Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

628 results about "Ilmenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

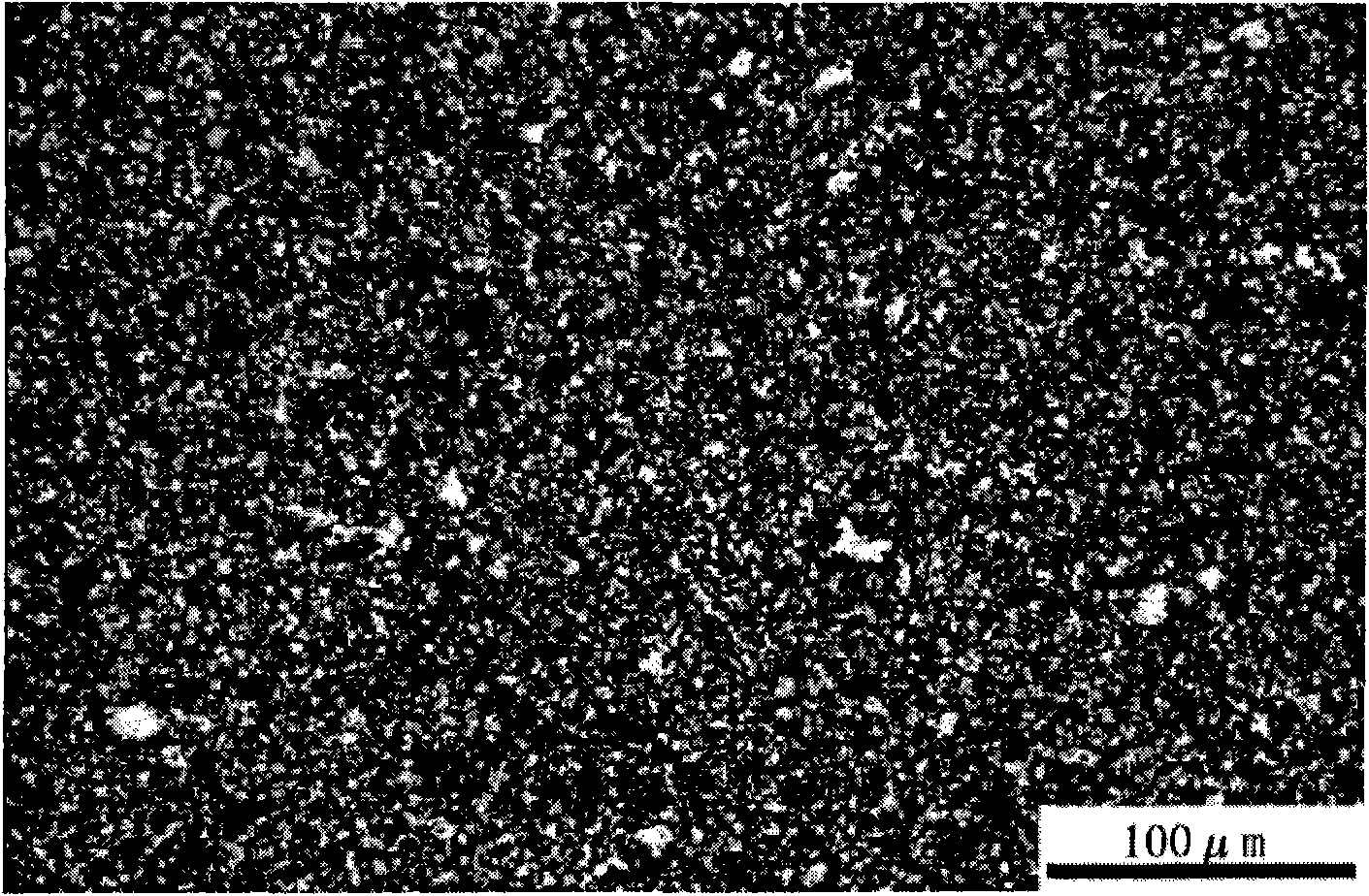

Ilmenite, also known as manaccanite, is a titanium-iron oxide mineral with the idealized formula FeTiO₃. It is a weakly magnetic black or steel-gray solid. From a commercial perspective, ilmenite is the most important ore of titanium. Ilmenite is the main source of titanium dioxide, which is used in paints, printing inks, fabrics, plastics, paper, sunscreen, food and cosmetics.

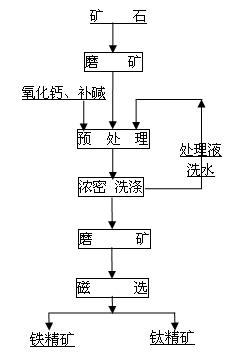

Beneficiating method for ilmenite

ActiveCN102181626AIncrease alkali concentrationHigh in ironBlast furnace detailsProcess efficiency improvementMagnetiteIlmenite

The invention discloses a beneficiating method for ilmenite, relating to a method for preparing titanium concentrate and iron concentrate by beneficiating crude ilmenite. The method is characterized in that: a beneficiating process of the method orderly comprises the following steps of: (1) grinding the crude ilmenite; (2) performing alkaline leaching pretreatment under the conditions of heating, oxygenating and pressurizing; (3) filtering pulp which is subjected to the alkaline leaching pretreatment; (4) washing filter residue and grinding; and (5) performing magnetic separation to obtain the titanium concentrate and the iron concentrate. In the method provided by the invention, the characteristic of iron and titanium compact symbiosis and the isomorphism occurrence characteristic of vanadium are damaged from the source of vanadium titano-magnetite by adopting the pretreatment process, so that mineral transformation of the vanadium titano-magnetite is realized, dissociation on lattice layers of titanium and iron is realized, high-quality iron concentrate and titanium concentrate with lower iron content are obtained through grinding and the magnetic separation process, an alkaline medium used in the pretreatment can be recycled, and the process has a small influence on environment and a bright application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

