Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

430 results about "Titanium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

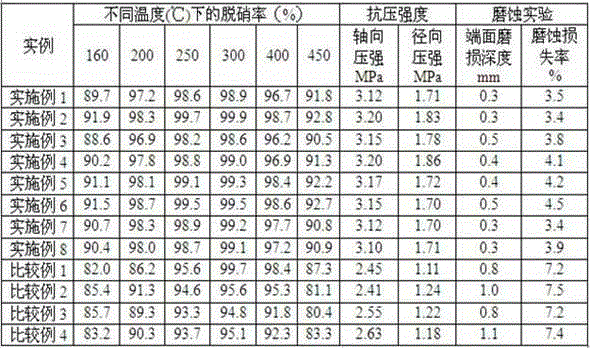

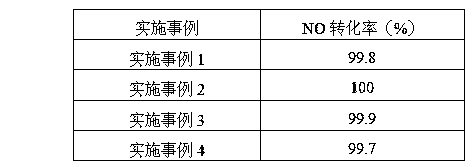

Preparation method of high-strength flue gas denitration catalyst

ActiveCN103769137ALarge specific surface areaHigh strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsGlass fiberWear resistant

The invention discloses a preparation method of a high-strength flue gas denitration catalyst. The preparation method comprises the following steps: taking titanium sulfate as the titanium source and critic acid as the complexing agent to prepare a TiO2-SiO2 composite carrier through an impregnation method, loading an active component and an auxiliary agent on the TiO2-SiO2 composite carrier so as to obtain denitration catalyst powder, mixing the denitration catalyst powder with glass fiber, wood slurry, polyacrylamide, carboxymethyl cellulose, ammonia water, and deionized water, and then subjecting the mixture to processes of kneading, aging, extruding, drying, and burning so as to obtain a honeycomb denitration catalyst. The preparation method has the advantages of simple preparation technology, low cost, and tight combination between TiO2 and SiO2 in the composite carrier. The prepared denitration catalyst has the advantages of good mechanical strength, wear-resistant property, and catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

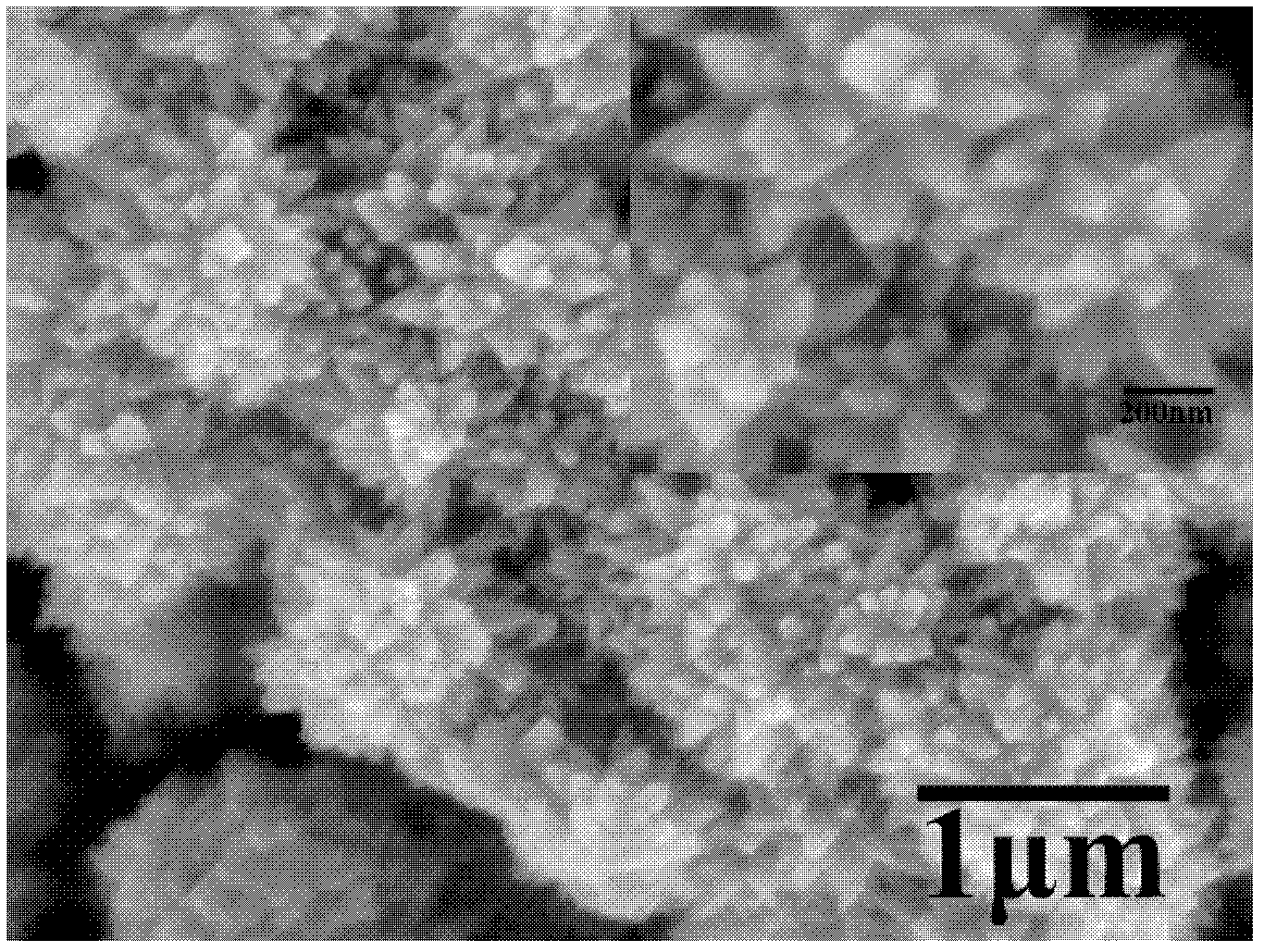

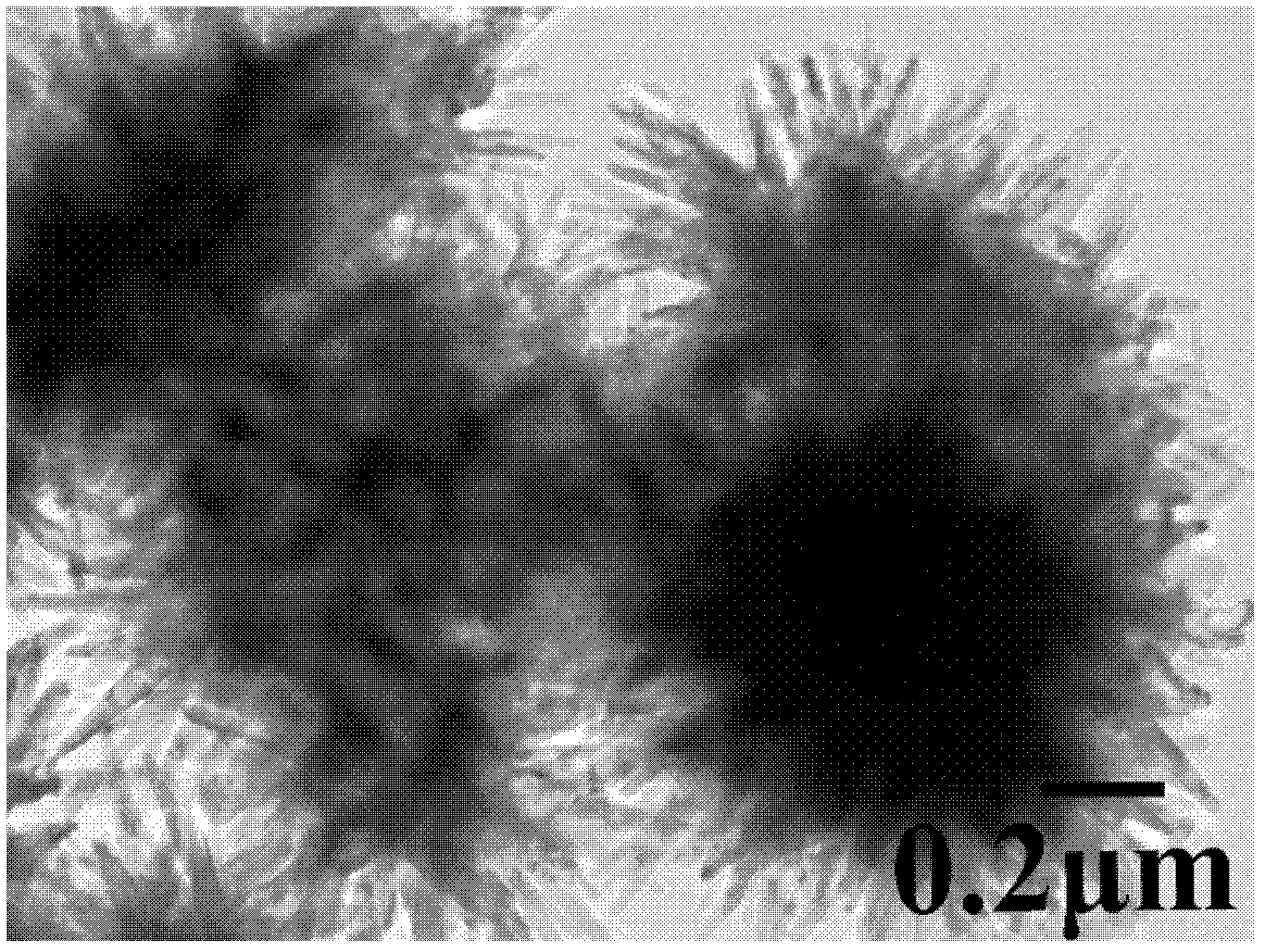

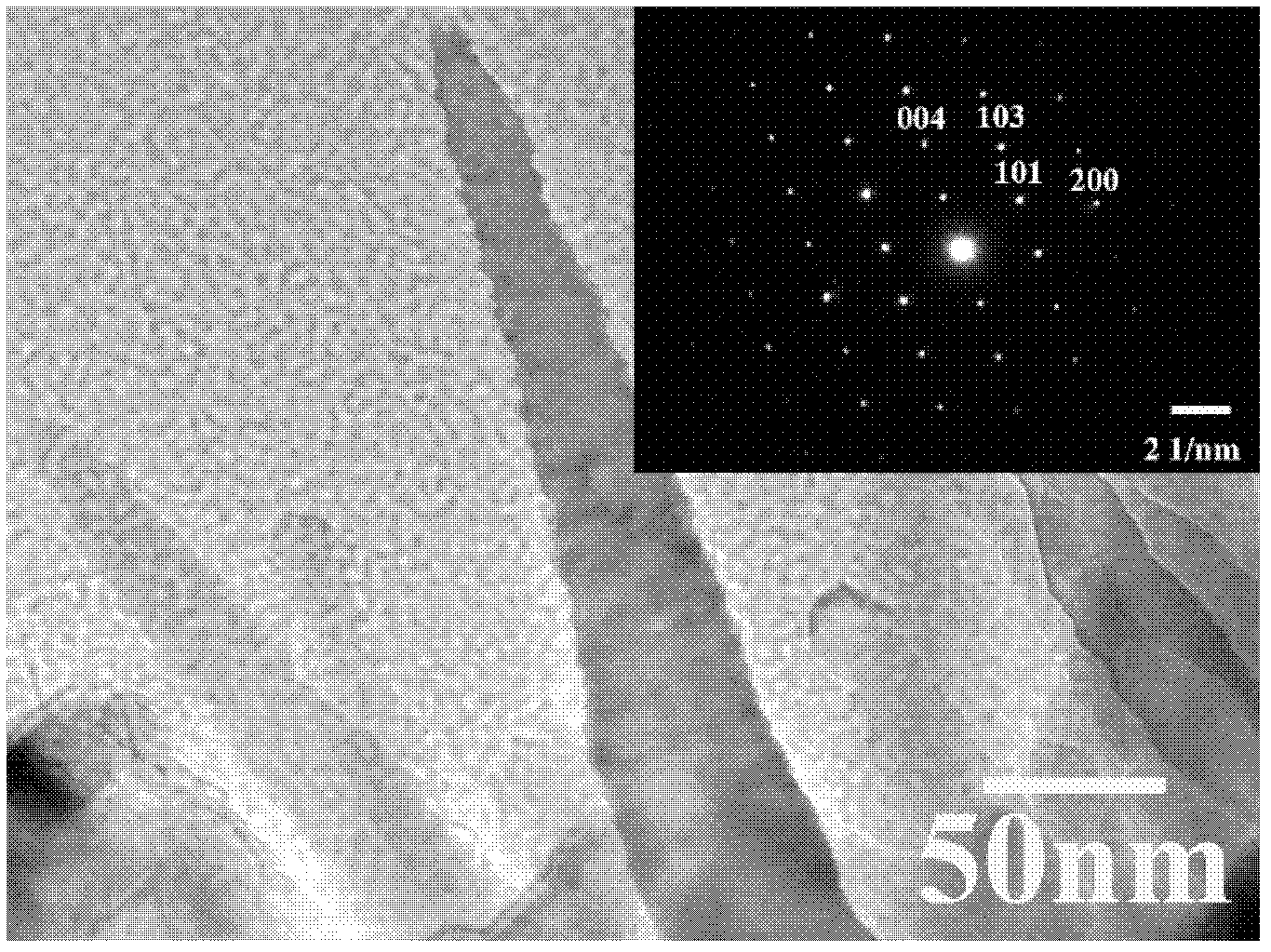

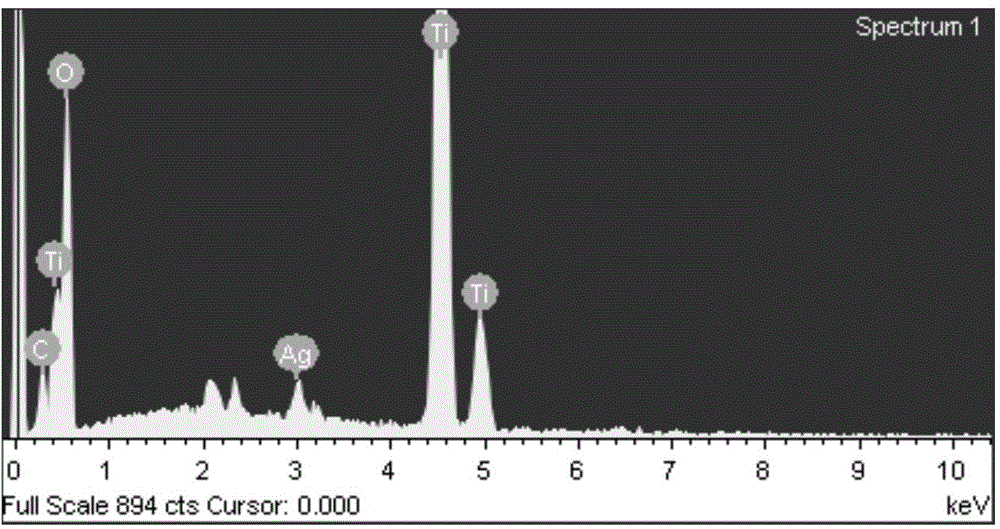

Method for preparing silver-carrying nano titanic oxide

InactiveCN101300982AEnhance photocatalytic antibacterial effectPlay antibacterial functionBiocideDisinfectantsPhosphoric acidSlurry

