Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213results about How to "High content of impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and structure for manufacture of light emitting diode devices using bulk GaN

ActiveUS8252662B1Minimize re-absorptionThickness minimizationSemiconductor/solid-state device manufacturingSemiconductor devicesCrystalline materialsGallium nitride

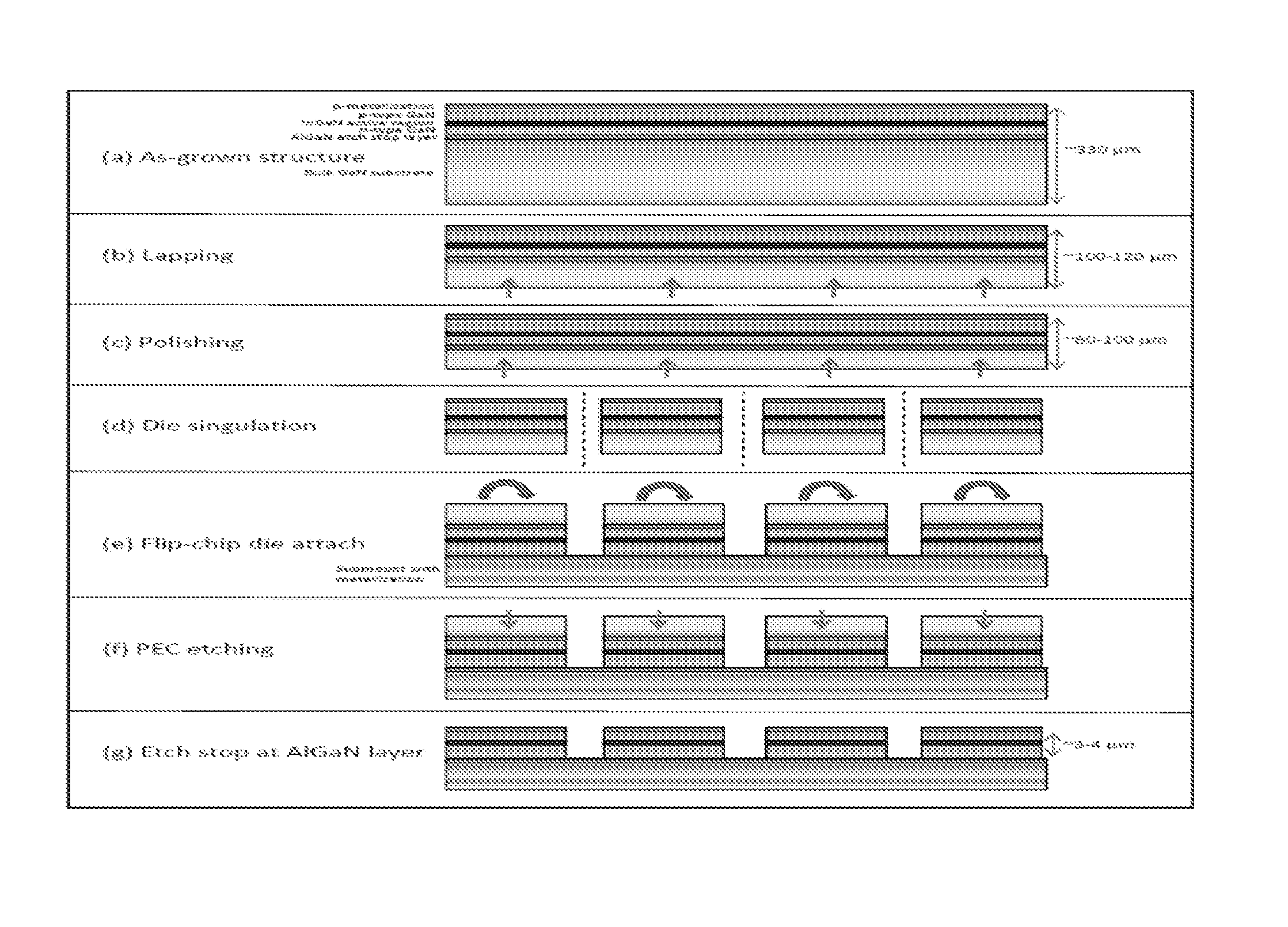

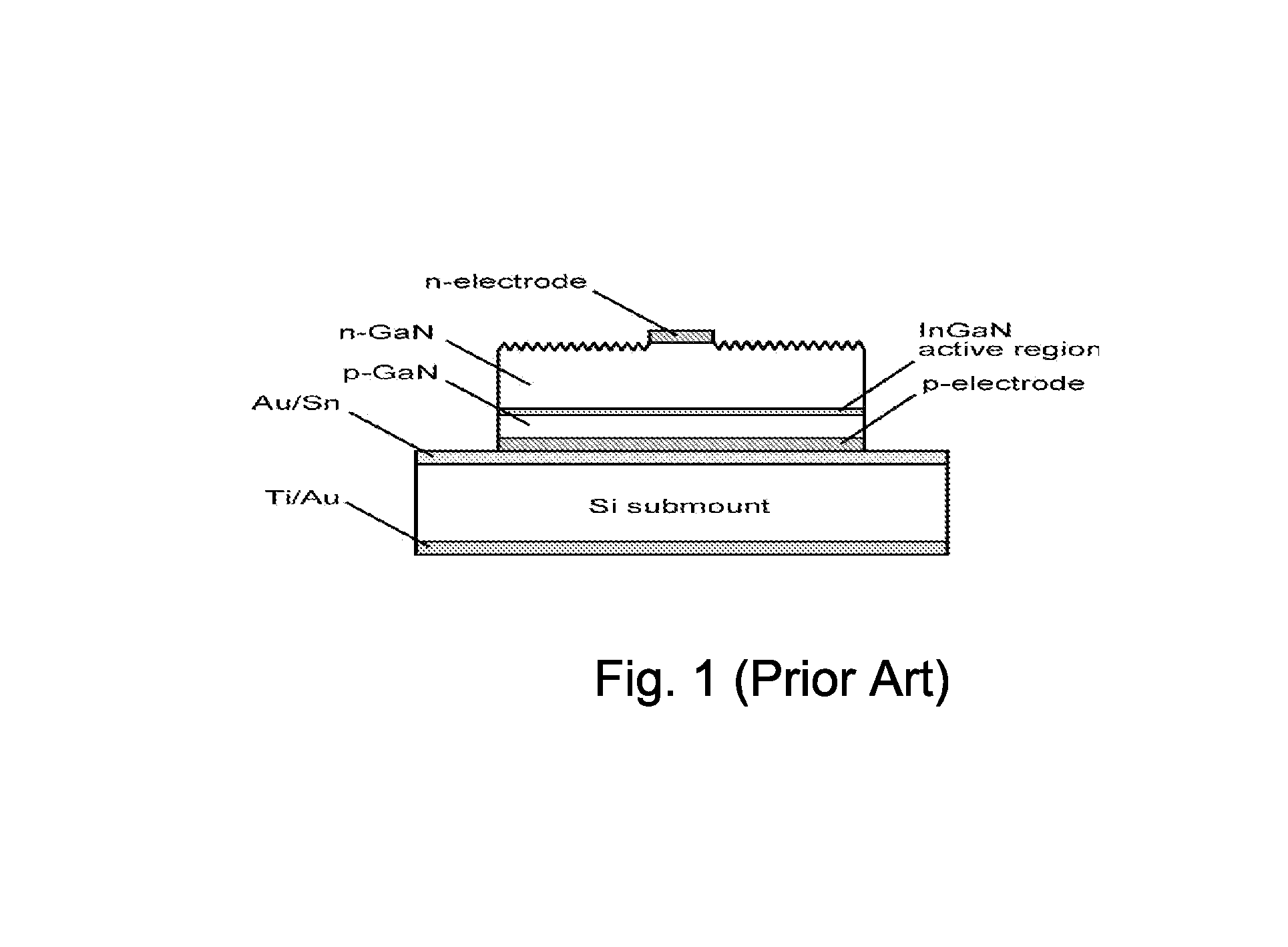

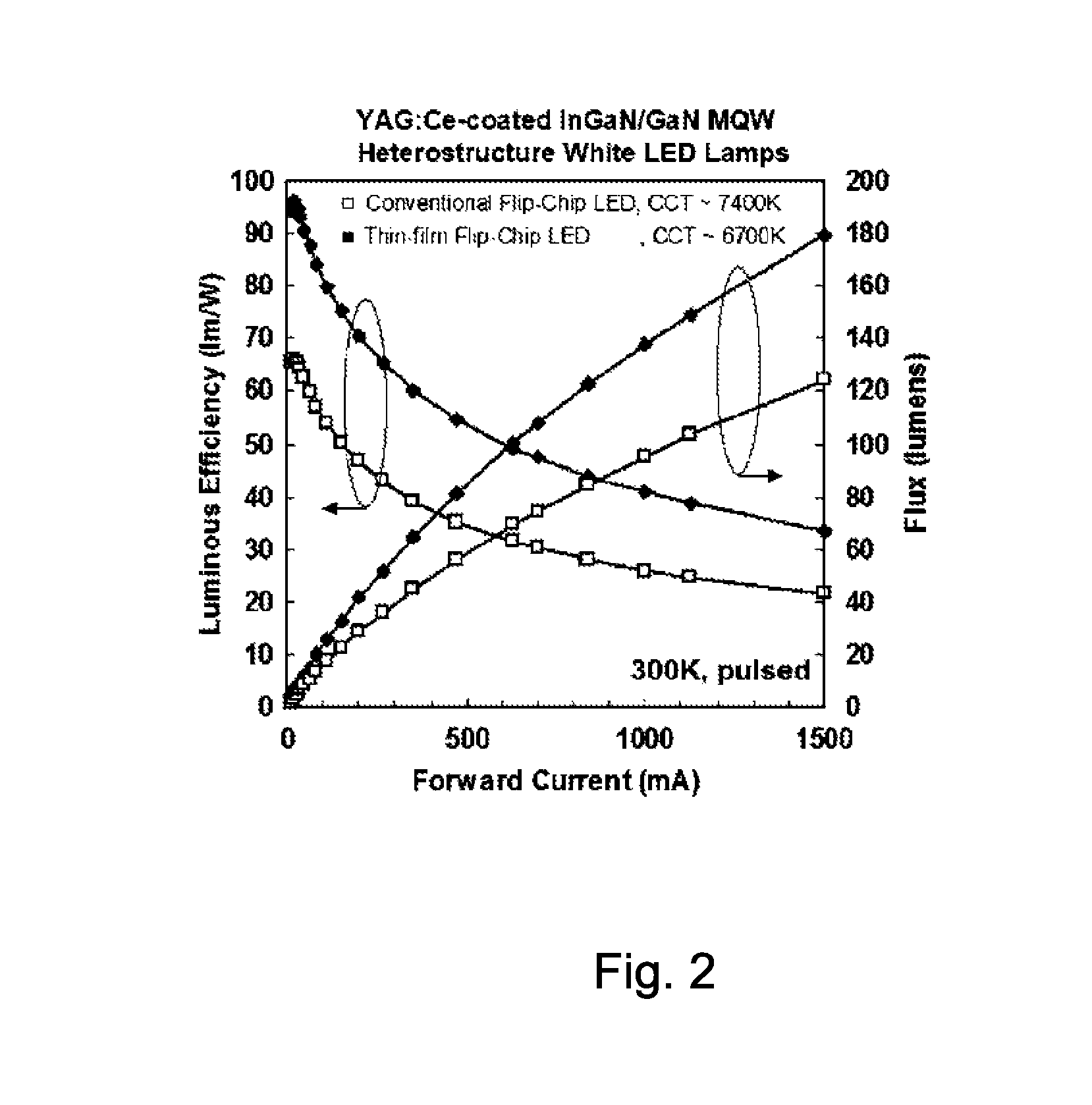

A method for manufacturing a plurality light emitting diodes includes providing a gallium nitride containing bulk crystalline substrate material configured in a non-polar or semi-polar crystallographic orientation, forming an etch stop layer, forming an n-type layer overlying the etch stop layer, forming an active region, a p-type layer, and forming a metallization. The method includes removing a thickness of material from the backside of the bulk gallium nitride containing substrate material. A plurality of individual LED devices are formed from at least a sandwich structure comprising portions of the metallization layer, the p-type layer, active layer, and the n-type layer. The LED devices are joined to a carrier structure. The method also includes subjecting the gallium nitride containing bulk crystalline substrate material to at least one etching process to selectively remove crystalline material underlying the etch stop layer, wherein the etch stop layer is exposed, and the etch stop layer remains substantially intact.