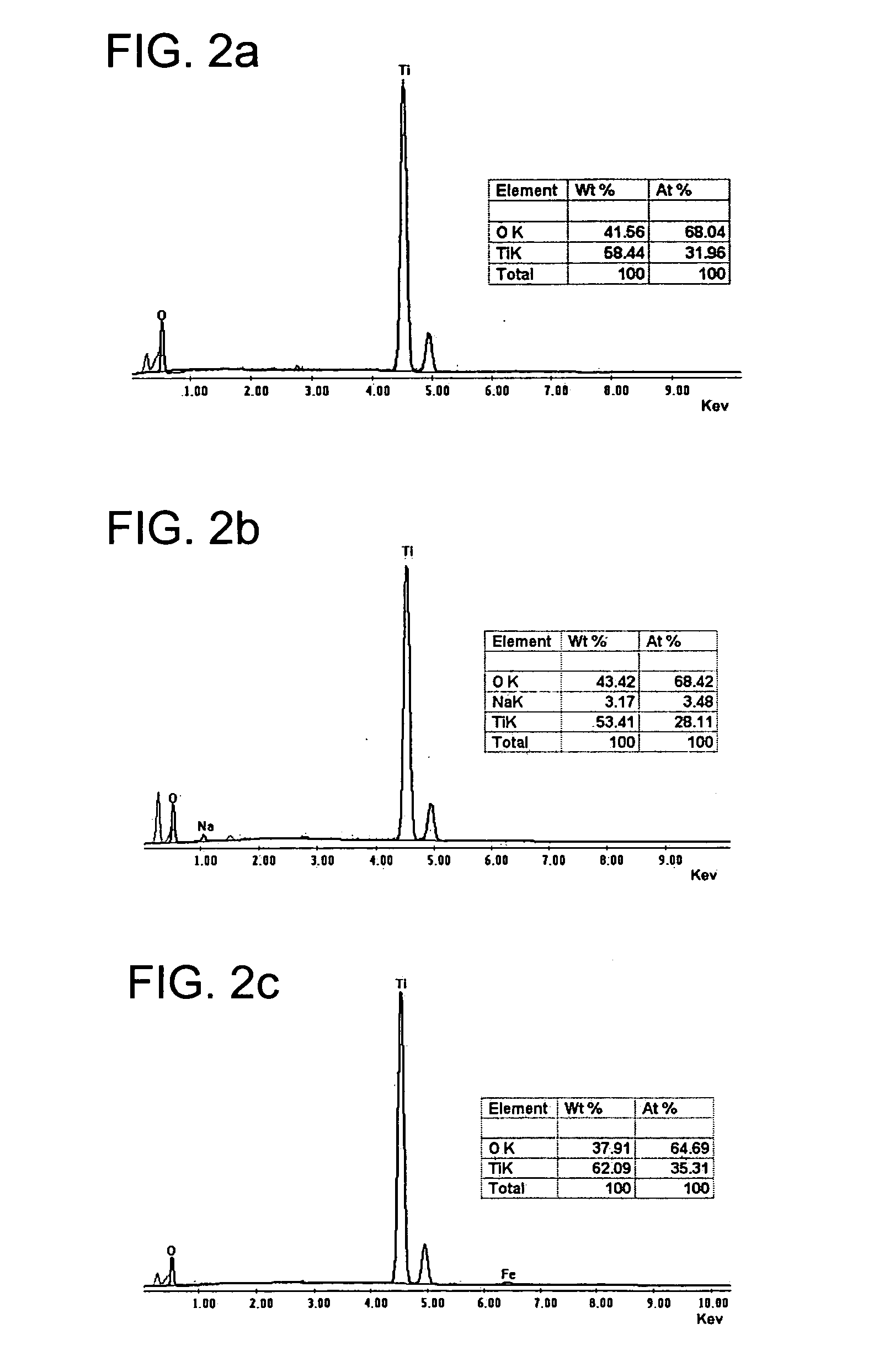

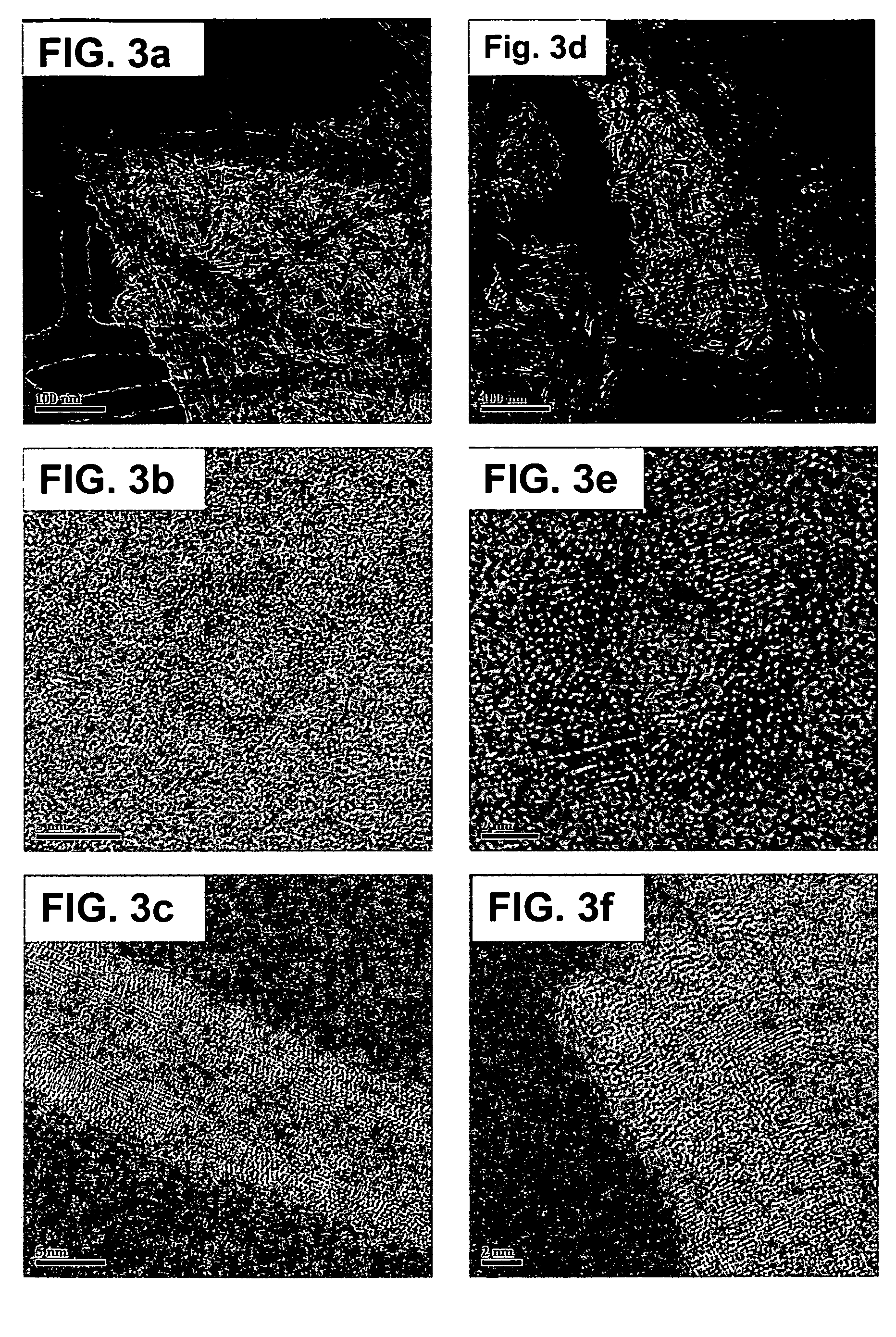

Nanostructured titanium oxide material and its synthesis procedure

ActiveUS20060078726A1Stable nanotubular structureLarge specific surface areaMaterial nanotechnologyLayered productsFiberNanowire

Nanomaterials of the JT phase of the titanium oxide TiO2-x, where 0≦x≦1 having as a building block a crystalline structure with an orthorhombic symmetry and described by at least one of the space groups 59 Pmmn, 63 Amma, 71 Immm or 63 Bmmb. These nanomaterials are in the form of nanofibers, nanowires, nanorods, nanoscrolls and / or nanotubes. The nanomaterials are obtained from a hydrogen titanate and / or a mixed sodium and hydrogen titanate precursor compound that is isostructural to the JT crystalline structure. The titanates are the hydrogenated, the protonated, the hydrated and / or the alkalinized phases of the JT crystalline phase that are obtained from titanium compounds such as titanium oxide with an anatase crystalline structure, amorphous titanium oxide, and titanium oxide with a rutile crystalline structure, and / or directly from the rutile mineral and / or from ilmenite. The titanates are submitted to dynamic thermal treatment in an inert, oxidizing or reducing atmosphere to produce the JT phase of the TiO2-x, where 0≦x≦1 with an orthorhombic structure.

Owner:INST MEXICANO DEL GASOLINEEO

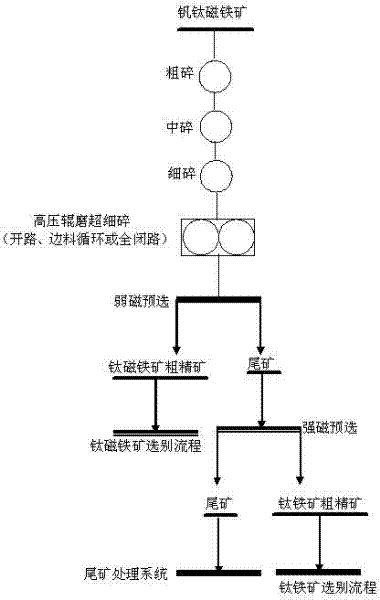

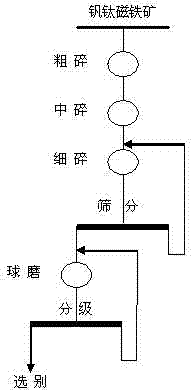

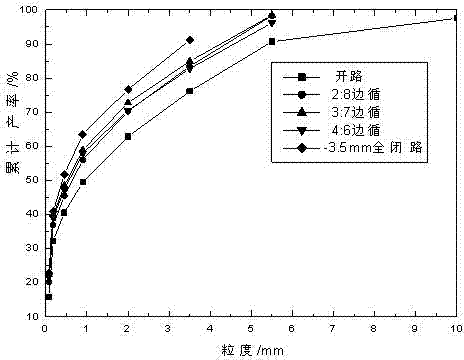

High-pressure roller milling-preselection processing method for vanadic titanomagnetite

InactiveCN102172556AHigh tail yieldRaise the gradeMagnetic separationGrain treatmentsMagnetiteEngineering

The invention discloses a high-pressure roller milling-preselection processing method for vanadic titanomagnetite. The raw ore is subjected to coarse crushing, secondary crushing, fine crushing and high-pressure roller milling superfine crushing, an open circuit crushing, scrap circulation crushing or fully-closed circuit crushing method is adopted, and low-intensity magnetism and high-intensity magnetism preselection is performed. The method disclosed by the invention reduces the energy consumption of crushing and ore milling and improves the ore selection efficiency in comparison with the conventional process; and the low-intensity magnetism and high-intensity magnetism preselection can separately select the main target ores-titanomagnetite and ilmenite in the vanadic titanomagnetite with higher pertinence, and the ore selection flow is simpler. By adopting a high-pressure roller mill as the superfine crushing apparatus after fine crushing, the particle size of the final crushed product can be reduced, and meanwhile, the preselection tailing discarding before milling is realized, the milling grade is improved and the energy consumption of ore milling is reduced. Compared with the traditional process, the particle size of the product is small, the equipment operation rate is high, and the unit crushing energy consumption is low. Meanwhile, the superfine crushed product can besubjected to preselection tailing discarding so as to improve the milling grade, reduce the energy consumption of ore milling, lighten the burden on subsequent selection process and improve the production efficiency.

Owner:NORTHEASTERN UNIV +1

Medicament for mineral separation and floatation of ilmenite in Shandong province

The invention discloses a medicament for mineral separation and floatation of ilmenite in Shandong province, comprising a collector-MOH, a modifier, an inhibitor and an activator, wherein the mass percentage concentration of the collector-MOH, the modifier, the inhibitor and the activator is a solution with the concentration being 1-10%. The composite mineral separation medicament by matching makes up the defects of single medication, and improves the quality and efficiency of the floatation; and titanium concentrates containing TiO2 with the concentration being 40-48.73% can be produced after fine separation of the floatation.

Owner:山东太生钛业有限公司

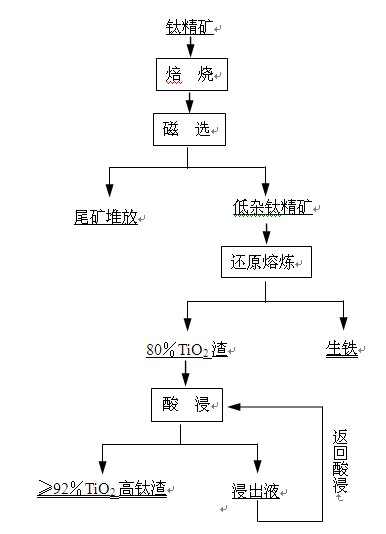

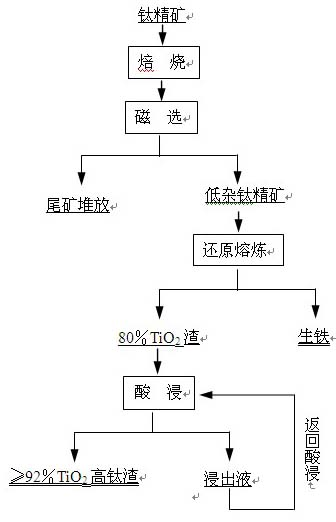

Method for preparing titanium-enriched material from high-impurity-content ilmenite concentrate

The invention discloses a method for preparing a titanium-enriched material from high-impurity-content ilmenite concentrate, which relates to the technical field of a preparation method of a titanium-enriched material. The technical route is as follows: raw ore, magnetic separation, iron concentrate, tailings, floatation, ilmenite concentrate, roasting, magnetic separation, reduction smelting, titanium slag, purification and titanium-enriched material. The invention integrates the advantages of an electric-furnace smelting method and an acid leaching method, and overcomes the defects of the two methods; and thus, the method provided by the invention can be used for treating high-impurity-content rock-type ilmenite concentrate, and can also be used for producing a high-quality titanium slag product.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

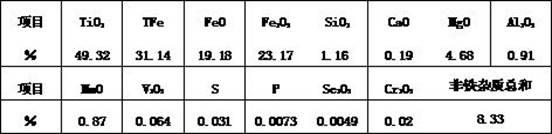

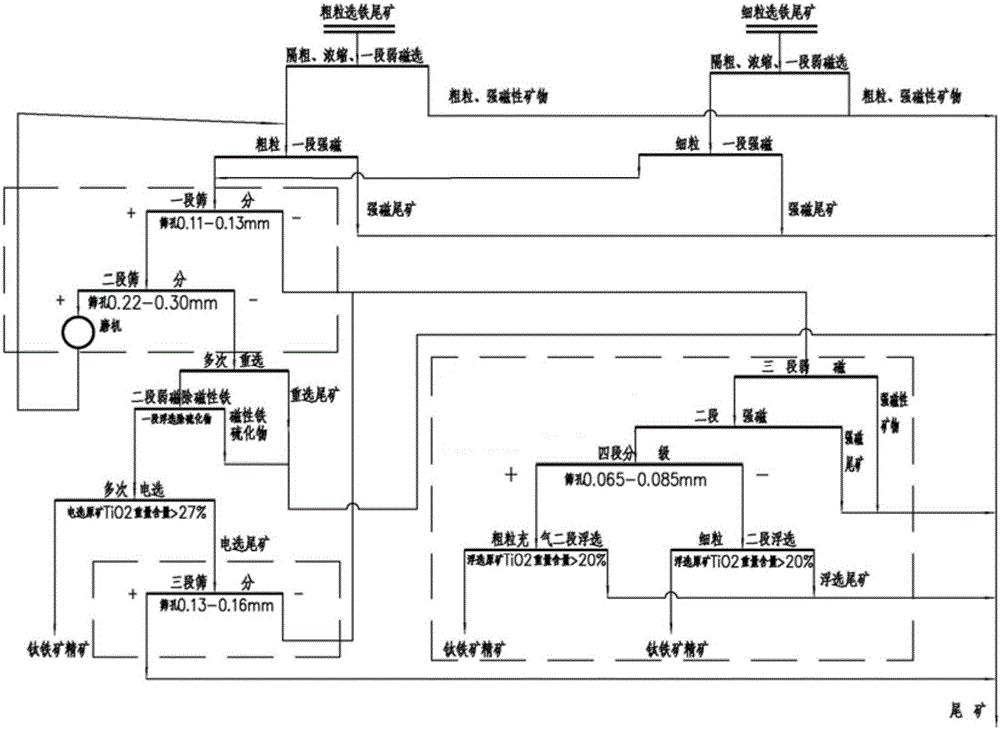

Beneficiation method of low-grade ilmenite

ActiveCN103041912AQuality assuranceHigh recovery rateWet separationMaterials scienceMagnetic separation

The invention provides a beneficiation method of low-grade ilmenite. The beneficiation method includes the following steps: screening and grading raw ore to obtain coarse grain materials and fine grain materials, subjecting the coarse grain materials and fine grain materials to first-stage iron removal respectively to obtain coarse grain iron tailings, fine grain iron tailings and inferior iron ore concentrates, subjecting the coarse grain iron tailings with iron removed to first-stage high intensity magnetic separation to obtain high intensity concentrates and tailings, subjecting the high intensity concentrates to spiral gravity to obtain gravity concentrates and subjecting the gravity concentrates to ore grinding, subjecting the fine grain iron tailings with iron removed to first-stage high intensity magnetic separation and second-stage high intensity magnetic separation sequentially to obtain high intensity magnetic concentrates and mixing the high intensity magnetic concentrates with the gravity concentrates with ore ground to be graded, and subjecting the unqualified graded mixed concentrates to ore grinding and subjecting the qualified mixed concentrates to second-stage iron removal, three-stage high intensity magnetic separation and flotation sequentially to obtain the final ilmenite concentrates. The beneficiation method of ilmenite is applicable to low-grade ilmenite. According to the beneficiation method, the quality of the ilmenite concentrates can be ensured while the recovery of the ilmenite concentrates can be improved, thereby great economic benefit can be obtained.