The present invention provides a method for preparing a nano silver-carrying titanium dioxide antiseptic. The aqueous ammonia solution and silver nitrate solution are dropped into the titanium sulfate solution simultaneously with continuous stirring. The final reaction pH is controlled by ammonia water. The titanium and silver are leaded to coprecipitate. The solution is filtered and washed after maturing. Afterwards the powder of nano silver-carrying titanium dioxide antiseptic is prepared by drying and calcining. The titanic acid or metatitanic can also be taken as precursor. The slurry containing 15-25% of recursor is added with silver nitrate solution with a concentration of 20-30gL<-1>, and the phosphoric acid, sulfuric acid or hydrochloric acid is added with a concentration of 10-15mgL<-1>. The solution is reacted, filtered and washed under the temperature of 50-60 DEG C. The solid object is dried, crushed, calcined and cooled, and the power of nano silver-carrying titanium dioxide antiseptic is obtained. The invention uses generating an indissoluble silver salt with a preparing technique of titanium dioxide to obtain the sustained-releasing of silver and color changing prevention. Furthermore the complex of the electron pair and the cavity is avoided. The photocatalysis antimicrobial effect of titanium dioxide is reinforced. The color, luster, granularity and dispersibility of the product can be well controlled.

Owner:CENT SOUTH UNIV

Method for preparing hollow glass microsphere coating titanium dioxide

InactiveCN102002263AEasy to depositExtended service lifePigment treatment with organosilicon compoundsReflecting/signal paintsFiltrationDistilled water

The invention discloses a method for preparing titanium dioxide for coating surfaces of hollow glass microspheres. The method comprises: washing the hollow glass microspheres with alkali liquor to remove impurities and etching to improve activity; performing surface activation and modification by using a silane coupling agent; mixing the activated hollow glass microspheres and distilled water in a mass ratio of 1:10; fully stirring at 40 to 90 DEG C; in the stirring process, dripping solution of titanium sulfate at a constant speed with in 2 to 6 hours according to a mass ratio of the hollow glass microspheres to the titanium sulfate of 1:0.8-1:1.6; slowly adding alkali liquor, keeping the pH value of the reaction system between 5 and 7, and stirring first at a speed of 400r / min for the first 1 / 5 of reaction time and then at a speed of 100 to 300r / min for the rest 4 / 5 of reaction time; and after the reaction is finished, standing, performing suction filtration, washing with distilled water, drying and calcining. The hollow glass microspheres coated with the titanium dioxide can serve as filler for reflective and thermal-insulation coating. Compared with common hollow glass microspheres, the hollow glass microspheres can be used for preparing and synthesizing high-performance coating combining various thermal-insulation mechanisms.

Owner:SHANGHAI UNIV

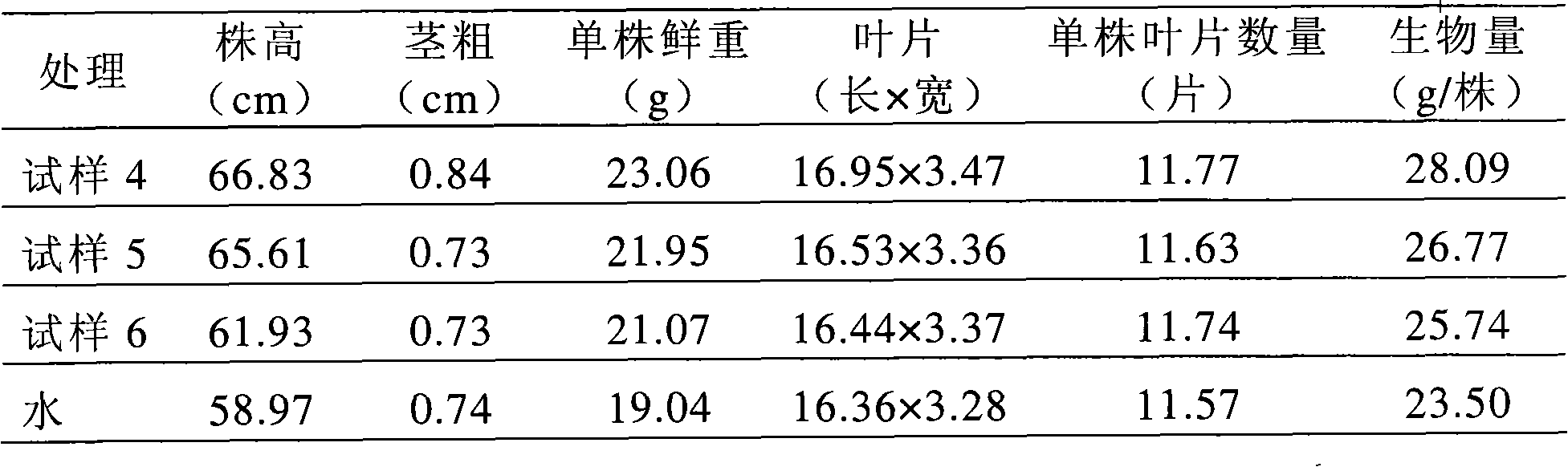

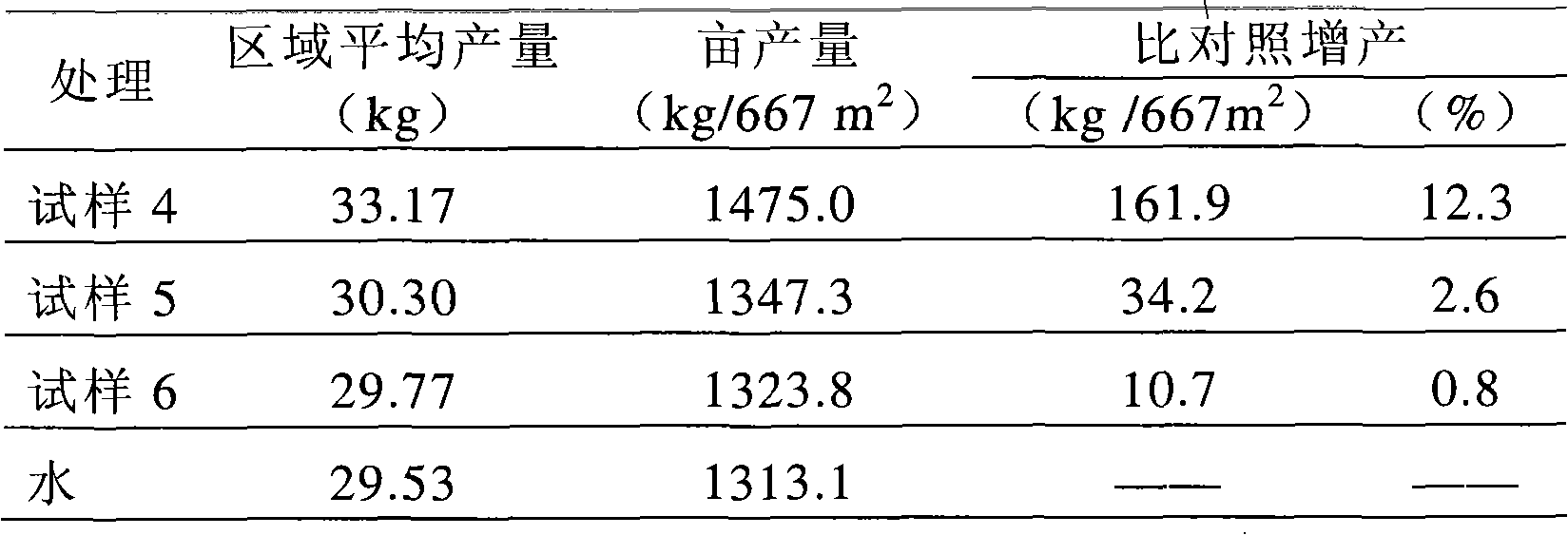

Titanium-complex-containing liquid fertilizer, preparation method thereof, and solid fertilizer containing the same

The invention relates to a preparation method of a titanium-complex-containing liquid fertilizer, which comprises the following steps: 1) dissolving titanyl sulfate or titanium sulfate in water; 2) adding a ligand A; 3) adding a ligand B; and 4) aging, wherein the ligand A and the ligand B are independently selected from tartaric acid, citric acid, malic acid, mandelic acid and lactic acid, and the ligand A and the ligand B are different; the ligand A, the ligand B and Ti (IV) meet the following relationship: 2 <= (the total mole number of the ligand A and the ligand B): the mole number of Ti (IV) <= 12. The invention also relates to the liquid fertilizer prepared by the method, and a solid fertilizer containing the liquid fertilizer. The titanium-complex-containing liquid fertilizer uses few ligands, has higher stability, and is still clear and transparent when being put for more than one year, and the concentration of titanium ion in a solution is almost unchanged, so the liquid fertilizer is of an excellent functional fertilizer.

Owner:SINOFERT HOLDINGS +1

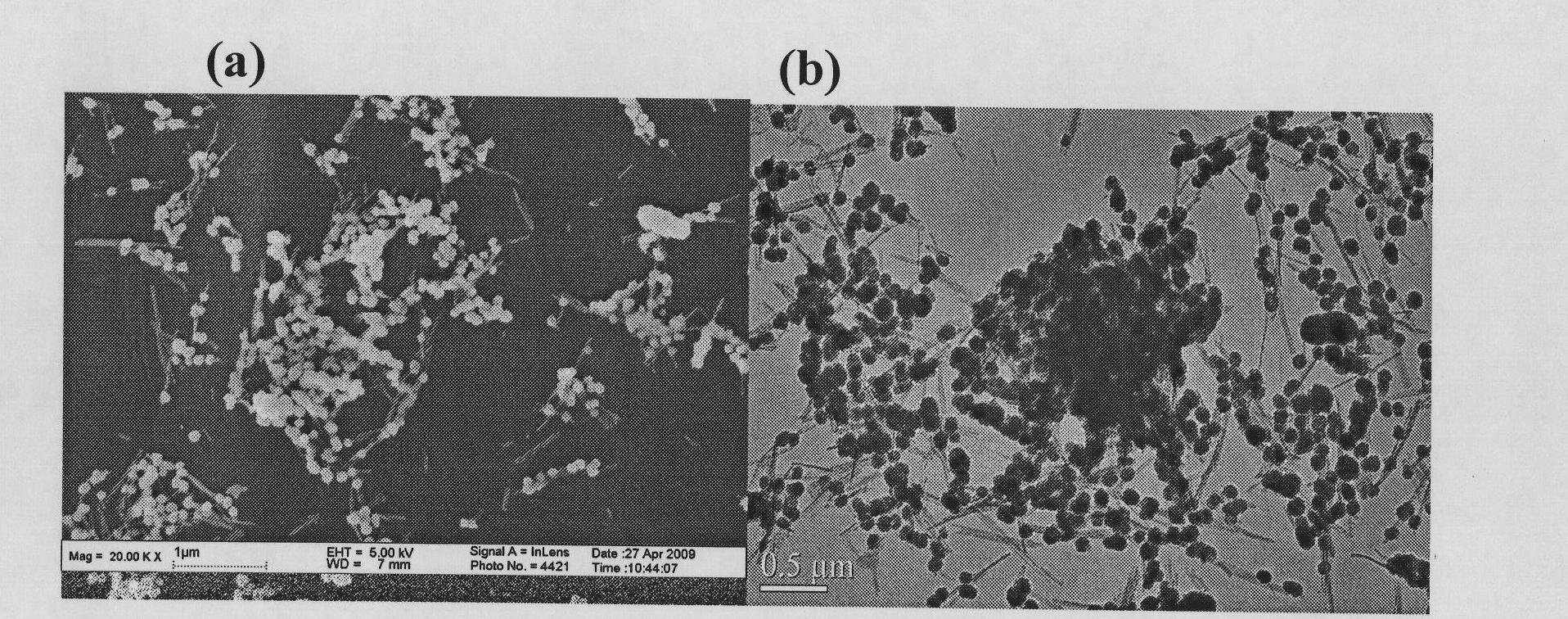

Method for preparing multiwall carbon nanotube-supported titanium dioxide catalyst

InactiveCN101966449ASimple methodEasy to operateCatalyst activation/preparationPtru catalystCarbon nanotube

The invention discloses a method for preparing a multiwall carbon nanotube-supported titanium dioxide catalyst, which belongs to the field of photochemical catalyst materials. The method comprises the following steps: adding multiwall carbon nanotubes and titanium sulfate into methanol respectively, and dispersing by ultrasonic waves and magnetic stirring; performing a solvothermal reaction, namely preparing a nano composite material by a solvothermal process to obtain the multiwall carbon nanotube-supported titanium dioxide catalyst; repeatedly washing the multiwall carbon nanotube-supported titanium dioxide catalyst, and drying under vacuum to obtain supported catalyst solid powder; dispersing the solid powder by ultrasonic waves and magnetic stirring, and preparing TiO2 / MWCNT by a hydrothermal process; and repeatedly washing the obtained TiO2 / MWCNT to obtain the multiwall carbon nanotube-supported titanium dioxide catalyst. In the TiO2 / CNT prepared by the method, the TiO2 is selectively and uniformly loaded on the surface of CNT. The method combining the solvothermal and hydrothermal processes has the advantages of simplicity, high maneuverability and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

SCR (Selective Catalytic Reduction) flue gas denitrification catalyst and preparation method thereof

