Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61 results about "Blue Copperas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for reclaiming valuable resource in acidic etching waste liquid

InactiveCN101215062AImprove liquidityReduce cooling energy consumptionChlorine/hydrogen-chlorideMultistage water/sewage treatmentLiquid wasteWater vapor

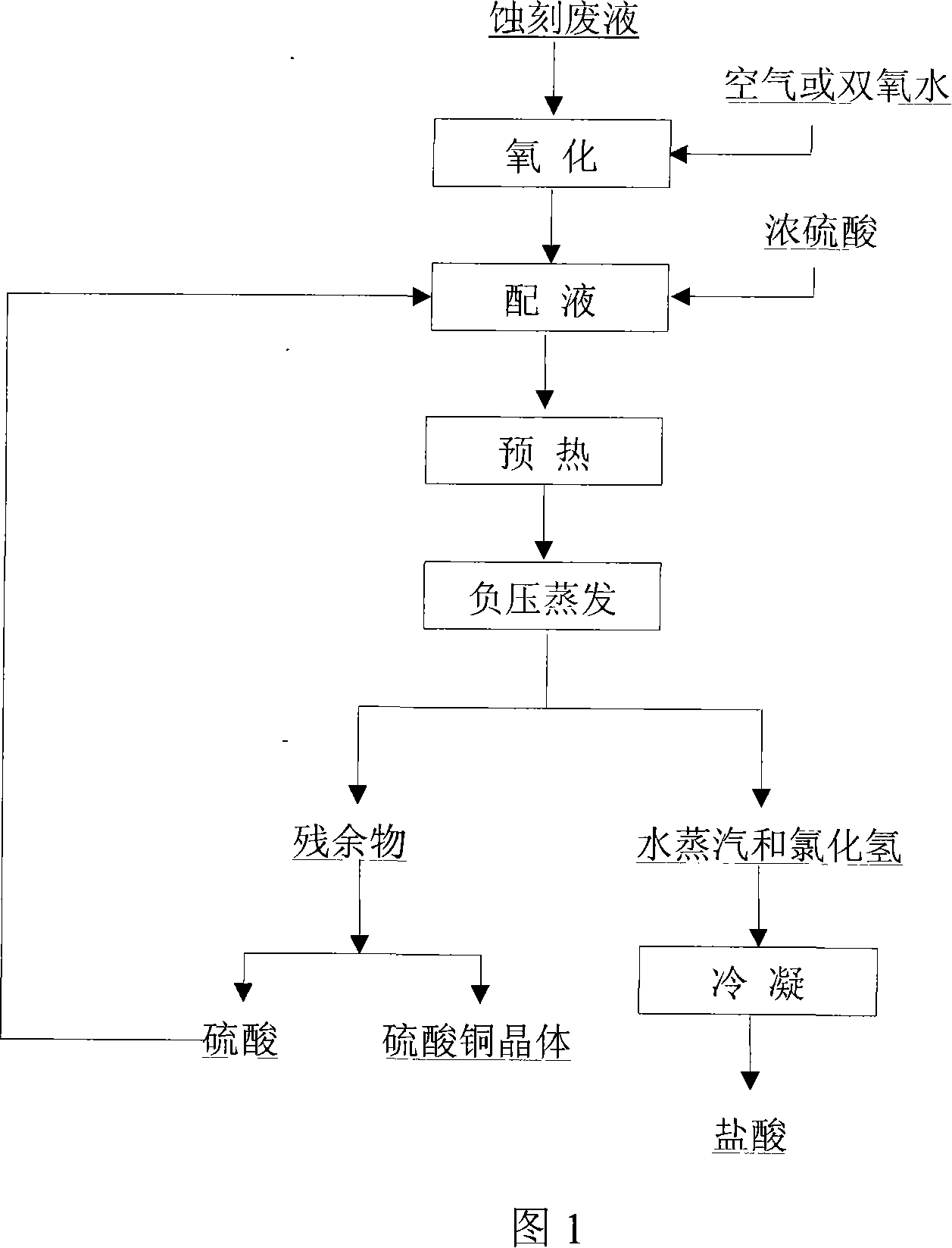

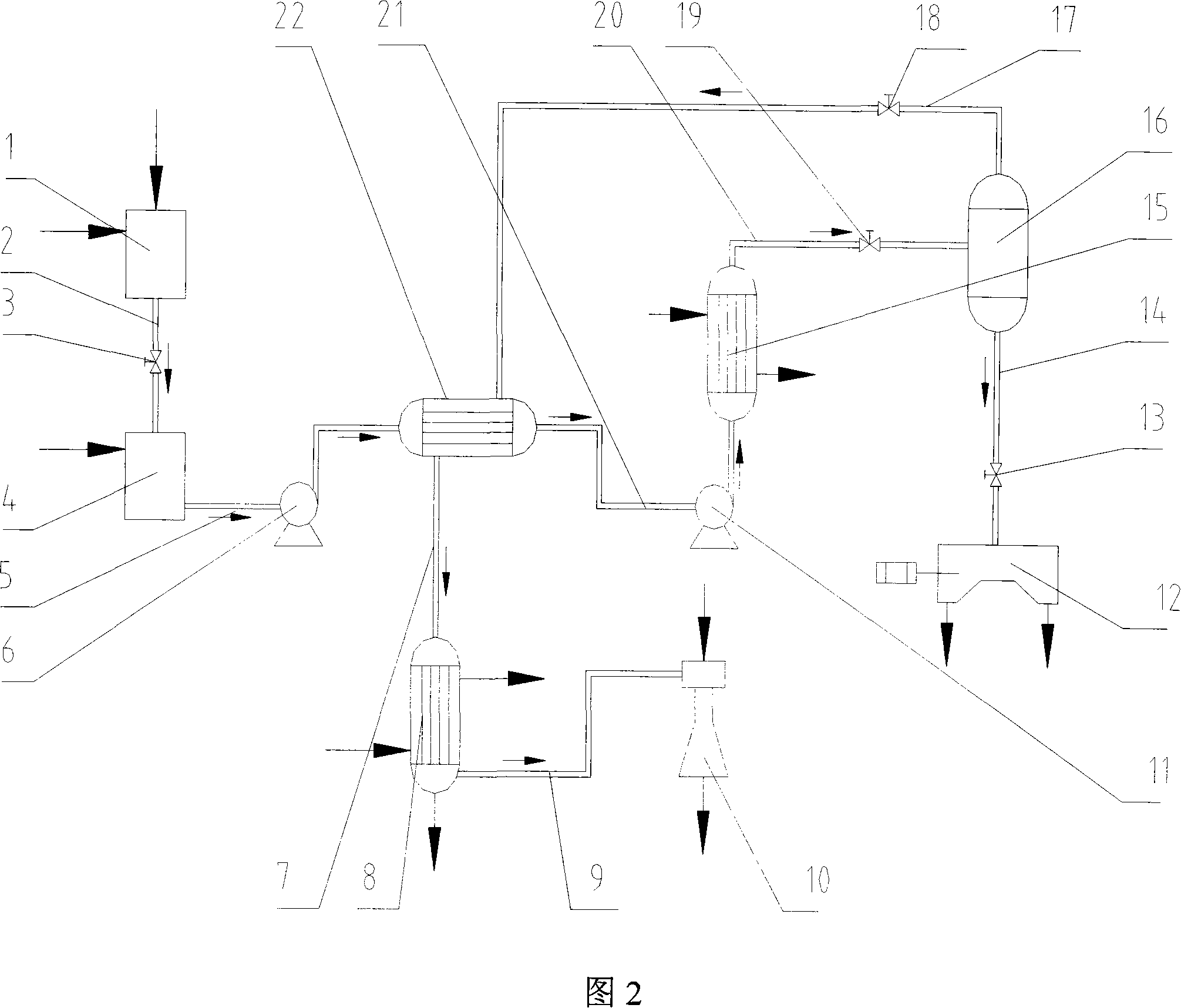

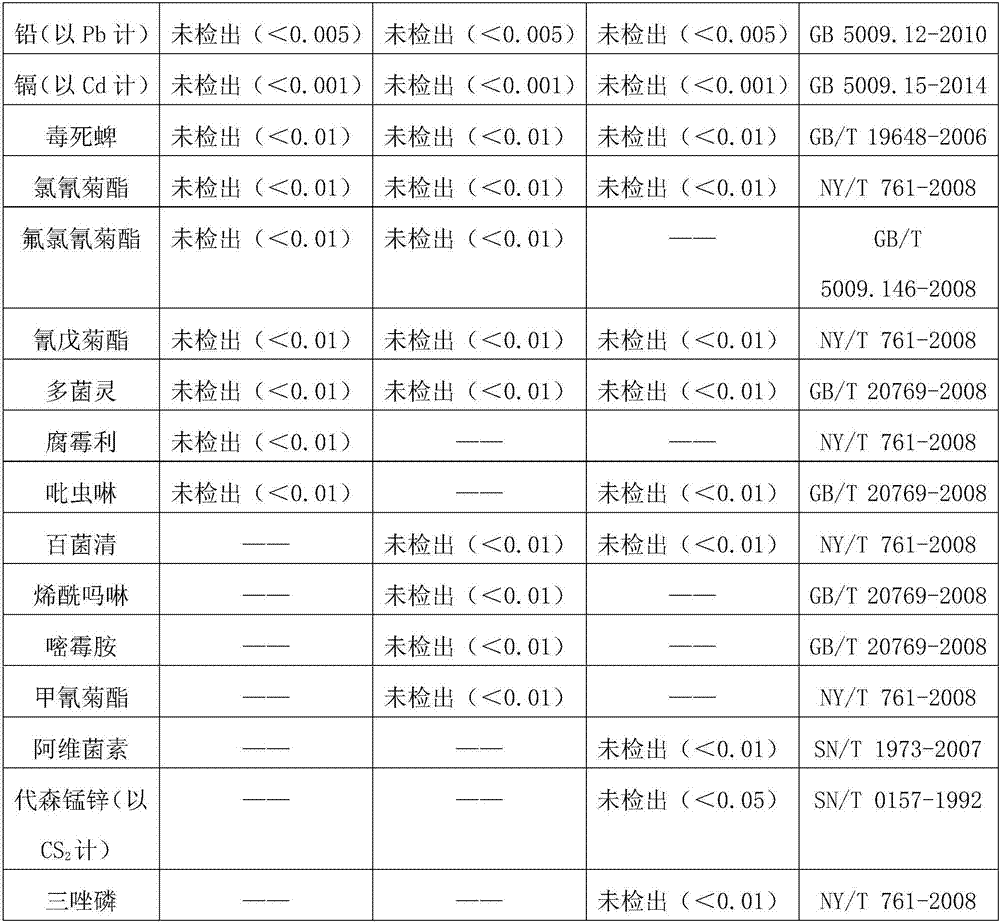

Provided are system of value resource in acidic corrosion waste fluid and a recycling method. The recycling method of the invention includes the following steps that adding oxidation agent and concentrated sulfuric acid into the corrosion waste fluid, pre-heating and heating the corrosion waste fluid, evaporating out water vapor and hydrogen chloride under negative pressure and recycling hydrochloric acid, the residue separates hydric sulphate from blue copperas crystal via centrifugal filtration and recycle hydric sulphate, washing blue copperas crystal by blue copperas crystal solution and absolute ethyl alcohol and recycling blue copperas. The recycling system comprises an oxidation ditch, a dosage bunker, a pre-heater, a heat booster, an evaporation tank, a filter, a cooler, a spraying and absorbing device and the like. The recycling method of the invention increases the recovery rate of metal copper and hydrogen chloride, with both recovery rates more than 99%. The method can employ scheme of batch operation or continuous recycling, which is adapted for industry utilization.

