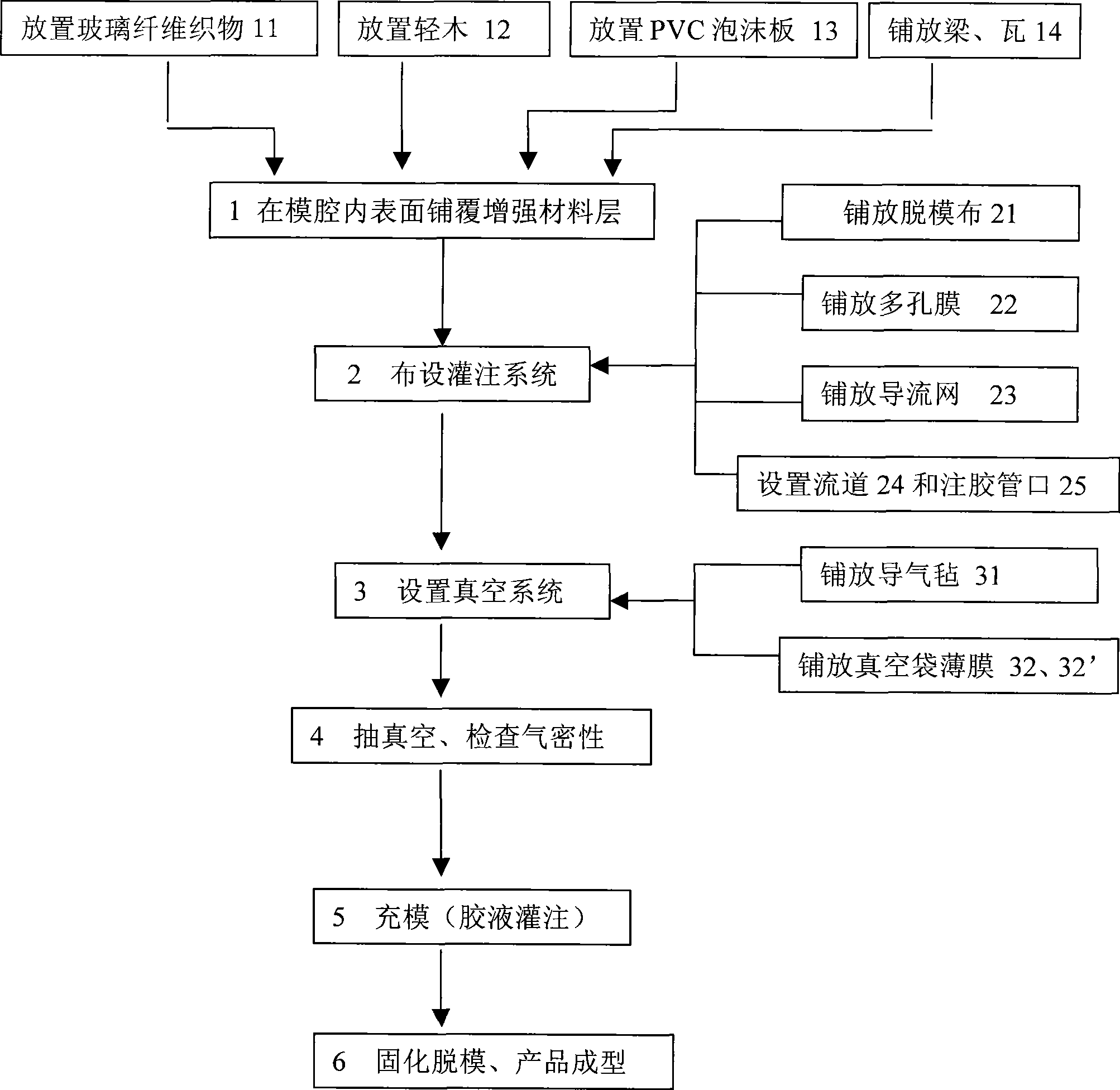

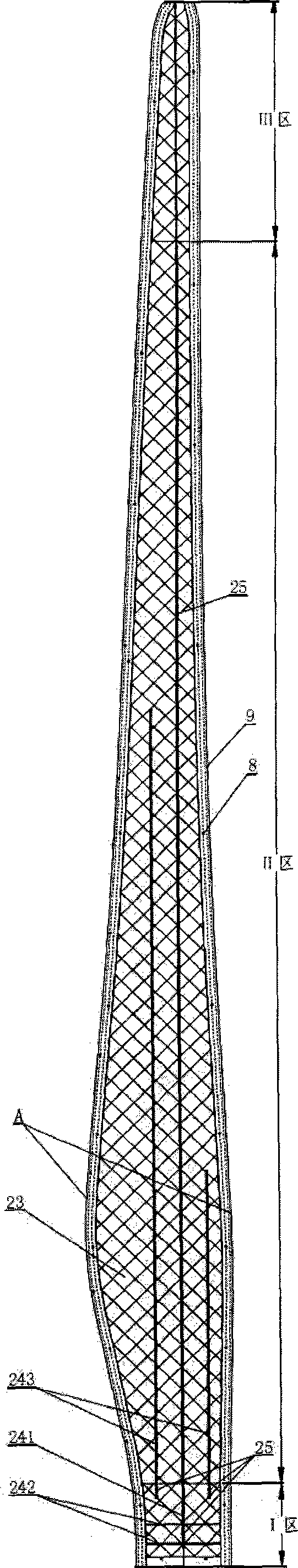

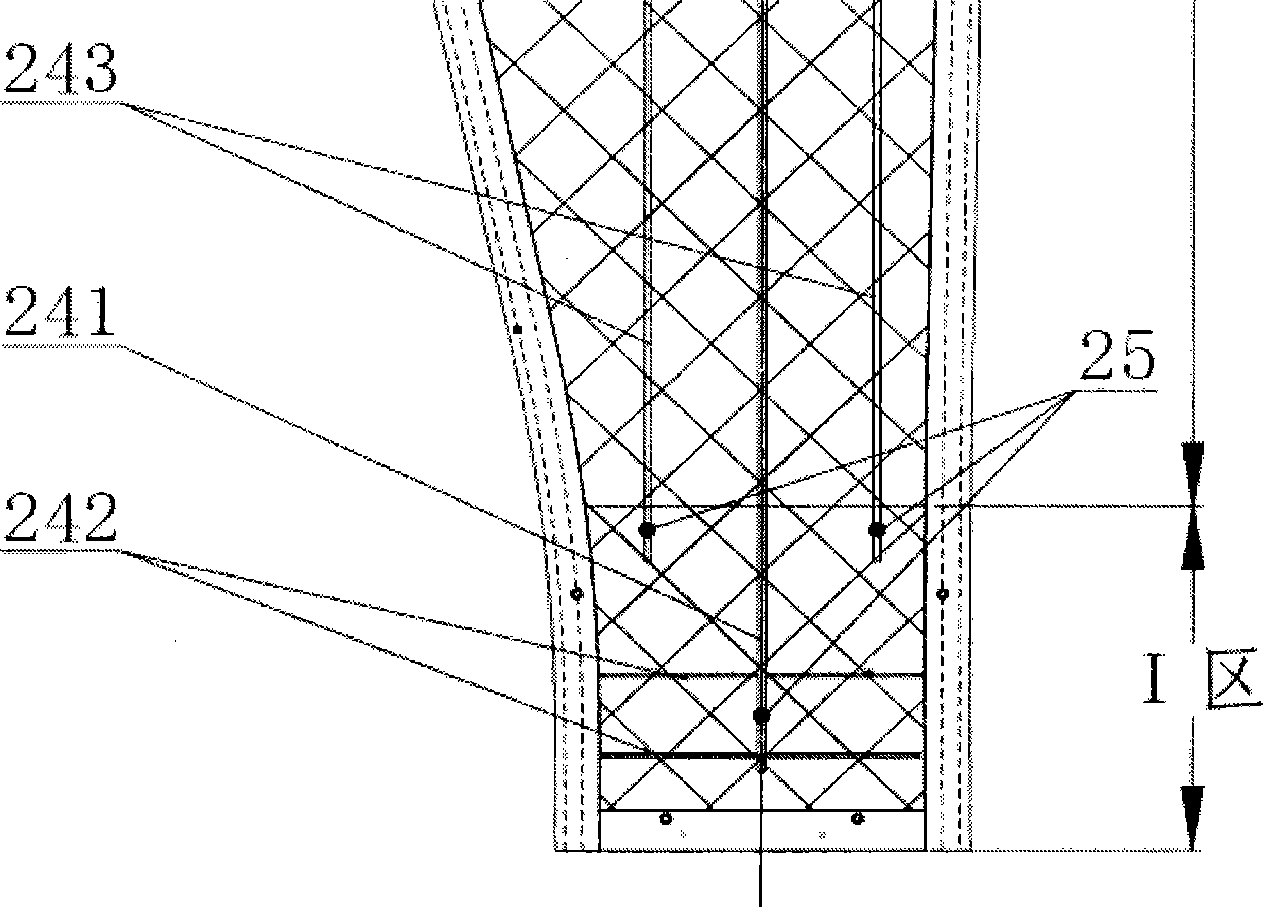

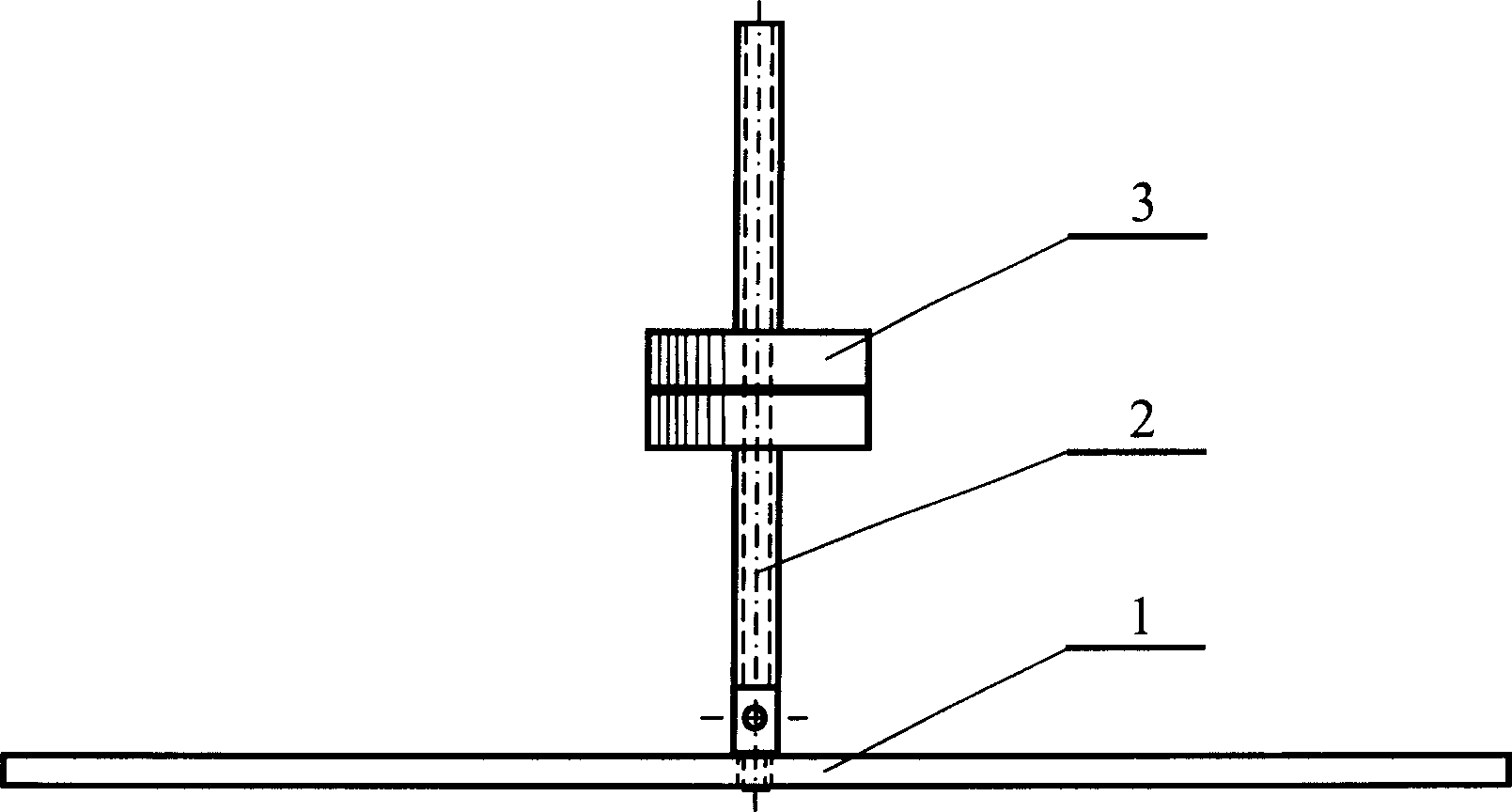

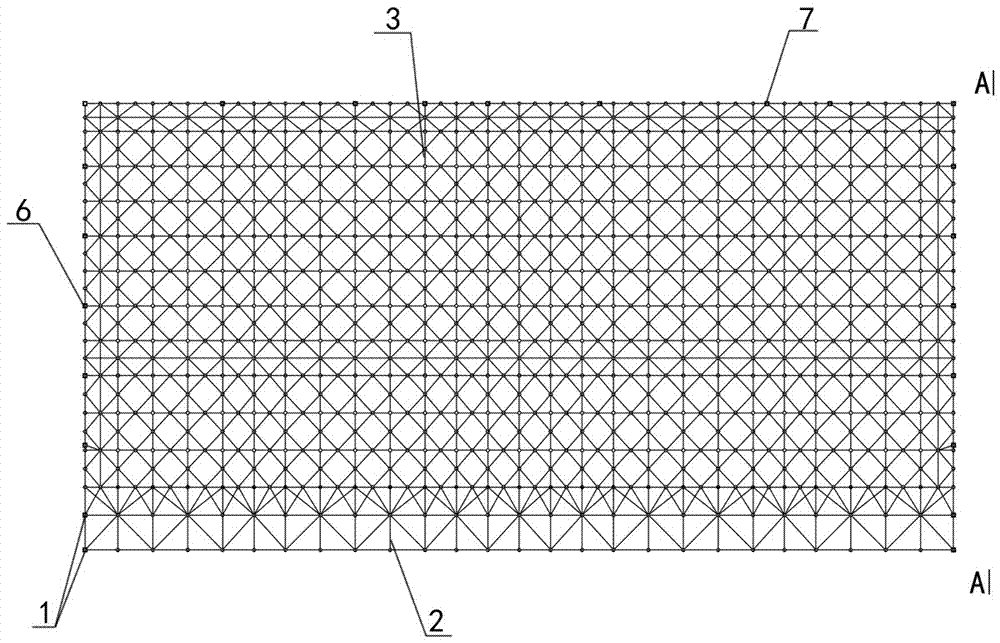

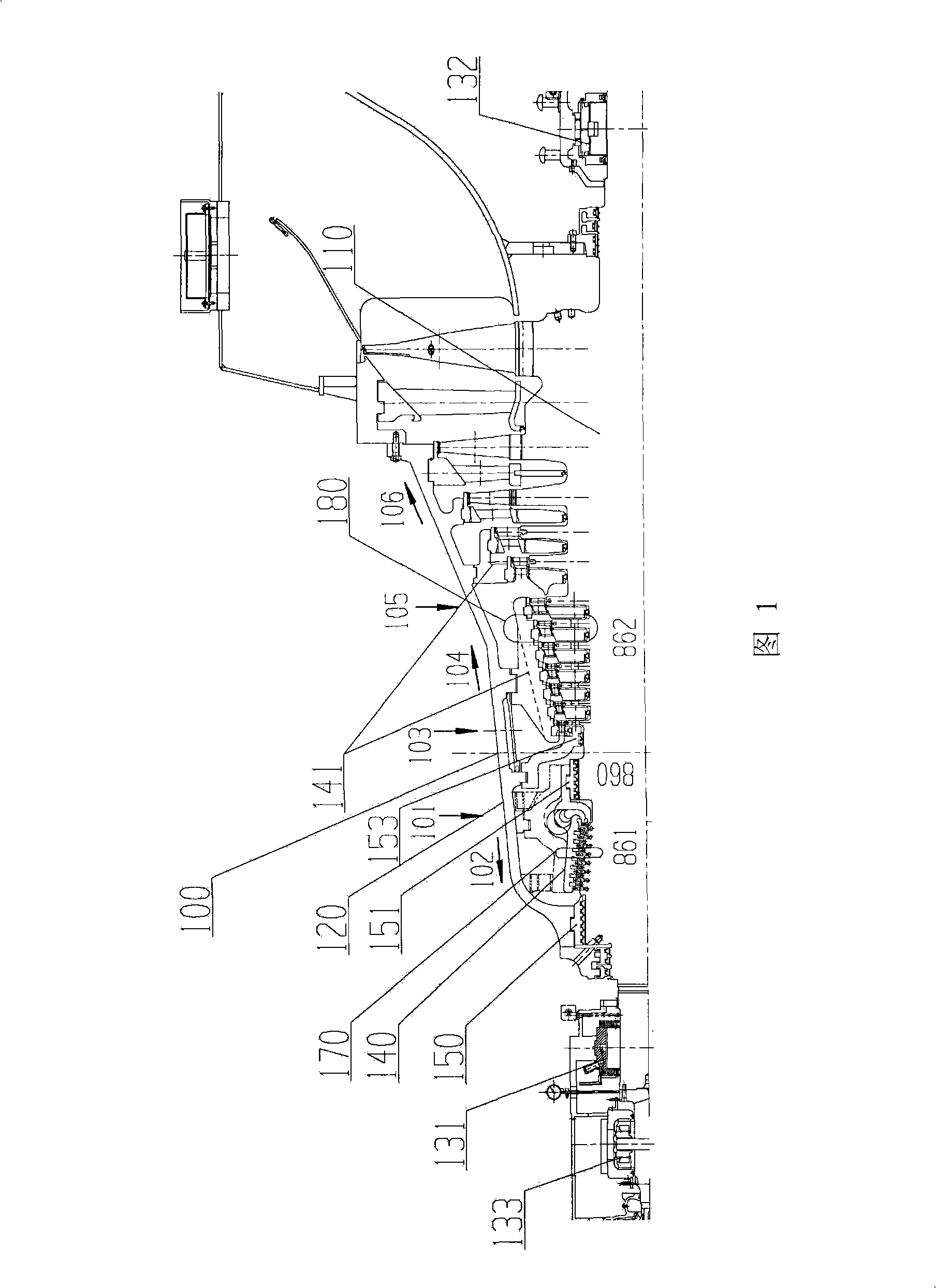

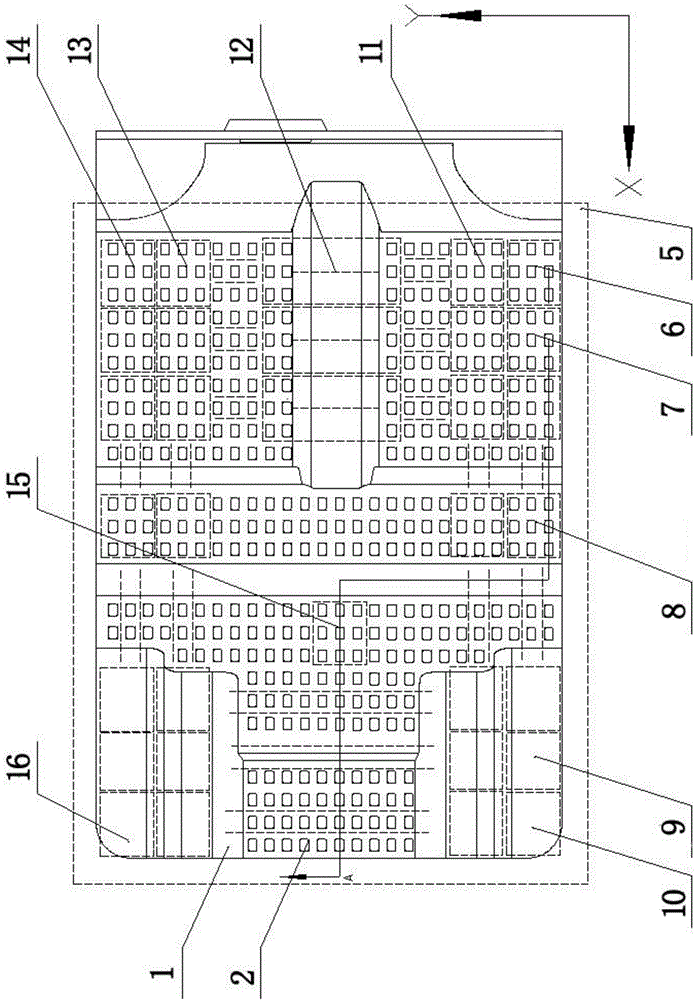

Megawatt level composite material wind electricity blade vacuum guiding and forming technique

ActiveCN101456256AHarm reductionImprove molding efficiencyFinal product manufactureDomestic articlesElectricityTurbine blade

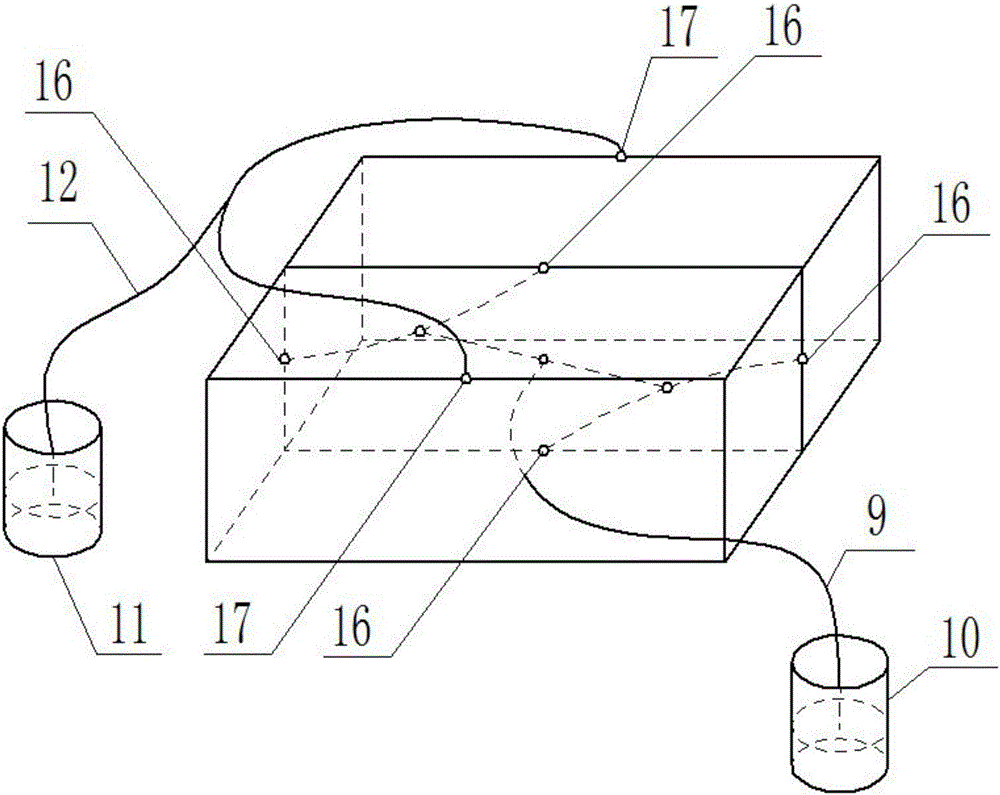

The invention discloses a vacuum infusion forming process for a megawatt grade composite material wind turbine blade. The process comprises a step of spreading and cladding reinforced material layers in an upper mold cavity and a lower mold cavity of a mould of the blade respectively and a step of solidification, demoulding and product forming, and is characterized by comprises the following steps between the two steps: 1)distributing injection systems on the surfaces of the reinforced material layers; 2) distributing vacuum systems on the outer surface of the injection systems spread and covered with flow channels in the step 1); 3) checking the airtight performance of an vacuumizing opening; 4) mould filling ( filling rubber liquid); and 5), solidification, demoulding and product forming. The vacuum infusion process can complete mould filling in 1.5 hours, improves the forming efficiency of large blades, saves special equipment and achieves low production costs. Products formed by the process are uniform in quality distribution and good in process repeatability, and can reduce volatilization of harmful gases and environmental pollution and ensure heath of operators and are easy to promote and use compared with a hand lay up process and a wet spreading process.

