Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

873 results about "Copper sulfate pentahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

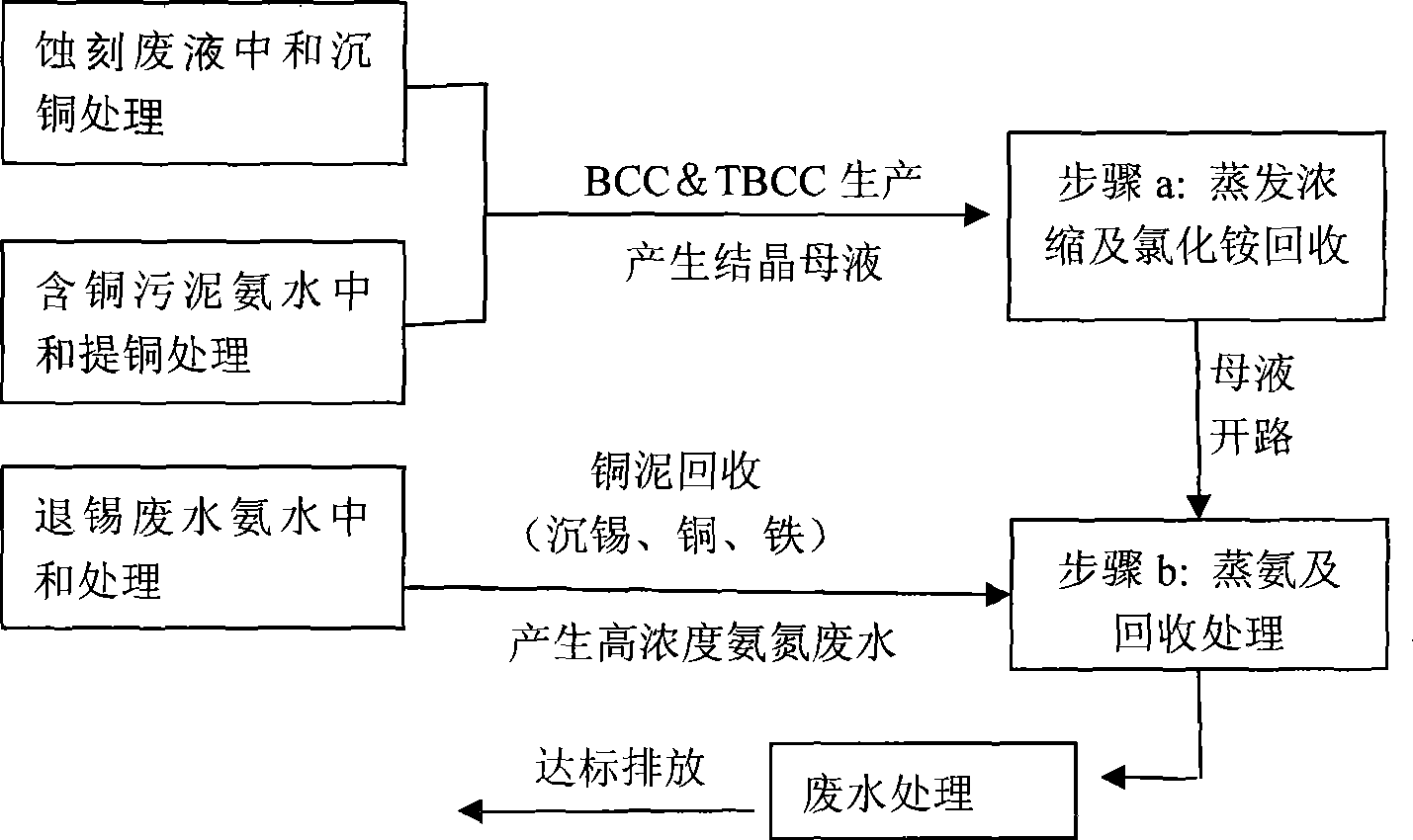

Method for producing basic copper chloride, cupric sulfate pentahydrate from copper-containing etching waste liquid

ActiveCN101391800AEfficient removalImprove product qualityCopper chloridesMultistage water/sewage treatmentCopper chlorideSulfate

