Gas-Filliing Packaging Method and Packaging Machine Therefor

a packaging method and gas filling technology, applied in the directions of transportation and packaging, packaging goods types, shock-sensitive objects, etc., can solve the problems of easy collapse, difficult to maintain the shape of the bag, and the imprint of the grip of the bag, etc., to achieve good quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

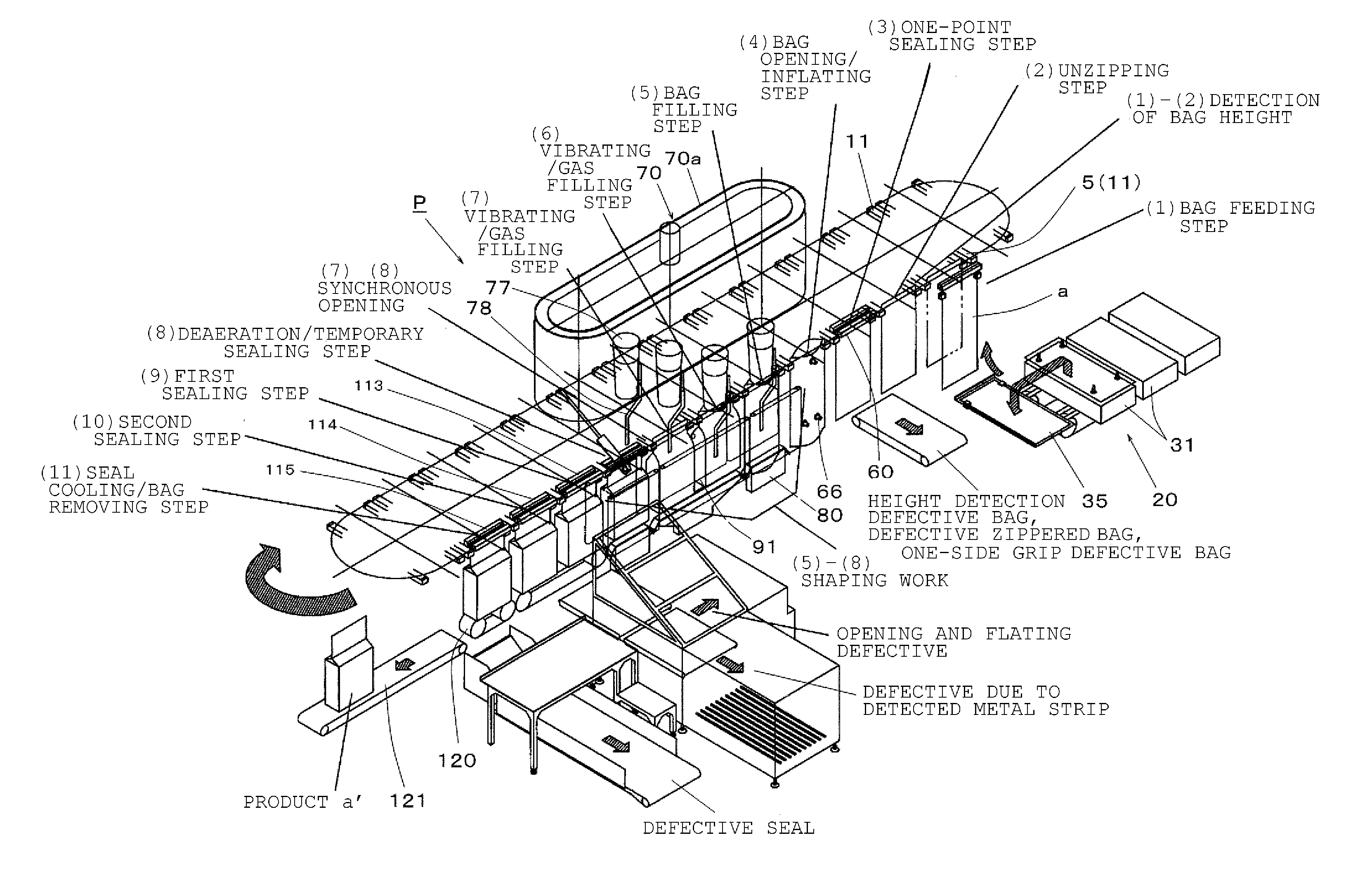

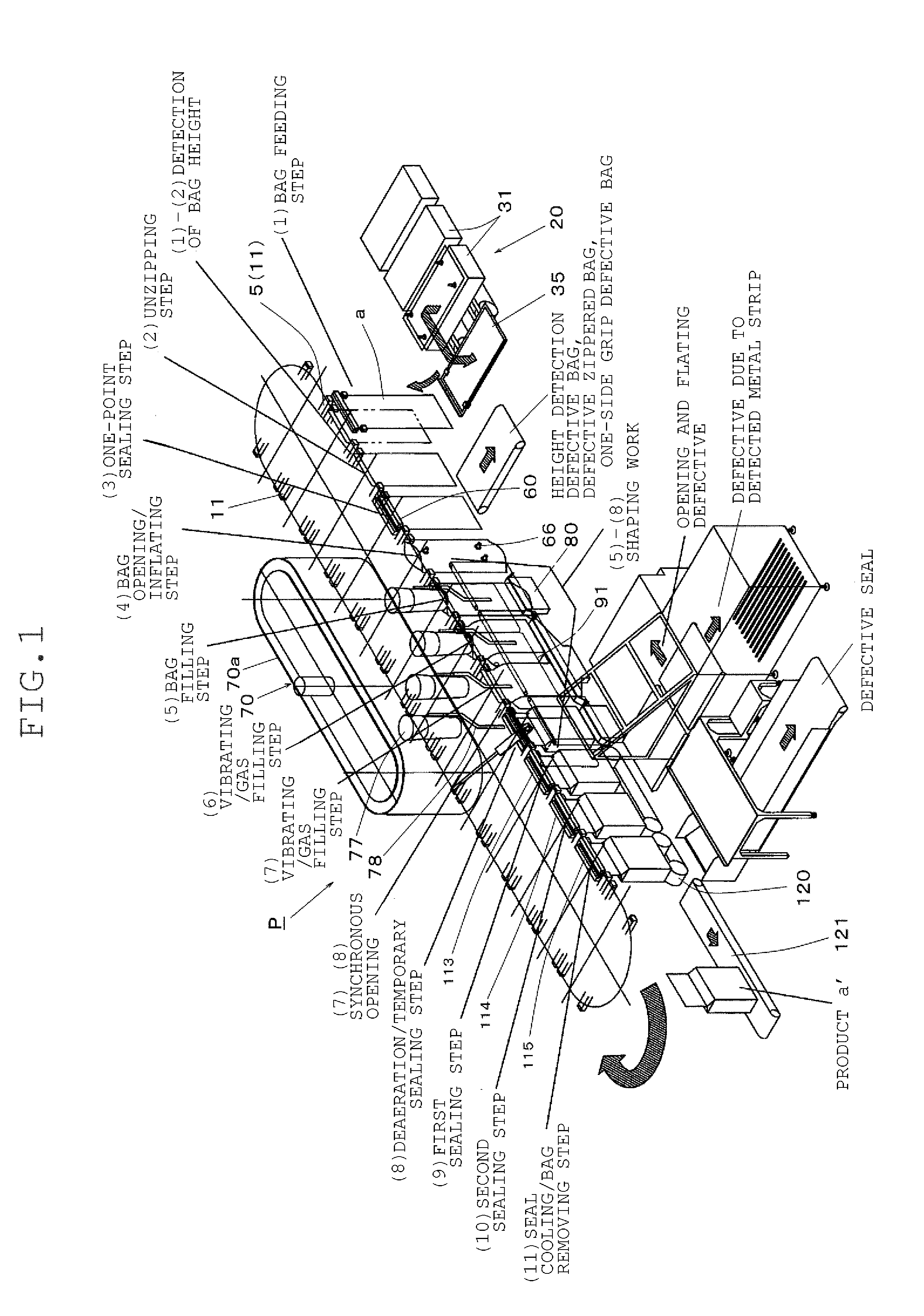

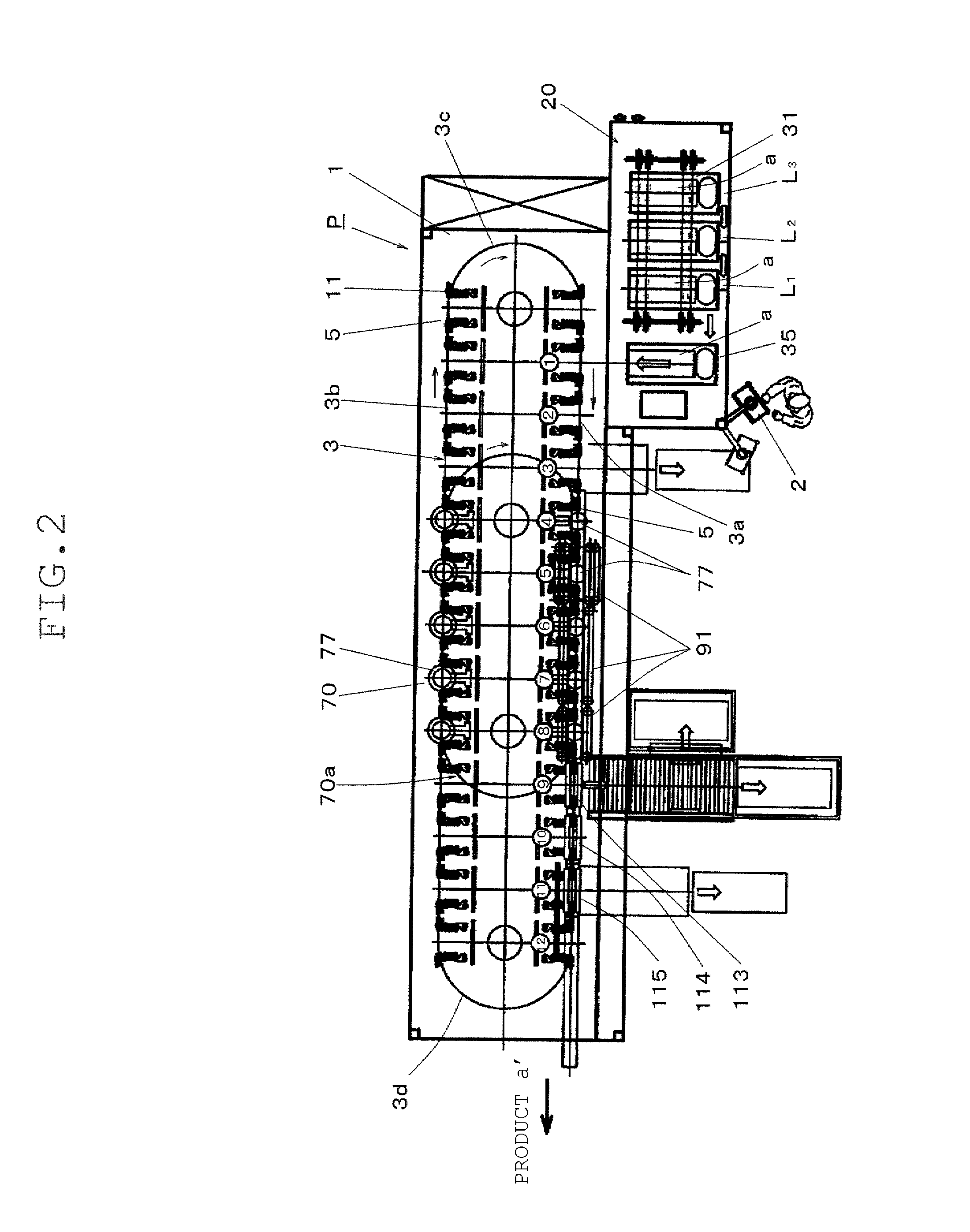

[0051]An embodiment of the invention will be described with reference to the accompanying drawings.

[0052]Referring to FIGS. 1 and 2, a track type gas-filling packaging machine P is shown to which the gas-filling packaging method and machine each according to the present invention are applied. The packaging machine P continuously executes shaping during steps from filling a large-sized bag with an article such as about 10 to 20-kilogram rice, pet food or fertilizer and sealing the bag to temporarily sealing a bag mouth, whereby packaging can be executed which achieves stable products that are unlikely to cause collapse when the products are laid out flat. Furthermore, the packaging machine P can automatically execute all works including switch of related apparatus with change in a bag size based on operator's instructions. The packaging process includes a bag feeding step (1), an unzipping step (2) in which a zippered bag is unzipped when the zippered bag is used, a one-point sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com