Owner:SLT TECH

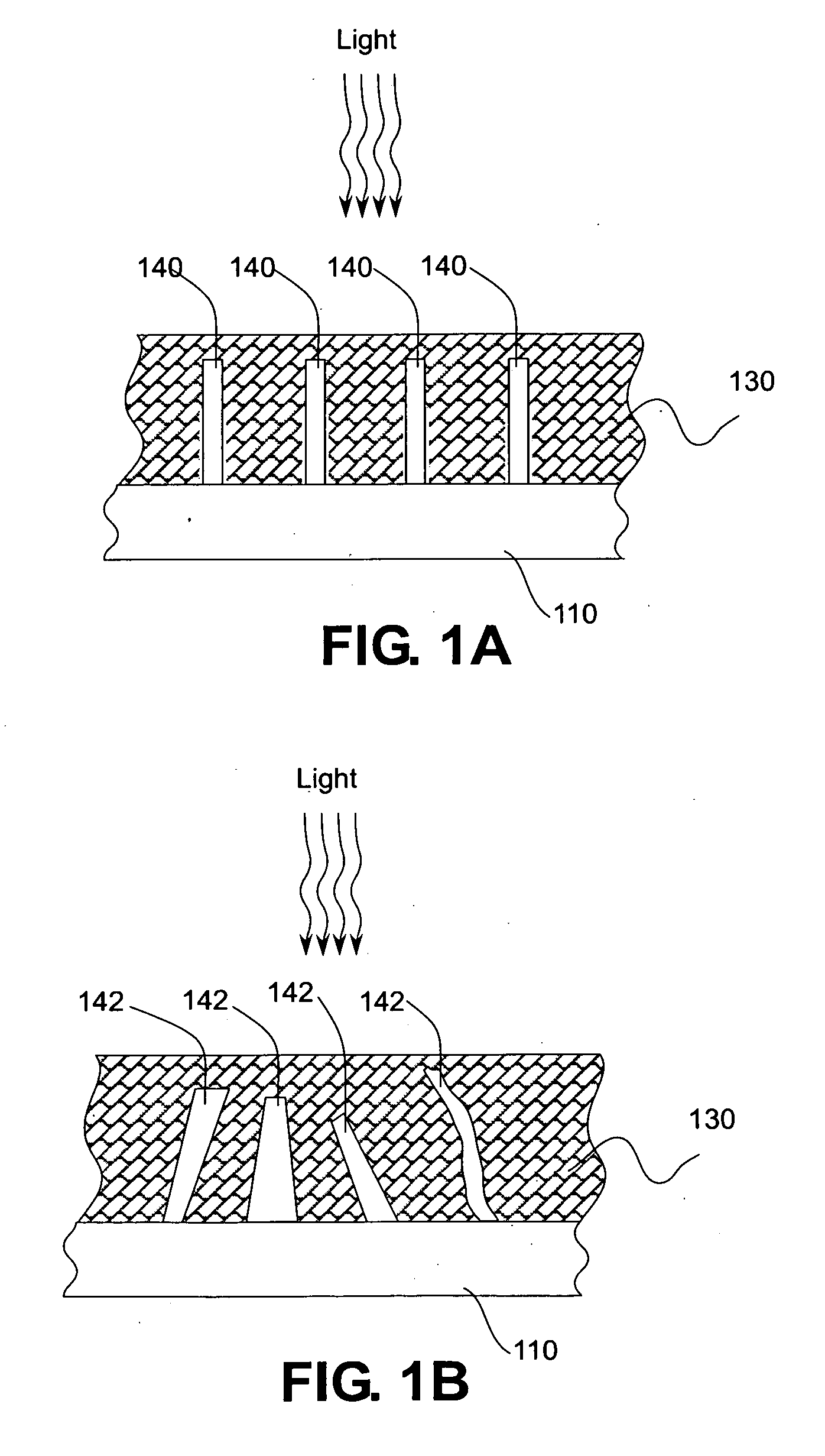

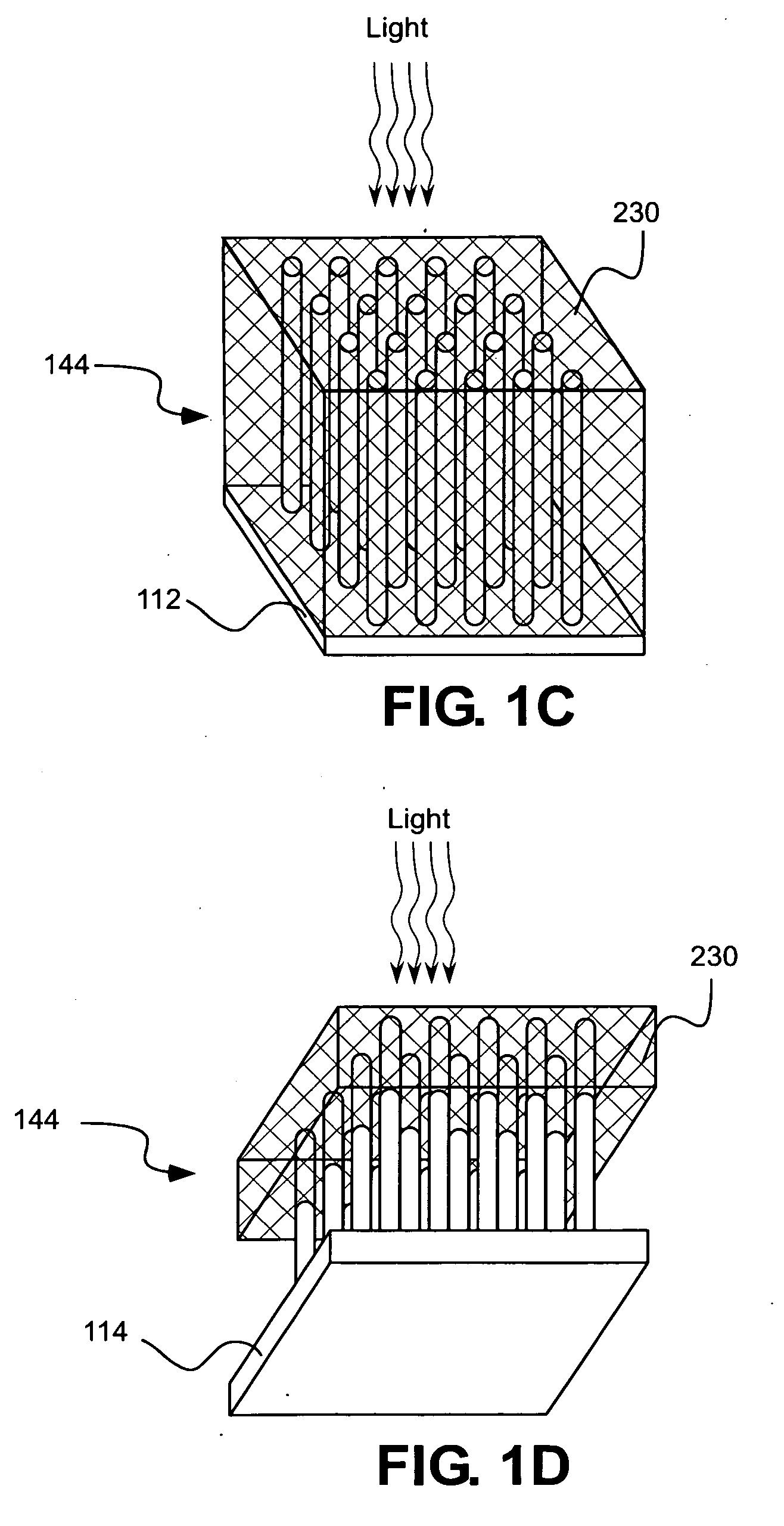

Structures of ordered arrays of semiconductors

InactiveUS20090020150A1Low minority-carrier diffusion lengthImprove equipment efficiencyElectrolytic capacitorsPV power plantsSemiconductor structureCharge carrier