Owner:SINOMATECH WIND POWER BLADE

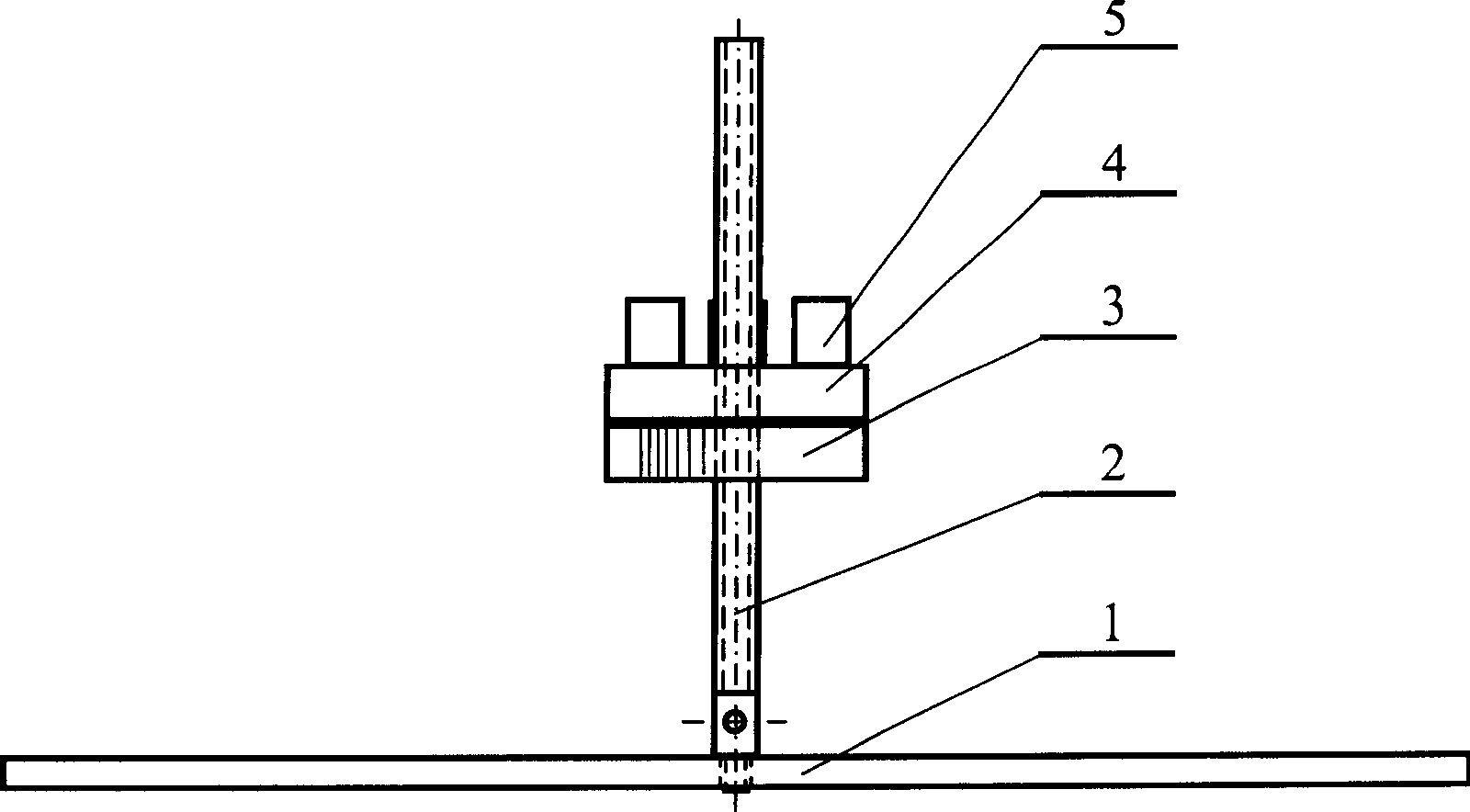

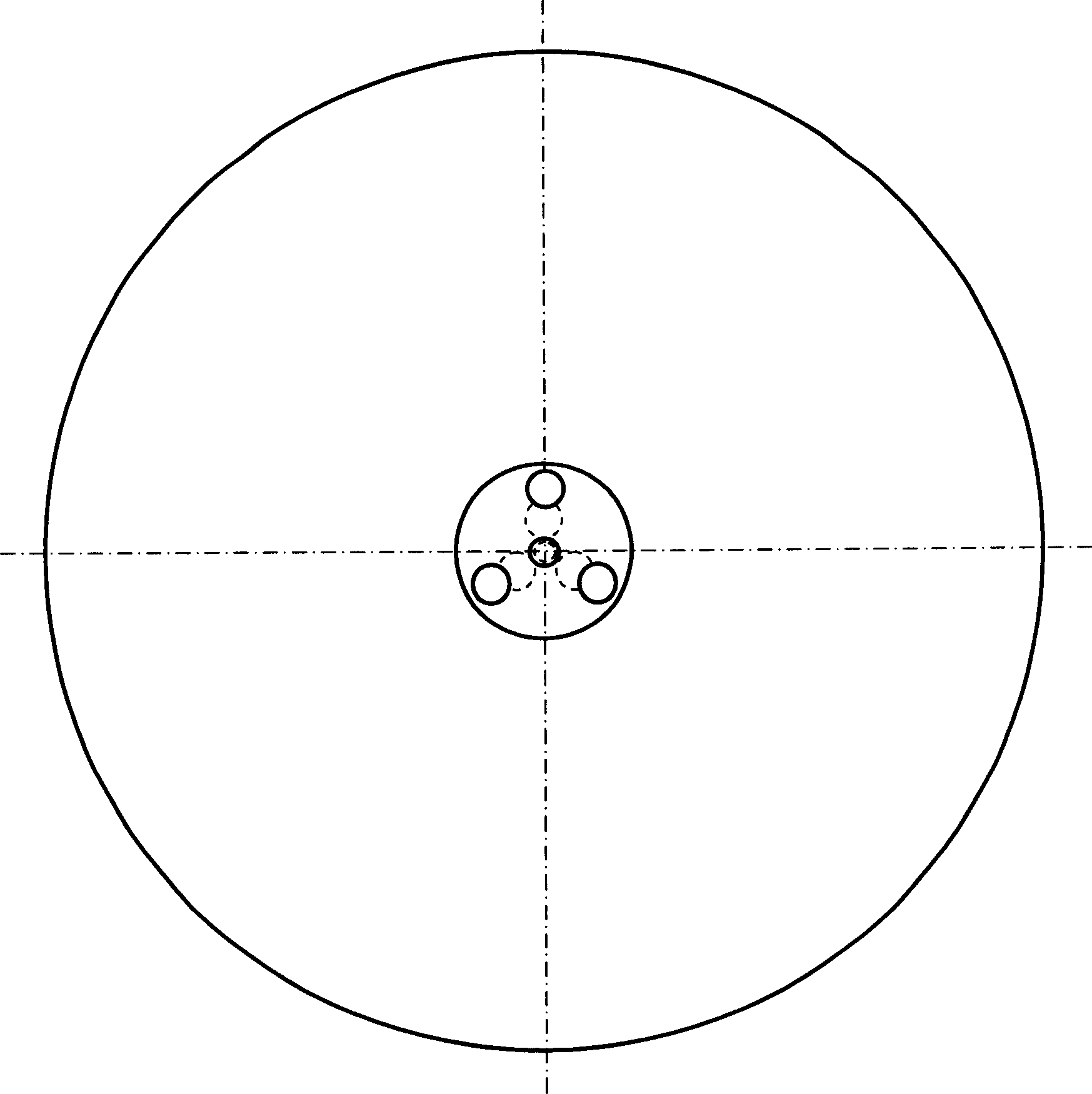

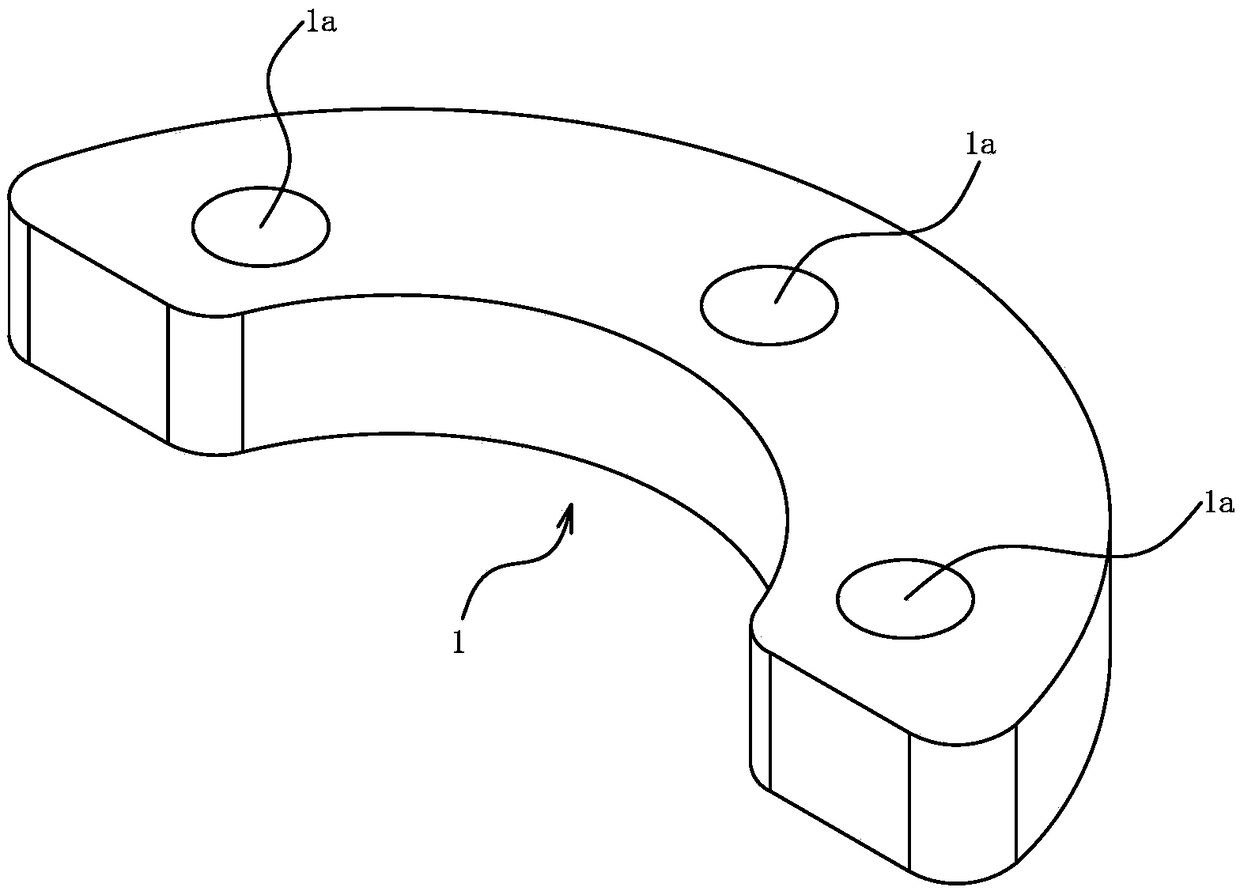

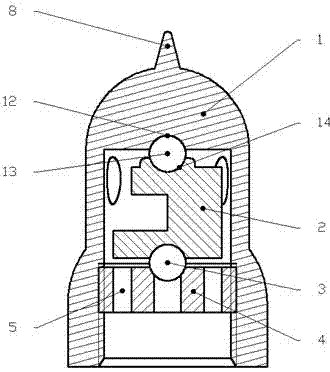

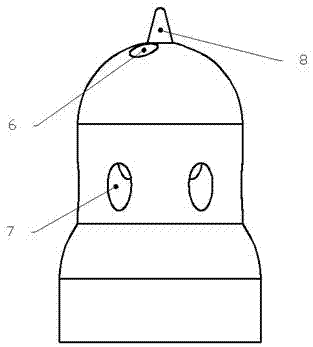

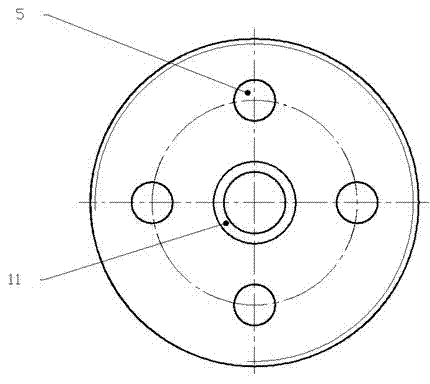

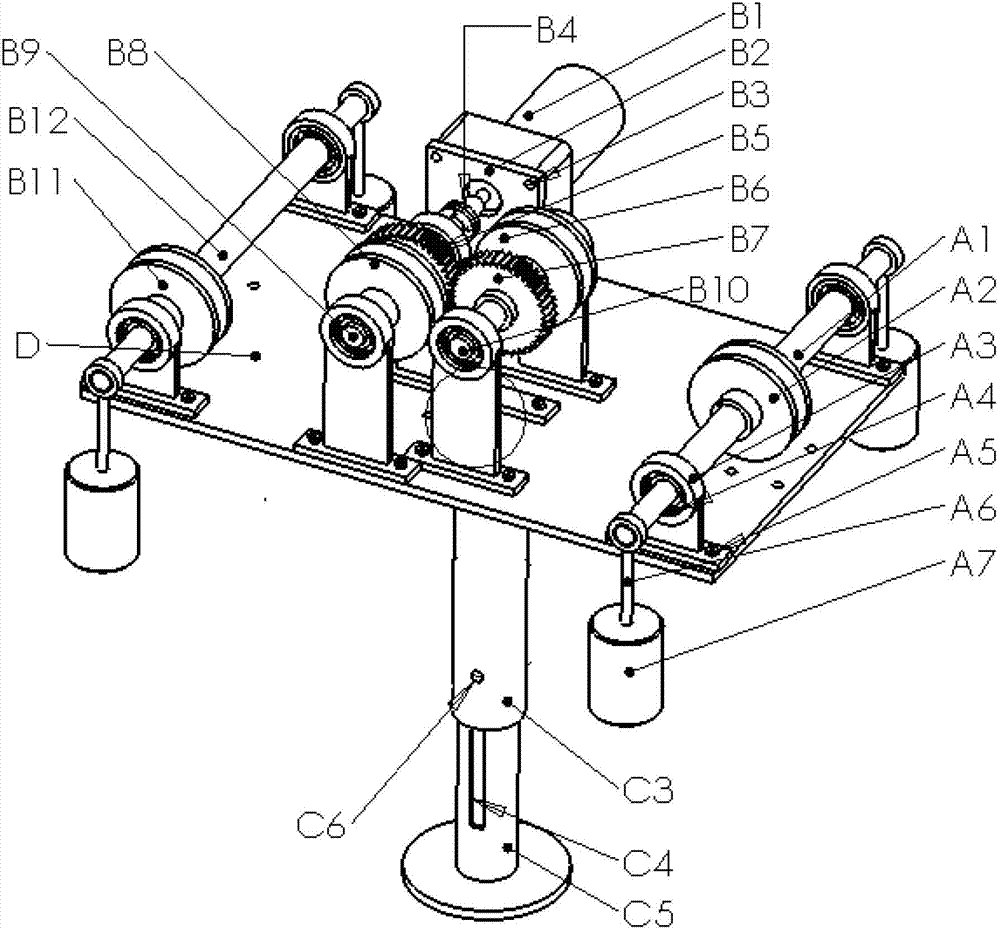

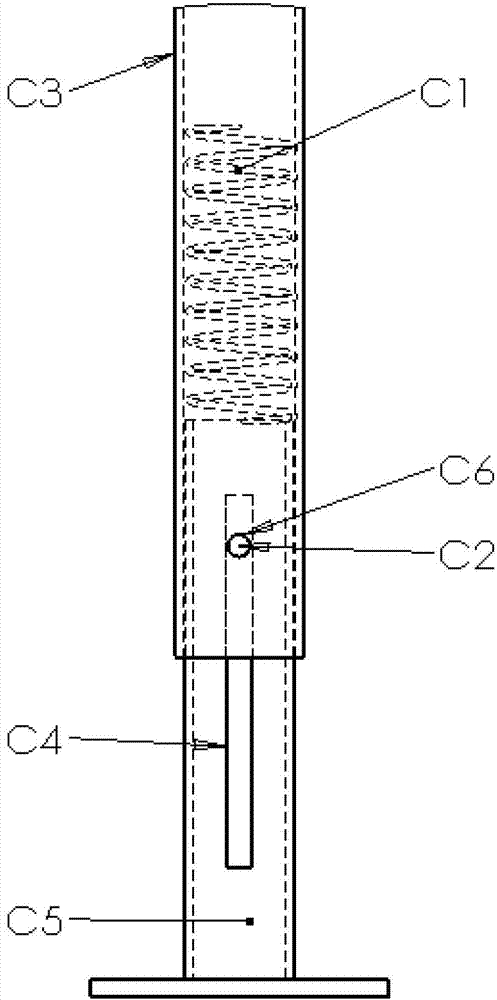

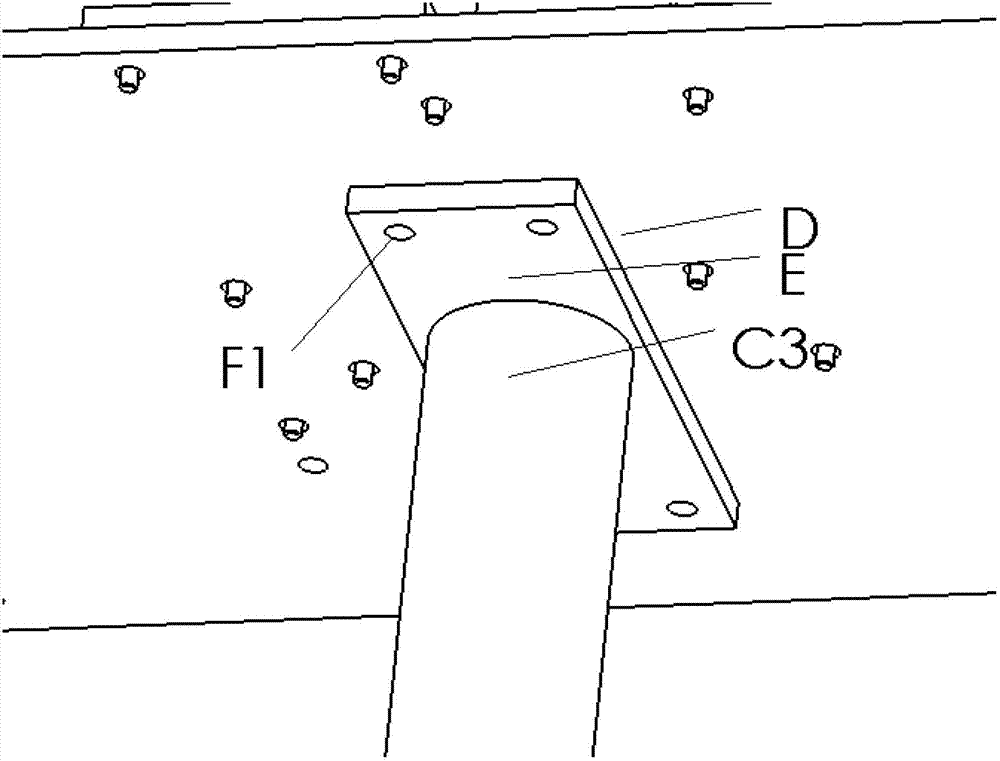

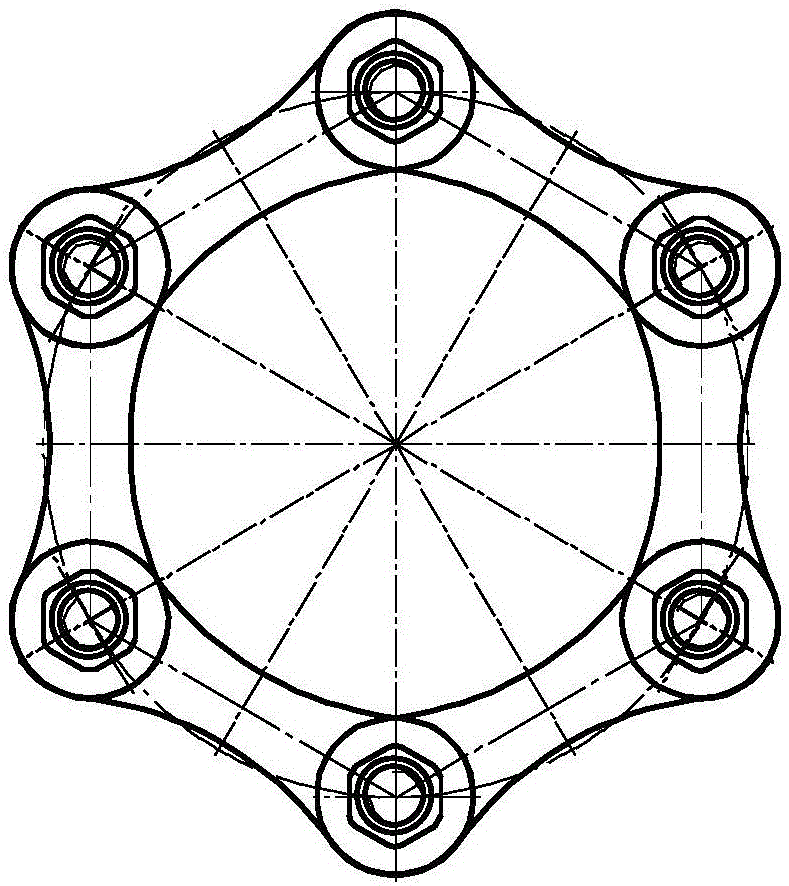

Externally loading centroid adjuster of air-floating rotating table

InactiveCN1818601AUniform mass distributionStructural/machines measurementEngineeringMechanical engineering