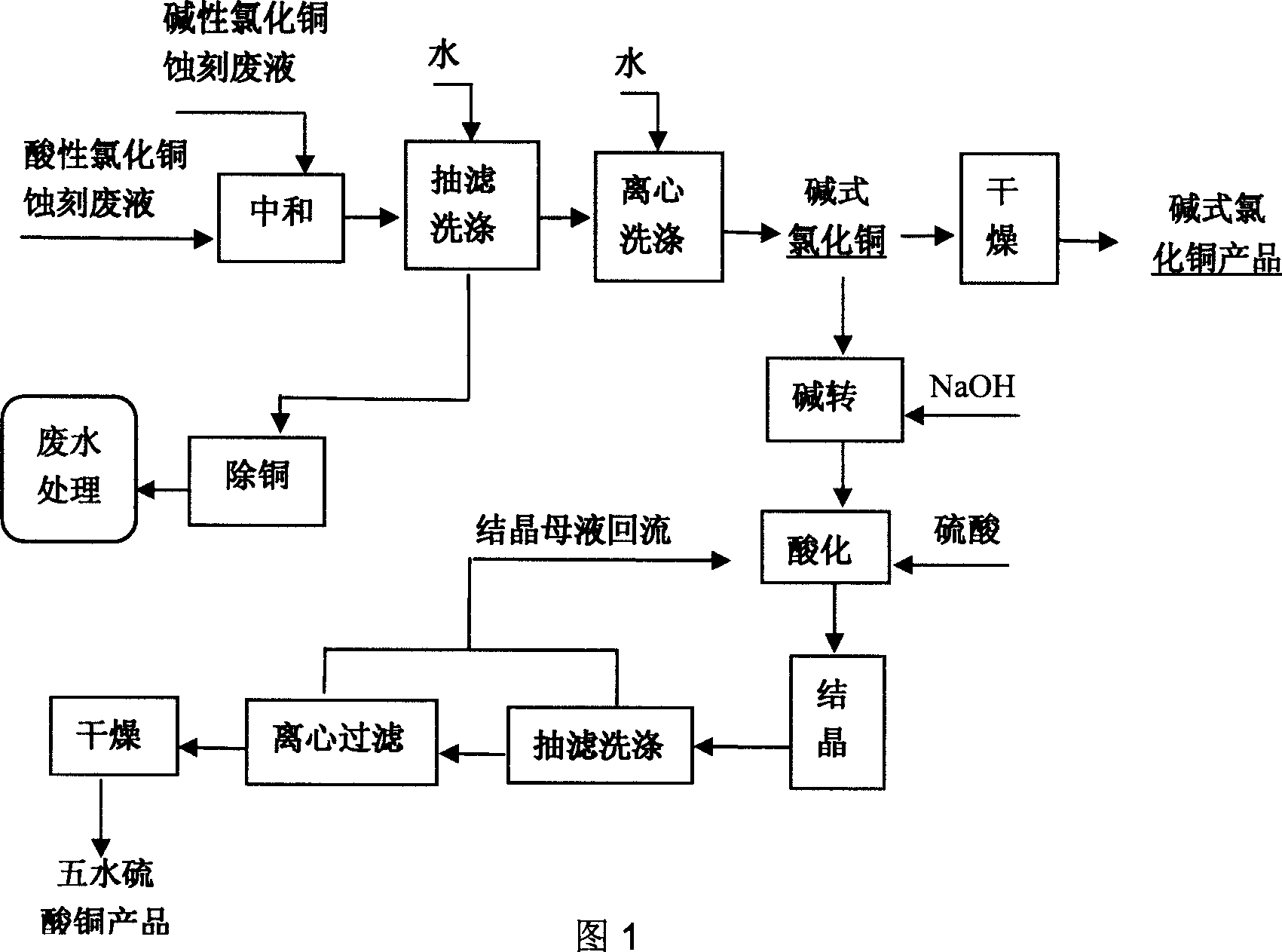

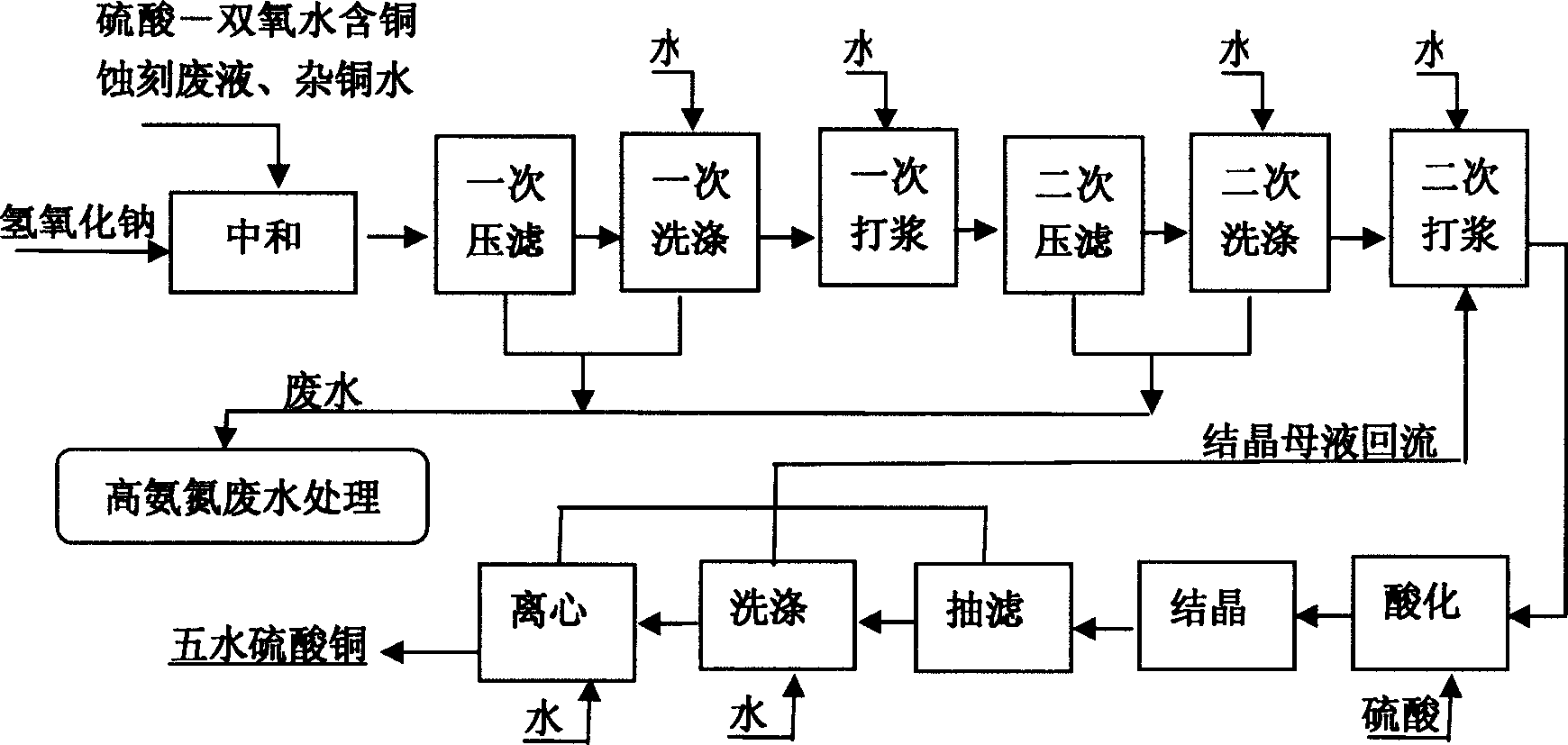

The invention relates to a method for producing copper chloride hydroxide and blue vitriod by using cupriferous etching wastewater; the method comprises the following steps: acidic copper chloride etching wastewater and alkaline copper chloride etching wastewater are neutralized and crystallized to get acidic copper chloride crystal under the condition of strictly controlling filling liquid and the Ph range of a reaction kettle, and then pumped and filtrated, and centrifugated; part of the obtained alkaline copper chloride crystal is dried to obtain finished products while the other is added with NaOH solution for alkali conversion to obtain copper oxide, and then is acidulated by sulphuric acid, crystallized, washed, centrifugated, and dried to obtain blue vitriod products. The method for producing blue vitriod by directly using sulphuric acid-oxyful etching wastewater includes the following steps: sulphuric acid-oxyful etching wastewater and composition brass wasterwater in a PCB manufacture are blended together and added with NaOH to form cupric hydroxide precipitation which filtrated, washed, and then acidulated by sulphuric acid to obtain copper sulphate solution; after the copper sulphate solution is cooled, crystallized, centrifugated and dried, and the blue vitriod is obtained.

Owner:HUIZHOU DONGJIANG ENVIRONMENTAL PROTECTION TECH

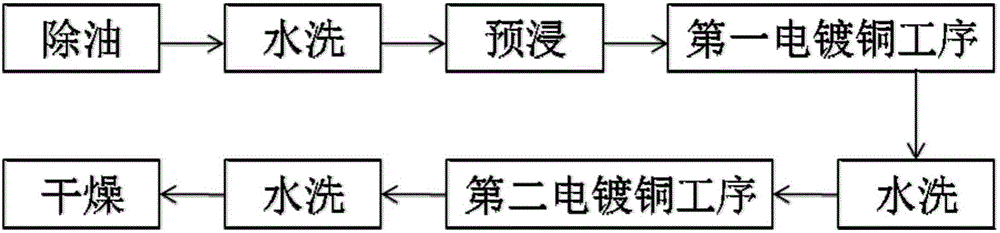

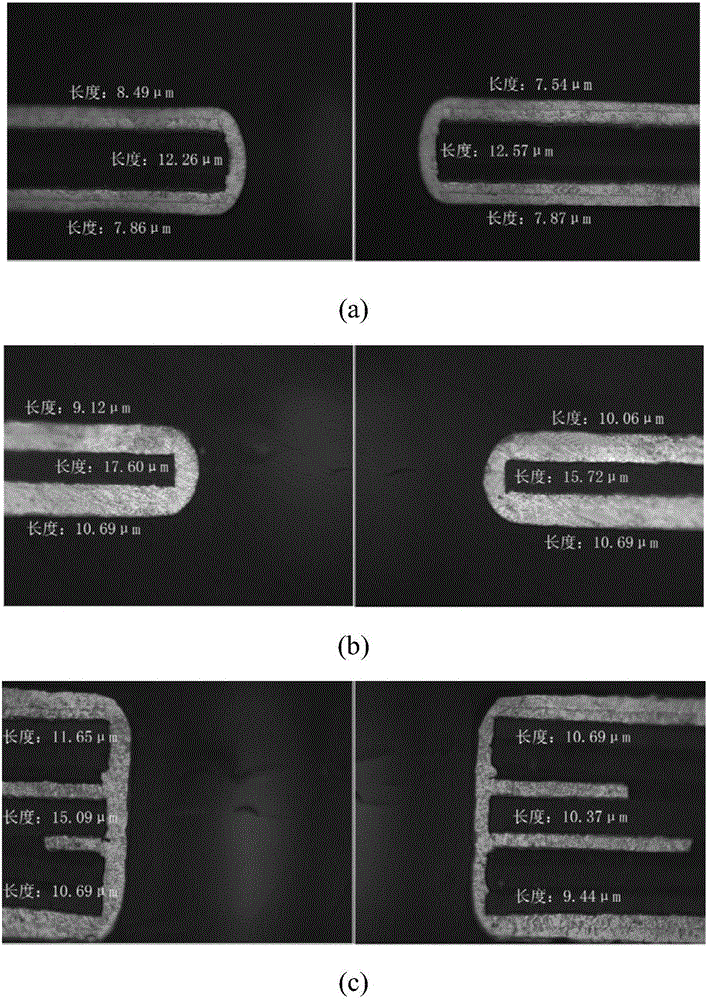

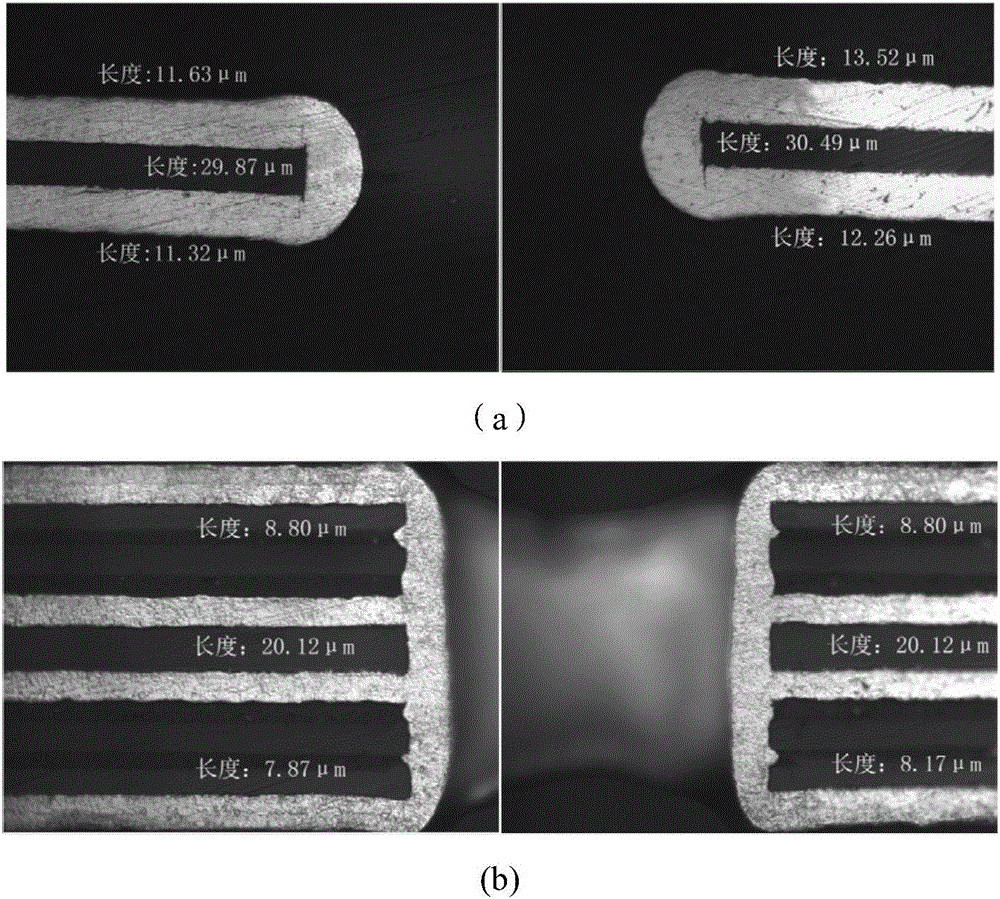

Electroplating solution and electroplating method for electroplating through holes and blind holes of circuit boards

The invention discloses an electroplating solution for electroplating through holes and blind holes of circuit boards. The electroplating solution comprises the following components: 160-180g / L of copper sulfate pentahydrate, 20-50g / L of sulfuric acid, 0.05-0.07g / L of chloride ions, 0.5-1.5g / L of accelerant, 7-30g / L of inhibitor, 10-30g / L of leveling agent and the balance of water. The electroplating solution provided by the present invention is applicable to electroplate through holes and blinds holes of circuit boards, and in particular capable of realizing simultaneously hole-filling electroplating of a through hole and a blind hole in one groove of a circuit board; as a result, the electroplating steps are reduced and the production efficiency is improved.

Owner:苏州禾川化学技术服务有限公司

Copper plating solution for embedding fine wiring, and copper plating method using the same

InactiveUS20030085133A1Semiconductor/solid-state device manufacturingSemiconductor devicesCopper platingSulfur

The present invention provides a copper plating solution for embedding fine wiring, wherein it contains copper sulfate at 100 to 300 g / L as copper sulfate pentahydrate, sulfuric acid at 5 to 300 g / L, chlorine at 20 to 200 mg / L, a macromolecular surfactant at 0.05 to 20 g / L for controlling the electrodeposition reaction, sulfur-based saturated organic compound at 1 to 100 mg / L for accelerating the electrodeposition reaction, leveling agent composed of a macromolecular amine compound at 0.01 to 10 mg / L and reductant at 0.025 to 25 g / L for stabilizing the copper plating solution. The copper plating solution of the present invention for embedding fine wiring can plate the wafer surface provided with fine wiring patterns with sub-micron order gaps in-between and coated with copper serving as the metallic seed film, to fill the gaps neither leaving any defect therein nor dissolving the metallic seed film.

Owner:ELECTROPLATING ENGINEERS OF JAPAN LTD

Process for production of gypsum/fiber board

ActiveUS20050161853A1Increase ratingsIncreased rehydration rateSolid waste managementWood working apparatusSlurryCellulose fiber

An improved process calcining a gypsum / cellulosic fiber slurry to produce a composite gypsum / cellulosic fiber product resides in adding a selected crystal modifier to the gypsum / cellulosic fiber slurry prior to the heating step to reduce the time necessary to carry out the calcination process, to reduce the temperature at which the calcination process is run or to increase the aspect ratio of the acicular calcium sulfate alpha hemihydrate crystals formed during the calcination process. Useful crystal modifiers include aluminum sulfate, aluminum chloride, chlorine, zinc sulfate, iron (III) sulfate, aluminum sulfate hexadecahydrate, iron (II) sulfate heptahydrate, iron (III) sulfate pentahydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, copper chloride dehydrate, manganese sulfate monohydrate and trisodium phosphate.

