Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

899 results about "Pollution prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pollution prevention (P2) is a strategy for reducing the amount of waste created and released into the environment, particularly by industrial facilities, agriculture, or consumers. Many large corporations view P2 as a method of improving the efficiency and profitability of production processes by waste reduction and technology advancements. Legislative bodies have enacted P2 measures, such as the Pollution Prevention Act of 1990 and the Clean Air Act Amendments of 1990 by the United States Congress.

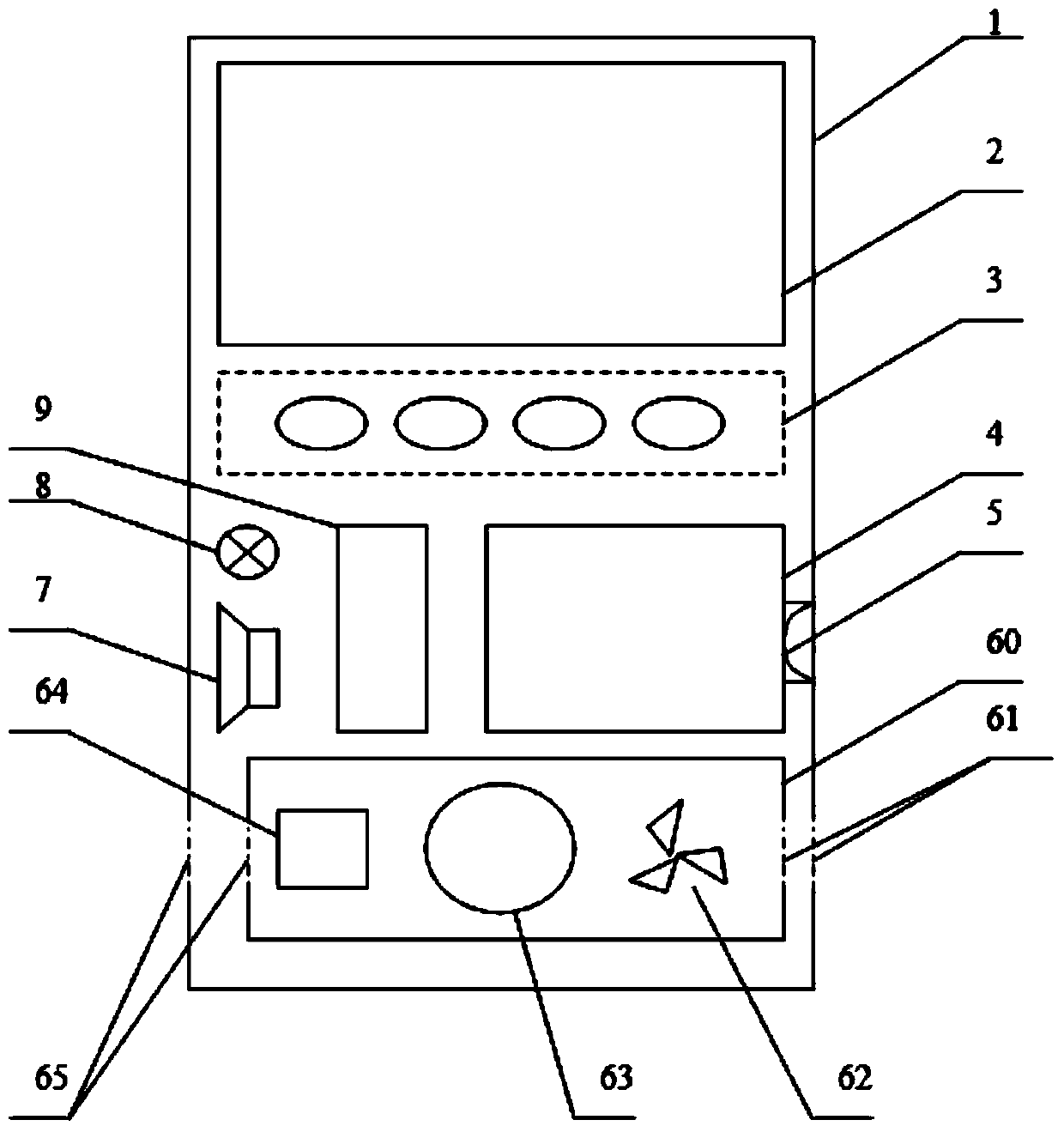

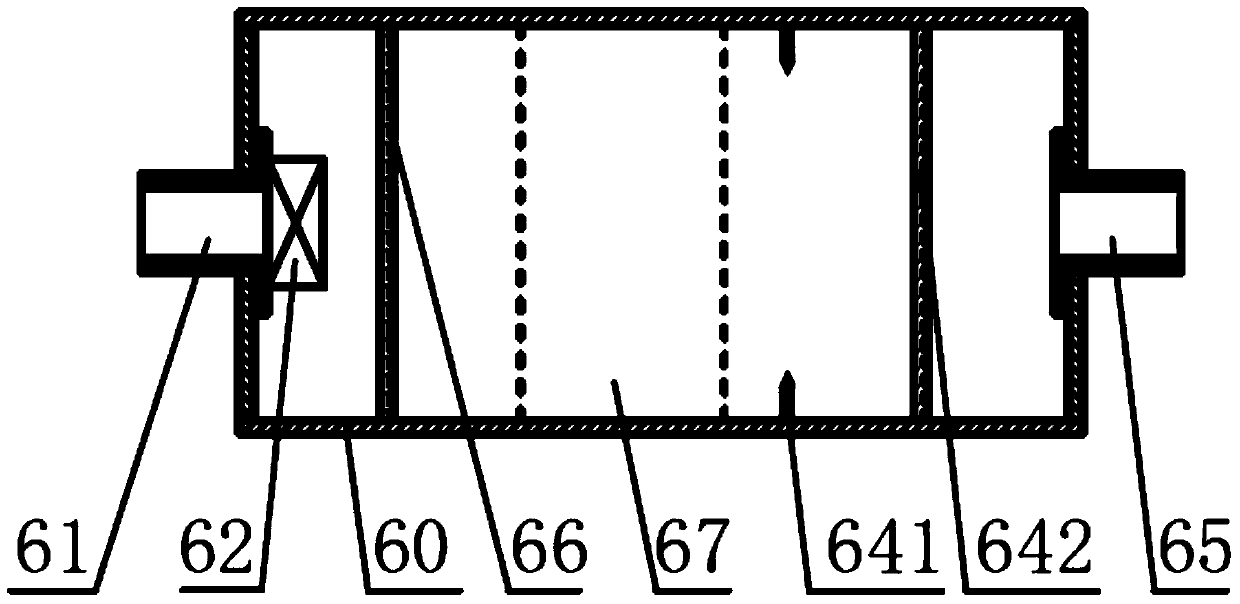

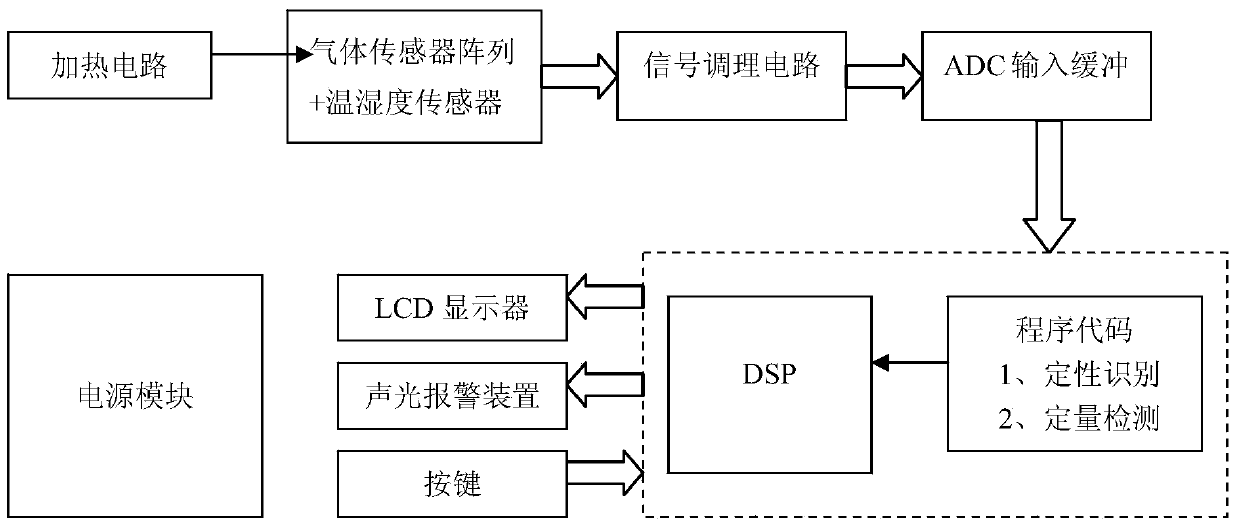

Electronic nose for detecting indoor air quality

InactiveCN103728348AExpand the scope of detectionEffective identificationMaterial resistanceNasal cavityHigh concentration