Owner:HARBIN INST OF TECH

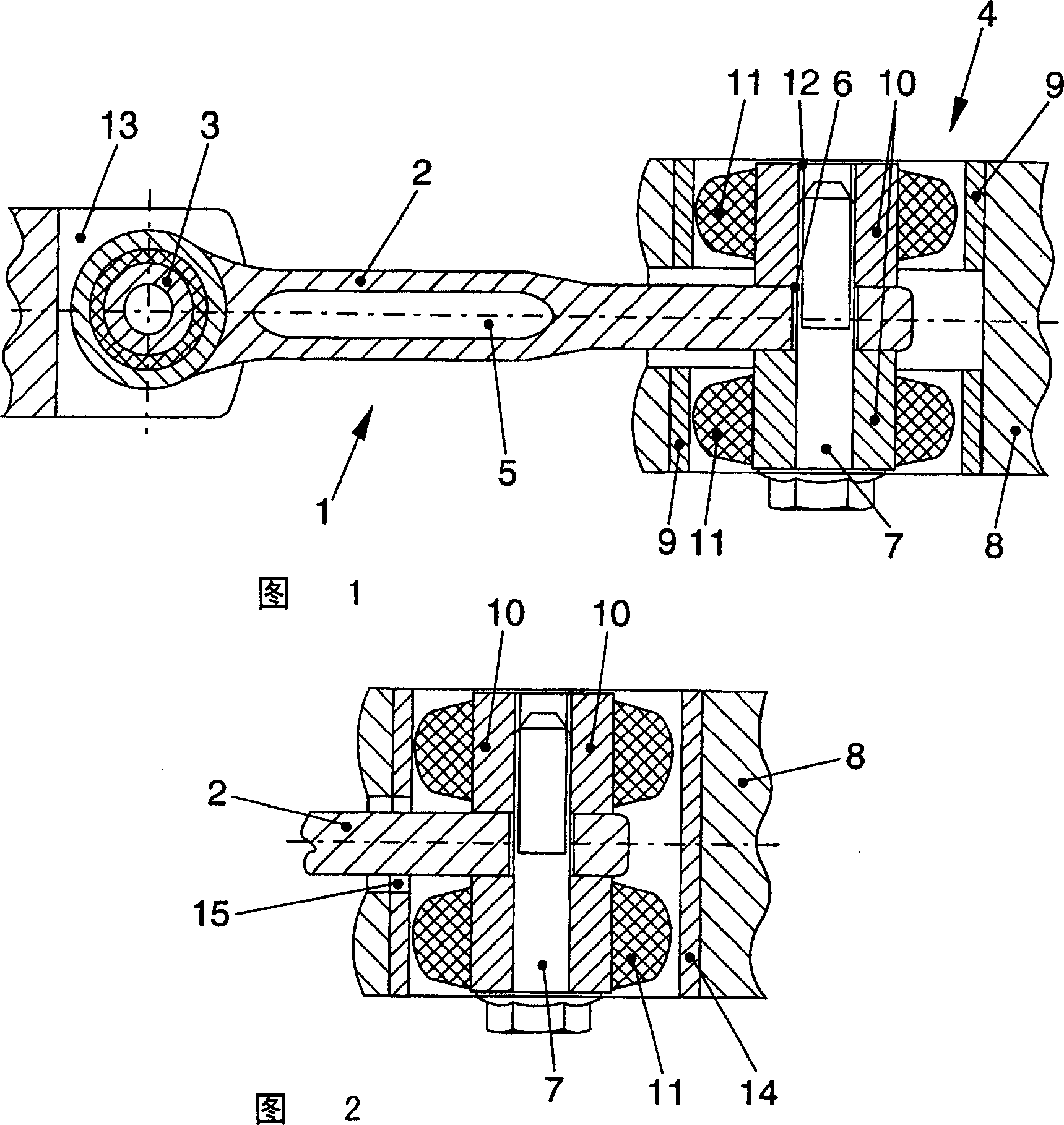

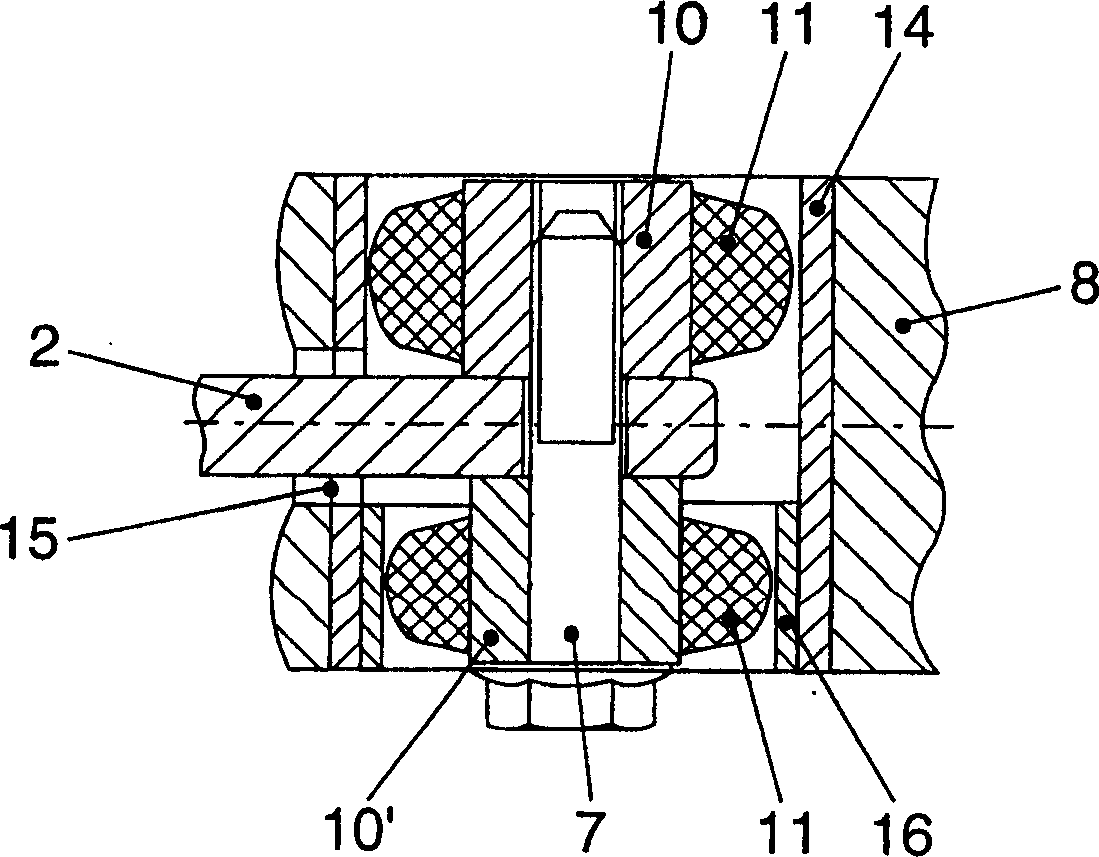

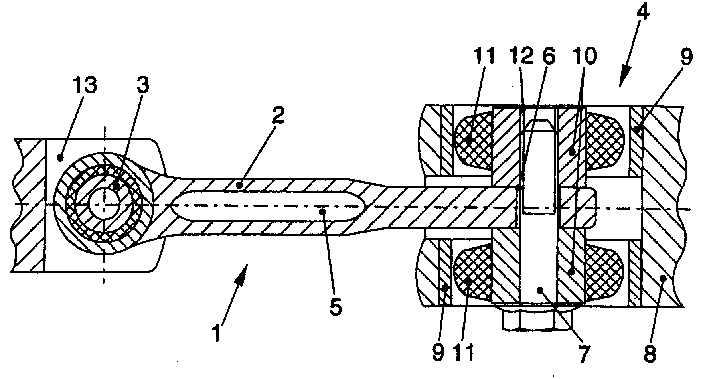

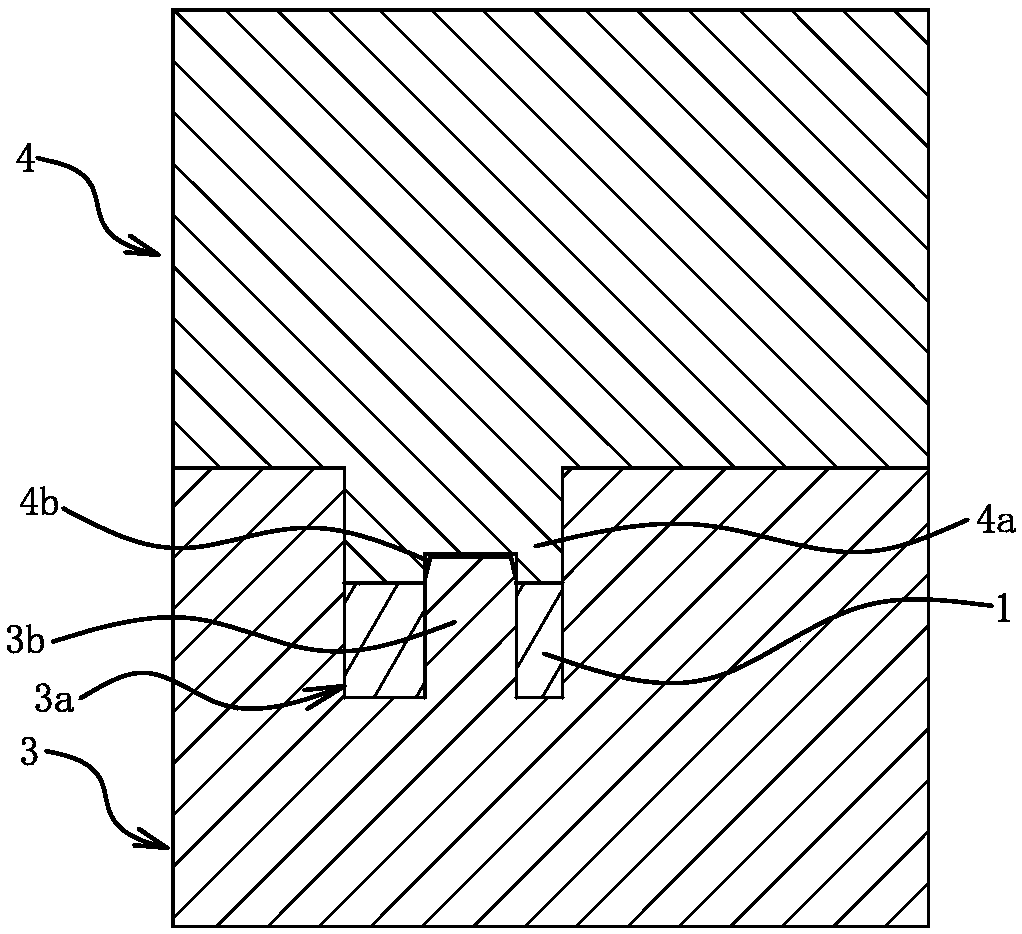

Swing seat for automobile machine set

InactiveCN1380205AEasy to replaceUniform mass distributionSuspensionsUnderstructuresVehicle frameEngineering

The invention relates to a swing support for an automobile unit, which has a support arm (2), a first bearing (3) connected to the unit end of the support arm (12), and a support arm (2) body or vehicle The second bearing (4) connected to the frame end. A vibration damper (11) is arranged between each bearing core (10) of the bearing (3,4) and the bearing outer ring (9,14), wherein the second bearing (4) is made as a split bearing, which It has two bearing cores (10), and at least one bearing outer ring (9, 14).

Owner:VOLKSWAGEN AG

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

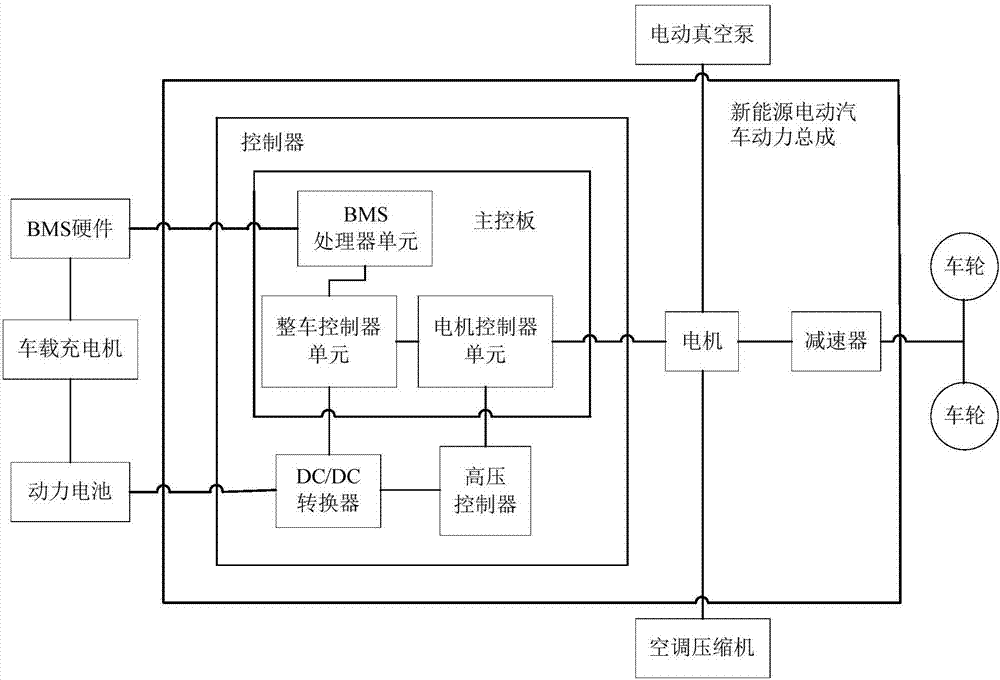

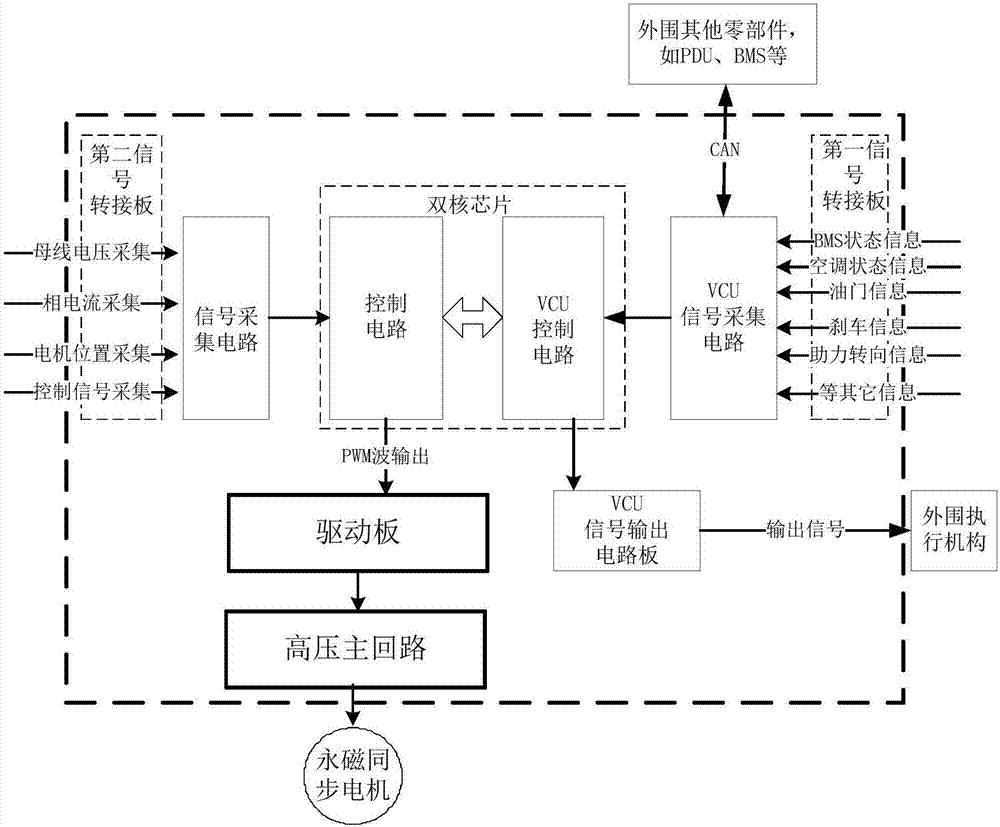

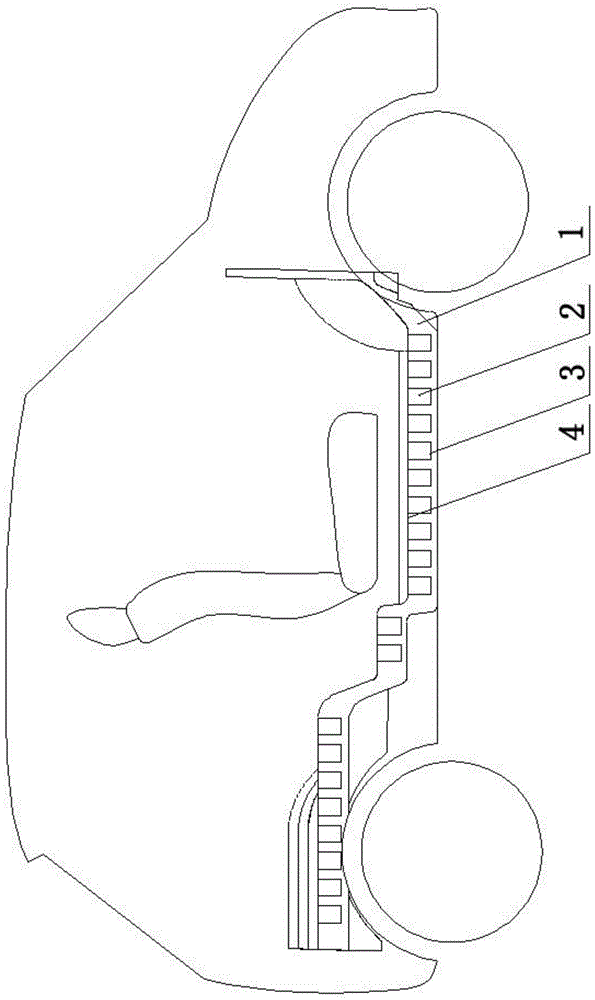

Power train of new energy electric vehicle

PendingCN107128159AOptimize layoutQuick changeElectric propulsion mountingElectric/fluid circuitConvertersElectric machine

The invention provides a power train of a new energy electric vehicle and belongs to the field of new energy vehicle application. The power train comprises a controller, a motor and a decelerator connected with the output end of the motor, wherein the controller comprises a main control panel, as well as a DC / DC converter and a high pressure controller which are connected with the main control panel; the output end of the main control panel is connected with the input end of the motor; and the DC / DC converter is connected with the high pressure controller. The power train has the following beneficial effects: the space is fully utilized reasonably, mass distribution is balanced, part layout and directions of high-voltage and low-voltage wiring harnesses are optimized, the power train and the whole vehicle can be favorably maintained, and the assembly and maintenance workloads are reduced; and parts can be quickly produced and replaced, and the mounting accuracy and speed of the whole vehicle are improved.