Owner:UNITED STATES GYPSUM CO

Copper plating solution for PCB (printed circuit board) through holes and PCB blind holes, as well as preparation method and plating method of copper plating solution

InactiveCN103572334AIncrease consumptionLight in massPrinted element electric connection formationCopper platingPhysical chemistry

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB through holes and PCB blind holes, and a preparation method and a plating method of the copper plating solution. Each liter of the copper plating solution comprises the following components according to contents: 100-250g of copper sulfate pentahydrate, 100-200g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is (1-1.25) : 1. The plating method comprises the following steps: putting a PCB with through holes and blind holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a good deep plating capability as high as 92% above, has a hole-filling rate as high as 96% above, and is dense, smooth, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

Electric copper plating liquid and electric copper plating process thereof

The invention relates to an electric copper plating liquid and an electric copper plating process thereof. The electric copper plating liquid is made with the following components: 20 g / l of copper sulfate pentahydrate, 20 g / L-300 g / L of sulfuric acid, 25 g / L-120 mg / L of chlorine ion, 0.1 mg / L-20 mg / L of a brightening agent, 1 mg / L-2000 mg / L of an inhibitor, and the balance of deionized water; the brightening agent is selected from alkyl thiol sulfonate or two of its derivatives; the inhibitor is selected from one or any of nonionic surfactants. The electric copper plating liquid of the invention enables greatly improved plating current and greatly improved throwing power (TP) of flexible board through-hole plating, TP reaching to higher than 200%, an electric copper plating layer in each hole is flat, and the quality meets various requirements of flexible board.

Owner:GUANGDONG GUANGHUA SCI TECH +1

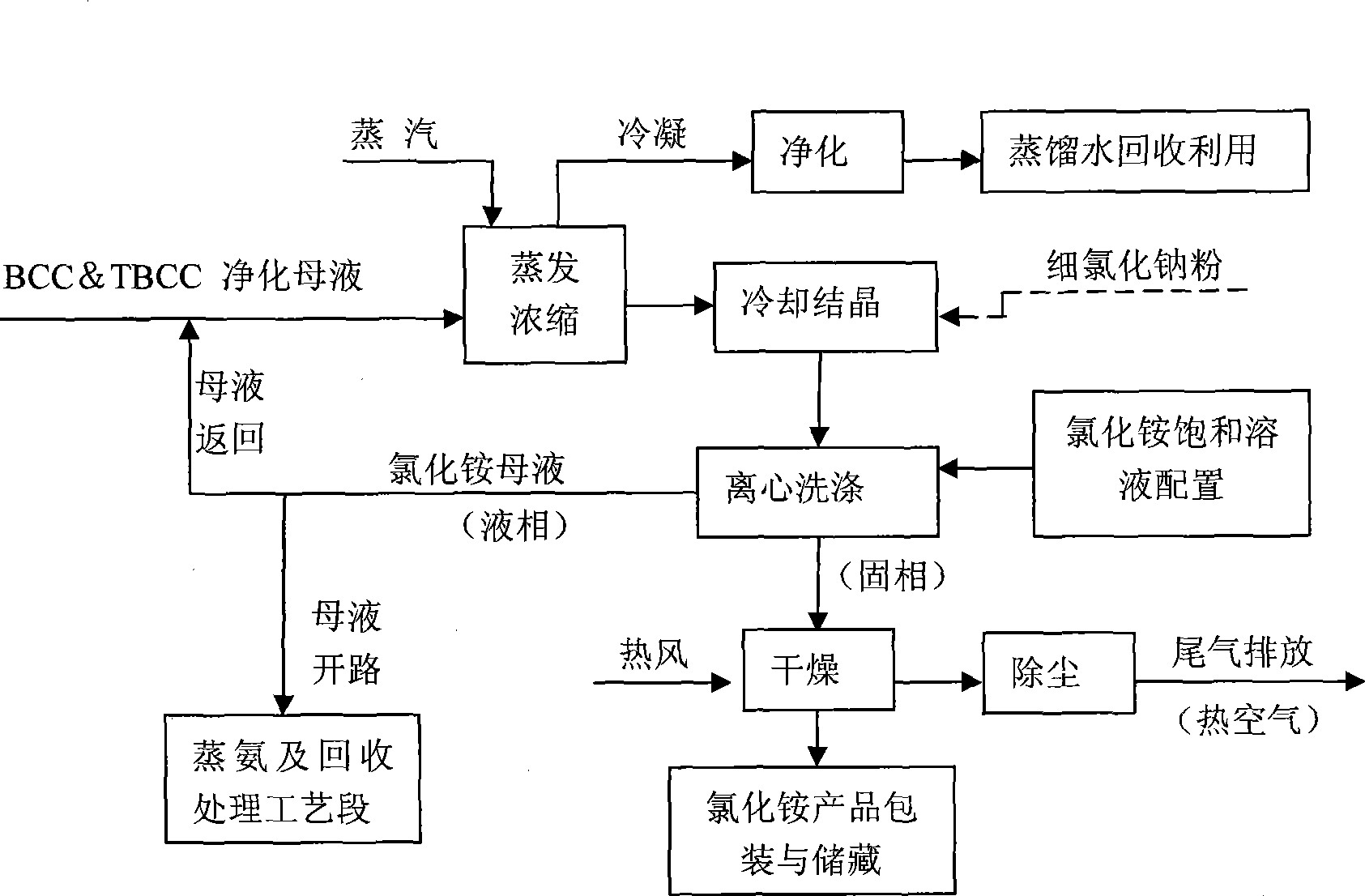

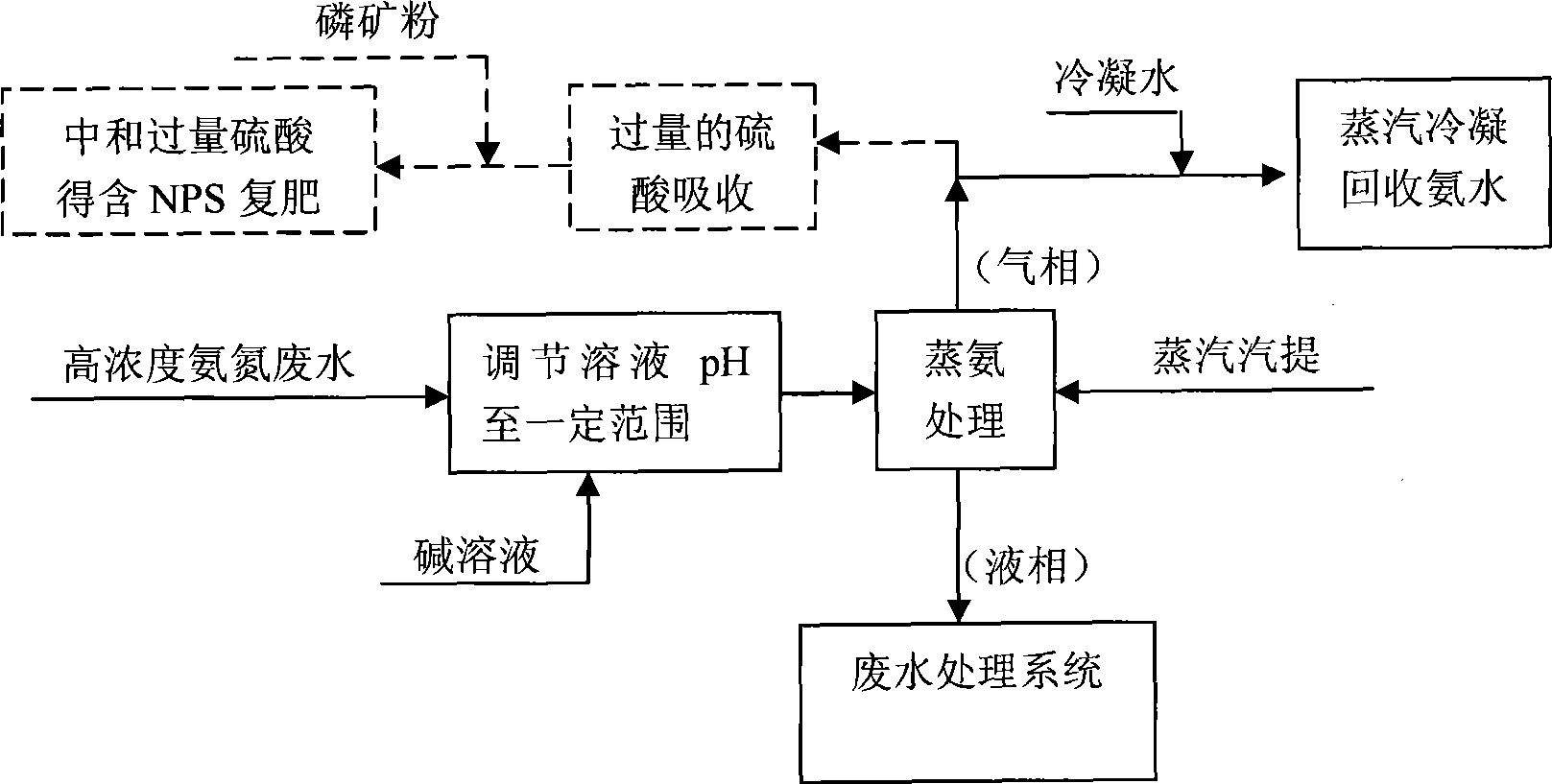

Method for recovery processing of ammonia nitrogen from printed circuit board waste liquid

ActiveCN101391799ARealize resource utilizationEasy to handleClimate change adaptationSewage/sludge fertilisersHigh concentrationLiquid waste

The invention relates to a method for recycling ammonian in ammonian waste water with high concentration, in particular to a method for recycling ammonian in printed wiring board waste water; crystallization mother liquid containing ammonium chloride with high concentration which is generated from processes such as producing alkaline copper chloride, Alpha crystallization type alkaline copper, blue vitriod and the like by using wiring board etching waster water, firstly is evaporated, concentrated and crystallized by one or two combination in multiple effect evaporation technique of mechanical compression, evaporating and compression with heat so as to recycle most ammonium chloride; secondly, Ph is adjusted and ammonian is evaporated so as to recycle ammonia or ammonium sulphate; ammonian waste water generated from removing tin water from ammonia and recycling tin mud are treated by evaporating ammoniac after directly adjusting Ph; and the residual sewage is further treated in the sewage treatment system. By using the method, both of the removal rates of ammonian waste water for wiring board and the recovery rate of ammonia are more than 99.8 percent; the method has good treatment effect, high efficiency, little amount of steam usage, low running cost, and good popularization and application prospect.

Owner:深圳市宝安东江环保技术有限公司

Preparation method of copper-coated tungsten composite powder

InactiveCN101537491AHigh sintering activityUniform thicknessLiquid/solution decomposition chemical coatingWater bathsBipyridine

The invention discloses a preparation method of copper-coated tungsten composite powder, belonging to the technical field of powder metallurgy. Corresponding tungsten powder and blue vitriod are employed according to the weight ratio of composite powder to be prepared and the tungsten powder is pre-treated; copper sulphate and seignette sol are dissolved into solution; bipyridine is added and NaOH is used to adjust pH value to 12-14; an appropriate amount of formaldehyde solution and the tungsten powder are added; the mixture is heated and then stirred continuously in constant-temperature bathing at 30-60 DEG C until the tungsten powder is red; the tungsten powder is washed, dried, reduced and annealed, thereby obtaining copper-coated tungsten composite powder. The preparation method of copper-coated tungsten composite powder has wide application range and is applicable to tungsten-powder coating coppers with different finenesses and shapes. The preparation method of copper-coated tungsten composite powder prepares copper-coated tungsten composite powder in different content ratios according to different requirements. The copper-coated tungsten composite powder obtained by the method of the invention has excellent sintering activity, thereby improving the combination property of tungsten copper alloy.