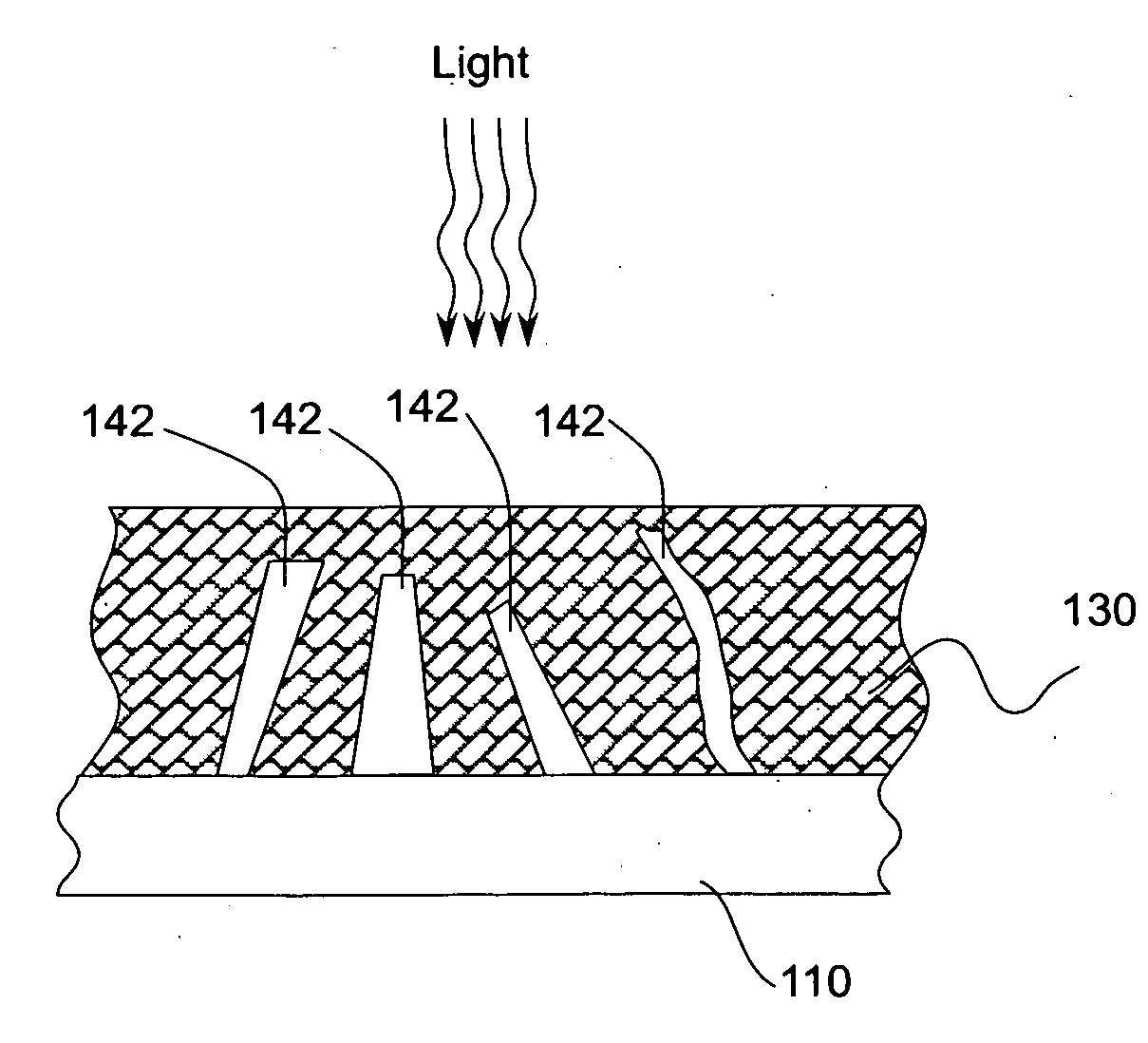

A device having arrays of semiconductor structures with dimensions, ordering and orientations to provide for light absorption and charge carrier separation. The semiconductor structures are formed with relatively high aspect ratios, that is, the structures are long in the direction of received light, but have relatively small radii to facilitate efficient radial collection of carriers.

Owner:CALIFORNIA INST OF TECH

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

Lenalidomide composition tablets and preparation method thereof

ActiveCN105534981AThe preparation process is stableStable manufacturing processOrganic active ingredientsOrganic chemistryBeta-CyclodextrinsSodium stearyl fumarate