InactiveCN106732759AFast hydrolysisTightly boundMolecular sieve catalystsDispersed particle separationCarboxylic saltPolyacrylamide

The invention discloses a preparation method of an SCR (Selective Catalytic Reduction) flue gas denitrification catalyst. The preparation method comprises the following steps: (1) firstly preparing a mixed solution of titanium sulfate and amino carboxylate, adding powdered molecular sieve into the mixed solution for dipping, and carrying out drying and roasting to prepare a TiO2-molecular sieve composite carrier; (2) dipping the TiO2-molecular sieve composite carrier prepared in the step (1) into dipping liquid containing an active component and an adjuvant precursor, and carrying out drying and roasting to obtain denitrification catalyst powder; (3) mixing the denitrification catalyst powder obtained in the step (2) with glass fiber, wood pulp, polyacrylamide, carboxymethyl cellulose, ammonia water and deionized water, and carrying out kneading, aging, extrusion, drying and roasting to obtain a cellular denitrification catalyst. The preparation method is simple in preparation process and low in cost; the obtained denitrification catalyst is wide in active temperature range, high in denitrification activity and high in SO2 and H2O poisoning resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bergmeal particle loaded nano TiO2 preparation method

InactiveCN1970149ARegulate microcirculationEasy to makeWater/sewage treatment by irradiationCatalyst activation/preparationWater bathsPhoto catalytic

It relates to a bergmeal particles loading nanometer TiO2 in the filed of photo catalytic material field. Using dilute sulphuric acid scrubbing bergmeal for several times, washing with iconic solution, it gets rid of icons like Al, Fe,Ca,Mg and drying, making 0.05-0.5mol / L aquadrate solution, adding with bergmeal particles 0.4-6.4g / L into a detergent, making 0.01-0.05mol / L basic titanium sulfate solution and mixing them of same volumes, adjusting PH value to 1-3, heating the mixture in 50-90DEG C temperature, blending, depositing, filtering, washing deposits with iconic solutions for several timees, drying, calcining in 300-800DEG C oven to make the product. It is simple in structure with high negative loading and tightly binding product, suitable for treating formaldehyde gas inside the house, regulating water microcirculation. It can also be used for making fillers of varied shapes, for the drawing and degrading of organics in the waste water, and the recovery of the product.

Owner:TIANJIN UNIV

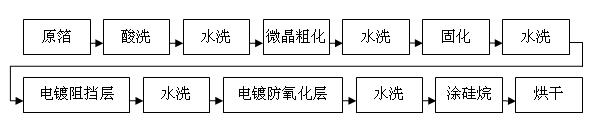

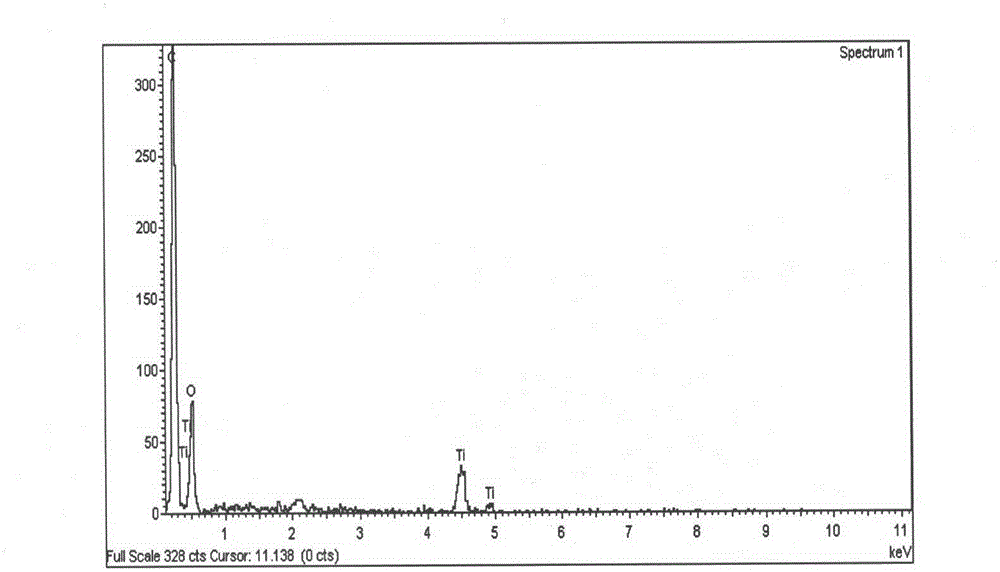

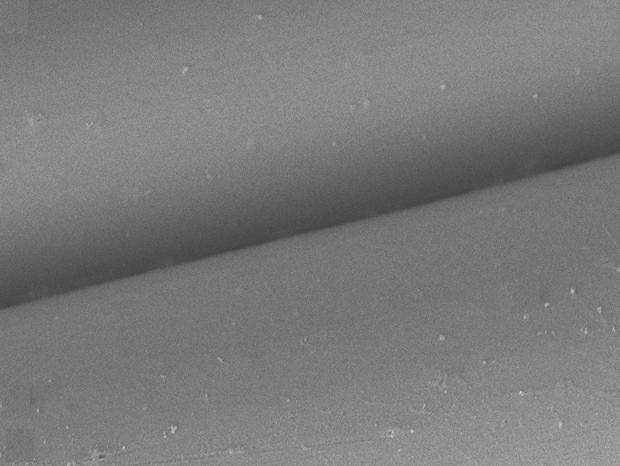

Additive for electrolytic copper foil and surface treatment process of very low profile electrolytic copper foil

ActiveCN102560584AEnhanced depth capabilitiesMicrocrystalline effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentElectrolysisMolybdate

The invention belongs to the technical field of electronic materials, particularly relates to a surface treatment process of a very low profile electrolytic copper foil, in particular to an additive used during the surface treatment of the very low profile electrolytic copper foil. The additive is composed of three components: titanous sulfate, titanium sulfate and molybdate, wherein the contents of the three components in the electroplate liquid are respectively 50-150mg / L, 150-250mg / L and 70-118mg / L (molybdate radical). The additive is used to be added into a microcrystalline coarsening slot; and the three components are used cooperatively, so that the treated copper foil coarse layer crystalline grains are small and dense, achieving a microcrystalline effect. In the invention, the addition amount of each additive and proper electroplating process conditions such as content of cuprate, temperature and current density are found out in the coarsening slot for the surface treatment, so that the treated 18-micron very-low profile electrolytic copper foil can meet the following technical indicators: the anti-stripping strength is equal to or greater than 1.0kg / cm and the value of surface roughness Rz is smaller than or equal to 5.1 microns.

Owner:惠州联合铜箔电子材料有限公司

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for preparing perovskite structure lead titanate monocrystal nano rod

InactiveCN101619494ASimple processEasy to controlPolycrystalline material growthFrom normal temperature solutionsLead nitratePotassium hydroxide

The invention relates to a method for preparing a perovskite structure lead titanate monocrystal nano rod. A titanium and lead oxyhydroxide mixed sediment for hydrothermal reaction is prepared by a two-step precipitation method. The method comprises the following steps: taking titanium sulfate as a raw material for precipitating titanium, taking lead nitrate as a raw material for precipitating lead and taking potassium hydroxide as a precipitating agent; precipitating titanium ions; precipitating lead ions; after the product is filtered and washed, obtaining the mixed sediment containing the titanium ions and the lead ions; mixing and dispersing the mixed sediment and the potassium hydroxide in deionized water; sealing the mixture in a reaction kettle; and carrying out hydro-thermal treatment at 160-240 DEG C for 5-48 hours to obtain the perovskite structure lead titanate monocrystal nano rod. The invention has simple technology process, no pollution and low cost and is easy to control and carry out mass production.