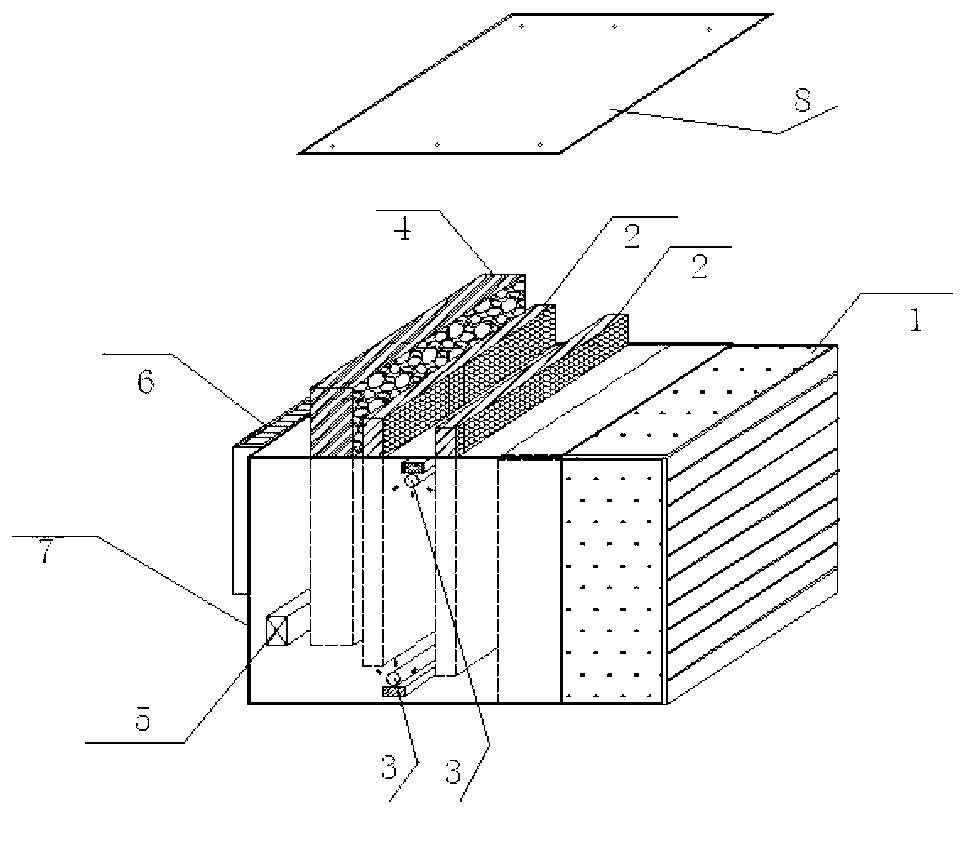

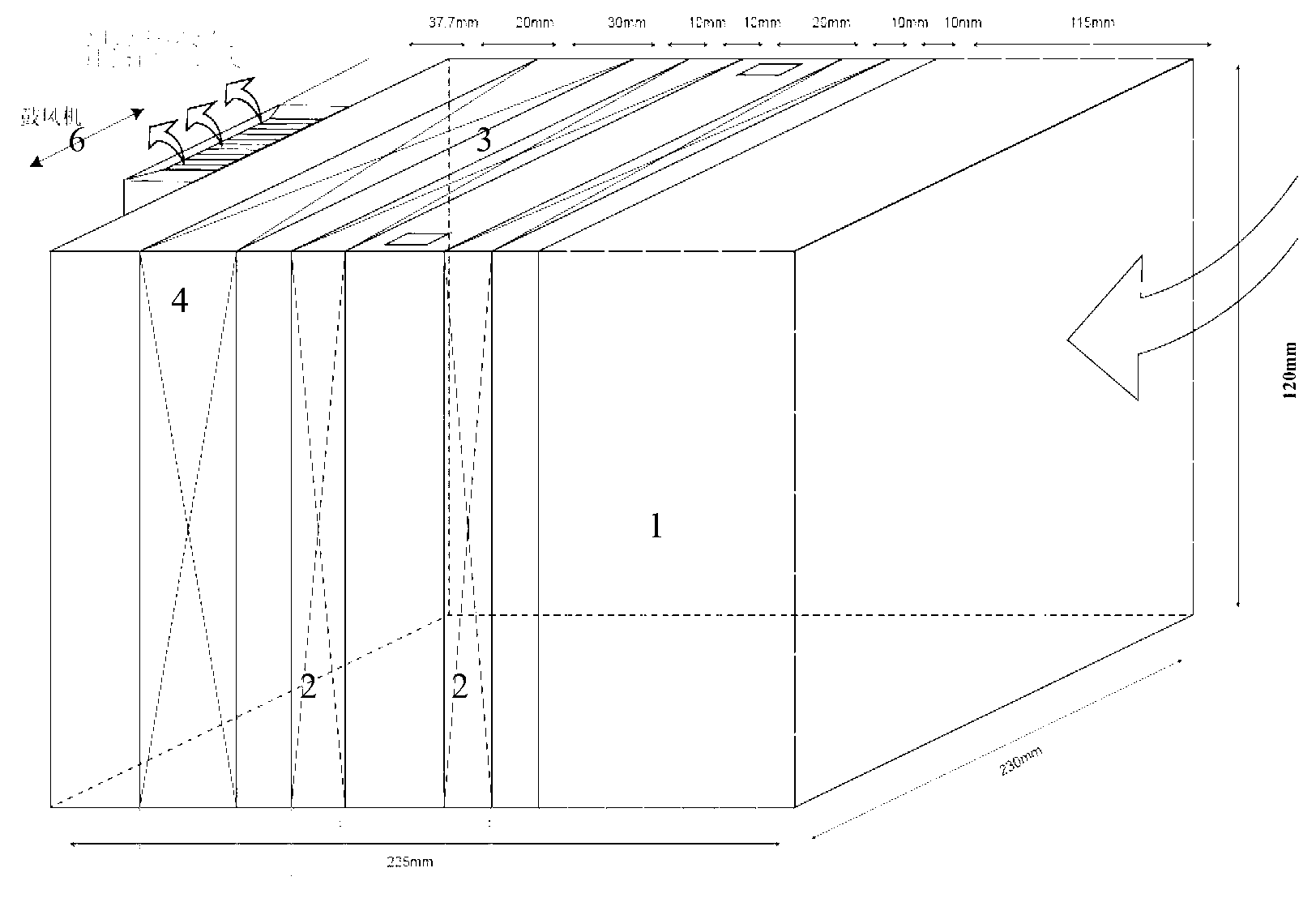

The invention discloses an electronic nose for detecting indoor air quality. The electronic nose mainly comprises a nose frame, a shell, a suction fan, HEPA (High Efficiency Particulate Air) filter paper, a nasal cavity, a gas sensor array and a processing circuit integration module thereof, a DSP (digital signal processor), a human-computer interaction interface, a harmful gas absorption and purification device and the like. The electronic nose is characterized in that indoor air to be detected is sucked into the nasal cavity by the suction fan through the HEPA filter paper to perform a full reaction with the gas sensor array; the measurement and identification of harmful gases in the air are completed inside the nasal cavity; then the harmful gas absorption and purification device is used for absorbing and purifying harmful gases with high concentration. The electronic nose has the characteristics of small size, anti-interference, quickness, accuracy, secondary pollution prevention and the like, and is suitable for detecting the harmful gases in the indoor air.

Owner:JIANGSU UNIV

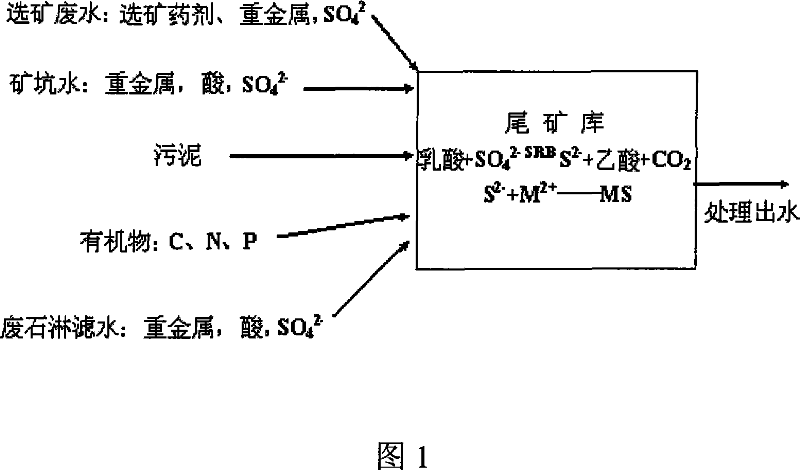

Method for restoring mine entironment

InactiveCN101037268ALow costLow infrastructure costWaste water treatment from quariesWater contaminantsEcological environmentSulfate-reducing bacteria

A method of repairing mine ecological environment comprises the treatment of mine environment contamination, wherein the tailings, the barren rock, the smelting slag, the waste water from ore cleaning, the waste water from smelting, the acid mine drainage and the ore yard leachwater which are generated from mine development are collected into the tailings storage, at the same time, sludge and organic matter capable of being degradated by microbiology are added therein, and then the tailings storage is given an anaerobic environment artificially, so that, under the action of microbiology and sulfate reducing bacteria, sulfur ion is generated and the pH value of the tailings storage is increased, a plurality of heavy metal ions are cured and settled by sulfur ion to avoid migration, a biomembrane layer-sulfate reducing bacteria reducing-induction biomineralization precipitation composite geochemical barrier is generated in the tailings storage. The repairing of mine ecological environment is realized by the treatment of mine environment contamination. The present invention can be used for tailings storage pollution prevention in tour, and can be used for closing the repairing of mine ecological environment, or can be used for designing new tailings storage by using the technology of the present invention.

Owner:ELION ECOLOGICAL RESTORATION

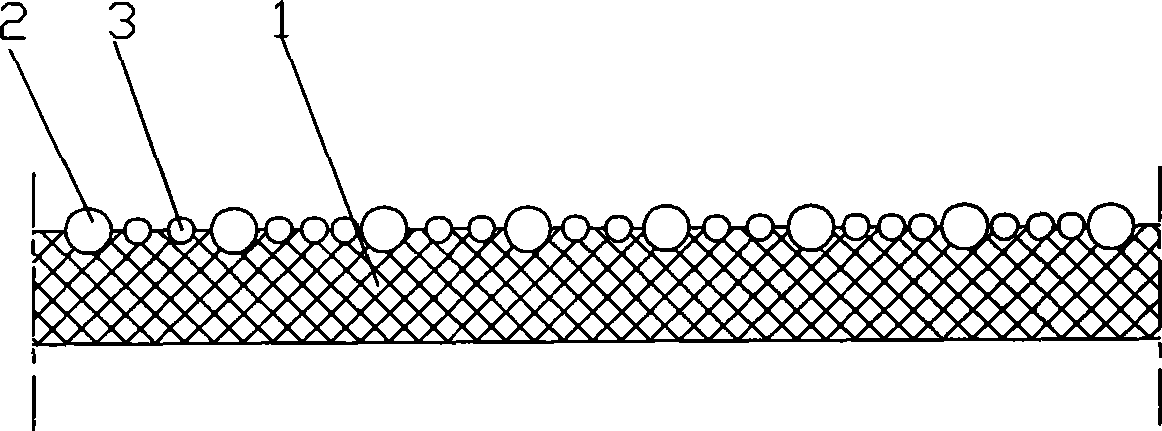

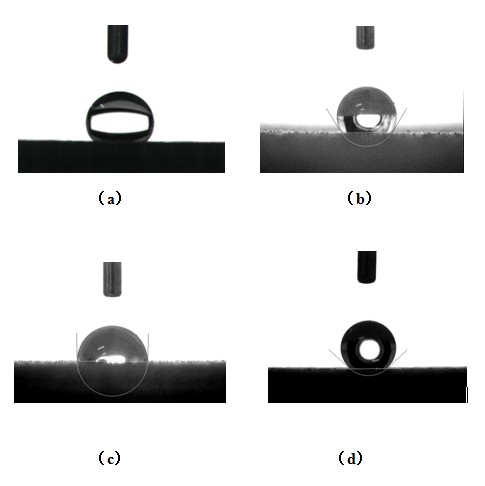

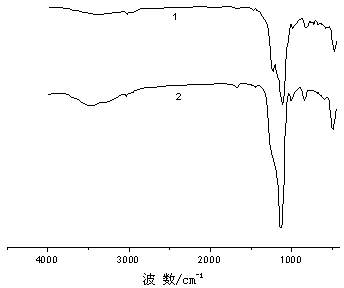

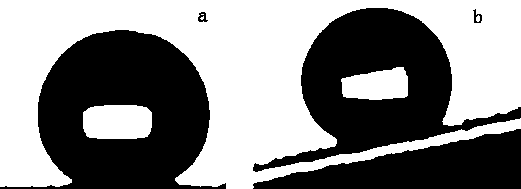

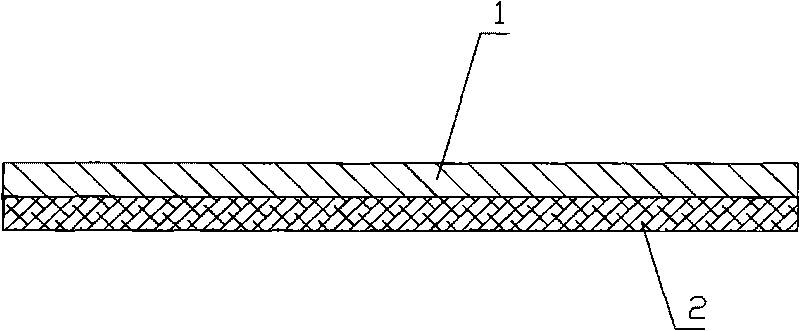

Ultra-hydrophobic film of thermoplastic substrate

InactiveCN101474895AFlexible useEasy to useSynthetic resin layered productsWater contactPollution prevention

The invention discloses a super-hydrophobic film for a thermoplastic matrix, which comprises a thermoplastic film matrix and a super-hydrophobic layer. The super-hydrophobic layer consists of micro-scale powder particles and nano-scale powder particles arranged at intervals and embedded into the film matrix, and the micro-scale powder particles and the nano-scale powder particles form micro-scale protrusions and nano-scale protrusions on the surface of the thermoplastic film matrix and have low surface energy or are modified by low surface energy substances. The super-hydrophobic film has the advantages of simple structure, easy preparation and lower cost; a water contact angle of the super-hydrophobic layer is between150 and 165 degrees, and a roll angle is less than 5 degrees; the super-hydrophobic film also has the advantages of stable performance, low cost and excellent mechanical property, and can be applied to the occasions needing water proofing, pollution prevention, mist resistance, snow cover resistance, ice coating resistance, oxidation prevention and the like; when the thermoplastic film matrix is adopted, the super-hydrophobic film can be flexible to use, can be manufactured into an adhesive tape structure to be adhered on the surface of other matrixes, and is convenient and simple to use; and by adopting a hot pressing method for preparation, the thermoplastic film matrix and the super-hydrophobic layer are firmly combined, and the preparation method is simple and easy to operate and has low manufacturing cost.

Owner:CHONGQING UNIV

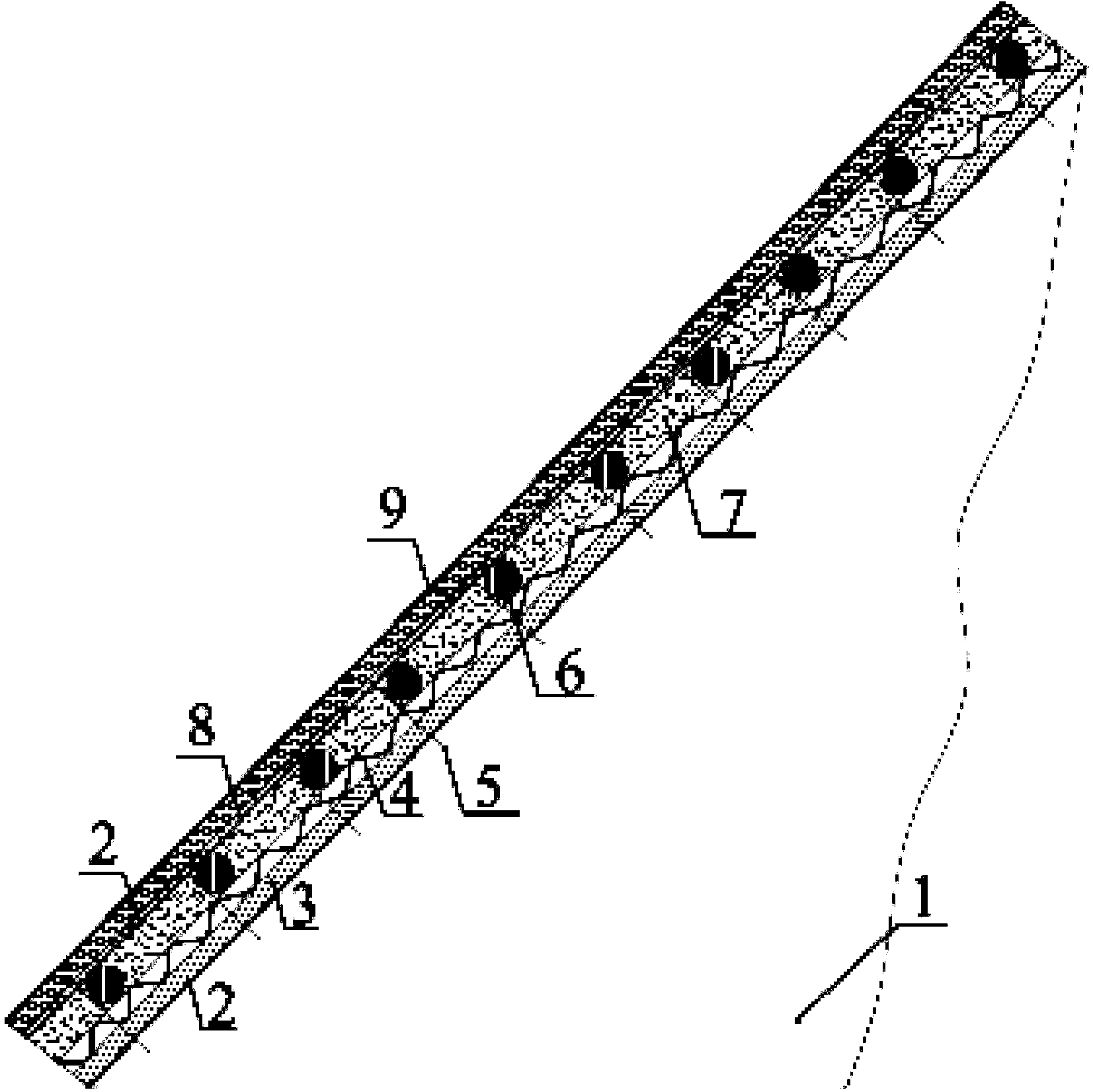

Pollution prevention and vegetation recovery method for metal sulphide ore solid waste storage yard