Owner:UNIV OF SCI & TECH BEIJING

Method for displaying original austenitic grain boundary of martensitic heat-resistant steel

InactiveCN102721593AErosion speed is fastEasy to operatePreparing sample for investigationEtchingAlcohol

The invention relates to a method for displaying an original austenitic grain boundary of martensitic heat-resistant steel, and belongs to the technical field of metallographic sample preparation. The method comprises the process steps of polishing and etching. A polished sample is put into an etching agent, the etching time is 5 to 10 seconds, and the sample is taken out when copper decorating the surface of the sample is observed, washed cleanly by alcohol and dried by blowing; and the clear original austenitic grain boundary can be observed under a metallographic microscope. According to the formula, the etching agent comprises the following components: 5 to 15 g of copper sulfate pentahydrate, 30 to 50 ml of hydrochloric acid and 50 to 70 ml of deionized water. The method has the advantages that the clear original austenitic grain boundary of the martensitic heat-resistant steel can be etched out at normal temperature while a martensitic structure is not displayed, the method is convenient to operate, and the corrosion rate of austenite is higher than that of picric acid solution.

Owner:UNIV OF SCI & TECH BEIJING

Copper plating solution for PCB (printed circuit board) through holes, and preparation method and plating method thereof

InactiveCN103572335AGood throwing abilityImprove toughnessPrinted element electric connection formationCopper platingPhysical chemistry

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB through holes, and a preparation method and a plating method thereof. Each liter of the copper plating solution comprises the following components according to contents: 70-150g of copper sulfate pentahydrate, 100-300g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is 1: (1.5-2). The plating method comprises the following steps: putting a PCB with through holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a good uniform plating capability as high as 95% above, and is dense, smooth, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

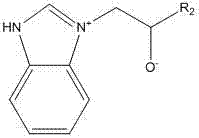

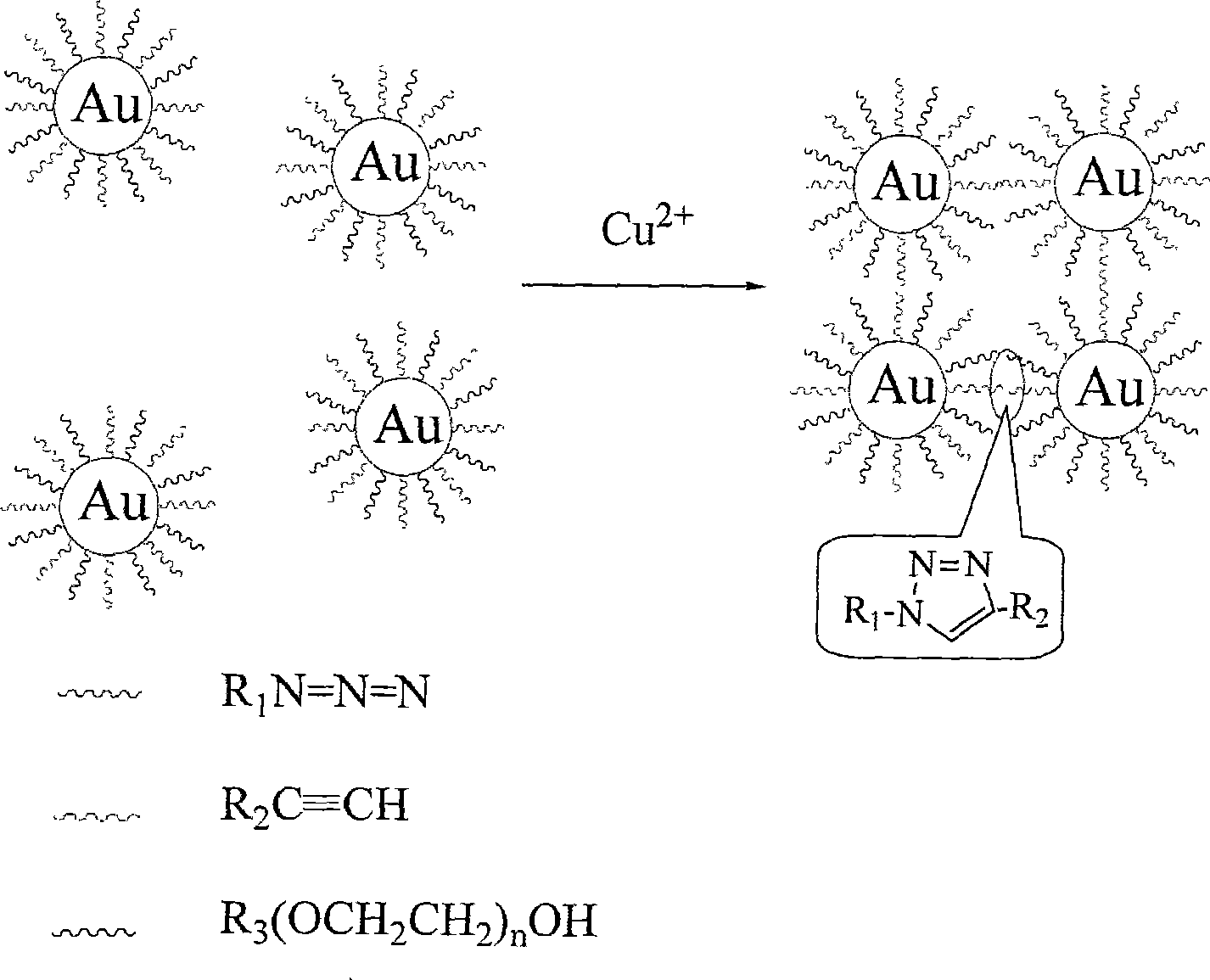

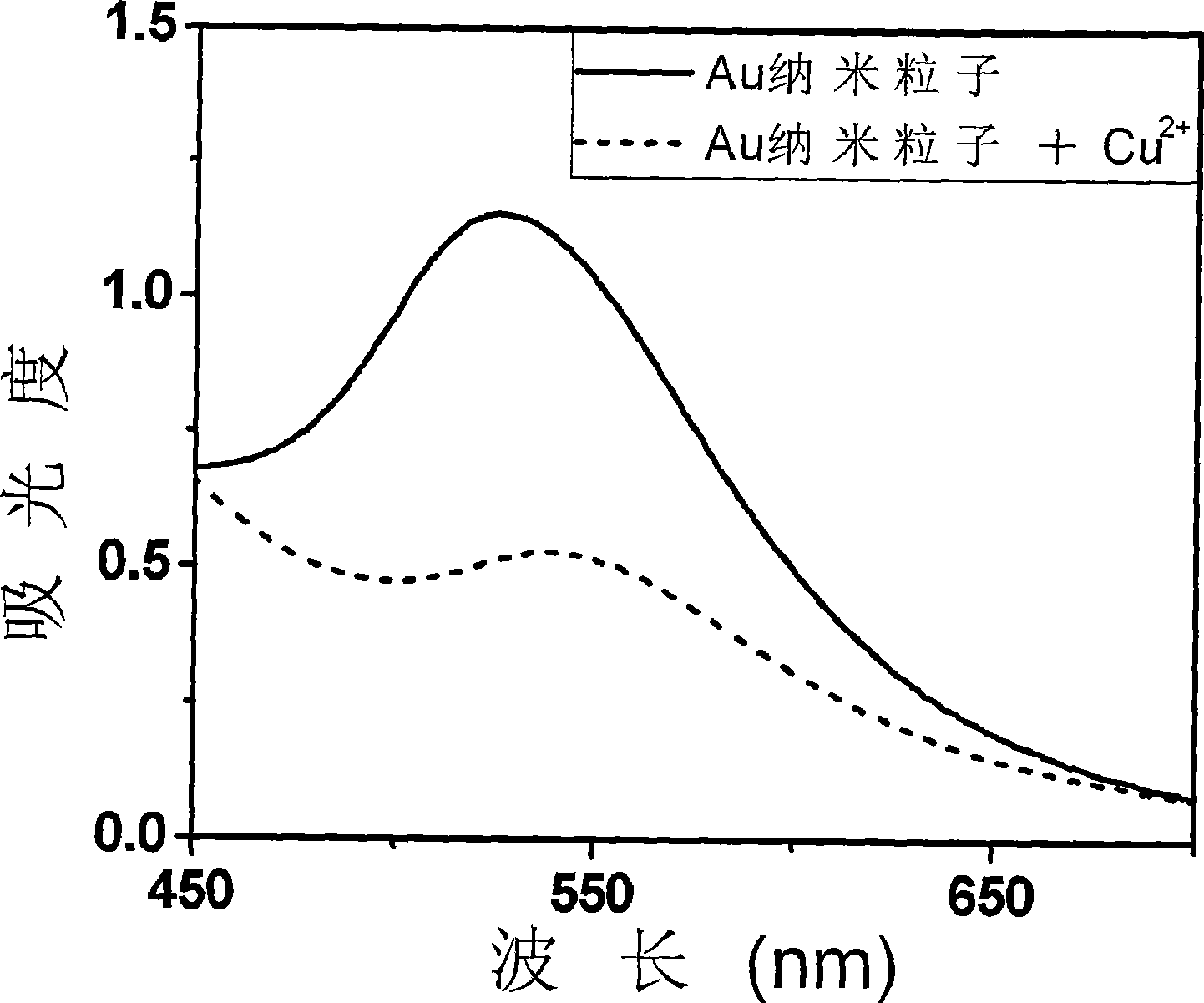

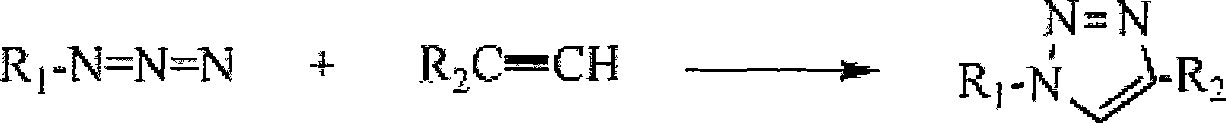

Method for qualitatively detecting CU<2+> in solution directly by eye

InactiveCN101435778ALow costConvenient direct detectionMaterial analysis by observing effect on chemical indicatorAzideReducing agent