Owner:ZHEJIANG UNIV

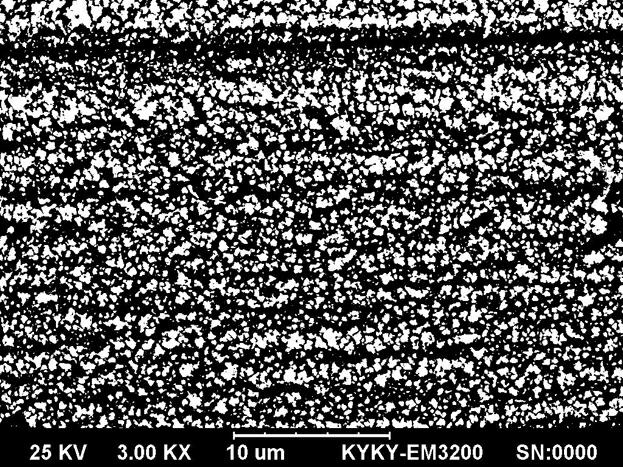

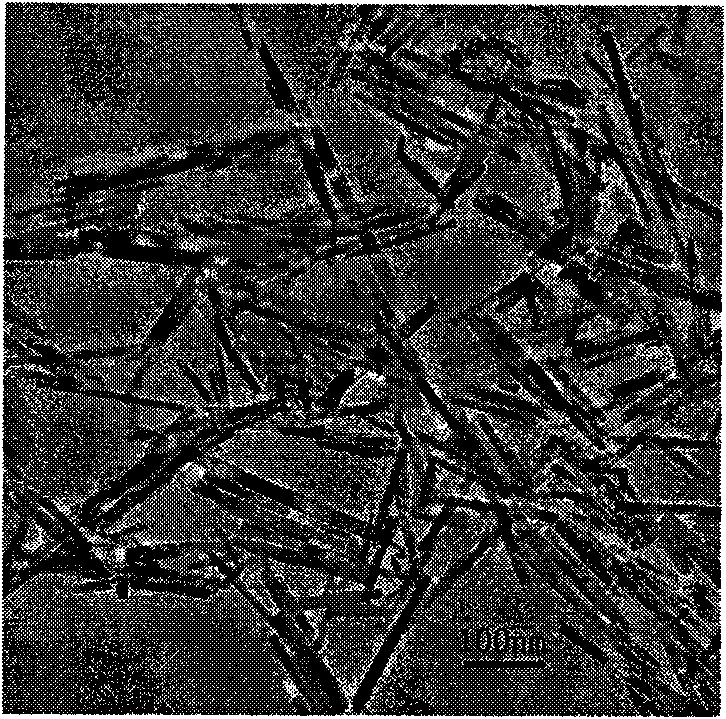

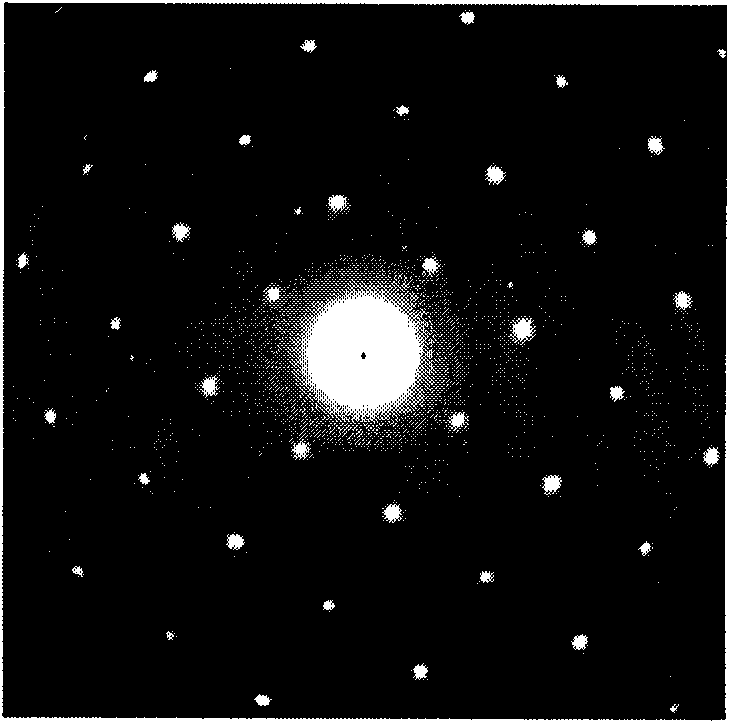

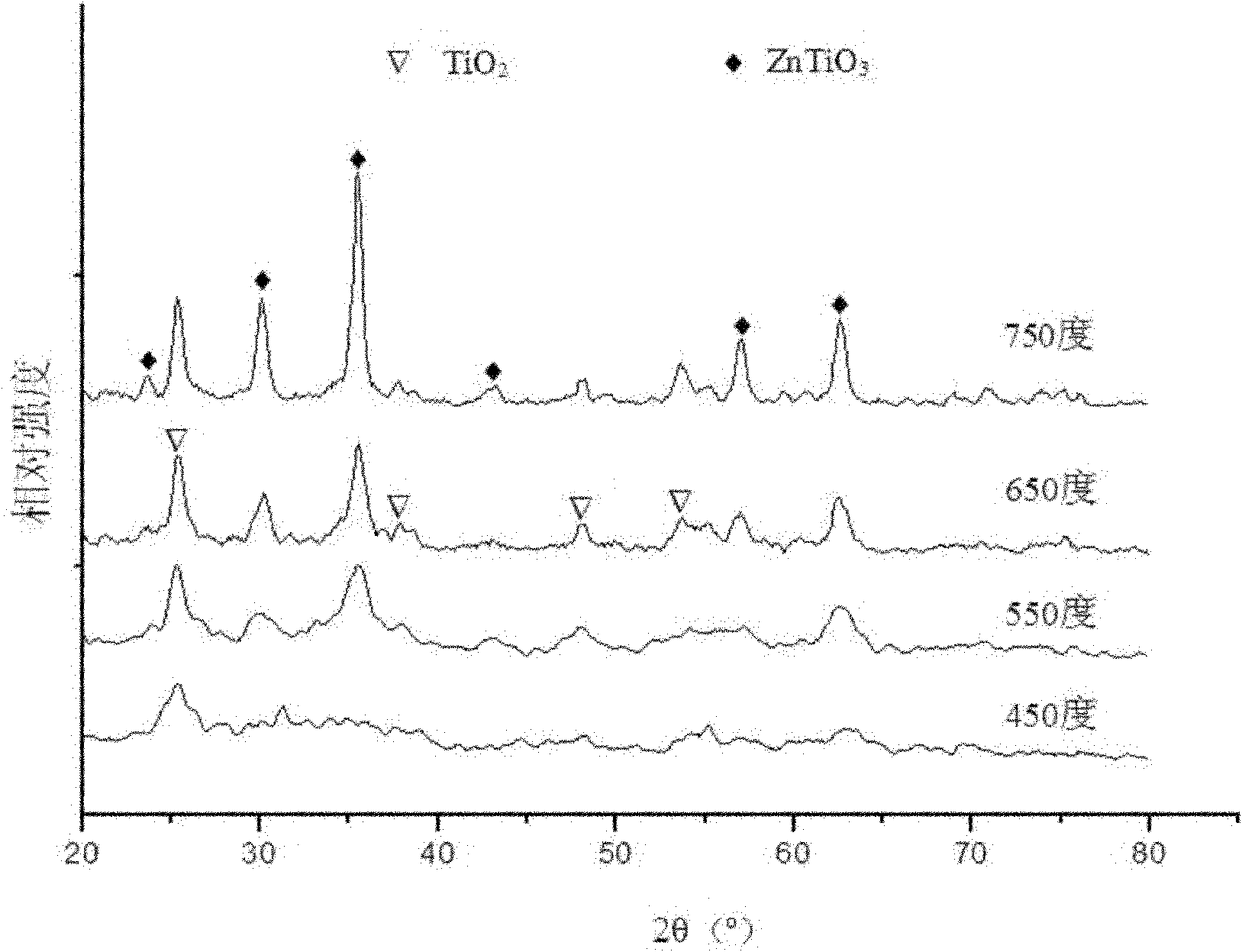

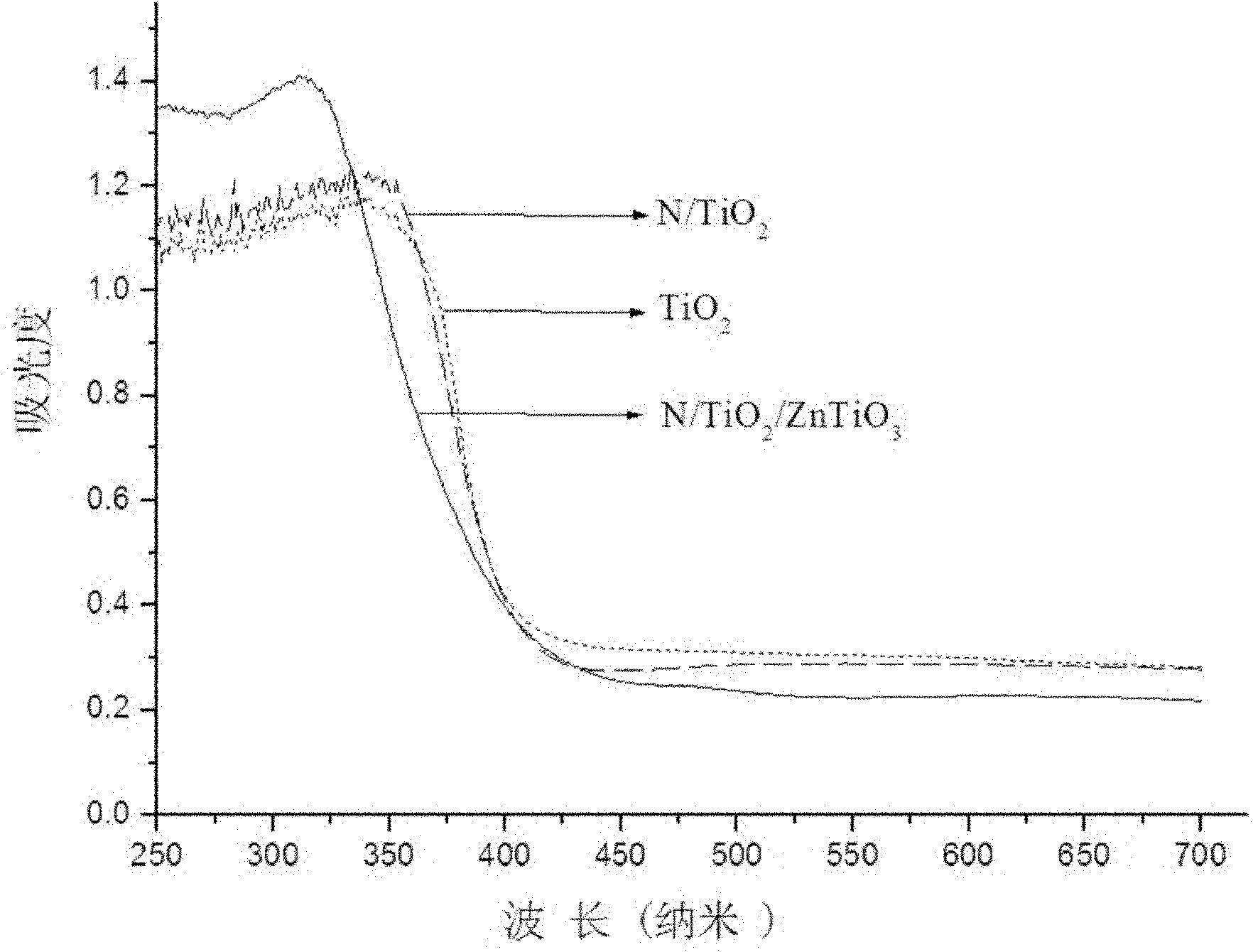

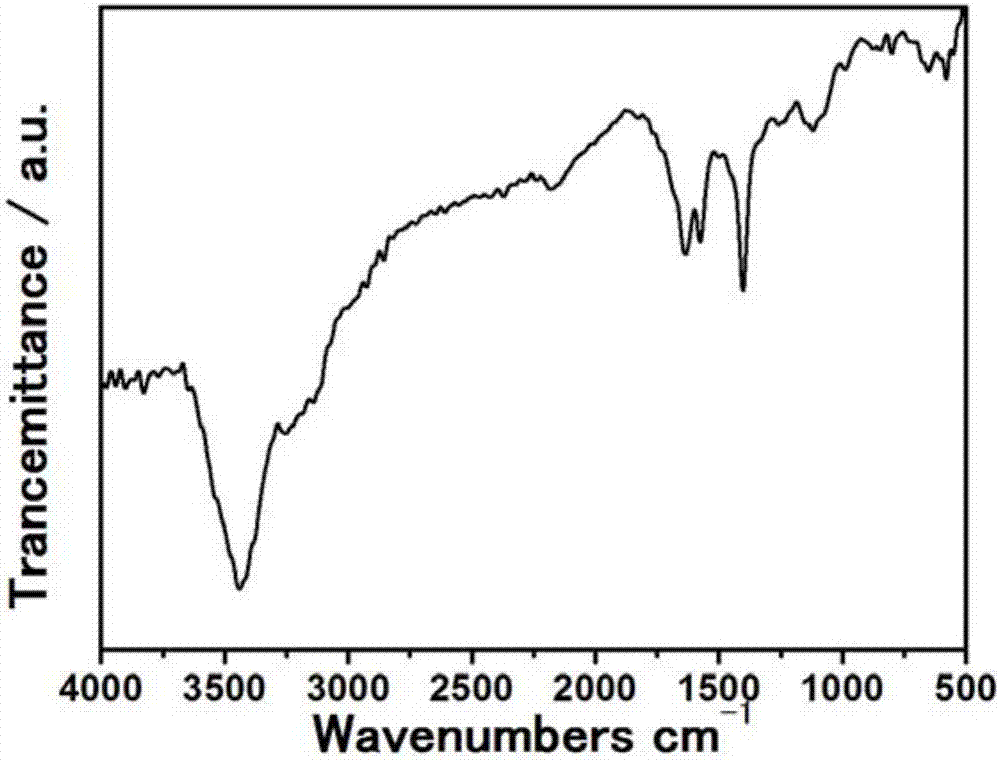

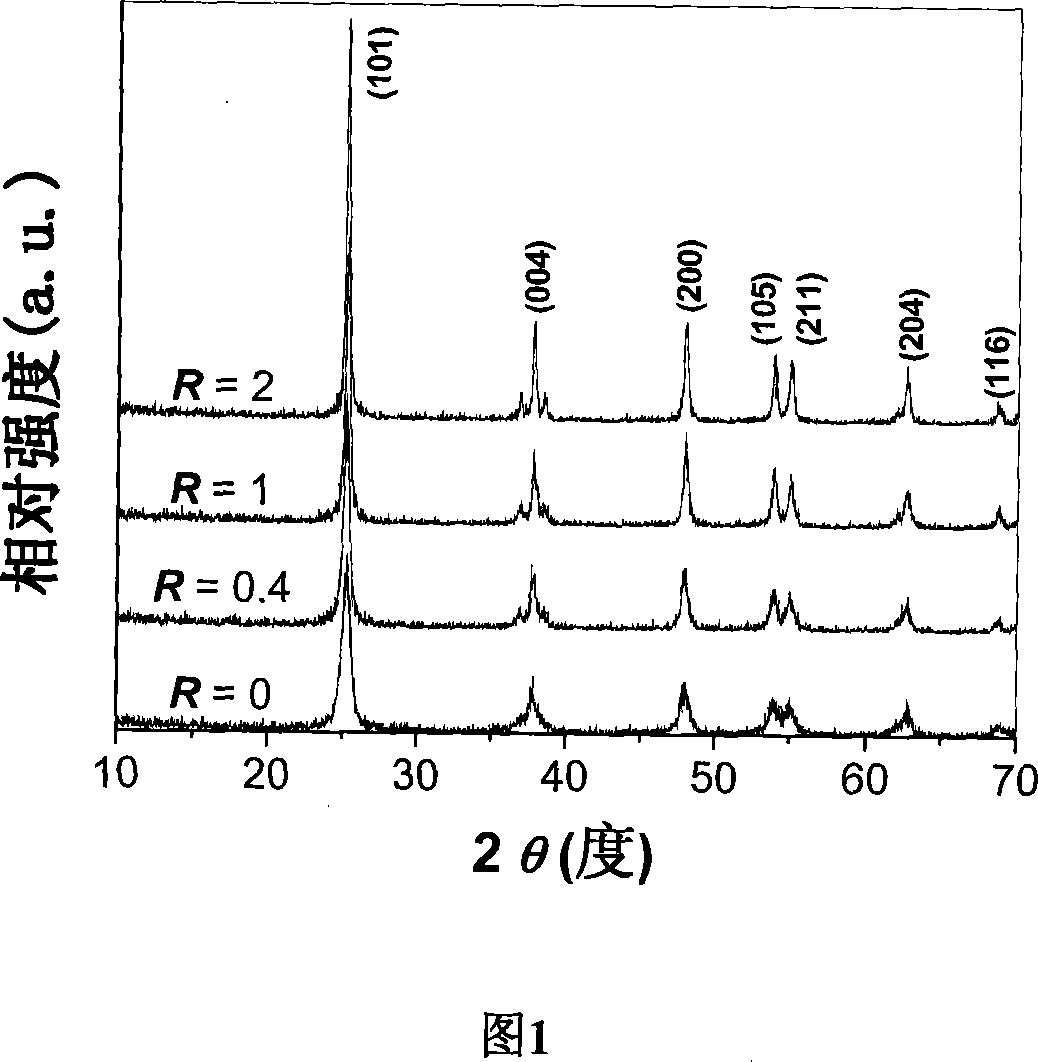

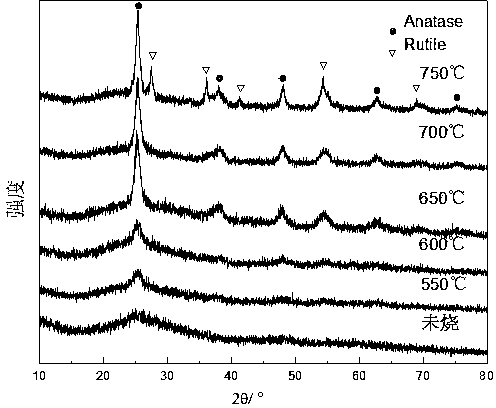

Preparation method of composite photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate

InactiveCN102139206AImprove surface propertiesMild reaction conditionsBiocideWater/sewage treatment by irradiationWater bathsSpectral response

The invention relates to a preparation method of semiconductor composite antibacterial photocatalyst containing nitrogen-doped titanium dioxide and zinc titanate, and belongs to the technical field of the treatment of environmental pollution. The semiconductor composite antibacterial photocatalyst is prepared a uniform coprecipitation method which comprises the following steps of: preparing a mixed solution in the amount-of-substance ratio of titanium sulfate to urea to zinc ions of 1:10:0; continuously mixing the mixed solution; raising the temperature of a water bath to 60 DEG C; adding a surfactant (sodium dodecyl benzene sulfonate) into the mixed solution based on the concentration of 20mg / 150ml; keeping a constant temperature for 0.5h; raising the temperature to 90-100 DEG C again; keeping the temperature for 3-6h; adding ammonia water into the solution to regulate to pH (potential of hydrogen) to be 6-8; washing and drying the obtained product; and forging the product at the temperature of 400-800 DEG C. The preparation method has the advantages of short process flow, simple equipment, simple and convenient operation, and low price of raw materials. The prepared semiconductor composite has the advantages of having good dispersibility, visible spectral response and low energy consumption, and is an environment-friendly antibacterial purification material.