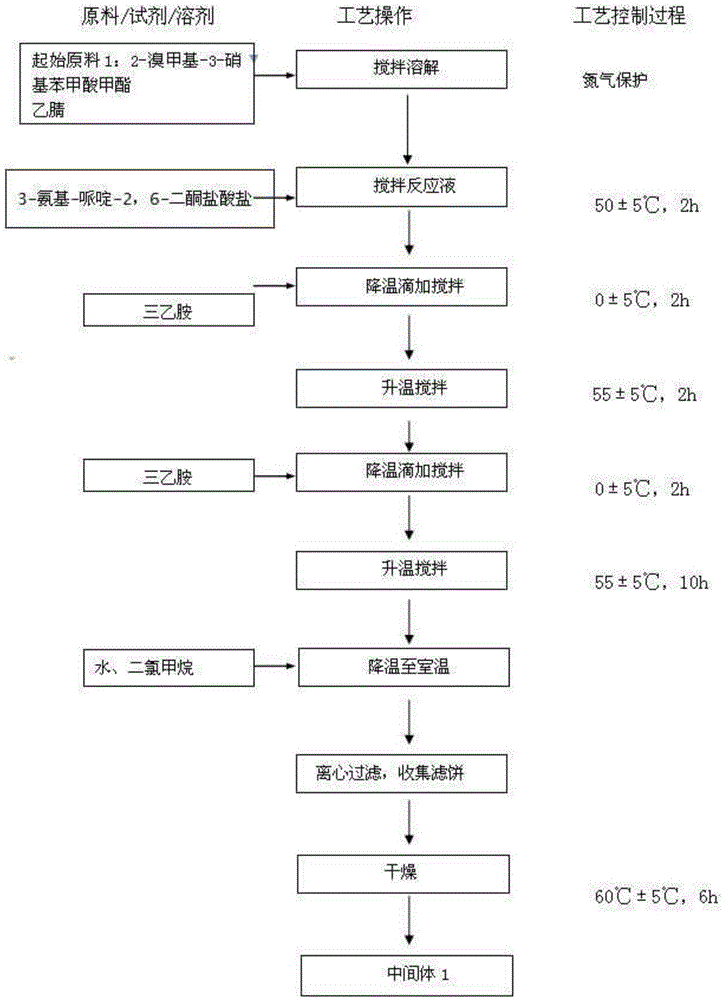

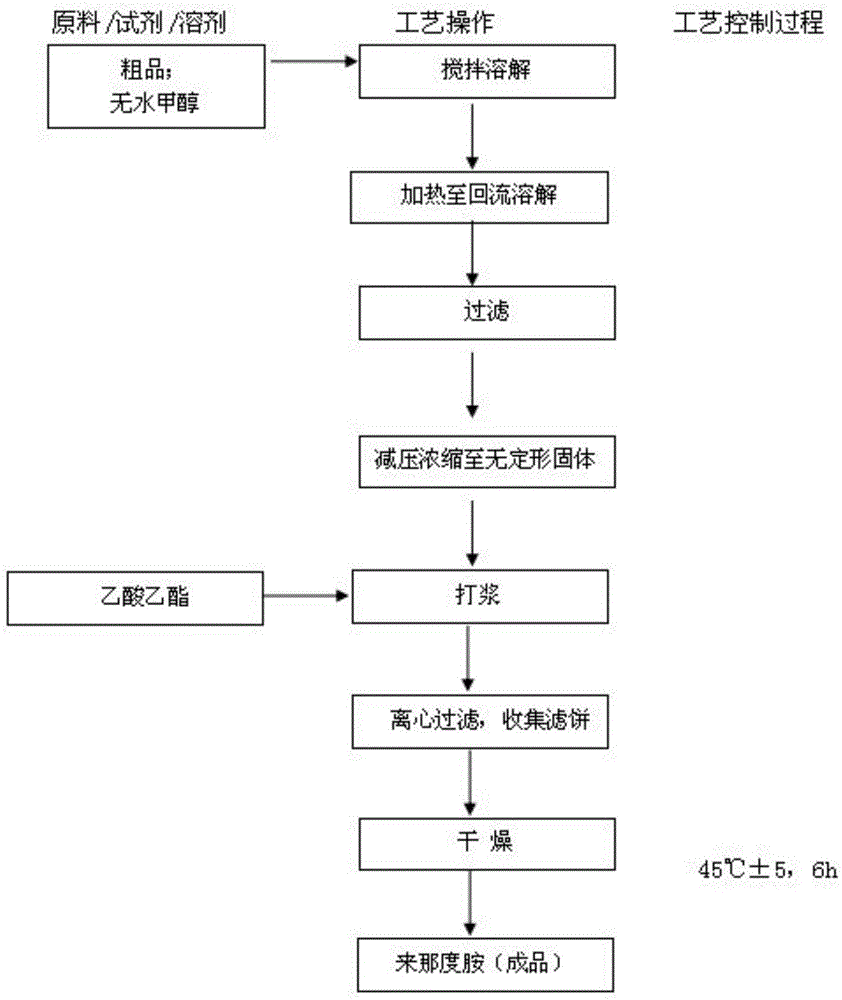

The invention discloses lenalidomide composition tablets and a preparation method thereof. The tablets comprise components in percentage by weight as follows: 10%-18% of lenalidomide crystals, 28%-40% of lactose, 28%-40% of microcrystalline cellulose, 1%-5% of konjac glucomannan, 10%-15% of beta-cyclodextrin, 5%-10% of sodium carboxymethyl starch, 0.5%-1.5% of sodium stearyl fumarate and 0.5%-1.5% of powdered cellulose. The preparation technology of the lenalidomide composition tablets is stable, simple and easy to operate, technological parameters are reliable, and the production cycle is shorter; experimental research shows that the lenalidomide raw material is stable in crystal form, higher in purity and capable of meeting the quality requirement of final products; the synthesis technology is concise, stable, feasible and applicable to mass production; the quality is controllable, the stability is better, and the lenalidomide raw material is unchanged under conditions of affecting factors such as the high temperature, high humidity and 10 days of illumination and is stable after being stored for 6 months under the acceleration condition.

Owner:DEYANG HUAKANG PHARMA

Heavy crude oil hydrocracking method

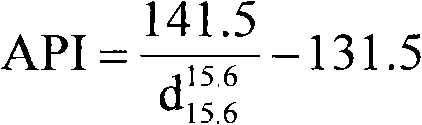

The invention relates to a heavy crude oil hydrocracking method. In the method, heavy crude oil is sequentially subjected to the steps of a hydrogenation protective agent, a hydrodemetallization agent, a hydrodesulfurization agent I, a hydrocracking agent and a hydrodesulfurization II in the presence of hydrogen, wherein the filling weight percentage of the hydrogenation protective agent, the hydrodemetallization agent, the hydrodesulfurization