Owner:郝屿

Method for preparing fertilizer containing humic acid concentrated chelating trace elements

InactiveCN104478574AIncrease concentrationReduce dosageOrganic fertilisersFertilizer mixturesZINC SULFATE HEPTAHYDRATEPlant growth

The invention relates to a method for preparing a fertilizer containing trace elements, and particularly relates to a method for preparing a fertilizer containing humic acid concentrated chelating trace elements. The method comprises the following steps of firstly, adding supernate containing humic acid, ethylene diamine tetraacetic acid and sodium hydroxide sequentially into a reaction kettle, and stirring until dissolving; then adding heptahydrate, manganese sulfate monohydrate, blue copperas and iron vitriol sequentially into the reaction kettle, chelating, and stirring until dissolving; and then adding boric acid, ammonium molybdate, citric acid, caprylyl / capryl glucoside APG0810 into a reaction kettle, and stirring until dissolving. The invention provides a plant growth adjusting agent which is high in nutritional element concentration, is stable and uniform in solution, contains biochemical humic acid and the like, is beneficial to plant absorption, is high in biodegradability and is low in blade and soil pollution.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

Method for preparing black ceramic membrane by magnesium alloy differential arc oxidation

InactiveCN101476146AGuaranteed corrosion resistanceGuaranteed wear resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a method for preparing a magnesium alloy micro-arc oxidating black ceramic film which belongs to the magnesium alloy surface treating technique field. Blue copperas metal cation Cu(2+) is used as a coloring additive that is added into an alkali basic electrolyte with sodium silicate as main salt after being complex by complexing agent ammonia, an electrical parameter suitable to the electrolyte is set for micro-arc oxidating and coloring, various electrolyte has various coloring effect to film, the ceramic film color is determined by metal oxidation of film or structure composed by the salt and silicate. Sodium silicate prepares black ceramic film on the magnesium alloy surface as main salt. The black ceramic film obtained by the magnesium alloy micro-arc oxidating has better corrosion resistance and hardness, and has characteristics of uniform color, high black degree. The method has widely application prospect.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

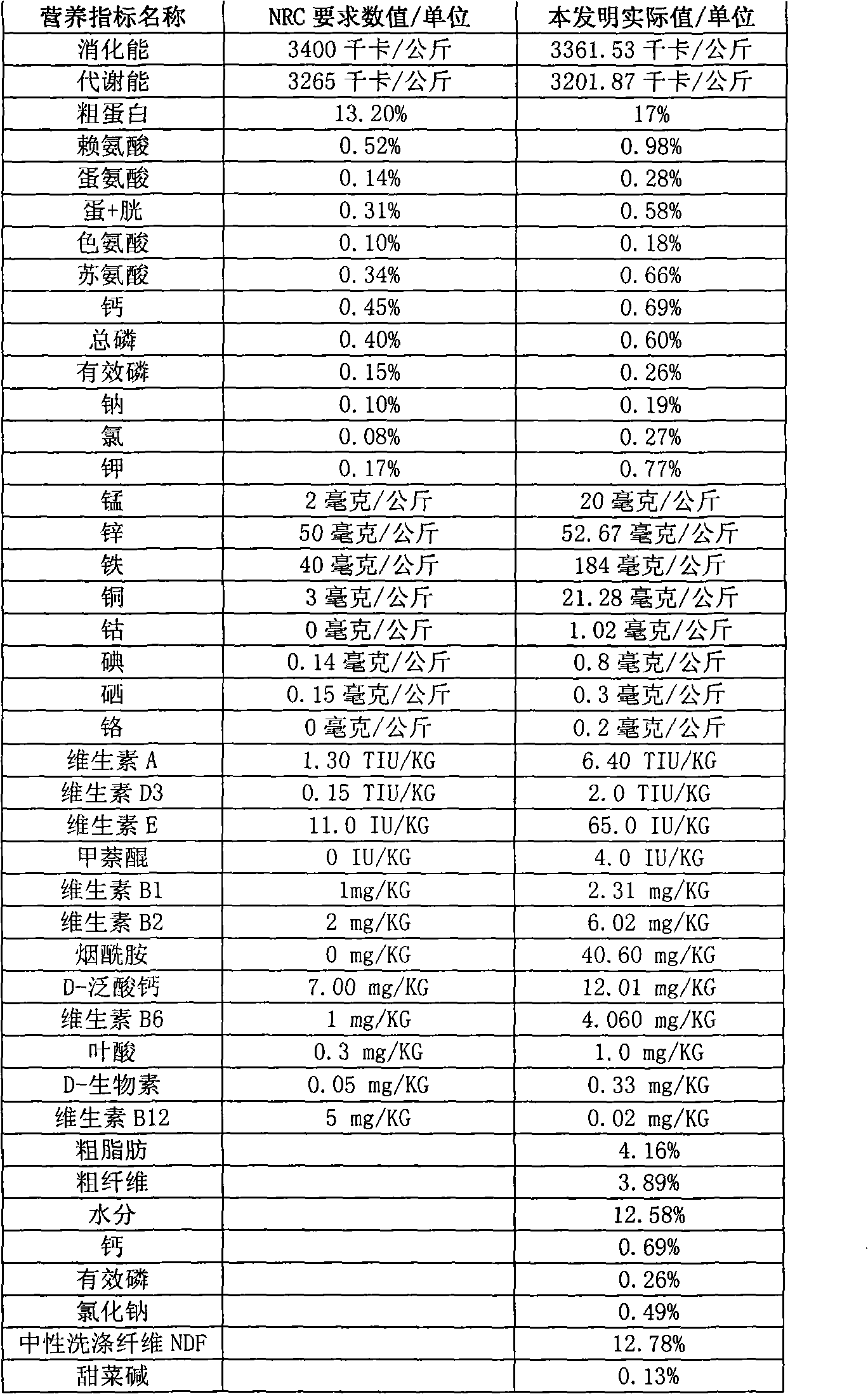

Shoat feed and preparation method

InactiveCN101912065AImprove the status quo of low productionAdjust the farming structureAnimal feeding stuffAccessory food factorsPhytaseCalcium formate

The invention discloses a shoat feed and a preparation method. The shoat feed is prepared from the following raw materials in a ratio: northeast corn, soybean meal CP43, rice bran meal, puffed soybean meal, Ronggang molasses yeast, citric acid residue meal, calcium hydrophosphate, calcium formate, 0.5 percent shoat premix, salt, 98.5 percent L-lysine hydrochloride, granular acidifying agent-II, 99 percent DL-methionine, 97 percent betaine hydrochloride Betaine [C5H11NO2], 98.5 percent L-threonine, Mycofix-Plus3.0, blue copperas, 98 percent L-tryptophan, phytase 5,000mu / g, 10 percent colistin sulfate, coated acetyl kitasamycin*500, and 1806Z-LUCTA. The preparation method comprises the following steps of: A, proportioning the raw materials according to the components and the weight ratio; B, crushing: crushing the raw materials by using a crusher respectively; C, mixing the crushed raw materials; D, drying and packing; E, inspecting; and F, metering and packing. The shoat feed has the advantages of reasonable formula, rich nutritional components, good taste and easy digestion, improves the immunologic function of shoats and is suitable for large-scale breeding.

Owner:WUHAN JIA YUAN HUA ENVIRONMENTAL PROTECTION SCI & TECH

Non-toxic environment-friendly normal temperature steel nigrescence treating agent and preparation method thereof

InactiveCN102994996APromote environmental protectionQuality improvementMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a non-toxic environment-friendly normal temperature steel nigrescence treating agent, which consists of the following components by mass percent: 1-5% of blue copperas, 1-4% of zinc dihydrogen phosphate, 1-6% of zinc nitrate, 0.1-0.3% of citric acid, 1-2% of EDTA(ethylene diamine tetraacetic acid)-disodium, 1-6% of sodium thiosulfate, 1-4% of ammonium molybdate, 0.5-1.5% of nickel sulfate hexahydrate, 0.1-0.6% of hydroquinone, 0.5-1.5% of potassium dichromate and the balance of water. The steps of the preparation method is as follows in sequence: firstly adding water calculated and weighted into a reaction kettle, starting a stirrer, controlling the rotated speed within 60 turns per minute, then sequentially and slowly adding the blue copperas, nickel sulfate hexahydrate, citric acid, zinc dihydrogen phosphate, zinc nitrate, EDTA-disodium, sodium thiosulfate, ammonium molybdate, hydroquinone, and potassium dichromate that are calculated and weighted into the reaction kettle, wherein each raw material added into the reaction kettle needs to be stirred for complete dissolution so as to obtain yellowgreen white out uniform liquid finally.

Owner:DALIAN SANDAAOKE CHEM

Plant nutrient solution and preparation method thereof

InactiveCN107353142AIncrease productionComparable performanceSuperphosphatesMagnesium fertilisersCalcium nitrate tetrahydratePhosphoric acid

The invention provides a plant nutrient solution and a preparation method thereof. The plant nutrient solution is mainly prepared from, 380-420 parts of potash nitrate, 80-100 parts of potassium phosphate, 50-70 parts of hybridized adsorbing agent, 180-220 parts of epsom salt, 1.8-2.2 parts of manganese sulfate monohydrate, 2-3 parts of boric acid, 12-18 parts of Ferric sodium ethylene diamine tetraacetate, 380-420 parts of calcium nitrate terahydrate, 0.3-0.5 part of blue copperas, 0.8-1.2 parts of heptahydrate, 0.006-0.010 part of ammonium octamolybdate, 0.001-0.005 part of calcium superphosphate, 0.0008-0.0012 part of sodium chloride, 0.0008-0.0012 part of sodium molybdate and 0.0015-0.0025 part of ferrous sulfate. The plant nutrient solution is suitable for all plant growth, and the plant yield can be effectively increased; the plant nutrient solution can be used for fish culture and suitable for fish growth.

Owner:王福权

Superconductive medium radiator

InactiveCN1763466AImprove thermal conductivityFast heat transfer rateHeat-exchange elementsHeat exchange apparatusDielectricPotassium permanganate

The invention discloses a superconductive dielectric radiator which comprises the following weight quantity parts: re-distilled water 1000, potassium dichromate 0-17, blue copperas 0-30, kalium sulphuricum 17-27, chromic acid anhydride 9-19, alcohol or acetone 200-700, kalium hypermanganicum 0.5-2, wherein the vacuum degree of superconductive dielectric radiating pipe cavity is 0.03-0.1 MPa; the shell material is aluminum alloy or copper. The superconductive dielectric radiator contains high heat conductivity, quick heat conduction speed, little temperature difference and good inoxidizability.

Owner:孙善民

Pig's feed pre-mixing material and preparing method

InactiveCN1977633AImprove immunityImprove qualityAnimal feeding stuffAccessory food factorsLicorice rootsCopper sulfate pentahydrate

The present invention discloses a pig feed premixed material and its preparation method. It is made up by using blue copperas, copper sulfate monohydrate, zinc sulfate monohydrate, calcium iodate, organic selenium, choline chloride, enzyme preparation, calcium hydrogen phosphate, stone powder, edible salt, astragalus root, lonicera flower, licorice root and zeolite powder according to a certain mixing ratio through a certain preparation process. Said invention can raise immunity of pig and can raise quality of pig meat.