Owner:WUHAN UNIV OF TECH

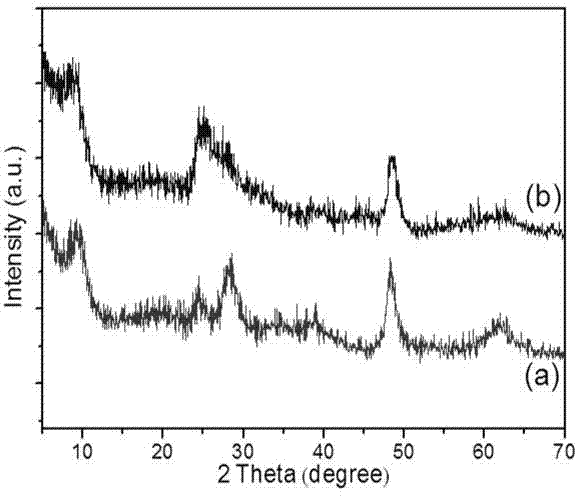

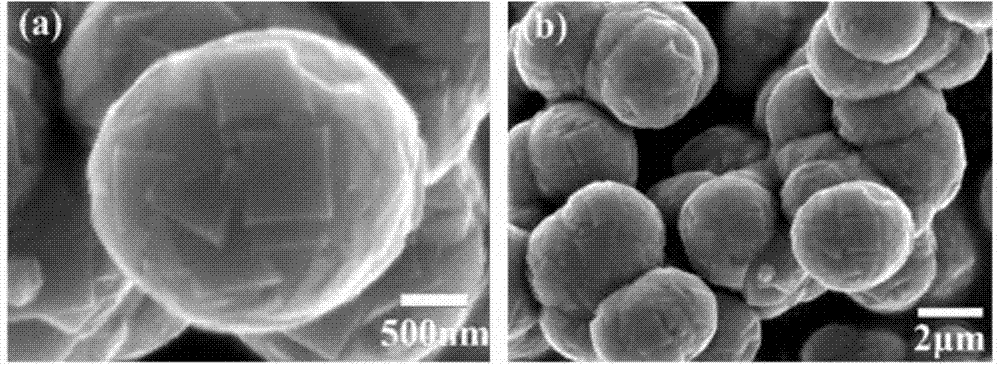

G-C3N4/TiO2 multilevel structure and preparation method thereof

ActiveCN107081166AImprove photocatalytic efficiencyImprove photocatalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationCalcinationTitanium sulfate

The invention discloses a g-C3N4 / TiO2 multilevel structure and a preparation method thereof. The g-C3N4 / TiO2 multilevel structure is characterized in that the g-C3N4 / TiO2 multilevel structure can be used as a high-performance photocatalyst. According to the method, inorganic titanium sulfate, hydrogen peroxide, sodium hydroxide and ethylene glycol as raw materials are prepared into a mixed solution, the mixed solution is transferred to a reaction kettle with polytetrafluoroethylene as the lining and subjected to a hydrothermal reaction, and a precursor is obtained; the precursor is acidized and calcined, and then TiO2 of a multilevel structure is obtained; urea or cyanurotriamide or dicyandiamide is supported onto the surface of the TiO2 of the multilevel structure, the photocatalyst of the g-C3N4 / TiO2 multilevel structure is obtained after calcination, and preparation and supporting of g-C3N4 are completed in one step. The g-C3N4 / TiO2 multilevel structure and the preparation method thereof have the advantages that the precursor in use is low-cost inorganic titanium sulfate salt, the preparation technology is simple and the cost is low; the photocatalyst of the g-C3N4 / TiO2 multilevel structure prepared through the method has very good photocatalytic activity in the aspects, such as photocatalytically splitting of water into hydrogen and degradation of organic contaminants in water.

Owner:东营睿港管道工程有限责任公司

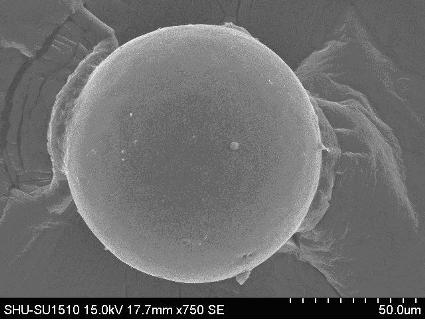

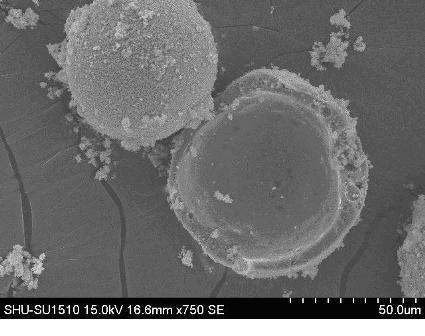

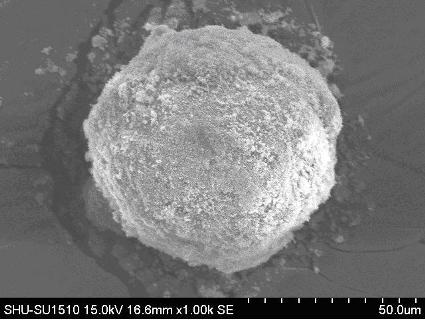

Fluoride modulated self-conversion method for preparing high active censpheres of titanium dichloride

A fluoride modified self-converting process for preparing high-activity hollow TiO2 microballs includes such steps as preparing the solution of diluted sulfuric acid, adding titanium sulfate to preparing the solution of titanium sulfate and sulfuric acid, preparing the solution of ammonium fluoride, proportionally mixing them together, filling the mixed solution in a hydrothermal reactor, sealing, hydrothermal reaction, collecting the white solid deposit, water washing, and drying.

Owner:WUHAN UNIV OF TECH

Preparation method of nano calcium carbonate/titanium dioxide composite powder with core-shell structure

ActiveCN104031421AEvenly dispersedSmall granularityTitanium dioxidePigment treatment with non-polymer organic compoundsHigh concentrationInorganic Chemical

The invention discloses a preparation method of nano calcium carbonate / titanium dioxide composite powder with a core-shell structure, belonging to the technical field of inorganic chemical synthesis. The preparation method for preparing the nano-level CaCO3 / TiO2 composite powder with the core-shell structure comprises the steps of leaching calcium carbonate by using a low-concentration titanium sulfate solution, then mixing leached calcium carbonate with a urea solution, and gradually dripping a high-concentration titanium sulfate solution or titanyl sulfate solution under heating conditions by using sodium dodecyl benzene sulfonate as a dispersing agent, thus preparing the nano CaCO3 / TiO2 composite powder with the core-shell structure. The preparation method is simple and feasible; an obtained product is relatively small and uniform in granularity and strong in ultraviolet absorption ability, shows the properties of titanium dioxide on the surface to a large extent, can be widely applied to the field of paper-making filler, coatings and the like, also can be used as an ultraviolet shielding material, and can be used for effectively reducing the cost of materials.

Owner:JILIN UNIV

Novel production process of titanium dioxide powder

The invention discloses a novel production process of titanium dioxide powder, comprising the process steps of performing ilmenite acidolysis, crystallizing, titanium liquid fine pressure filtering, concentrating, hydrolyzing, water-washing, bleaching, performing salt treatment, calcining and on the like. The process directly performs a hot-pressing treatment to a product of the ilmenite acidolysis by a filter press without subjecting to a settlement process. The technical scheme of the invention adopts the hot pressing filter method as follows: the mixed product of the titanyl sulfate and titanium sulfate after acidolysis, with a high temperature due to the acidolysis heat releasing, is directly pressure filtered by the filter press without subjecting to the settlement process and a cooling process. As the mixed product has low viscosity and good fluidity due to a high temperature, the content of the solid impurity in the pressure filtered titanium liquid is notably reduced, the crystal is big and the content of the residual titanium in the ferrous is low, so that the titanium yield is improved, meanwhile, the production period is shortened.

Owner:LOMON BILLIONS GRP CO LTD

Alumina plate ceramic membrane with superhydrophobic surface and preparation method thereof

InactiveCN107352980AAchieve low temperature preparationLower sintering temperatureSemi-permeable membranesMembranesMetallurgyCeramic membrane

The invention relates to an alumina plate ceramic membrane with a superhydrophobic surface. The preparation method of the alumina plate ceramic membrane is characterized by: firstly mixing alumina micro powder with a fluxing agent, and taking titanium sulfate as the precursor to modify the surfaces of alumina particles; then employing phase transformation tape casting and high temperature sintering to prepare a ceramic membrane; and finally using microwave assisted treatment on the ceramic membrane, and conducting surface grafting of fluorosiloxane, thus obtaining the alumina plate ceramic membrane with a superhydrophobic surface. The alumina plate ceramic membrane provided by the invention is grafted with fluorosiloxane on the surface, realizes modification from hydrophilcity to hydrophobicity, and expands the application range of ceramic membrane.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Method for preparing titanium dioxide loaded biomass carbon aerogel material

InactiveCN106390970AAbundant raw materialsLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationBiomass carbonMaterials preparation

The invention belongs to the technical field of material preparation and particularly relates to a method for preparing a titanium dioxide loaded biomass carbon aerogel material. According to the method, natural plant tissue such as watermelon peels serves as a raw material, and biomass carbon aerogel is prepared by a hydrothermal method in combination with a freeze-drying technique. The titanium dioxide loaded biomass carbon aerogel composite material is prepared through uniformly stirring titanium sulfate and the biomass carbon aerogel in distilled water and then carrying out a hydrothermal reaction. The diameter of the titanium dioxide loaded biomass carbon aerogel material prepared according to the method disclosed by the invention is 0.7 to 0.9 micron. The method has the following advantages that natural wastes serve as the raw material, so that the cost is low, and the efficient resource utilization of the wastes is achieved; and the preparation process is simple, the operation is simple and convenient, the requirements on environment-friendliness are met, and the wastes are treated with the wastes, so that mass production is facilitated.

Owner:镇江华科生态电镀科技发展有限公司 +1

Magnetic bifunctional catalyst, preparation method therefor and application of magnetic bifunctional catalyst in methanol catalyzed reaction

ActiveCN105521798AAcidicEasy to assembleOrganic compound preparationCarboxylic acid esters preparationPolyethylene glycolParamagnetism

The invention relates to a magnetic bifunctional catalyst, a preparation method therefor and application of the magnetic bifunctional catalyst in a methanol catalyzed reaction and belongs to the technical field of magnetic bifunctional catalysts and fine chemical industry. According to the magnetic bifunctional catalyst, the surface of each magnetic Fe3O4 core is coated with a TiO2 shell layer with a mesoporous structure, and mesopore of each TiO2 shell layer are loaded with catalytic active components such as Pd, Au and Pd-Au. The method comprises the steps: preparing Fe3O4 cores with super paramagnetism; then, coating the surface of each magnetic Fe3O4 core with the TiO2 shell layer with the mesoporous structure by an ultrasonic-hydrothermal method in a manner of taking titanium sulfate, titanyl sulfate and the like as a titanium source and taking polyethylene glycol as a template agent, so as to prepare magnetic TiO2@Fe3O4 nanospheres; and finally, loading the catalytic active components such as Pd, Au and Pd-Au into the mesopore of each TiO2 shell layer. The magnetic bifunctional catalyst has very good methanol conversion ratio and overall selectivity of methylal and methyl formate, and the reacted catalyst can be separated and recovered by an external magnetic field.

Owner:BEIJING UNIV OF CHEM TECH

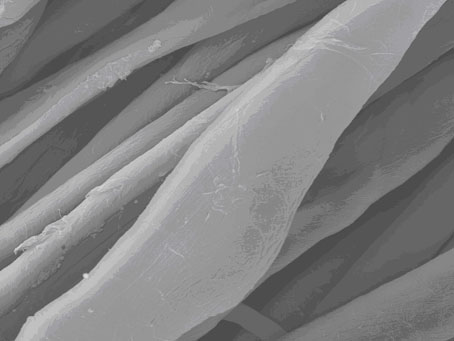

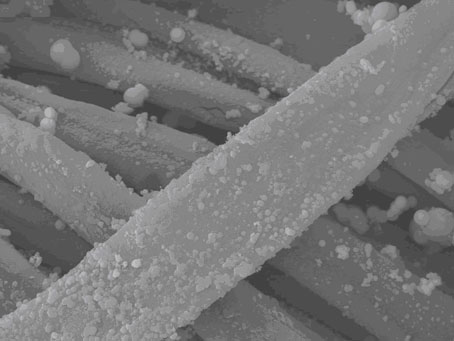

A kind of method that prepares nano titanium dioxide film on the surface of polyester fabric

InactiveCN102277723AImprove wash resistanceImproves UV resistancePhysical treatmentFibre typesPolyesterTitanium sulfate

The invention discloses a method for preparing a nano titanium dioxide thin film on the surface of a dacron. The method provided by the invention comprises the following steps of: firstly, ultrasonically vibrating and washing the dacron to be treated for 10-30 min at a temperature in a range of 60-90 DEG C by utilizing treating fluid under the conditions that the frequency is 28 kHz and the poweris 100 w; then drying the dacron for future use; secondly, utilizing titanium sulfate solution and urea solution to subject the dacron to a hydro-thermal reaction; finally, washing the dacron by utilizing the washing solution in the bath ratio of 1 to 30-50 for 15-30 min at a temperature of 100 DEG C; repeatedly washing the dacron by hot water and cold water and then drying to prepare the nano titanium dioxide thin film on the surface of the dacron. The method for preparing the nano titanium dioxide thin film on the surface of the dacron provided by the invention saves raw materials, is convenient for operating and has a good use effect; and the washing resistance of the modified dacron is obviously improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Method for preparing titanate, titanic acid and titanium dioxide

ActiveCN104261465AImprove cycle performanceIncrease capacityMaterial nanotechnologyAlkali titanatesTitanium tetrafluorideMicro nano

The invention discloses a method for preparing titanate, titanic acid and titanium dioxide. The method for preparing titanate comprises the following steps: carrying out hydrolysis reaction on a titanium source to obtain hydrated titanium acid precipitates, wherein the titanium source is selected from one or a composition of more of titanium sulfate, titanyl sulfate, titanium tetrachloride, titanium tetrafluoride, titanium ethoxide, titanium propoxide, tetrabutyl titanate, ethylene glycol titanium, glycerol titanium and ammonium fluorotitanate; dispersing the hydrated titanium acid precipitates in an aqueous hydrogen peroxide solution containing strong base for hydrothermal reaction, and thus obtaining sea urchin titanate with a micro-nano hierarchical structure. The method can overcome some defects of titanate, titanic acid and titanium dioxide prepared into nanowire or nanotube structures.