Owner:PANGANG GRP MINING

Collector for floating ilmenite and preparation method thereof

The invention discloses a collector for floating ilmenite and a preparation method thereof. The collector is mainly prepared from the following components by mass percent: 40-60% of peroxide fatty acid soup, 5-15% of emulsifiers, 10-30% of oil substance and the balance of water. The preparation method comprises the following steps: mixing the components uniformly according to the mass percent ratio, throwing the mixture into a reaction kettle and stirring the mixture for 0.5-1 hour, thus obtaining the collector. The collector has the advantages of small amount, low cost, strong collecting capability, safety, nontoxicity, capability of reducing the amount of media such as modifiers.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Ilmenite beneficiation method and equipment

InactiveCN104607296AGood beneficiation indexAlleviate the shortageGrain treatmentsWet separationIlmeniteEngineering

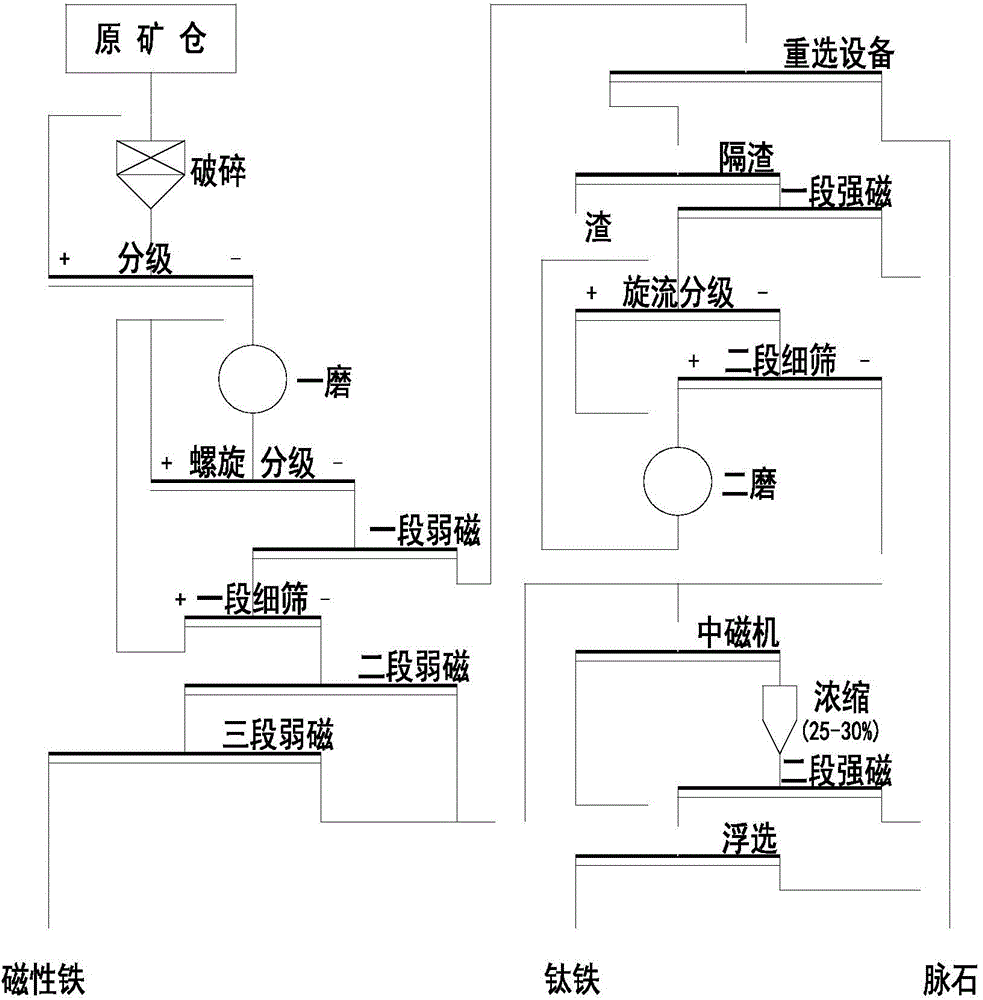

The invention provides an ilmenite beneficiation method and equipment, and is suitable for comprehensive utilization of low grade ilmenite resources. The method and the equipment provided by the invention can be used for separating materials by fully using three kinds of physical differences of useful components in ilmenite magnetic iron and ferrotitanium and useless gangues, such as magnetism, density and surface hydrophilicity, as well as the property of the stage degree of dissociation. In the whole separating process, by using a magnetic-gravity separation-flotation combined process, the magnetic iron which is the strongest in magnetism is separated by using a magnetic separating method firstly, and then the ferrotitanium is selected by using a method of gravity separation combined with strong magnetic combined flotation. In the whole separating process, a graded ore grinding and graded beneficiation method is adopted, and in the process of separating the ferrotitanium, ore is secondarily ground, so that the ferrotitanium containing part of impurities after strong magnetism in the first stage is further dissociated, and therefore, relatively good beneficiation indexes are obtained.

Owner:LONGI MAGNET CO LTD

Collector for flotation collecting ilmenite and its preparation method

The invention discloses a collector to float and collect ilmenite and preparing method, which comprises the following parts: oleic acid, powdered ore floatation agent, emulsifier and alkaline.

Owner:TITANIUM FILIALE PANZHIHUA STEEL

Technology for producing vanadium chromium manganese alloyed pig iron by melting vanadium extraction tailings

InactiveCN102337444AUnreasonable useBlast furnace detailsRecycling and recovery technologiesManganeseDolomite

The invention provides a technology for producing vanadium chromium manganese alloyed pig iron by melting vanadium extraction tailings. According to the technology, the vanadium extraction tailings are mainly prepared into a grain raw material with its granularity being 5-150 millimeters as a raw material in a melting furnace. The grain raw material, which contains agglomerate, cooled agglomerated pellets (blocks) and metallized pellets (blocks), is mixed with coke, ilmenite (blocks or pellets), limestone, dolomite and fluorite. And the mixture is melted by the melting furnace to obtain the alloyed pig iron containing vanadium, chromium and manganese. Based on different components of the grain raw material, the ratio of the grain raw material to ilmenite (blocks or pellets) to limestone to dolomite to fluorite is 1: (0-0.25): (0-0.40): (0-0.10): (0-0.15). According to the proportioning principle, the weight ratio of CaO to SiO2 to TiO2 in the melting furnace slag is controlled within the range of 1: (0.5-1.0): (0.6-1.6), and the slag melting point is made low. The melting furnace is a blast furnace, a submerged arc furnace and a hot-blast cupola.

Owner:王洪东

Novel metal ceramic composite material and preparation method thereof

The invention relates to a novel metal ceramic composite material and a preparation method thereof. The novel metal ceramic composite material adopts Al2O3 ceramic as matrix and adopts Ti(C, N) ceramic hard particles and Fe metal as disperse phase. The novel metal ceramic composite material comprises the following main components by weight percent: 50-70 percent of Al2O3, 20-30 percent of Ti(C, N), 5-20 percent of Fe and the balance of inevitable impurities such as Mn, Si, Ca and the like. The preparation method selects Panzhihua ilmenite (FeTiO3) as raw material rich in China, adopts a hot pressed sintering technique to directly prepare low-cost Al2O3 / Ti(C, N) / Fe metal ceramic composite material on the basis of carbothermal and aluminithermic reduction. Compared with the similar metal ceramic composite material, the novel metal ceramic composite material has quite good comprehensive mechanical property and excellent wear resistance, corrosion resistance, oxidation resistance, thermal shock resistance and the like, also has simple preparation technique and low cost and opens up a new way for fully and effectively utilizing rich resources in China.

Owner:CHONGQING UNIV

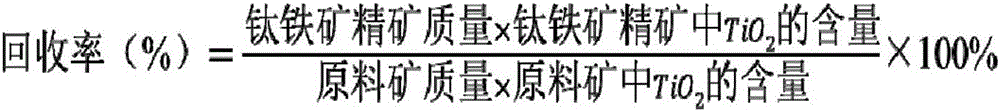

Method for recycling ilmenite from vanadium titano-magnetite iron dressing tailings

ActiveCN106179720AOvercome costsHigh recovery rateMechanical material recoveryWet separationMagnetiteClassification methods

The invention discloses a method for recycling ilmenite from vanadium titano-magnetite iron dressing tailings. The method comprises the steps that the specific susceptibility of main gangue in the iron dressing tailings, the specific susceptibility of the ilmenite in the iron dressing tailings and the content of TiO2 in the iron dressing tailings are determined; when the iron dressing tailings meet the condition 1, the iron dressing tailings are subjected to first-section strong magnetic separation, first-section strong magnetism concentrates are subjected to one-time or multi-time reselection, and gravity concentrates are obtained; the gravity concentrates are subjected to first-time flotation and one-time or multi-time electric separation, and ilmenite concentrates are obtained, wherein the condition 1 can be shown in the formula: X1>(X2*60%), the total amount of the iron dressing tailings serves as a standard, the content of the TiO2 in the iron dressing tailings is lower than 5 wt%, X1 is the specific susceptibility value of the main gangue in the iron dressing tailings, and X2 is the specific susceptibility value of the ilmenite in the iron dressing tailings; and otherwise, the iron dressing tailings are subjected to a strict granularity classification method. By mean of the method, the production cost of the ilmenite is reduced, and the grade of the TiO2 of selected raw ore obtained after electric separation and flotation is improved.

Owner:PANGANG GRP MINING

Method of preparing synthetic rutile from ore type ilmenite concentrate

InactiveCN1923703AEliminate the hidden danger of loopingImprove reducibilityTitanium dioxideIlmeniteTitanium

The invention discloses an artificial rutile preparing method through rock ilmenite concentrate, which comprises the following steps: preheating rock ilmenite concentrate in the rotary kiln to reduce directly; separating the corrosion of reduced ilmenite; immersing material with titanium in the diluted acid to remove impurity to prepare the artificial rutile.