The invention provides a method of directly using eyes to qualitatively detect Cu<2+> in a solution. The method comprises the following steps: terminal alkynyl functionalized mercaptan and terminal azido functionalized mercaptan are synthesized respectively; sodium citrate is used as a stabilizer to prepare gold nano-particles with the particle size of 14 nanometers; monomolecular layers of which the tail ends are provided with acetylene linkage and azide groups are self-assembled and formed on the surfaces of the gold nano-particles respectively by a ligand exchange method; the gold nano-particles subjected to two types of surface modification are mixed and added with blue vitriod and reducing agent; Cu(I) formed through reduction is taken as a catalyst, so as to allow the acetylene linkage to have cyclization reaction with the azide groups and cause the gold nano-particles to be accumulated; and the Cu<2+> in the solution is detected by observing the changes of the color and precipitation phenomenon of the gold nano-particles through naked eyes. The method can detect the existence of the Cu<2+> in a mixed solution with a plurality of metal cations. The method is characterized in good function of detecting and identifying ions, obvious phenomenon and simple operation.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Full-nutrient paddy rice seedling breeding matrix and preparation method thereof

The invention discloses a paddy rice seedling breeding matrix, and belongs to the technical field of soilless culture. The full-nutrient paddy rice seedling breeding matrix is prepared from the following raw materials: decomposed organic manure, turf, clay, zeolite powder or bentonite, vermiculite, fine river sand, rice hull powder or corn straw powder or mushroom residue powder, soybean meal, ammonium sulfate, calcium superphosphate, potassium chloride, magnesium sulfate heptahydrate, zinc sulfate heptahydrate, ferrous sulfate heptahydrate, boric acid, copper sulfate pentahydrate, manganese sulfate monohydrate and sodium metasilicate nonahydrate. The full-nutrient paddy rice seedling breeding matrix disclosed by the invention has the advantages of high fertilizer-retaining property and water-retaining property, good air permeability, high buffering, full nutrient and more persistence in fertility, achieves the pH of 5.0-5.5, and is lower in cost by utilizing agricultural wastes, namely rice hulls, corn straws, mushroom residues and the like, suitable for batch production, good in seedling breeding effect and convenient for a farmer to use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Specialized biological compound fertilizer for grape

The invention discloses a specialized biological compound fertilizer for grape. A first formula is that a total amount of nitrogen phosphor and potassium is 30% with a ratio of 1: 0.8 : 1.2; and the proportion (by weight) of each raw material is as follows: 62.8 parts of fresh semi-dried chicken manure, 0.2 part of a calcium magnesium phosphate fertilizer, 23.8 parts of potassium fulvic acid, 2 parts of borax, 1 part of copper sulfate pentahydrate, 1 part of zinc sulfate heptahydrate, 1 part of ferrous sulfate heptahydrate, 3.2 parts of amino acids, 2 parts of microbial agents, 1 part of a synergist and 2 parts of a conditioner. A second formula is that a total amount of nitrogen phosphor and potassium is 25% with a ratio of 1: 0.8 : 1.38; and the proportion (by weight) of each raw material is as follows: 76 parts of fresh semi-dried chicken manure, 4 parts of potassium sulphate, 2 parts of amino acid chelated (complexed) zinc, boron, copper and ferrum, 8.5 parts of nitrohumate,3.5 parts of amino acids, 3 parts of a microbial preparation, 1 part of a synergist and 2 parts of a conditioner. A product is obtained by stirring the above materials uniformly, spray granulating, and drying at a low temperature or air drying.

Owner:NANTONG ZHONGKE RUIZHI TECH SERVICE

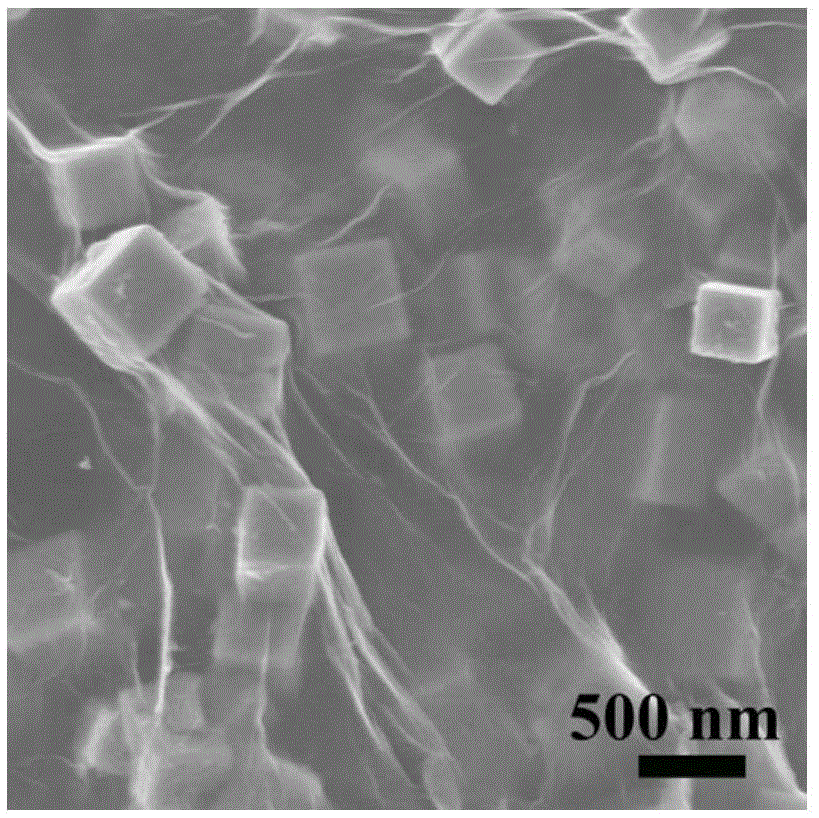

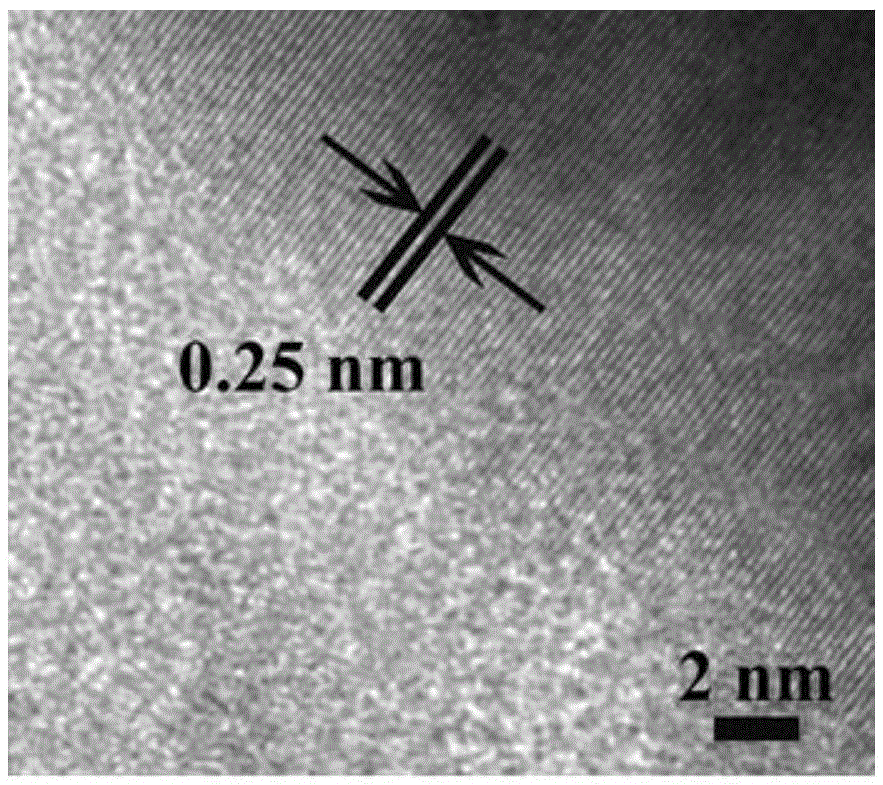

Preparation method of cubic cuprous oxide/graphene nanocomposite

InactiveCN105664943AGood lookingImprove photocatalytic efficiencyWater/sewage treatment by irradiationWater treatment compoundsWater bathsGraphene nanocomposites

The invention discloses a preparation method of a cubic cuprous oxide / graphene nanocomposite with efficient photocatalysis capability. According to the method, the composite can be prepared with a simple one-pot reduction method. Firstly, graphene oxide is prepared with an improved Hummers method, copper sulfate pentahydrate and graphene oxide are ultrasonically dispersed in water and mechanically stirred in a water bath at the temperature of 50-60 DEG C to be uniformly mixed, a sodium hydroxide solution is dropwise added to the mixture, copper hydroxide precipitates are formed, then, a glucose solution is added, the mixture reacts for 2-3 h, sufficient reduction is performed, centrifugation, washing and drying are performed, and a cubic cuprous oxide / graphene photocatalyst with the efficient photocatalysis capability is obtained. The process is simple, the cost is low, the product has uniform morphology, and the cubic cuprous oxide / graphene nanocomposite has excellent capability of photocatalytic degradation of organic dye under the visible light and has great application potential in environmental governance and solar energy utilization.

Owner:SHANGHAI JIAO TONG UNIV

Mixed additive for electrolytic profile-free copper foil

ActiveCN104099644ASimple componentsRaw materials are easy to getElectroforming processesSulfonateRough surface

The invention belongs to the technical field of electrolytic copper foil processing, and relates to a mixed additive for electrolytic profile-free copper foil. An aqueous mixed additive solution per liter comprises 15-30 mg of hydrolyzed collagen, 2-20 mg of 9-phenyl-acridine substitute, 4-10 mg of wliphatic amine oxyethylate sulfonate, 10-30 mg of sulfonate, 2-15 mg of polyethylene glycol, 0.2-0.8 mg of tetrahydrothiazolyl thione, 50 g of sulfuric acid and 20 g of copper sulfate pentahydrate. According to the mixed additive, the components are simple, and raw materials are easy to obtain; and according to the profile-free copper foil obtained by adopting the mixed additive, the thickness of the profile-free copper foil is 12-15 mu m, the rough surface namely the crystal growth surface Rz is smaller than 1.0 mu m, the typical value is 0.7 mu m, the glossiness at 60 degrees is 720, the tensile strength at the normal temperature is larger than or equal to 600 MPa, the tensile elongation at the normal temperature is larger than or equal to 12%, the tensile strength at the high temperature of 180 DEG C is larger than or equal to 260 MPa, and the tensile elongation at the high temperature is larger than or equal to 10%.

Owner:SHANDONG JINBAO ELECTRONICS

Method of using liquid-phase reduction method to prepare nano copper powder loaded graphene

InactiveCN102581295AEvenly distributedSimple methodGrapheneNanotechnologyMetal particleSurface modification

The invention relates to a method of using a liquid-phase reduction method to prepare nano copper powder loaded graphene, which solves the problems of complexity and high cost of existing graphene preparation methods. The method includes: taking graphite, adding concentrated sulphuric acid and mixing to obtain a mixture A; adding potassium permanganate, bathing in water, adding distilled water for diluting, adding hydrogen peroxide solution and diluted hydrochloric acid, cooling to the room temperature, leaching to obtain solid, adding distilled water to the solid, and placing in a semipermeable membrane for dialyzing until neutral to obtain sol; adding distilled water into the sol, adding copper sulfate pentahydrate, ultrasonically mixing, sequentially adding hydrazine hydrate solution and NaOH solution, mixing, centrifuging to obtain the product, washing and drying to obtain the nano copper powder loaded graphene. The method is simple and low in cost, no surface dressing agent is needed, and metal particles on the surface of graphene are uniform in distribution and stable in chemical performance.