ActiveCN103806454APrevent oxidationReduce pollutionExcavationsHorticultureRecovery methodRevegetation

The invention relates to a pollution prevention and vegetation recovery method for a metal sulphide ore solid waste storage yard. The method comprises the following steps of conducting stabilizing treatment on side slopes of the storage yard, laying a two-way geogrid, building intercepting ditches in the slope faces of the storage yard, spraying an acidic improvement layer, laying a flexible isolating layer, laying ecological sticks, laying a two-way geogrid, spraying a base material layer, spraying a seed layer and laying a protective layer, so that plants have sufficient water and nutrition during growth. Due to the fact that the acidic improvement layer is built for neutralizing H+, the plant growth condition can be built; the flexible isolating layer and vegetation recovery are combined for preventing H2O and O2 from making contact with tailings, sulfide minerals in waste rock can be effectively prevented from being oxidized, and therefore waste water acidification and heavy metal ion leaching are prevented. According to the pollution prevention and vegetation recovery method, the problem of environmental pollution of pollutants in the metal sulphide ore solid waste storage yard can be effectively reduced, the area of green plants can be increased, and the good ecological environment is built; the pollution prevention and vegetation recovery method is simple in construction technology, easy to implement, high in efficiency and suitable for large-area application.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

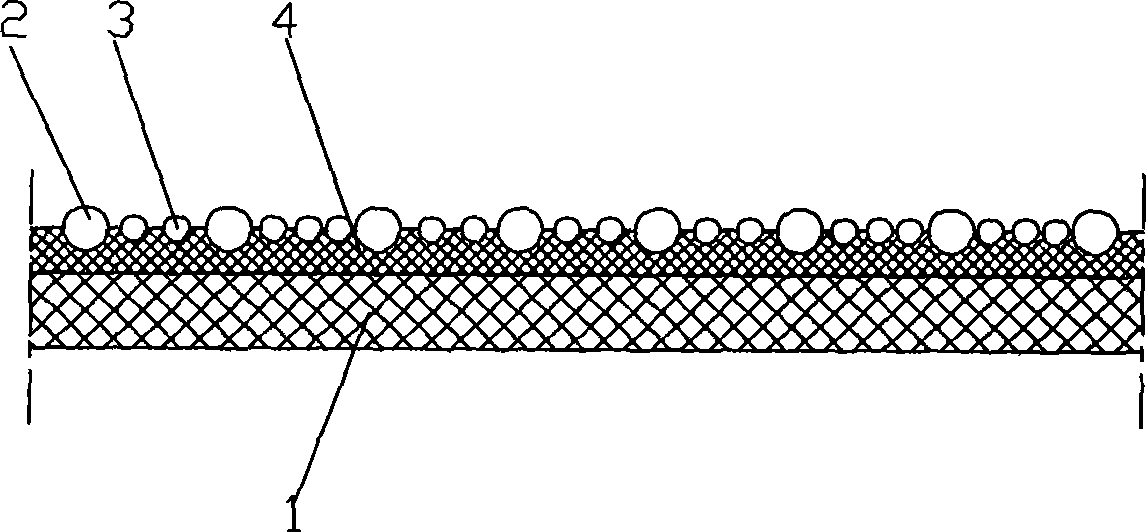

Ultra-hydrophobic film of compound structure

ActiveCN101474896ASimple structureHigh strengthSynthetic resin layered productsOxidation resistantHardness

The invention discloses a super-hydrophobic film with a composite structure, which comprises a film matrix, an adhesive layer and a super-hydrophobic layer. The adhesive layer is adhered to the film matrix; and the super-hydrophobic layer consists of micro-scale powder particles and nano-scale powder particles which are arranged at intervals and embedded into the film matrix, have low surface energy or are modified by low surface energy substances, and micro-scale protrusions and nano-scale protrusions are formed on the surface of the adhesive layer. The super-hydrophobic film has the advantages of simple structure, easy preparation and lower cost; a water contact angle of the super-hydrophobic layer is between150 and 165 degrees, and a roll angle is less than 5 degrees; the super-hydrophobic film is provided with the adhesive layer and has no special requirement on a matrix material; and a super-hydrophobic structure can be arranged on the matrix with higher hardness; the super-hydrophobic film self has certain strength and hardness and excellent mechanical property, can be used in the occasions with higher mechanical requirements, and can also be used in the occasions needing water proofing, pollution prevention, mist resistance, snow cover resistance, ice coating resistance, oxidation prevention and the like; and the super-hydrophobic film adopts the film matrix, occupies little space, and is convenient and simple to use.

Owner:CHONGQING UNIV +1

Composite multifunctional air-activating dust-cleaning sterilization device

InactiveCN103292386AHigh effect of sterilization and dust removalHumanized remote control operationCombination devicesLighting and heating apparatusOxygen ionsCell membrane

The invention provides a composite multifunctional air-activating dust-cleaning sterilization device comprising a shell, a sterilization dust cleaner and a base. The sterilization dust cleaner is mounted inside the shell, and comprises a mounting shell, a coarse filtrating screen, a two-point potential difference electrostatic sterilization dust-removing unit, photocatalyst filtrating screens, ultraviolet lamps, coconut shell crystal porous adsorption activated carbon, a negative oxygen ion generator and a mute blower. By the device, just entered air can be ionized effectively in an inlet stage so as to kill bacteria and germs momentarily, various organic compounds and part of inorganic substances are decomposed oxidatively by the aid of the photocatalysis nanoscale titanium dioxide photocatalyst filtrating screens, bacterial cell membranes and protein of curing viruses are destroyed, and multi-functional air cleaning effects of sterilization, deodorization, mildew proofing, pollution prevention and self cleaning are achieved by the aid of activated adsorption and negative oxygen ion activation technologies.

Owner:DONGGUAN JINCAI IND

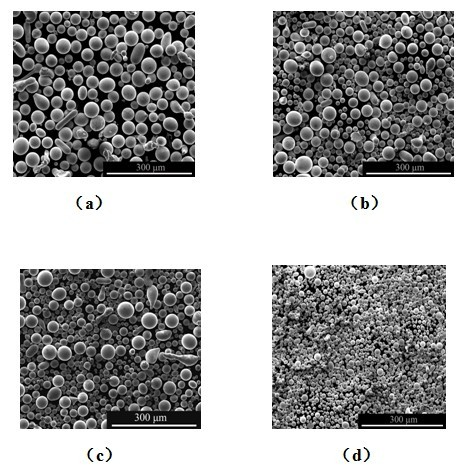

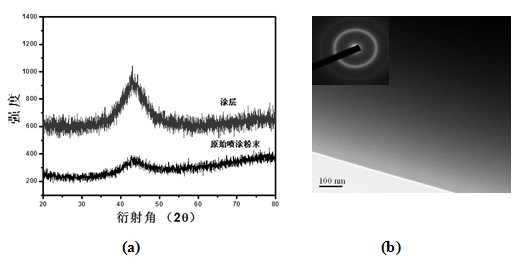

Hydrophobic amorphous alloy coating and preparation method thereof

InactiveCN102041467AHigh glass forming abilityHigh degree of spherificationMolten spray coatingHardnessAlloy coating

The invention discloses a hydrophobic amorphous alloy coating which is prepared by taking Fe-based amorphous alloy powder as a raw material and adopting a supersonic flame spraying technique. The Fe-based amorphous alloy powder is composed of the following elements and inevitable impurities: 10.0-17.0% of Cr, 12.0-20.0% of Mo, 4.0-8.0% of B, 10.0-18.0% of C, 0.0-5.0% of Y and balance of Fe. The invention also discloses a preparation method of the coating. The amorphous alloy coating obtained by the invention not only has better lyophobic property, but also has better corrosion resistance, and high hardness and binding strength, thus having great application prospect on the facilities in the fields of underwater drag reduction, pollution prevention of ship shells, scale prevention on four walls of a boiler, hydraulic power and oil-gas field development and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for producing synthetic rutile

InactiveCN101244841AAvoid pollutionReduce manufacturing costTitanium dioxideIlmenitePollution prevention

The invention relates to a production method of artificial rutile, belonging the technical field of chemical engineering, which provides a method of producing high-taste artificial rutiles made of raw ilmenite containing Mg with high Ca contents and has good production continuousness, low energy consumption and less pollution. The production method provided by the invention comprises the following steps: a. ilmenite concentrate is oxidized and roasted at 800-1100 DEG C, and then reduced and roasted at 600-900 DEG C; b. the reduced and roasted ilmenite concentrate is leached by hydrochloric acid with 18-24 percent concentration under normal pressure; c. cleaned and filtered; d. the filter cake is collected and calcined. The production method can used for producing artificial rutile, and has the advantages of low production cost, environmental pollution prevention, low production energy consumption, and easy capacity for continuous production, thereby enjoying wide application prospect.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