Owner:CENT SOUTH UNIV

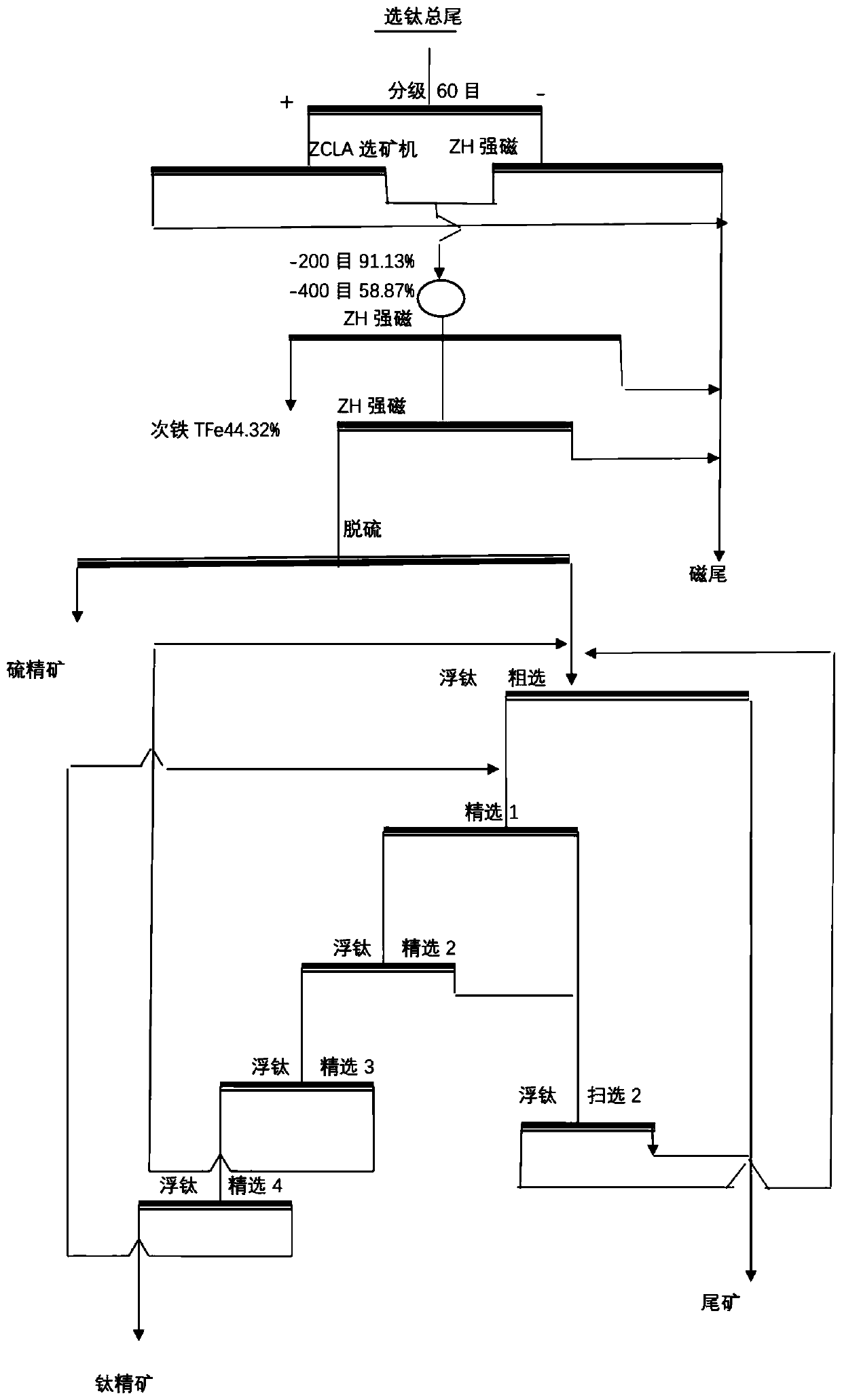

Method for recycling micro-particle ilmenite through vanadium-titanium magnetite titanium beneficiation main tailings

ActiveCN110882826AIncrease profitAvoid wastingFlotationMagnetic separationMagnetiteMagnetic separator

The invention belongs to the technical field of mineral processing, and particularly relates to a method for recycling micro-particle ilmenite through vanadium-titanium magnetite titanium beneficiation main tailings. For the problems that in the prior art, the micro-particle yield of micro-particle-level ilmenite in vanadium-titanium magnetite titanium beneficiation main tailings is large, and themicro-particle-level TiO2 distribution rate is high, according to the technical scheme of the method, classifying equipment is adopted for classifying the vanadium-titanium magnetite titanium beneficiation main tailings, a ZCLA concentrating machine is adopted for enrichment for the coarse fraction, a ZH combined magnetic separator is adopted for enrichment for the fine fraction, and after concentrates of two devices enter a ball mill for ore grinding, the ZH combined magnetic separator is adopted for one roughening and one refining, ZH concentrates with the TiO2 grade larger than 18% are obtained, then preselection desulfuration and one-roughening, four-refining and one-sweeping refining are conducted, and titanium concentrates with the TiO2 grade larger than 47% are obtained.

Owner:SICHUAN LOMON MINING & METALLURGY +1

Comprehensive utilization method of waste denitration catalyst

The invention relates to a comprehensive utilization method of an waste denitration catalyst, and belongs to the field of comprehensive utilization of waste catalysts. The method comprises the following steps: crushing a waste denitration catalyst, and then separating vanadium pentoxide out of the waste denitration catalyst by pickling reduction; carrying out the operations such as enrichment, oxidation, molybdenum precipitation, deamination and the like on the separated vanadium pentoxide, so as to reach the purification target. By adopting the method, the vanadium pentoxide in the waste denitration catalyst can be separated from other metal oxides and is further purified, the material left after the vanadium pentoxide is separated out is used for replacing ilmenite to serve as the raw material for producing titanium dioxide by a sulfuric acid method, thereby reaching the comprehensive utilization of the waste denitration catalyst.

Owner:LUOHE XINGMAO TITANIUM IND

Beneficiation method of ilmenite

The invention discloses a beneficiation method of ilmenite and relates to the method for performing beneficiation on an ilmenite raw ore to prepare iron ore concentrate and ilmenite concentrate. The beneficiation method is characterized in that the beneficiation process comprises the following steps of (1) smashing the ilmenite raw ore; (2) grinding the ilmenite raw ore; (3) performing alkaline leaching pretreatment under conditions of water adding, temperature rising, oxygen adding and pressurization; (4) filtering ore pulp after the alkaline leaching pretreatment; (5) washing a filtered filter residue phase and performing ore grinding; (6) utilizing a washbox and performing magnetic separation to obtain the iron ore concentrate and the ilmenite concentrate. According to the method, dense symbiosis features of titanium and iron and isomorphism occurrence features of vanadium are damaged from the source of vanadium titanium magnetite ores by means of the treatment procedure, mineral transformation of the vanadium titanium magnetite is achieved, dissociation on lattice levels of titanium and iron is achieved, and the high-quality iron ore concentrate and the low-iron ilmenite concentrate can be obtained through a magnetic separation process and ore grinding. Alkali medium utilized by pretreatment can be recycled, therefore, influence of the process on the environment is small, and the beneficiation method has good application prospects.

Owner:GUANGXI KESHENGDA MACHINERY MFG

Method for preparing lithium titanate precursor and lithium iron phosphate precursor by comprehensively utilizing ilmenite

InactiveCN101875488ALow costMake full use ofTitanium compoundsPhosphorus compoundsLithium iron phosphatePhosphate

The invention discloses a method for preparing a lithium titanate precursor and a lithium iron phosphate precursor by comprehensively utilizing ilmenite. The method is characterized by comprising the following steps of: 1) separating ferrotitanium: performing ball milling on the ilmenite, leaching the ilmenite with sulfuric acid, cooling and filtering the leached ilmenite to obtain filter residue and filtrate; 2) preparing a lithium titanate precursor: washing the obtained filter residue with dilute sulfuric acid, dissolving the filter residue in 75 to 90 percent sulfuric acid, diluting the mixture, adding a precipitator into the mixture for reaction, cooling, standing and filtering the mixture, and drying the filter residue to obtain the precursor of the lithium titanate; and 3) preparing the lithium iron phosphate precursor: diluting the filtrate, adding oxidant and precipitator into the solution, controlling the pH value of the system with aqueous solution of alkali, and washing, filtering and drying the precipitate after the reaction to obtain the precursor of the lithium iron phosphate, namely ferric phosphate. The method has the advantages of wide raw material source, simple process flow, high and stable product quality, and low cost and comprehensive and full utilization of the ilmenite.