Owner:NINGBO NANOJP NEW MATERIAL TECH CO LTD

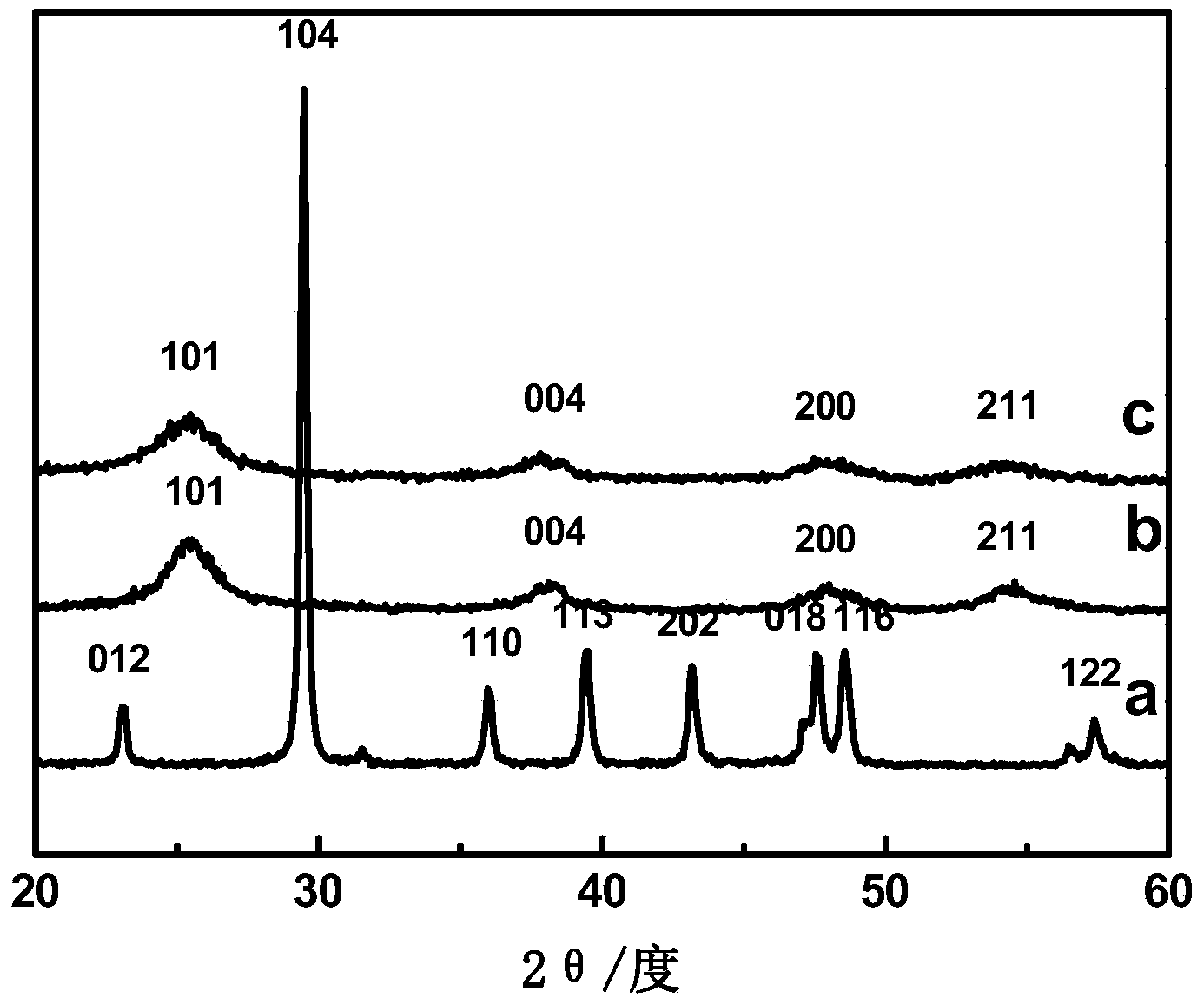

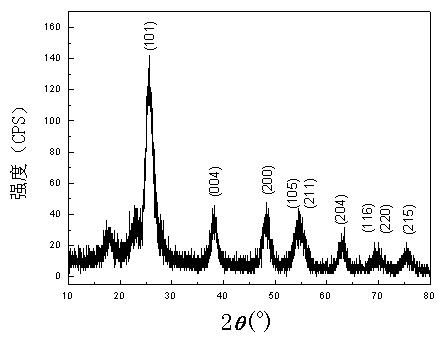

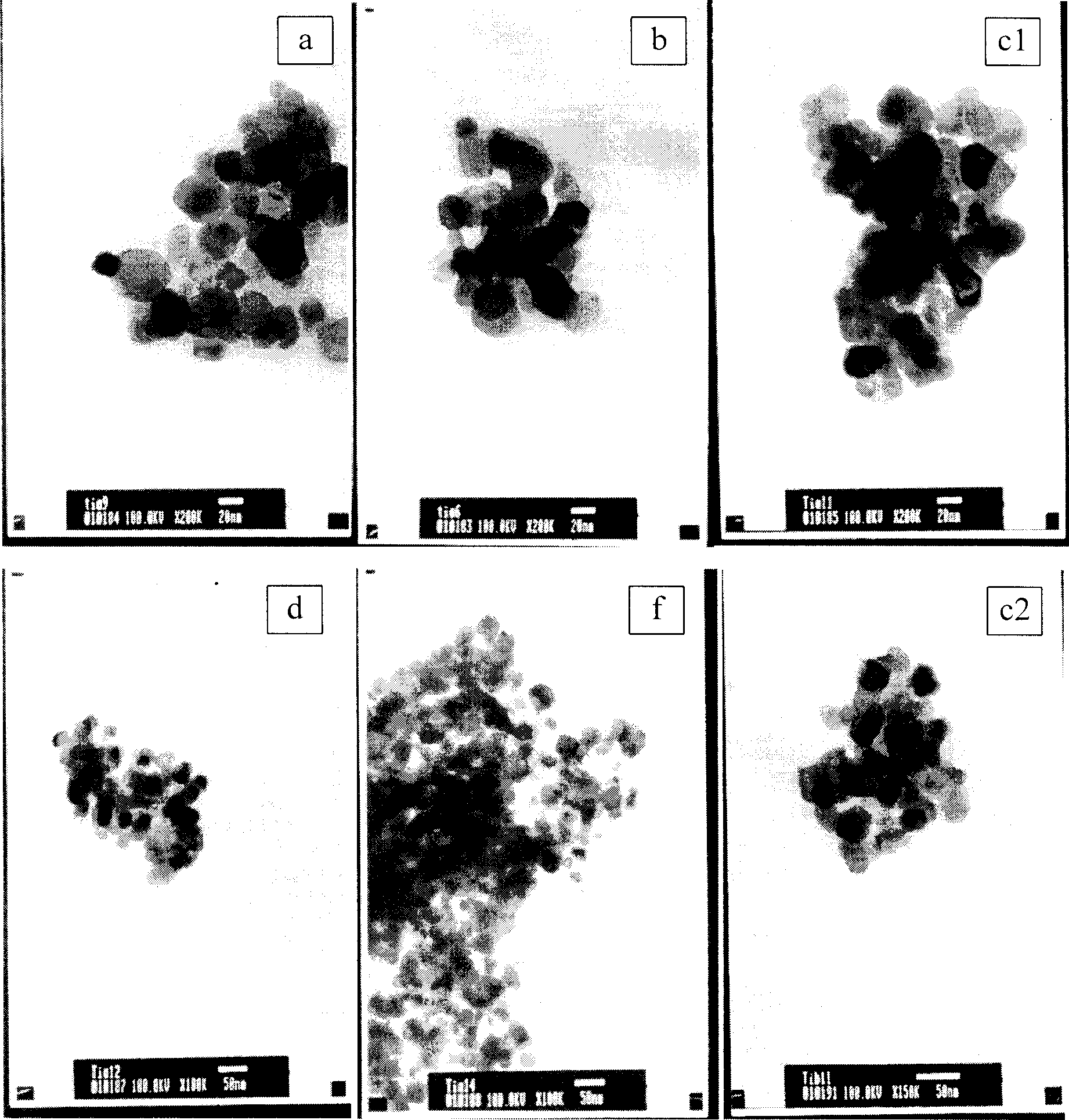

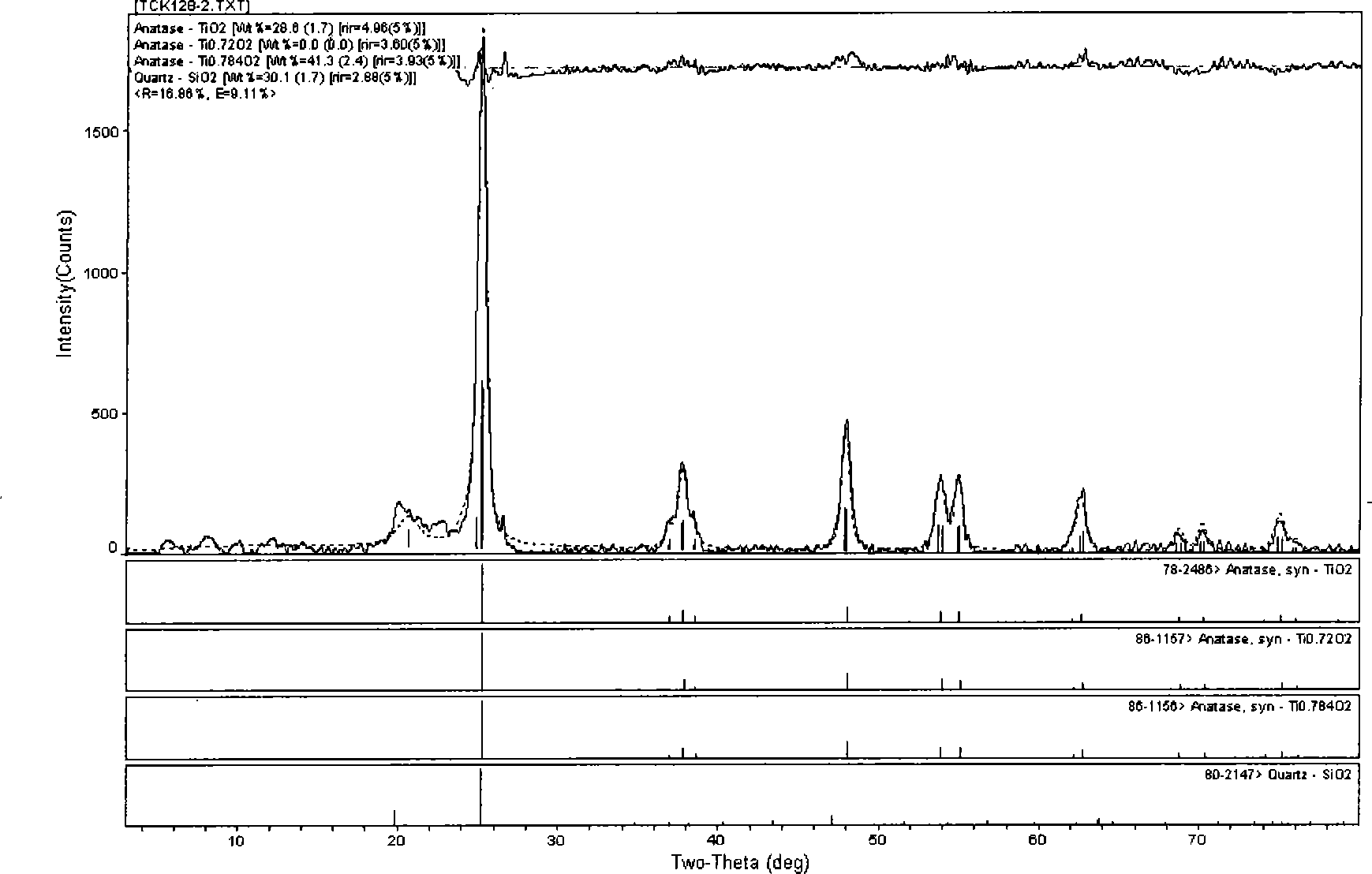

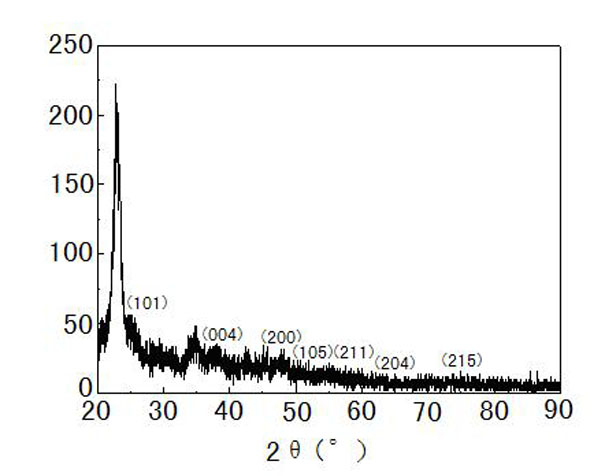

Method for preparing nano titanium dioxide in anatase type from fluid of hydrothermal crystallized titanium sulfate

InactiveCN1415550AStable structureImprove performanceOxide/hydroxide preparationTitanium dioxideDispersityNano catalyst

A process for preparing nano anatase-type TiO2 from the solution of titanium sulfate by hydrothermal crystallizing includes such steps as hydrothermal precrystallizing at 80-150 deg.C, and sintering at 350-800 deg.C. Its advantages are high dispersity and stability, low cost and less environmental pollution.