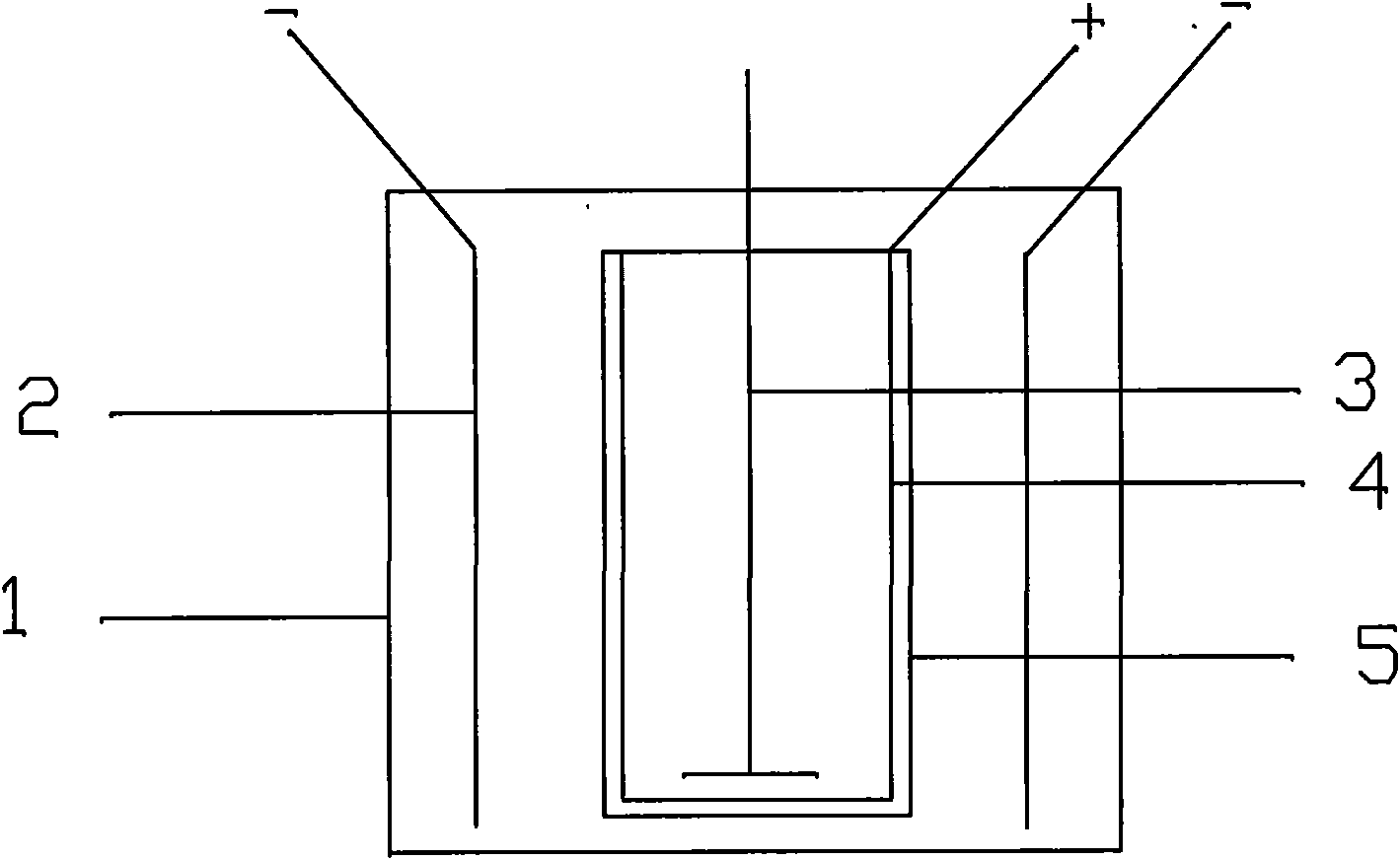

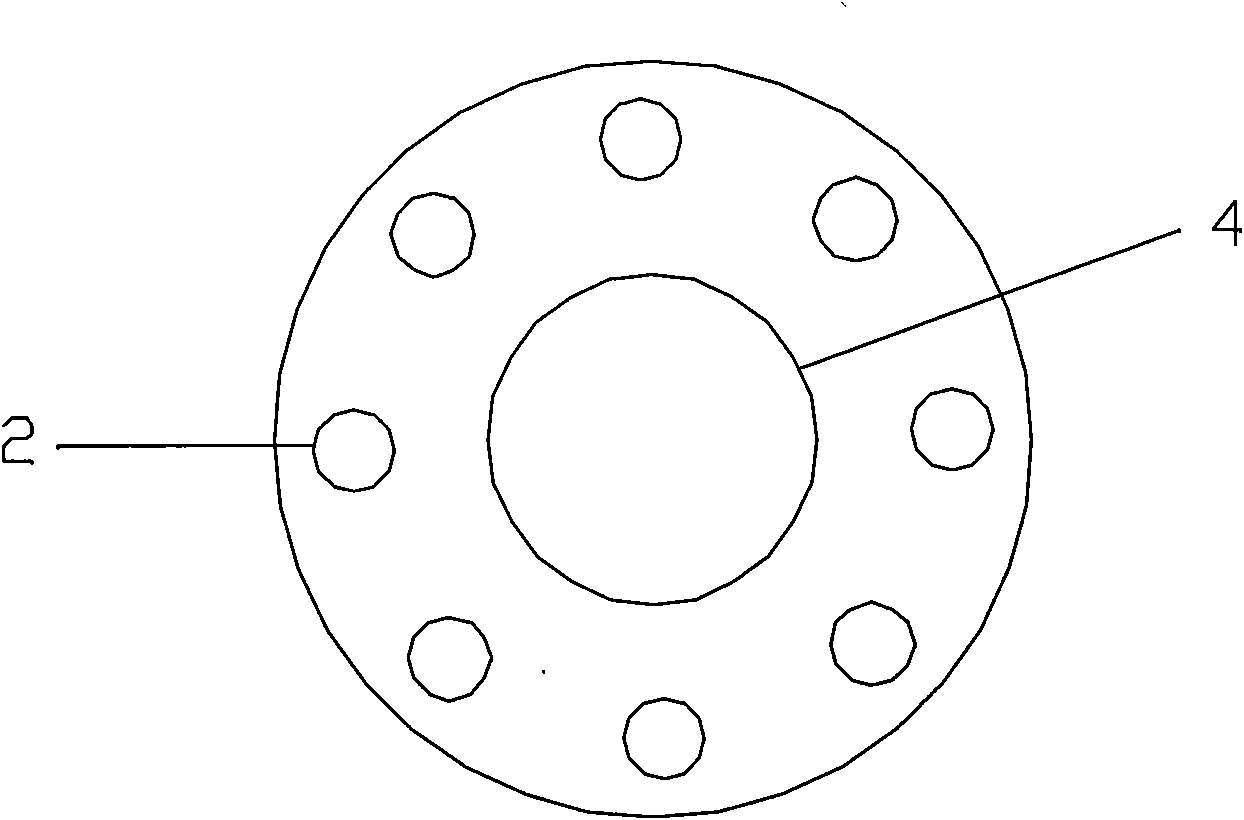

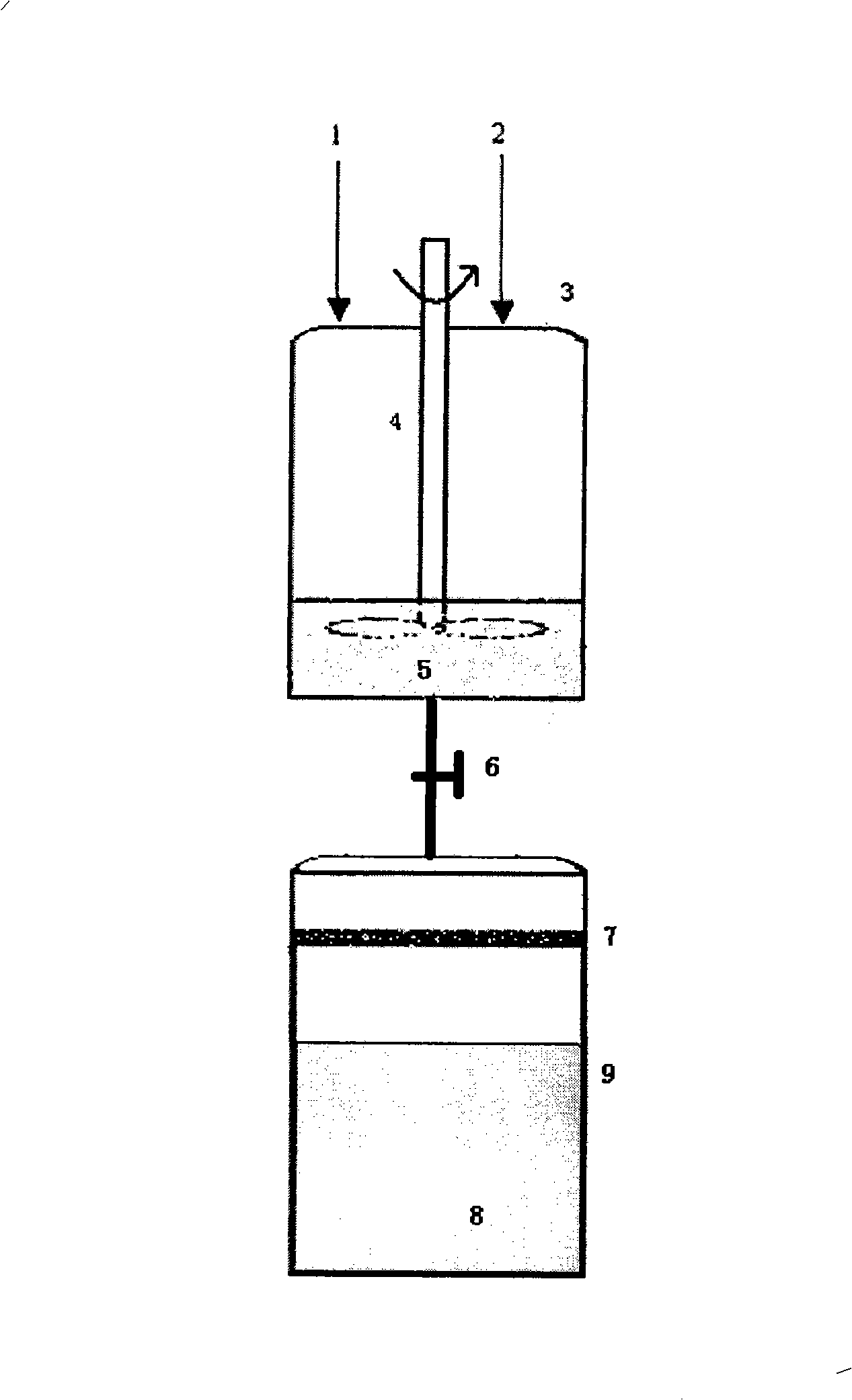

Device for recovering copper in old electronic printed circuit board and method

InactiveCN101538722AElectrolytic deposition achievedAvoid pollutionPhotography auxillary processesProcess efficiency improvementElectrolysisVolumetric Mass Density

The invention provides a device for recovering copper in an old electronic printed circuit board by a suspension electrolysis method and a method. The suspension electrolysis device which comprises a groove body, a stirrer, a cathode and an anode is adopted; wherein, the anode is an anode basket, and a membrane is arranged between the anode basket and the cathode. The formulation of electrolyte used for recovering the copper in the old electronic printed circuit board comprises 10-50g / L of Cu<2+>, 100-180g / L of H2SO4 and 10-30mg / L of Cl<->; the mass ratio between the raw material of the circuit board and the electrolyte is 1:5-1:10, and the density of cathode current is 2-4A / dm<2>. The copper produced by the method takes the metal in the old electronic printed circuit board as the main raw material, and prepared by the suspension electrolysis method. The suspension electrolysis method utilizes the oxidization of the anode and anode energy in the electrolytic deposition process, can realize electrolytic deposition of the metal under the conditions of low cell voltage and low energy consumption, and has remarkable advantages in the aspects of metal separation and environmental pollution prevention.

Owner:TIANJIN UNIV

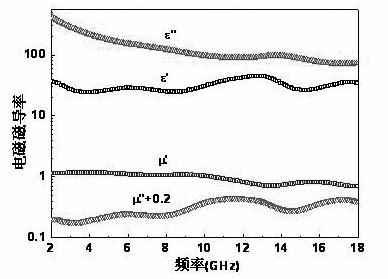

Carbonized bacterial cellulose/magnetic composite wave-absorbing material and preparation method thereof

InactiveCN102093840ASimple preparation processIncrease productivityOther chemical processesInorganic material magnetismFiberCarbon fibers

The invention discloses a carbonized bacterial cellulose / magnetic composite wave-absorbing material. The carbonized bacterial cellulose / magnetic composite wave-absorbing material is characterized in that: the material is formed by compounding carbonized bacterial cellulose and a nano-magnetic material, the volume ratio of the carbonized bacterial cellulose to the nano-magnetic material is between 1:20 and 5:1, and the nano-magnetic material is one of ferrite or magnetic metal and alloy thereof. The carbonized bacterial cellulose and the nano-magnetic material are compounded, and an obtained biomass mesh-shaped nano-carbon fiber / magnetic composite material can be taken as an ideal microwave absorbent; the wave-absorbing material has the characteristics of thinness, lightness, width and strongness; the carbonized bacterial cellulose / magnetic composite wave-absorbing material has the advantages of low cost, simple preparation technology, environment-friendliness and the like; and the composite wave-absorbing material has broad application prospect in the field of electromagnetic pollution prevention, radar stealth and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

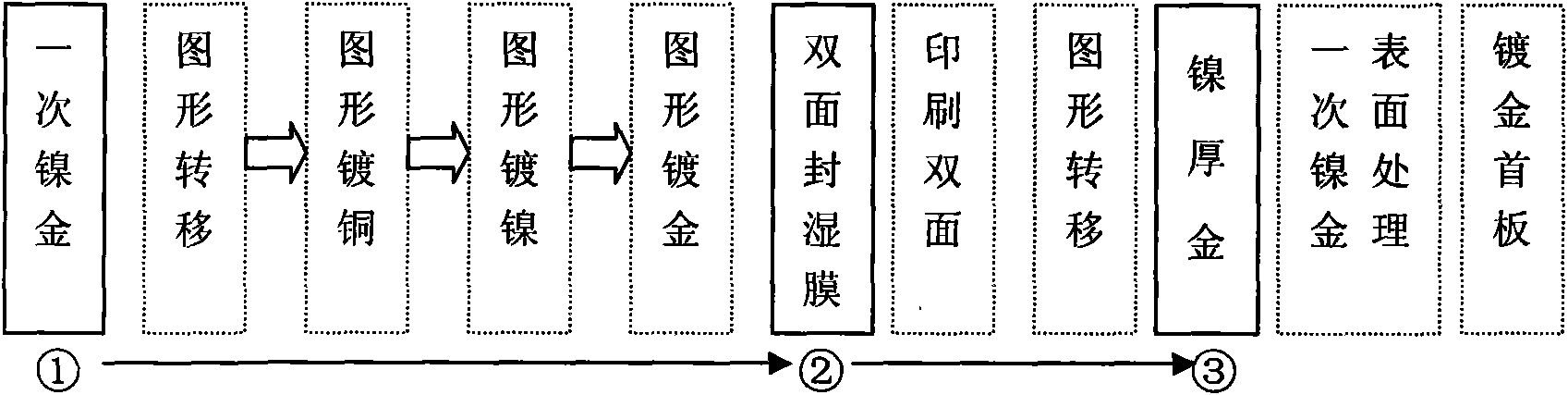

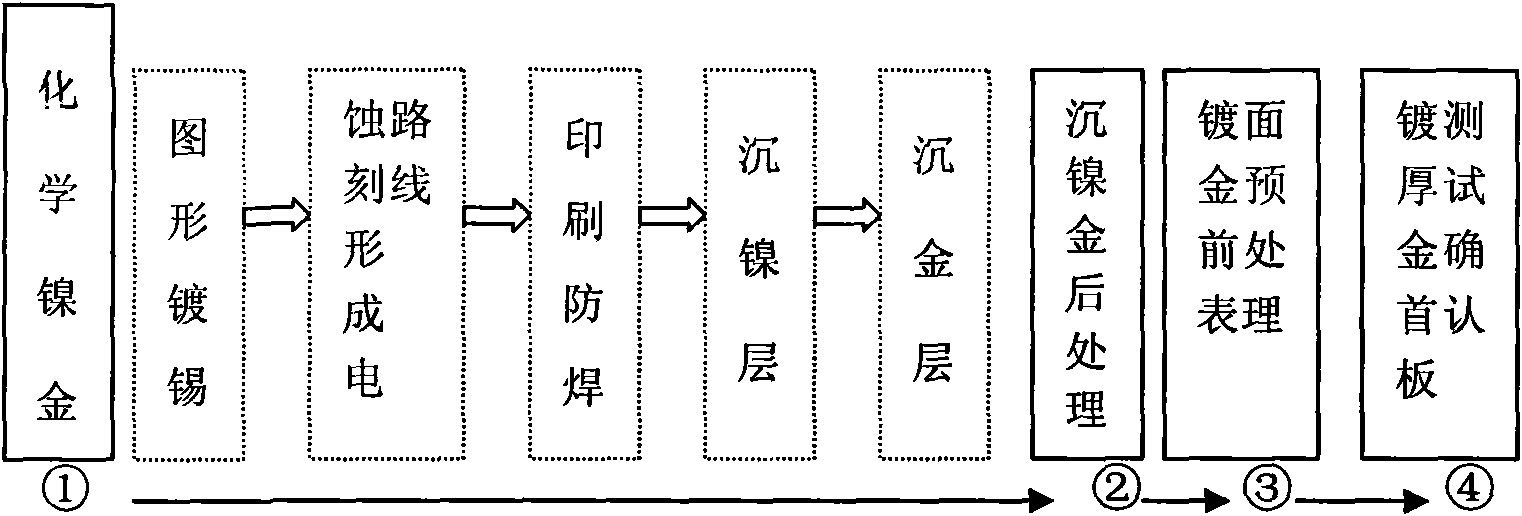

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427ANo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