Owner:CENT SOUTH UNIV

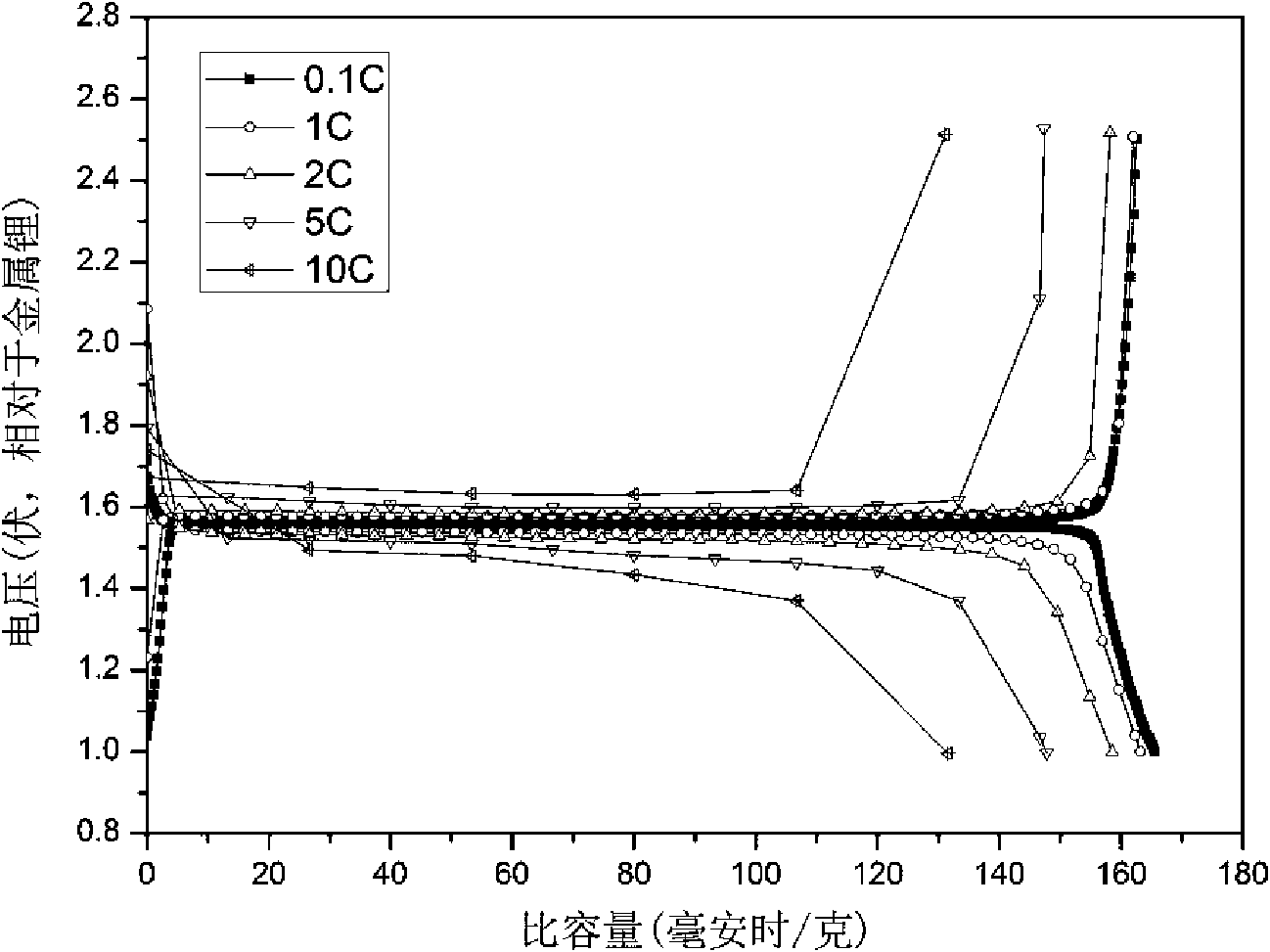

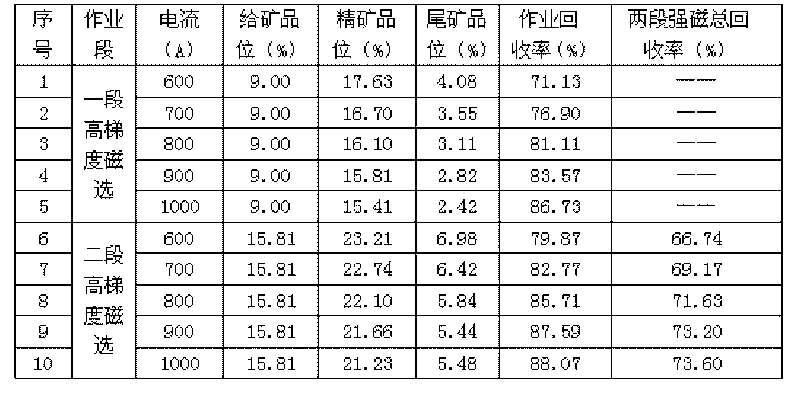

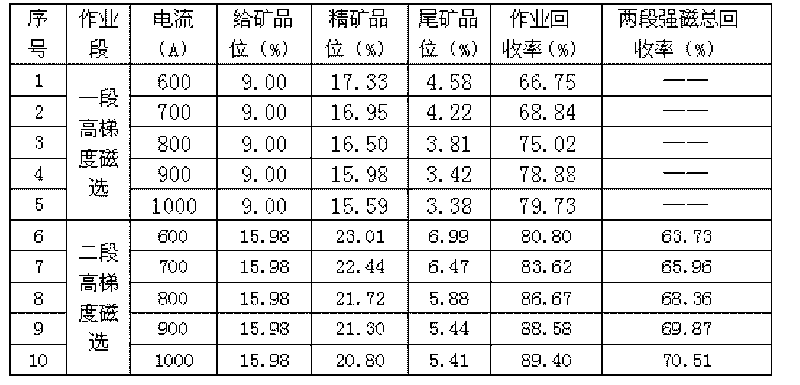

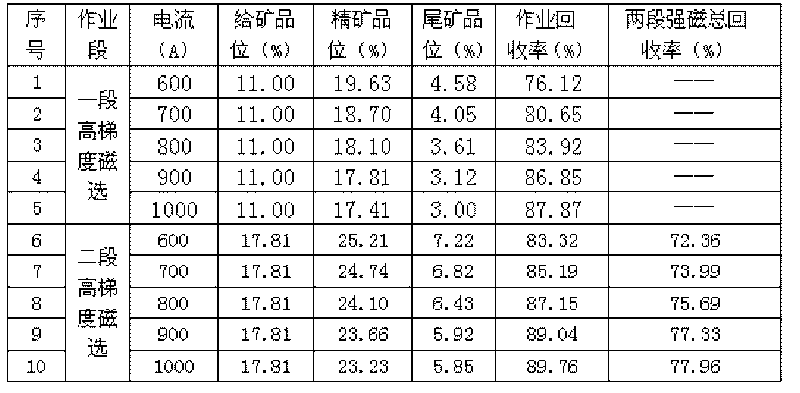

Process for recycling ilmenite through two stages of magnetic separation

ActiveCN101722103AImprove qualityHigh recovery rateHigh gradient magnetic separatorsIlmeniteTitanium

The invention relates to the field of ilmenite separation, in particular to a process for recycling ilmenite from a raw ore through magnetic separation. The technical problem to be solved is to provide an ilmenite recycling process with high recovery rate. The technical scheme for solving the technical problem is to provide the process for recycling the ilmenite through two stages of high-gradient magnetic separation. The process comprises the following steps: performing primary high-gradient magnetic separation on the raw ores after a preparation operation to obtain a primary high-gradient magnetic concentrate; and performing secondary high-gradient magnetic separation on the primary high-gradient magnetic concentrate after the preparation operation to obtain a secondary high-gradient magnetic concentrate. The process can be applied in the field of the ilmenite separation, improves the recovery rate of titanium and reduces production cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

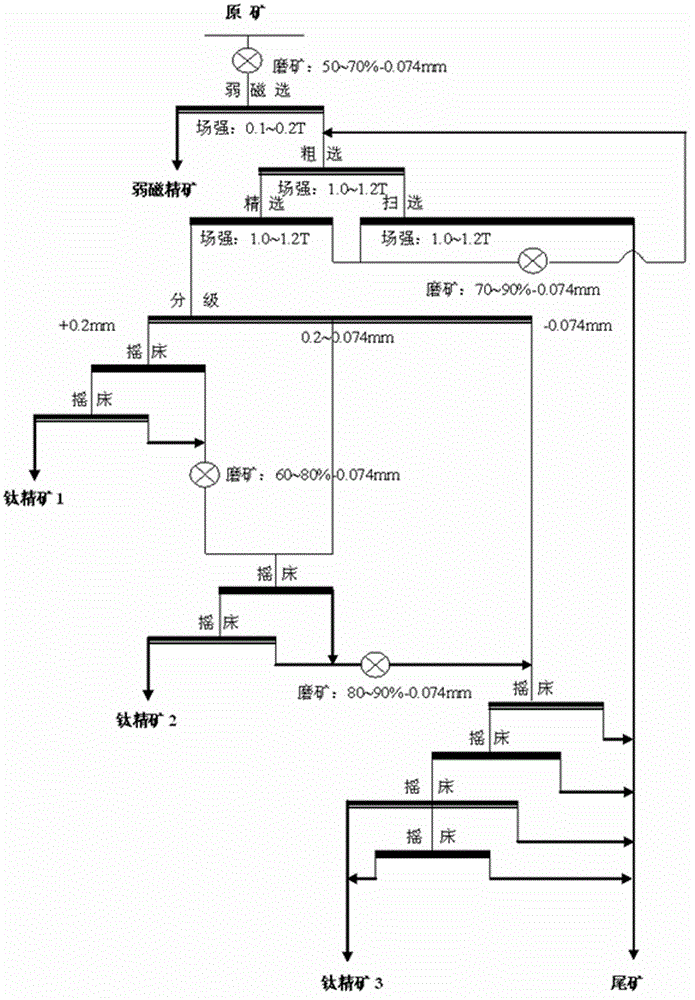

Beneficiation technology for rock-type primary ilmenite

The invention discloses a beneficiation technology for rock-type primary ilmenite. The technology includes the steps of pretreatment, low-intensity magnetic separation, high-intensity magnetic separation, classification and aftertreatment. The method includes the specific steps that raw ore is completely crushed, and closed-circuit grinding is conducted; a low-intensity magnetic separator is used for conducting magnetic separation, and after a ferromagnetic mineral is removed, low-intensity magnetic separation tailings are obtained; the low-intensity magnetic separation tailings are subjected to magnetic separation through a high-gradient high-intensity magnetic separator, so that high-intensity magnetic separation concentrate and high-intensity magnetic separation tailings are obtained; the high-intensity magnetic separation concentrate is classified into a coarse fraction product, a medium fraction product and a fine fraction product; final ilmenite concentrate and final tailings of the beneficiation technology are obtained through aftertreatment. According to rock-type primary ilmenite ore which is not industrially used at present, the above technical scheme is used for beneficiation, and the technological process is simple. According to the reselection and magnetic separation technological processes, no drug is needed, the policy requirements of cleaner production and circular economy of China are met, and the purposes of energy saving, emission reduction, consumption reduction and comprehensive utilization of resources are achieved.

