Foam sandwich composite material for aviation dining car and preparation method of foam sandwich composite material

A technology for composite materials and dining cars, which is applied in the field of foam sandwich composite materials for aviation dining cars and its preparation, and can solve problems such as difficulty in meeting the design requirements of high-performance sandwich structure composite materials, excessive emissions of volatile organic compounds, and insufficient processing of composite materials. Achieve the effect of overcoming the large difference in resin content, facilitating infiltration, and reducing the volatilization of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

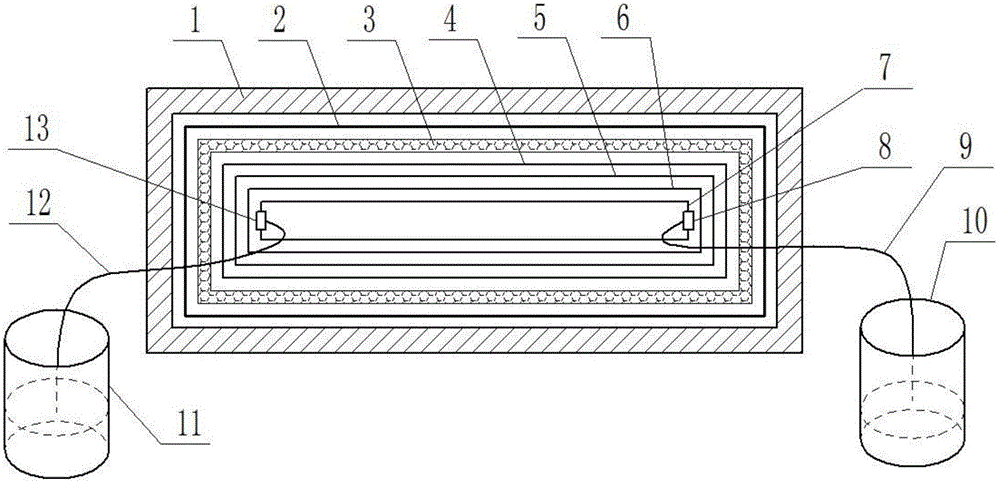

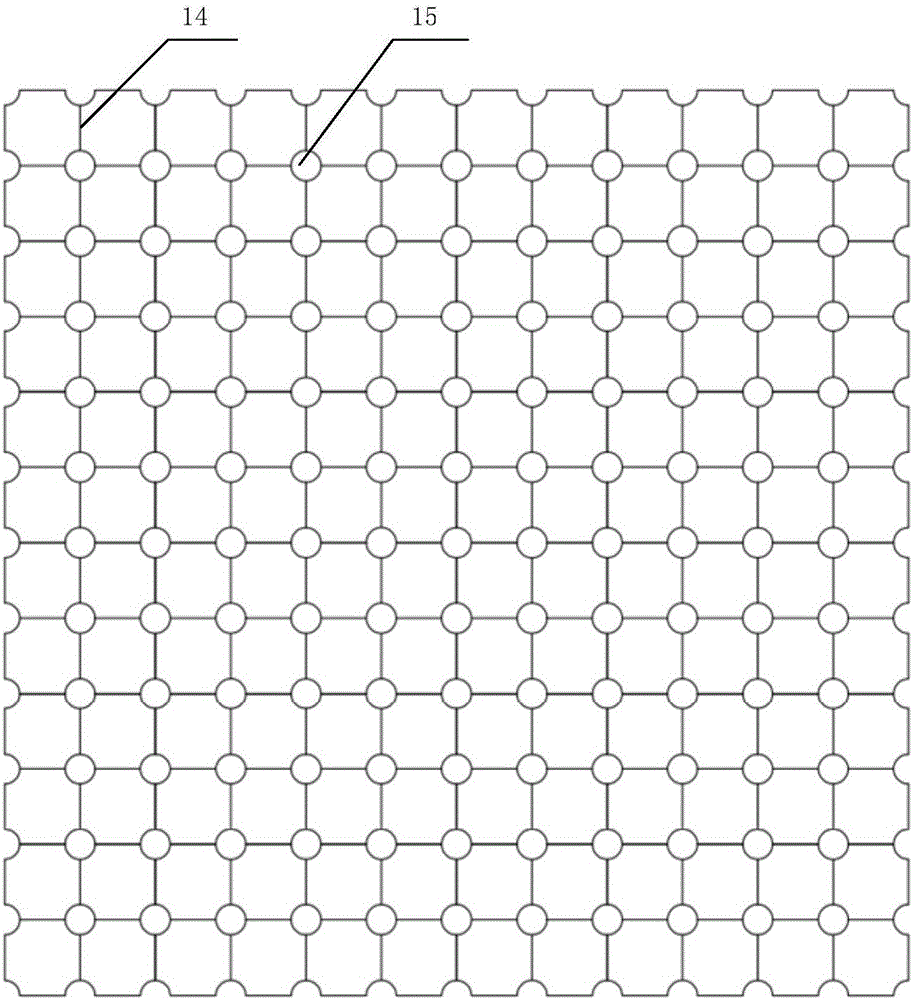

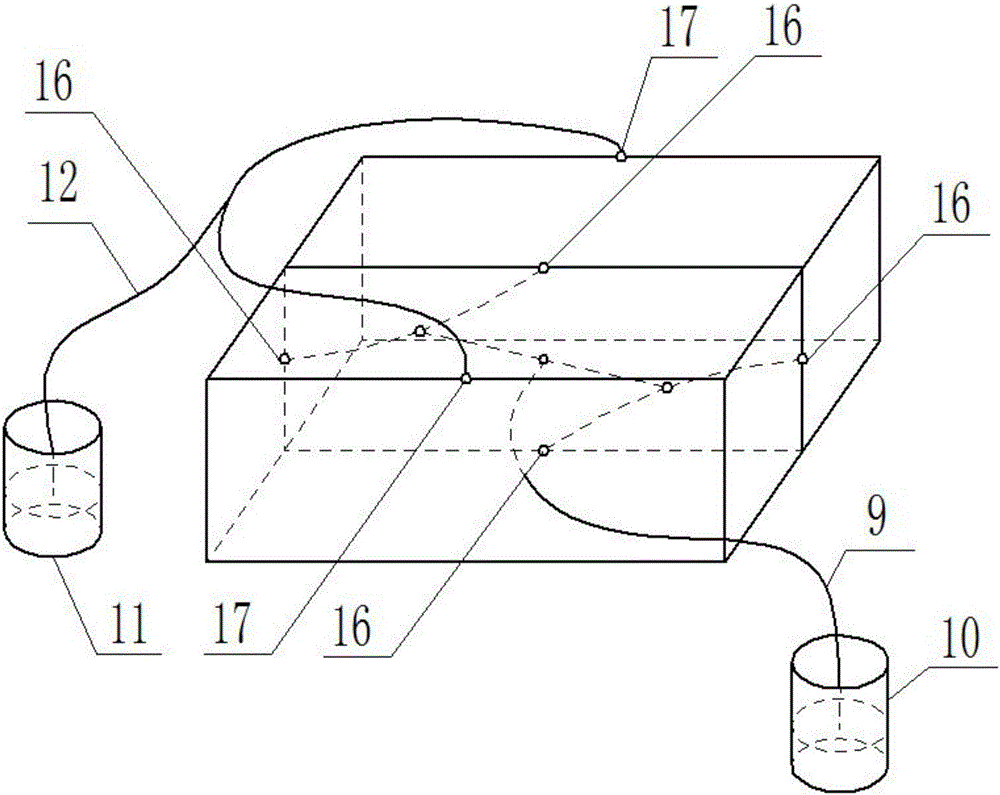

[0045] See attached Figure 1-3 , the outer fiber fabric layer 2 of the foam sandwich composite material used for the main frame of the aviation dining car is 3 layers of biaxial glass fiber plain weave fabric, the inner fiber fabric layer 4 is 2 layers of biaxial carbon fiber plain weave fabric, and the foam core 3 of the sandwich layer is hard Quality polyurethane foam, the foam is provided with connected holes 15 and grooves 14, wherein: foam core density 49kg / m 3 , the thickness is 12mm, the hole diameter is 2.5mm, the hole density is 330 / m 2 , groove width 2.5mm, groove depth 4mm, groove density 64 pieces / m 2 , Epoxy resin is selected for the vacuum introduction molding process (initial viscosity 400mpa·s, operation time 45min). Its preparation method is as follows:

[0046] (1) Preparation before layering

[0047] Grinding and cleaning the working surface of the metal mold 1, coating the mold release agent, assembling the mold 1 and sealing the joints with adhesive s...

Embodiment 2

[0061] The outer fiber layer of the foam sandwich composite material used for the main frame of the design aviation dining car is 1 layer of biaxial fiberglass plain weave fabric, 2 layers of warp-knitted aramid fiber plain weave fabric, and the inner fiber layer is 3 layers of biaxial fiberglass plain weave fabric. The layer is polymethacrylimide foam, and the foam is provided with connected holes and grooves, wherein: the foam density is 54kg / m 3 , thickness 10mm, hole diameter 2.8mm, hole density 360 / m 2 , groove width 2.2mm, groove depth 4.2mm, groove density 72 pieces / m 2 , The vacuum introduction molding process uses phenolic resin (initial viscosity 360mpa·s, operating time 52min). Its preparation method is as follows:

[0062] Each structure described in this embodiment can refer to the attached Figure 1-3 .

[0063] (1) Preparation before layering

[0064] Grinding and cleaning the working surface of the metal mold 1, coating the mold release agent, assembling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com