Copper plating solution for PCB (printed circuit board) through holes and PCB blind holes, as well as preparation method and plating method of copper plating solution

A technology of electroplating copper and solution, which is applied in the direction of electrical connection formation of printed components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A copper electroplating solution for through-hole blind holes of PCB, each component and content thereof of the copper electroplating solution are:

[0093] Copper sulfate pentahydrate: 100g / L

[0094] Sulfuric acid: 100g / L

[0096] Brightener: 5g / L

[0097] Carrier: 3g / L

[0098] Leveling agent: 2g / L

[0099] Deionized water balance;

[0100] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1:1.

[0101] The brightener is a mixture of sodium 3-mercapto-1-propanesulfonate and ethylene thiourea with a weight ratio of 1.5:1; the carrier is made of polyethylene glycol with a molecular weight of 5000 and A mixture of polypropylene glycol in a weight ratio of 1.8:1.

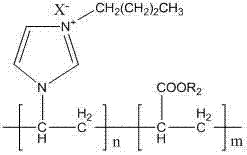

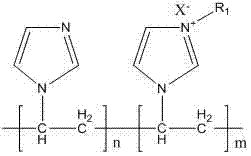

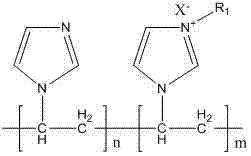

[0102] The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.2:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Vinyl-N'-butylimid...

Embodiment 2

[0121] A copper electroplating solution for through-hole blind holes of PCB, each component and content thereof of the copper electroplating solution are:

[0122] Copper sulfate pentahydrate: 140g / L

[0123] Sulfuric acid: 120g / L

[0125] Brightener: 15g / L

[0126] Carrier: 10g / L

[0127] Leveling agent: 5g / L

[0128] Deionized water balance;

[0129] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1.17:1.

[0130] The brightener is a mixture of sodium 3-mercapto-1-propanesulfonate and ethylene thiourea in a weight ratio of 2:1; the carrier is made of polyethylene glycol with a molecular weight of 8000 and A mixture of polypropylene glycol in a weight ratio of 2:1.

[0131] The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.5:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Vinyl-N'-butylimida...

Embodiment 3

[0150] A copper electroplating solution for through-hole blind holes of PCB, each component and content thereof of the copper electroplating solution are:

[0151] Copper sulfate pentahydrate: 220g / L

[0152] Sulfuric acid: 180g / L

[0154] Brightener: 35g / L

[0155] Carrier: 20g / L

[0156] Leveling agent: 15g / L

[0157] Deionized water balance;

[0158] And the concentration ratio of copper sulfate pentahydrate to sulfuric acid is 1.22:1.

[0159] The brightener is a mixture of sodium 3-mercapto-1-propanesulfonate and ethylene thiourea with a weight ratio of 2.5:1; the carrier is made of polyethylene glycol with a molecular weight of 10000 and A mixture of polypropylene glycol in a weight ratio of 2.2:1.

[0160]The leveling agent is a mixture of leveling agent A and leveling agent B with a weight ratio of 1.8:1; wherein, the leveling agent A is a polyvinylimidazolium quaternary ammonium compound, and the leveling agent B is N- Vinyl-N'-but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com