Electroplate liquid of alkaline electrocoppering titanium alloy and preparing method and electroplating technology of electroplate liquid

An electroplating solution and electroplating copper technology, applied in the field of metal surface treatment, can solve the problems of poor anti-impurity ability of the plating solution, weak gravity, low hardness of copper layer, etc., and achieve strong anti-sulfide corrosion, good binding force, and Abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

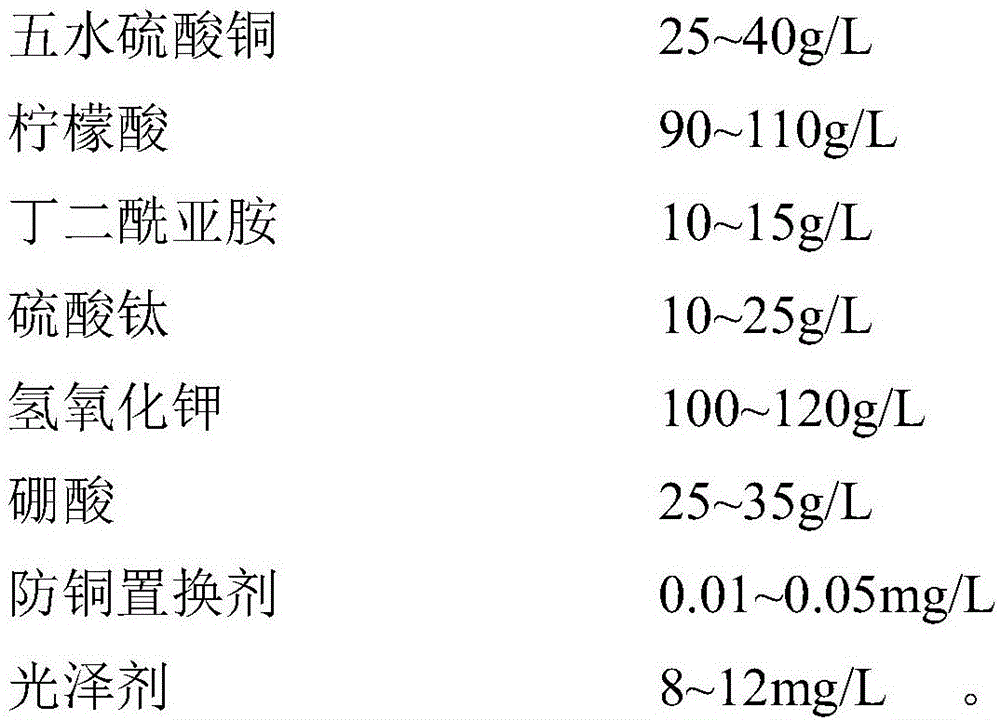

[0028] A kind of electroplating solution of alkaline electroplating copper-titanium alloy, its electroplating solution formula is as follows:

[0029]

[0030] The preparation method of the present invention comprises the steps of:

[0031] (1) Boric acid is placed in hot water at a temperature of 60° C. and stirred evenly, then copper sulfate pentahydrate is added to mix with it and stirred evenly to obtain solution a;

[0032] (2) Put citric acid and succinimide into hot water at a temperature of 50° C., mix and stir evenly to obtain solution b;

[0033] (3) putting titanium sulfate into sulfuric acid with a mass percentage of 5%, fully stirring and dissolving to obtain solution c;

[0034] (4) Potassium hydroxide is placed in cold water, fully stirred and dissolved to obtain solution d;

[0035] (5) After the solution a, solution b, solution c, and solution d obtained in the above steps are cooled to normal temperature, mix and stir evenly, then stand and filter, add a...

