Digital pre-laminating film

A pre-coating and digital technology, applied in the field of digital pre-coating, can solve the problems of unsatisfactory composite effect of digital prints, and achieve the effects of bright and beautiful colors, rich three-dimensional texture and high adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

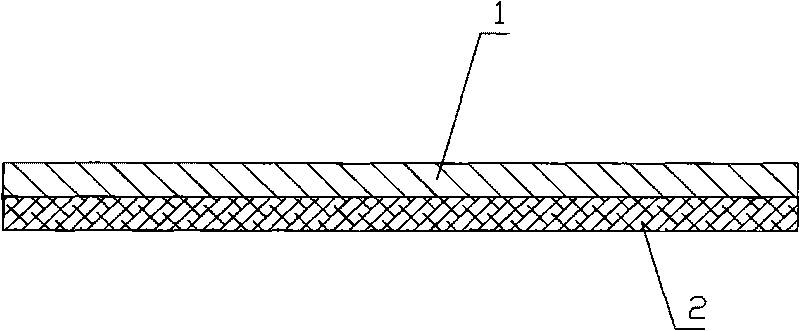

[0023] Embodiment 1: as figure 1 As shown, the digital pre-coating film is composed of a substrate layer 1 and a hot melt adhesive layer. The substrate layer 1 and the hot melt adhesive layer 2 are combined together. The substrate layer is biaxially oriented polypropylene film (BOPP) or biaxially stretched Stretched polyester film (BOPET); the hot melt adhesive layer is a mixture of ethylene-vinyl acetate (EVA) and petroleum resin after coupling treatment.

[0024] The ethylene-vinyl acetate (EVA) and the petroleum resin of the hot-melt adhesive layer account for the weight percent example of the hot-melt adhesive layer respectively through the coupling treatment: the ethylene-vinyl acetate (EVA) through the coupling treatment is 92%, Petroleum resin is 8%. The coupling-treated ethylene-vinyl acetate (EVA) is formed by soaking ethylene-vinyl acetate (EVA) with 5% coupling agent and alcohol mixture, making it fully mixed and then drying. The coupling agent is a silane couplin...

Embodiment 2

[0030] Embodiment 2: digital pre-coating film, is made up of substrate layer and hot-melt adhesive layer, and substrate layer and hot-melt adhesive layer are compounded together, and substrate layer is biaxially stretched polypropylene film or biaxially stretched polyester film; The hot melt adhesive layer is a mixture of ethylene-vinyl acetate (EVA) and petroleum resin after coupling treatment.

[0031] The ethylene-vinyl acetate (EVA) of the coupling treatment of the hot melt adhesive layer and the petroleum resin account for the weight percent example of the hot melt adhesive layer respectively: the ethylene-vinyl acetate (EVA) of the coupling treatment is 94%, Petroleum resin is 6%. The coupling-treated ethylene-vinyl acetate (EVA) is formed by soaking ethylene-vinyl acetate (EVA) with 5% coupling agent and alcohol mixture, making it fully mixed and then drying. The coupling agent is a silane coupling agent, an epoxy coupling agent or an amino coupling agent. Wherein, th...

Embodiment 3

[0034]Embodiment 3: digital pre-coating film, is made up of substrate layer and hot-melt adhesive layer, and substrate layer and hot-melt adhesive layer are compounded together, and substrate layer is biaxially stretched polypropylene film or biaxially stretched polyester film; The hot melt adhesive layer is a mixture of ethylene-vinyl acetate (EVA) and petroleum resin after coupling treatment.

[0035] The ethylene-vinyl acetate (EVA) and the petroleum resin of the hot-melt adhesive layer account for the percentage by weight of the hot-melt adhesive layer respectively: the ethylene-vinyl acetate (EVA) through the coupling is 88%, Petroleum resin is 12%. The coupling-treated ethylene-vinyl acetate (EVA) is formed by soaking ethylene-vinyl acetate (EVA) with 5% coupling agent and alcohol mixture, making it fully mixed and then drying. The coupling agent is a silane coupling agent, an epoxy coupling agent or an amino coupling agent. Wherein, the VA content in ethylene-vinyl ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com