Owner:深圳市大地和电气股份有限公司

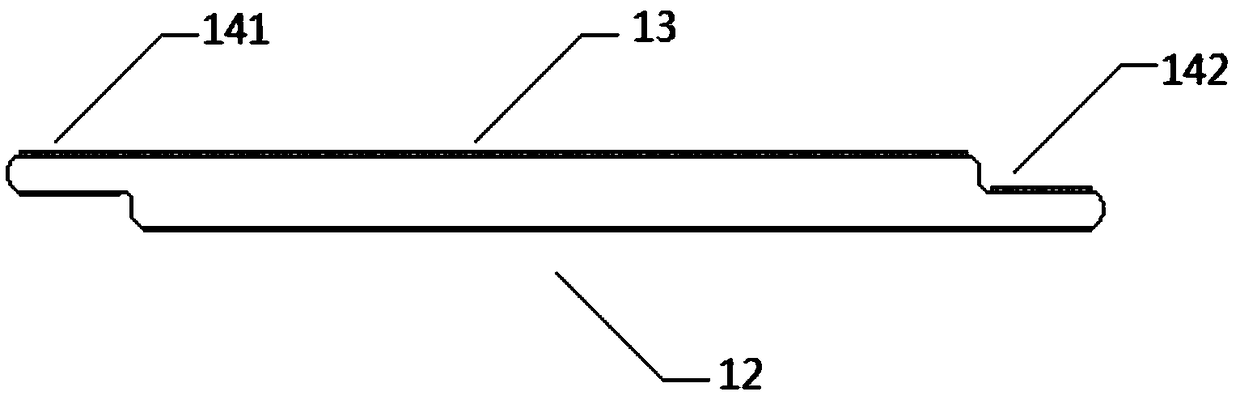

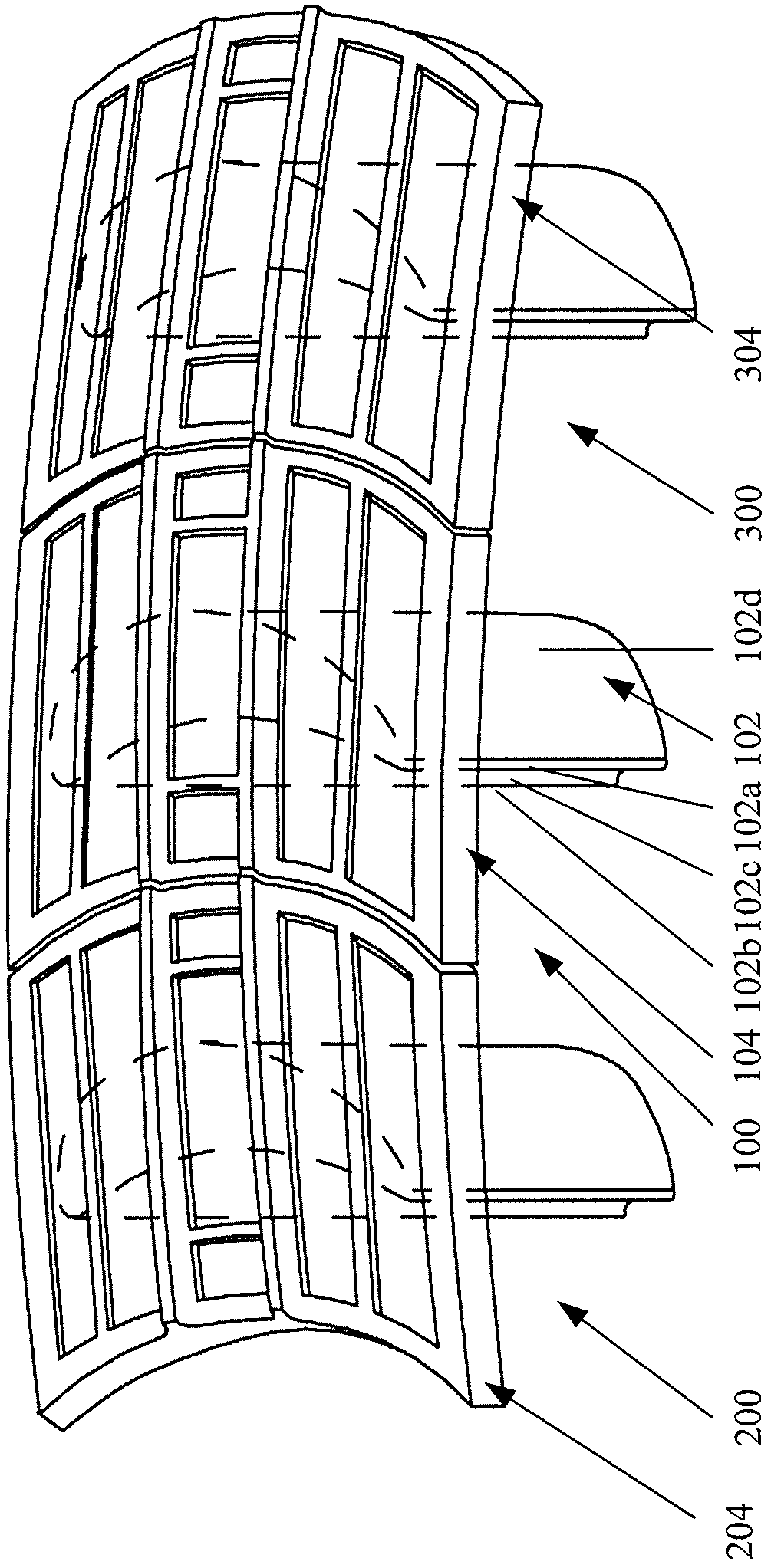

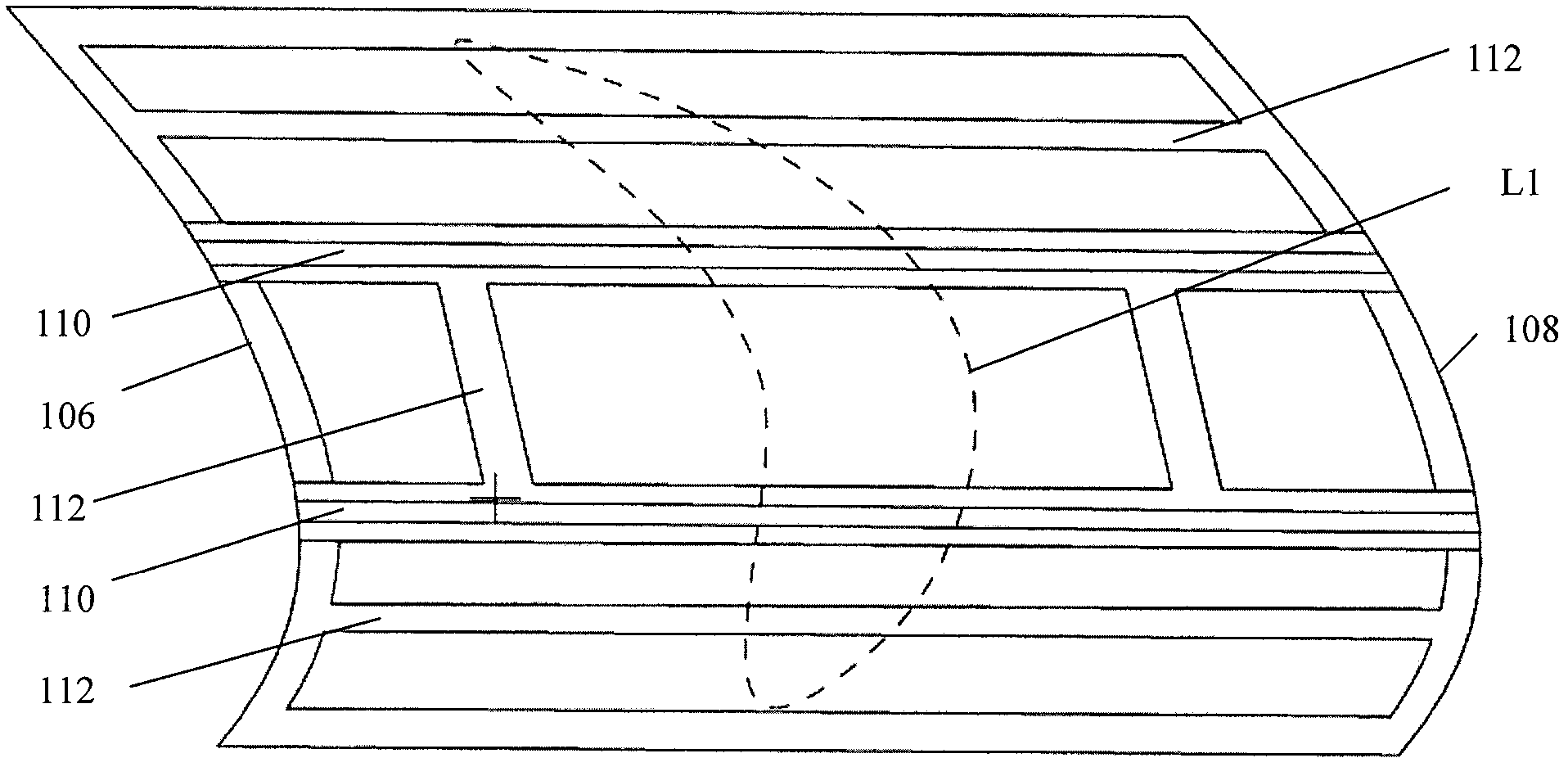

Wind power blade main beam or subsidiary beam structure and fabrication method thereof

InactiveCN109372708AAvoid Bubble ProblemsImprove bindingMachines/enginesWind energy generationElectricityEngineering

The invention discloses a wind power blade main beam or subsidiary beam structure. The wind power blade main beam or subsidiary beam structure comprises plate materials, low-surface-density fabric andresin, wherein the plate materials are superimposed in both the chord direction and the longitudinal direction and comprise main plates and side plates arranged at the end portions of the main plates, the thickness of the side plates is less than that of the main plates, the superimposed parts of the adjacent plate materials in the chord direction are superimposed through the side plates of the adjacent plate materials, and the thickness of the superimposed parts of the side plates is not more than that of the main plates, the low-surface-density fabric is arranged between the adjacent platematerials in the longitudinal direction, and the positions between the plate materials as well as the positions between the plate materials and the low-surface-density fabric are filled with the resin. By means of the plate materials and a fabrication method, the resin passage length and the number of corners are effectively increased, excessive penetration of the molten lower-layer resin towardsupper layers is prevented, the flowing speed of the resin can be effectively controlled, the situation that the interlamination resin content is low to cause defects is prevented, the use ratio of theresin is increased, and the quality of wind power blades obtained finally is good.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

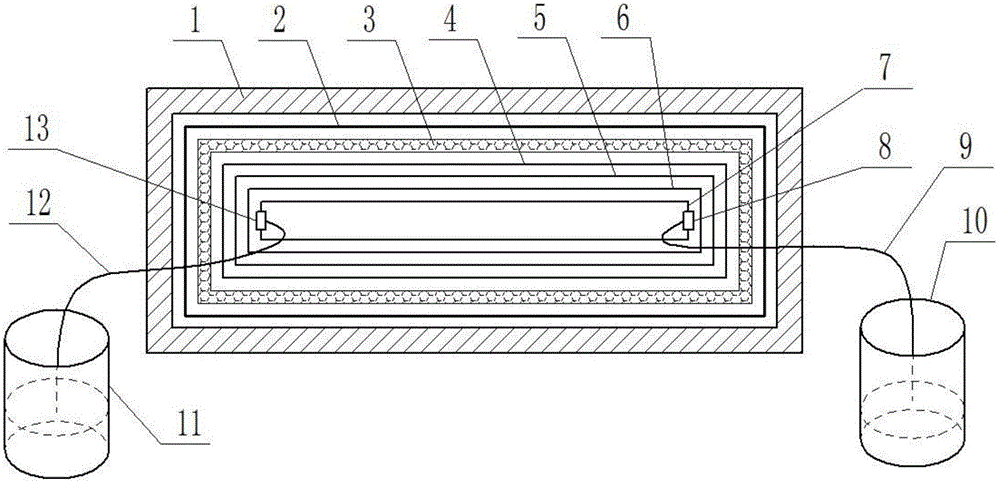

Foam sandwich composite material for aviation dining car and preparation method of foam sandwich composite material

The invention discloses a foam sandwich composite material for an aviation dining car and a preparation method of the foam sandwich composite material. The preparation method of the foam sandwich composite material mainly comprises the steps of preparation before laminating, reinforcing material laminating, glue injection system arranging, vacuum system arranging, air tightness inspecting, resin pouring and solidification demolding. According to the preparation method, holes and grooves are formed in foam cores of reinforcing material laminating layers, and the holes and the grooves communicate with one another; and after vacuumizing is conducted, resin is poured, and complete wetting of the reinforcing material laminating layers is ensured. The prepared composite material is stable in quality, high in production efficiency, low in cost, small in pollution, good in strength and interference bonding performance, and long in service life.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Current collection body for battery

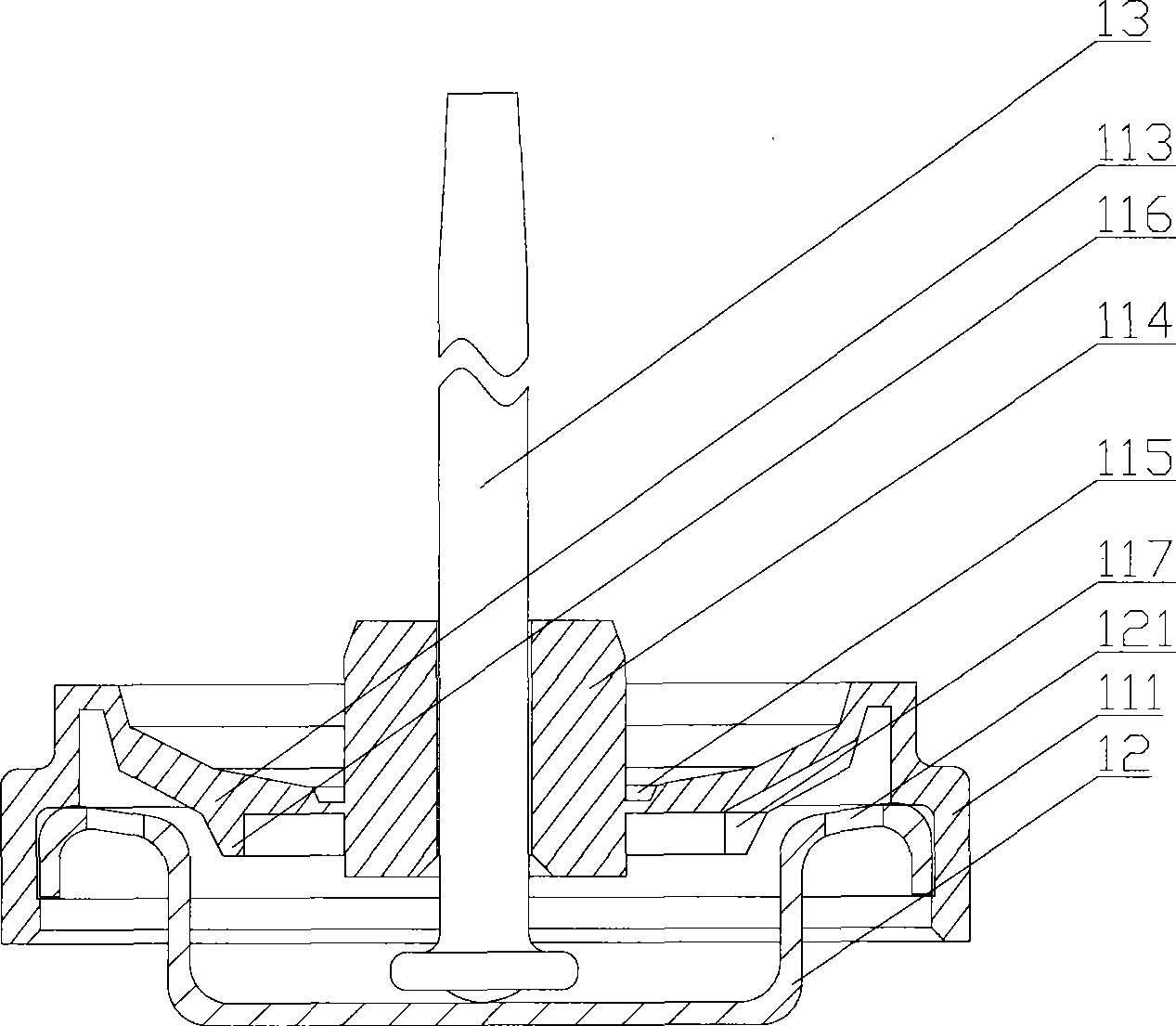

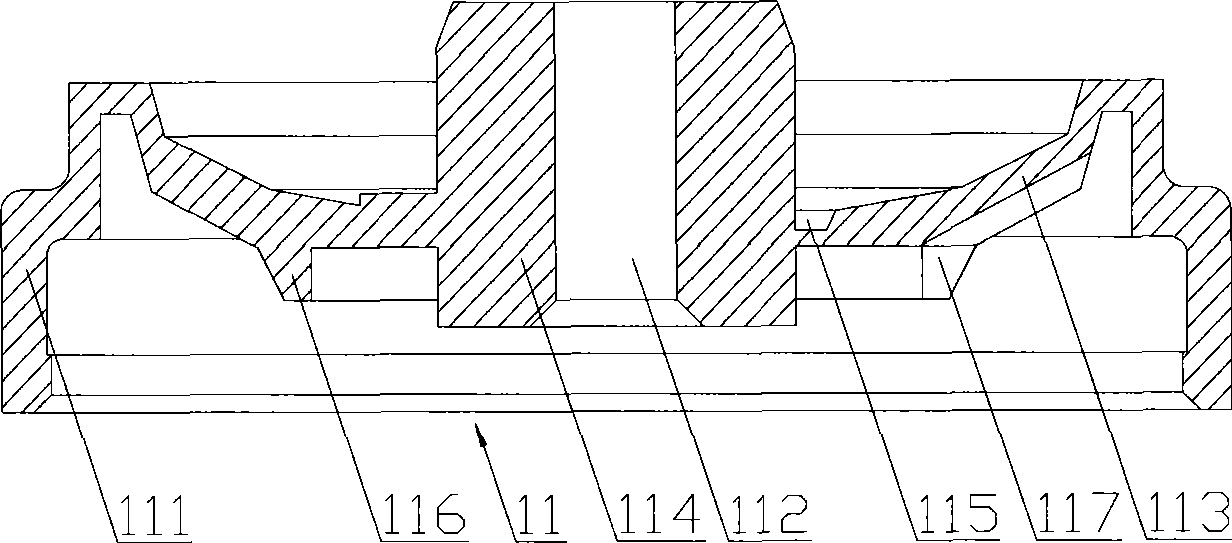

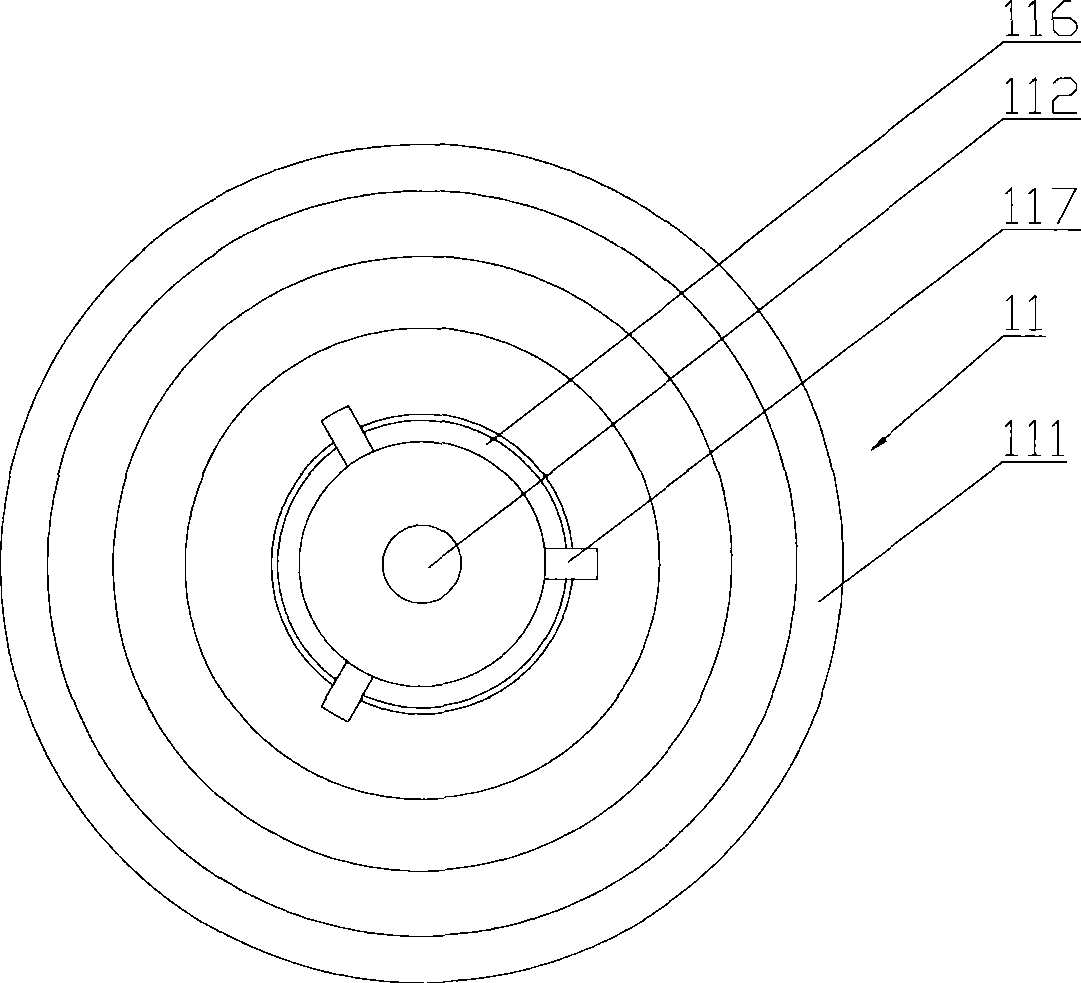

ActiveCN101425567AUniform mass distributionExtended service lifeSmall-sized cells cases/jacketsElectrode carriers/collectorsCapacitanceMechanical engineering

The invention discloses a battery collector body. A sealing ring thereof is a rotating body; the bottom cover of the rotating body is provided with a raised structure protruding towards the sealing ring; and a deflation hole on the bottom cover is arranged in the raised structure. The raised structure is used for supporting the sealing ring when the sealing ring falls down due to a broken explosion-proof channel, thereby a broken opening communicated with the sealing ring and a deflation channel of the deflation hole are formed. Because the sealing ring is the rotating body, the mass distribution of the sealing ring is more uniform during the injection mold and processing, thereby the problem that the sealing ring is friable and easily broken in the prior art is effectively avoided, the service life is prolonged, and the reliability is improved. Because the deflation hole is arranged in the raised structure and is not on an identical plane with the bottom surface of the bottom cover, the tail end of a holddown spring is not easy to extend. In addition, because the thickness of the sealing ring is relatively lowered, the inside of the battery is ensured to have a larger space filled with active substances, thereby the capacitance of the battery is obviously improved.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

Manufacturing method for high-quality cotton linter

ActiveCN103103841ALow grayscaleLow impurity contentFibrous raw materialsPulp and paper industryImpurity

The invention discloses a manufacturing method for high-quality cotton linter. The processing steps includes that (1) gross cottonseeds of raw material of the cotton linter are purified, stone and dust in the gross cottonseeds are eliminated, and the purified gross cottonseeds are obtained; (2) the obtained purified gross cottonseeds are sent to a delinter to have linter peeled and the impurity content of the purified gross cottonseeds is controlled, so that the cotton linter with low impurity is obtained; (3) the cotton linter with low impurity is sent to a lower linter collecting machine to have the dust eliminated, and the dedusted cotton linter is obtained; (4) the dedusted cotton linter is sent to a shell-linter separator where the linter is effectively separated from the impurities, and the cotton linter without impurity is obtained; (5) the cotton linter without impurity is sent to a cleaning machine where the linter is further separated with the impurities, and the high-quality cotton linter is obtained. According to the manufacturing method for the high-quality cotton linter, the gross cottonseeds are preliminarily purified, the cotton linter with the low impurity content is obtained through the delinter, and then the lower linter collecting machine, the shell-linter separator and the cleaning machine are utilized in sequence, so that the impurities and the dust in the cotton linter are eliminated, and the cotton linter which is low in dust content and impurity content, high in quality and even in mass distribution is obtained.

