Method and system for reclaiming valuable resource in acidic etching waste liquid

A technology of acidic etching waste liquid and etching waste liquid, applied in chemical instruments and methods, copper sulfate, chlorine/hydrogen chloride, etc., can solve problems such as difficulty in completely replacing hydrogen chloride, low copper recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

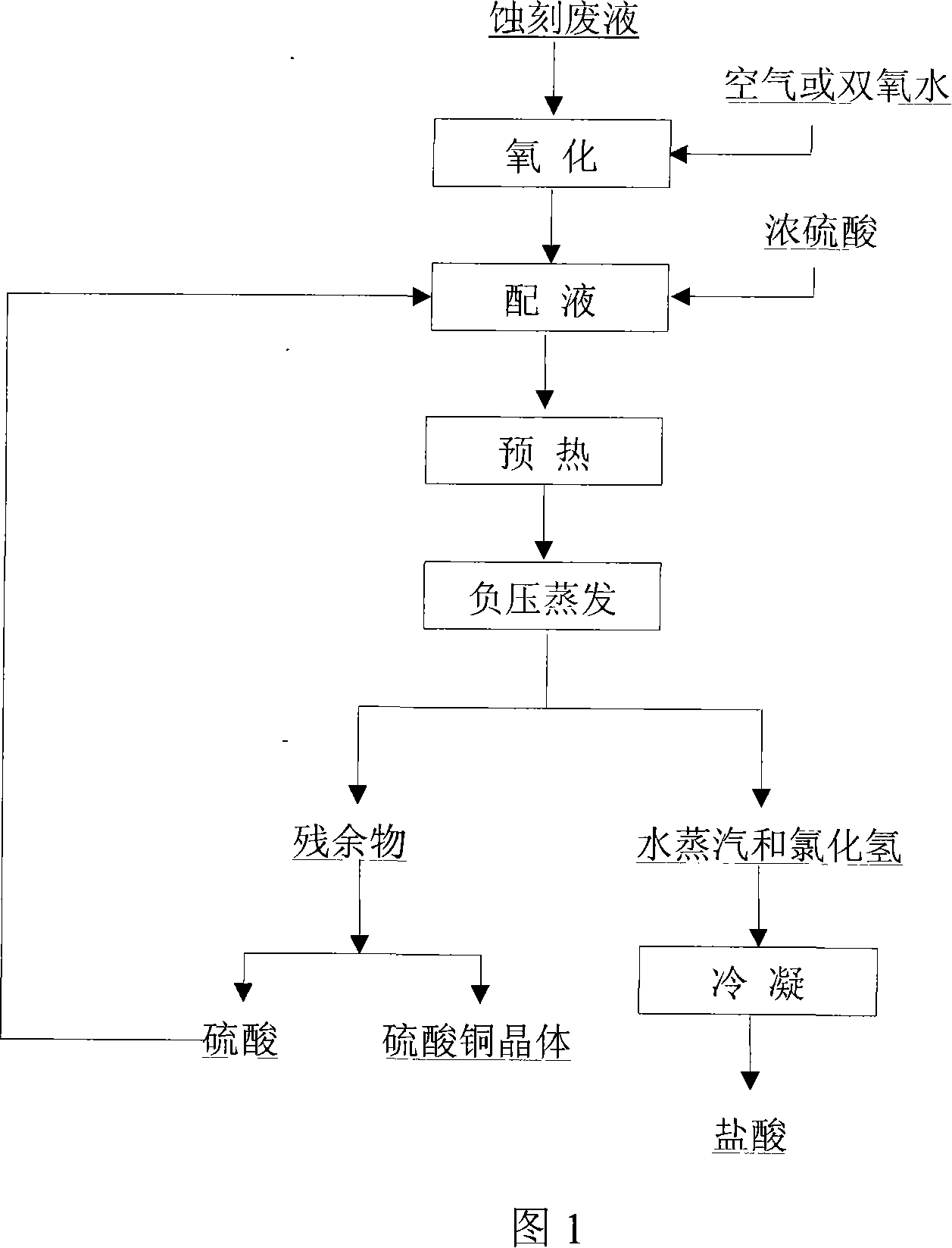

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

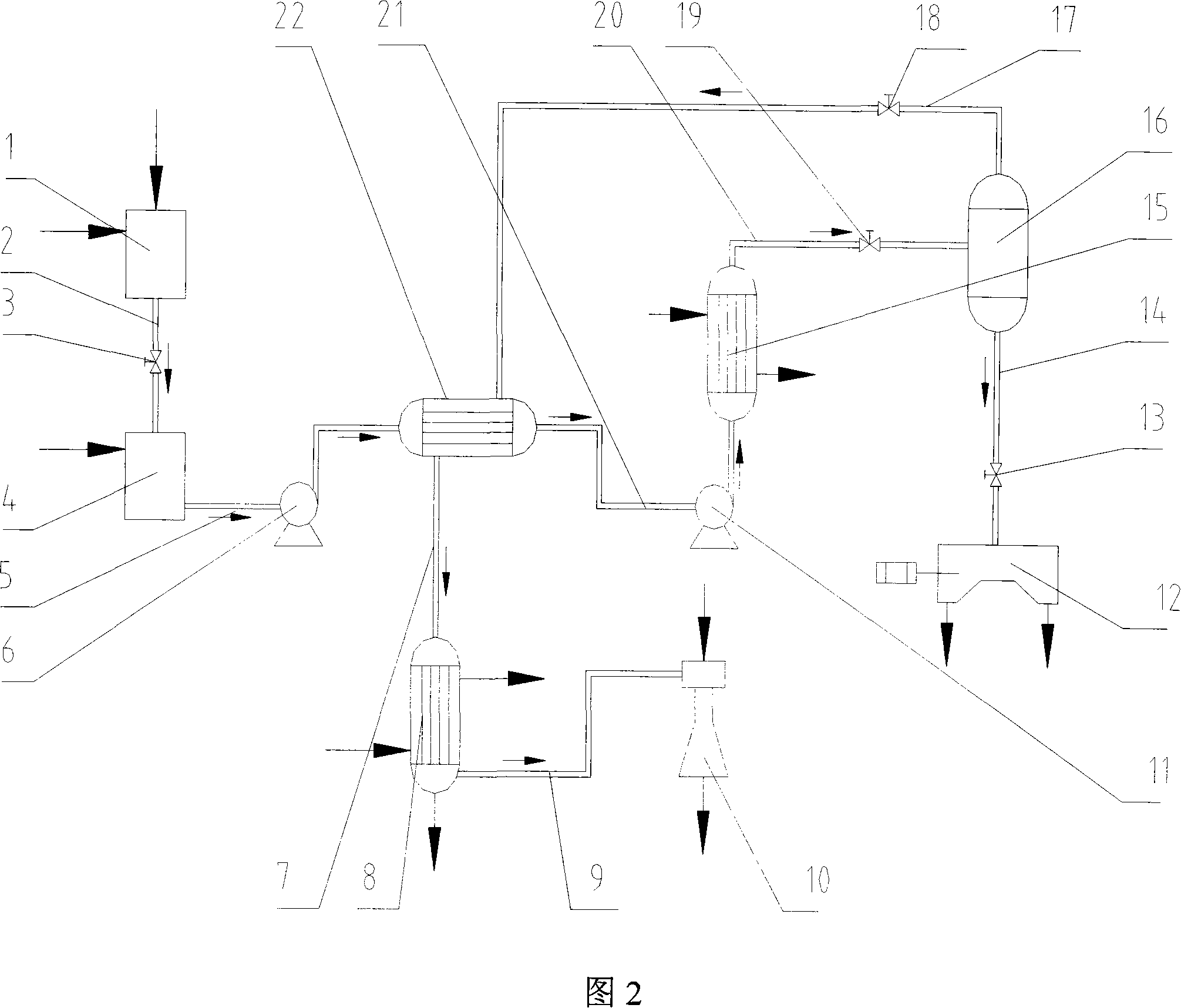

Embodiment 1

[0040]2000L etching waste solution (9.2wt% same content, 14.5wt% chlorine content, 1.3g / mL density) was oxidized by bubbling air under stirring conditions until the solution was transparent. Mix 400L of 98wt% concentrated sulfuric acid with the oxidized etching waste liquid and keep stirring to form the etching waste liquid. Heat the etching waste liquid with 0.07MPa saturated water vapor, then carry out negative pressure evaporation, the pressure is 0.06MPa, discharge the residue, and filter, then wash the copper sulfate crystal with saturated copper sulfate aqueous solution and absolute ethanol to obtain CuSO 4 .5H 2 O 939.1Kg, the purity is 99%. The recovery rate is 99.5%. Produced water vapor and hydrogen chloride were condensed to obtain 1542.7Kg of 25wt% hydrochloric acid with a recovery rate of 99.5%.

Embodiment 2