Owner:KUNMING METALLURGY INST

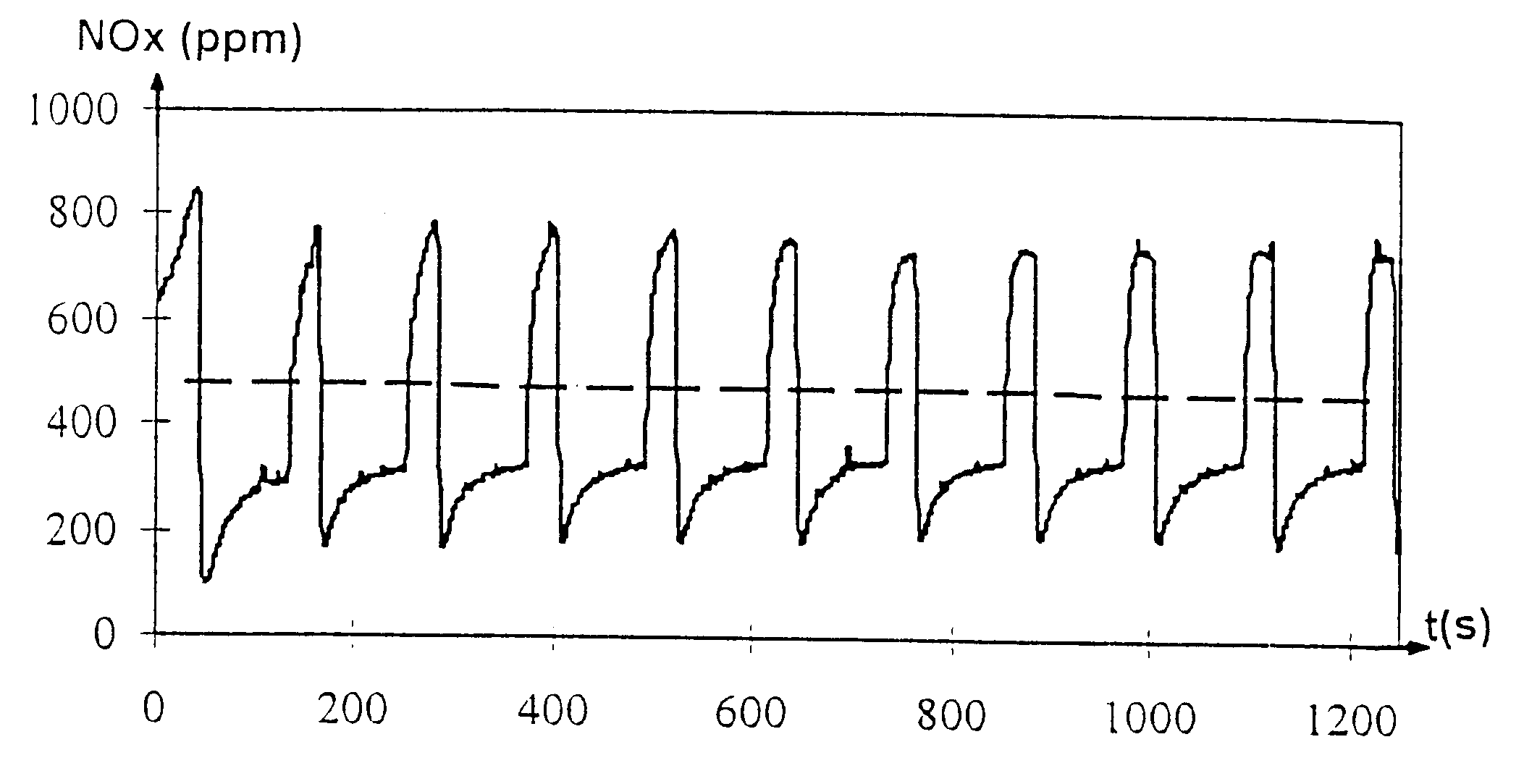

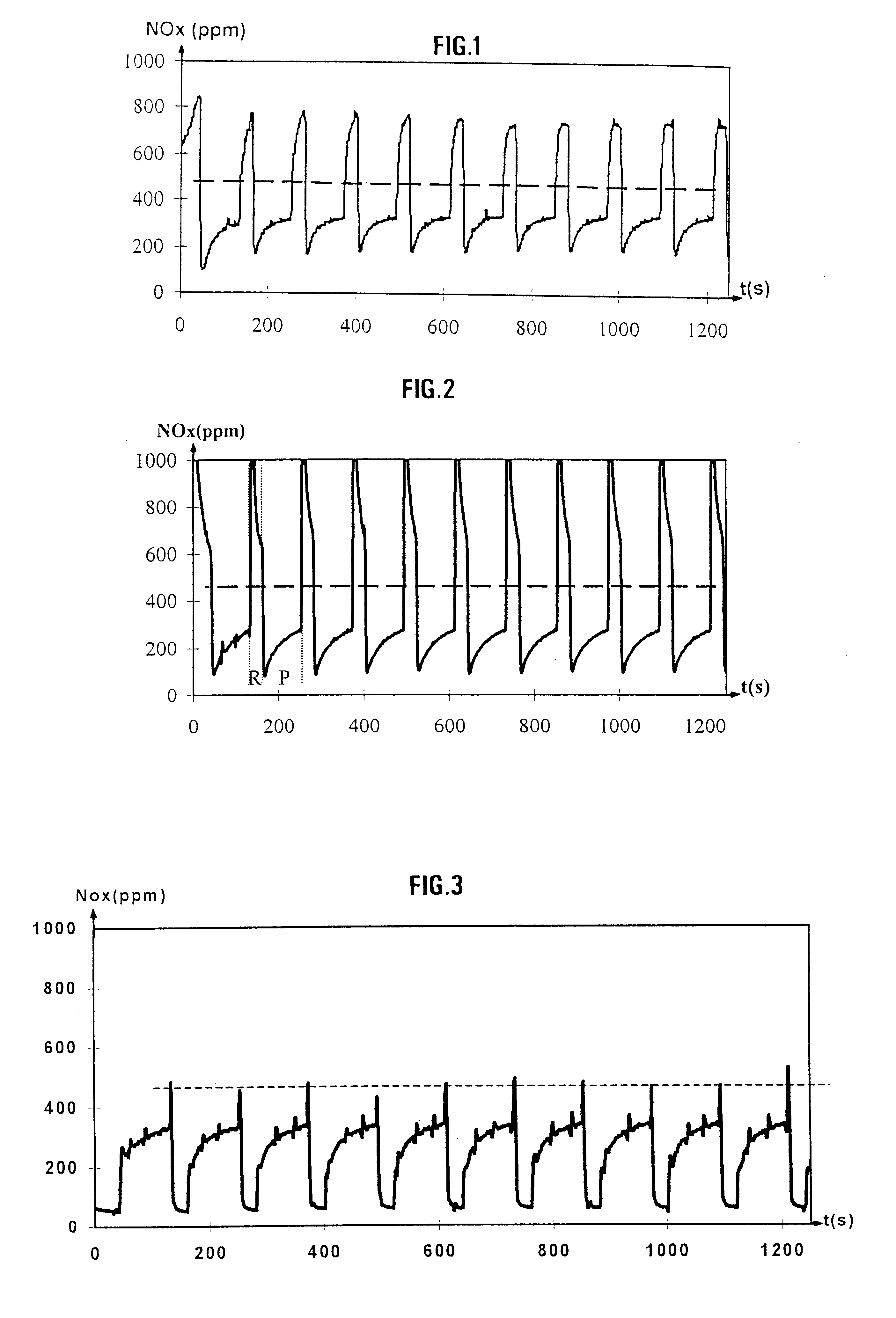

Method of removing nitrogen oxides using an ilmenite material

InactiveUS6616904B1Easy to manageLess poisoningExhaust apparatusIsotope separationGas compositionInternal combustion engine

The invention relates to materials for removing the nitrogen oxides NO and NO2 present in exhaust gases, particularly from internal combustion engines of automotive vehicles running in a medium containing a superstoichiometric proportion of oxidizing agents, said materials being capable of absorbing the nitrogen oxides and of desorbing the nitrogen oxides when the temperature is raised, relative to the absorption temperature, or when the gas composition is changed to a rich mixture, said materials being mixed oxides in which the metals A and B are all octahedrally coordinated and are arranged to form the ilmenite structure ABO3. These materials absorb the nitrogen oxides and do not become poisoned in contact with the sulfur oxides and carbon oxides containing in the gases. In the presence of a group VIII metal, the material is capable of eliminating the adsorbed nitrogen oxides by reduction when the gas composition is changed to a rich mixture.

Owner:INST FR DU PETROLE

Inorganic ferrotitanium polymeric coagulant with ilmenite as raw material and preparation technology thereof

InactiveCN104386787AReduce manufacturing costWater treatment compoundsProcess efficiency improvementReaction temperatureMaterials science

Belonging to the technical field of water treatment, the invention relates to an inorganic ferrotitanium polymeric coagulant with ilmenite as the raw material and a preparation technology thereof. The technology comprises the steps of: (1) taking ilmenite as the main raw material, under certain temperature and stirring conditions, taking sulfuric acid of different concentrations respectively to dissolve ilmenite, then carrying out foam type curing and leaching two-stage reaction; and (2) under certain temperature and stirring conditions, employing a sodium hydroxide solution with certain concentration to adjust the acid-base value of the leaching solution, controlling the pH value at 0.5-1.5, and then carrying out polymerization reaction under a reaction temperature of 20DEG C-60DEG C. The method provided by the invention can prepare the inorganic ferrotitanium polymeric coagulant with the advantages of high ilmenite utilization rate, low preparation cost, excellent water treatment effect, and especially high organic matter removal and color removal efficiency. The inorganic ferrotitanium polymeric coagulant provided by the invention can be widely applied to urban sewage, industrial wastewater and other fields.

Owner:UNIV OF JINAN

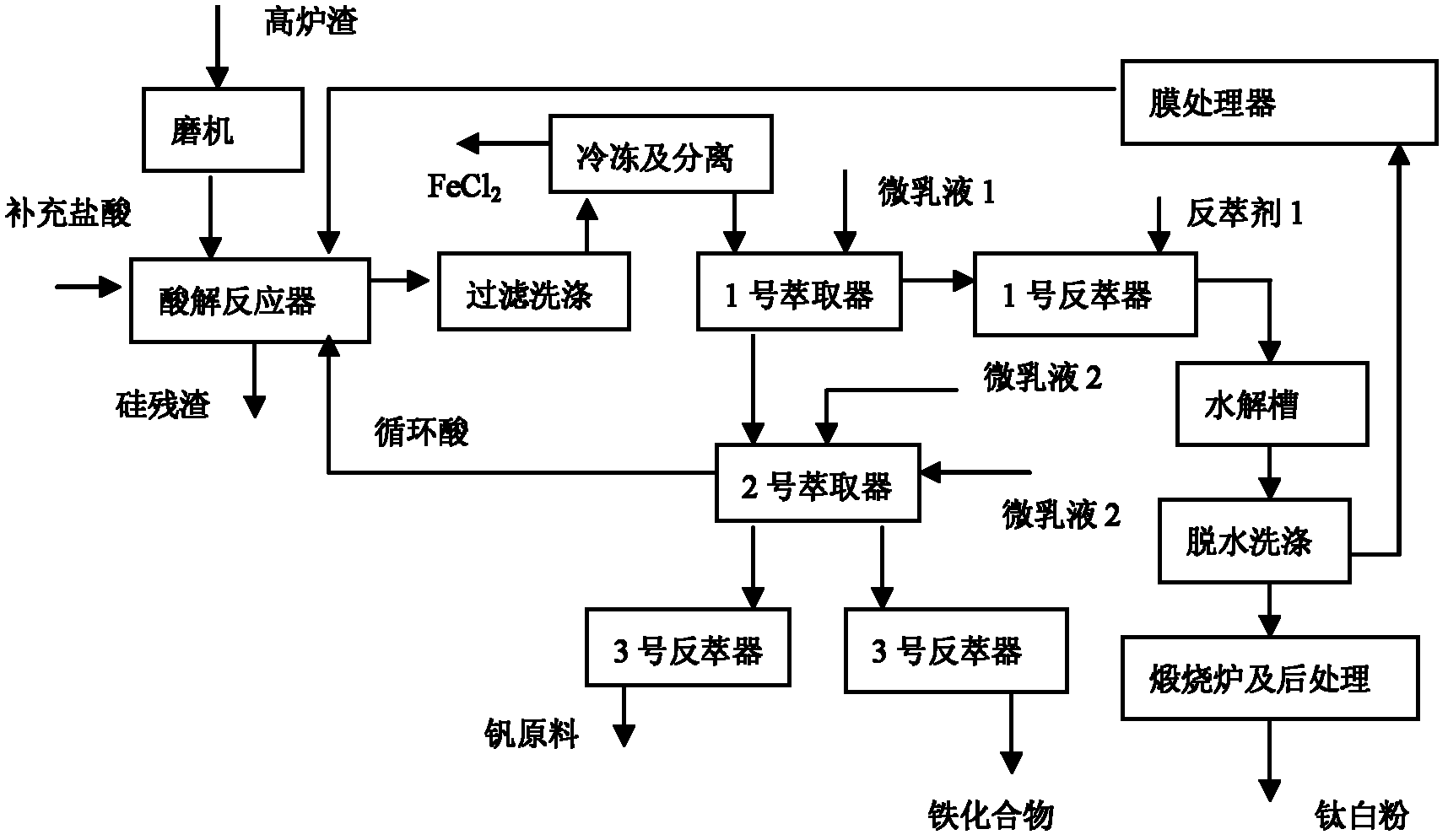

Preparation method of pigment-level titanium dioxide powder by cyclic hydrochloric acid micro emulsion method

InactiveCN102602991AOvercoming decomposition difficultiesSolve pollutionTitanium dioxideSlagRaffinate

The invention discloses a preparation method of pigment-level titanium dioxide powder by a cyclic hydrochloric acid micro emulsion method. The preparation method mainly comprises the following steps of: carrying out acidolysis on titanium-enriched blast furnace slag or ilmenite by utilizing hydrochloric acid to obtain a clear acidolysis liquid; extracting titanium with an organic micro emulsion; collecting titanium in the clear acidolysis liquid by superfine liquid ball formed by a micro emulsion film in the organic micro emulsion; separating organic micro emulsion into organic extract liquor and raffinate; carrying out reextraction on the obtained organic extract liquor with reextraction agent to remove titanium; and hydrolyzing and calcining the obtained reextraction titanium liquid to obtain rutile type titanium dioxide, extracting and removing the impurities, such as iron, aluminum, magnesium and vanadium, in the raffinate by the organic micro emulsion, and returning obtained regenerated hydrochloric acid back to the acidolysis process. By using the method of the invention, the problems that the preparation method of the titanium dioxide powder in the prior art is high in vitriol cycle energy consumption and industrialization is hard to realize can be overcome, various byproducts can be prepared while the titanium dioxide powder is prepared, and resources in raw materials can be comprehensively recycled, so that the pollution problem of blast furnace slag on environment can be basically solved.