InactiveCN103965673AExcellent superhydrophobic propertiesFrost resistantCoatingsCoated membraneSolar battery

The invention discloses a preparation method of a super-hydrophobic, super-oleophobic and high transparency triple-function coating film, belongs to the field of novel materials, and particularly belongs to the field of self-cleaning optical materials. The method comprises the steps of firstly assembling large-grained SiO2 nano particles on a glass substrate, so as to form the lower layer of the fine structure of a functional coating layer, simultaneously adding pore-foaming agent, so as to adjust and control space filling factors, then assembling upper layer fluoride SiO2 nano fine particles, and constructing a two-stage uneven surface coating layer with a suspension structure and super-hydrophobic, super-oleophobic high and transparency functions. The functional film has frost prevention, fog prevention, pollution prevention, bacteriostasis and self-cleaning properties, also has excellent translucency, can effectively prevent properties of optical elements, photoelectron elements, solar batteries and laser systems from being influenced by environment in severe environment, greatly expands the application range of the equipment, guarantees the operational reliability, and prolongs the service life, thereby greatly improving the practical values of the equipment.

Owner:JIANGNAN UNIV +1

Preparation of super-hydrophobic coating with nanocrystalline cellulose/silicon dioxide composite template process

The invention discloses a method for preparing a super-hydrophobic coating with a nanocrystalline cellulose / silicon dioxide (NCC / SiO2) composite template process. The method comprises the following steps: (1) treating microcrystalline cellulose (MCC) with 56% sulfuric acid; (2) performing centrifugal washing; (3) replacing water in an NCC suspension solution with ethanol; (4) grinding for later use; and (5) freezing a sample to subzero 30 DEG C and performing vacuum freeze-drying. The method has the advantages that stearic acid is taken as a modifier and can produce a dehydration reaction with surface -OH of SiO2 / NCC, and stearic acid further introduces hydrophobic -CH3 groups, so that the surface energy of SiO2 / NCC is reduced; and an NCC and SiO2 compound has not only the properties of a biopolymer material but also the properties of an inorganic material such as weather resistance, hardness and the like, can be used for modifying indoor and outdoor coatings, and can play a role in aspects of building floor cleaning, furniture pollution prevention and the like.

Owner:广东新红阳科技有限公司

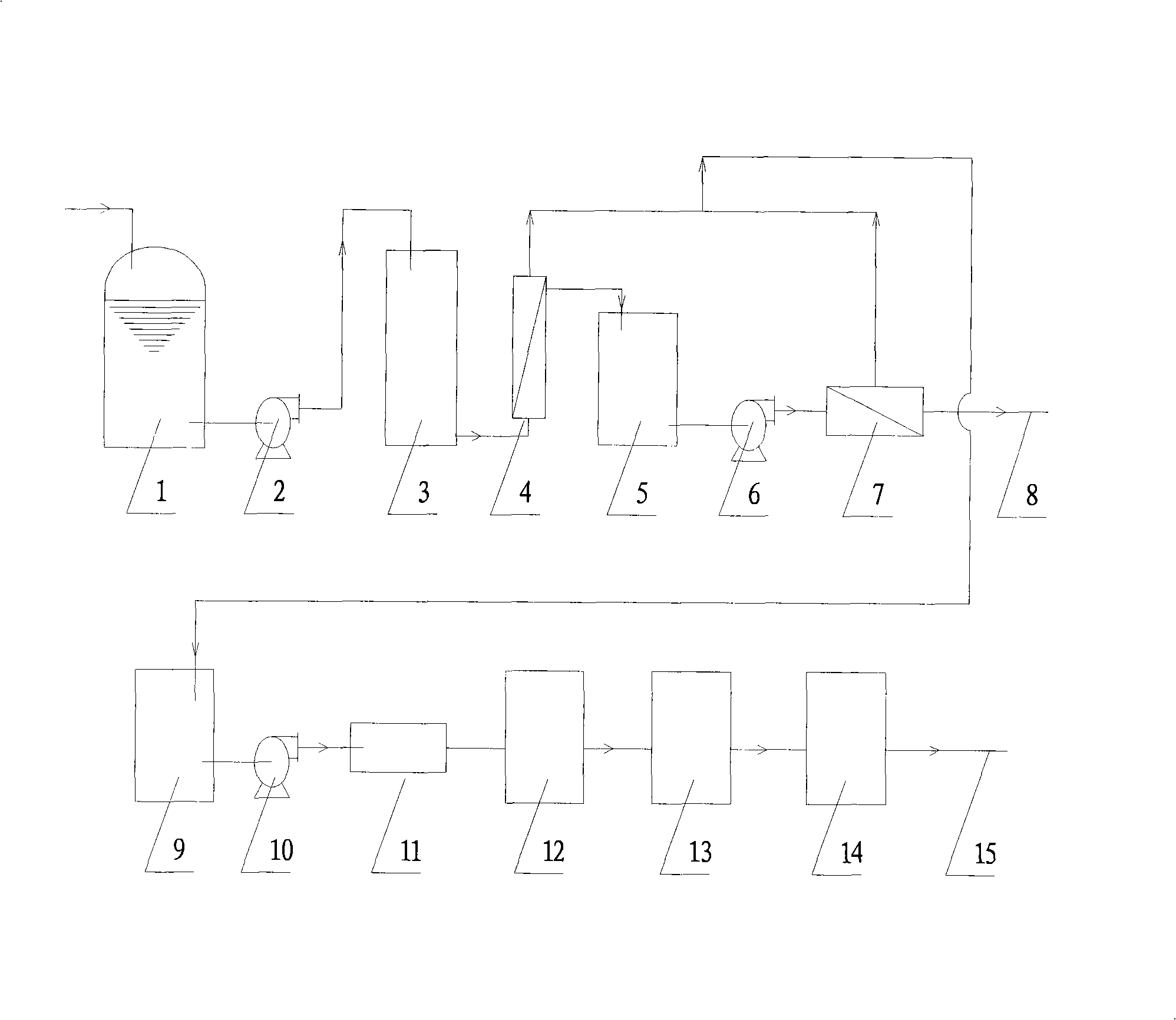

Reclamation and comprehensive treatment method for paper-making waste water

ActiveCN101337750ASolve the problem of large water consumptionWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisInorganic saltsMicrowave

The invention discloses a comprehensive processing method of paper-making wastewater reuse. By adopting the method, after being pre-processed, paper-making wastewater discharged enters ultra-filtration, reverse osmosis or nanofiltration; membrane permeation liquid can be directly reused for power plants or taken as process water; due to being rich in inorganic salt, various additives, lignin, fibrin, hemicellulose and other organisms, as well as various colonies, concentrated solution which is subjected to membrane interception can not be discharged directly. The concentrated solution is processed by adopting the microwave technique; the concentrated solution after being processed can achieve State Discharge Standards, thereby being discharged directly. Particularly, the pollution prevention and the recovery of a membrane system and the microwave treatment of the membrane concentrated solution can be discharged according to standards. A majority of paper-making wastewater can be reused by adopting the method, and a small amount of residual wastewater can be discharged according to standards, thereby completely solving the problem that the water consumption is large in a paper-making industry.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

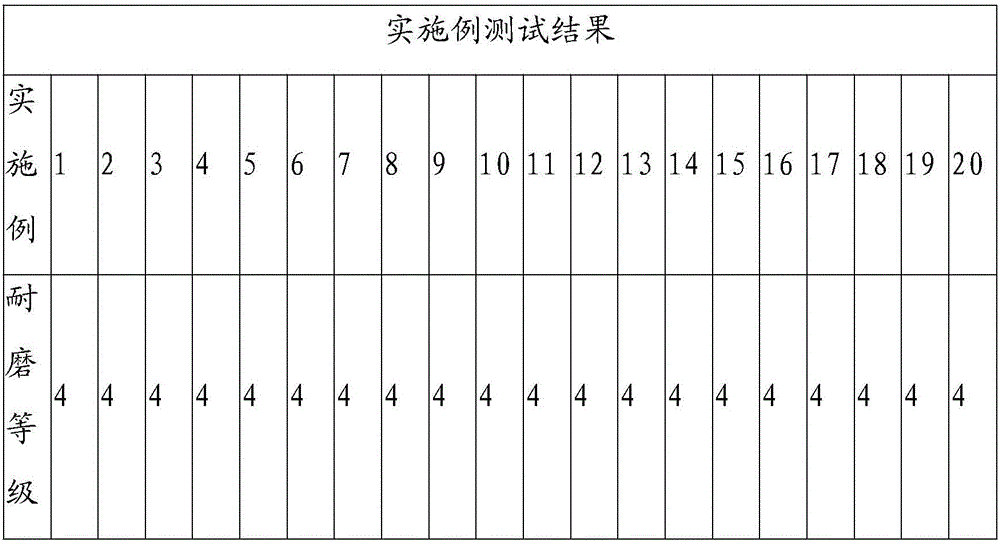

Wear-resistant organosilicone synthetic leather and manufacturing method thereof

InactiveCN106498759AEnvironmentally friendlyResistant to hydrolysisTextiles and paperEnvironmental resistanceWear resistant

The invention discloses wear-resistant organosilicone synthetic leather and a manufacturing method thereof. The wear-resistant organosilicone synthetic leather comprises a wear-resistant surface glue layer, a bottom glue layer and a base material which are successively connected from top to bottom. The wear-resistant organosilicone synthetic leather has wear resistance while having properties of environmental protection, hydrolysis resistance, ageing resistance and pollution prevention, therefore, the service life of a finished product is prolonged, the application range of the finished product is expanded, a manufacturing process is simple, and the wear-resistant organosilicone synthetic leather is easy to process, and is suitable for industrial production.

Owner:SALIRONE INC HUIZHOUCAMPUS

Method for treating water body containing tetracycline antibiotics by powdered activated carbon

InactiveCN101337706AEfficient removalLow equipment requirementsFatty/oily/floating substances removal devicesLiquid separationMedicineApplication areas

The invention belongs to the field of pollution prevention and control and discloses a method for treating a water body containing tetracycline antibiotics by using powdered activated carbon. The method comprises the steps of adding powdered activated carbon and the water body polluted by tetracycline antibiotics into a container, performing treatment by using the method of intermittent churning for a proper time, and then removing powdered activated carbon from the water body. The method has the advantages of simple operation, low cost, less time consumption, wide application area, safety and friendliness to the environment, as well as adaptability to industrialized application.

Owner:NANJING UNIV

Frame sealant composition, liquid crystal pollution prevention method, liquid crystal display panel and display device

InactiveCN102702987AReduce spreadImprove anchoring abilityOther chemical processesLayered productsDisplay deviceEngineering

The invention provides frame sealant composition, a liquid crystal display unit and a liquid crystal pollution prevention method using the frame sealant composition. The frame sealant composition comprises, by weight, 20-30 parts of ultraviolet double-bond polymeric monomer, 15-20 parts of thermally polymerized monomer, 5-20 parts of polymerizable oligomer, 0.1-5 parts of optical initiator, 10-20 parts of thermal curing agent and 0-20 parts of granulated additive. The polymerizable oligomer is polyethyleneglycol diacrylate or derivatives thereof. The polymerizable oligomer reacts with polymer of the ultraviolet double-bond polymeric monomer to generate network high polymer, and accordingly anchorage of the network high polymer on surrounding unreacted thermally polymerized monomers is enhanced effectively, and pollution of liquid crystal by the frame sealant is reduced.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Super-hydrophobic and anti-pollution flashover one-component adhesive, and preparation method and application thereof

InactiveCN103965827ADurable shockLower surface energyNon-macromolecular adhesive additivesCoatingsCross-linkPolymer science

The invention relates to super-hydrophobic and anti-pollution flashover one-component adhesive, and a preparation method and application thereof, and belongs to the technical field of adhesives and coatings. The adhesive comprises the following components in part by mass: 100 parts of hydroxyl-terminated polysiloxane, 50 to 150 parts of fire retardant, 1 to 5 parts of hydrophobic enhancer, 0.2 to 2 parts of structure modifier, 3 to 15 parts of cross-linking agent, and 0.2 to 5 parts of catalyst. The method comprises the steps of performing vacuum drying treatment to the hydroxyl-terminated polysiloxane, reinforcing filler, the fire retardant, the hydrophobic enhancer and the structure modifier which are mixed for 1 to 3 hours at 80 to 150 DEG C, cooling the mixture, feeding the cross-linking agent and the catalyst to the mixture, uniformly mixing, and then obtaining the adhesive. The adhesive can be dissolved in organic solvent and then is served as coating. The adhesive has the advantages that the adhesive can be directly used, the bonding strength is high, the flame retardant rating is high, the pollution prevention effect is good, the technology is simple, the controllability is good, the adhesive can be directly used and can also be dissolved in solvent to perform coating operation, and the like.