Owner:民惠食品(重庆)有限公司

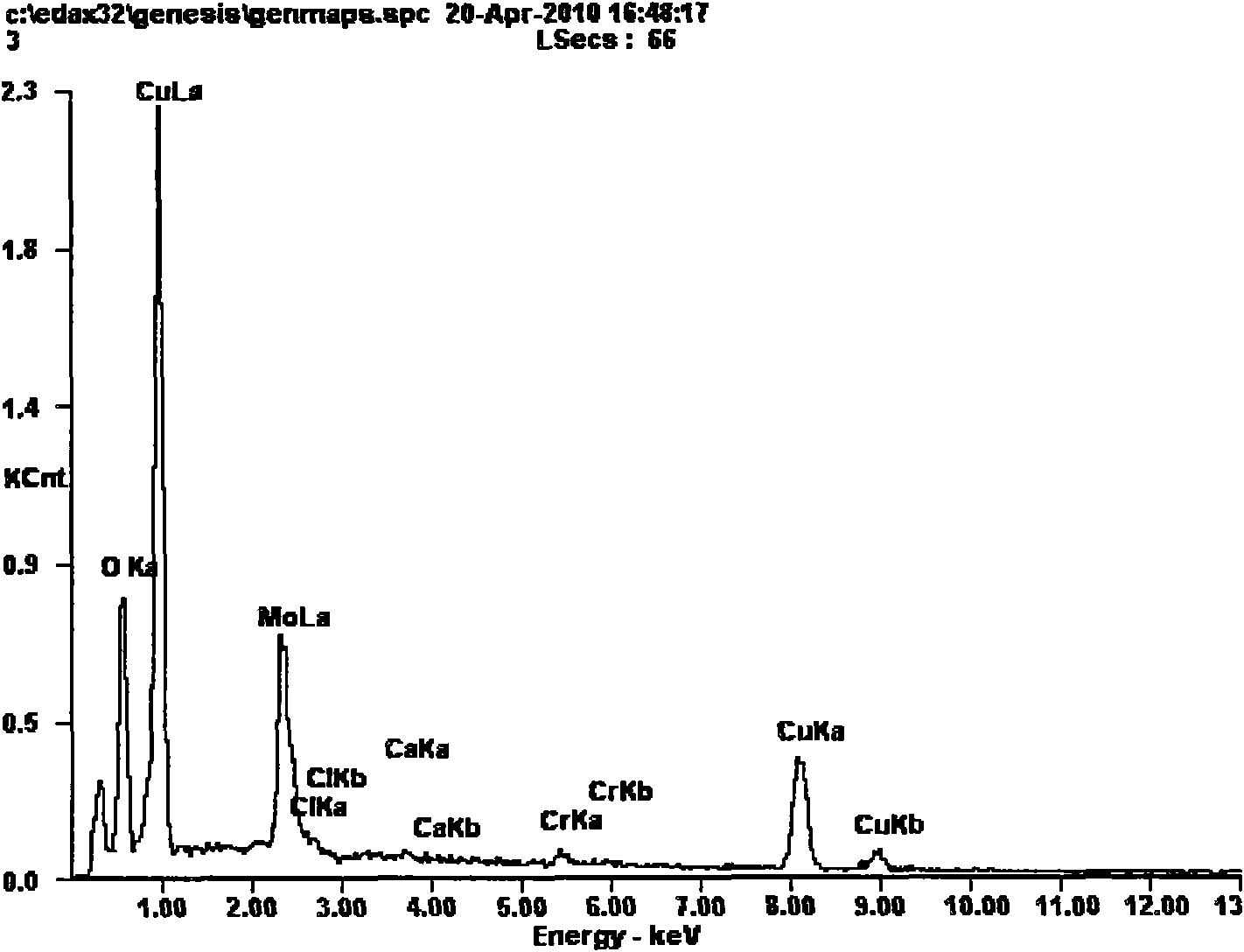

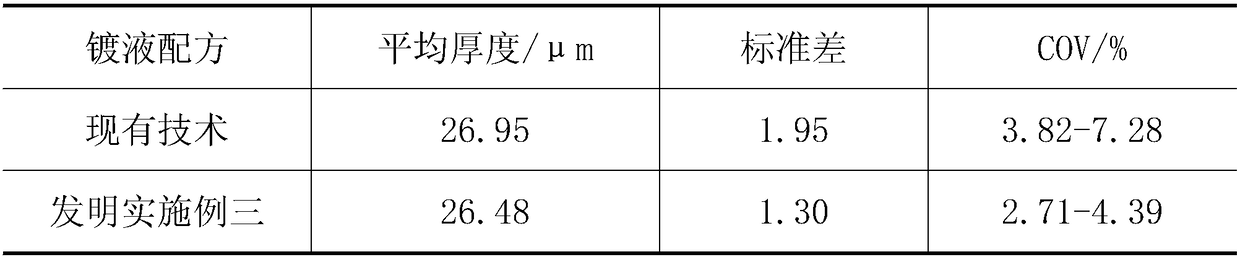

Copper-chromium-molybdenum ternary alloy coating and preparation method thereof

The invention discloses a copper-chromium-molybdenum ternary alloy coating and a preparation method thereof. The preparation method comprises the following steps of: dissolving a nitric acid with distilled water, adding sodium molebdate hexahydrate for stirring and dissolving, adjusting a pH value to be 1.5 to 3.3, sequentially adding lanthanum chloride, ammonium sulfate and ammonium formate, adjusting the pH value to be 2.1 to 4.0, sequentially adding blue copperas, chromium sulfate hexahydrate and a boric acid, adding the remaining distilled water, and adjusting the pH value to be 2.0 to 3.8 to obtain electroplating solution; performing polishing and chemical washing on the surface of a substrate, placing the treated substrate into an electroplating bath, dipping the substrate into the electroplating solution, electroplating and depositing the substrate for 30 to 60 minutes at 40 to 55 DEG C, taking the substrate out after the electroplating is finished, and washing and drying the substrate to obtain the copper-chromium-molybdenum ternary alloy coating. In the copper-chromium-molybdenum ternary alloy coating and the preparation method thereof, the alloy components of the surface can be changed according to specific requirements so as to improve the hardness, strength and wear-resisting property of the surface, while the component of a core part is also Cu with high electrical conductivity and thermal conductivity.