Owner:HEILONGJIANG UNIV

Water culture nutrient solution of blueberry and preparation method thereof

InactiveCN102101803APromote absorptionReturn to normal growthFertilizer mixturesBiotechnologyCalcium nitrate tetrahydrate

The invention belongs to the technical field of fruit tree culture, in particular to a water culture nutrient solution prescription of a blueberry and a preparation method thereof. In the technology, the water culture nutrient solution of a blueberry comprises the following elements: 95-110mg / L of N, 10-15mg / L of P, 125-135mg / L of K, 80-90mg / L of Ca, 20-28mg / L of Mg, 4-6mg / L of Fe, 0.3-0.6mg / L of B, 0.4-0.6mg / L of Mn, 0.04-0.06mg / L of Zn, 0.02-0.04mg / L of Cu and 0.002-0.004mg / L of Mo. A pH value of the water culture nutrient solution is 4.8 to 5.5. The preparation method of the nutrient solution comprises the following steps of: weighing EDTA (Ethylene Diamine Tetraacetic Acid) ferrisodium, boric acid, manganese sulfate tetrahydrate, zinc sulphate heptahydrate, copper sulfate pentahydrate and ammonium molybdate tetrahydrate for dissolving into water and blending into 100 times of trace element mother liquor for storage and later use; additionally weighing calcium nitrate tetrahydrate, potassium nitrate, monopotassium phosphate and magnesium sulfate heptahydrate for dissolving into water; absorbing the trace element mother liquor into the solution according to the consumption; adding water for quantifying to needed volume; uniformly stirring; and adjusting the pH value of the solution to be 4.8 to 5.5 with 0.1mg / L dilute H2SO4 or dilute NaOH. By utilizing the technology, the water culture aims of growing a plurality of aquatic roots in 20 days after a blueberry seedling is transplanted and having the plant survival rate of more than 90 percent can be achieved.

Owner:JINLING INST OF TECH

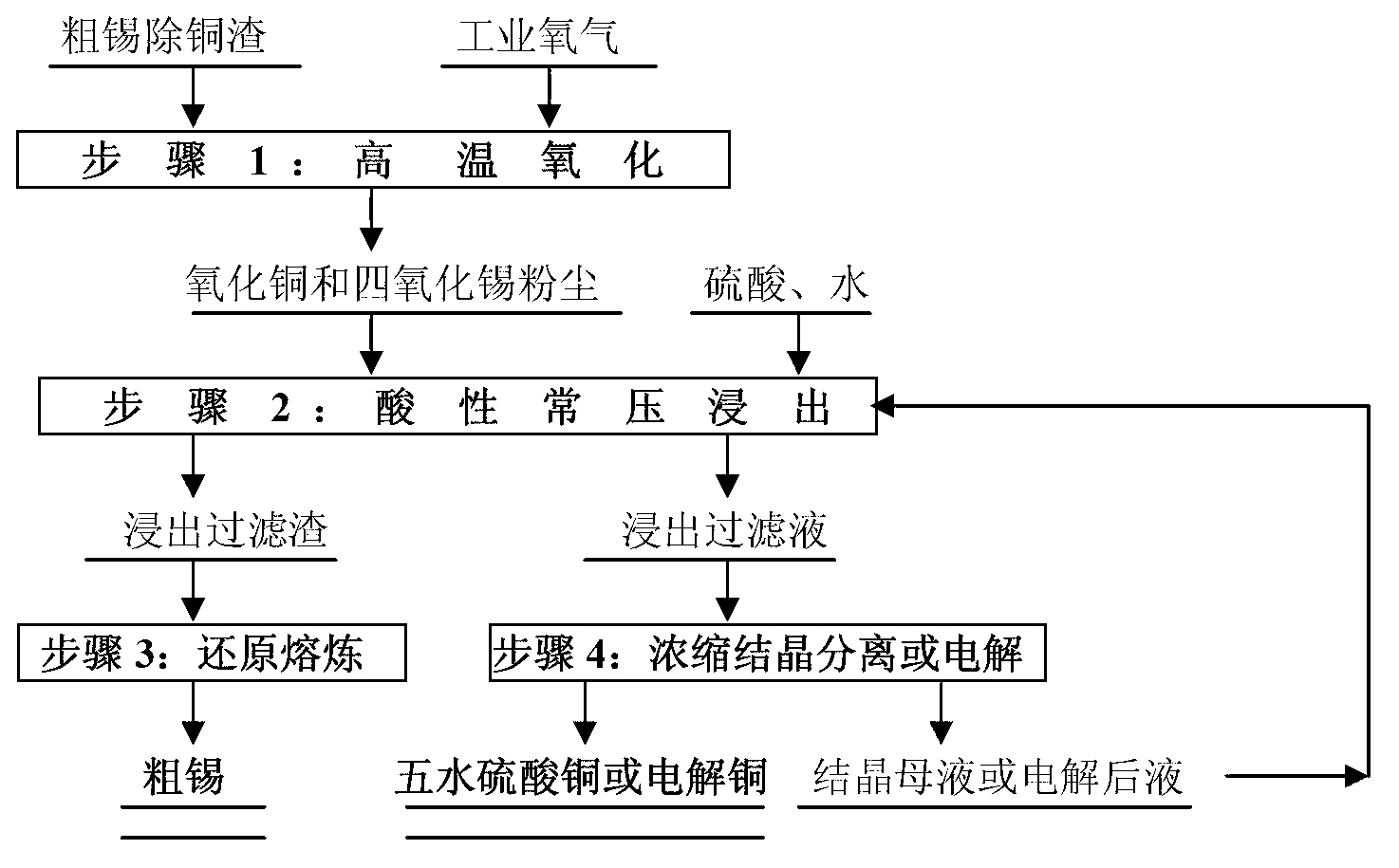

Treatment method of coarse tin decoppered slag

InactiveCN102851514AImprove direct yieldSafe separationProcess efficiency improvementElectrolysisSlag

The invention relates to a treatment method of coarse tin decoppered slag, which comprises the following steps: jetting industrial oxygen with the purity of 93-98.5% to the surface or inside of the coarse tin decoppered slag at the temperature of 850-1250 DEG C until the coarse tin decoppered slag is completely oxidized into copper oxide and tin tetroxide dust; leaching the copper oxide and tin tetroxide dust for 2-3 hours under atmospheric pressure and temperature under the condition of the initial acid of 70-120 g / L to obtain leached filtered slag, and carrying out reduction smelting to produce coarse tin; concentrating the leached filtrate to crystallize, and separating to produce chalcanthite product, or carrying out electrolysis to produce electrolytic copper; and returning the crystallization mother solution or electrolysis solution to the leaching process for solution preparation. The invention can separate tin and copper in the crude tin decoppered slag in a safe and efficient way, and does not generate waste water, waste gas or waste residue.

Owner:LAIBIN CHINA TIN SMELTING

Preparation method of graphene/copper composite material

InactiveCN103736993AGood dispersionThe reaction conditions are mild and safeLiquid/solution decomposition chemical coatingWater bathsFiltration

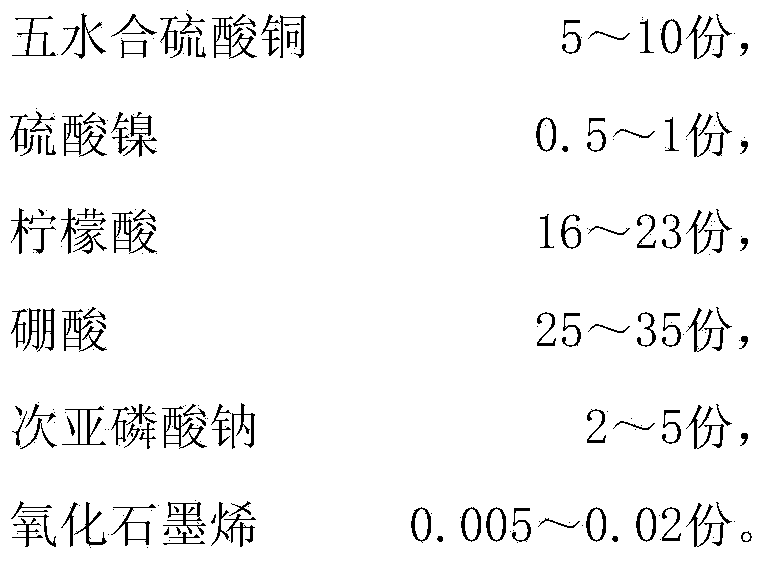

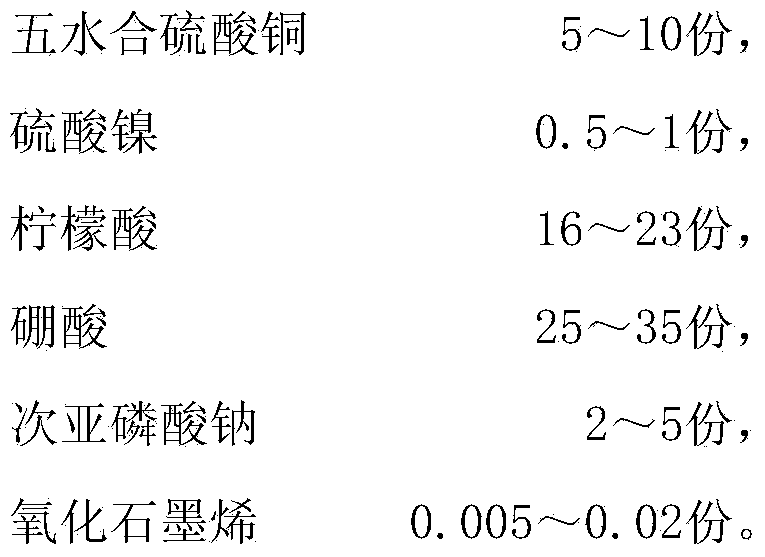

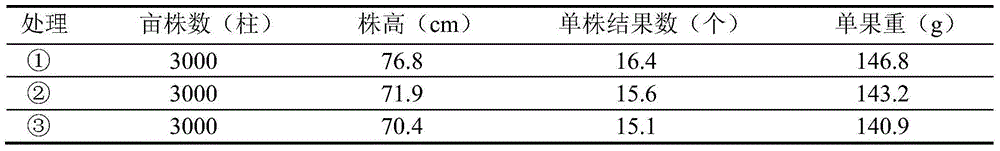

The invention discloses a preparation method of a graphene / copper composite material. The preparation method includes the following steps: step 1, weighing copper sulfate pentahydrate, nickel sulfate, citric acid and boric acid so as to prepare a mixed solution A, and stirring the mixed solution A; step 2, placing the mixed solution A in a magnetic stirring water bath kettle for heating the mixed solution A, then adding graphene oxide solution into the mixed solution A, stirring, and preparing a mixed solution B; step 3, adding sodium hypophosphite solution into the mixed solution B, stirring, and performing an accelerated reaction and ultrasound dispersion treatment so as to obtain a solution of the graphene / copper composite material which is evenly dispersed; step 4, performing repeated suction filtration on the solution by using a microfiltration membrane, repeatedly washing filter residues until PH (potential of hydrogen) value of the filter residues is neutral, performing vacuum drying, and performing reduction so as to obtain the composite graphene / copper composite material. The preparation method of the graphene / copper composite material is simple, convenient to operate, and low in cost, and has good application prospect.