Owner:TIANJIN HANGRUI FENGYUAN TECH

Non-point source pollution calculation method based on remotely sensed image element

ActiveCN102867120ARapid Pollution Load EstimationSolve the problem of difficult pollution estimationSpecial data processing applicationsSlope lengthDrainage basin

The invention provides a non-point source pollution calculation method based on a remotely sensed image element. The method comprises the following steps of: 1, constructing a land utilization database and a vegetation coverage database; 2, constructing a soil type database, a soil nitrogen and phosphorus attribute database and a gradient and slope length geographic space database; 3, constructing a farmland nitrogen and phosphorus balance amount space database; 4, calculating dissolved state non-point source loads and adsorption type non-point source loads of non-point source pollutants under different pollution types according to database information in the steps from 1 to 3 and the pollution types; and 5, calculating a total amount of non-point source pollutants in a river according to the dissolved state non-point source loads and the adsorption type non-point source loads. By the method, under the condition that a data condition is limited, a non-point source pollution space distribution feature and a source intensity feature can be quickly obtained based on remotely sensed data; effective pollution monitoring measures can be supplied to a pollution prevention, treatment and management department; and important technology support can be supplied to flow domain pollution management.

Owner:SATELLITE ENVIRONMENT CENT MINIST OF ENVIRONMENTAL PROTECTION

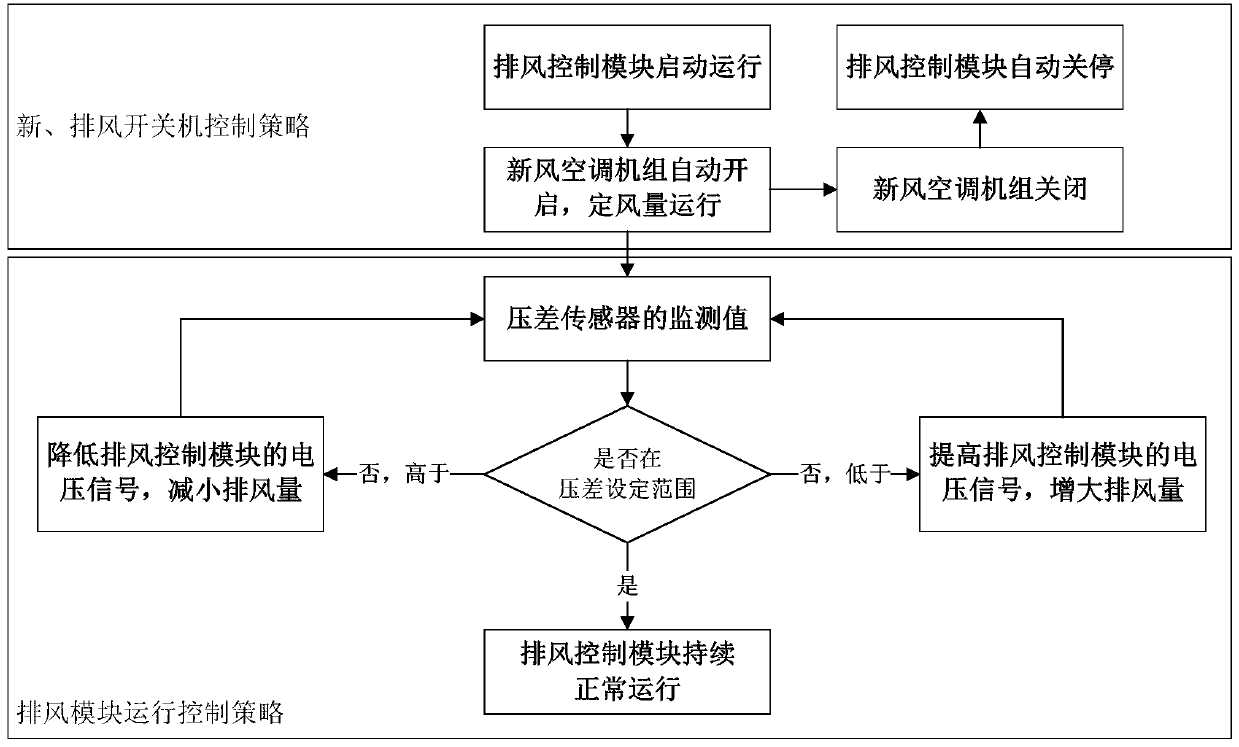

Mobile type infectious disease emergency protection integrated intelligent square cabin

ActiveCN111441618ARealize intelligent monitoringRealize the alarmHospitalsSchoolsFresh airEngineering

The invention discloses a mobile type infectious disease emergency protection integrated intelligent square cabin. The mobile type infectious disease emergency protection integrated intelligent squarecabin comprises a mobile emergency isolation square cabin body, a ventilation air conditioner system, a secondary pollution prevention treatment system, an emergency guarantee system and an intelligent managing system, the interior of the mobile emergency isolation square cabin body is divided into a medical work area, a buffer room and wards, medical toilets are configured in the medical work area, toilets for patients are configured in the wards, the ventilation air conditioner system comprises a fresh air conditioner unit, an exhaust fan set, a pressure difference sensor, an air quality sensor, a temperature sensor, a fresh air control module, and an exhaust control module, the secondary pollution prevention treatment system comprises a pollution discharge device and a purifying and disinfecting treatment device, moving, negative pressure isolation, ventilation air conditioning, secondary pollution prevention treatment, emergency guarantee and intelligent managing are integrated, under the sudden epidemic, rapid response is achieved, in-time treatment is achieved, crossed infection and secondary pollution can be prevented, and the emergency protection is met.

Owner:CHONGQING HAIRUN GREEN TECH GRP CO LTD

Multi-dimension decorative wood-grained ceramic tile with original edges and production method of multi-dimension decorative wood-grained ceramic tile with original edges

ActiveCN110372416AReduce glossGuaranteed decorative effectCeramic materials productionClaywaresBrickWear resistance

The invention discloses a multi-dimension decorative wood-grained ceramic tile with original edges and a production method of the multi-dimension decorative wood-grained ceramic tile with the originaledges. The method comprises the steps of (1) conducting compression moulding on a preform body, and placing the preform body subjected to compression moulding in a roller kiln for drying to form a ceramic tile green body; (2) applying matte cover glaze on the ceramic tile green body to form a matte cover glaze layer; (3) conducting ink-jet printing on the matte cover glaze layer, and applying deep-carving ink to form a pattern decoration and deep-carving ink composite layer; (4) applying matte transparent glaze on the pattern decoration and deep-carving ink composite layer to form a matte transparent glaze layer; (5) applying dry granule glaze on the matte transparent glaze layer to form a dry granule glaze layer; and (6) conducting feeding, firing and forming to obtain the multi-dimension decorative wood-grained ceramic tile with the original edges. The flatness of surfaces of the ceramic tile green body is improved, that is to say, effects of pattern decoration, bump texture, senseof depth, surface texture and the like are guaranteed, and meanwhile, a product feels exquisite, and has use effects of a matte property, skid resistance, wear resistance, pollution prevention and thelike.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Method for preparing waterproof and oilproof ceramic coating on surface of base material

The invention discloses a method for preparing a waterproof and oilproof ceramic coating on the surface of a base material. The method comprises the following steps of uniformly mixing a tetraethyl orthosilicate ingredient A, a silica sol ingredient B, a fluorocarbon chain substituted silane coupling agent ingredient C and a long-carbon-chain substituted silane coupling agent ingredient D under the protection of nitrogen gas, adding a catalyst E, carrying out hydrolytic condensation reaction for 1-5 hours at the temperature of 40-80 DEG C, so as to prepare a fluorosilicone modified ceramic coating material, coating the surface of the base material, which is soaked for 3-7 days with alkaline anhydrous ethanol with the pH value of 9-11, with the ceramic coating material in a spin coating manner, and carrying out heat treatment, thereby obtaining the base material surface with excellent waterproof and oilproof properties. The ceramic coating material can be applied to the fields of cooking utensils, metallurgy, the corrosion and pollution prevention of oceans, and the like. The method has the advantages that the process is simple, the operation is easy, the repeatability is good, and the coating material is good in caking property, is transparent and is convenient in application.

Owner:ZHEJIANG UNIV

Digital pre-laminating film

InactiveCN101705060AImprove completenessImprove quality stabilityMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolyesterCoupling

The invention discloses a digital pre-laminating film which is characterized in that the digital pre-laminating film is composed of a base material layer and a hot melt adhesive layer, wherein the base material layer and the hot melt adhesive layer are compounded; the base material layer is a two-way stretch polypropylene film or a two-way stretch polyester film; the hot melt adhesive layer is the mixture of EVA processed in a coupling manner and petroleum resin in the following weight percent: 85-94% of EVA processed in a coupling manner and 6-15% of petroleum resin. After the invention uses a digital print surface, the print surface is smooth and light, thus greatly improving the glossiness and the fastness of the print, prolonging the service life of the product, and performing the protective functions of water prevention, pollution prevention, abrasion resistance, hard fold and the like. The print after being covered with film has vivid and beautiful appearance and is full of three-dimensional texture. The invention is suitable for heating mounting and laminating for advertising paper printing and the like for advertising spray painting, colour painting and the like and opens a new application field in the heating mounting and pre-laminating field.

Owner:胡敏生

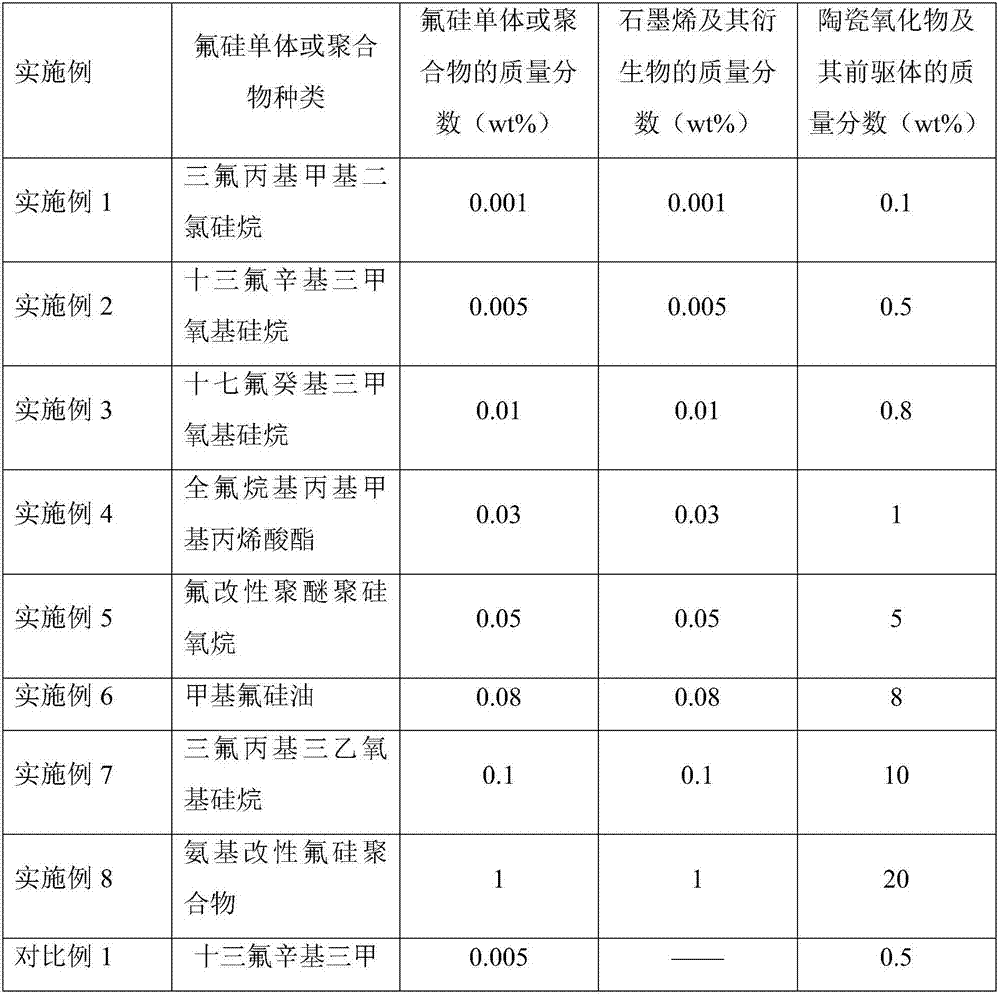

Graphene-based coating and application thereof

InactiveCN106883646ASolution to short lifeImprove high temperature resistanceFireproof paintsAnti-corrosive paintsMicrospherePollution prevention

The invention provides a graphene-based coating dispersion, which at least includes graphene or its derivatives, ceramic oxide or its precursor, fluorosilicon monomer or its polymer, water, wherein graphene and its derivatives are selected from graphite at least one of graphene, graphene oxide, graphene quantum dots, graphene oxide quantum dots, graphene microspheres, graphene oxide microspheres, nano-graphene, nano-graphene oxide, and functionalized graphene. The coating prepared by the coating dispersion of the present invention has good water repellency, oil repellency, antistatic property, abrasion resistance, adhesion and corrosion resistance, etc., and can be applied to the surface antifouling of bathroom, marine equipment, automobile, Anti-oil, waterproof, anti-corrosion, anti-wear and other protection. The preparation process of the coating dispersion liquid of the invention is simple, easy to control, low in cost and has broad application prospects.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Process for silver extraction by acidifying calcination and leaching of lead silver slag