agent I, the hydrocracking agent and the hydrodesulfurization agent II are respectively 2-20%, 10-78%, 10-78%, 5-50% and 5-50% by taking an integral catalyst as a reference. According to the method provided by the invention, the heavy crude oil with the API (American Petroleum Institute) degree smaller than 20 can be processed to obtain hydrogenated crude oil with enhanced API and reduced viscosity, and moreover, the operating period of a hydrogenation processing device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing active peptide of laver

InactiveCN102154423ANot easy to extractHigh content of impuritiesFermentationFreeze-dryingUltrafiltration

The invention discloses a method for preparing active peptide of laver. The method is characterized by comprising the following steps of: drying and crushing porphyra yezoensis serving as a raw material, taking the part with particle size of between 150 and 200 meshes, adding water into the raw material according to a weight volume ratio of the raw material to water as 1 to 100g / mL and uniformly mixing; filling the material liquid into an ultrasonic cell disruptor for disruption and centrifuging to obtain supernatant; adjusting the pH value of the supernatant to be 7.0, adding papain for enzymolysis, inactivating, cooling and centrifuging to obtain enzymatic hydrolyzate; and performing ultrafiltration on the enzymatic hydrolyzate, concentrating filtrate and performing vacuum freeze dryingto obtain a freeze-dried product of the active peptide of the laver. The method has the advantages of more reasonable preparation process, simple process, high operability and high extraction rate; the prepared active peptide of the laver contains fewer impurities; and the biological activity is also kept to the greatest extent.

