Turbine rotor blade, rotating assembly and turbine engine

A technology for turbine rotors and rotating components, applied in engine components, machines/engines, blade support components, etc., can solve the problems of stress concentration, reduced service life of turbine rotor blades, large amount of cantilever in local structures, etc., to achieve machinability improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

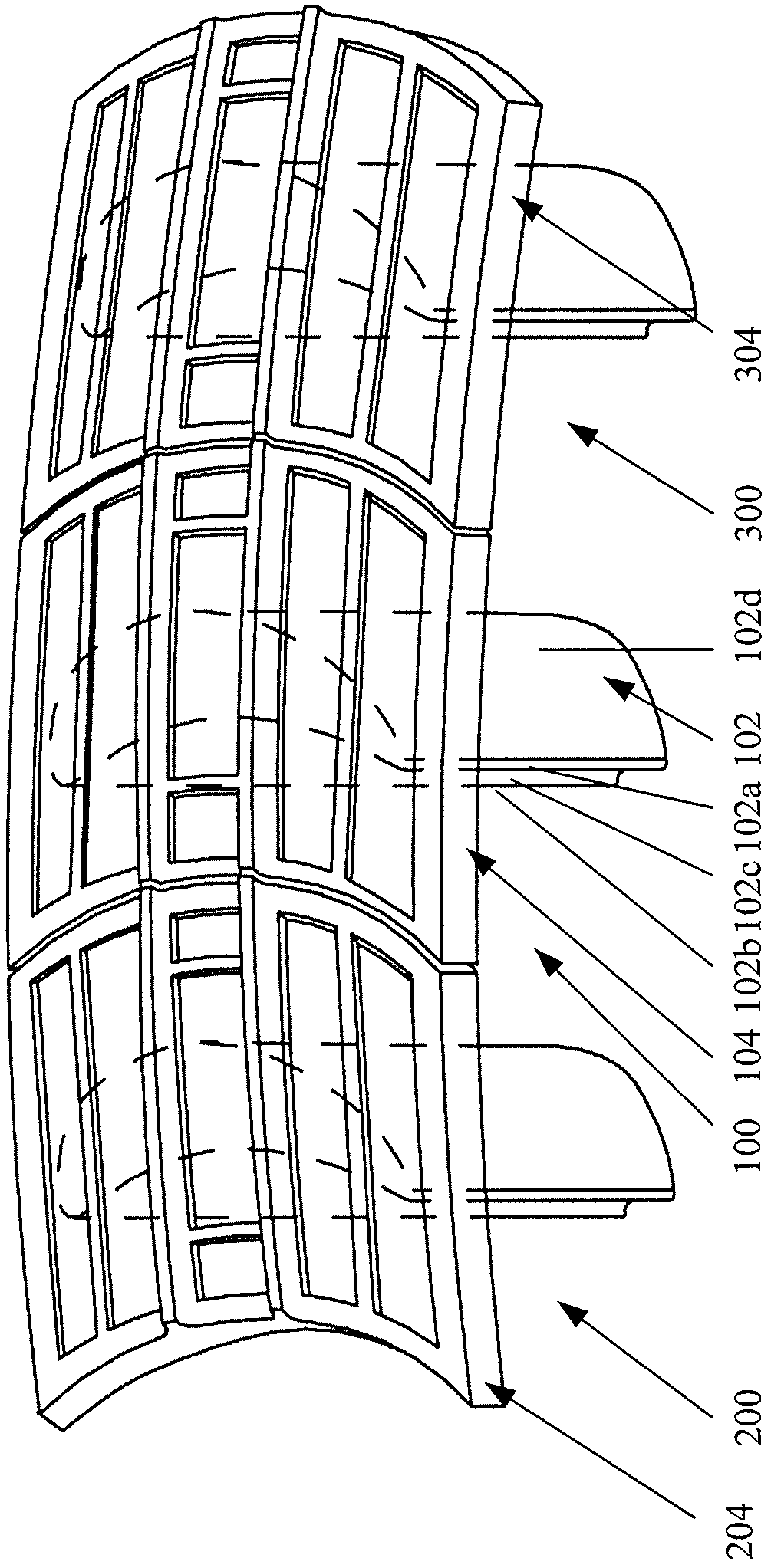

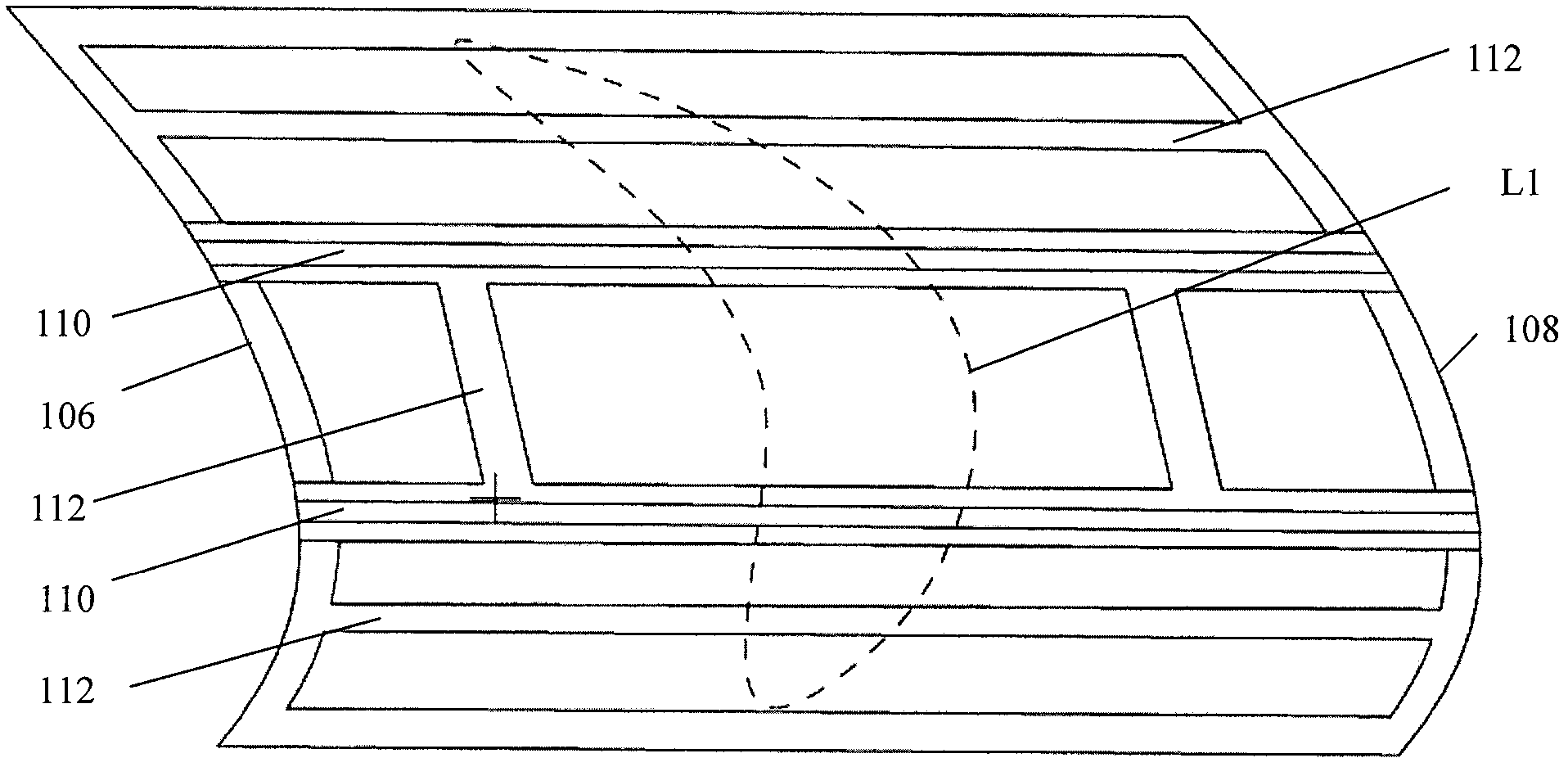

[0021] Such as figure 1 and figure 2 As shown, among them, figure 1 A schematic diagram showing three turbine rotor blades arranged adjacently in pairs, figure 2 for figure 1 A schematic diagram of the shroud portion of a turbine rotor blade. The three turbine rotor blades are represented by reference numerals 100, 200 and 300 respectively. The turbine rotor blade shown in the figure is a preferred embodiment of the present invention. Below, one of the turbine rotor blades 100 is taken as an example for illustration . Turbine rotor blade 100 includes an airfoil portion 102 and a shroud portion 104 . Wherein, the airfoil portion 102 has a blade leading edge 102a, a blade trailing edge 102b, a pressure surface 102c, and a suction surface 102d; 102, which has a shroud leading edge 106 and a shroud trailing edge 108. Here, the airfoil portion 102 and the shroud portion 104 are integrally formed. Both the front edge 106 of the shroud and the trailing edge 108 of the shrou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com