Owner:SHANGHAI JIAO TONG UNIV

Plant infusion nutrient solution and preparation method thereof

InactiveCN101811909AImprove stress resistanceHigh activityFertilizer mixturesCalcium nitrate tetrahydrateHigh absorption

The invention discloses plant infusion nutrient solution and a preparation method thereof and aims to provide nutrient solution which can be directly infused into the plants, stimulate the tree activity, promote the plants to rapidly take root and sprout, quickly supply nutrition to the trees, and enhance the tree stress resistance, and a preparation method of the nutrient solution. The proportion of the nutrient solution is that: every 1,000ml of deionized water contains 0.05 to 0.1g of monopotassium phosphate, 0.02 to 0.045g of potassium nitrate, 0.15 to 0.3g of calcium nitrate tetrahydrate, 0.11 to 0.2g of magnesium sulfate heptahydrate, 0.03 to 0.06g of ferrous sulphate heptahydrate, 0.07 to 0.15g of disodium ethylene diamine tetraacetate, 0.015 to 0.025g of manganese sulfate tetrahydrate, 0.012 to 0.018g of zinc sulfate heptahydrate, 0.04 to 0.06g of copper sulfate pentahydrate, 0.015 to 0.022g of ammonium molybdate, 0.015 to 0.02g of indolebutyric acid, and 0.008 to 0.015g of 6-benzylaminopurine. The plant infusion nutrient solution satisfies the needed nutrient in the process of transplanting big trees, has high absorption utilization ratio, quick response, stable form, high activity, and is easily absorbed by the plants.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

Preparation method of conductive silver composite nano particles coated by polypyrrole

The invention discloses a copper-silver composite nano particle and the preparation method thereof. The preparation method includes the steps as follows: weighing a certain amount of chalcanthite solid and dissolving the chalcanthite solid in the solution containing a organic protective agent; holding a specific temperature under the condition of stirring; adding a reducing agent for reaction lasting for 12-24 hours; and slowly adding the silver nitrate solution to the solution for reaction lasting for another 12 hours. The prepared copper-silver composite nano particles encapsulated by polypyrole has good dispersity. The preparation method has the outstanding characteristics that the prepared nano particles is in a homogeneous dispersion, and is encapsulated by the conducting polypyrole on the periphery; the preparation process is comparatively easy and the experimental parameters are easy to control; compared with the single silver powder, the composite nano material has low power, good dispersity, strong stability and feasible industrialized production.

Owner:ZHEJIANG NORMAL UNIVERSITY

Liquid compound trace element fertilizer and preparation method thereof

ActiveCN104892208AImprove absorption efficiencyImprove absorption and utilization efficiencyFertilizer mixturesVitamin CAntioxidant

The invention discloses a liquid compound trace element fertilizer and a preparation method thereof. The fertilizer comprises the following ingredients by weight percent: 0-1.0% of citric acid, 0-1.0% of ascorbic acid (vitamin C), 0-1.0% of hydroxylamine hydrochloride, 0-1.0% of sorbitol, 0-1.0% of xylitol, 0-1.0% of mannitol, 0.46-38% of ferrous sulfate heptahydrate, 0.13-24% of manganese sulfate monohydrate, 0.18-3.3% of copper sulfate pentahydrate, 0.25-2.3% of zinc sulphate monohydrate, 0.25-4% of disodium octaborate tetrahydrate, 0.08-1.5% of ammonium molybdate, and the balance of pure water, wherein the dosage of the citric acid, the dosage of the ascorbic acid and the dosage of the hydroxylamine hydrochloride cannot be 0 at the same time, and the dosage of sorbitol, the dosage of xylitol and the dosage of mannitol cannot be 0 at the same time. According to the invention, an antioxidant prepared from one, two or more of the citric acid, ascorbic acid and hydroxylamine hydrochloride can effectively inhibit ferrous ions from being hydrolyzed into ferric ions, so that the iron ion absorption efficiency is improved, and the color of the product does not change at a high temperature; the raw material resources are rich, the production cost is low, and the equipment and production technologies are simple.

Owner:中化农业(新疆)生物科技有限公司

Method for separating and recovering copper from waste electronic appliances

InactiveCN102643995AIncrease contentEasy to recycleProcess efficiency improvementCopper sulfateMetal recycling

The invention relates to a method for separating and recovering metal from waste electronic appliances; aiming at the problems of high cost and complicated technological process in the existing metal recovery of waste electronic appliances, and the current situation that except the recovery of most valuable gold, the recovery of other metal elements is not fully considered about, the invention particularly provides a method for separating and recovering copper from the waste electronic appliances, which is low in production cost, quick and simple. According to the method, blocks or powder of the crushed waste electronic appliances, or metal powder which is obtained by sorting the powder is taken as raw material, and hydrochloric acid solution and sulfuric acid solution containing an oxidizing agent are respectively used as leaching reagents, the metal copper is recovered from the raw material by two-step selective leaching, and finally, copper sulfate pentahydrate or metal copper can be obtained.

Owner:SICHUAN UNIV

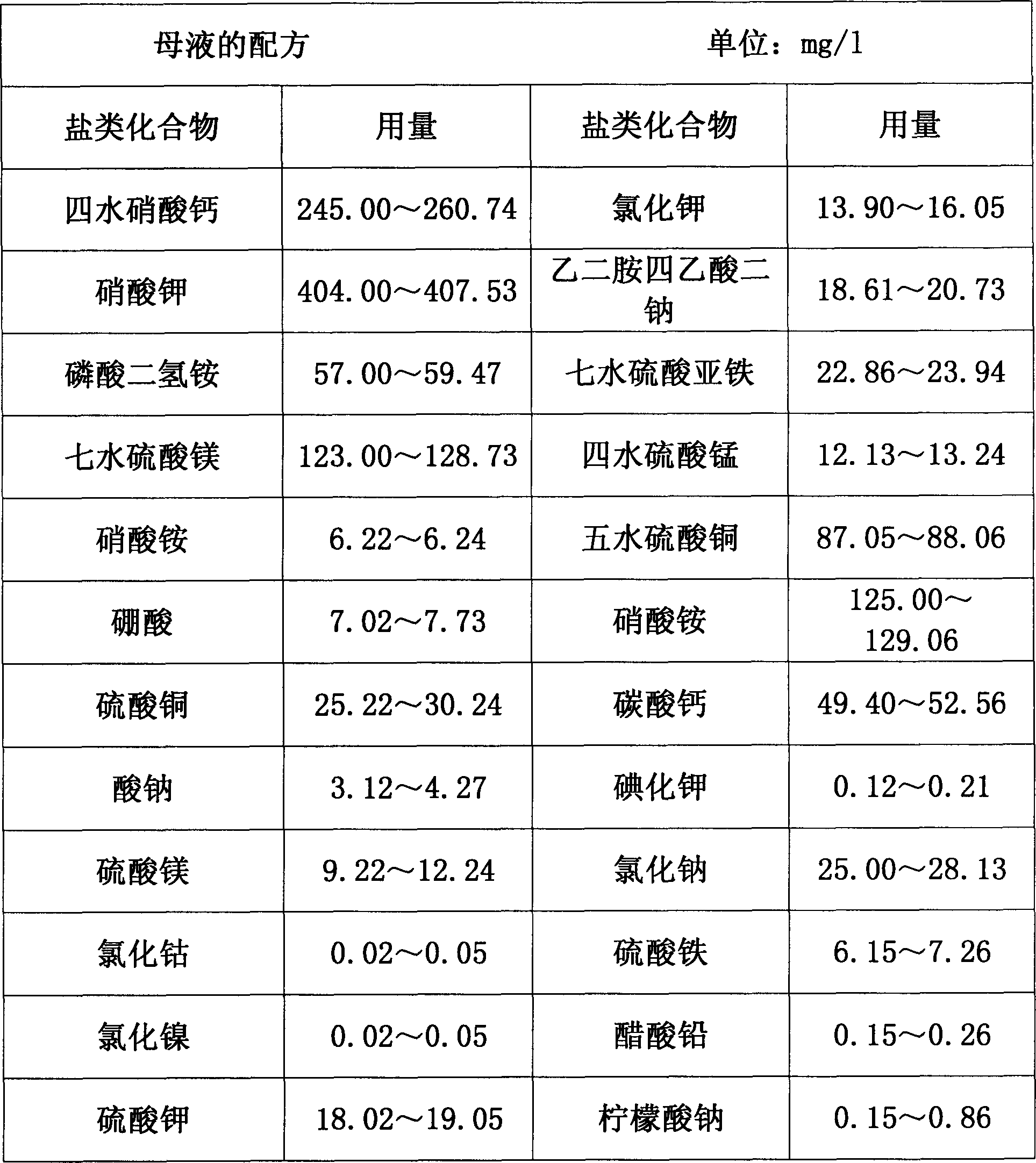

Water culture nutrient solution of spinach beet

InactiveCN103626559APromote growthShorten the growth cycleFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention discloses a water culture nutrient solution of spinach beet. The water culture nutrient solution comprises macroelements, microelements and water as well as calcium nitrate tetrahydrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ammonium nitrate, boric acid, copper sulfate, sodium silicate, magnesium sulfate, cobalt chloride, nickel chloride, potassium sulfate, potassium chloride, ethylene diamine tetraacetic acid, ferrous sulfate septihydrate, manganese sulfate tetrahydrate, copper sulfate pentahydrate, ammonium nitrate, calcium carbonate, potassium iodide, sodium chloride, ferric sulfate, lead acetate and sodium citrate. According to the water culture nutrient solution of the spinach beet, the absorption utilization rate is high and the waste caused by nutrition excess or deficiency resulted by no pertinence of a water culture nutrient solution of the spinach beet in the past is avoided.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Method for preparing fertilizer containing humic acid concentrated chelating trace elements

InactiveCN104478574AIncrease concentrationReduce dosageOrganic fertilisersFertilizer mixturesZINC SULFATE HEPTAHYDRATEPlant growth

The invention relates to a method for preparing a fertilizer containing trace elements, and particularly relates to a method for preparing a fertilizer containing humic acid concentrated chelating trace elements. The method comprises the following steps of firstly, adding supernate containing humic acid, ethylene diamine tetraacetic acid and sodium hydroxide sequentially into a reaction kettle, and stirring until dissolving; then adding heptahydrate, manganese sulfate monohydrate, blue copperas and iron vitriol sequentially into the reaction kettle, chelating, and stirring until dissolving; and then adding boric acid, ammonium molybdate, citric acid, caprylyl / capryl glucoside APG0810 into a reaction kettle, and stirring until dissolving. The invention provides a plant growth adjusting agent which is high in nutritional element concentration, is stable and uniform in solution, contains biochemical humic acid and the like, is beneficial to plant absorption, is high in biodegradability and is low in blade and soil pollution.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

Carp feed and preparation method thereof

The invention discloses a carp feed and a preparation method thereof. The carp feed is obtained through the following steps: grinding fish meal, puffed corn flour, soybean lecithin, brewer's yeast, fish oil, rosemary powder, corn protein powder, rice bran, meat bone meal, wheat bran, cottonseed meal, wheat, shell powder, a composite additive, an auxiliary additive, a composite feed attractant, puffed wall-broken blood powder, fermented soybean protein powder, calcium dihydrogen phosphate, choline chloride, garlicin, copper sulfate pentahydrate, ferrous sulfate monohydrate, zinc sulfate, manganese sulfate, 1% calcium iodate, 1% sodium selenite, heavy calcium powder, sodium chloride, magnesium glycinate, potassium chloride, copper glycinate, ferrous glycinate, zinc methionine, manganese glycinate, potassium iodate, cobalt methionine and sodium selenite to form powder, adding water, stirring, and uniformly mixing. The carp feed can effectively improve the immunity of carp, reduces the diseased death rate of carp, has no influences on water, and guarantees normality of water.

