Compressor high manganese steel balancing weight and manufacturing method thereof

A production method and technology of a balancing block, which are applied in the field of compressors, can solve the problem of high production cost, and achieve the effects of low processing cost, improved dimensional consistency, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

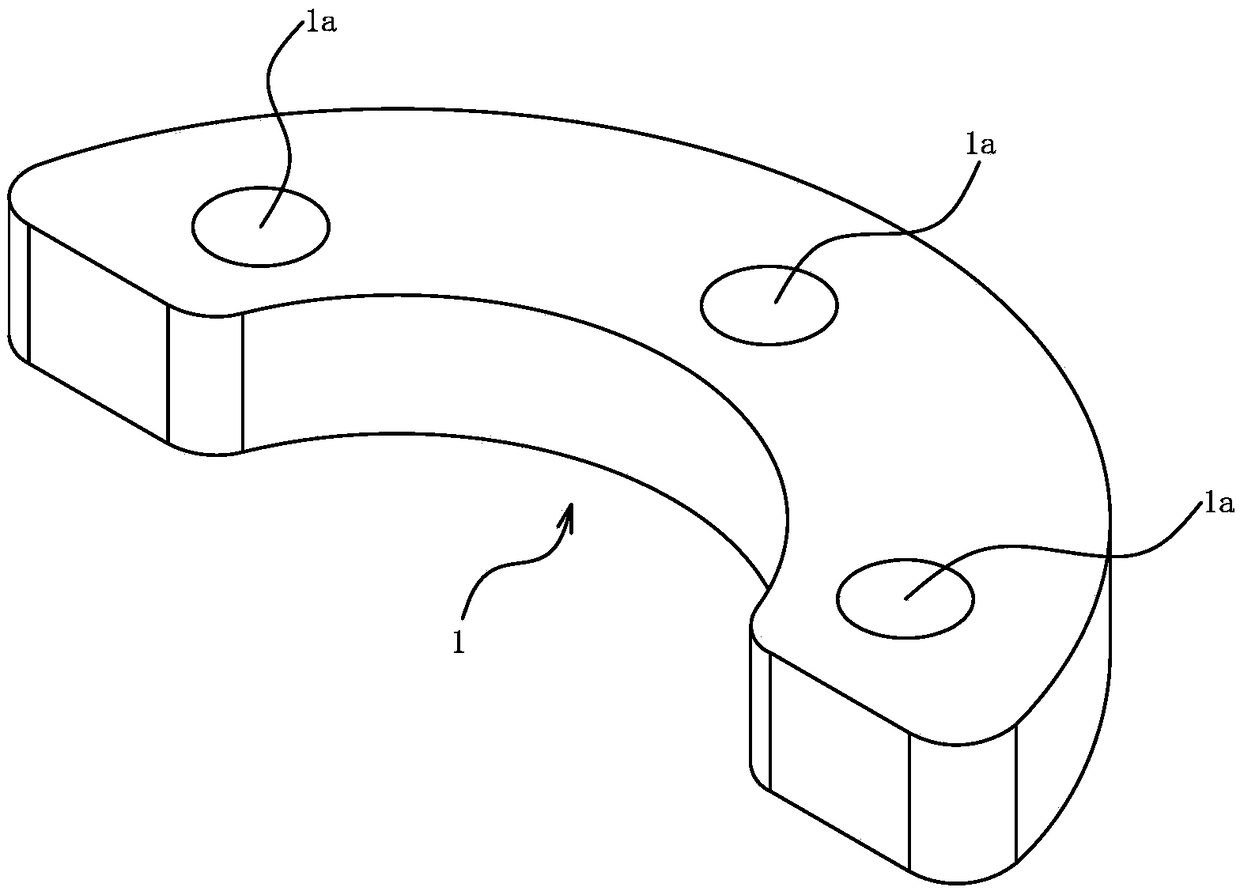

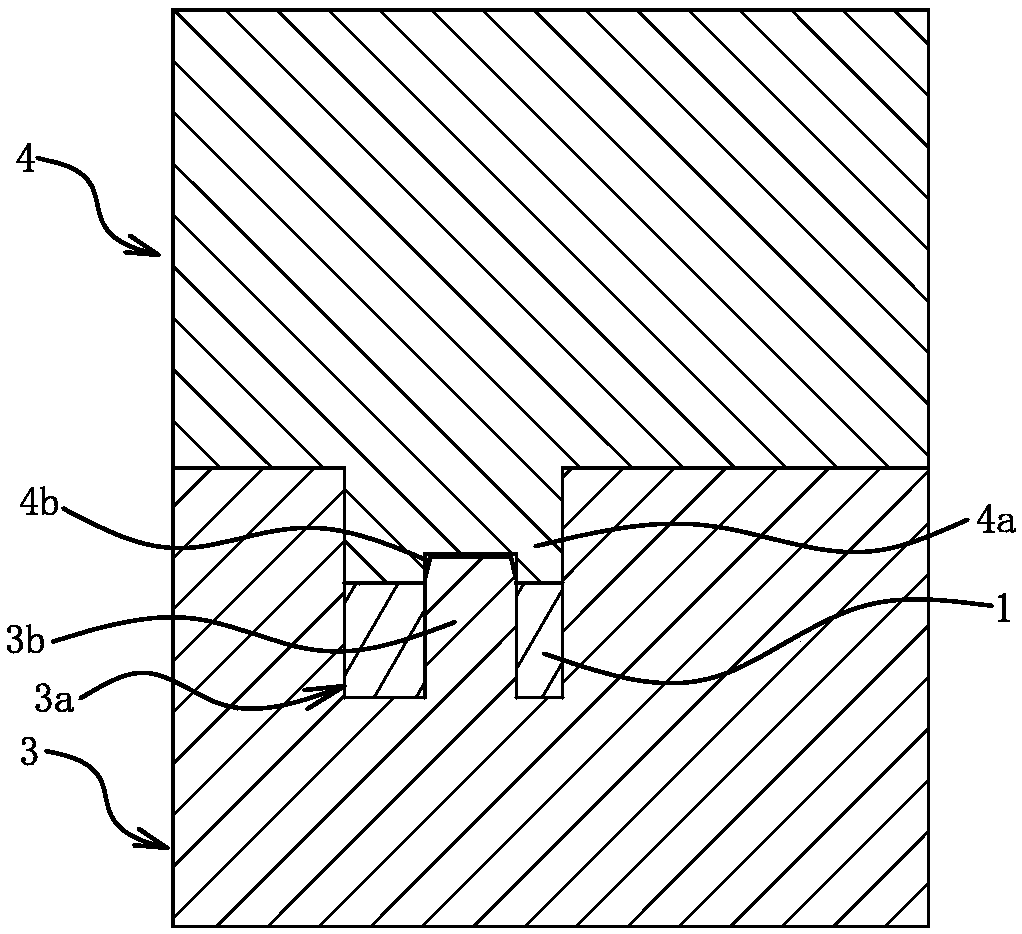

[0020] like figure 1 As shown, a high manganese steel balance weight of a compressor is roughly in the shape of a semicircle, and a plurality of holes 1a are opened on the high manganese steel balance weight of the compressor. It is a straight hole; the number and shape of the hole 1a can be adjusted according to the actual situation, such as a stepped hole.

[0021] A method for making a high manganese steel balance block for a compressor is carried out according to the following sequential steps. The first step is to mix alloy powder; the alloy powder is formed by mixing high manganese steel powder and a lubricant, and the weight of the lubricant is the 0.3%-0.5% of powder weight. High manganese steel powder is compose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com