Graphene-based coating and application thereof

A graphene-based, graphene-based technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of short service life, scarcity of environmentally friendly coatings, unfavorable environmental protection, etc., and achieve good high temperature resistance, simple preparation process, The effect of good water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

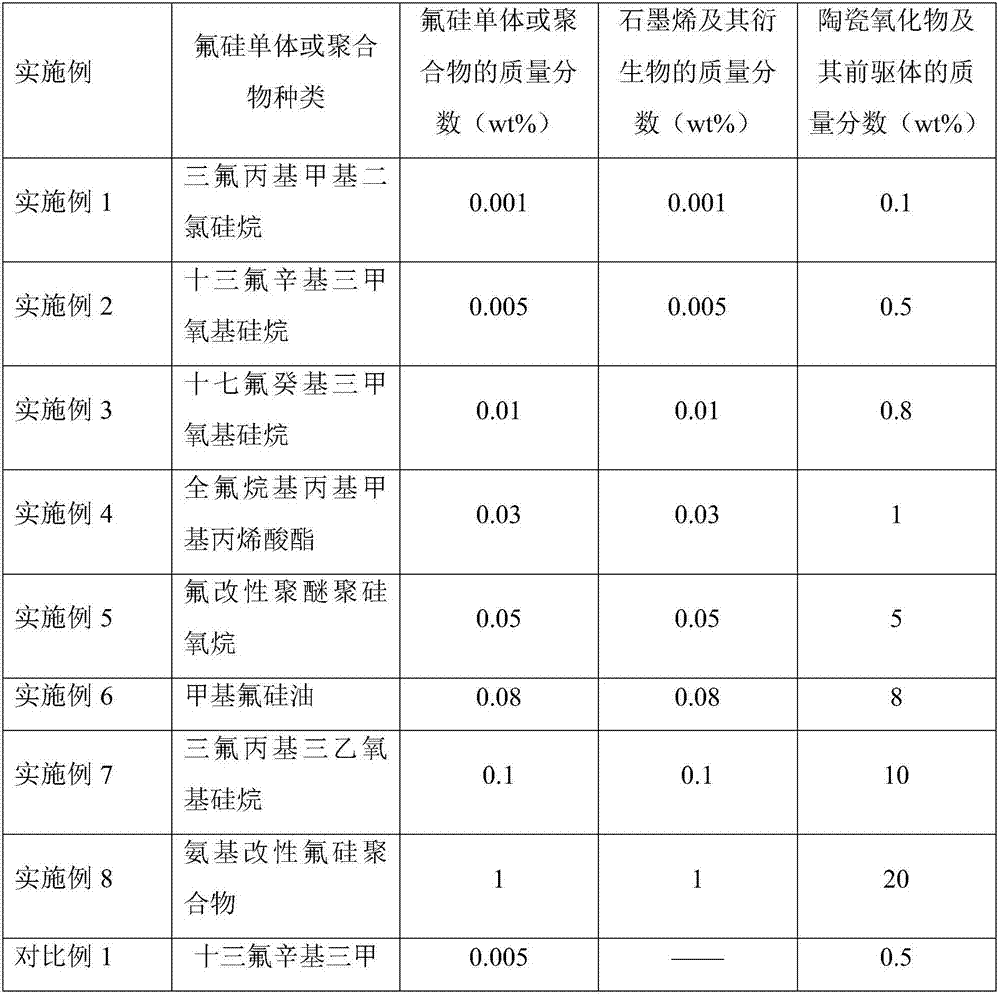

Examples

preparation example Construction

[0010] The graphene-based coating dispersion has a simple preparation process, is suitable for various coating methods, has good controllability, low cost, is environmentally friendly, and is suitable for large-scale application and promotion. Because graphene has the properties of antistatic, wear-resistant, acid and alkali corrosion resistance and high temperature resistance, the graphene-based coating prepared by the graphene-based coating dispersion of the present invention has good antistatic properties, wear resistance and corrosion resistance. Sexuality and long life, high temperature resistance and other characteristics.

[0011] According to the present invention, the ceramic oxide is selected from at least one of silicon dioxide, zirconium dioxide and titanium dioxide; all of them have good wear resistance, corrosion and film-forming properties. Preferably the precursor of the ceramic oxide is selected from ethyl silicate, propyl silicate, butyl silicate, ethyl titan...

Embodiment 1~8

[0022]Add water and 10mg / ml graphene oxide aqueous dispersion to the container, place it in an ultrasonic cleaner for ultrasonic dispersion for 2 hours, stir and disperse for 30 minutes; add 30wt% nano-silica aqueous dispersion, place it in an ultrasonic cleaner for ultrasonic dispersion 2h, stir for 30min; add 10wt% trifluoropropylmethyldichlorosilane aqueous dispersion, stir for 30min; add acetic acid to adjust the pH of the coating dispersion to 4, add 0.01wt% sodium dodecylbenzenesulfonate Surfactant, prepared graphene-based coating dispersion. Among them, the particle size D of graphene 90 50nm, the particle size of nano-silica D 90 5nm. Clean the surface of the copper alloy faucet base, remove oil and oxidizer according to the conventional method, immerse it vertically in the graphene-based coating dispersion, keep it for 10 minutes, take out the graphene-based coating dispersion at a rate of 2cm / min, and put it in 200℃ In a blast drying oven, cure for 4 hours, and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com