Owner:邯郸晨光植物蛋白有限公司

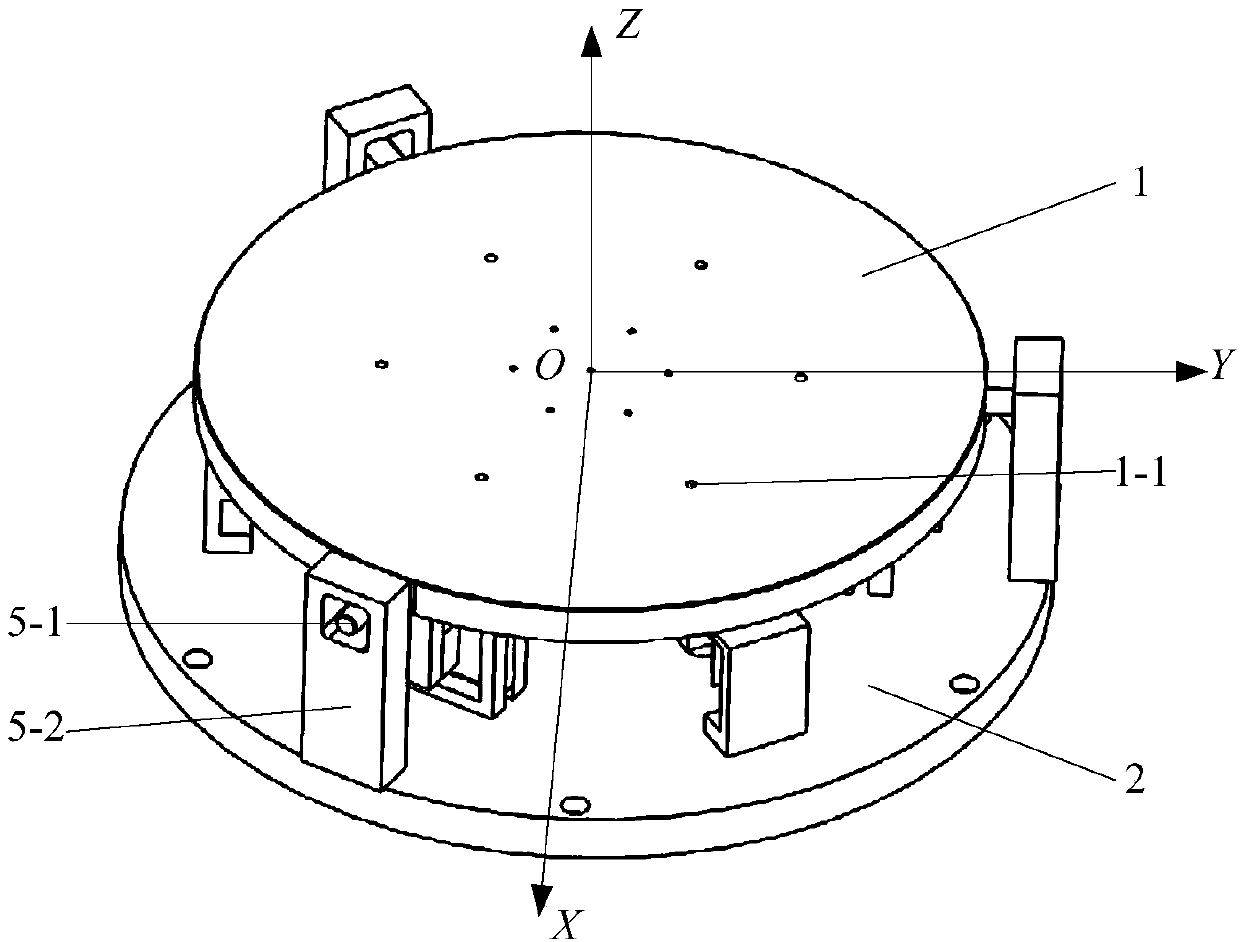

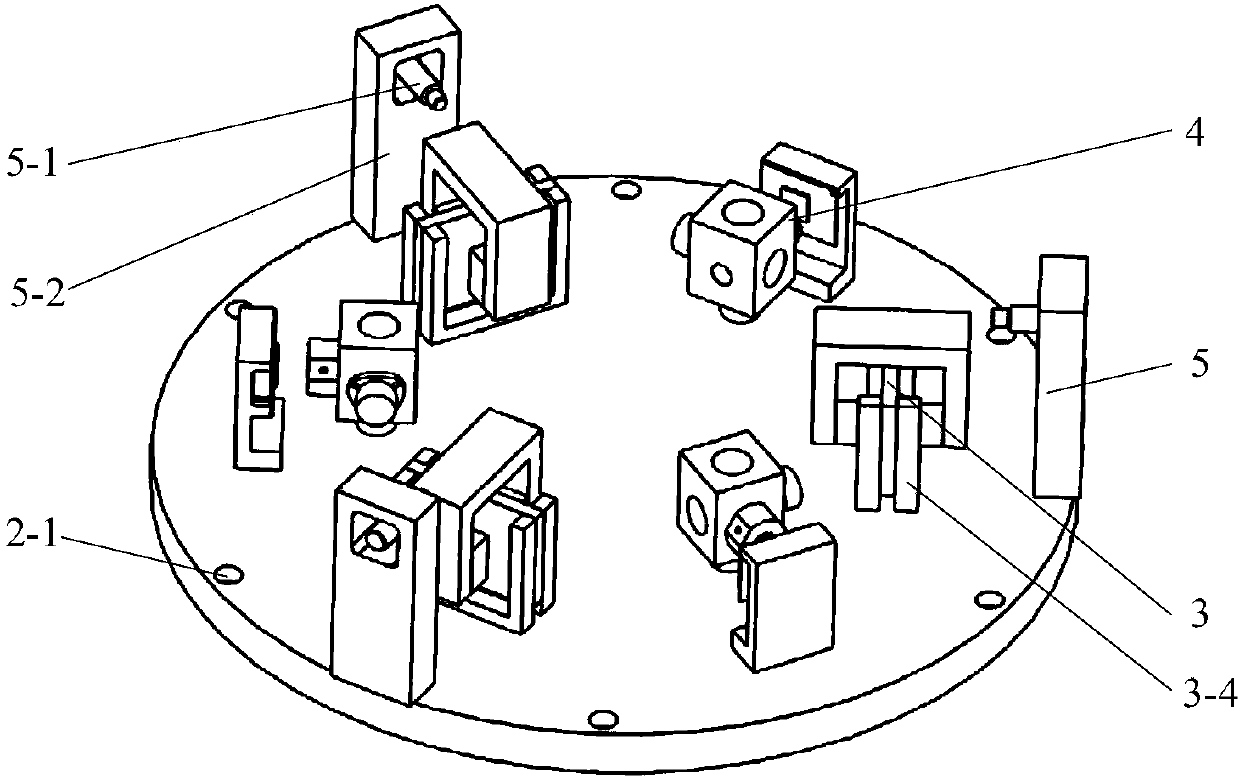

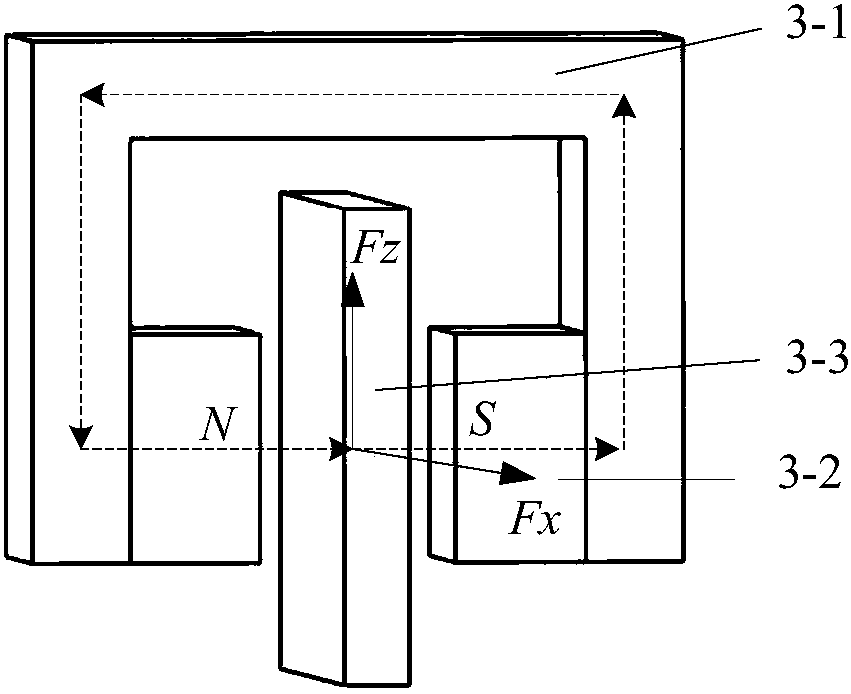

Electromagnetic positioning vibration isolation platform

ActiveCN107264844ANo interferenceAccurate measurementCosmonautic vehiclesCosmonautic partsForce linesClassical mechanics

An electromagnetic positioning vibration isolation platform comprises a base, a working platform, an acting force output system, an acceleration measuring unit, a position measuring unit and a controller; three groups of biaxial electromagnetic exciters form the acting force output system; the biaxial electromagnetic exciters consist of first working parts and second working parts; the first working parts comprise permanent magnets and magnet yokes; the permanent magnets and the magnet yokes form closed magnetic circuits; the magnet yokes are fixed together with a working platform; the second working parts comprise circuit boards and coil brackets; the coil brackets are fixed together with the base; the circuit boards are fixed on the coil brackets; coils are arranged on the circuit boards; the coils are positioned within the closed magnetic circuits; all magnetic force lines that penetrate through the coils have same directions; the coils comprise (i)x( / i)-direction lorentz force generation parts and (i)z( / i)-direction lorentz force generation parts; current directions of all leads in the (i)x( / i)-direction lorentz force generation parts are as same as each other; and current directions of all leads in the (i)z( / i)-direction lorentz force generation parts are as same as each other. The electromagnetic positioning vibration isolation platform has the advantages that each component is simply mounted and placed and the micro acceleration speed can be measured and controlled.

Owner:ZHEJIANG UNIV

Efficient continuous casting and continuous rolling production technology for special-shaped copper rod

InactiveCN109852813AGuaranteed purityGood continuous casting effectWork treatment devicesMetal rolling arrangementsElectrolysisNitrogen gas

The invention discloses an efficient continuous casting and continuous rolling production technology for a special-shaped copper rod. The efficient continuous casting and continuous rolling productiontechnology includes the following steps that smelting is conducted, heat insulation treatment is conducted, continuous casting treatment is conducted; copper blank heat rolling is conducted; the rolled special-shaped copper rod is cooled and blown to be dry through a vacuum anti-oxidation tube and a cooling groove, and a coloring treatment technology is conducted on the special-shaped copper rod;and wax is rapidly and evenly smeared on the surface of the special-shaped copper rod, then rod winding is conducted, and afterwards, packaging is conducted. By means of the technology, in the process of smelting electrolytic copper raw materials, coke, pure nitrogen and a powdery slagging agent are used for conducting multiple refining, and impurities in copper liquid can be removed more thoroughly; in the heat insulation treatment process, degassing and deslagging are conducted at the same time, and purity of the copper liquid can be further ensured; in the continuous casting treatment process, ultrasonic treatment is used, the continuous casting effect of the copper liquid can be better, and mass distribution of the copper blank obtained after continuous casting can be more uniform; the continuous casting and continuous rolling technology is used for producing the special-shaped copper rod, and the production efficiency is higher.

Owner:GUIXI HONGSHI METAL

Large wide airliner multi-position maintenance hangar roof diagonal truss structural system

ActiveCN106968382ARelieve stressThe maximum internal force is reducedBuilding roofsStructural systemEngineering

A large wide airliner multi-position maintenance hangar roof diagonal truss structural system comprises roof bearing columns arranged along three edges of a hangar at intervals and a roof steel structure fixed to the tops of the roof bearing columns and further comprises gate truss bearing columns arranged along the open edge of the hangar and a gate truss fixed to the tops of the gate truss bearing columns. The roof steel structure is connected with the gate truss, the hangar comprises a single-span hangar body and a multi-span hangar body, the roof steel structure comprises a main structural frame covering the hangar and further comprises a diagonal truss and a linear truss which are arranged in the main structure frame, and the linear truss intersects with the diagonal truss. Based on the shortest transfer path theory of force, the diagonal truss and the linear truss are arranged in the hangar, a roof is divided and surrounded, the pressure of the gate truss is effectively relieved, and it is possible to implement the ultralow-airspace height-limited-place ultra-large-span multi-position maintenance hangar.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