Owner:SOUTH CHINA UNIV OF TECH

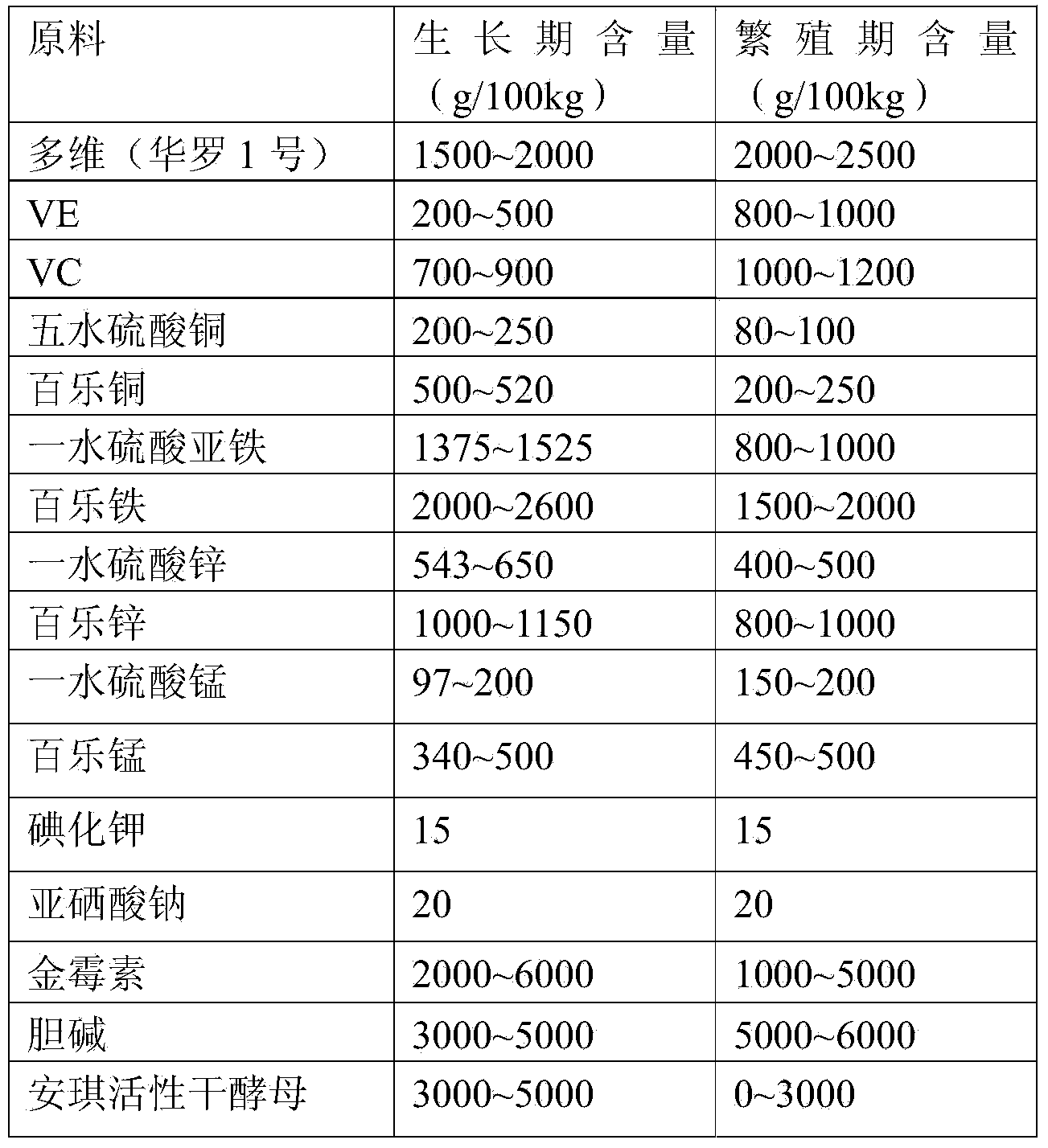

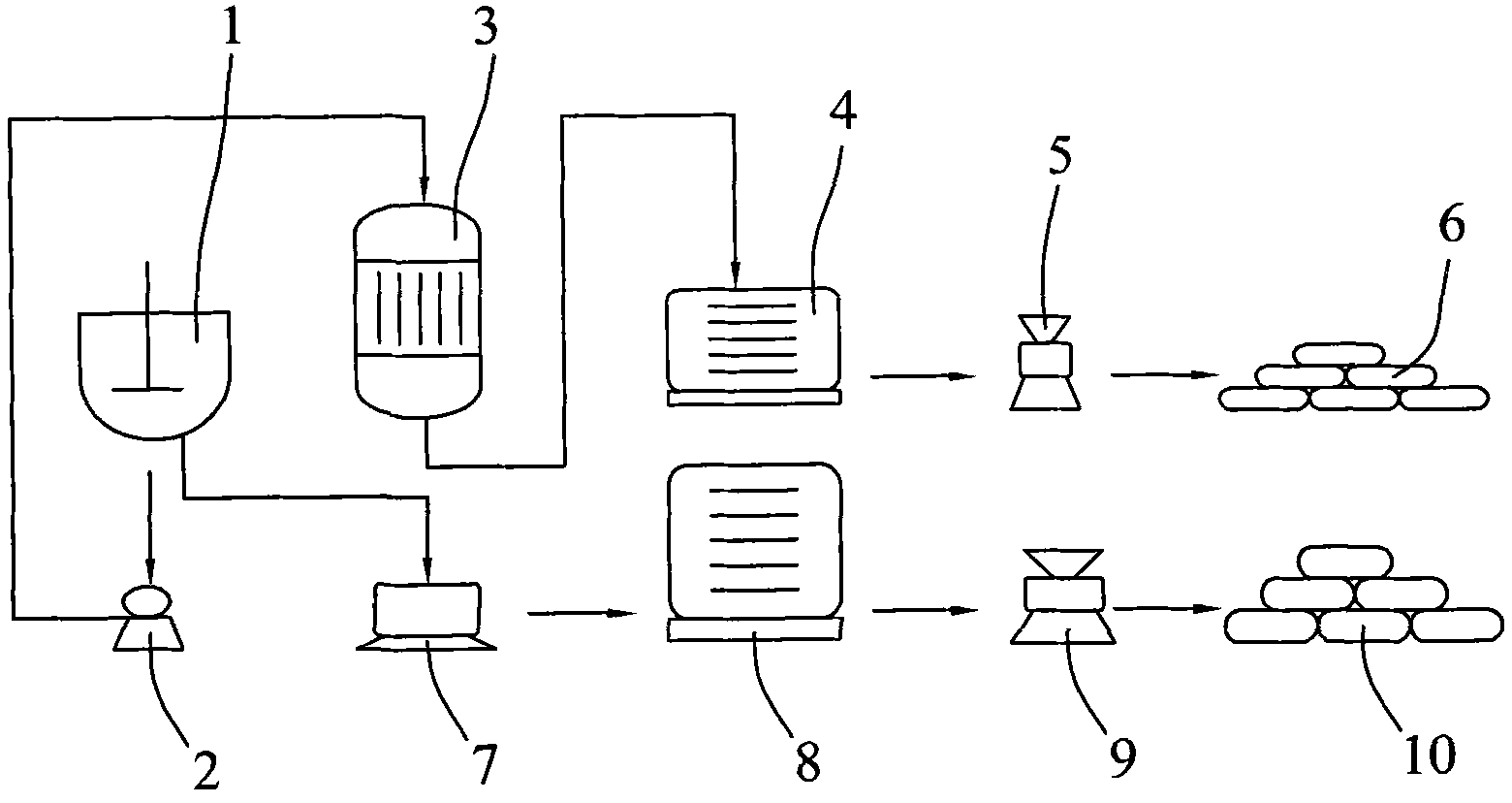

Composite premix feed for foxes and raccoon dogs

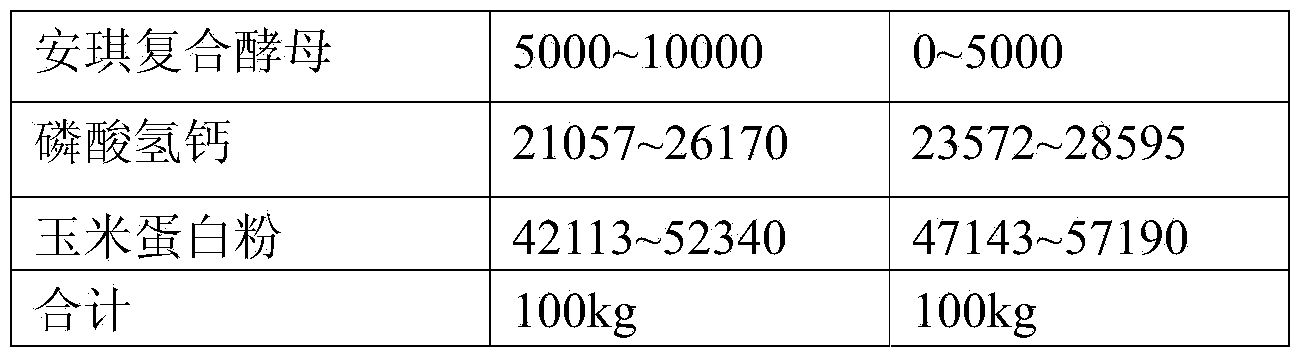

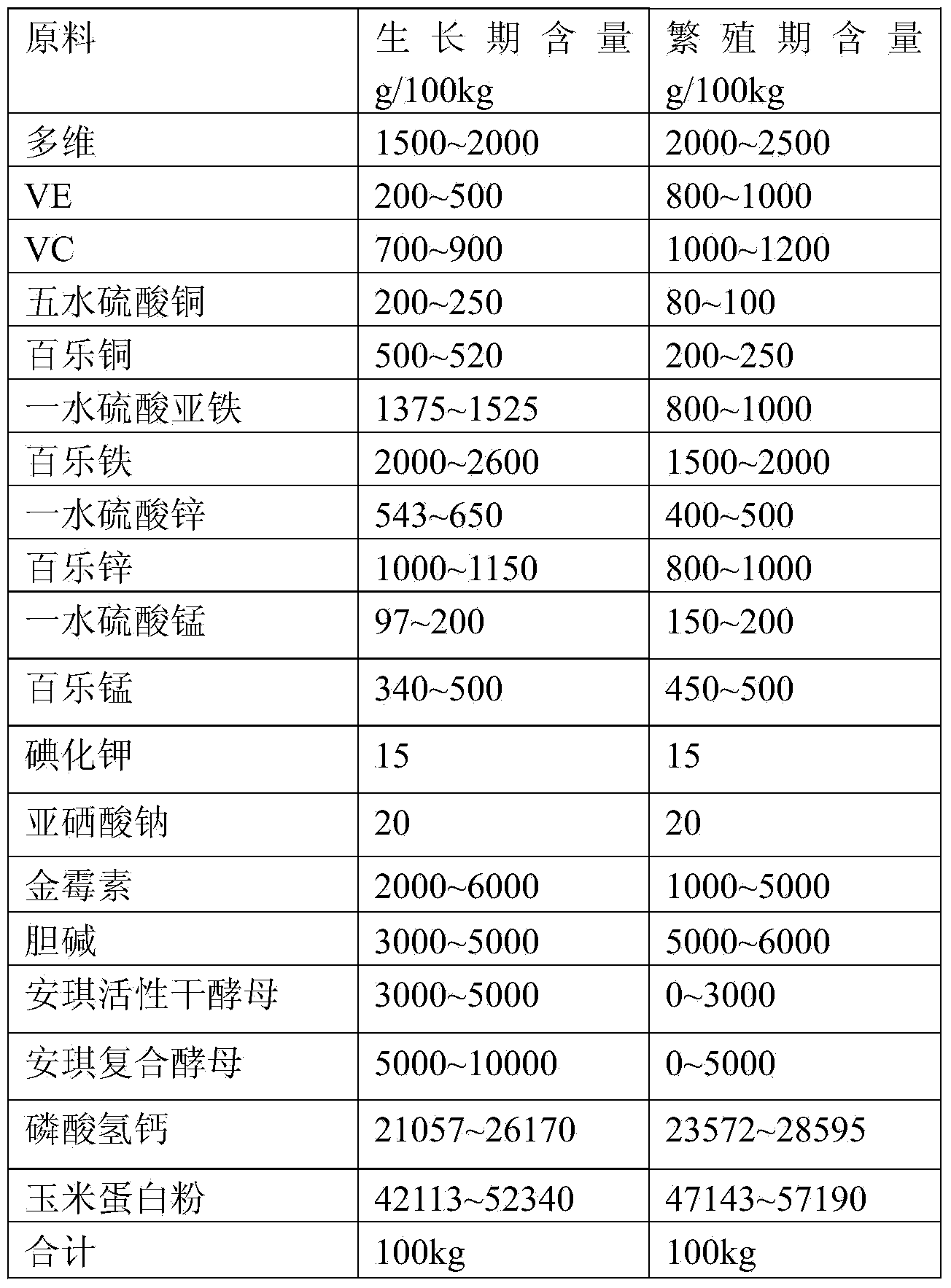

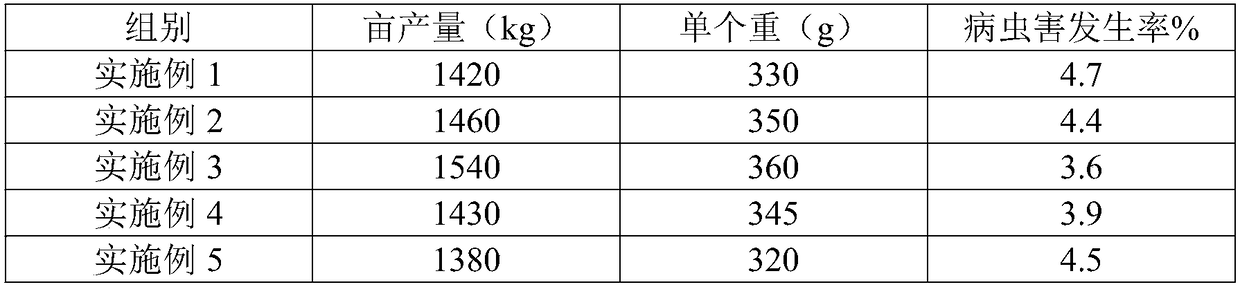

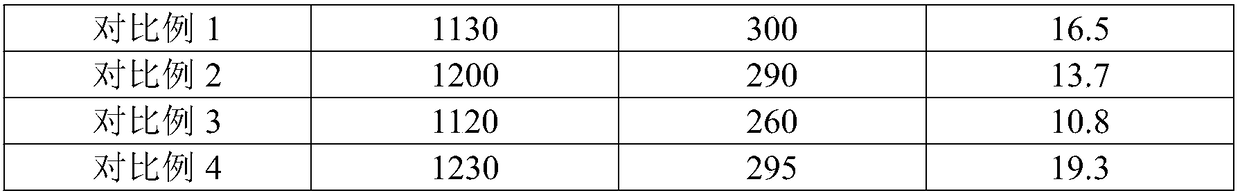

The invention relates to a composite premix feed for foxes and raccoon dogs. The composite premix feed is applied to the field of fox and raccoon dog breeding or the field of fur animal feed production and is particularly used for improving the productivity of the foxes and the raccoon dogs. The composite premix feed comprises formulas for the growth period and the reproduction period. The formula mainly comprises multi-vitamin, blue copperas, baile copper, ferrous sulfate monohydrate, baile iron, zinc sulfate monohydrate, baile zinc, manganese sulfate monohydrate, baile manganese, potassium iodide, sodium selenite, aureomycin, choline, angel active dry yeast, angel composite yeast, calcium hydrophosphate and corn protein powder. Composite premix feed constituents and contents of the constituents for two key production stages, namely the growth period and the reproduction period, of the foxes and the raccoon dogs are researched; the growth performance of the foxes and the raccoon dogs is improved, and the reproduction performance of seed beast is improved.

Owner:INST OF SPECIAL ANIMAL & PLANT SCI OF CAAS

Culture method for improving contents of cordyceps militaris hypha and cordycepin in silkworm chrysalis cordyceps

InactiveCN106810366AIncrease productionPromote secretionMagnesium fertilisersAlkali orthophosphate fertiliserTrace element compositionBiological activation

The invention belongs to the field of edible fungi cultivation, and particularly relates to a culture method for improving contents of cordyceps militaris hypha and cordycepin in silkworm chrysalis cordyceps. The method includes cultivation of cordyceps militaris hypha and cultivation of silkworm chrysalis cordyceps. The cultivation of cordyceps militaris hypha is prepared by performing culture activation in a solid culture base and cultivating liquid culture in a liquid culture base, wherein the solid culture base and the liquid culture base include 0.083-0.81% of trace element composition by weight; the trace element composition is selected from one or more of ferric sulfate tetrahydrate, zinc sulfate octahydrate, blue copperas, manganese sulfate monohydrate, sodium cobalt dehydrate; the technical scheme disclosed in the invention is simple in method, and high in efficiency.

Owner:北京新创青龙湖种植专业合作社

Copper electroplating dissolving solution and rapid high-depth blind hole filling process

The invention discloses a copper electroplating dissolving solution and a rapid high-depth blind hole filling process. The copper electroplating dissolving solution comprises a first additive, a second additive, a blue copperas solution, a sulfuric acid solution, a hydrochloric acid solution and purified water. The rapid high-depth blind hole filling process is completed by preparing the copper electroplating dissolving solution, filling holes in the initial phase, filling the holes in the outburst phase, filling the holes in the recovery stage, and changing current and time. In this way, through the copper electroplating dissolving solution and the rapid high-depth blind hole filling process, the blind holes in a circuit board are plated, the hole filling rate is high and is more than 95%, the surface of a plating is flat, and the flatness reaches over 95%; cavities and seams are avoided in hole filling and copper plating, the surface deposition thickness is small, and the ductility is good; good gloss, high toughness and low internal stress are achieved, and the quality of the circuit board is improved.

Owner:FOREWIN FPC SUZHOU

Lucid ganoderma laccase preparation and production method thereof

The invention relates to ganoderam lucidum karst laccase preparation, which in detail relates to a blue copperas- containing liquid laccase preparation produced with Ganoderma lucidum through inclined-plane culture and two- stage fermentation, the blue copperas concentration is 0.15- 0.40 mol / l. The culture medium of first- stage comprises amylaceum, maize flour, bran flour and water, and the culture condition is 25- 35 Deg. C and for 6- 12 days. The further fermentation culture medium comprises bran flour, peanut shell powder, maize flour and water, and the culture condition is 25- 35 Deg. C and for 3- 7 days. The enzymatic activity of said preparation is 32841.36U / l (taking ABTS as substrate). It can be used in field of textile, paper making, food and beverage after being diluted for 200- 250 times, and used for biological sensor production.

Owner:ANHUI UNIVERSITY

Method for controlling apple rot disease

The invention relates to a method for using the drug that prevents doting apple tree, wherein said method is characterized in plating blue copperas solution, which should be plated on to branches, cuts and saw cuts. The invention can reduce cost with simple process.

Owner:黄同宣

Planting method of juicy peach containing multiple trace elements

InactiveCN108184534ARich sourcesThe ratio is scientific and reasonableCalcareous fertilisersMagnesium fertilisersTrace element compositionAntioxidant

The invention belongs to the technical field of fruit planting, and particularly relates to a planting method of juicy peach containing multiple trace elements. The planting method includes steps of (1), soil preparation; (2), fixed planting; (3), fertilization management; (4), pest control; (5), reshaping and trimming; (6), harvesting. Through using planting base fertilizer consisting of seaweedfertilizer, chelating agent, antioxidant and trace elements, the absorbing efficiency of crops can be effectively improved, and the juicy peach is rich in multiple trace elements and other nutrient components; the planting base fertilizer has extremely strong effect in promoting crops growth and improving its nutrition value; besides, by applying the leaf fertilizer, fruit expanding fertilizer andothers, the fruit tree has faster absorbing speed, the nutrition use is more sufficient; the planting base fertilizer is prepared from seaweed fertilizer, ascorbic acid, hydroxylamine hydrochloride,xylitol, mannite, iron vitriol, manganese sulfate monohydrate, blue copperas, zinc sulphate monohydrate, disodium octaborate tetrahydrate, magnesium sulfate, and ammonium molybdate.

