Swing seat for automobile machine set

A technology of swing support and unit, applied in the direction of mechanical equipment, power plant, vehicle parts, etc., to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

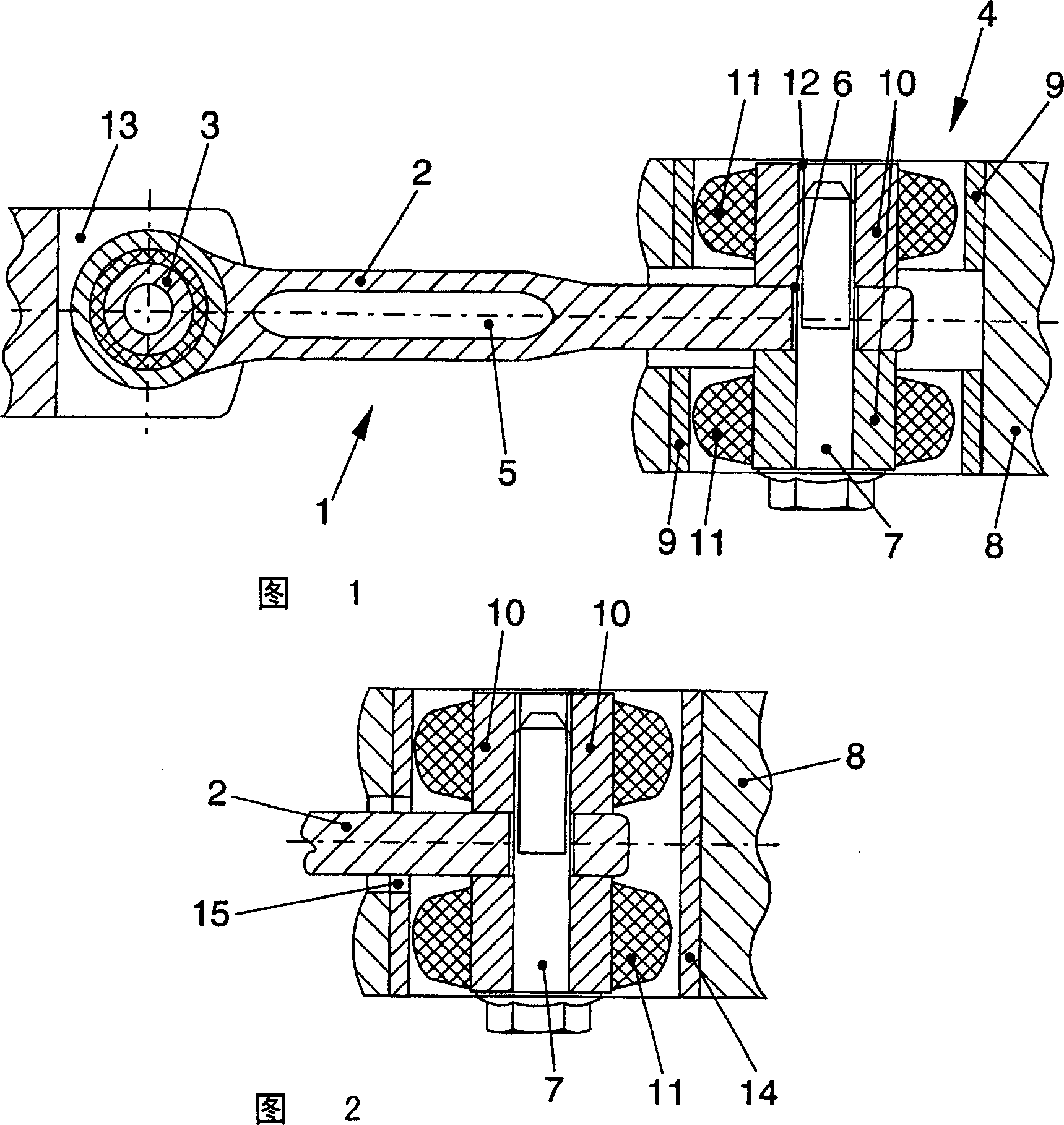

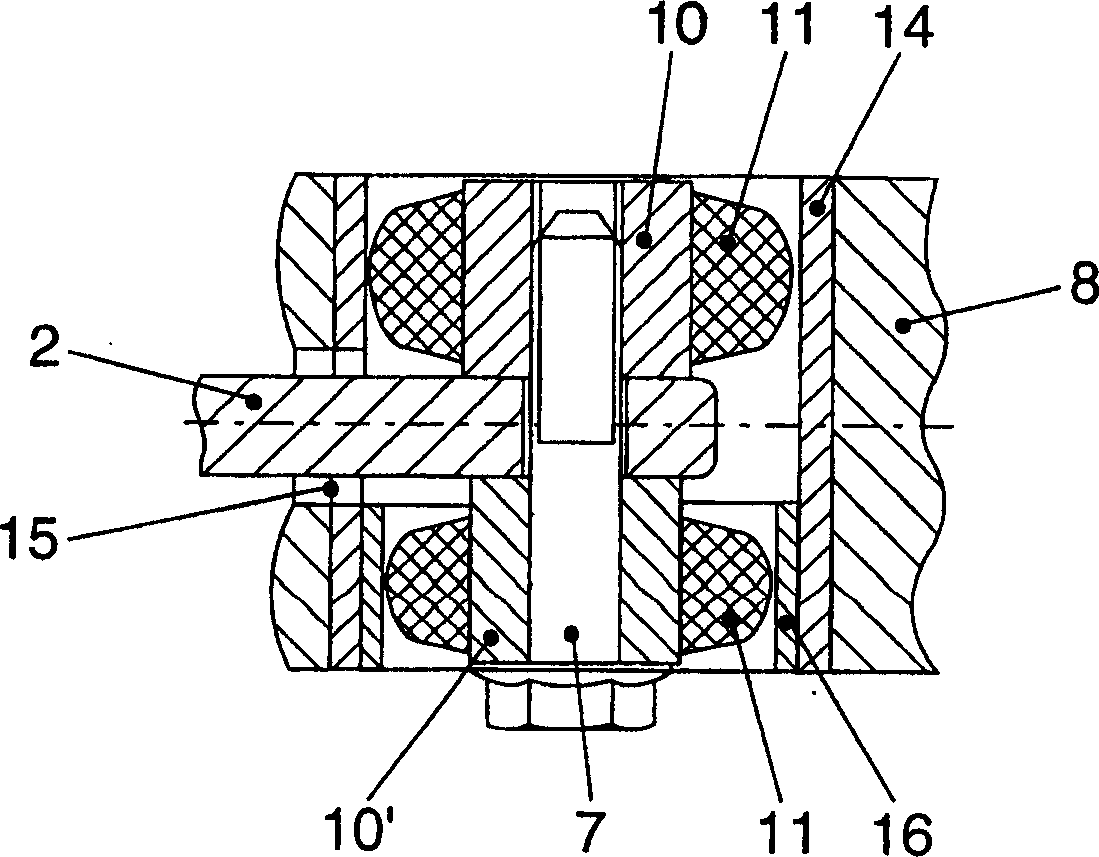

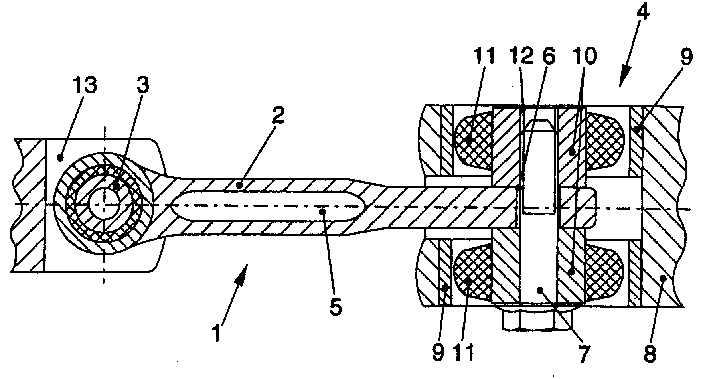

[0021] It is easy to see from FIG. 1 that the oscillating support 1 of the present invention mainly has a support arm 2 , a first bearing 3 and a second bearing 4 .

[0022] The support arm 2 is roughly made into a straight rod shape. In the embodiment shown, there is a gap 5 for weight reduction. The supporting arm 2 can be made such as an aluminum alloy casting or a welded steel structure.

[0023] The bearing 4 is installed in the housing 8 shown in the figure. The oscillating support 1 of the present invention is installed between the units not shown in detail. These units can be, for example, the internal combustion engine and the vehicle body or the subframe of the automobile. At this time, the installation option of the oscillating support can be that the bearing 3 is connected with the engine end, and the bearing 4 is connected with the engine end. The body ends are connected, and vice versa.

[0024] According to the embodiment of FIG. 1 , the bearing 4 has a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com