Embodiment 2

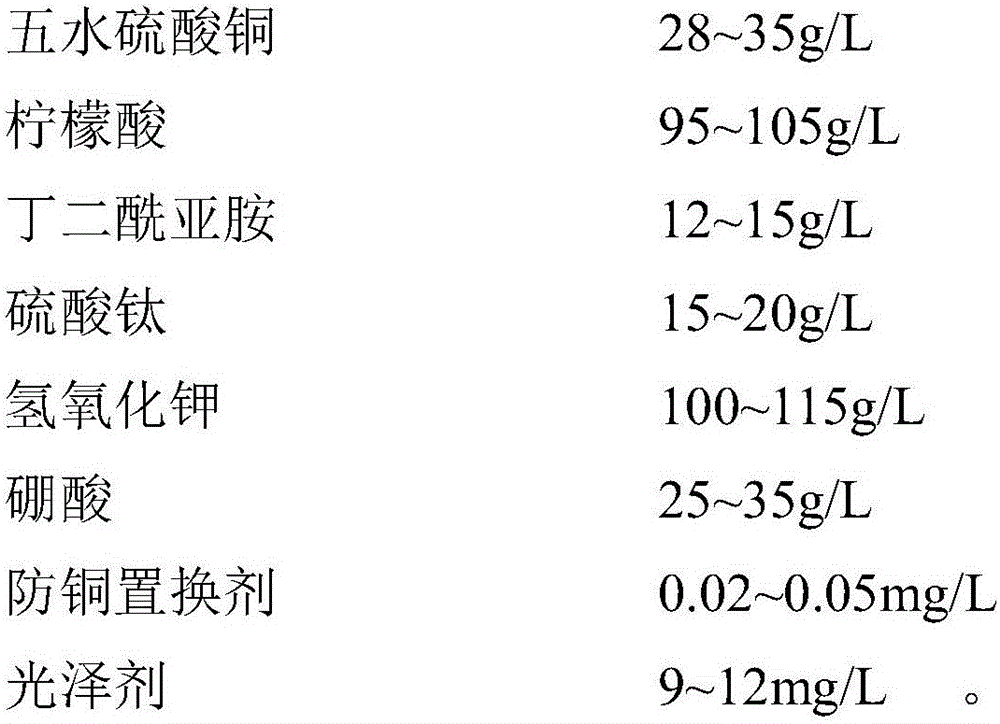

[0039] A kind of electroplating solution of alkaline electroplating copper-titanium alloy, its electroplating solution formula is as follows:

[0040]

[0041] The preparation method of the present invention comprises the steps of:

[0042] (1) Boric acid is placed in hot water at a temperature of 60° C. and stirred evenly, then copper sulfate pentahydrate is added to mix with it and stirred evenly to obtain solution a;

[0043] (2) Put citric acid and succinimide into hot water at a temperature of 60° C., mix and stir evenly to obtain solution b;

[0044] (3) putting titanium sulfate into sulfuric acid with a mass percentage of 5%, fully stirring and dissolving to obtain solution c;

[0045] (4) Potassium hydroxide is placed in cold water, fully stirred and dissolved to obtain solution d;

[0046] (5) After the solution a, solution b, solution c, and solution d obtained in the above steps are cooled to normal temperature, mix and stir evenly, then stand and filter, add a...

Embodiment 3

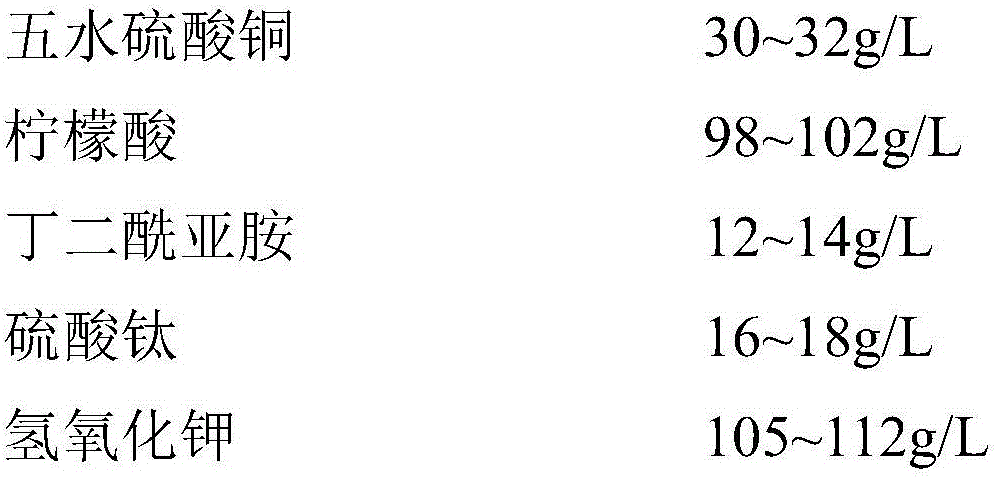

[0050] A kind of electroplating solution of alkaline electroplating copper-titanium alloy, its electroplating solution formula is as follows:

[0051]

[0052] The preparation method of the present invention comprises the steps of:

[0053] (1) Boric acid is placed in hot water at a temperature of 60° C. and stirred evenly, then copper sulfate pentahydrate is added to mix with it and stirred evenly to obtain solution a;

[0054] (2) Put citric acid and succinimide into hot water at a temperature of 60° C., mix and stir evenly to obtain solution b;

[0055] (3) putting titanium sulfate into sulfuric acid with a mass percentage of 5%, fully stirring and dissolving to obtain solution c;

[0056] (4) Potassium hydroxide is placed in cold water, fully stirred and dissolved to obtain solution d;

[0057] (5) After the solution a, solution b, solution c, and solution d obtained in the above steps are cooled to normal temperature, mix and stir evenly, then stand and filter, add a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com