ActiveCN102251122AShort processThe actual operating conditions are looseProcess efficiency improvementResource utilizationSlag

A process for silver extraction by acidifying calcination and leaching of lead silver slag comprises the following steps of: water leaching, that is, leaching the lead silver slag with water to remove and separate soluble zinc sulfates, recovering the leachate, and keeping the leaching residues in reserve; acidifying calcination, that is, adding a mixture of the leaching residues and sulfuric acid into a stirring groove, stirring uniformly, placing the mixture in a fully-closed rotary kiln, slowly cooling to room temperature to obtain calcine in reserve; water washing, that is, putting the calcine after acidifying calcination and water in a leaching groove, heating and stirring, recovering the filtrate, and keeping the filtering residues in reserve; and finally ammonia leaching and silverextraction. The invention adopts processes of fire method preprocessing and wet method leaching, that is, separating zinc sulfate by water leaching, recovering silver by acidifying calcination and ammonia leaching, and returning ammonia leaching residues to system ingredients; valuable components such as silver, zinc, lead and the like are recovered comprehensively; the purposes of effective resource utilization, energy saving, and pollution prevention are reached; optimal technical and economic effect is obtained; and the invention has low implementation cost and reliable technology, has a metal silver leaching rate of up to above 80%, and a metal silver recovery rate of about 72%.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

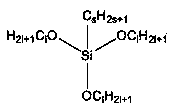

Non-toxic long-acting low-surface-energy antifouling resin and preparation method and application thereof

ActiveCN103012698ASolve the defect of insufficient adhesionLower surface energyAntifouling/underwater paintsPaints with biocidesAcrylic resinAdditive ingredient

The invention relates to the field of antifouling paint, in particular relates to a non-toxic long-acting low-surface-energy antifouling resin and a preparation method and application thereof, and in particular relates to a nano particle organic modified acrylic resin which is mainly used for antifouling of ships. The resin is non-hazardous to marine organisms, and integrates properties of self-cleaning, low surface energy, hydrolysis pollution prevention and the like. The resin comprises the following ingredients in parts by mass: 10-30 parts of nano particles, 50-100 parts of ethanol, 10-50 parts of organic silicon coupling agents, 2-9 parts of water, 0.1-1.0 part of hydrochloric acid, 30-60 parts of acrylic acid monomer, 0.01-1.0 part of initiator, and 20-100 parts of organic solvent. Through the hydrolysis of the organic silicon coupling agent, the nano particles are solidly combined with the acrylic acid monomer so as to form a structure that the nano particles are used as a nuclear and the organic silicon modified acrylic resin is used as a shell. The antifouling resin has the properties of no toxicity, low surface energy and good bottom paint adhesion force, and is provided with hydrolysis groups.

Owner:山东中科纳米科技有限公司

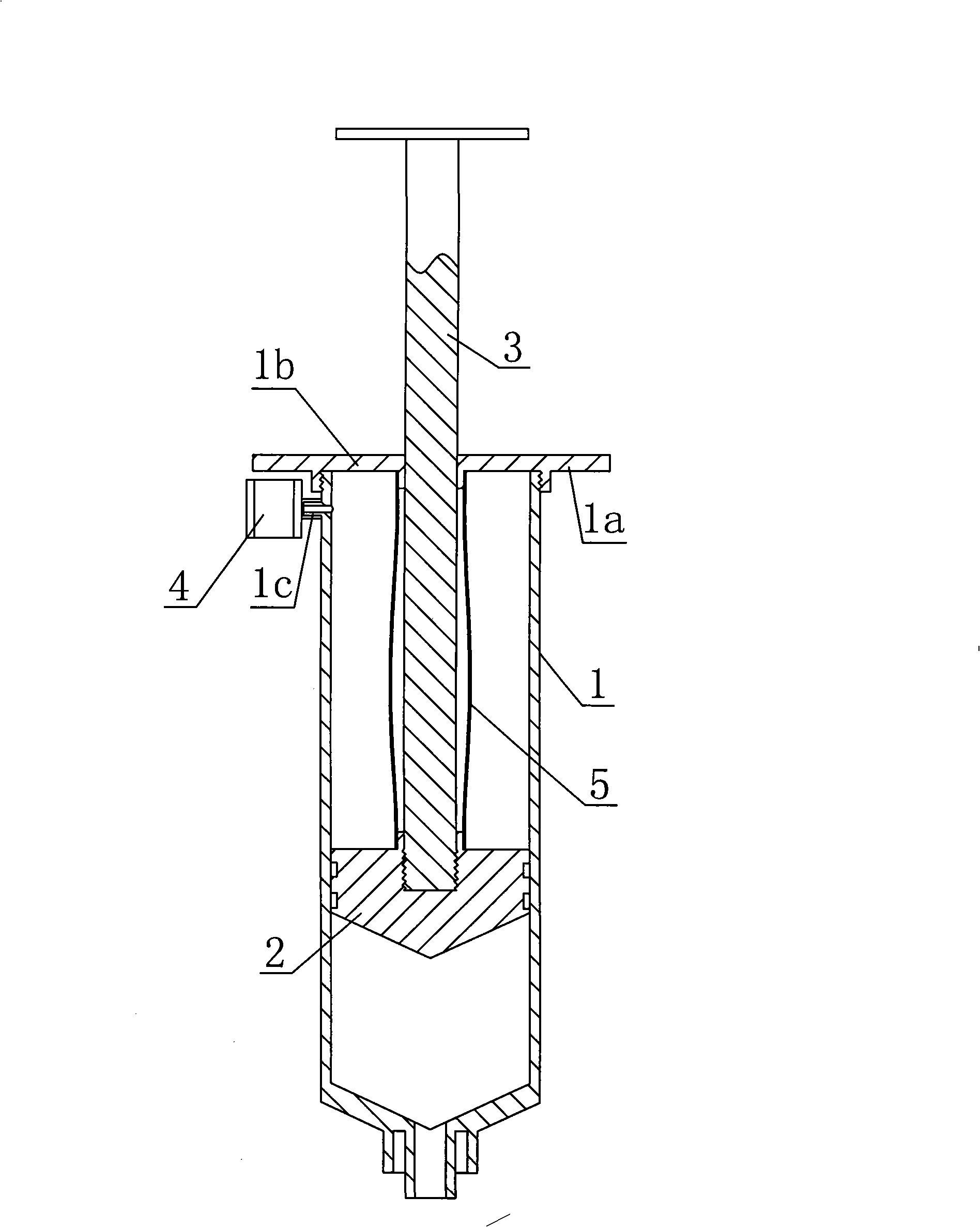

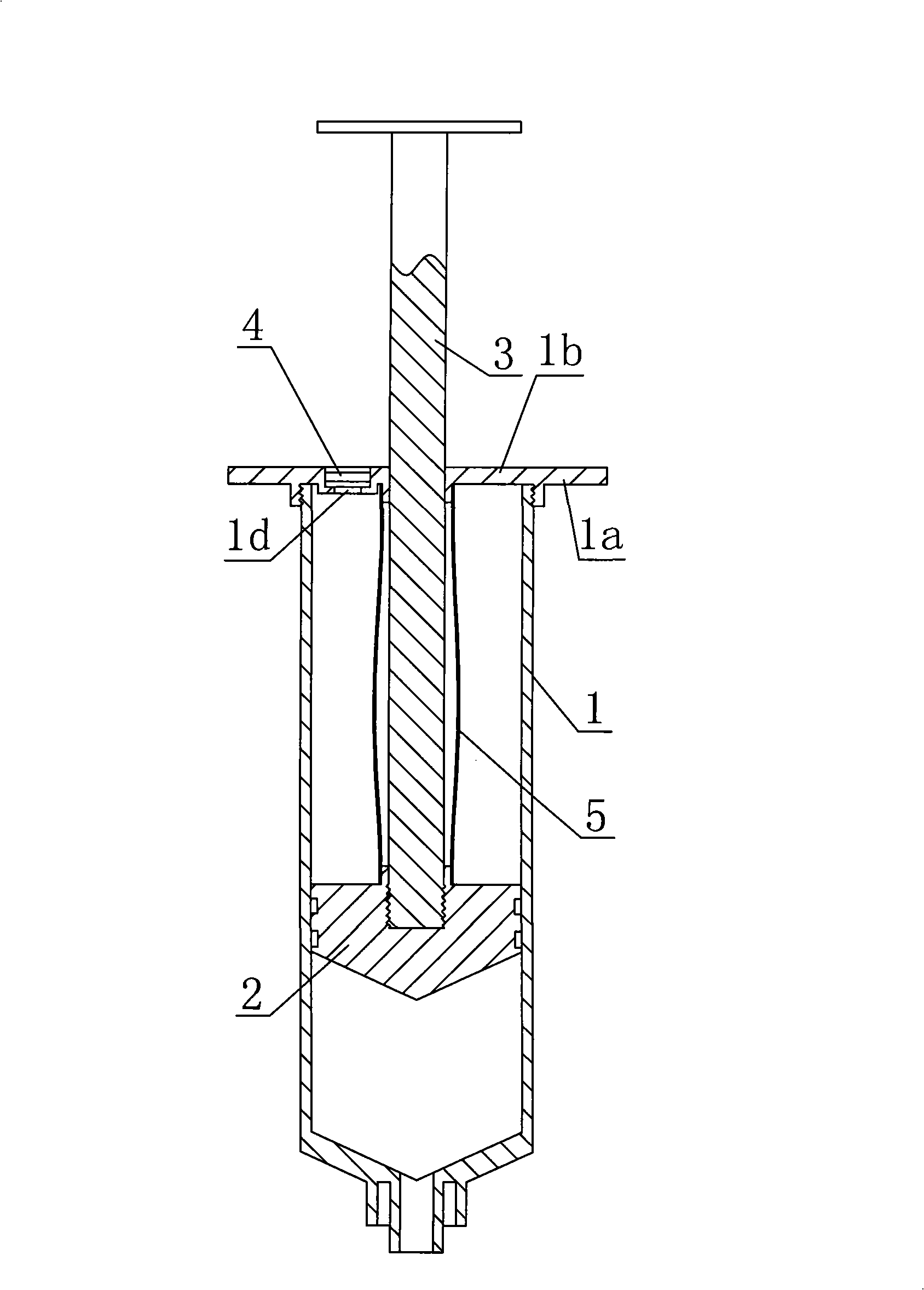

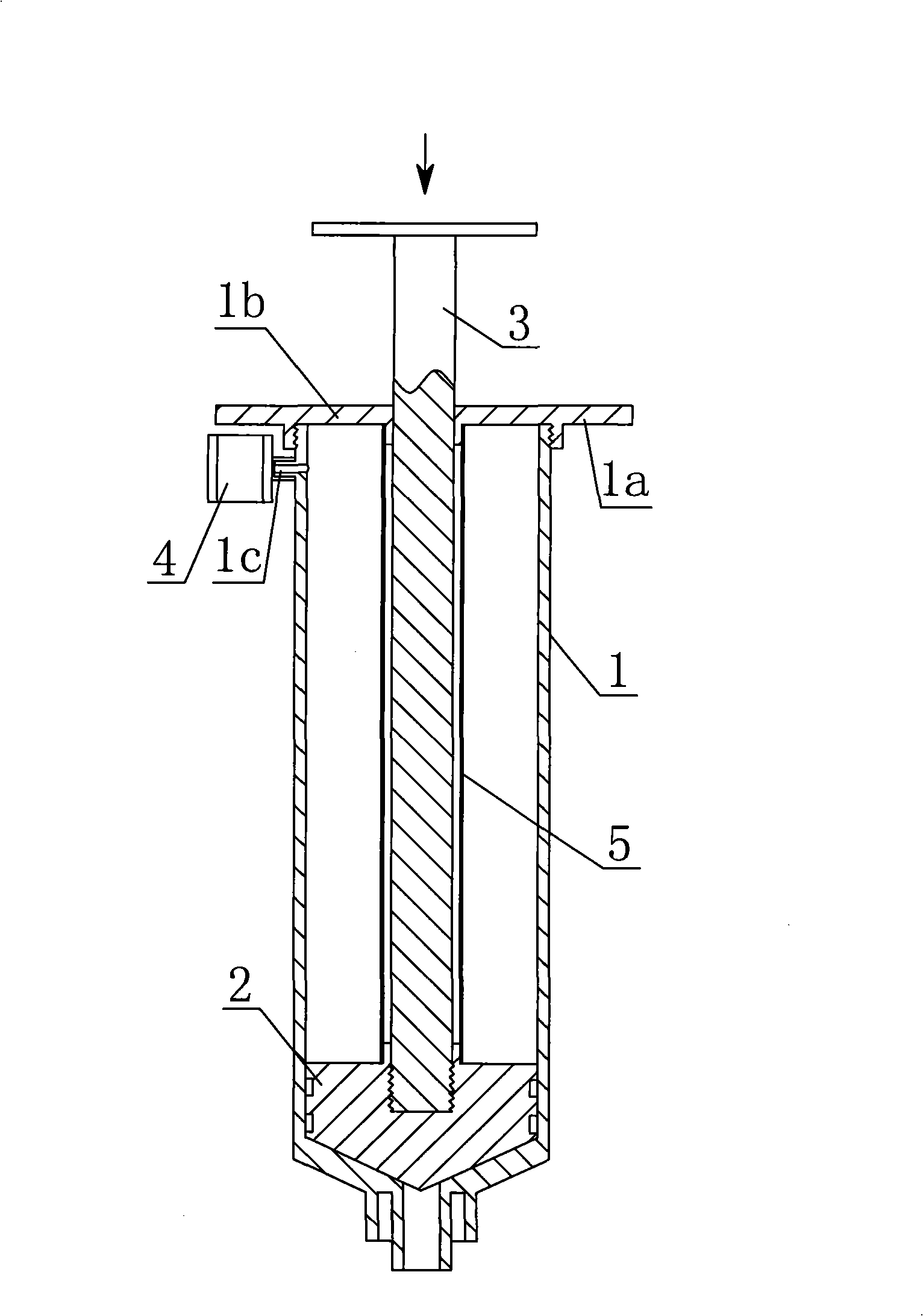

Automatic resorption type antipollution medicine adding syringe

InactiveCN101264359ARealize automatic suctionGreat suctionInfusion syringesIntravenous devicesBiochemical engineeringAir filter

The invention discloses an automatic resorption typed pollution prevention injector for adding medicine, comprising a syringe, a swing plate arranged at the rear end of the syringe, a piston arranged in the syringe, and a guide cover arranged at the rear end of the syringe. The injector is characterized in that: a cylindrical push rod is drilled through the middle of the guide cover and is connected with the piston, an air filter is connected with the rear end of the syringe, the air filter is communicated with the intracavity of the syringe; wherein, an elastic piamater sleeve is arranged on the external periphery of the cylindrical push rod between the guide cover and the piston, the natural length of the elastic piamater sleeve is shorter than the stroke of the piston in the syringe; the automatic resorption typed pollution prevention injector is used for blending injected medical solution. The injector has the advantages of labor saving and convenient use.