Owner:JIANGSU EFFORT TECH & DEV

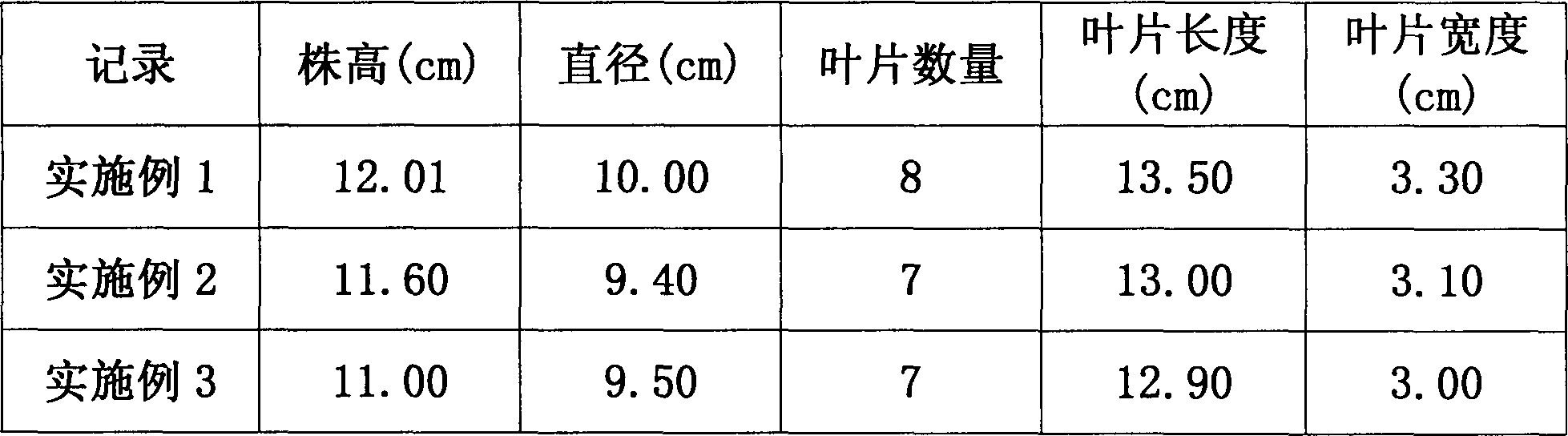

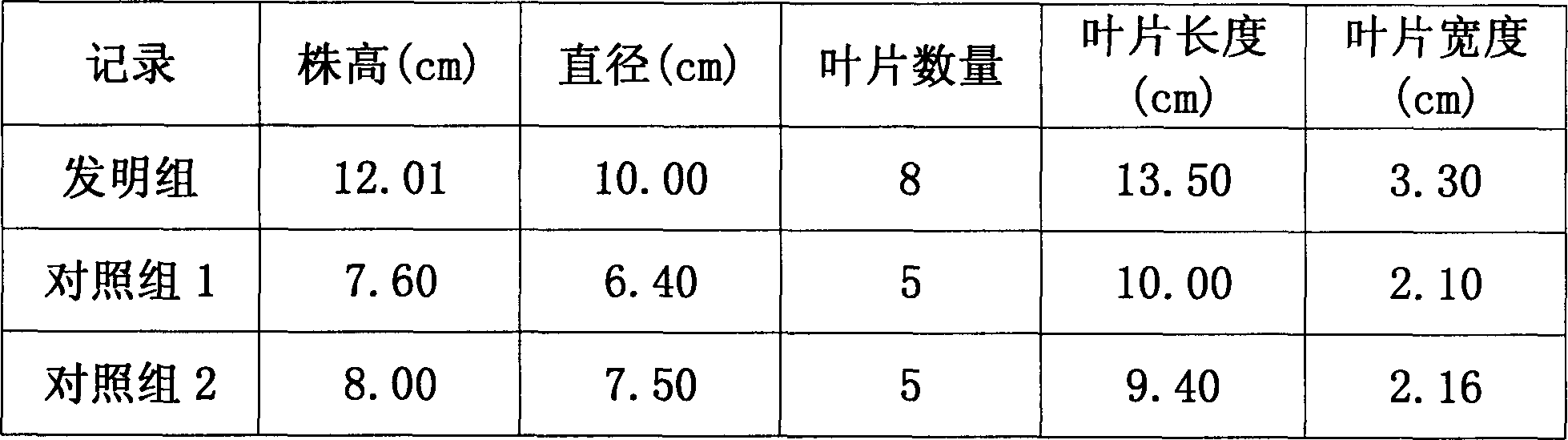

Premixed feed for minks at breeding period and preparation method thereof

InactiveCN103875996AReduce the incidence of intestinal diseasesLow costAnimal feeding stuffPantothenic acidZinc sulphate monohydrate

The invention discloses premixed feed for improving the growth speed and the nutrient substance digestion rate of minks at a breeding period. The premixed feed per one kilogram comprises the following raw material components: 265g-300g of corn protein powder, 15g-20g of compound vitamin B, 25g-35g of a complex enzyme preparation, 250000-300000 IU of vitamin A, 12g-15g of vitamin C, 2000-2500 IU of vitamin E, 50000-80000 IU of vitamin D, 0.6g-1g of vitamin K, 25g-28g of methionine, 15g-18g of lysine, 0.5g-1g of biotin, 55g-70g of choline chloride, 7g-9g of ferrous sulfate monohydrate, 9g-12g of copper sulfate pentahydrate, 10g-12.5g of manganese sulfate, 16g-20g of zinc sulphate monohydrate, 5g-6g of sodium selenite, 6g-8g of cobalt chloride, 5g-6g of potassium iodate, 10g-15g of yeast, 0.5g-0.6g of pantothenic acid, 3g-5g of nicotinamide, 0.5g-0.6g of folic acid, 140g-150g of calcium hydrogen phosphate, 30g-40g of table salt and 260g-300g of puffed corn powder. The premixed feed can be used for effectively improving the daily gain and the digestion rate of proteins, fat and carbohydrates of the minks at a breeding period, reducing the diarrhea rate of the minks and improving the culture benefits of the minks.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Method for coloring magnesium alloy composite film by micro-arc oxidation

The invention discloses a method for coloring a magnesium alloy composite film by micro-arc oxidation. The method comprises the following steps: (1) grinding an AZ91 magnesium alloy, washing with water, washing with alkali, washing with water, cleaning with ultrasonic waves and washing with deionized water for 2-3 times; (2) placing the AZ91 magnesium alloy serving as an anode in a micro-arc oxidation electrolyte and carrying out micro-arc oxidation treatment, wherein the cathode is stainless steel; (3) dissolving 1-10ml of ethyl Orthosilicate in 40-50ml of absolute ethyl alcohol; adding 1-2g of zirconium oxychloride; magnetically stirring for 0.5-1.5 hours at constant temperature in a 50 DEG C water bath; adding 0.1-0.5g of copper sulfate pentahydrate and 5-20mg of glucose and continuously stirring for 0.5-1 hour at 50 DEG C; after the liquor is cooled, obtaining a green SiO2-ZrO3 colloid; and (4) immersing a micro-arc oxidation film sample in the SiO2-ZrO3 colloid; soaking; slowly pulling the sample out at a uniform velocity; repeatedly pulling the sample twice; drying; soaking again; slowly pulling the sample out at the uniform velocity; drying; then heating to 150-200 DEG C; and curing for 0.5-1 hour. According to the method disclosed by the invention for surface treatment of the magnesium alloy, a uniform green film with high corrosion resistance can be obtained.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing black ceramic membrane by magnesium alloy differential arc oxidation

InactiveCN101476146AGuaranteed corrosion resistanceGuaranteed wear resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a method for preparing a magnesium alloy micro-arc oxidating black ceramic film which belongs to the magnesium alloy surface treating technique field. Blue copperas metal cation Cu(2+) is used as a coloring additive that is added into an alkali basic electrolyte with sodium silicate as main salt after being complex by complexing agent ammonia, an electrical parameter suitable to the electrolyte is set for micro-arc oxidating and coloring, various electrolyte has various coloring effect to film, the ceramic film color is determined by metal oxidation of film or structure composed by the salt and silicate. Sodium silicate prepares black ceramic film on the magnesium alloy surface as main salt. The black ceramic film obtained by the magnesium alloy micro-arc oxidating has better corrosion resistance and hardness, and has characteristics of uniform color, high black degree. The method has widely application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Direct acidity oxygen pressure leaching treatment method of crude tin copper removal residues

InactiveCN102876903AImprove direct yieldEasy to separateProcess efficiency improvementElectrolysisLiquid state

Disclosed is a direct acidity oxygen pressure leaching treatment method of crude tin copper removal residues. The method includes that the crude tin copper removal residues containing 55-75% of tin and 8-18% of copper produced when liquid-state crude tin is added to sulphur to remove copper are leached for 4-6 hours and filtered to obtain a filtrate and residues with final acid of 46-118g / L under the conditions that the temperature is 120-150 DEG C, oxygen partial pressure is 0.15-0.25MPa and the initial acid is 100-250g / L, the residues are subjected to reduction smelting to produce crude tin, the filtrate is subjected to concentration, cooling and crystallization to produce a copper sulfate pentahydrate product or subjected to electrolysis to produce electrolytic copper, and a crystallization mother liquor or an electrolyzed solution is returned to a leaching process for dispensing liquids. By means of the direct acidity oxygen pressure leaching treatment method of the crude tin copper removal residues, tin and copper in the crude tin copper removal residues can be rapidly and efficiently separated, and waste water, waste gases and waste residues are not generated.

Owner:LAIBIN CHINA TIN SMELTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com