Nano copper powder for electronic paste and preparation process

A nano-copper powder and a production process technology, applied in the field of nano-copper powder and its preparation process, can solve the problems of easy agglomeration of particles, difficult control of particle size distribution range and morphology, toxicity or pollution of reducing agents, etc., and achieve particle size distribution. Uniform, light particle agglomeration, high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

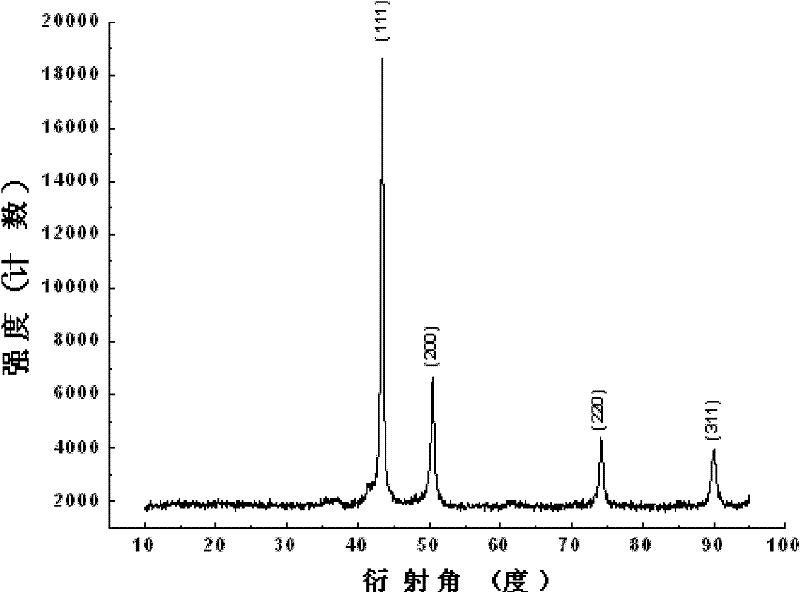

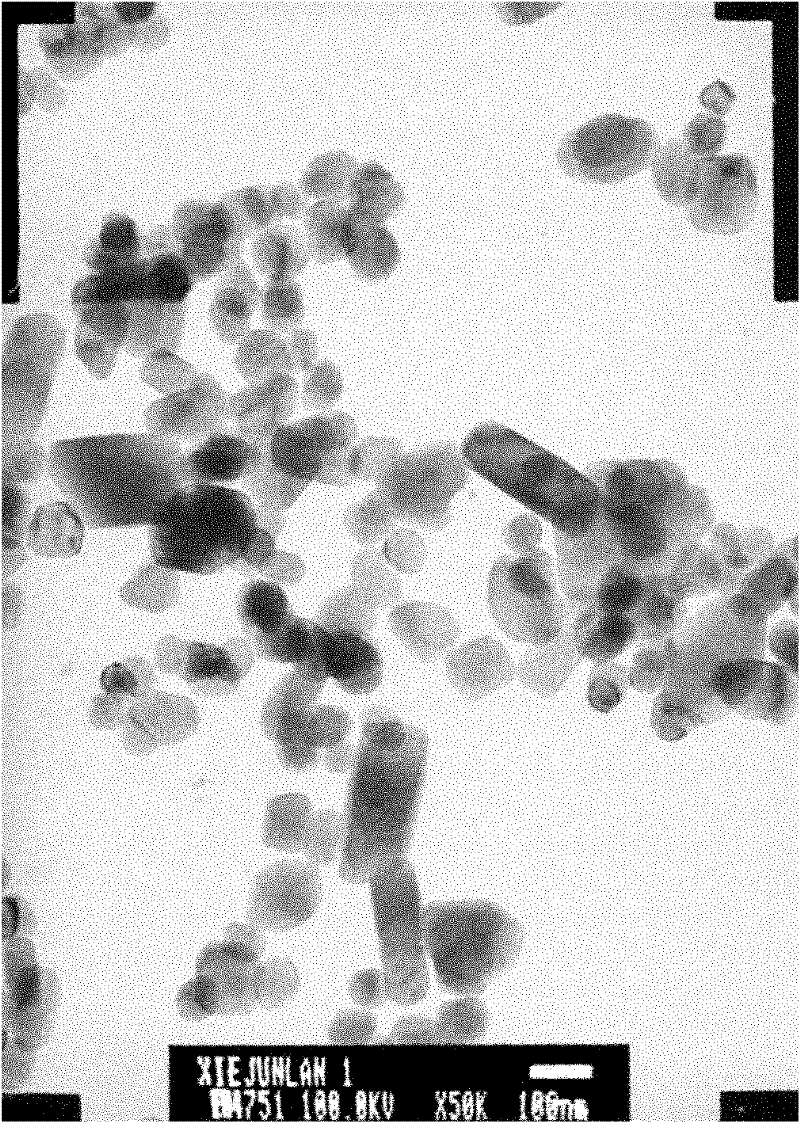

Embodiment 1

[0038] Take by weighing 500g copper sulfate pentahydrate and be dissolved in 3L deionized water, stir to make it dissolve completely, slowly add the strong ammoniacal liquor (28%) of 875g until solution is clear and transparent, be heated to 45 ℃; Take by weighing 2g sodium lauryl sulfate ( SDS) and 1g OP-10 were dissolved in 1L deionized water, and then the aqueous solution of the dispersant was slowly added to the copper sulfate aqueous solution, and stirred to disperse it evenly to form a mixed solution A. Weigh 540g of glucose and add it to A, stir to dissolve it to form a mixed solution B, add B to a 6L stainless steel high-temperature reaction kettle with a Teflon liner, tighten the reaction kettle, put it in an oven and heat it to 120°C , keep it warm for 2 hours, then cool down to room temperature naturally, take out the mixed solution, filter out the precipitate, wash it several times with deionized water and ethanol, put it in a vacuum drying oven, and dry it at 40°C ...

Embodiment 2

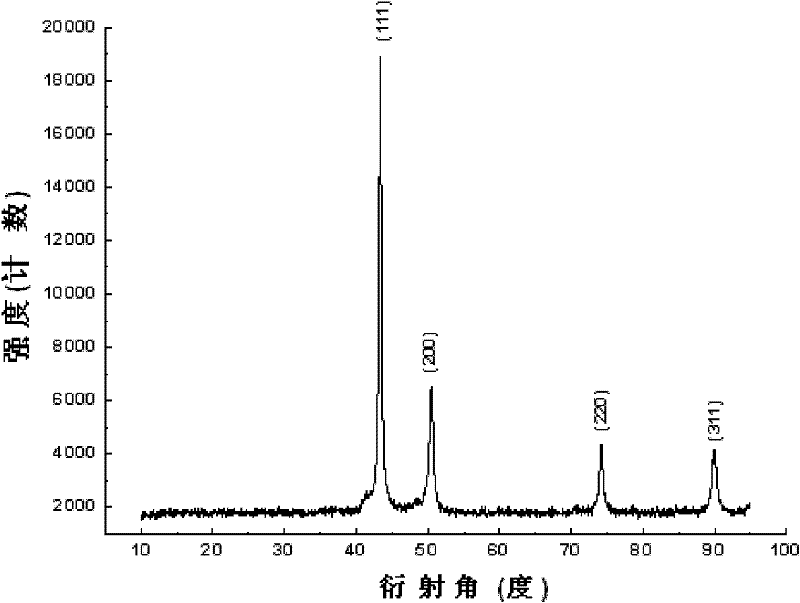