Owner:SICHUAN UNIV

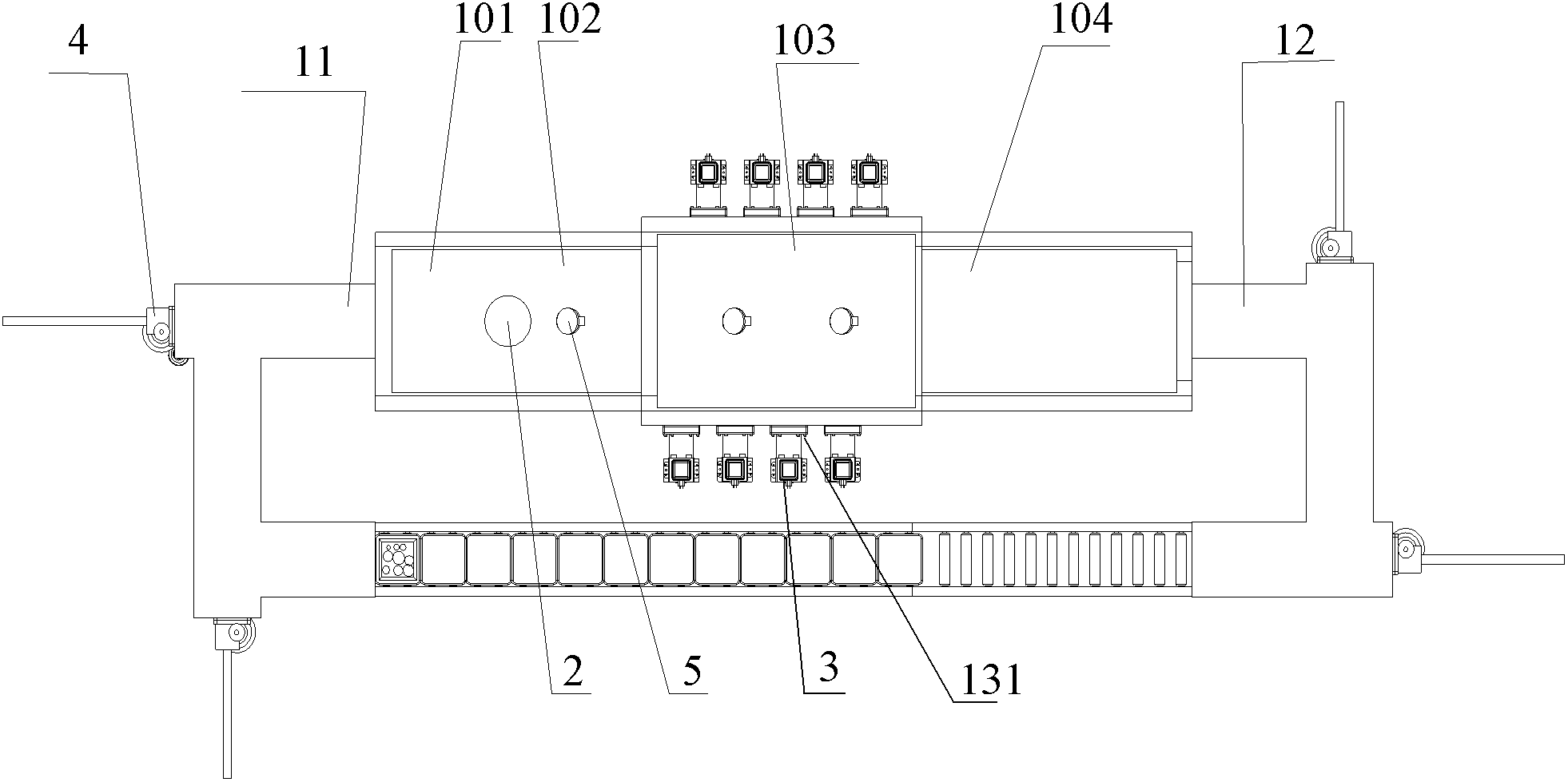

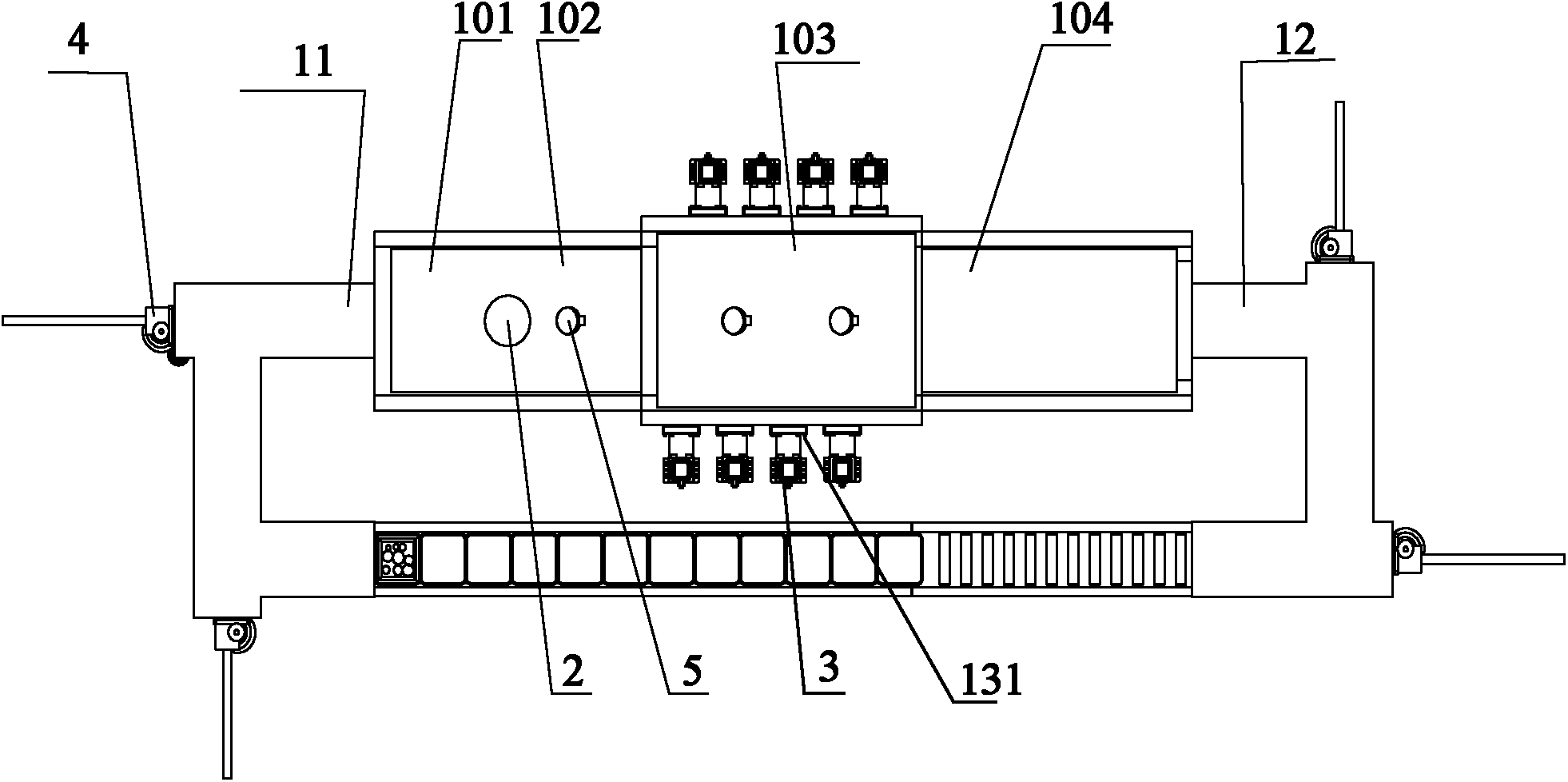

Technique for producing and reducing ilmenite in industrial microwave kiln

InactiveCN102534264AImprove yieldEnsure heating uniformityFluidised-bed furnacesMaterials scienceReducing agent

The invention provides a method for reducing ilmenite, which comprises the following steps: sending ilmenite, a reducer and a desulfurizer, which serve as raw materials, into a microwave high-temperature kiln; sequentially preheating, sintering and cooling; and sequentially pulverizing, screening, carrying out magnetic separation, and carrying out jet mil blending, wherein in the sintering process, microwaves of which the frequency is 2450MHz are emitted to the raw materials until the reduction temperature of the sintering belt in the kiln reaches 600-800 DEG C. In the sintering step, the microwaves of which the frequency is 2450MHz are emitted to the raw materials, so that the raw materials quickly absorb microwave energy from inside to outside, thereby ensuring the integral heating uniformity of the material, enhancing the heating uniformity of the raw materials, enabling the ilmenite to sufficiently participate into the reducing reaction, and being beneficial to enhancing the grade of the product; the microwave heating speed is high, so that the time for reaching the temperature required by the generation of the reducing reaction is shortened, thereby shortening the production cycle and lowering the energy consumption. Therefore, the ilmenite prepared by the method provided by the invention has the characteristics of high product yield and low energy consumption.