Owner:FOSHAN TUIQI AGRI RES INST GENERAL PARTNERSHIP +1

Feeding composite organic microelement additive and preparation method thereof

InactiveCN105494955AIncrease the gapPromote formationAccessory food factorsFeed additiveZinc sulphate monohydrate

The invention relates to the technical field of feed additive pretreatment, and in particular to a feeding composite organic microelement additive and a preparation method thereof. The additive is prepared by coating the surface of a composite organic microelement particle with a glycerol monolaurate layer and a pregelatinized starch layer from inside to outside in sequence, wherein the composite organic microelement particle is mainly prepared from the following raw materials: ferrous sulfate monohydrate, blue copperas, zinc sulphate monohydrate, manganese sulfate monohydrate, cobaltous sulfate heptahydrate, sodium selenite, organic acid, polysaccharide, peptide and protein. According to the additive, by taking the organic acid, the polysaccharide, the peptide and the protein as organic ligands to compound with various composite inorganic microelement compounds, the composite organic microelement microcrystal grains are produced, and the surface of each particle is coated with glycerol monolaurate and pregelatinized starch so as to isolate dissociation of gastric acid to composite organic microelements; after entering intestinal tracts, the composite organic microelement microcrystal particles release core composite organic microelements, therefore bioavailability of the composite organic microelements is increased.

Owner:河南艾德昕生物科技有限公司

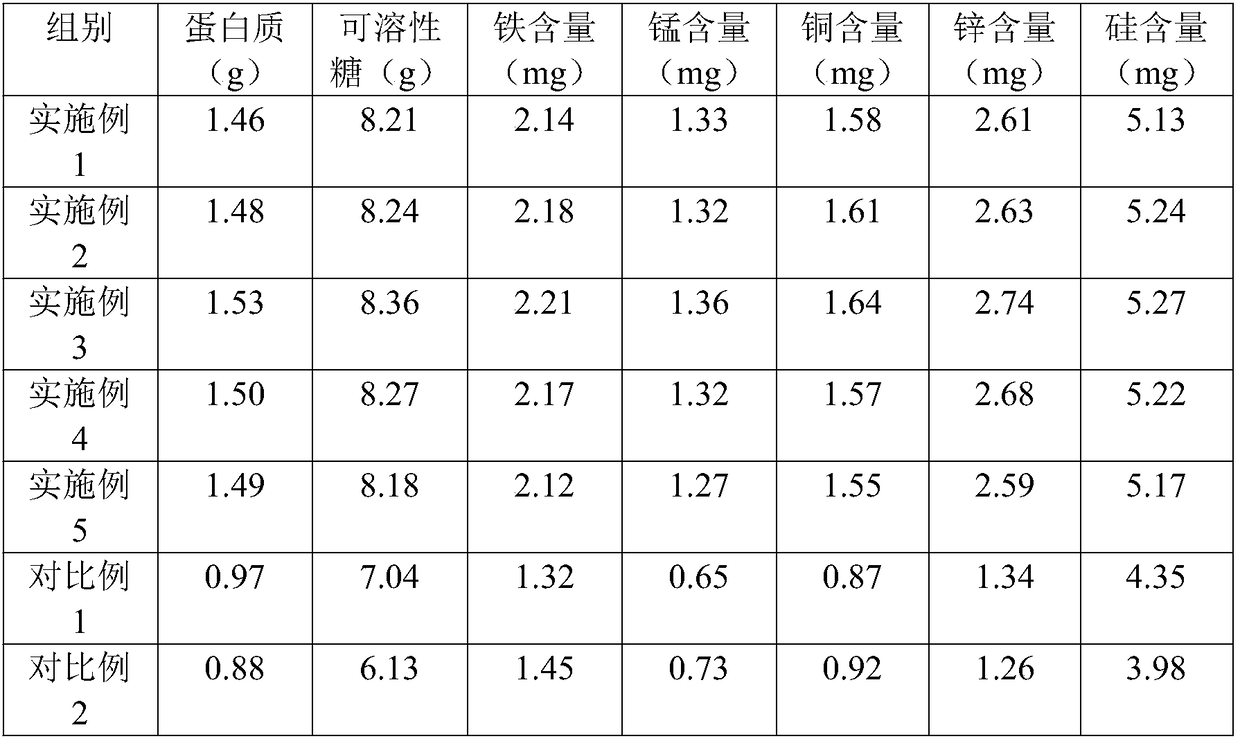

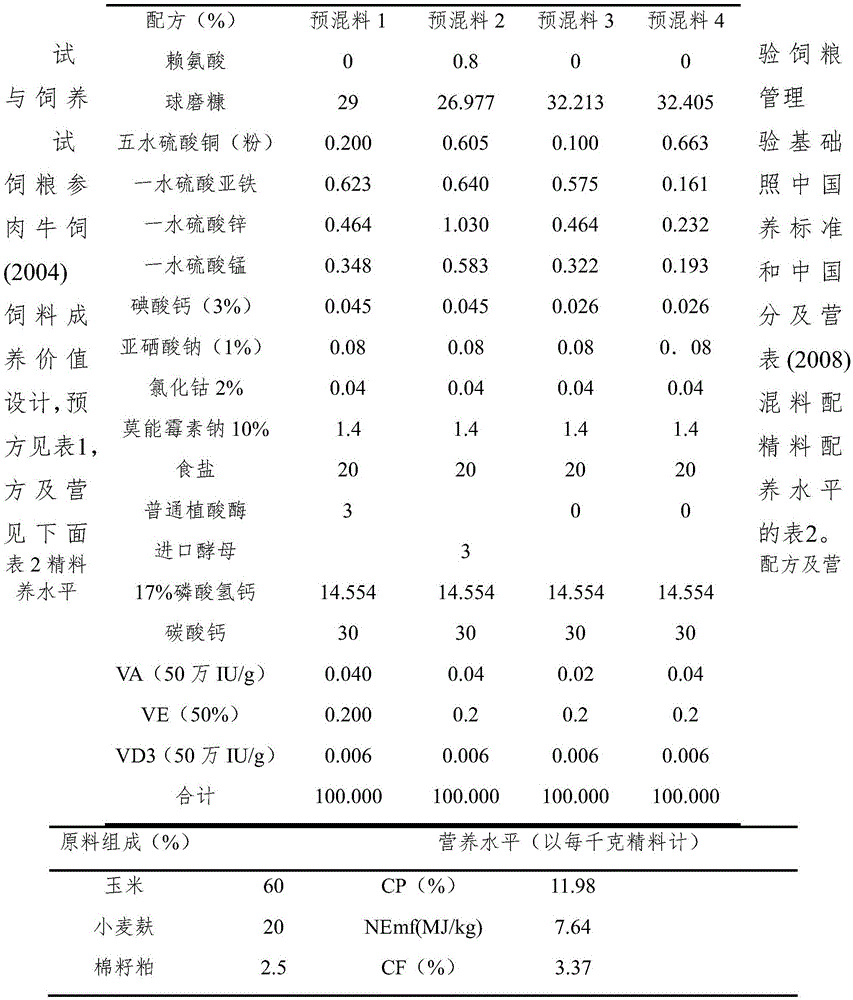

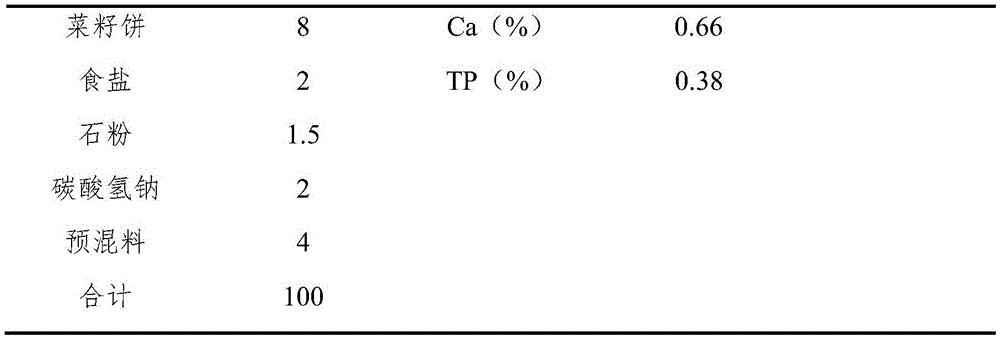

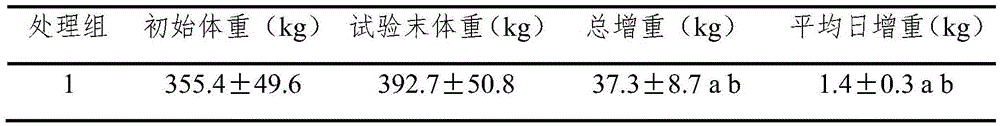

Beef cattle daily ration premixture with five-grain baijiu vinasse and feeding method

InactiveCN105638563AImprove use valueGood fattening effectFood processingAnimal feeding stuffFully developedCrossbred cattle

The invention relates to a beef cattle daily ration premixture with five-grain baijiu vinasse and a feeding method. The premixture is prepared from lysine, ball mill bran, blue copperas, ferrous sulfate monohydrate, zinc sulfate monohydrate, manganese sulfate monohydrate, calcium iodate, sodium selenite, cobalt chloride, monensin sodium, salt, common phytase, imported yeast, calcium hydrophosphate, VA, VE and VD3. The beef cattle feeding method includes the steps that 40 healthy simmental crossbred cattle with the similar age and weight are selected and divided into four groups in random; a pretest is conducted for 5 days, and a formal test is conducted for 27 days; neck frame type feeding is adopted, and the simmental crossbred cattle are fed on the five-grain baijiu vinasse daily ration twice a day and drink water twice. The optimal formula is screened and optimized, the five-grain baijiu vinasse feed resource is fully developed and used, the vinasse use ratio is increased, the cattle raising feed cost is reduced, an ideal fattening effect is achieved, and cattle raising benefits are increased.

Owner:宜宾市畜产品安全检测中心

Method for preparing blue copperas and co-producing calcium hydroxide by using phosphogypsum

InactiveCN101844788AReasonable production processSimple production equipmentCopper sulfatesCalcium/strontium/barium oxides/hydroxidesChemical reactionPhosphogypsum