[0043] Weigh 500g of copper sulfate pentahydrate and dissolve it in 3L of deionized water, stir to dissolve it completely, slowly add 500g of sodium tartrate until the solution is clear and transparent, heat to 45°C; weigh 2g of sodium dodecylbenzenesulfonate (SDBS) and 2g of polyvinyl alcohol (PVA) were dissolved in 1L of deionized water, and then the aqueous solution of the dispersant was slowly added to the copper sulfate aqueous solution, and stirred to disperse it evenly to form a mixed solution A. Weigh 250g of ethylene glycol and add it to A, stir to dissolve it to form a mixed solution B, add B to a 6L stainless steel high-temperature reactor with a polytetrafluoroethylene lining, tighten the reactor, and heat it in an oven until 190°C, keep warm for 4h, then cool down to room temperature naturally, take out the mixed solution, filter out the precipitate, wash several times with deionized water and ethanol, place in a vacuum drying oven, dry at 40°C for 4h, and finally ...

Embodiment 3

[0048] Weigh 500g of copper sulfate pentahydrate and dissolve it in 3L of deionized water, stir to dissolve it completely, slowly add 600g of sodium citrate until the solution is clear and transparent, and heat to 45°C; weigh 2g of sodium dodecyl sulfate (SDS) and Dissolve 2 g of polyvinyl alcohol (PVA) in 1 L of deionized water, then slowly add the aqueous solution of the dispersant to the aqueous solution of copper sulfate, and stir to disperse it evenly to form a mixed liquid A. Weigh 250g of ethylene glycol and add it to A, stir to dissolve it to form a mixed solution B, add B to a 6L stainless steel high-temperature reactor with a polytetrafluoroethylene lining, tighten the reactor, and heat it in an oven until 190°C, keep warm for 3h, then cool down to room temperature naturally, take out the mixed solution, filter out the precipitate, wash several times with deionized water and ethanol, place in a vacuum drying oven, and dry at 40°C for 4h, and finally obtain high-purity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com