Owner:SUN YAT SEN UNIV

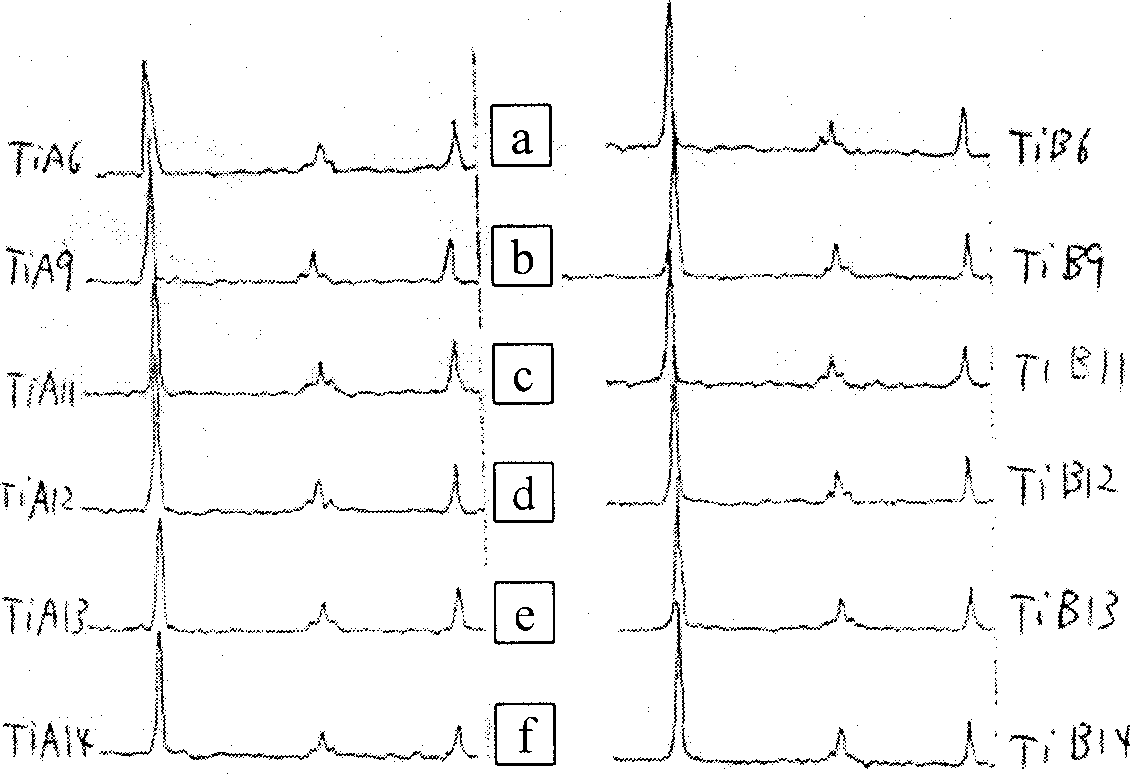

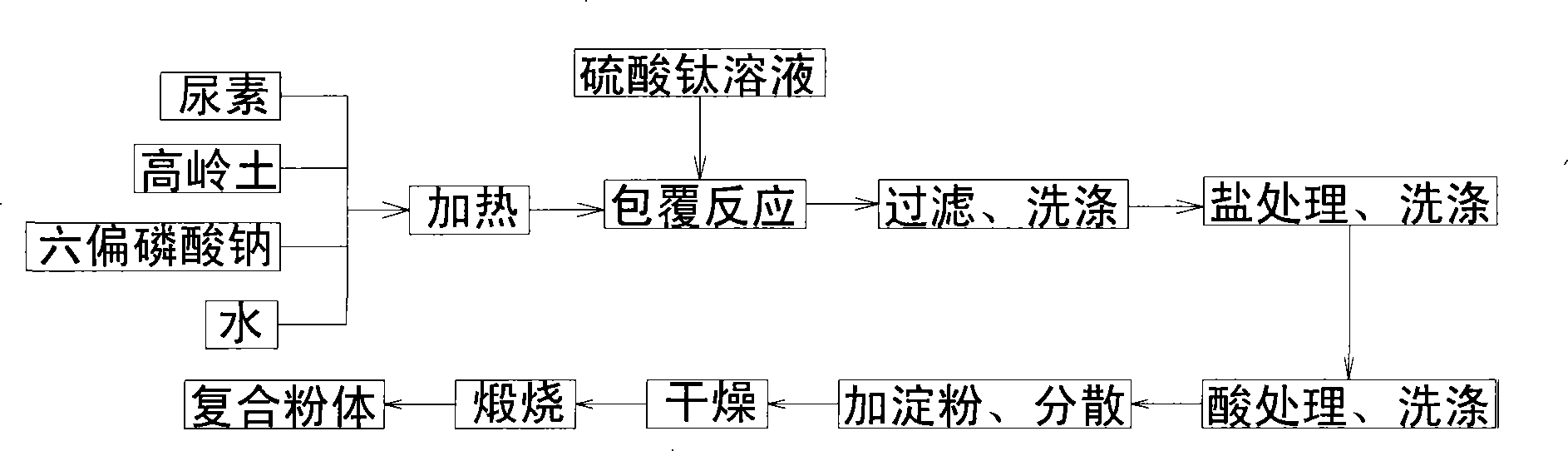

Titania coating kaolinite compound powder and method for preparing same

InactiveCN101250337AUniform whitenessSmall particle size distribution rangeInorganic pigment treatmentSODIUM METAPHOSPHATESodium phosphates

Titanium oxide coating kaolin composite powder belongs to a process for producing composite white pigment powder through the inorganic treatment method. The raw material formulation is formed by following components with percentage by weight: 12%-18% titanium sulfate, 6%-9% kaolin, 10%-19% carbamide, 0.15%-0.30% sodium hexametaphosphate, 0.5%-1.2% starch, 0.04%-0.08% water-soluble carbonate, 0.01%-0.05% phosphorus acid and rest amount of water. The preparation process comprises the steps of coating reacting, water scouring, salt treatment, acid treatment, dispersion, drying and calcination. The titanium oxide coating kaolin composite powder which is prepared through adopting the homogenous precipitation method has the advantages of even whiteness and small particle size distribution range, and each index all approximates to the index of titanium white powder.

Owner:中国高岭土有限公司

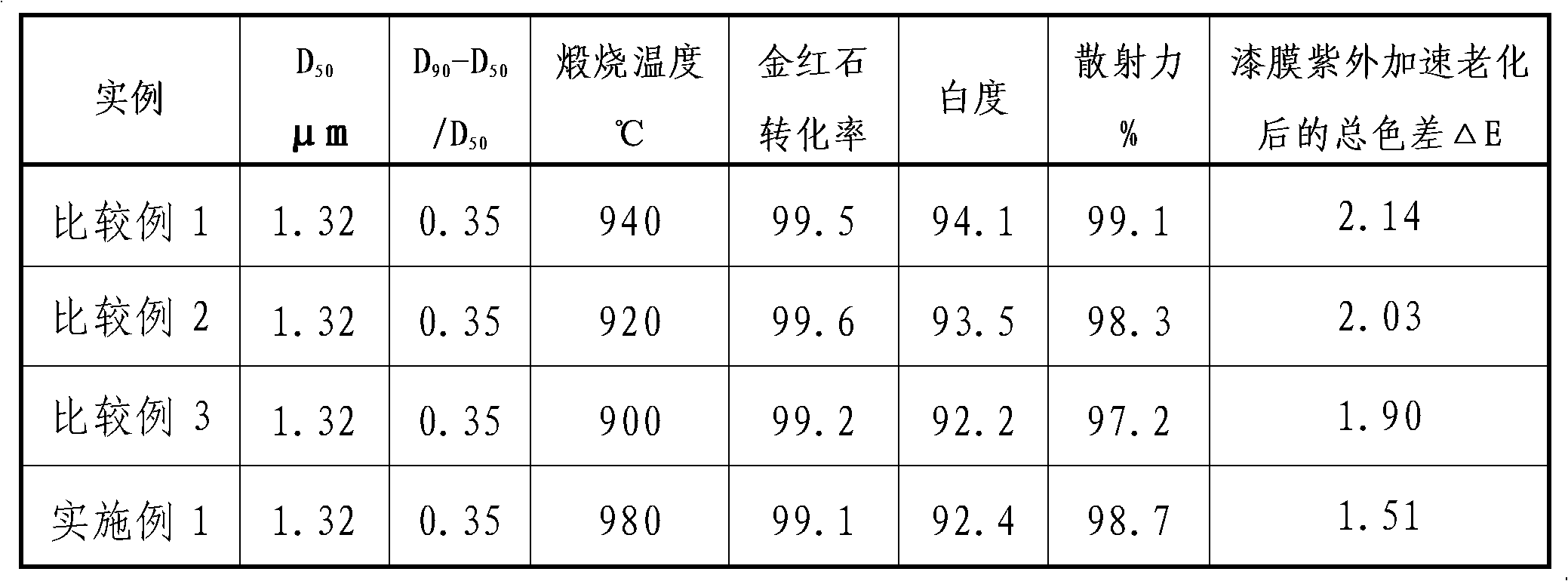

Preparation method of rutile titanium dioxide with stable lattice

InactiveCN101985364AImprove Pigment PerformancePigment properties such as high whitenessTitanium dioxideWater rinsingRutile

The invention relates to a preparation method of rutile titanium dioxide with stable lattice, belonging to the manufacturing technology of chemical industry product. The method comprises the following steps of: a, using 200g / L of titanium sulfate solution for the preparation of hydrolyzed seed crystals; b, adding 2.1 to 6.5% of the prepared seed crystals with homogeneous crystal nucleus by weight of TiO2 into the titanium sulfate solution for being heated and hydrolyzed, and preparing hydrolyzed metatitanic acid under the stirring speed of 30 to 70rpm; c, water rinsing and bleaching the hydrolyzed metatitanic acid, adding rutile calcining seed crystals and then bleaching, controlling the content of Fe2O3 to be less than 30ppm, and then adding 0.45 to 0.52% of KOH, 0.02 to 0.05% of H3PO4 and 0.20 to 0.55% of Al2(SO4)3 by weight of TiO2 in the metatitanic acid for treatment; and d. evacuating the treated metatitanic acid into filter cake under vacuum, and calcining at 900 to 980 DEG C, cooling and crushing the filter cake to obtain the rutile titanium dioxide. The rutile titanium dioxide production prepared according to the method of the invention has good pigment performance and stable rutile lattice.

Owner:JIANGSU TAIBAI GROUP

Co-precipitation preparation method of composite oxide denitration catalyst

InactiveCN103801325ALarge specific surface areaImprove denitrification activityDispersed particle separationCatalyst activation/preparationSodium metasilicatePtru catalyst

The invention discloses a co-precipitation preparation method of a composite oxide denitration catalyst and belongs to the technical field of preparation of nitric oxide reduction catalysts. The method comprises the following steps: in the presence of a solvent, mixing aluminum sulfate, titanium sulfate, ammonium vanadate and sodium metasilicate with at least one of ammonium tungstate, manganese chloride, nickel nitrate, cobalt nitrate and chromic nitrate; then placing an obtained precursor into a muffle furnace, and roasting the precursor to obtain the catalyst. According to the method, the use of TiO2 in a conventional V-W-Ti catalyst is reduced, and the cost is reduced; meanwhile, the specific surface area of the catalyst is increased. The formed catalyst contains two or more of components from Ti, Si, Al, V, W, Cr, Ni, Mn and Co; the denitration activity of the catalyst is favorably improved by the strong cooperative action of each active component and a carrier; the catalyst is applicable to SCR (selective catalytic reduction) denitration reaction at low temperature of 250-500 DEG C.

Owner:YANGZHOU UNIV

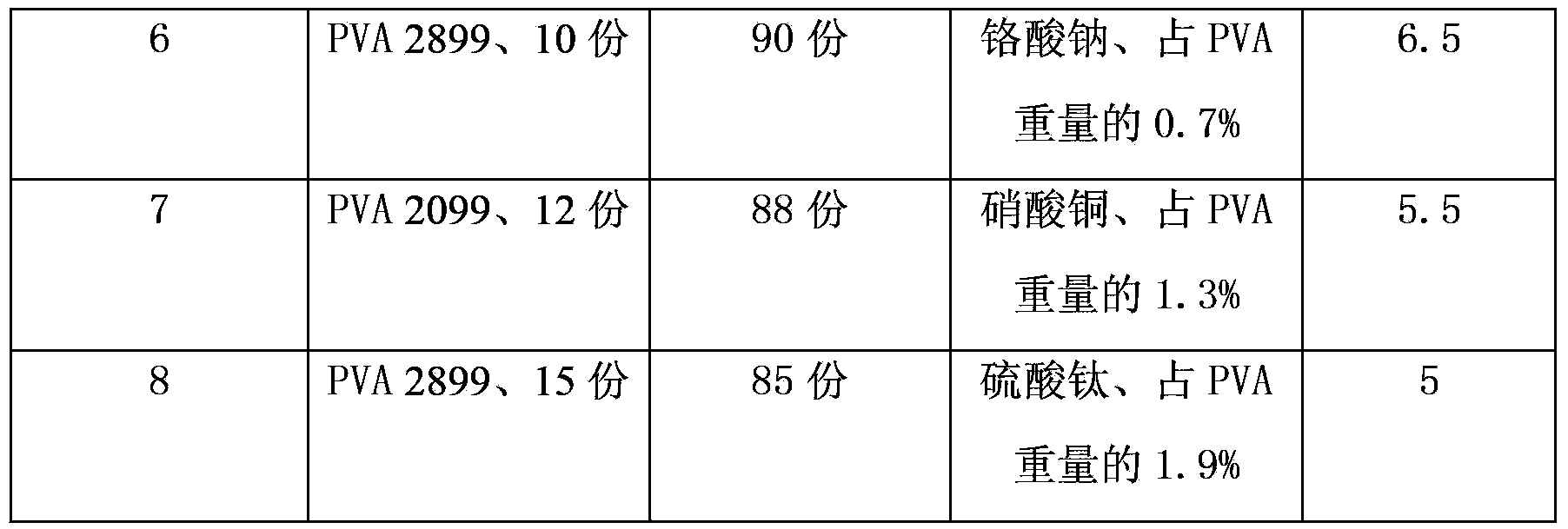

Fine-denier or superfine-denier polyvinyl alcohol fiber and preparation method thereof

ActiveCN103388189AImprove spinnabilityReduce the amount addedArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberCopper nitrate

A preparation method of a fine-denier or superfine-denier polyvinyl alcohol fiber comprises the following steps: dissolving 10-15 parts of polyvinyl alcohol in 85-90 parts of deionized water at 95-98DEG C for 2-5h to form a homogeneous solution, adding a thickening agent having a weight being 0.1-2% of the weight of polyvinyl alcohol, adjusting the pH value of the homogeneous solution to 3-6.5 through using acetic acid, and allowing the viscosity of the homogeneous solution to 5000-30000cp in order to prepare a polyvinyl alcohol spinning stock solution, wherein the thickening agent comprises anyone of boric acid, borax, copper sulfate, copper chloride, copper nitrate, sodium chromate, potassium chromate and titanium sulfate; moulding the spinning stock solution to obtain a nascent fiber; and post-processing the nascent fiber to prepare the polyvinyl alcohol fiber. The low-concentration polyvinyl alcohol spinning stock solution has the advantages of good spinnability, good storage stability, stable and continuous spinning process, and relatively few phenomena of broken filaments; and the yield is above 95%. The obtained fiber has a low linear density in a range of 0.16-1.00dtex, a tensile strength of 5-8cN / dtex and an elongation at break of 5-15%, and the Rp value of the obtained formalized fiber is 110-125DEG C.