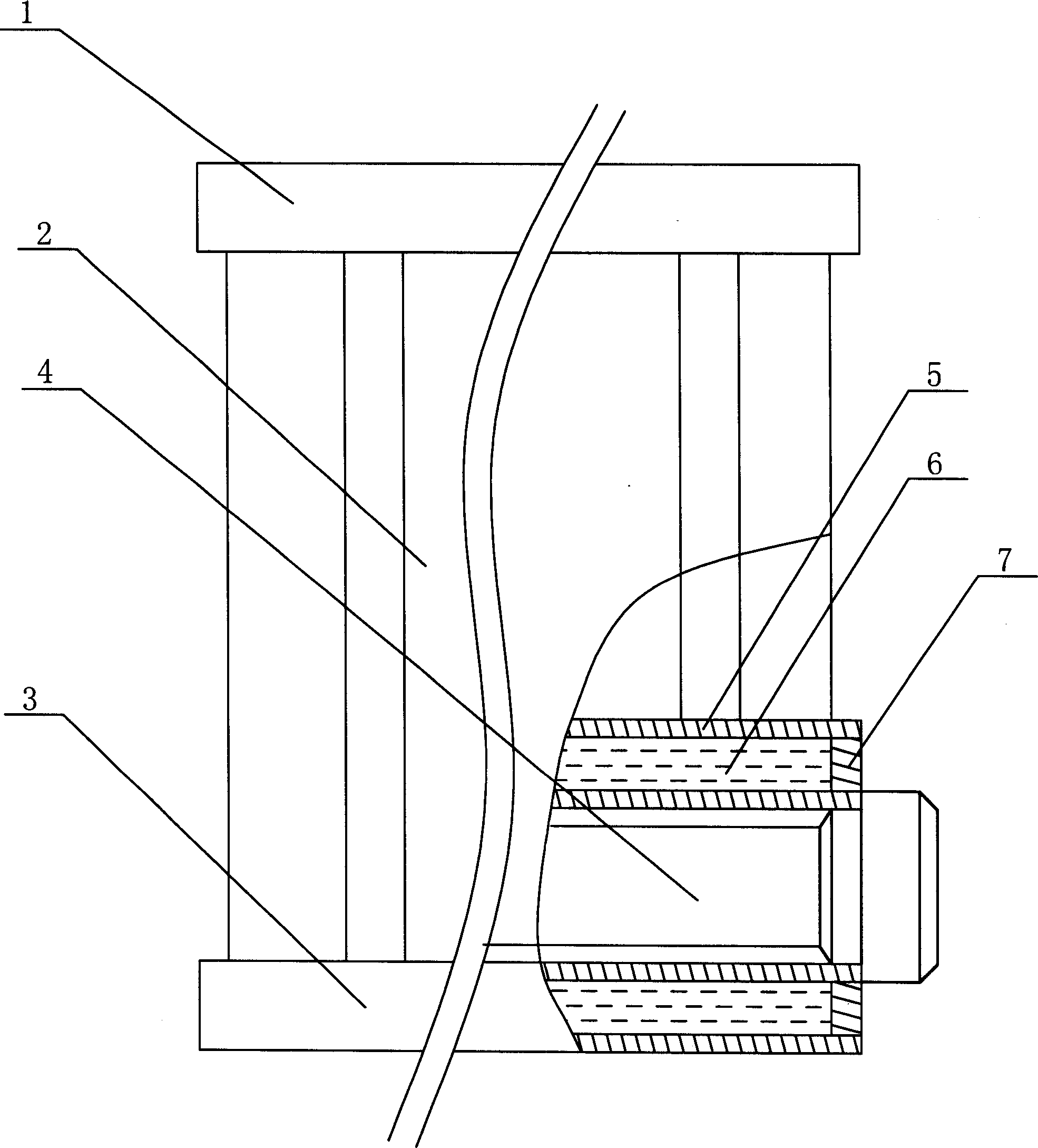

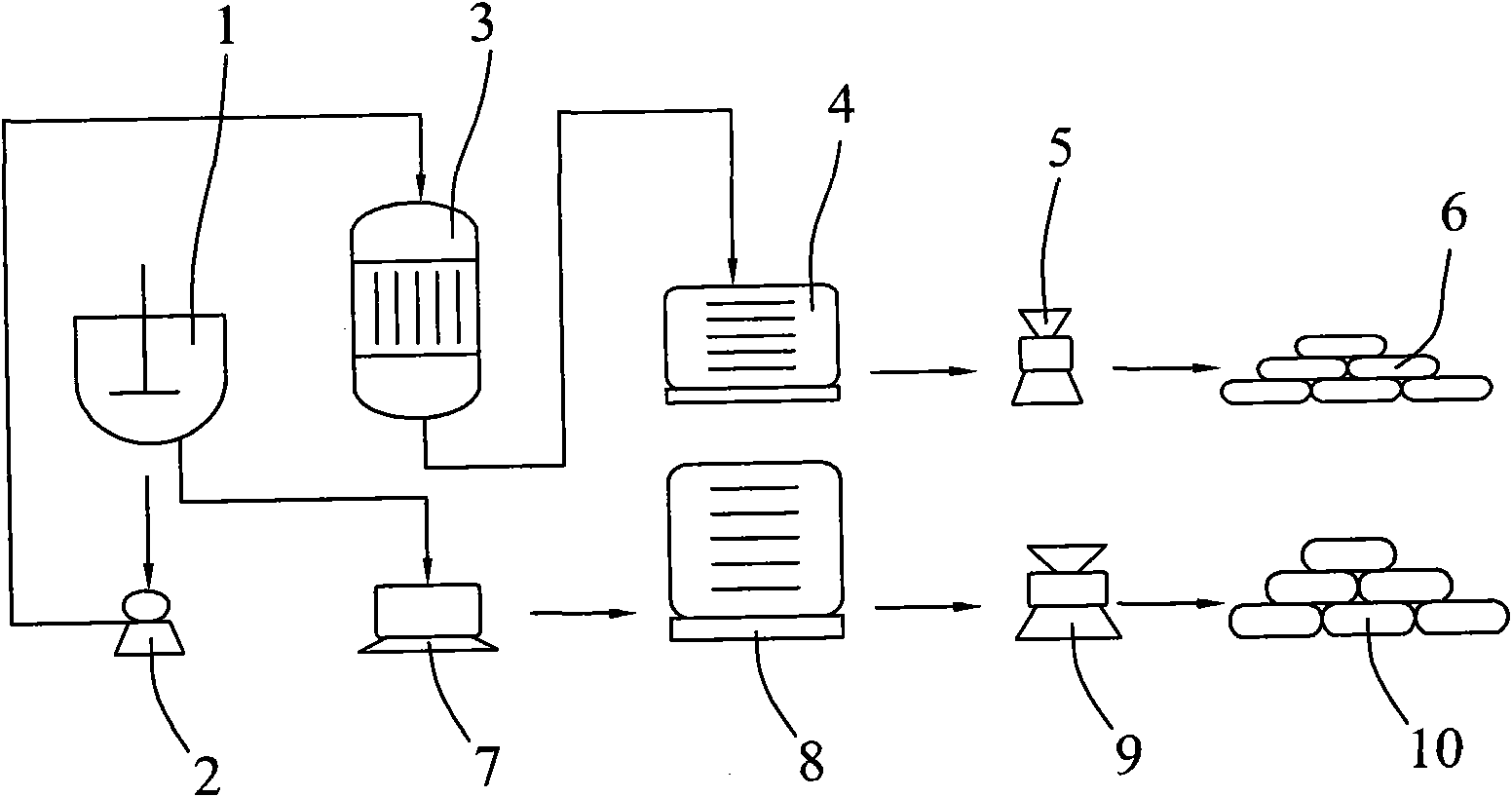

The invention discloses a method for preparing blue copperas and co-producing calcium hydroxide by using phosphogypsum. The method comprises the following steps of: (1) converting the amount of a pure substance of calcium sulfate contained in an industrial phosphogypsum product; throwing the phosphogypsum and the solution of copper hydroxide into a reactor; and performing a chemical reaction with slow stirring, wherein the mass ratio of pure substances of the calcium sulfate to the copper hydroxide is 1:0.52-0.92; (2) filtering a reaction product obtained in the step (1) in a filtering machine to obtain clarified solution of blue copperas and a calcium hydroxide filter cake; (3) feeding the clarified solution of the blue copperas obtained in the step (2) into a decompression distiller; distilling the solution of the blue copperas under a reduced pressure until the blue copperas starts separating out; discharging all of the blue copperas into a cooler for cooling to the normal temperature; and crashing the blue copperas by using a first crashing machine so as to obtain a blue copperas product; and (4) after washing the calcium hydroxide filter cake with water, centrifuging by using a centrifuge; performing solid-liquid separation; drying the solid by using a drier; and crashing the dried solid by using a second drier to obtain a calcium hydroxide product.

Owner:汪晋强

Microbial fermentation antibiont-free concentrated feed for pigs

InactiveCN104171744AGood for healthIncrease microbial contentAnimal feeding stuffBiotechnologyPotassium iodine

The invention discloses a microbial fermentation antibiont-free concentrated feed for pigs. The concentrated feed is prepared from the following raw material components in parts by weight: 100 parts of corn flour, 38 parts of bean pulp, 5 parts of Chenopodium album, 25 parts of spray protein, 25 parts of spray bran, 4 parts of compound trace elements, 5 parts of multivitamin, 10 parts of an enzyme additive and 25 parts of a fermented material additive, wherein the fermented material additive consists of lactobacillus plantarum, lactobacillus rhamnosus, bacillus licheniformis and lactic acid bacteria lactobacillus according to a mass ratio of 2:1:1:1; the compound trace elements consist of 30 percent of ferrous sulfate monohydrate, 8 percent of blue copperas, 9 percent of manganese sulfate monohydrate, 4 percent of zinc sulfate monohydrate, 2 percent of potassium iodide, 11 percent of calcium iodide and 36 percent of zeolite powder; and the enzyme additive consists of amylase, cellulase, protease and lipase according to a mass ratio of 2:1:1.5:1. The concentrated feed disclosed by the invention, without antibiotic drugs, is high in content of beneficial microorganisms and high in palatability, and can obviously improve the health level of pigs.

Owner:晋中市华阳农牧股份有限公司

Copper plating technology on graphite powder surface

The invention discloses a copper plating technology on graphite powder surface. The technology is as below: soaking the selected graphite raw material in a sodium hydroxide solution with concentration of 200 g / L for 30min, and washing with water to a neutral state; boiling the graphite in nitric acid solution with concentration of 20% for 20 min, then washing with water to neutral state, and drying at a temperature of 80 DEG C; preparing a plating solution from blue copperas, distilled water and sulfuric acid in the ratio of 1:100:2, then adding graphite, controlling the current density at 9A / dm<2> for 60-80 min, and indirectly mixing in the electroplating process, wherein the weight of the graphite and the plating solution is 1:150; after plating, washing to a neutral state, conducting passivation treatment by using 0.5% benzotriazole at the temperature of 50 DEG C for 7 min, and drying at 90 DEG C. The method has the advantages of simpleness, short plating time and low cost.

Owner:QINGDAO TAIHAODA CARBON MATERIAL

Nitrogen-phosphorus copper-zinc emission-reduction eco-friendly middle-stage pig compound premix feed

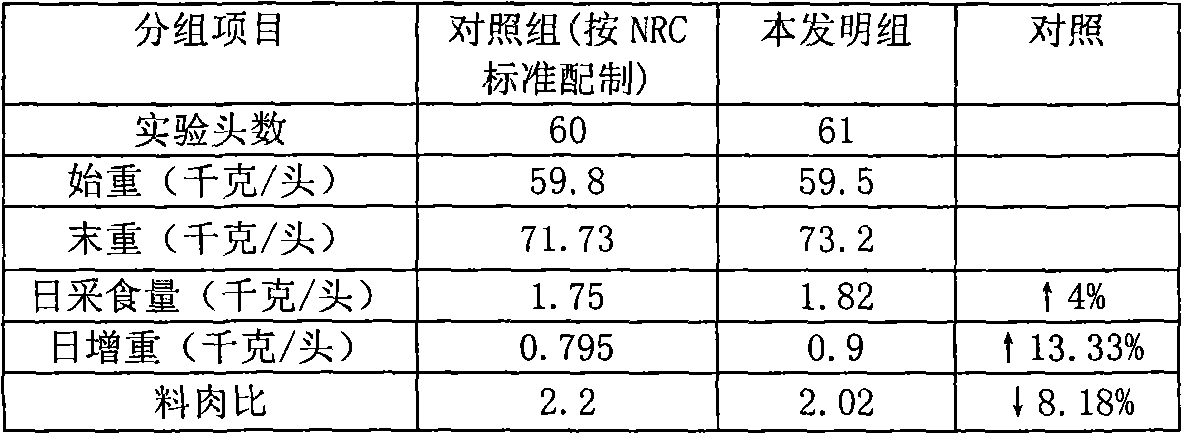

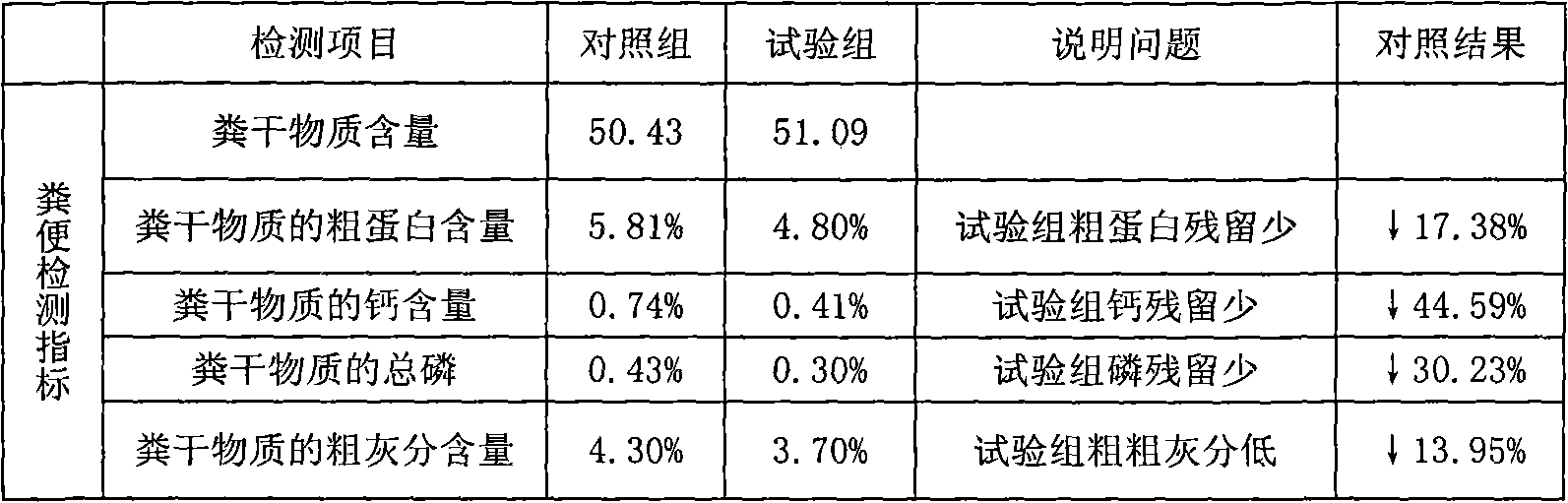

ActiveCN103750039AImprove utilization efficiencyReduce dosageFood processingAnimal feeding stuffPhytaseThreonine

A nitrogen-phosphorus copper-zinc emission-reduction eco-friendly middle-stage pig compound premix feed consists of raw materials by weight percentage: 0.616% of ferrous sulfate monohydrate, 0.308% of iron glycine, 0.611% of blue copperas, 0.123% of copper mothionine, 0.534% of zinc sulphate monohydrate, 0.18% of zinc methionine, 0.658% of manganese sulfate monohydrate, 0.013% of 1% sodium selenite premix, 0.012% of 1% cobalt chloride premix, 7.5% of sodium chloride, 5% of L-lysine, 2% of methionine, 1% of threonine, 0.8% of compound vitamin, 2.5% of compound enzyme, 1% of red skin pigment, 41% of mountain flour, 15% of calcium hydrogen phosphate, 2% of phytase, 0.05% of calcium propionate, 10% of zeolite powder, 8.795% of mixture of rice chaff and husk, and 0.3% of olaquindox. By changing the adding proportions of the L-lysine, the methionine, the threonine and the like, after the nitrogen-phosphorus copper-zinc emission-reduction eco-friendly middle pig compound premix feed provided by the invention is used, the nitrogen concentration of excrement can be reduced by 44%, the phosphorus concentration of the excrement can be reduced by 17%, the copper concentration of the excrement can be reduced by 45%, the zinc concentration of the excrement can be reduced by 34%, and the manganese concentration of the excrement can be reduced by 5%.

