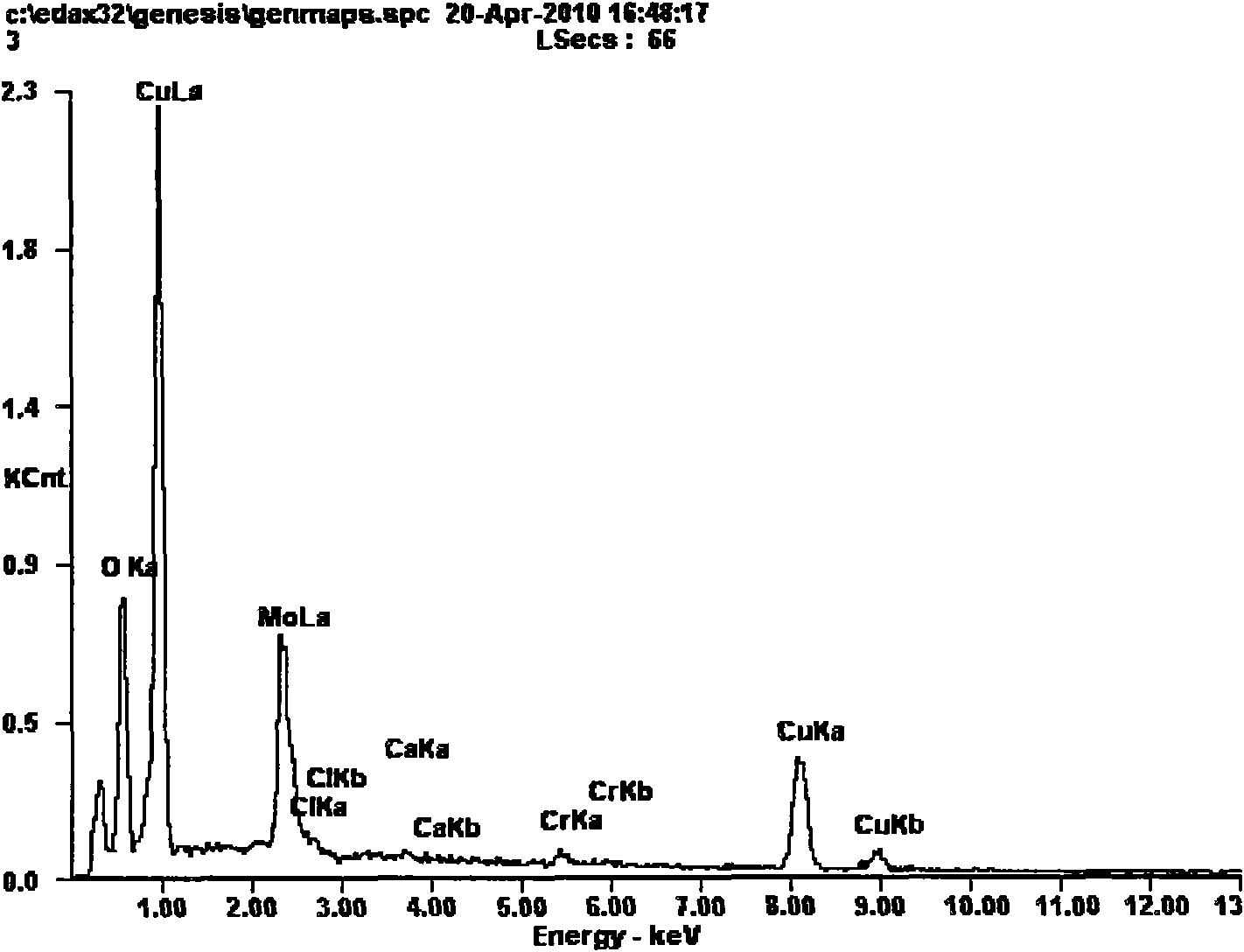

Copper-chromium-molybdenum ternary alloy coating and preparation method thereof

A ternary alloy and coating technology, applied in the field of copper-chromium-molybdenum ternary alloy coating and its preparation, can solve the problems of increased smelting segregation, increased crack notch sensitivity, unrealistic hardness and strength, and improved surface hardness. , the preparation method is simple, the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take a beaker washed with distilled water, add 60ml of distilled water to it, weigh and add 1.5g of C 6 h 8 o 7 (citric acid), to be C 6 h 8 o 7 Add 2.5g of Na after complete dissolution 2 MoO 4 ·6H 2 O, stir well to make Na 2 MoO 4 ·6H 2 O is completely dissolved, then add sulfuric acid to adjust the pH value of the solution to 2.6, after the adjustment is completed, add 0.4g of LaCl 3 ·nH 2 O and 2g of (NH 4 ) 2 SO 4 , adjust the pH value of the solution to 3.0 with sulfuric acid, and then add 7.5g of CuSO 4 ·5H 2 O, 7.5g of Cr 2 (SO 4 )3 ·6H 2 O and 3g of H 3 BO 3 , it is required that the previous drug is completely dissolved before adding the next drug, and adding distilled water to 100ml, and finally adjusting the pH value to 2.5 with sulfuric acid to obtain the electroplating solution, which is placed in the plating tank;

[0035] (2) Use a 20×10mm pure copper sheet as a plated piece, protect the non-plating surface (back) with insulating...

Embodiment 2

[0037] (1) Take a beaker washed with distilled water, add 60ml of distilled water to it, weigh and add 1.5g of C 6 h 8 o 7 (citric acid), to be C 6 h 8 o 7 Add 2.5g of Na after complete dissolution 2 MoO 4 ·6H 2 O, stir well to make Na 2 MoO 4 ·6H 2 O is completely dissolved, then add sulfuric acid to adjust the pH value of the solution to 2.7 lower than required, after the adjustment is completed, add 0.4g of LaCl in turn 3 ·nH 2 O, 3g of NH 4 COOH and 5g of (NH 4 ) 2 SO 4 ,, adjust the pH value of the solution to 2.8 with sulfuric acid, and then add 7.5g of CuSO 4 ·5H 2 O, 7.5g of Cr 2 (SO 4 ) 3 ·6H 2 O and 4g of H 3 BO 3 . It is required that the last drug is completely dissolved before adding the next drug, and add distilled water to 100ml, and finally adjust the pH value to 3.2 with sulfuric acid again to obtain the electroplating solution, and place the electroplating solution in the plating tank;

[0038] (2) Use a 20×10mm pure copper sheet as a ...

Embodiment 3

[0040] (1) Take a beaker washed with distilled water, add 60ml of distilled water to it, weigh and add 1.5g of C 6 h 8 o 7 (citric acid), to be C 6 h 8 o 7 After complete dissolution, add 1.5g of Na 2 MoO 4 ·6H 2 O, stir well to make Na 2 MoO 4 ·6H 2 O is completely dissolved, then add sulfuric acid to adjust the pH value of the solution to 2.7 lower than required, after the adjustment is completed, add 0.4g of LaCl in turn 3 ·nH 2 O, 5g of NH 4 COOH and 7g of (NH 4 ) 2 SO 4 , adjust the pH value of the solution to 2.1 with sulfuric acid, and then add 7.5g of CuSO 4 ·5H 2 O, 7.5g of Cr 2 (SO 4 ) 3 ·6H 2 O and 4g of H 3 BO 3 , it is required that the previous drug is completely dissolved before adding the next drug, and adding distilled water to 100ml, and finally adjusting the pH value to 3.2 with sulfuric acid again to obtain the electroplating solution, which is placed in the plating tank;

[0041] (2) Use a 20×10mm pure copper sheet as a plated piece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com