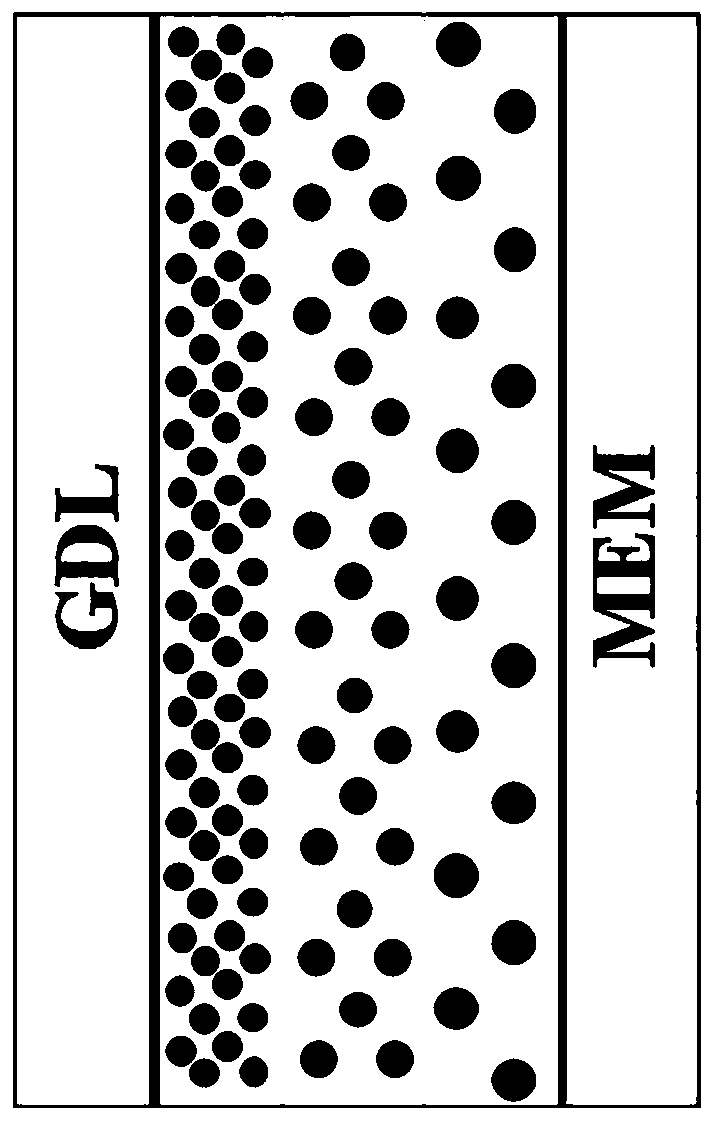

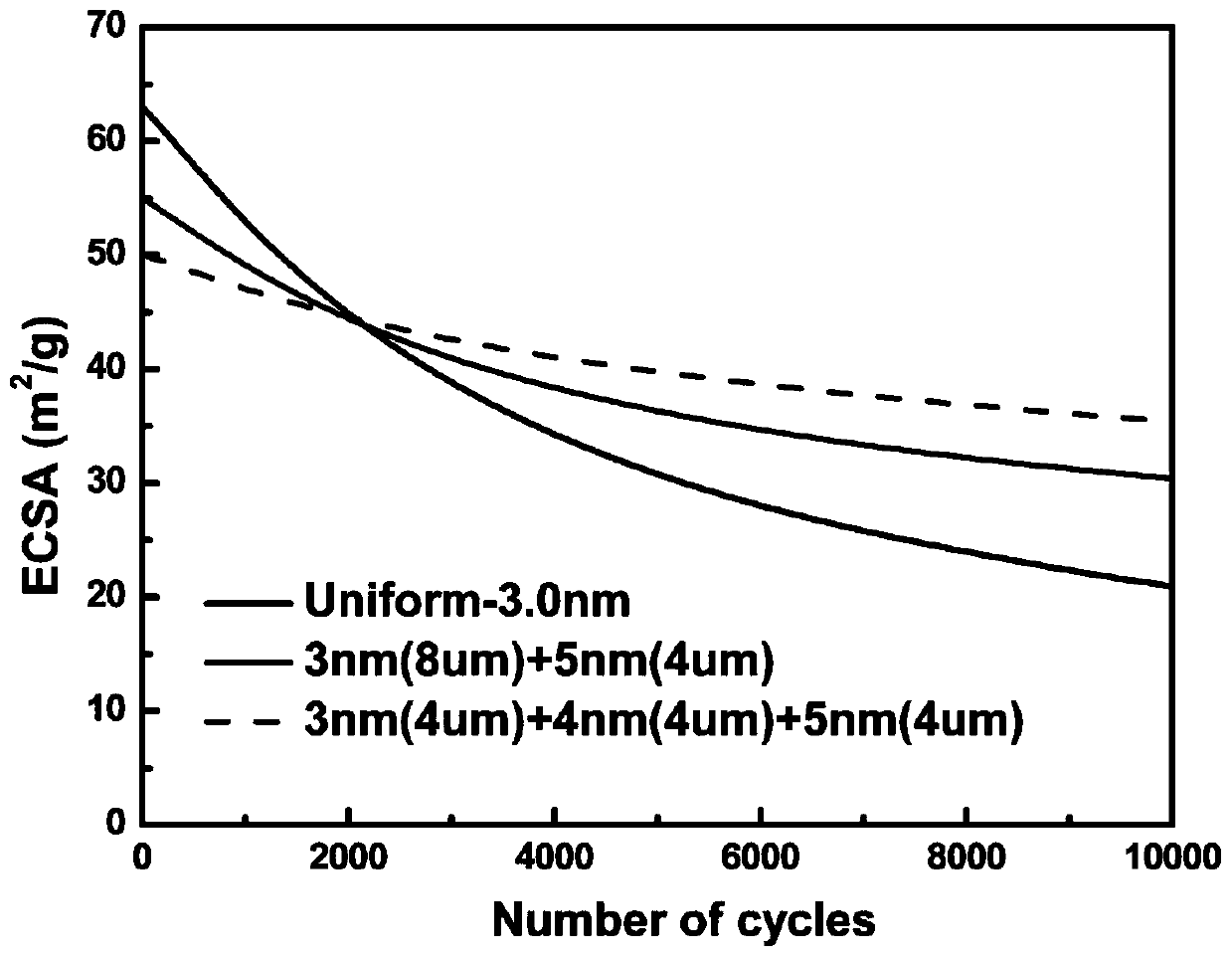

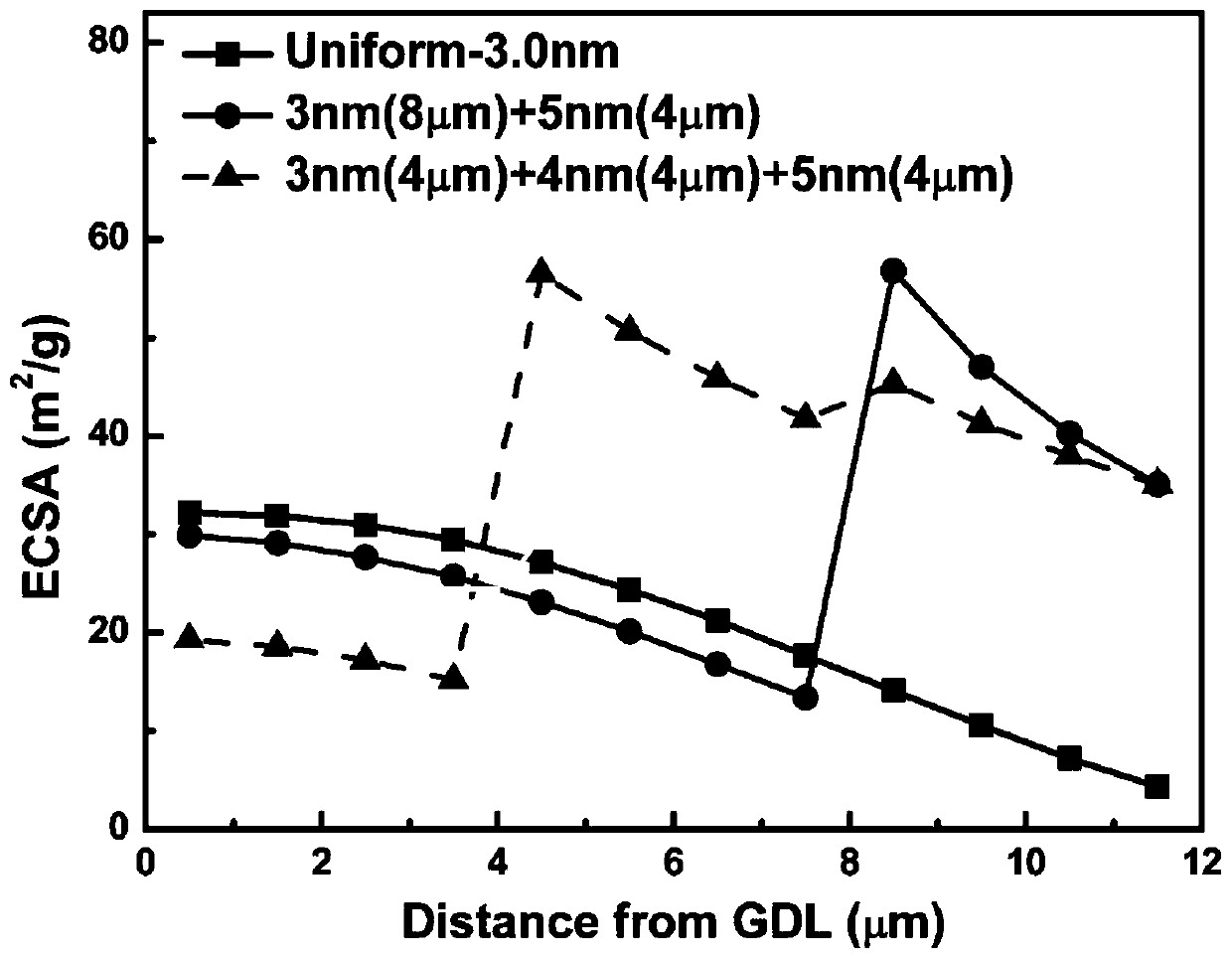

Cathode catalyst layer structure capable of enhancing catalyst durability and preparation method thereof

InactiveCN110993960AReduced ECSA and platinum mass lossIncreased durabilityCell electrodesFuel cellsChemistryCathode catalyst

The invention discloses a fuel cell cathode catalyst layer structure capable of enhancing catalyst durability, and relates to the technical field of fuel cells. The fuel cell cathode catalyst layer structure comprises a first catalytic part, a second catalytic part and a third catalytic part which are sequentially arranged in the direction from an area close to a diffusion layer side to an area close to a proton exchange membrane side; pure platinum catalysts are arranged in the first catalytic part, the second catalytic part and the third catalytic part; the platinum loading capacities of thepure platinum catalysts in the first catalytic part, the second catalytic part and the third catalytic part are sequentially decreased; the average particle sizes of the pure platinum catalyst particles in the first catalytic part, the second catalytic part and the third catalytic part are sequentially increased; the large-particle-size pure platinum catalyst is more corrosion-resistant, and thesmall-particle-size pure platinum catalyst improves the initial performance of the fuel cell, so that the loss of the specific surface area of the catalyst under potential scanning is conveniently reduced; and the attenuated cathode catalyst is more uniform in platinum specific surface area and platinum mass distribution, so that the attenuated oxygen and proton mass transfer loss is reduced, theperformance of the attenuated fuel cell is improved, and the durability is improved.

Owner:SHANGHAI JIAO TONG UNIV

Center shaft structure of delta robot

ActiveCN103895004AAdvantages of central axis structureSmall inertiaProgramme-controlled manipulatorArmsFiberCarbon fibers

The invention discloses a center shaft structure of a delta robot and belongs to the technical field of mechanical equipment. The problems that inertia is high, efficiency is lower and operation accuracy is reduced due to the fact that the center shaft structure of an existing delta robot is large in structural weight are solved. The center shaft structure of the delta robot comprises at least two robot driving arms and at least one robot operation arm, the robot driving arms are parallel, one ends of the robot driving arms are fixedly connected together via a fixing sleeve, the other ends of the robot driving arms are fixedly connected with a first slider, one ends of the robot operation arms penetrate the first slider, the robot operation arms can slide relative to the slider along the self axial direction, and both the robot driving arms and the robot operation arms are made of carbon fiber materials. The center shaft of the delta robot is simple in structure and light in weight, thereby being low in inertia and high in efficiency when in running.

Owner:杭州钱江机器人有限公司

Compressor high manganese steel balancing weight and manufacturing method thereof

InactiveCN109128137AUniform mass distributionQuality controllableTransportation and packagingMetal-working apparatusChemical compositionAlloy

The invention provides a compressor high manganese steel balancing weight and a manufacturing method thereof, and belongs to the technical field of compressors. The problem of high manufacturing costof an existing powder metallurgy high manganese steel balancing weight is solved. Alloy powder pressing molding and high temperature sintering molding are adopted in the compressor high manganese steel balancing weight, alloy powder is formed by mixing high manganese steel powder and a lubricant, and the high manganese steel powder is composed of the following chemical components of C with the weight percentage being less than or equal to 1.0%, Si with the weight percentage being less than or equal to 0.9%, Mn with the weight percentage being 15% to 21%, S with the weight percentage being lessthan or equal to 0.03%, P with the weight percentage being less than or equal to 0.06% and the balance Fe. The compressor high manganese steel balancing weight and compressor high manganese steel balancing weights produced by using the manufacturing method of the compressor high manganese steel balancing weight have the advantages of lower manufacturing cost and higher product quality, and meanwhile have the advantages of high precision of the compressor high manganese steel balancing weights and the density approaching that of a casting forming balancing weight.

Owner:浙江百达精工股份有限公司

Self-advancing type high-pressure jet sprayer for radial horizontal well drilling

ActiveCN102518398AUniform mass distributionWith rotating jetLiquid/gas jet drillingHigh pressureAerospace engineering

The invention relates to a self-advancing type high-pressure jet sprayer for radial horizontal well drilling, which mainly comprises a shell, a turbine rotor, wear-resistant steel balls, a baffle plate and the like. The self-advancing type high-pressure jet sprayer is technically characterized in that a tip, a forward spray nozzle and a backward spray nozzle are processed on the shell, hard alloy is welded on the outer surface of the shell, the turbine rotor is mounted in the shell, spherical grooves are processed at the upper end and the lower end of the turbine rotor, the turbine rotor is positioned via the upper wear-resistant steel ball and the lower wear-resistant steel ball, the upper wear-resistant steel ball is placed between the inside of the shell and the corresponding spherical groove of the turbine rotor, the lower wear-resistant steel ball is placed between the turbine rotor and a spherical groove on the baffle plate, the shell is connected with the baffle plate in a threaded manner, and four to six water injection holes are uniformly distributed on the baffle plate. The self-advancing type high-pressure jet sprayer is simple in structure and reliable in work, and can be widely applied to radial horizontal well drilling operation.

Owner:SOUTHWEST PETROLEUM UNIV

Symmetrical centrifugal force power single-leg jumping machine

The invention provides a symmetrical centrifugal force power single-leg jumping machine, comprising a motor module for supplying power, a mass block group, a supporting plate and a spring leg sleeve for storing energy, wherein the supporting plate is an axisymmetric body; the mass block group comprises even number of mass blocks and the mass blocks are axially symmetrically distributed by taking the supporting plate as a symmetry axis; the mass block group and the motor module are connected through a transmission shaft; the motor module drives the mass blocks at the two sides of the symmetry axis of the supporting plate to rotate in an opposite direction; a component force of a generated centrifugal force in the vertical direction is overlapped and a component force of the centrifugal force in the horizontal direction is offset; and the motor module is fixedly arranged at one side of the supporting plate and the spring leg sleeve is fixedly arranged at the other side of the supporting plate. The symmetrical centrifugal force power single-leg jumping machine disclosed by the invention has the characteristics of stability in jumping, simplicity in controlling and the like.

Owner:BEIJING JIAOTONG UNIV

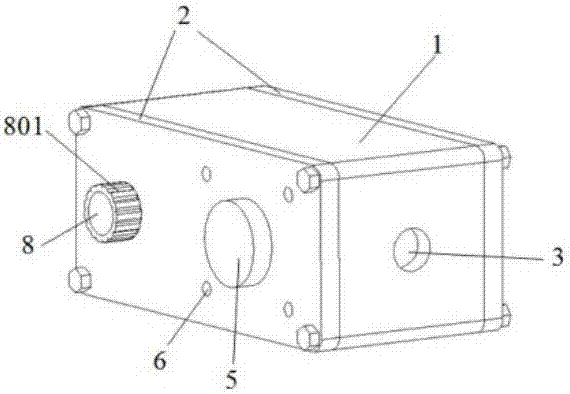

Mini-type driver and mechanical arm and running-in device thereof

ActiveCN107378938ASmall form factorMiniaturizationProgramme-controlled manipulatorElectricityMotor drive

The invention provides a mini-type driver. The mini-type driver comprises a shell, a motor, a transmission mechanism, an output shaft, a circuit board and a control line, wherein the motor drives the output shaft through the transmission mechanism to output power; the output shaft comprises a hollow shaft section and is provided with a ring piece electric brush; one end of the control line is connected with the circuit board; and after the other end of the control line is rotationally and electrically connected with the ring piece electric brush to be switched, the other end of the control line penetrates through the output shaft and is led out of the shell via the hollow shaft section. The mini-type driver is compact in structure, simple in line arrangement, high in reliability and small in mechanical transmission error; after the control line inside the mini-type driver is rotationally and electrically connected with the ring piece electric brush to be switched, the line arrangement operation is greatly simplified, so that the line arrangement problem of the control line is not considered during design of a mechanical arm. The invention further provides a running-in device and method of the mini-type driver. The mini-type driver is stable in transmission and the working life is prolonged through secondary assembly after high-speed grinding.

Owner:北京勤牛创智科技有限公司

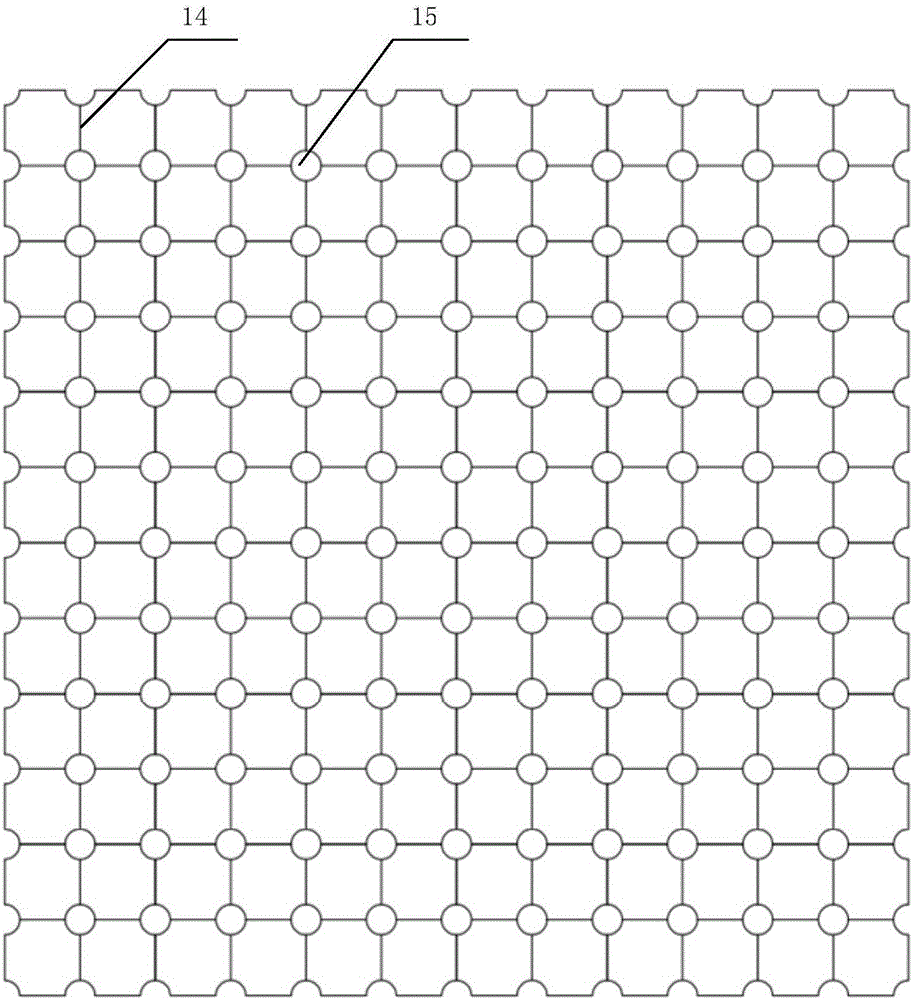

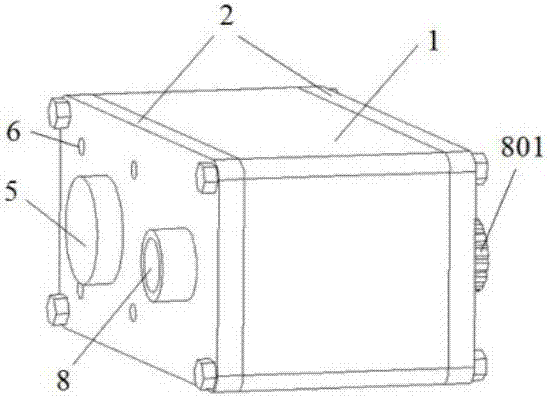

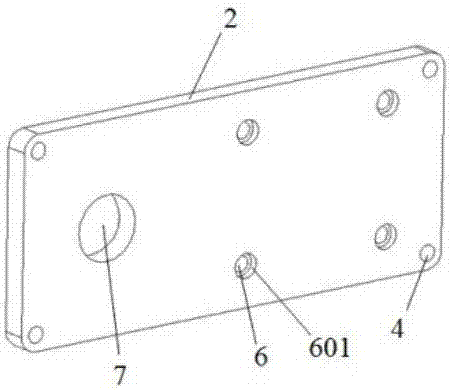

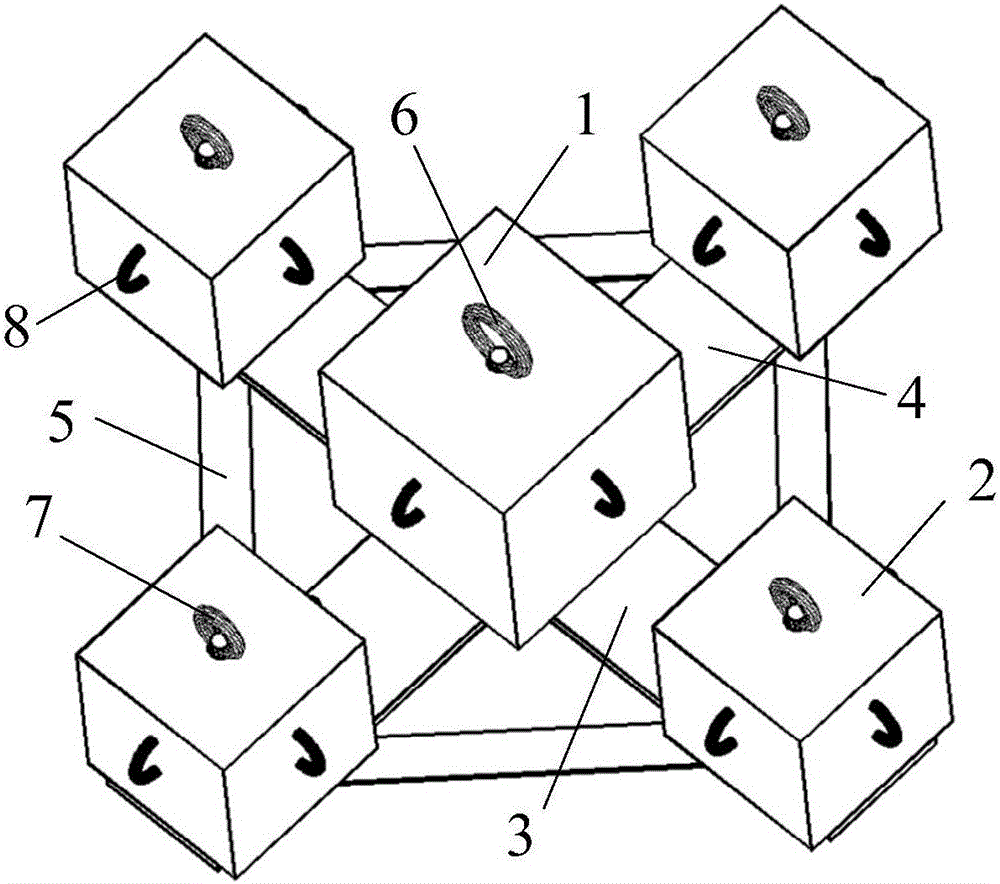

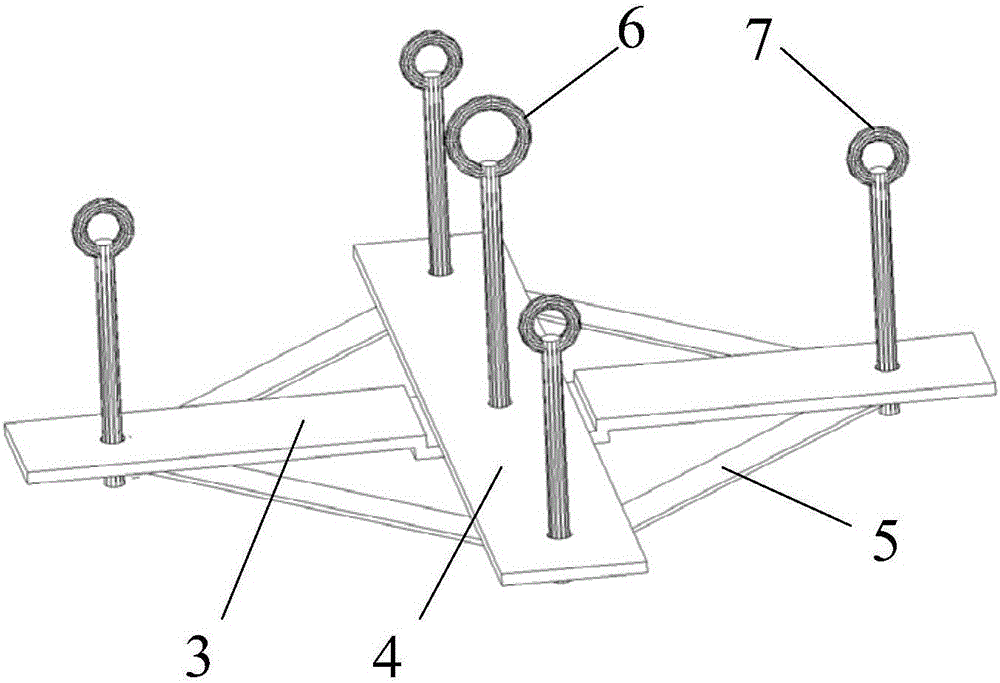

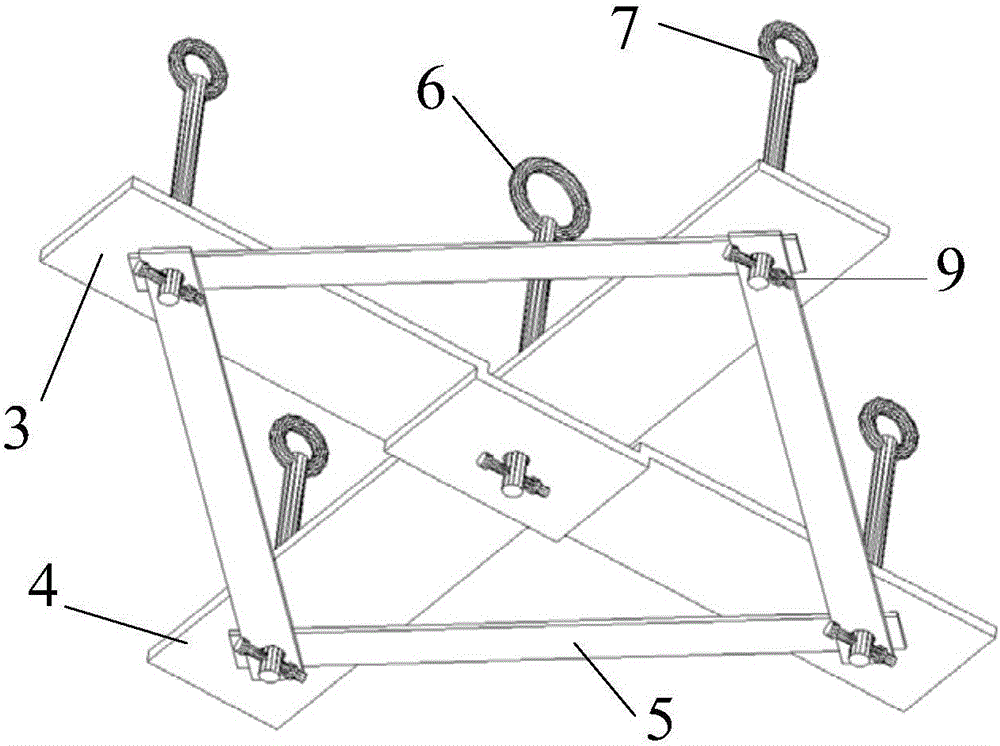

Assembled-type cement pier anchoring system for net cage fixation

InactiveCN105961224ALarge peripheral sizeUniform mass distributionClimate change adaptationPisciculture and aquariaMass distributionSeabed

The invention discloses an assembled-type cement pier anchoring system for net cage fixation. The anchoring system is composed through assembly of a main cement sunk lump, four subsidiary cement sunk lumps, a horizontal connecting baseplate, a longitudinal connecting baseplate and four rib plates, wherein the main cement sunk lump and the subsidiary cement sunk lumps are cubes, and a preformed hole is formed in the vertical center axis of the each cube; and the horizontal connecting baseplate and the longitudinal connecting baseplate are assembled into a criss-crossed baseplate structure, the main cement sunk lump is assembled at the criss-crossed center axis, and the four subsidiary cement sunk lumps are assembled on end parts of the horizontal connecting baseplate and the longitudinal connecting baseplate respectively. An anchoring system to be lifted has a large overall weight; the criss-crossed system formed through the assembly has large overall dimensions, uniform mass distribution and strong overturning resistance and can get adapted to stormy effects in random directions, and various seabed geological conditions; and construction duration on seas is very short; and large anchoring force can be provided.

