Backwater utilizing method for ore-dressing of polymetallic ore

A polymetallic ore and metal technology, applied in chemical instruments and methods, flotation, energy and wastewater treatment, etc., can solve the problems of waste of resources, affecting the quality of beneficiation, loss of metals, etc., to achieve easy operation and control, avoid secondary pollution, The effect of small impact on the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

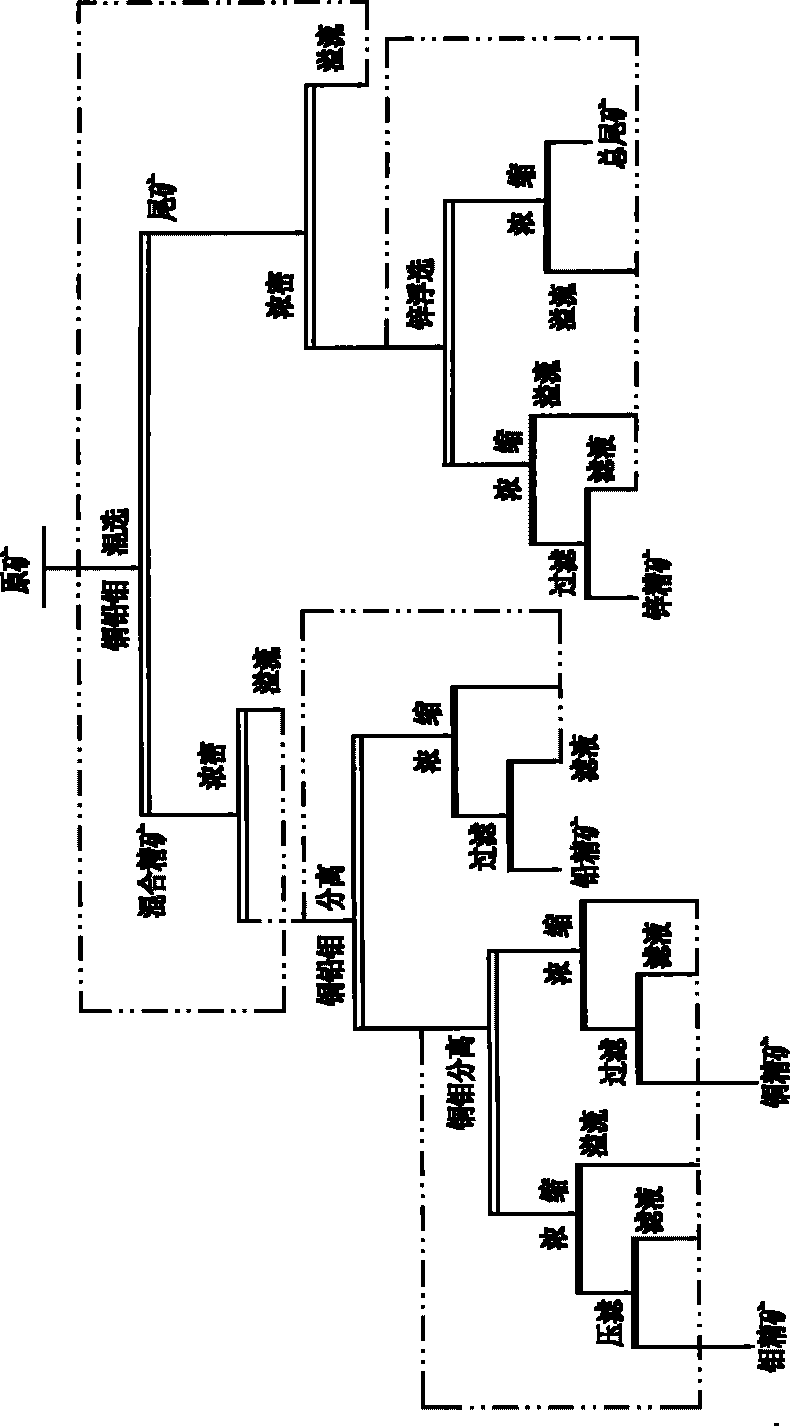

[0012] Copper-lead-zinc-molybdenum raw ore is crushed and ground to a particle size of 70%-200 mesh and enters the copper-lead-molybdenum mixed flotation system. The system consists of one coarse, three fine and three sweeps to produce copper, lead, molybdenum mixed concentrate and tailings. The former will enter the copper-lead separation operation, and the latter will enter the zinc selection system. The copper-lead mixed concentrate and tailings are respectively densely dehydrated, and the generated water is returned to the upper-level mixed flotation system for reuse. The concentrate produced by the zinc flotation system is zinc concentrate, and the tailings are the final tailings, which are also dehydrated separately, and the resulting backwater is returned to the zinc flotation system. By analogy, the copper-lead-molybdenum mixed concentrate enters the copper-molybdenum and lead separation system to produce copper-molybdenum concentrate and lead concentrate, which are de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com