Owner:HUAIHAI INST OF TECH

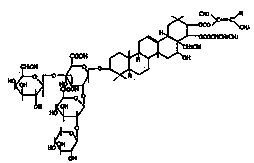

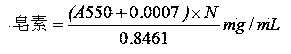

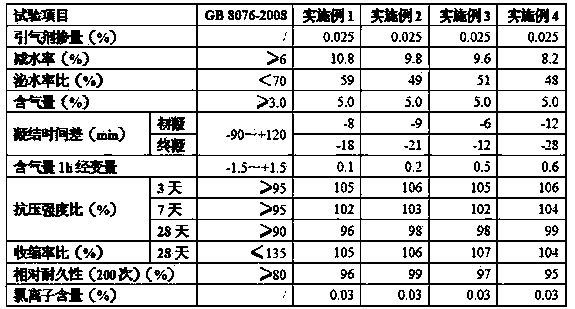

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

Preparing and refining method for hydroxychloroquine and preparation method for sulfate of hydroxychloroquine

ActiveCN108658858AAvoid hyperbaric reactionsEasy to operateOrganic chemistryKetone solventsHydroxychloroquine Sulfate

The invention discloses a preparing and refining method for hydroxychloroquine and a preparation method for a sulfate of the hydroxychloroquine. The refining method for the hydroxychloroquine comprises the following steps: performing crystallization on a crude product of the hydroxychloroquine in a mixed solvent of a ketone solvent and an ester solvent to obtain a refined product of the hydroxychloroquine, wherein a content of the hydroxychloroquine in the crude product of the hydroxychloroquine is higher than 92%. According to the method disclosed by the invention, purity of the refined product of the hydroxychloroquine prepared by the method can reach 99.9%, a maximum content of a single impurity is controlled within 0.06%, and a total content of other impurities is lower than 0.04%; andpurity of the hydroxychloroquine sulfate prepared from the hydroxychloroquine can reach 99.8%, and a maximum content of a single impurity is controlled within 0.06%.

Owner:SHANGHAI ZHONGXI SUNVE PHARMA

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732314AHigh aromatic contentHigh content of impurities such as sulfurTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of a catalytically cracked diesel fraction undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked recycle oil and catalytically cracked slurry are separated out; a part or all of the catalytically cracked diesel fraction is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction; and the catalytically cracked recycle oil is fed back to the catalytic cracking device and then undergoes a catalytic cracking reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

New treatment method of threonine mother liquid

ActiveCN103723894AWell mixedReduce usageOrganic compound preparationMultistage water/sewage treatmentBacterial agentChemistry

The invention relates to a new treatment method of threonine mother liquid. The method comprises a step of adding an alcohol substance into a threonine mother liquid solution obtained in an extraction process of threonine mother liquid so as to reduce the solubility and separate out threonine, and a compound microbial bacterial agent is added into other impurities to reach the emission standard. The method provided by the invention has the advantages of low production cost, high threonine extraction yield and little wastewater discharge, is economical and environment-friendly and has a broad application prospect.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Method for extracting ecdysone from common cyanotis root and ecdysone thereof

ActiveCN101735299AHigh content of impuritiesHigh puritySolvent extractionSteroidsSolventEthyl acetate

The invention discloses a method for extracting ecdysone from common cyanotis roots and the ecdysone thereof, belonging to the technical field of the extraction and the separation of effective components of plants. The method comprises the following steps of: decocting 0.5-1kg of common cyanotis roots by 10L of water, or extracting by using 1-95 percent methanol or ethanol, and the ratio of the using amount of the methanol or the ethanol to the common cyanotis roots is 5L-10L to 1kg; filtering, decompressing and concentrating to obtain liquid with the relative density of 1.05-1.20; regulating a pH value to 6-10 by using alkali; then extracting by a mixed solvent with normal butanol and ethyl acetate, wherein the ratio of the normal butanol and the ethyl acetate is 4:6-0.5:9.5; washing, decompressing and concentrating to obtain a fluid extract with the relative density of 1.2-1.3; adding 50-95 percent methanol or ethanol for dissolving and dilution, passig through overhigh alkali type anion exchange resin, and eluting, concentrating and drying in a decompressing way to obtain the ecdysone. Compared with a conventional method, the method enhances the yield by 1.16-1.38 percent.

Owner:YUNNAN PHYTOPHARML

Selective hydrogenation catalyst for pyrolysis gasoline

InactiveUS6576586B2Improve and increase utilization factorReduce lossesRefining by selective hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCrystal structure

A selective hydrogenation catalyst for pyrolysis gasoline. The catalyst mainly consists of a support of delta, alpha mixed alumina covered by palladium and alkali metal and / or alkaline-earth metal which are distributed on the support surface, and the support has 0.5 to 09. ml / g of specific pore volume. 40 to 200 Å pores account for more than 85% of the total pore volume. The specific surface area is 70 to 140 m2 / g, and alpha crystal structure in the alumina support is 0.5 to 5% based on the weight percentage of delta, alpha mixed alumina support. The catalyst includes palladium in amount of 0.05 to 0.4 wt %, alkali metal and / or alkaline-earth metal in amount of 0.05 to 2.0 wt %.

Owner:PETROCHINA CO LTD

Method for preparing ammonia water and calcium chloride solution through decomposition recovery of ammonium chloride waste liquor

InactiveCN104876383ASimple processEmission reductionCalcium/strontium/barium chloridesWater contaminantsHigh concentrationLiquid waste

The invention discloses a method for preparing ammonia water and calcium chloride solution through the decomposition recovery of ammonium chloride waste liquor. The method comprises the following steps: the waste liquor is pretreated, and ammonium chloride and calcium oxide or calcium hydroxide powder is added into the pretreated ammonium chloride waste liquor; ammonia is distilled from the treated ammonium chloride waste liquor and is transferred into an ammonia absorption tower after being condensed, and a reaction liquid flows out from the bottom of a distillation tower; ammonia is absorbed from the condensed ammonia in the absorption tower by using desalted water, and the tail gas is exhausted after residual ammonia is washed by a tail gas washing tower; reaction liquid out of the bottom of the distillation tower is subjected to flash vaporization for recycling the energy and then is transferred into a clarifying barrel, and the clarified calcium chloride supernatant is used as the target product. According to the invention, the method is particularly suitable for the transformation of ammonium chloride wastewater treatment technology of enterprises in the existing rare earth industry, potassium carbonate industry and baking soda industry, and is simple in process; the ammonia is recycled by using desalted water through multi-stage absorption, and the recovery rate is up to 99%; the high-concentration calcium chloride solution can be used for producing calcium chloride products and the products can be recycled so as to have better economic benefits.