[0042] Add 30% hydrogen peroxide to 2500 L of the same waste etching solution as in Example 1 under agitation until the solution is transparent. Mix 750L of 95wt% concentrated sulfuric acid with the above solution and keep stirring. Heat the etching waste liquid with 0.08MPa saturated water vapor, then evaporate under negative pressure, discharge the residue, and obtain CuSO by filtration 4 .3H 2 O and CuSO 4 .5H 2 The mixture of O was 1092.6Kg, and the recovery rate was 99.2%. The generated water vapor and hydrogen chloride were condensed to obtain 1848.6Kg of 26wt% hydrochloric acid with a recovery rate of 99.2%.

Embodiment 3

[0044] Under stirring conditions, air was blown into 300 L of the etching waste liquid of Example 1 for oxidation treatment until the solution was transparent. Mix 120L of 98% concentrated sulfuric acid with the above clear solution and keep stirring. Heat the etching waste liquid with 0.08MPa saturated water vapor, then carry out negative pressure evaporation, discharge the residue, obtain copper sulfate crystals by filtration, then wash with saturated copper sulfate aqueous solution and absolute ethanol, and perform purification treatment to obtain 140.3Kg CuSO 4 .5 H 2O with a purity of 99.2% and a recovery of 99.3%. Produced water vapor and hydrogen chloride were condensed to obtain 224.4Kg of 25wt% hydrochloric acid with a recovery rate of 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com