Owner:HEFEI UNIV

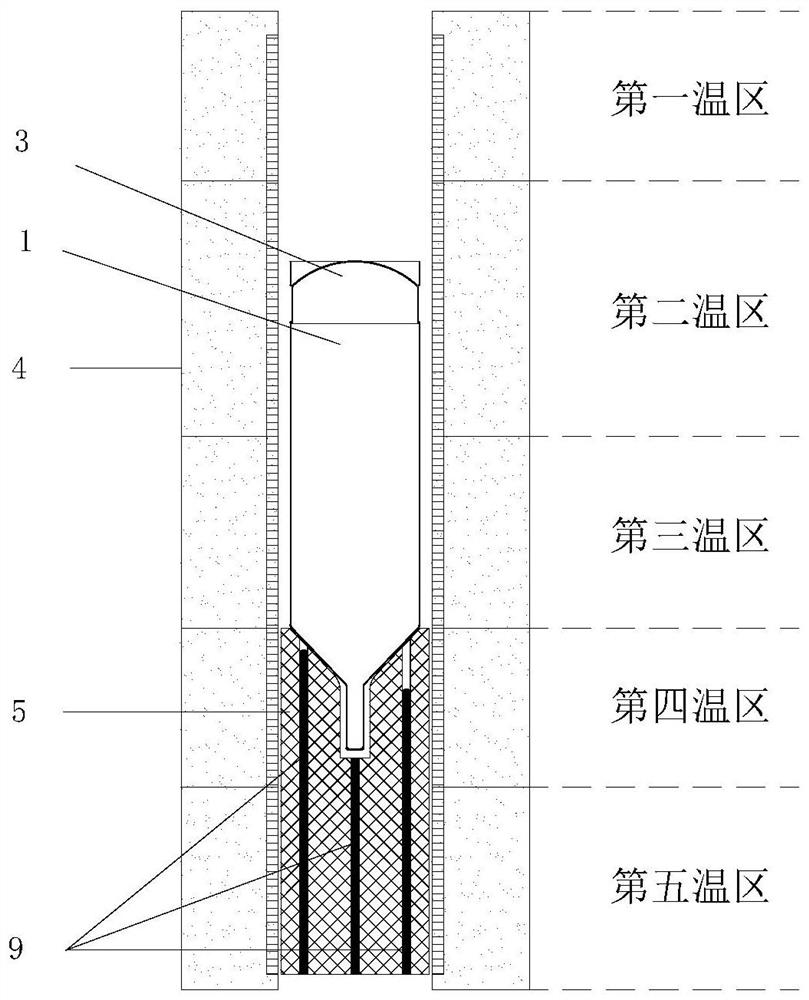

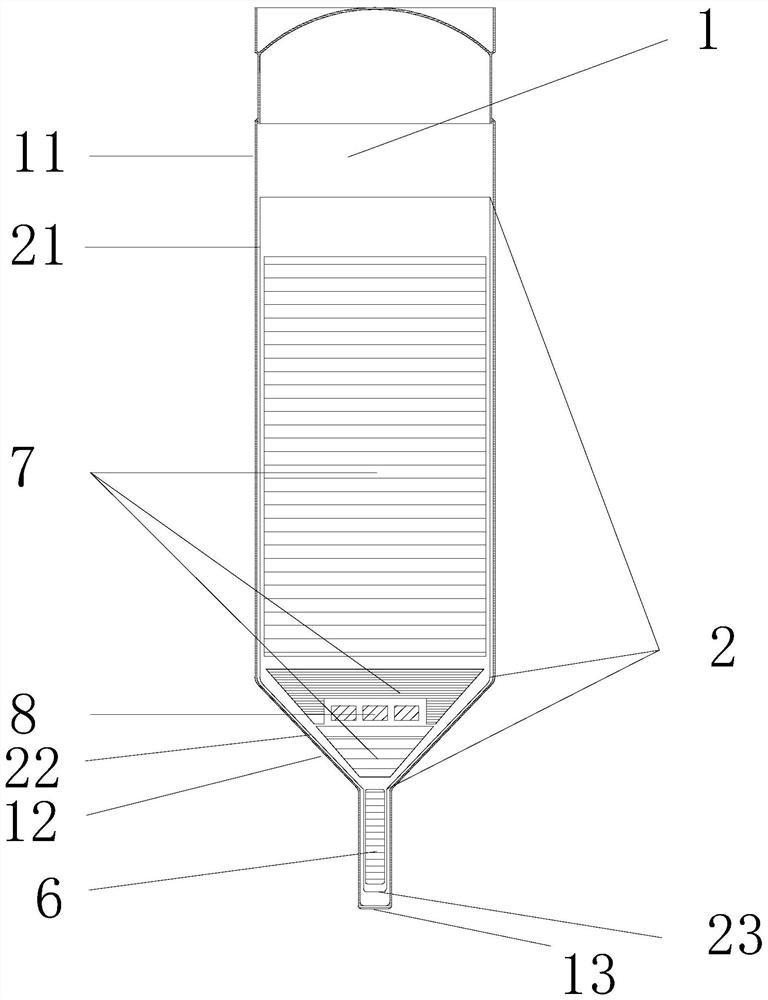

Method and device for preparing indium antimonide single crystal

ActiveCN111809229ALow process experience requirementReduce dislocation densityPolycrystalline material growthFrom frozen solutionsPhysicsDislocation

The invention provides a preparation method and device of an indium antimonide single crystal, and relates to the field of crystal preparation. The preparation method comprises the following steps: adding indium antimonide seed crystals, indium antimonide polycrystals and diboron trioxide into a closed container; carrying out crystal growth by adopting a vertical Bridgman method (VB method); in this way, the crystals begin to grow from the bottom of the melt and are not interfered by dross, automation of crystal growth can be achieved by controlling a heating program, and compared with a Cz method, the method is low in requirement for technological experience of crystal pulling workers, high in finished product success rate, low in dislocation density and stable and controllable in quality. By arranging a heating area with independent temperature control above the closed container, the heat preservation effect can be achieved, materials can reach the set temperature more accurately, and the overall mass distribution of obtained crystals is more uniform.

Owner:安徽光智科技有限公司

Automobile transmission shaft operation state monitoring apparatus and method for detecting fault of transmission shaft

ActiveCN107631875AGuaranteed accuracyAvoid misjudgmentMachine bearings testingDriver/operatorDrive shaft

The invention discloses an automobile transmission shaft operation state monitoring apparatus. The apparatus herein includes an installation pedestal which fixedly sleeves the shaft sleeve of the automobile transmission shaft. The installation pedestal is fixedly provided with a master vibration monitoring apparatus which is intended for monitoring the vibration state of the transmission shaft. Anautomobile which is provided with the transmission shaft is also fixedly provided therein with a slave vibration monitoring apparatus which is intended for monitoring the vibration state of the entire automobile. The master vibration monitoring apparatus and the slave vibration monitoring apparatus are in wireless connection to a zigbee center node through the zigbee technology. The zigbee centernode saves a vibration threshold value. The zigbee center node acquires the vibration data of the transmission shaft and the entire automobile from the master vibration monitoring apparatus and the slave vibration monitoring apparatus, and compares the two vibration data and the threshold values so as to determine whether the transmission shaft has faults. According to the invention, the apparatus herein can perform real-time monitoring on the vibration and torque states of the transmission shaft in the time when the automobile travels, and can send alarms to a driver and a traffic managementauthority.

Owner:HENAN TONGXIN TRANSMISSION CO LTD

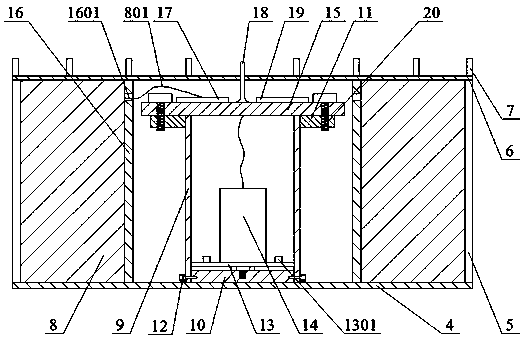

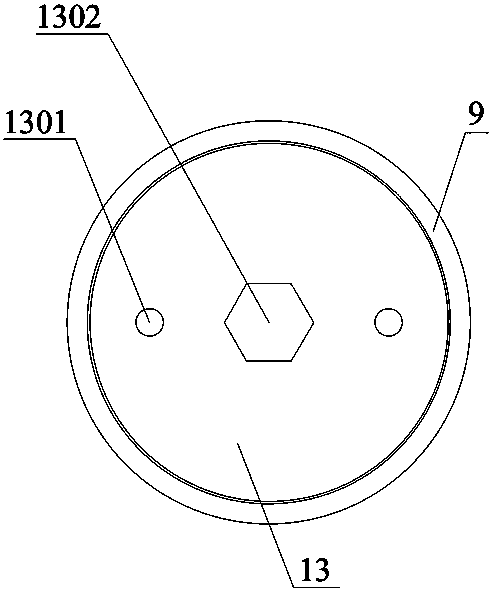

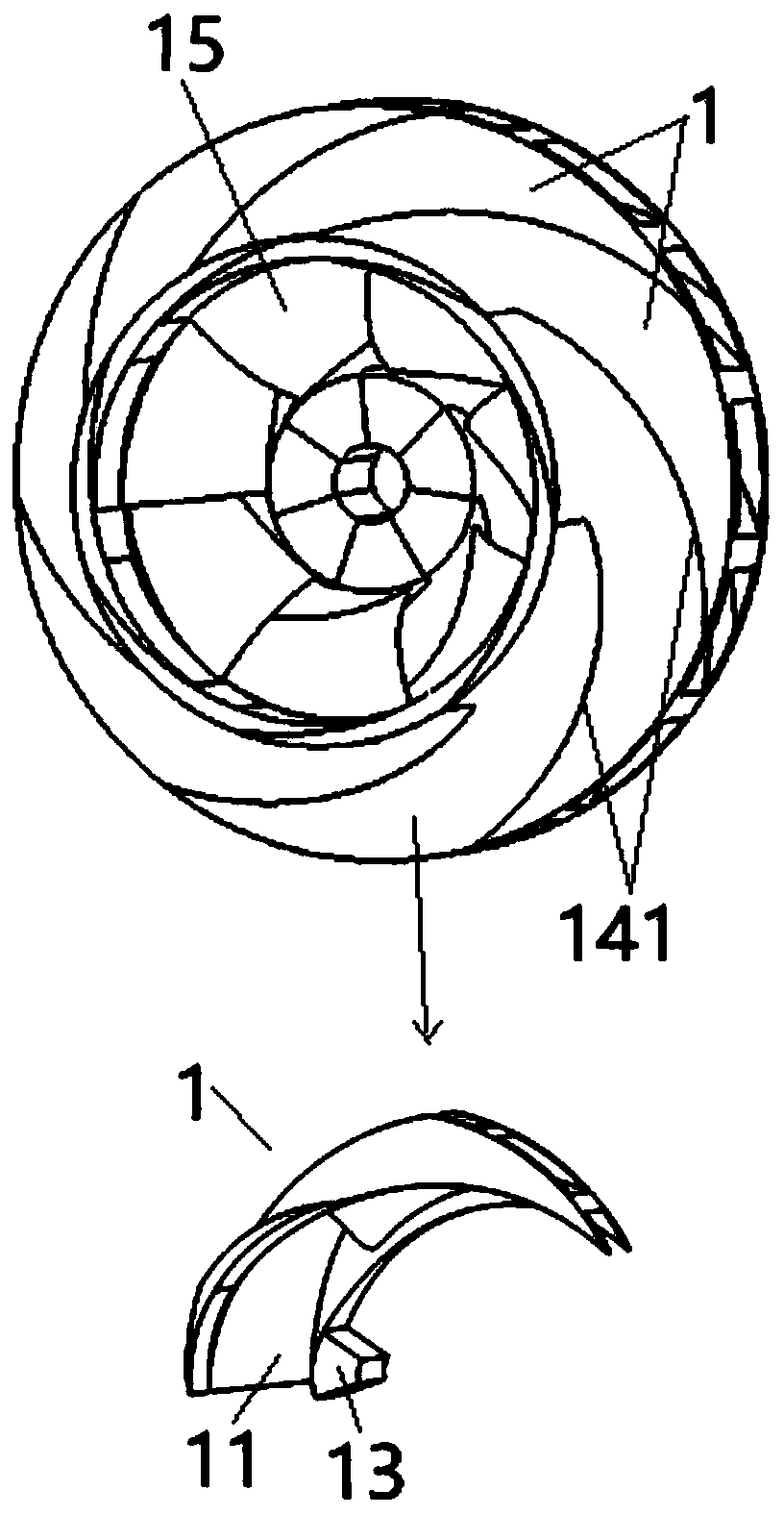

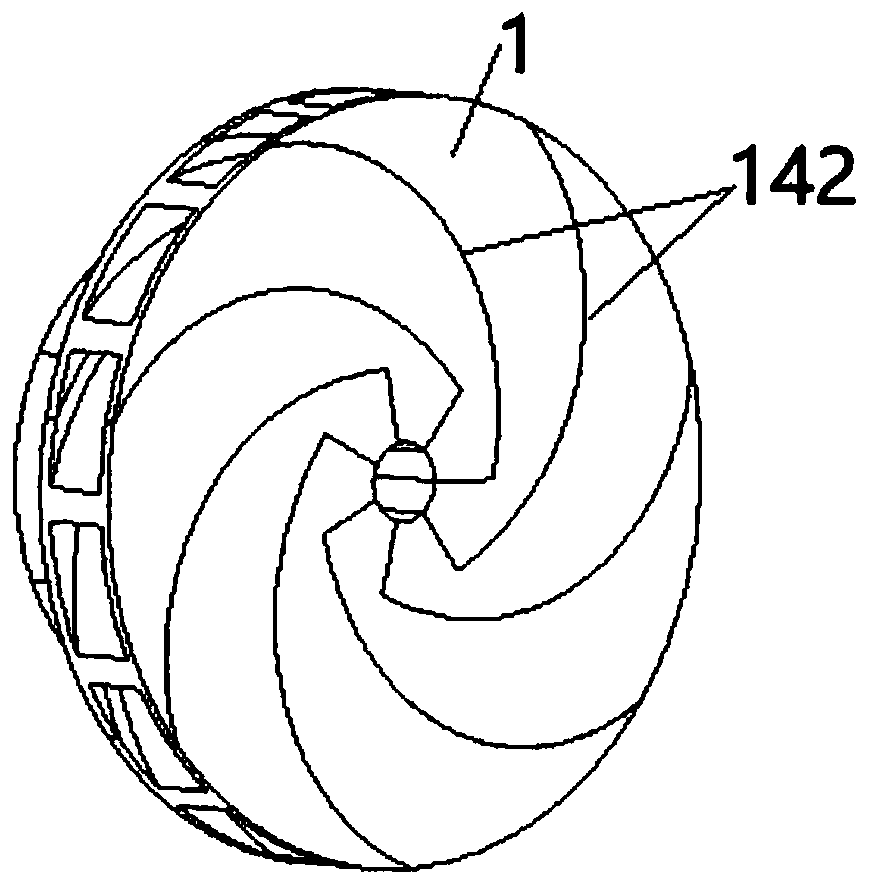

Closed impeller provided with twisted blades and applicable to water pump and machining technology of closed impeller

InactiveCN109909692ABig space warpSolve unprocessable problemsPump componentsPumpsStructural reliabilityImpeller

The invention discloses a closed impeller provided with twisted blades and applicable to a water pump and a machining technology of the closed impeller. The impeller comprises single twisted blades; aplurality of single twisted blades are assembled sequentially to form the closed impeller; each single twisted blade is formed through overall milling by the aid of a five-axis CNC machine tool; assembled positions of every two adjacent single twisted blades are connected through welding and form welding lines; and the number of the welding lines is equal to that of the single twisted blades of the closed impeller. According to the impeller and the technology, the manufacturing accuracy, the surface smoothness and the weight uniformity of the closed impeller are substantially improved, the manufacturing cycle of the closed impeller is substantially shortened, the problems of large machining difficulty and the like of the overall large-distortion and multi-blade milling technology are solved, meanwhile, the structural reliability and the hydraulic performance of the closed impeller are improved, and vibration of the closed impeller is reduced.