Owner:南城华农恒青农牧有限公司

PVC wood-plastic building material for heat insulation and water proofing of building

The invention discloses a PVC wood-plastic building material for heat insulation and water proofing of a building. The PVC wood-plastic building material is prepared by, by weight, 100-105 parts of polyvinyl chloride, 15-18 parts of kaolin, 30-35 parts of wood powder, 5-7 parts of carbonyl iron powder, 0.8-1.2 parts of blue copperas, 4-6 parts of nitrile rubber, 0.2-0.4 part of titanate coupling agent NDZ201, 0.4-0.6 part of silane coupling agent YH62, 3-4 parts of fatty acid soap, 5-6 parts of alundum powder, 6-7 parts of steel slag powder and 3-4 parts of olive oil. The PVC wood-plastic building material has high performance in the aspects of corrosion prevention, heat insulation, water proofing and fire proofing; the wood powder is high in filling quantity, and the PVC wood-plastic building material has good mechanical performance and high practicability.

Owner:ANHUI BEIMA TECH CO LTD

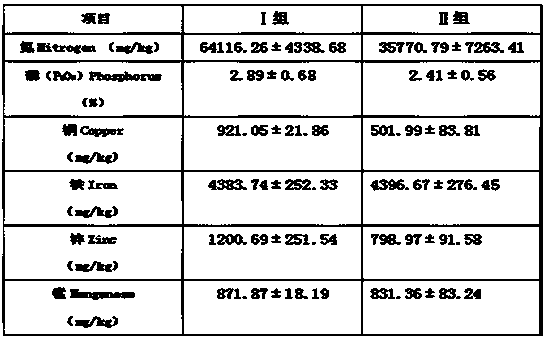

Preparation method of flame retardant conductive fiber

A preparation method of a flame retardant conductive fiber comprises the specific steps of: immersing pretreated fiber, yarn or tows in a conductive liquid; heating up to 90-100 DEG C; and soaking for 1-2 h until the fiber turns uniform bright black. The conductive liquid comprises 100-200g / L blue copperas, 150-250 g / L sodium thiosulfate, 0.3-0.5g / L scandium and 0.5-0.7g / L yttrium. The method modifies a same base fiber to obtain functional fiber with flame retardance and electrical conductivity, and the price of the fiber is significantly lower than that of a product with similar performance.

Owner:无锡中斯盾科技有限公司

Electroplate liquid of alkaline electrocoppering titanium alloy and preparing method and electroplating technology of electroplate liquid

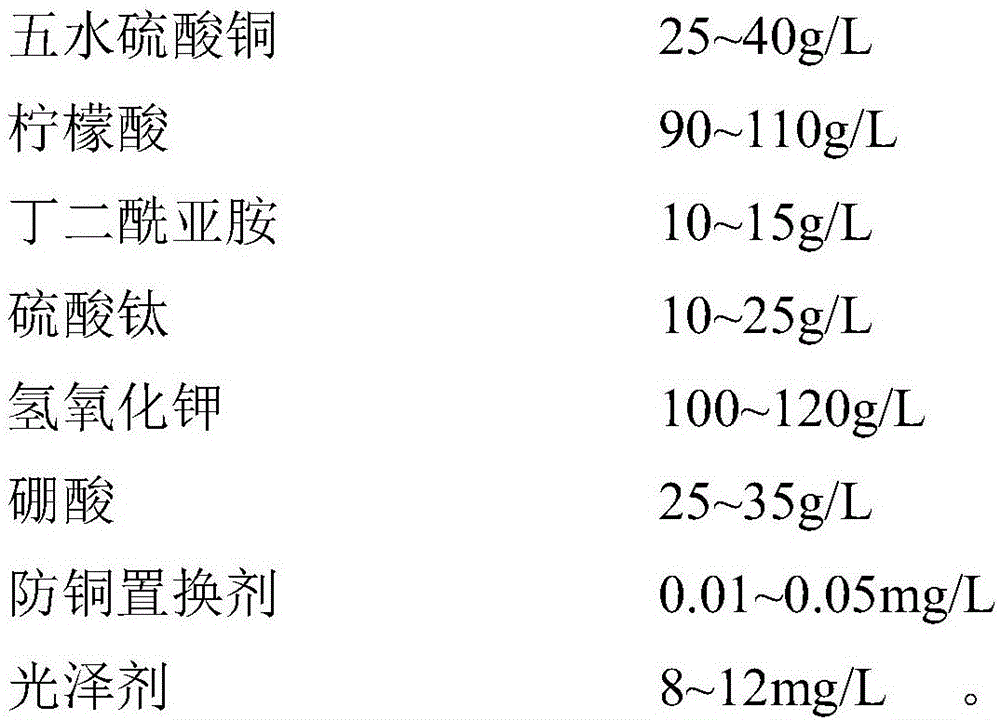

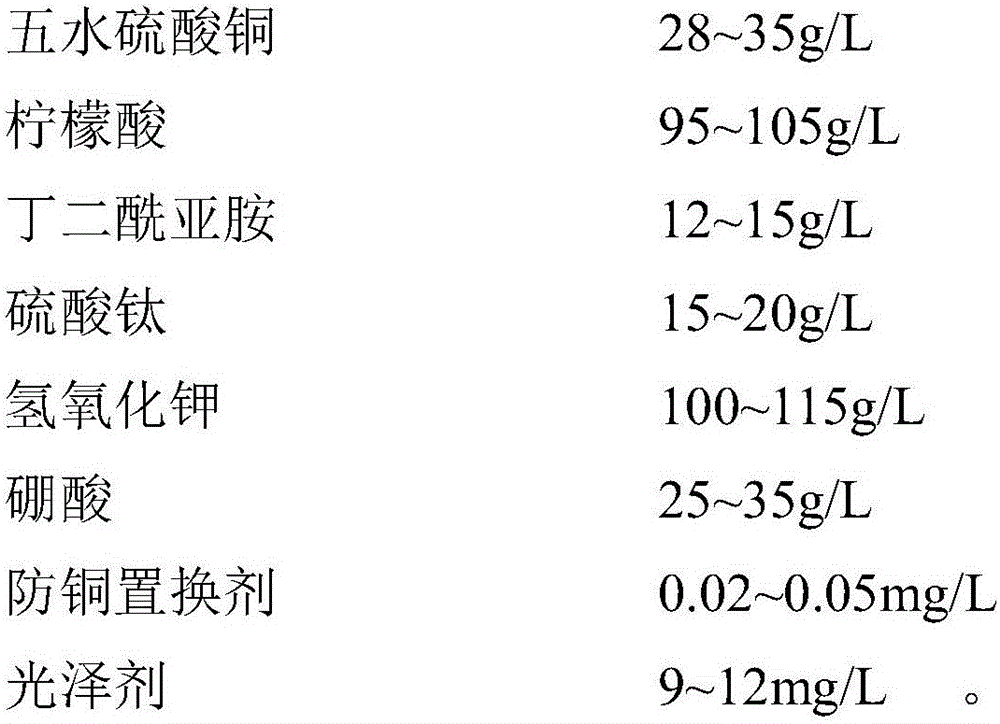

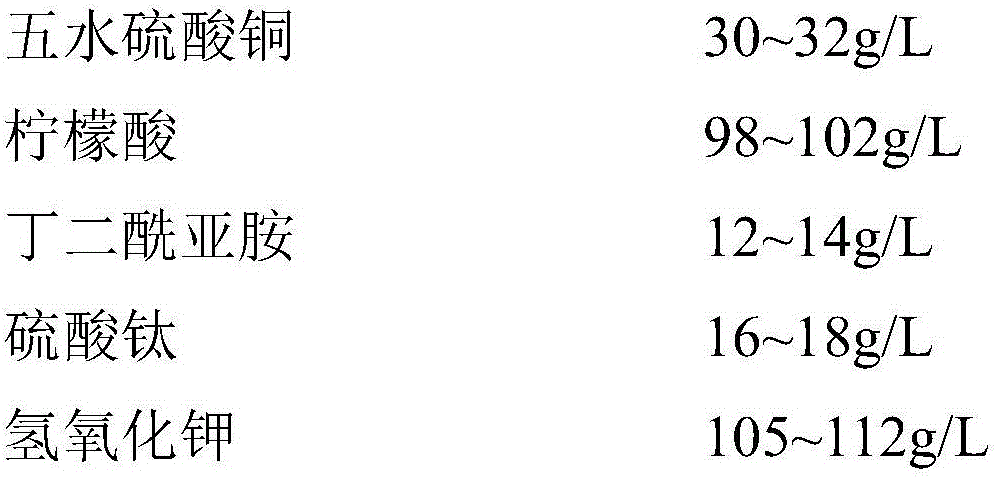

InactiveCN105862092AStrong resistance to sulfide corrosionHighly corrosivePotassium hydroxideSulfide

The invention discloses an electroplating solution for alkaline electroplating copper-titanium alloy, a preparation method and an electroplating process. The formula of the electroplating solution is as follows: copper sulfate pentahydrate 25-40g / L, citric acid 90-110g / L, succinyl Amine 10-15g / L, titanium sulfate 10-25g / L, potassium hydroxide 100-120g / L, boric acid 25-35g / L, anti-copper replacement agent 0.01-0.05mg / L, gloss agent 8-12mg / L. The electroplating solution of the present invention is cyanide-free and phosphorus-free, and the electroplating process can obtain copper-titanium copper that is bright, fine, harder than a pure copper layer, strong in wear resistance, good in bonding with meridian rubber, and strong in sulfide corrosion resistance alloy plating.

Owner:武汉吉和昌新材料股份有限公司 +1

Pig feed and production method thereof

The invention relates to a pig feed and a production method thereof. the pig feed comprises the following components in percentage by weight:62-63% of corn starch, 8-9% of wheat bran, 23-24% of soy bean meal, 3.8-4.2% of premix and 1.2-1.8% of fat powder, wherein the premix comprises the following components in percentage by weight: 3.5-4% of zeolite powder, 0.18-2.2% of choline, 0.1-0.13% of blue copperas, 0.09-0.1% of ferrous sulfate monohydrate, 0.04-0.06% of zinc sulphate monohydrate, 0.04-0.05% of manganese sulfate monohydrate, 0.03-0.05% of cobalt chloride, 0.015-0.016% of sodium selenite, 0.06-0.07% of potassium iodide, 0.07-0.08% of multiple vitamins for pig, 0.02-0.03% of betaine, 0.02-0.03% of phytase and 0.02-0.05% Gannan medical stone. The production method of the pig feed comprises the following steps of: respectively crushing the materials to 6-12 meshes, lifting the crushed materials into a powder material bin, then conveying to a mixing tank under the accurate control of a computer and then conveying to a mixer for mixing to obtain the premix, then pouring in the mixer from a small material port of the mixer; and mixing for 5-6 minutes, discharging and lifting to ato-be-prepared bin, conveying the mixture into a granulator to prepare the mixture into granules, cooling in a cooling tower, then lifting to a classifying screen and screening the granules on the classifying screen, conveying qualified granules into a finished product bin, granulating the unqualified granules again by the process flow, and packaging the finished products with fine plastic bags for sale.

