Wind power blade main beam or subsidiary beam structure and fabrication method thereof

A wind power blade and manufacturing method technology, applied in the wind power blade main beam or auxiliary beam structure and the field of manufacturing, can solve the problems of large difference in resin content, prone to quality defects, low resin content, etc., to improve the bonding performance, increase the Length and number of corners, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1) Clean the surface of the main beam or auxiliary beam mold, lay a release cloth on the main beam or auxiliary beam mold, lay a resin film on the release cloth, and lay a surface density of 100g / m above the resin film 2 Prepregs for glass fiber triaxial fabrics;

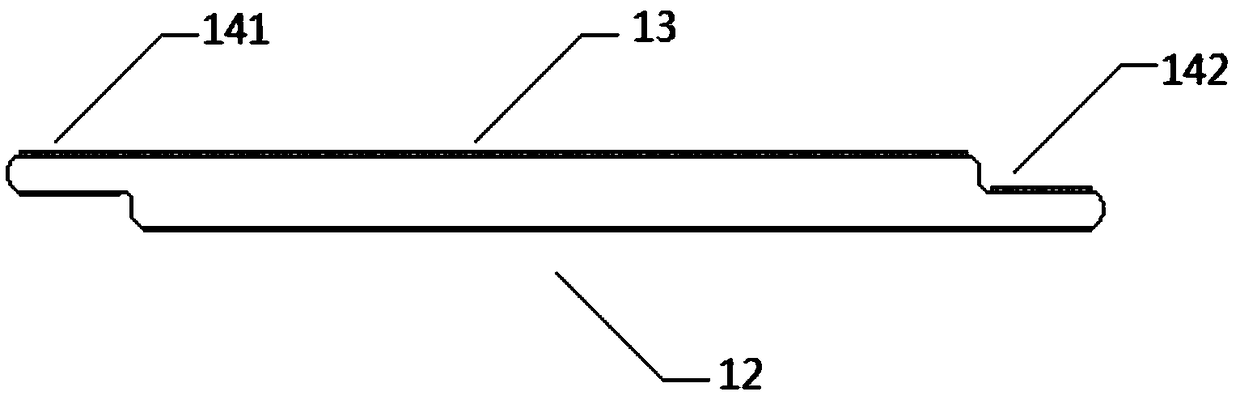

[0064] 2) Both the upper surface and the lower surface of the pultruded sheet are laid with release cloth, and the sheet without the release cloth is laid on the prepreg of the glass fiber triaxial fabric. It is closely attached to the facade of the main beam or auxiliary beam mold, and the superimposed part of the adjacent plates in the chord direction is superimposed between the side plates of the adjacent plates to form a Z-shaped channel;

[0065] 3) Lay multiple layers of resin film between adjacent layers of boards in the longitudinal direction, and the surface density of the laying above the resin film is 100g / m 2 Prepregs for glass fiber triaxial fabrics;

[0066] 4) Repeat steps 2) and 3), so that ...

Embodiment 2

[0069] 1) Clean the surface of the main beam or auxiliary beam mold, lay a release cloth on the main beam or auxiliary beam mold, and lay resin powder on the release cloth. The surface density of the laying surface above the resin powder is 300g / m 2 carbon fiber biaxial fabric;

[0070] 2) Both the upper surface and the lower surface of the pultruded sheet are laid with release cloth, and the sheet without the release cloth is laid on the carbon fiber biaxial fabric. The façade of the beam mold is solid, and the overlapping parts of the adjacent plates in the chord direction are superimposed between the side plates of the adjacent plates to form a Z-shaped channel;

[0071] 3) Lay multiple layers of resin film between adjacent layers of boards in the longitudinal direction, and the surface density of the laying above the resin film is 300g / m 2 carbon fiber biaxial fabric;

[0072] 4) Repeat steps 2) and 3), so that the laying is completed in a cycle, and the uppermost layer ...

Embodiment 3

[0075] 1) Clean the surface of the main beam or auxiliary beam mold, lay a release cloth on the main beam or auxiliary beam mold, and lay a resin film on the release cloth;

[0076] 2) Both the upper surface and the lower surface of the pultruded sheet are laid with release cloth, and the sheet with the release cloth removed is laid on the resin film. The facade is solid, and the overlapping parts of adjacent panels in the chord direction overlap each other through the side panels of adjacent panels to form a Z-shaped channel;

[0077] 3) laying a multi-layer resin film between adjacent layers of boards in the longitudinal direction;

[0078] 4) Repeat steps 2) and 3), so that the laying is completed in a cycle, and the uppermost layer is the board;

[0079] 5) Lay release cloth, VAP film, and vacuum film on the main beam or auxiliary beam mold that has been laid in step 4). The edge of the vacuum film is sealed with a sealing tape, and the vacuum device is connected through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com