Owner:SHANGHAI MICROPOWERS

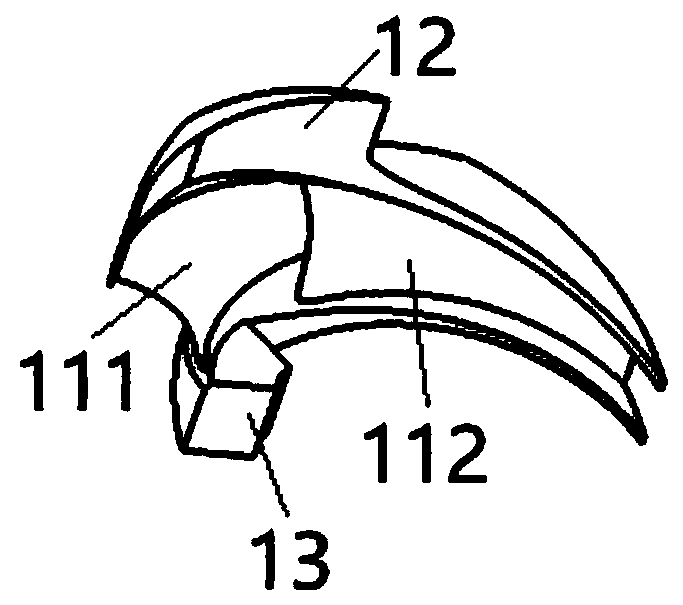

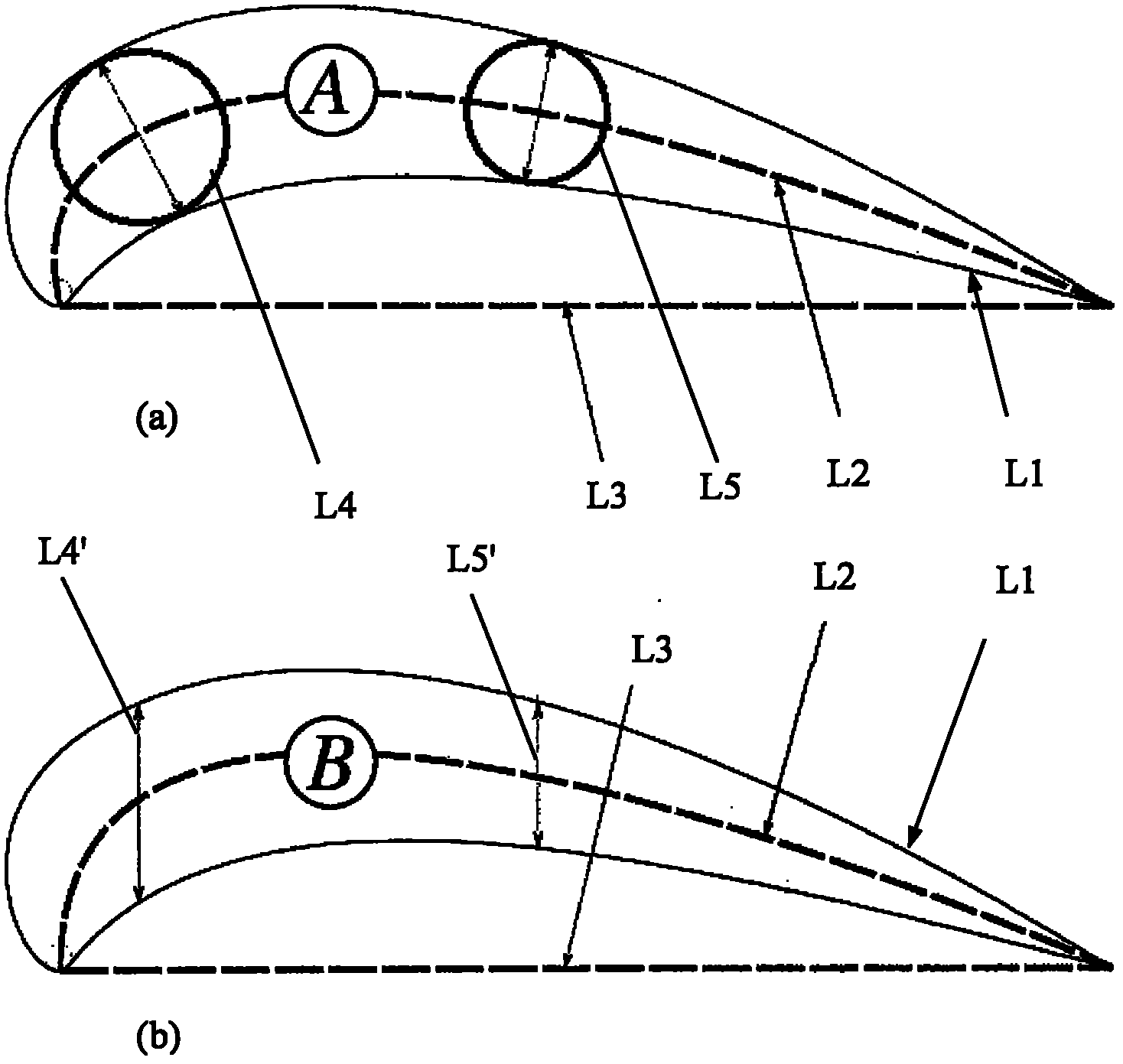

Turbine rotor blade, rotating assembly and turbine engine

ActiveCN103184889AUniform mass distributionMeet strength requirementsBlade accessoriesMachines/enginesStress concentrationTurbine blade

The invention relates to a turbine rotor blade, which comprises a wing-shaped part and a blade crown part, wherein the blade crown part is formed on the free end of the wing-shaped part through generally, circumferentially and axially extending along the center of a turbine rotor, and is provided with a blade crown front edge and a blade crown back edge, wherein the blade crown front edge and the blade crown back edge are respectively in smoothly transited arc shapes. The blade crown front edge and the blade crown back edge are designed into arc shapes, the processibility of the blade crown part can be improved, and meanwhile, the weight distribution of the blade crown part can be more uniform through the arc-shaped blade crown front edge and the arc-shaped blade crown back edge, so the stress concentration effect is reduced.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

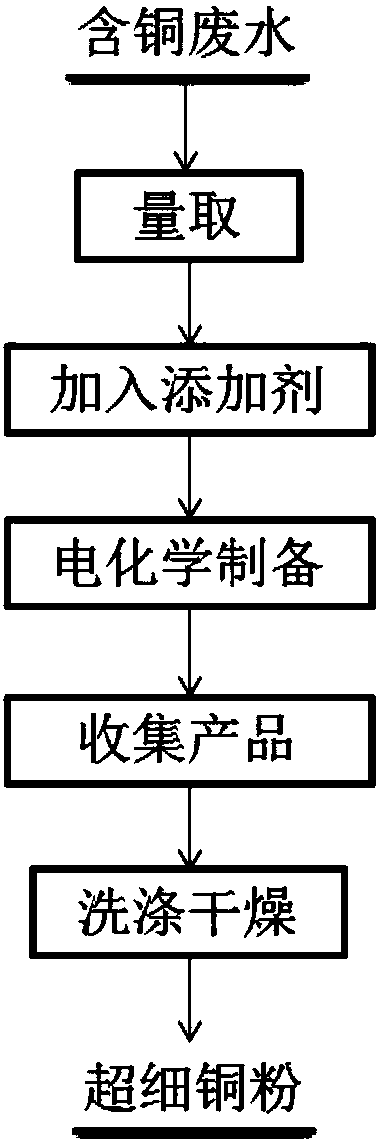

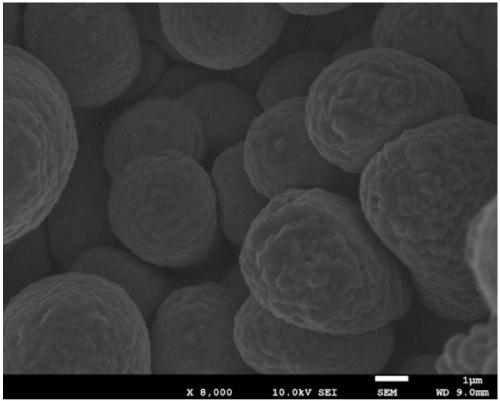

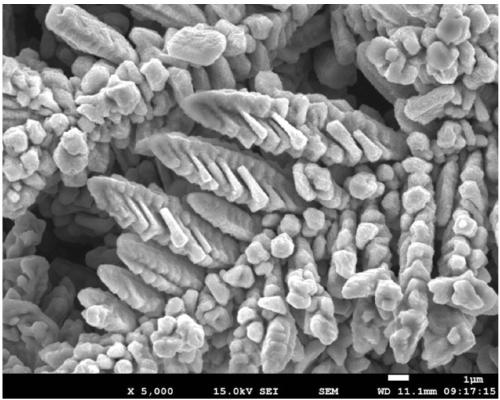

Preparation method of ultrafine spherical copper powder

The invention relates to a preparation method of ultrafine spherical copper powder. The method comprises the following steps: taking a copper-containing solution with potassium ferrocyanide as an electrolyte, performing electrolysis in an electrochemical device, and obtaining copper powder at a working electrode after electrolysis is completed. The electrochemical method can be used for recoveringall copper-containing solutions, especially low-concentration copper-containing wastewater produced in industry, and the ecological environment is protected. The additive potassium ferrocyanide is added in the process of preparing the ultrafine copper powder by electrolysis, morphology and size of the metallic copper powder obtained by electrolysis recovery can be changed, and the prepared ultrafine copper powder has particle diameter of 1-5 mu m and has spherical appearance and uniform particle size and mass distribution. The whole operation flow is simple, the production cost is low, and the method has good economic benefits and application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Single-cylinder, reaction and impulse turbine

ActiveCN101493016AIncrease the shaft diameterReduce shaft diameterMachines/enginesThree stageLogical part

The invention relates to a technology of single-casing steam turbines; a single-casing, reaction and impulse steam turbine, comprises a horizontally placed cylinder and a rotor in the cylinder; the rotor is supported by bearings in the front and in the back; the cylinder is divided into two logic parts, namely, a high-pressure part and a medium-low pressure part; the high-pressure part is provided with a plurality of reaction stages, therein each comprises a static blade and a movable blade; the static blades of the reaction-type stages are arranged on a high-pressure cylinder; the movable blades are arranged on the rotor; the medium-low pressure part is provided with a plurality of impulse stages, therein each comprises a static blade and a movable blade; the static blades of the impulse stages are arranged on a retaining ring; and the movable blades are arranged on the rotor. The high-pressure part and the medium-low pressure part are in a contraflow configuration. The inventive steam turbine overcomes the problem of insufficient rigidity of rotors with a traditional impulse design and difficult self balancing of impulse force of rotors with the traditional reaction design of single-casing three-stage reheating combined cycle steam turbine of 100MW.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Preparation method for solid polymer ferric sulfate zinc flocculant

ActiveCN104692510AWide variety of sourcesUniform mass distributionIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateIndustrial waste water

The invention relates to a preparation method for solid polymer ferric sulfate zinc flocculant. The preparation method comprises the steps that firstly, solid seven-hydrate ferrous sulfate is acidized through concentrated sulfuric acid; secondly, sodium chlorate is added into the mixture and stirred slowly so that tan uniform liquid can be formed; thirdly, solid zinc sulfate is added into the liquid and mixed with the liquid to be uniform, and solid powdery zinc sulfate is added again and stirred slowly to be completely dissolved; afterwards, carbon oxidation materials are added so that the curing rate of the flocculant can be increased, and water bath heating is performed; finally, dry heating and room-temperature curing are performed through an electric jacket, so the faint yellow solid polymer ferric sulfate zinc flocculant can be obtained in a short time. According to the preparation method, none of waste liquid, waste residue and waste gas are produced in the production process; the curing rate of the product is high, mass distribution is uniform, the content of flocculation active components is high, and the flocculation effect is good, and therefore the preparation method can be applied to treatment for industrial waste water, domestic sewage, source water and the like.

Owner:HUNAN UNIV OF SCI & TECH

Timing chain wheel

InactiveCN106763651AUniform mass distributionIncrease cooling areaPortable liftingGearing detailsSprocketMass distribution

The invention discloses a timing chain wheel which comprises a chain wheel body; a shaft hole is formed in the chain wheel body; and mounting of the chain wheel body is realized through the shaft hole. According to the scheme disclosed by the invention, the timing chain wheel is improved, first radiating holes are formed in the chain wheel body; the first radiating holes are arranged in the peripheral direction of the chain wheel body; and the first radiating holes are uniformly arranged along the circumference of the chain wheel body, so that mass distribution, in the peripheral direction, of the chain wheel is uniform. A depth extending direction of the first radiating holes is parallel to the axis of the chain wheel body, i.e., the first radiating holes are formed in the axial direction of the chain wheel body; the first radiating holes are formed, so that the radiating area of the chain wheel body is increased, and therefore, heat generated in a rotation process of a chain disc can be effectively radiated, influences, on working efficiency of the timing chain wheel and an engine, of heat are reduced, and service lives of the timing chain wheel and the engine are prolonged.

Owner:CHONGQING JUE LANG MOTORCYCLE SPARE PARTS

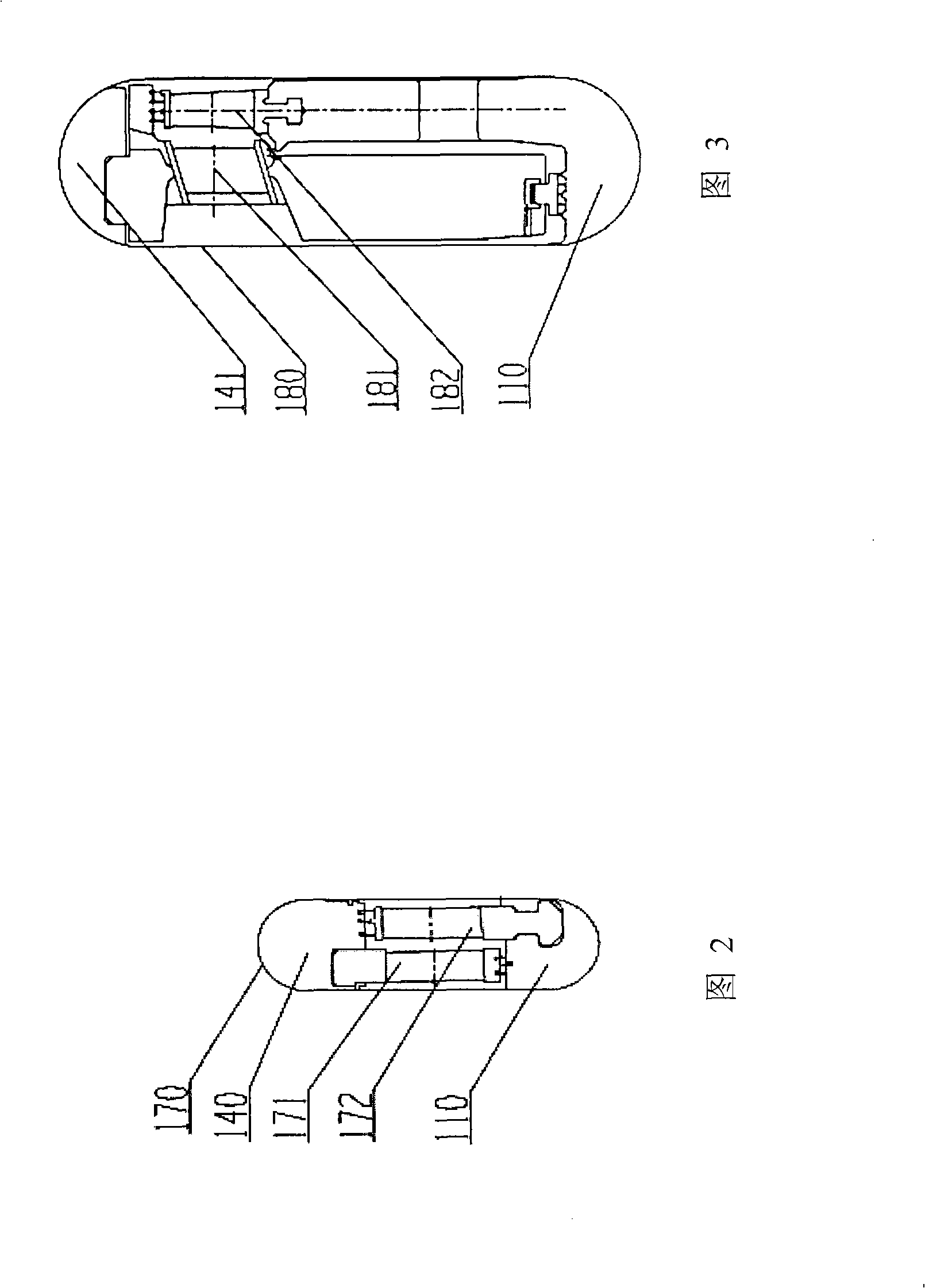

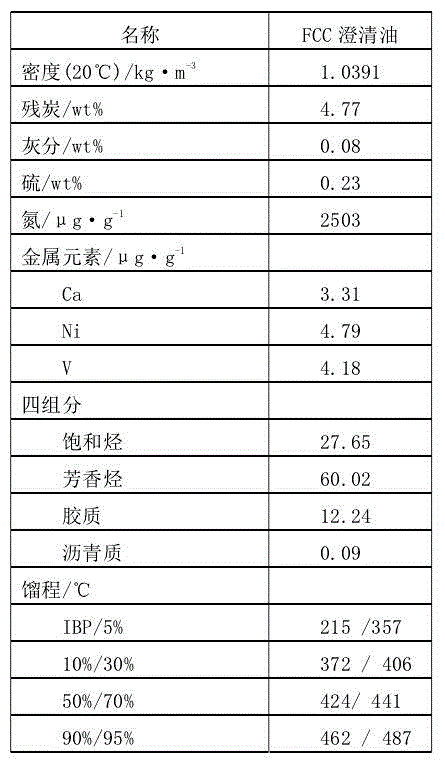

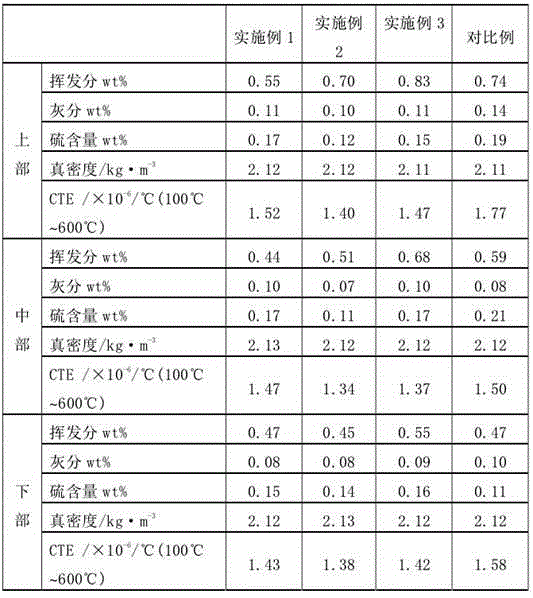

Method and apparatus for production of homogeneous needle coke

ActiveCN105733630AEasy to manufactureSolve the problems caused by different residence timeTreatment with plural serial stages onlyCoking carbonaceous materialsOperation modeWarming process

The present invention provides a method and apparatus for the production of homogeneous needle coke. A pretreatment reactor equipped with a stirrer is added before a coking heating furnace; an operation mode of three-section constant temperature and two-section heating is applied to the coking heating furnace, wherein the second section of heating process uses a rapid heating operation mode with heating rate of 50-90 DEG C / h, a first section of heating process and reflux of heavy distillate oil are conducted at the same time, and the second section of heating process and reflux of intermediate distillate oil and heavy distillate oil are conducted at the same time. The present invention can significantly shorten time required for development into an intermediate liquid crystal in a coke tower, and helps full development and even distribution of the intermediate liquid crystal in the coke tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

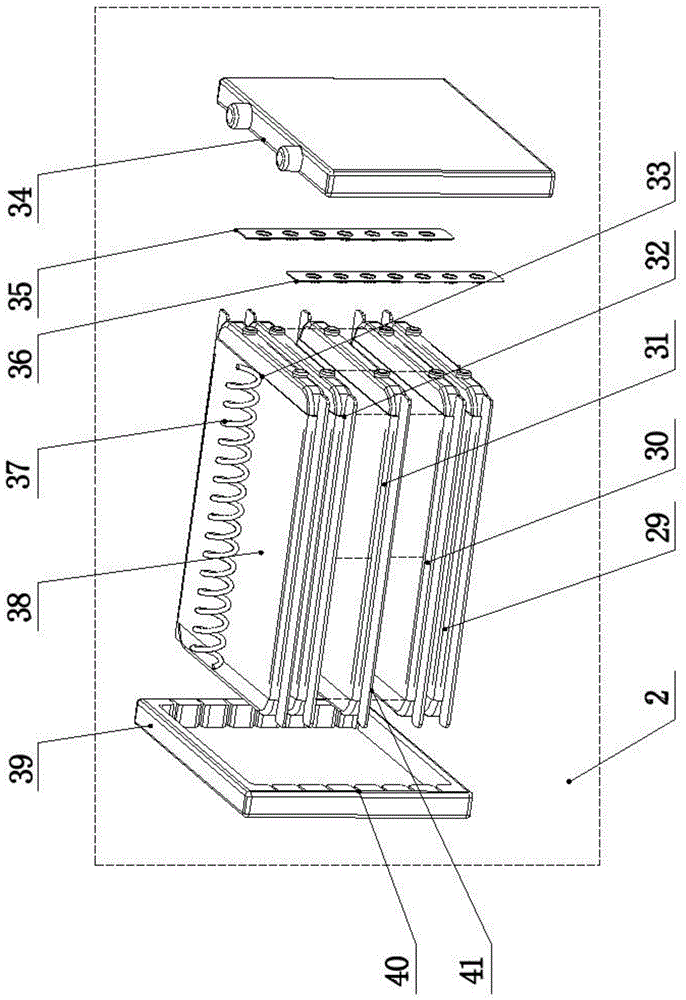

Electric automobile chassis calculus battery pack

InactiveCN104900828AReduce the volume of space occupiedUniform mass distributionElectric propulsion mountingSecondary cellsModularityElectrical battery

The invention relates to an electric automobile chassis calculus battery pack. The electric automobile chassis calculus battery pack comprises a chassis; the upper plane of the chassis is provided with battery installing grooves; the battery installing grooves are provided with calculus battery monomers; the calculus battery monomers comprise a plurality of overlapped battery monomers Ei; the calculus battery monomers are arranged on the transverse plane and the longitudinal plane of the chassis in a matrix block manner according to the shape and the size of the chassis; an A battery pack matrix is formed on the transverse plane X-Y, and a B battery pack matrix is formed on the longitudinal plane X-Z. According to the matrix arrangement of the calculus battery pack, breaking up the whole of large heavy battery monomers into parts is realized, the electric automobile chassis calculus battery pack is embedded into an electric automobile chassis, space occupied by electric automobile batteries is reduced, uniform automotive body mass distribution is realized, it is convenient for battery chassis production modularization, and convenient for automotive body modularization final assembly, and at the same time, battery safety in electric automobile body collision is improved.

Owner:NINGBO GMF TECH

Flexible coupling of wind generator set and assembling or replacing method of flexible coupling

ActiveCN106050959AAvoid leasingShorten maintenance timeClutchesYielding couplingDynamic balanceCoupling

The invention discloses a flexible coupling of a wind generator set and an assembling or replacing method of the flexible coupling. The assembling or replacing method is characterized by comprising the following steps: designing and manufacturing parts by unit, assembling the parts to form five unit components, namely a brake disc component, a left flexible connecting sheet component, a middle connector component, a right flexible connecting sheet component and a generator side coupling component; carrying out dynamic balance tests and adjustments of the unit components separately so that the unit components have symmetric structures and dynamically balanced configuration; assembling the unit components to form the flexible coupling; and carrying out a dynamic balance test and an adjustment of the whole flexible coupling so that the whole flexible coupling has dynamically balanced configuration. According to the invention, the parts of the flexible coupling, which are designed and manufactured by unit, can be reliably assembled and conveniently and separately disassembled and replaced, so that the problem of inconvenience caused by breakdown maintenance of the conventional flexible coupling is effectively solved, the maintenance time is greatly shortened, a great amount of maintenance cost is saved, and the flexible coupling has high practicability.

Owner:绵阳国顺电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com