Owner:湖南阳东微波科技有限公司

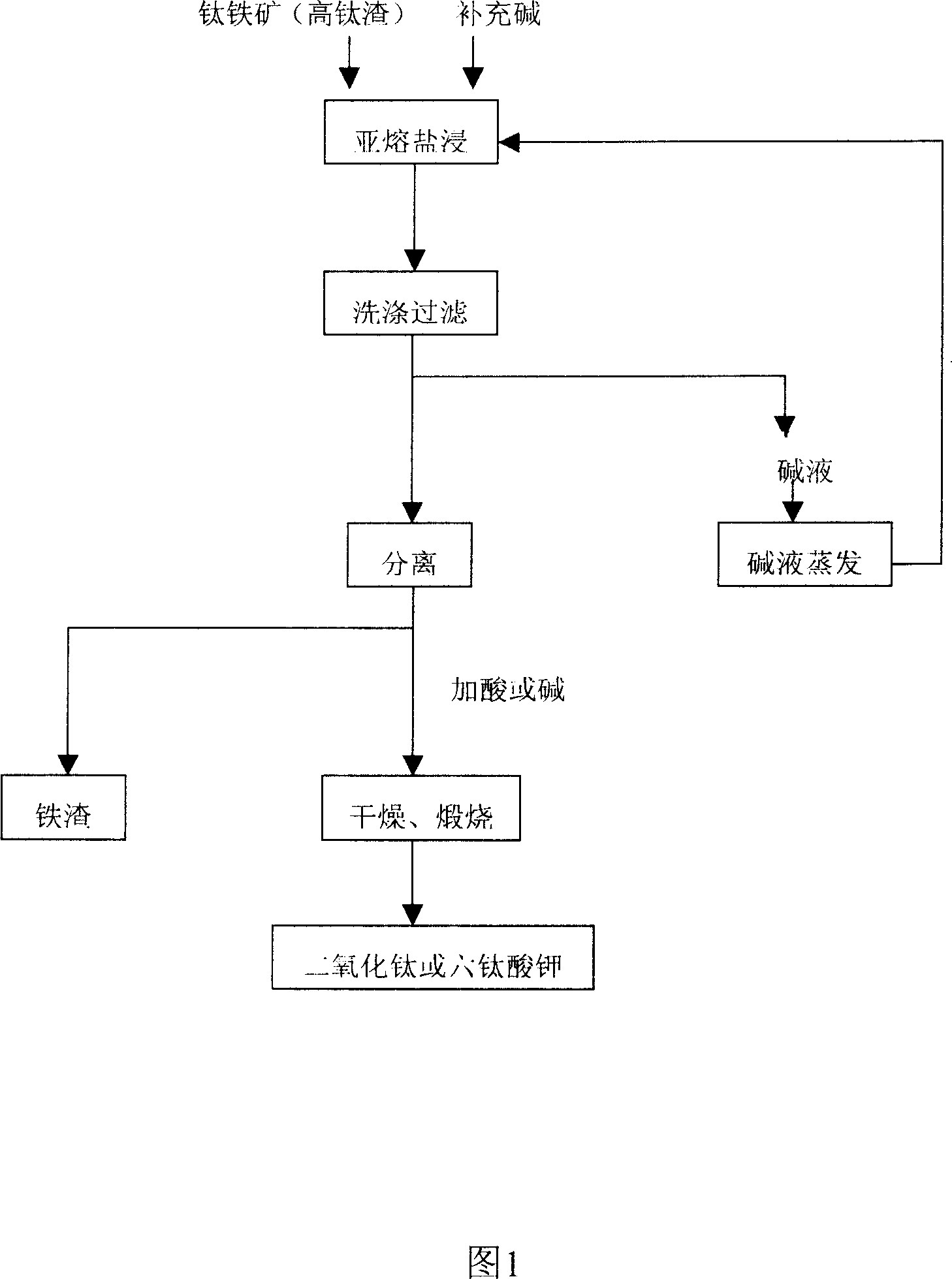

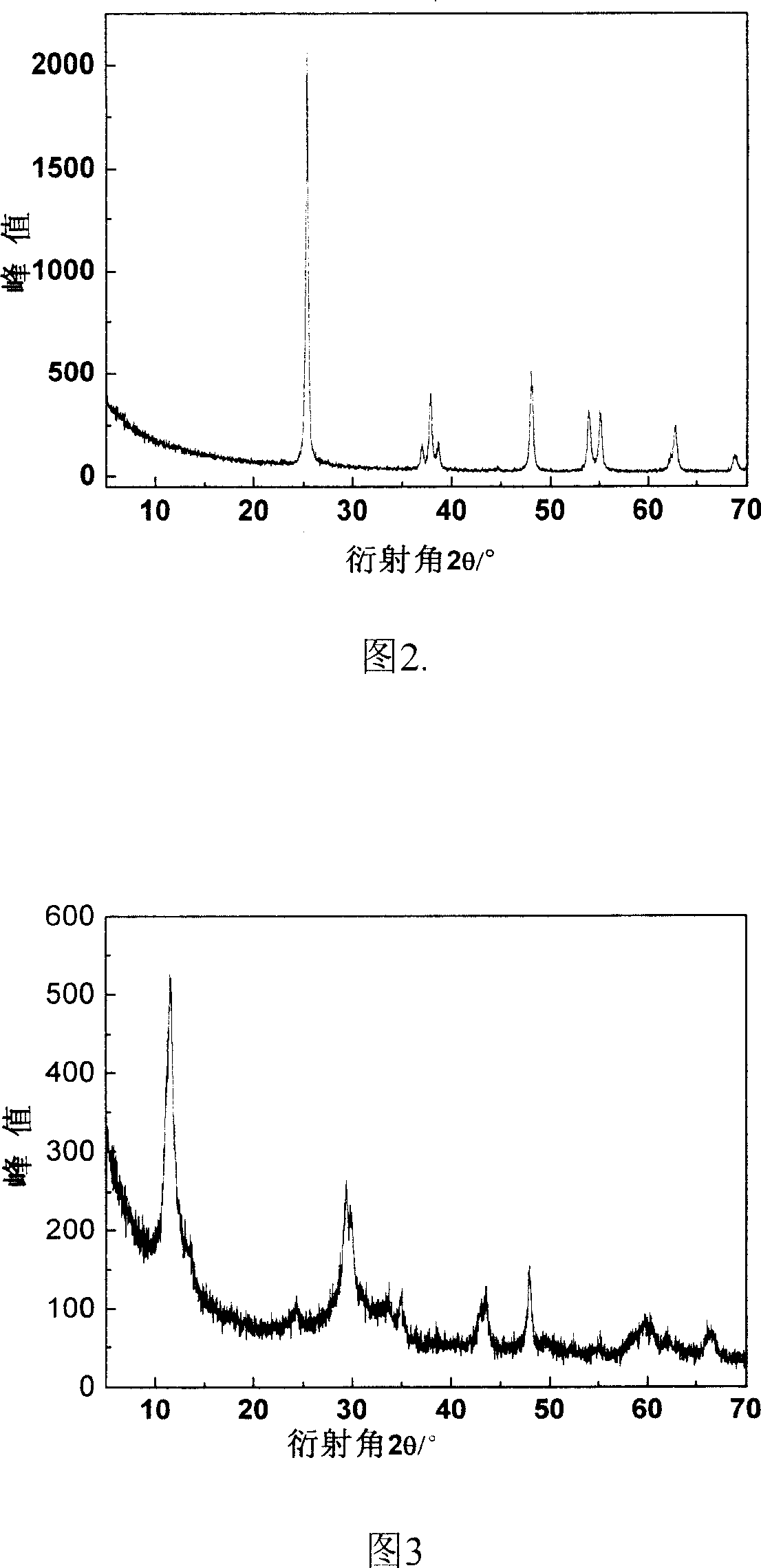

Process for clean producing titanium dioxide and potassium hexatitanate wiskers by titanium iron ore or high-titanium dreg sub-molten salt

The invention relates to a method to produce titanium dioxide and K2Ti6O13 whisker from using ilmenite or high titanium slag as raw material. It includes the following steps: ilmenite or high titanium slag reacting in KOH liquid phase medium, and the weight ratio is 4:1-8:1; gaining the mixture reaction product of alkali liquid, barium titanate and iron enriched slag; taking hydrolysis or acidolysis, burning and purifying to the product to gain purified titanium dioxide and K2Ti6O13 whisker. The reacting temperature is 240-350 degree centigrade and the yield is over 99%. The recycled titanium dioxide could be used as dye, coating, etc; and the K2Ti6O13 whisker could be used as insulating material, refractory material, and friction material.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing ferro-titanium

The invention relates to a method for preparing ferro-titanium. The method comprises the following steps: smelting titanium slag of ilmenite concentrate in an electric furnace, after smelting of the titanium slag is finished, adding at least one kind of alkali carbonate in the electric furnace, leading in air or oxygen gas, stirring to enable titanic oxide in the titanium slag to be converted into titanate, using graphite as the positive pole and molten iron at the bottom of the electric furnace as the negative pole to conduct electrolysis, generating metallic titanium, enabling the metallic titanium to enter molten iron to form liquid-phase ferro-titanium, discharging the molten iron and the liquid-phase ferro-titanium to be cooled under protection of inert gas, and obtaining the ferro-titanium. The ferro-titanium is obtained through the method for preparing the ferro-titanium. A certain amount of the at least one kind of alkali carbonate is added in a molten body after smelting of the titanium slag is finished, the oxygen gas is led in to enable the titanic oxide to be converted into the titanate, the graphite is used as the positive pole, the molten iron is used as the negative pole, and then electrolysis is carried out to prepare the ferro-titanium. The method has the advantage of being simple in operation, and the production cost of the ferro-titanium can be effectively reduced.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

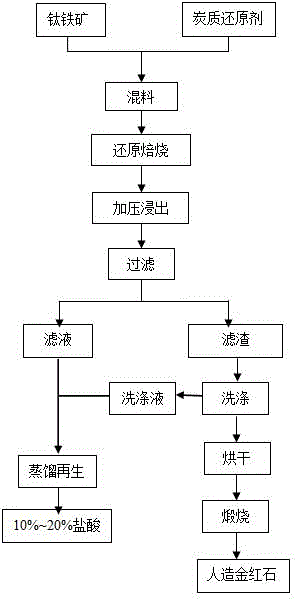

Process for making artificial rutile by leaching of mohsite hydrochloric acid

The invention relates to a process for making artificial rutile by leaching of mohsite hydrochloric acid and belongs to the technical field of metallurgy. The process includes using mohsite graded at 45-52% as raw materials, and distributing carbonaceous reducing agent for reducing roasting, pressure leaching, filtering, roasting, and regenerating of hydrochloric acid, so that impurity removal of mohsite and recycling of hydrochloric acid are effectively realized and artificial rutile is made. The process is characterized in that mohsite and carbonaceous reducing agent are uniformly mixed for reducing roasting, and leaching rate of impurities like silicon, iron, calcium and magnesium is increased; hydrochloric acid is regenerated by distilling leaching mother liquor and can be reused in leaching; filter slag can be roasted after pressurized leaching and filtering so as to obtain artificial rutile. The process has the advantages of high leaching speed, high impurity removal efficiency, high grade and recyclability of hydrochloric acid. In addition, the process is applicable to industrial production in the aspects of technique, equipment, economy and environment protection.

Owner:KUNMING METALLURGY INST

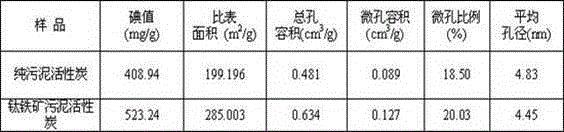

Novel method for improving city sludge active carbon performance

InactiveCN102745687AEasy to handleImprove pore structureCarbon compoundsActivated carbonTube furnace

The invention discloses a method for adopting city sewage processing factory residual sludge and natural ilmenite as raw materials, and for producing active carbon by using zinc chloride as an activating agent. The method comprises specific steps that: the raw material sludge is dried until the water content of the sludge is below 10%; the sludge is mechanically crushed, and is sieved by using a sieve of 120 meshes; ilmenite is crushed, and is sieved by using a sieve of 200 meshes; the ilmenite is added into the raw material sludge with a proportion of 1.5-2%, and the mixture is well mixed; the pretreated raw material sludge is impregnated in a zinc chloride solution with a concentration of 3mol / L under normal temperature for 24h; and the impregnated sludge is dried by baking under a temperature of 80 DEG C for 24h, wherein a solid-liquid ratio (a ratio of the mass of the sludge to the volume of the zinc chloride solution) is 1:2; the bake-dried sludge is placed in a tube furnace (a heating speed is 10 DEG C / min, N2 is adopted as a protective gas, and a flow rate is 30L / h), the temperature is increased to 525-550 DEG C, and further carbonization is carried out for 40-60min (carbonization and activation are carried out simultaneously); the activated carbonized product is cooled to room temperature, and is washed by using a hydrochloric acid solution with a concentration of 3mol / l; the product is rinsed by using water with a temperature of 70-80 DEG C, until the product is neutral; the rinsed product is dried by baking, and is grinded, such that the active carbon finished product can be obtained.

Owner:CHENGDU UNIV OF INFORMATION TECH

Novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production process

InactiveCN105289036ARealize cleaner productionReduce manufacturing costSolution crystallizationIron sulfatesSulfatePhysical chemistry

The invention discloses a novel method for performing vacuum crystallization on ferrous sulfate from titanium liquid in titanium dioxide production. According to the method, the conventional ferrous sulfate vacuum crystallization process and equipment are innovated. The process innovation refers to the operation of replacing the conventional method for generating vacuum by virtue of steam jet by a method for condensing water vapor above titanium liquid in a crystallization kettle so as to generate vacuum by virtue of cryogenic refrigeration. The equipment innovation refers to the operation of replacing the conventional secondary steam jet equipment and circulating cooling water equipment for cooling high-temperature acid containing liquid by the complete refrigerating equipment generating a certain low temperature. According to the method disclosed by the invention, ferrous sulfate is separated from the titanium liquid in the crystallization kettle, lots of high-temperature high-pressure steam can be saved, and the production cost of titanium dioxide by sulfuric acid method is greatly reduced. In addition, the acidic condensate extracted from the crystallization kettle by vacuum can return to be used for an ilmenite powder sulfuric acid dissolving process, so that the amount of sulfuric acid in the process of generating titanium dioxide by a sulfuric acid method is reduced, the emission amount of acid waste liquid is greatly reduced, and clean production is realized.

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

Method for manufacturing high-grade artificial rutile by ilmenite concentrate

The invention relates to a preparation method of high-grade synthetic rutile by using ilmenite concentrate. The technological procedure is as followings in sequence: firstly, a ball milling is activated; the mechanical ball milling is implemented to the ilmenite concentrate with a ball mill so as to activate the ilmenite concentrate; secondly, atmospheric pressure leaching; with a ratio ranging from 1:3 to 1:5 in volume, the ilmenite concentrate and the hydrochloric acid solution are heated to 90 to 105 DEG C in atmospheric pressure to carry out the leaching reaction for 4 to 6 hours, thereby a front body of the synthetic rutile is obtained; thirdly, solid-liquid separation, after the reaction is completed, the ground paste is cooled down to 30 DEG C to 50 DEG C, and then the front body of the synthetic rutile is separated from the mother solution by adopting a vacuum filtration, the separated mother solution can be prepared into revival hydrochloric acid and cycled to be used in atmospheric pressure leaching procedures; fourthly, washing, drying and calcining; the front body of the separated synthetic rutile is washed and dried, and then is calcined for 2 to 4 hours at a temperature of 800 DEG C to 1000 DEG C, thereby the powder synthetic rutile is obtained.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com