Method for preparing hollow glass microsphere coating titanium dioxide

A technology of hollow glass microspheres and titanium dioxide, applied in chemical instruments and methods, dyeing organosilicon compound treatment, inorganic pigment treatment, etc., can solve problems such as uneven deposition of titanium dioxide, low coating efficiency of titanium dioxide, and large amount of titanium raw materials. Achieve the effects of increased reflectance, high-efficiency coating, and increased whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

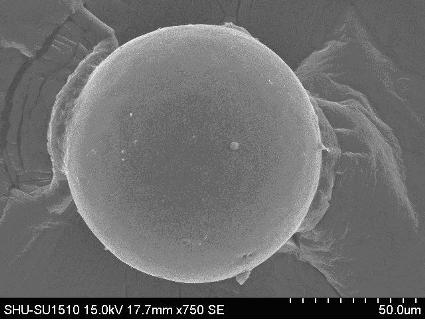

[0030] At room temperature, put 10g of hollow glass microspheres in a 50g beaker of 0.1mol / L NaOH solution, stir for 20min at a controlled stirring speed of 100r / min, then let it soak for 5h, dilute with distilled water, filter with suction, and rinse for 2-3 Secondary to neutral, dry at room temperature for later use; prepare 30g of a solution with a mass ratio of ethanol to water of 9.0:1, add 0.15g of 3-aminopropyltriethoxysilane (kh550) and stir evenly, then add micro beads, stirred at 70°C and 70r / min for 2h, directly suction filtered, and placed in a 100°C oven to react for 2h to obtain activated modified hollow glass microspheres.

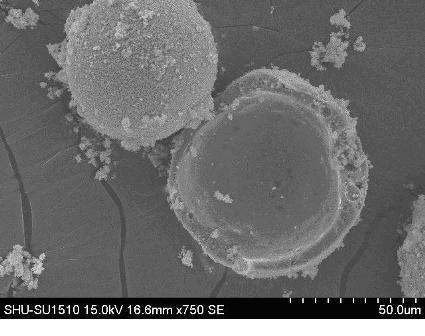

[0031] Add 5g of activated and modified hollow glass microspheres and 50g of distilled water into a four-neck flask, and fully stir for 15min at 70°C and 200r / min stirring speed to obtain a uniformly dispersed suspension of hollow glass microspheres; drop at a constant speed within 4h Add 60 g of titanium sulfate solution with a mass fractio...

Embodiment 2

[0033] The activation treatment of the hollow glass microspheres follows the corresponding part of Example 1.

[0034] Add 5g of activated and modified hollow glass microspheres and 50g of distilled water into a four-necked flask, and fully stir for 15min at 50°C and 200r / min stirring speed to obtain a uniformly dispersed suspension of hollow glass microspheres; drop at a constant speed within 3h Add 57g of titanium sulfate solution with a mass fraction of 7%, and at the same time adjust the pH value to 5 with potassium hydroxide with a mass fraction of 8%, and control the stirring speed at 400r / min during the first 1 / 5 of the reaction of dripping the titanium solution. After the 4 / 5 reaction time, control the stirring speed to 100r / min; after the reaction is completed, let it stand for half an hour, filter it with suction, rinse it with distilled water for 2-3 times, dry it at 25°C, 50min at 60°C, and dry at 135°C 1h, heat up to 600°C at a rate of 60°C / min for 4h, and cool to...

Embodiment 3

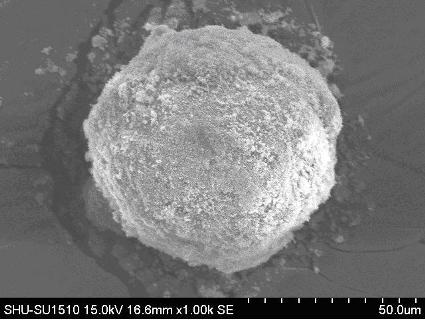

[0036] Put 10g of hollow glass microspheres in a 50g beaker of 0.5mol / L KOH solution, stir at a controlled stirring speed of 80r / min for 25min, then let it soak for 2h, dilute with distilled water, filter with suction, and rinse 2 to 3 times until medium Dry at room temperature for later use; prepare 30g of a solution with a mass ratio of ethanol to water of 8.6:1, add 0.3g of 3-(2,3-epoxypropoxy)propyltrimethoxysilane (kh560) and stir evenly and add an appropriate amount The acetic acid promotes the hydrolysis of kh560, then add the microbeads for drying, stir at 80°C and 50r / min for 1h, filter directly, and put them in an oven at 80°C for 5h to obtain activated modified hollow glass beads .

[0037] Titanium dioxide-coated hollow glass microspheres are treated according to the corresponding part of the implementation case 2. The effective utilization rate of titanium sulfate in the above process reaches 80%. This product can be directly used as a filler in reflective thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com