Owner:陈庆强

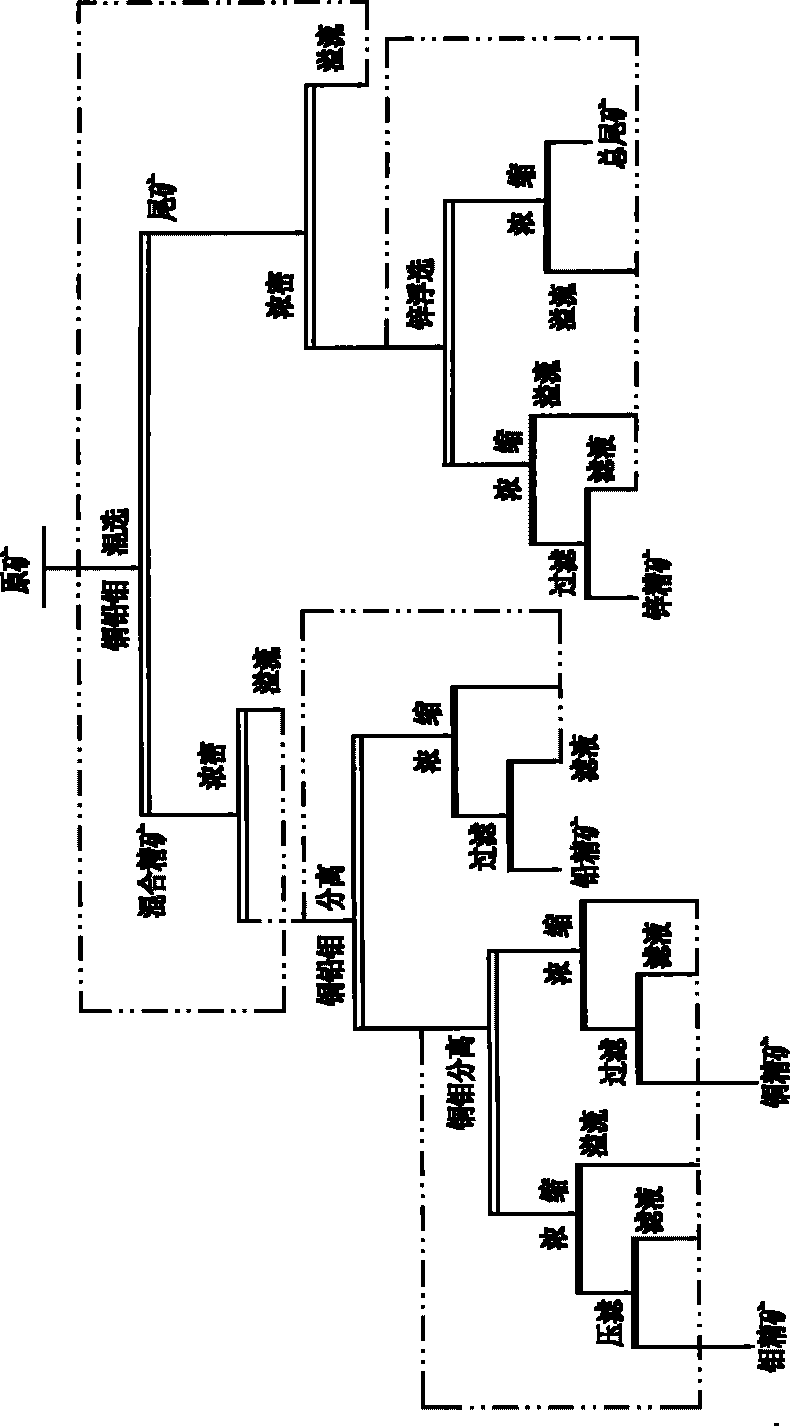

Backwater utilizing method for ore-dressing of polymetallic ore

InactiveCN101695684AReduce adverse effectsHigh content of impuritiesWater/sewage treatmentEnergy based wastewater treatmentEconomic benefitsPollution prevention

The technical scheme of the invention provides a backwater utilizing method for ore-dressing of a polymetallic ore, which comprises the following steps: selecting mixed concentrate of polymetallic ore orderly by adopting step-by-step mixed flotation; and performing separating flotation on the mixed concentrate to obtain the concentrate of a single ore. Intermediate products, concentrate and tailings generated by the mixed flotation of the polymetallic ore are subjected to dehydration; and the generated backwater is returned to a flotation operation used for a single metal ore. The backwater utilizing method of the technical scheme of the invention is suitable for the ore-dressing process of the polymetallic ore, particularly for the ore-dressing process of the polymetallic ore which is capable of obtaining a single metal ore by the step-by-step flotation. The backwater utilizing method for the ore-dressing of the polymetallic ore can improve an ore-dressing index to the maximum and ensures qualified products, meets relative policies of environment protection and pollution prevention of the State Environmental Protection Administration while enabling an enterprise to acquire good economic benefits, so the method has very practical significance for the development of a mine of which the ore properties are complex.

Owner:CINF ENG CO LTD

Renewable energy electric generating system

InactiveUS8169101B2Improve efficiencyElectrolysis componentsOther heat production devicesThermal energyElectrolysis

A system, apparatus and method for generating electricity from renewable geothermal, wind, and solar energy sources includes a heat balancer for supplementing and regulating the heat energy fed to a turbine generator; a hydrogen-fired boiler for supplying supplementary heat; and an injection manifold for metering controlled amounts of superheated combustible gas into the working fluids to optimize efficiency.Wind or solar power may be converted to hydrogen in an electrolysis unit to produce hydrogen. A phase separator unit that operates by cavitation of the geothermal fluids removes gases from the source fluid. A pollution prevention trap may be used to remove solids and other unneeded constituents of the geothermal fluids to be stored or processed in a solution mining unit for reuse or sale. Spent geothermal and working fluids may be processed and injected into the geothermal strata to aid in maintaining its temperature or in solution mining of elements in the lithosphere.

Owner:CANYON WEST ENERGY

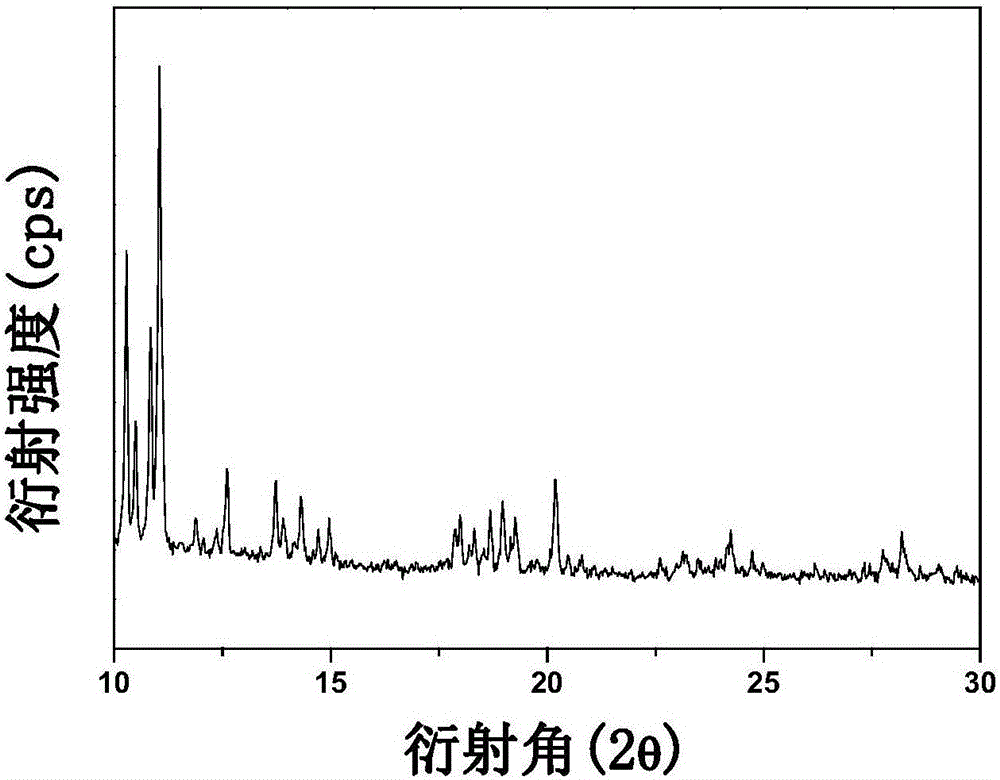

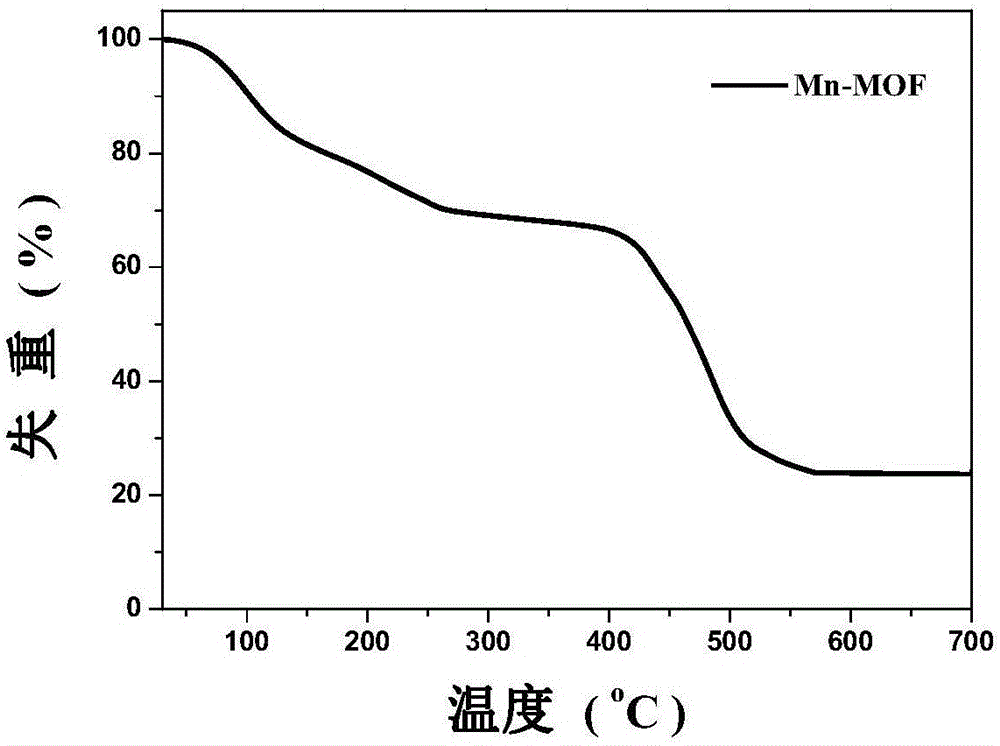

Mn base metal organic skeletal catalyst, and preparation method and application thereof in air pollution prevention

ActiveCN106345527AImprove thermal stabilityLarge specific surface areaGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsManganeseHeat stability

The invention provides a Mn base metal organic skeletal catalyst, and a preparation method and application thereof in air pollution prevention. The preparation method comprises the following steps of (1) dissolving manganese metal salt into an organic solvent, and obtaining an organic solution of the manganese metal salt; (2) mixing the organic solution of the manganese metal salt and an organic solution of an organic ligand, stirring and heating, and obtaining a reacted solution; (3) putting the reacted solution into a reaction kettle, putting into a drying oven, heating, obtaining a coarse crystal, filtering, washing and drying the coarse crystal, and obtaining a crystal; (4) roasting the crystal, and obtaining the Mn base metal organic skeletal catalyst. The preparation method is simple, easy to operate, and suitable for industrialized application; the Mn base metal organic skeletal catalyst prepared by adopting the preparation method is high in heat stability and large in specific surface area, and can be used for catalyzing CO and eliminating volatile organic pollutants in air and oxynitride containing sulfur dioxide atmosphere.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com