Owner:赣州正康生物科技有限公司

Stable electroplate liquid

The invention relates to the technical field of electroplate liquid, in particular to a stable electroplate liquid. The stable electroplate liquid comprises blue copperas, sulfuric acid, hydrochloricacid, an accelerator and a wetting agent; the accelerator is a mixture of one or more mercaptan compounds; the wetting agent is a mixture of one or more polyalcohol compounds; and the concentration ofthe blue copperas of the stable electroplate liquid is 70-85 g / L, the concentration of the sulfuric acid is 96-108mL / L, the concentration of the hydrochloric acid is 44-65mg / L, the concentration of the accelerator is 0.5-0.9mL / L, and the concentration of the wetting agent is 13-20mL / L. The stable electroplate liquid has the advantages of good stability, high uniform coverage ability and fast electroplating speed, and can be used in various industrial plating fields.

Owner:阿尔发埃德伟控汽车配件有限公司

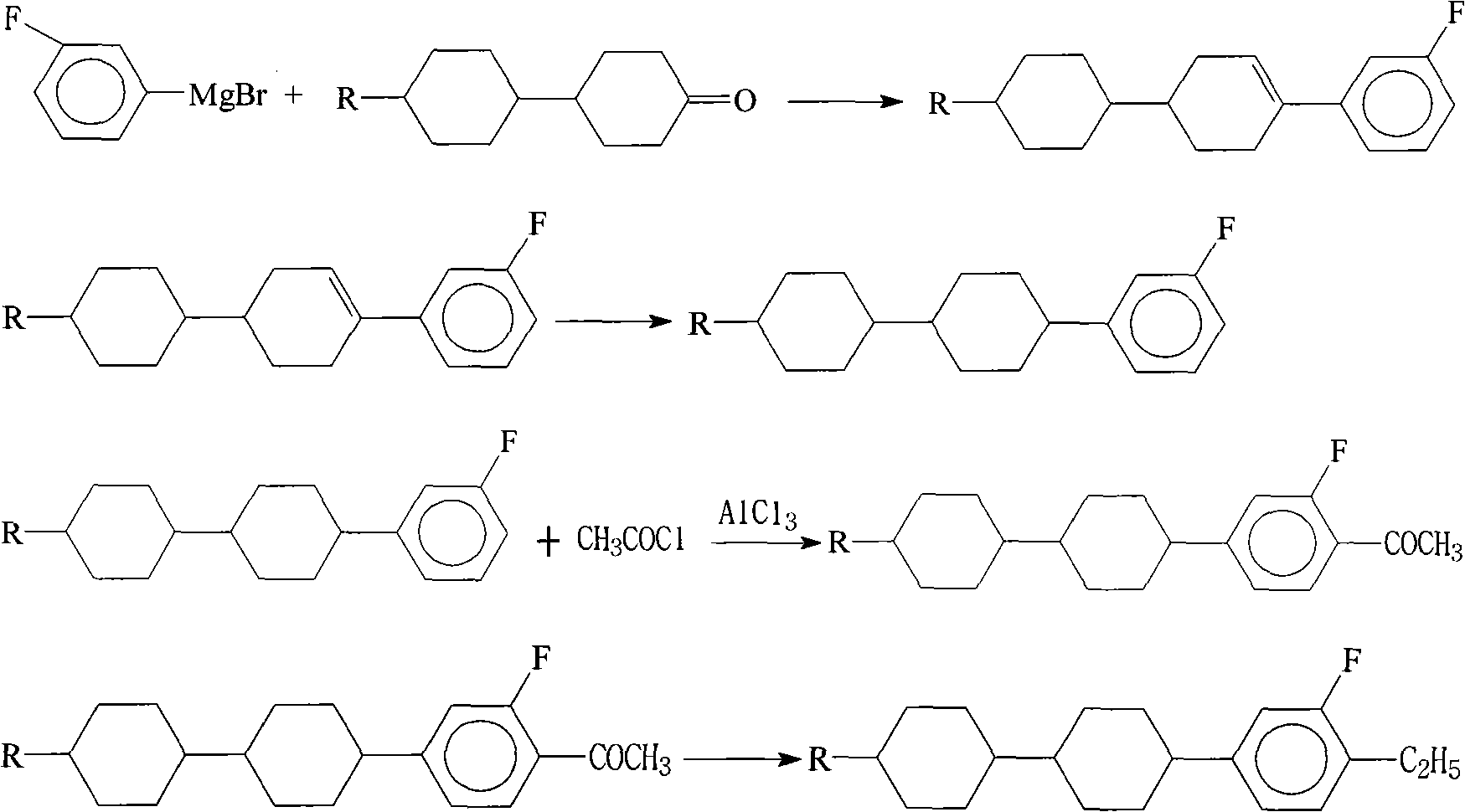

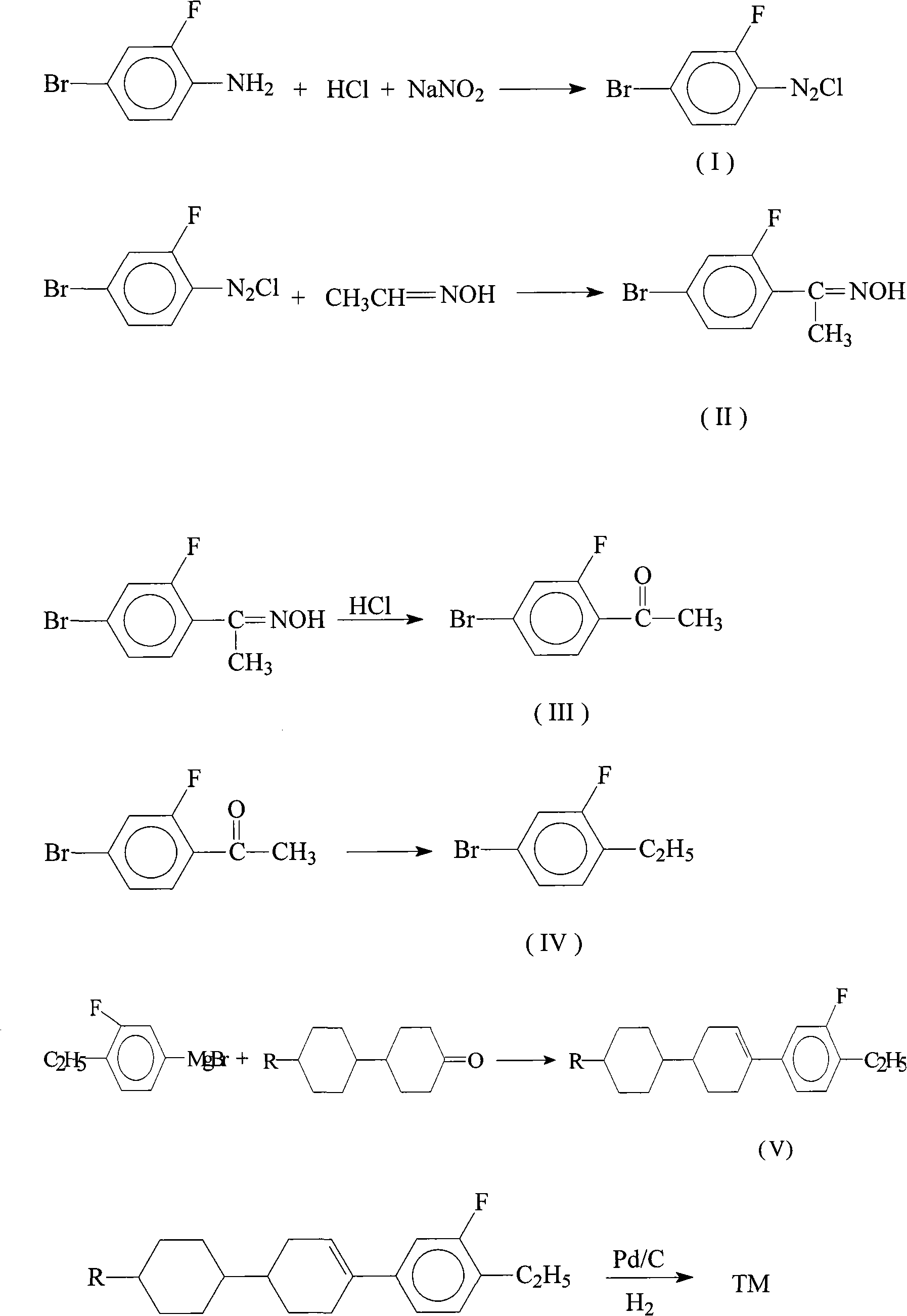

Method for synthesizing dicyclohexyl o-fluoroethylbenzene liquid crystal compound

InactiveCN101781165AHigh purityEasy to operateOrganic compound preparationHalogenated hydrocarbon preparationGrignard reagentDiethyl ether

The invention provides a method for synthesizing a dicyclohexyl o-fluoroethylbenzene liquid crystal compound, comprising the following steps: (1) using o-fluoro-p-bromoaniline as the raw material to react with sodium nitrite in the presence of hydrochloric acid to generate a compound (I); (2) reacting the compound (I) with acetaldoxime under the catalysis of blue copperas to obtain a compound (II); (3) hydrolyzing the compound (II) with hydrochloric acid to obtain a compound (III); (4) carrying out Huang-Minlon reduction on the compound (III) to obtain a compound (IV); (5) preparing the compound (IV) into a grignard reagent in tetrahydrofuran or diethyl ether, then reacting the grignard reagent with alkyldicyclohexylanone, and acidizing and dehydrating the reactant to obtain a compound (V); and (6) carrying out hydrogenation reduction on the compound (V) to obtain the compound shown in the molecular formula. By synthesizing the intermediate o-fluoro-p-bromoethylbenzene, the invention provides a new method for synthesizing bicyclohexane liquid crystal compound. The method is simple to operate and safe and can effectively improve the purity and the yield of the target compound.

Owner:BEIJING BAYI SPACE LCD MATERIALS TECH

Biochemical detection liquid for glucose in urine

InactiveCN1570632AQuick checkFast wayMaterial analysis by observing effect on chemical indicatorBiological testingSodium carbonate anhydrousCopper sulfate

This is a biochemistry detection liquid of urine glucose comprising 9.8-17.3w / v percents citric acid trisodium (sodium citrate) 5.3-100w / v percents anhydrous sodium carbonate, 1.3-1.73w / v percents blue copperas and distilled water. This invention offers biochemistry detection liquid and self-checking method of urine glucose for the mass scoutting and checking dynamically. Through the recording curve diagram in accordance with series detecting color result one can self-judge something: 1, warning signal of health and pathogenic factor; 2. forepart detectable rate of diabetes mellitus; 3, the synchronous tracking monitoring of curative effect during the treating course. The above liquid offers the likelihood of carrying out all this function.

Owner:赵青华

Preparation method of plating solution for copper plating on graphite powder surface

InactiveCN104593757AGuaranteed stabilityLiquid/solution decomposition chemical coatingAcetic acidCopper plating

The invention discloses a preparation method of a plating solution for copper plating on graphite powder surface. The method is as below: (1) weighing blue copperas, formaldehyde, EDTA, potassium sodium tartrate and a stabilizer according to the ratio of 1:1.6:1.6:1:0.001; and (2) fully dissolving and mixing the raw materials at the temperature of 60 DEG C, and adjusting the pH at 12-13 by using a 20% aqueous solution of sodium hydroxide. The invention uses the 20% aqueous solution of sodium hydroxide to adjust the pH at 12-13, and ensures the stability of plating solution, so as to ensure the continuousness, stability and uniformity of the coating.

Owner:QINGDAO TAIHAODA CARBON MATERIAL

Chemical copper plating solution

InactiveCN103160817AReduce pollutionAvoid damageLiquid/solution decomposition chemical coatingCopper platingCopper sulfate

The invention discloses a chemical copper plating solution. The chemical copper plating solution comprises, by weight, 10g / L to 15g / L of blue copperas, 20g / L to 30g / L of copper sulfate, 150g / L to 250g / L of sulfuric acid, 50g / L to 80g / L of citric acid, 100g / L to 150g / L of sodium hypophosphite, 15g / L to 25g / L of polyethylene imine alkyl salt, 1g / L to 5g / L of thiocarbamide and the balance water. Potential of hydrogen (PH) is 8 to 10, temperature is 40 DEG C to 60 DEG C, and copper plating time is 10 minutes to 15 minutes. The chemical copper plating solution is reasonable in formula, has no cyanide and formaldehyde, reduces environmental pollution and harm on staff, and is good in stability of the plating solution, long in service life and good in coating quality.

Owner:李平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com