Owner:CHINA PETROCHEMICAL CORP +2

Method for coating hollow microbeads with titanium-lanthanum oxides

InactiveCN102226042AImprove thermal insulation performanceImprove bindingReflecting/signal paintsPigment physical treatmentSurface oxidationRutile

The present invention discloses a method for coating hollow microbeads with titanium-lanthanum oxides. By the method, the surfaces of the hollow microbeads are evenly coated with rutile nano titanium oxide and have a good reflection effect, and the heat-insulation effect of the coating is improved. The method comprises: heating a mixed solution of titanium sulfate solution and lanthanum sulfate solution while stirring to 75-90 DEG C, maintaining the constant temperature and controlling the stirring speed at 500-800 rpm, and simultaneously adding soaked hollow microbeads to the mixed solution at a constant speed within 60-90 minutes; adjusting the pH value of the system to 8.0-9.5, then stirring the system at the stirring speed of 30-80 rpm for 40-90 minutes, and simultaneously ultrasonically vibrating the system; then filtering and washing until the material has a solid content of more than 40%; then carrying out microwave treatment for 15-25 minutes until the material has a solid content of more than 90% and fluffy oxidized surfaces; and heating the material in a roaster to 300 DEG C, maintaining for 1-3 hours, then heating to 900 DEG C and maintaining for 30-60 minutes so that titanium hydroxide coated on the surface of the hollow microbeads is transformed into rutile titanium dioxide.

Owner:TIANJIN HENGSHITONG ENG TECH DEV

Method for modifying surface of cotton fabric by adopting titanium sulfate and urea

ActiveCN101876142AImproves UV resistanceImprove antibacterial propertiesVegetal fibresUltravioletHigh pressure

The invention discloses a method for modifying the surface of cotton fabric by adopting titanium sulfate and urea, which comprises the following steps: ultrasonically oscillating and cleaning the cotton fabric to be modified at 80 DEG C, and then, drying the cotton fabric; weighing the cotton fabric and titanium sulfate according to the mass ratio of 3:2-10; weighing urea under the condition that the molar ratio of the titanium sulfate to the urea is 0.1-0.5:1; dissolving the titanium sulfate in deionized water under the condition that the volume ratio of the titanium sulfate to the deionized water is 1:6-30; adding the urea into the titanium sulfate solution, and stirring to obtain a mixed solution; soaking the cotton fabric into the mixed solution for 10-40min; putting the cotton fabric into a high-temperature and high-pressure reaction kettle for treating for 1.5-3h at the constant temperature of 130-160 DEG C; taking out the cotton fabric; washing the cotton fabric with washing liquid for 10-20min at 70-90 DEG C according to the bath ratio of 1:30-50; repeatedly washing the cotton fabric with hot water and cold water; and then, drying or naturally airing the cotton fabric to obtain the modified cotton fabric. The method of the invention is safe and pollution-free, has high production efficiency and saves raw materials; and the modified cotton fabric has good anti-ultraviolet and anti-bacterial properties and washing resistance.

Owner:BROS EASTERN

Flowerlike-structure titanium dioxide formed by spindle single crystal and preparation method thereof

InactiveCN102560649ALow costHigh crystallinityPolycrystalline material growthFrom normal temperature solutionsActive agentSingle crystal

The invention discloses a flowerlike-structure titanium dioxide formed by spindle single crystal and a preparation method thereof. The method includes firstly preparing 0.05mol / 1 titanic sulfate aqueous solution, then adding urea and ethylenediaminetetraacetic acid disodium salt, obtaining white suspension by magnetic stir for 3 hours, placing the mixture in an autoclave liner with polytetrafluoroethylene, then placing the autoclave in a microwave reaction instrument at a reacting temperature of 180 DEG C and keeping heating insulation for 10 minutes until the reaction is finished and the natural cooling of the autoclave is finished, taking out reaction products, repeatedly washing the products by using deionized water and anhydrous ethanol to remove surfactants, finally drying the products in a drying box at the temperature of 70 DEG C, and obtaining finished products. According to the flowerlike-structure titanium dioxide formed by spindle single crystal and the preparation method thereof, the titanium dioxide can be widely used in technologies of depollution of environment and dye-sensitized solar cells, and the method has the advantages of being rapid in synthesis, uniform in products and simple in operating and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

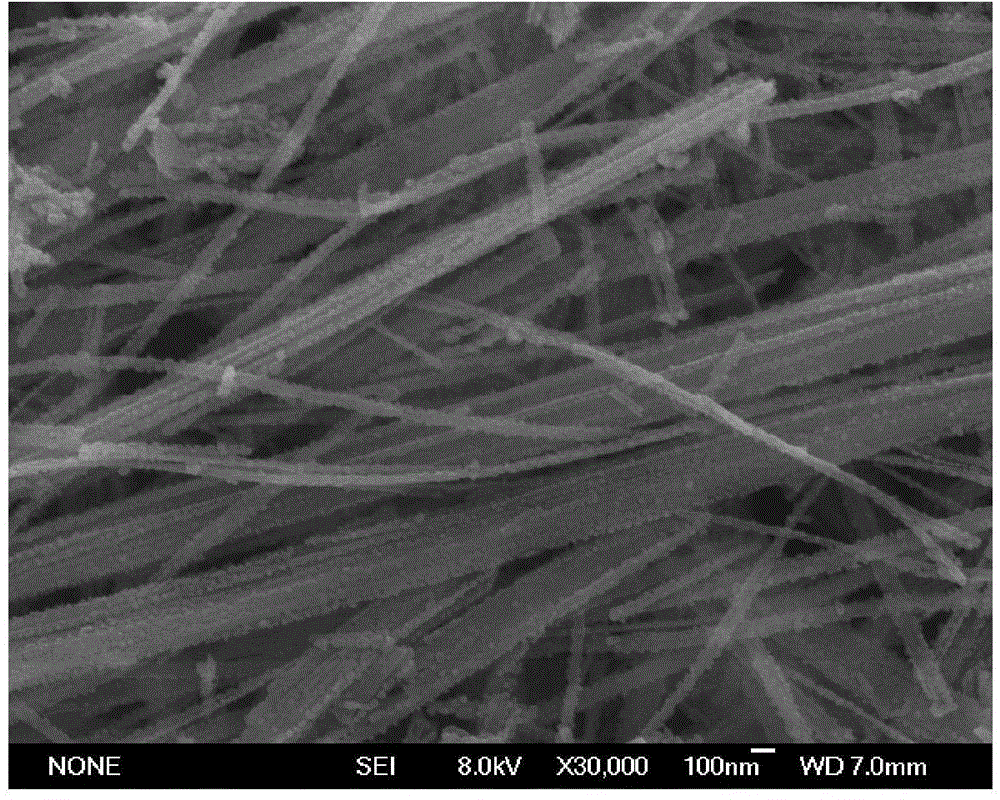

Precious metal loaded TiO2 nanorod photocatalyst preparation method

ActiveCN104923216AGood monodispersitySimple preparation processMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsDispersityTetrafluoroethylene

The invention discloses a precious metal loaded TiO2 nanorod photocatalyst preparation method. A precursor of a precious metal loaded TiO2 nanorod is obtained by one-step hydrothermal reaction of inorganic titanium sulfate and precious metal salt. The method includes: dissolving the titanium sulfate, the precious metal salt, hexamethylene tetramine and sodium hydroxide into water, stirring uniformly to obtain mixed solution, carrying out hydrothermal reaction in a high-pressure reactor with a tetrafluoroethylene liner to obtain the precious metal loaded TiO2 precursor, soaking in dilute sulphuric acid and calcining to obtain the precious metal loaded TiO2 nanorod. The precious metal loaded TiO2 nanorod photocatalyst preparation method has the advantage of simplicity in operation and high dispersity and excellent photocatalytic activity of precious metal / TiO2 nanorod photocatalyst.

Owner:四川发展环境科学技术研究院有限公司

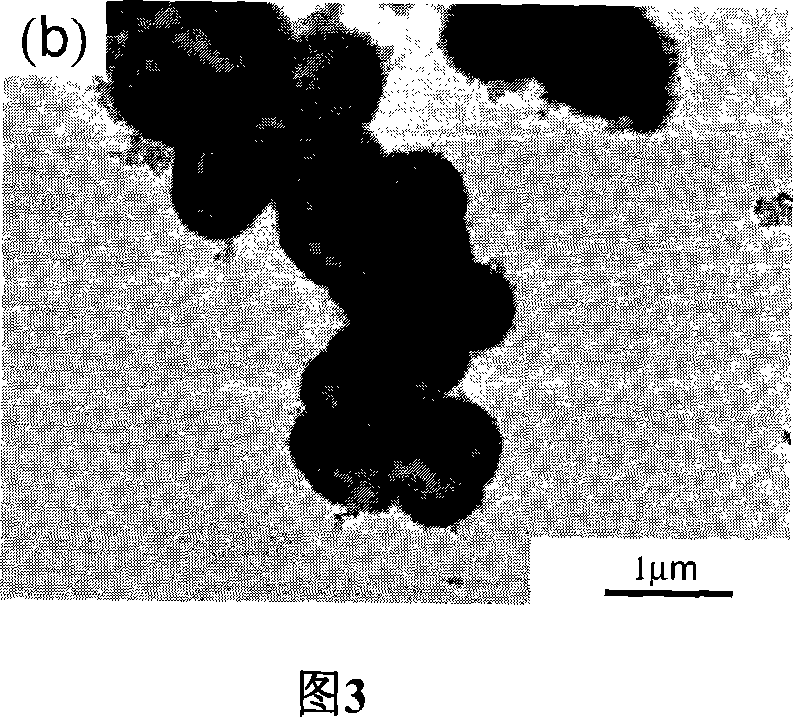

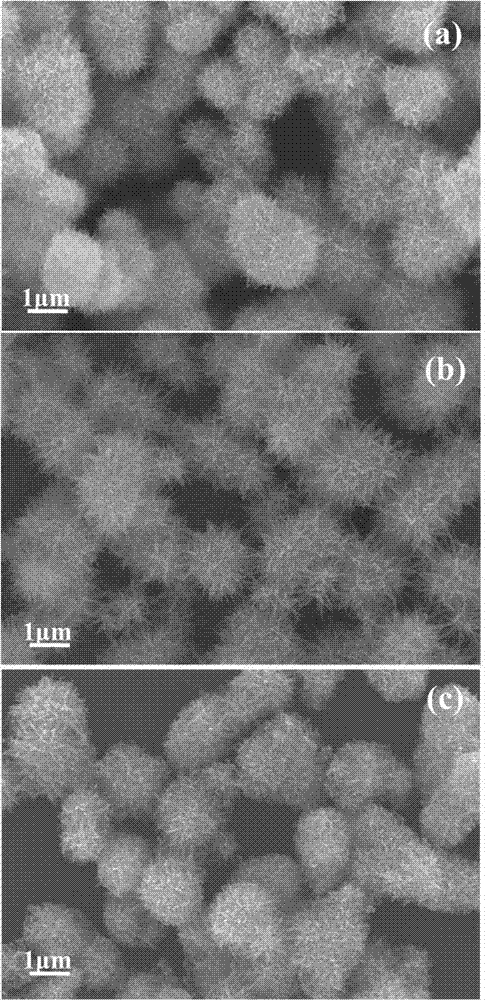

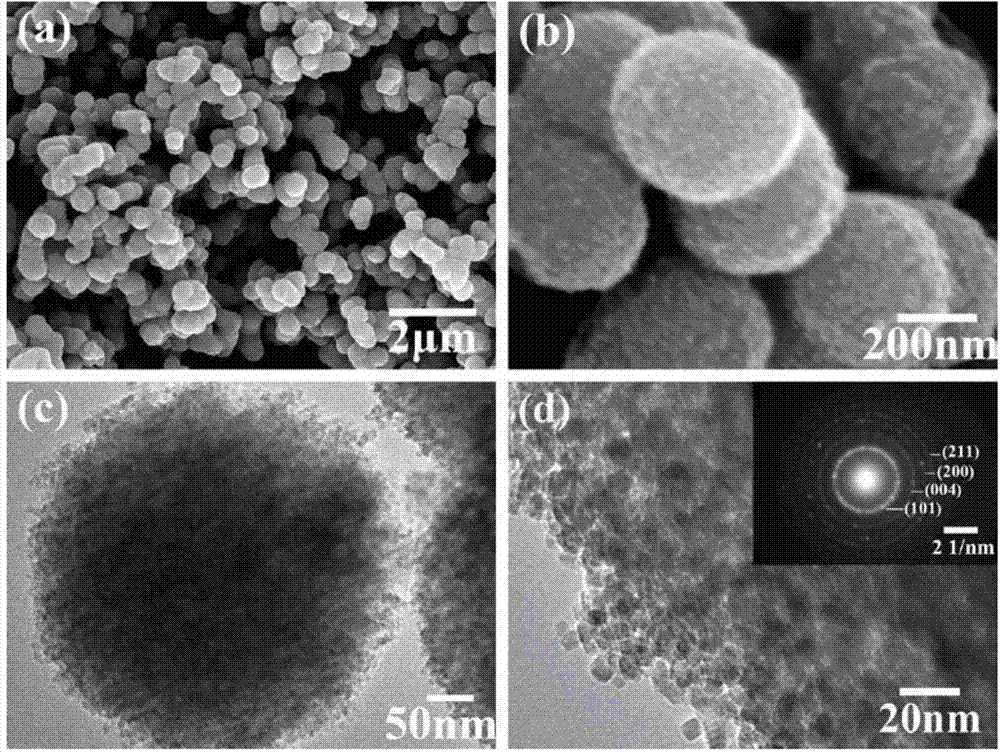

Micro/nano hierarchical titanium dioxide microspheres as well as preparation method and application thereof

ActiveCN103771506AEasy to makeNo further processing requiredPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereHydrolysis

The invention discloses micro / nano hierarchical titanium dioxide microspheres composed of different nano units (nano-particles, nano-sheets and nano-rods included) as well as a preparation method and an application thereof. The hydrolysis, nucleation and crystallization processes of the titanium source titanium sulfate are mainly controlled with urea, ethylenediamine tetraacetic acid and ammonium fluoride, and then the micro / nano hierarchical titanium dioxide microspheres are obtained through a one-step rapid microwave hydrothermal reaction. The preparation method is simple in preparation process, and only comprises the steps of adding a precursor at first and then carrying out the one-step microwave hydrothermal reaction without subsequent treatment. The preparation method is short in reaction time, high in yield and prone to large-scale production. The micro / nano hierarchical titanium dioxide microspheres can be widely applied to light degradation treatment of organic pollutants.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com