Oil-soluble molybdenum caprylate catalyst as well as preparation method and application thereof

A catalyst and oil-soluble technology, which is applied in the field of preparation of oil-soluble molybdenum octoate catalyst, can solve the problems of low metal content, high storage requirements, external vulcanization and other problems, and achieves the effects of low solid content, good dispersion effect and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

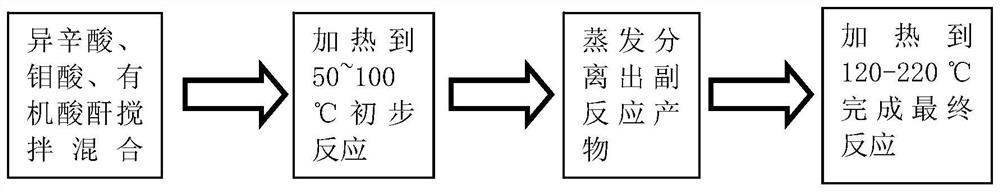

[0031] A kind of oil-soluble molybdenum octoate catalyst provided by the present example and preparation method thereof, comprises the steps:

[0032] 1) Add molybdic acid, acetic anhydride, and isooctanoic acid into the container at a molar ratio of 1:2:4, and mix them uniformly with an electromagnetic stirrer to obtain a mixed solution;

[0033] 2) Under the action of stirring, heat the mixture to 70°C and react for 1 hour;

[0034] 3) heating under vacuum to remove by-reaction product acetic acid;

[0035] 4) Heating to 150° C. to continue the reaction for 2 hours, and the oil-soluble molybdenum octanoate catalyst can be prepared after the reaction is completed.

Embodiment 2

[0037] A kind of oil-soluble molybdenum octoate catalyst provided by the present example and preparation method thereof, comprises the steps:

[0038] 1) Take ammonium molybdate, acetic anhydride, and isooctanoic acid and add them to the container to ensure that molybdenum atoms, acetic anhydride, and isooctanoic acid are added to the container at a molar ratio of 1:3:5, and mix evenly with an electromagnetic stirrer to obtain a mixed solution;

[0039] 2) Under the action of stirring, heat the mixture to 80°C and react for 1.5h;

[0040] 3) heating under vacuum to remove by-reaction product acetic acid;

[0041] 4) Heating to 160° C. to continue the reaction for 2 hours, and the oil-soluble molybdenum octanoate catalyst can be prepared after the reaction is completed.

Embodiment 3

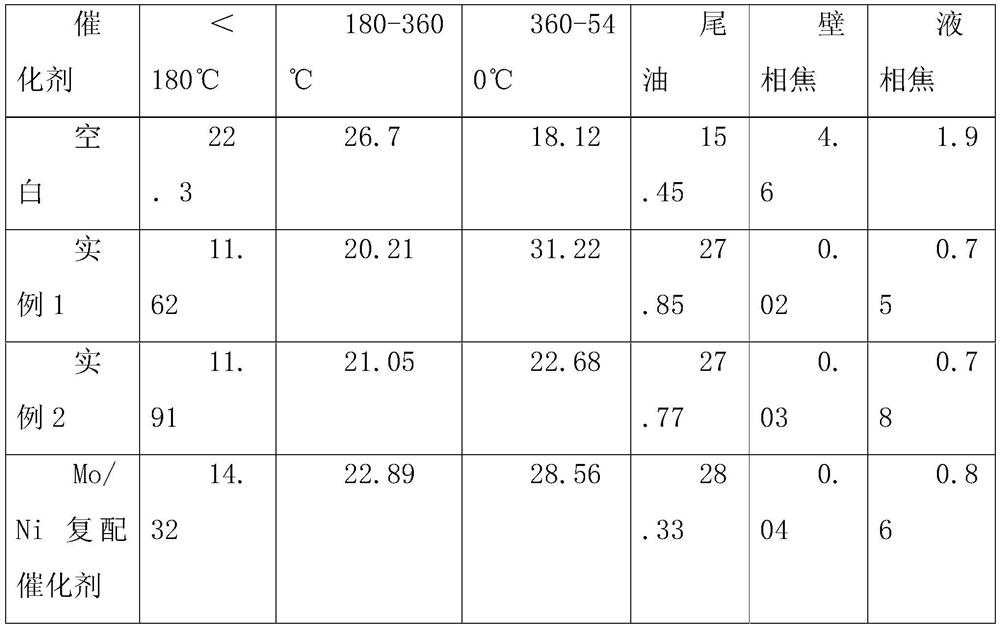

[0043] The catalyst prepared in the above examples was used in the suspended bed hydrocracking reaction for slagging reduction in the Middle East, and a blank Mo / Ni composite catalyst (Mo:Ni=1:1) prepared by adding metal Ni was used under the same conditions For comparison, the reaction temperature is 432°C, the reaction pressure is 12MPa, the reaction time is 60min, and 150ppm of catalyst (in terms of active metal total amount) is added. The properties of raw materials are shown in Table 1 below, and the distribution of test products is shown in Table 2 below:

[0044] Table 1. Raw oil properties

[0045] Analysis Project Middle East Slag Reduction Density (20℃), g / cm3 1.03 S content, wt% 5.1 N content, wppm 5420 Carbon residue, wt% 21.6 Ni content, wppm 65 V content, wppm 212

[0046] Table 2. Distribution of test products

[0047]

[0048] As can be seen from Table 2, compared with no catalyst, the coke formation situa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com