Owner:江苏大江干燥设备有限公司

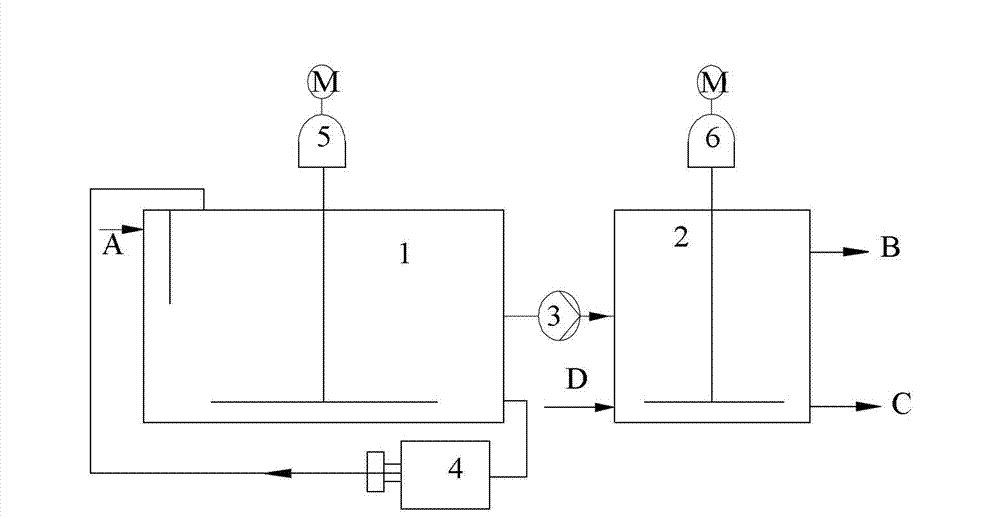

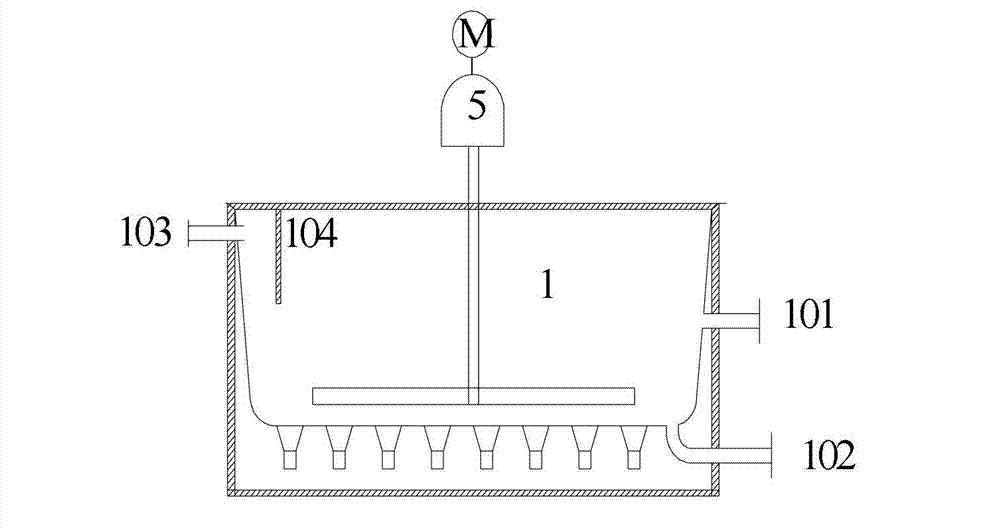

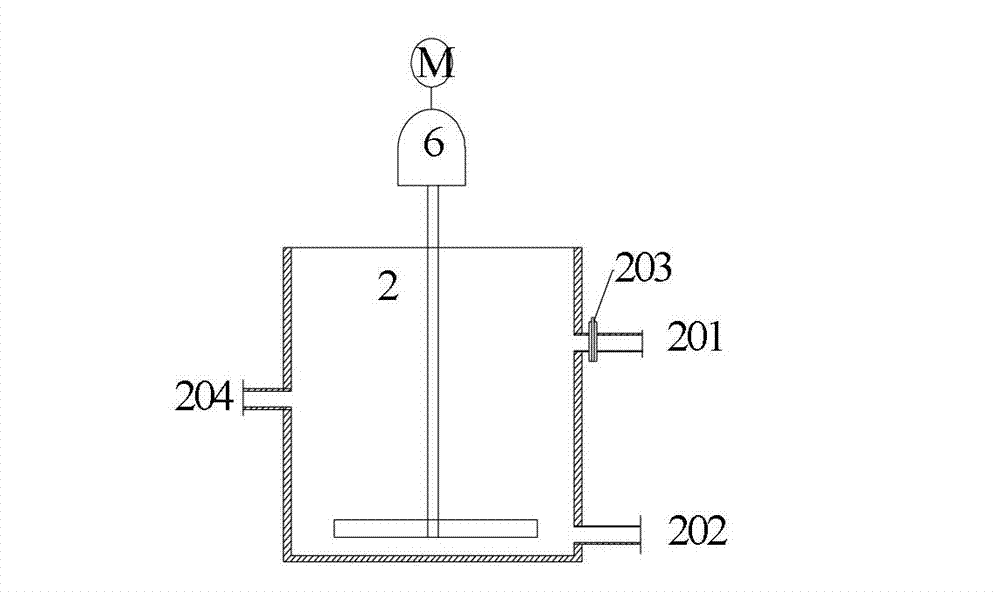

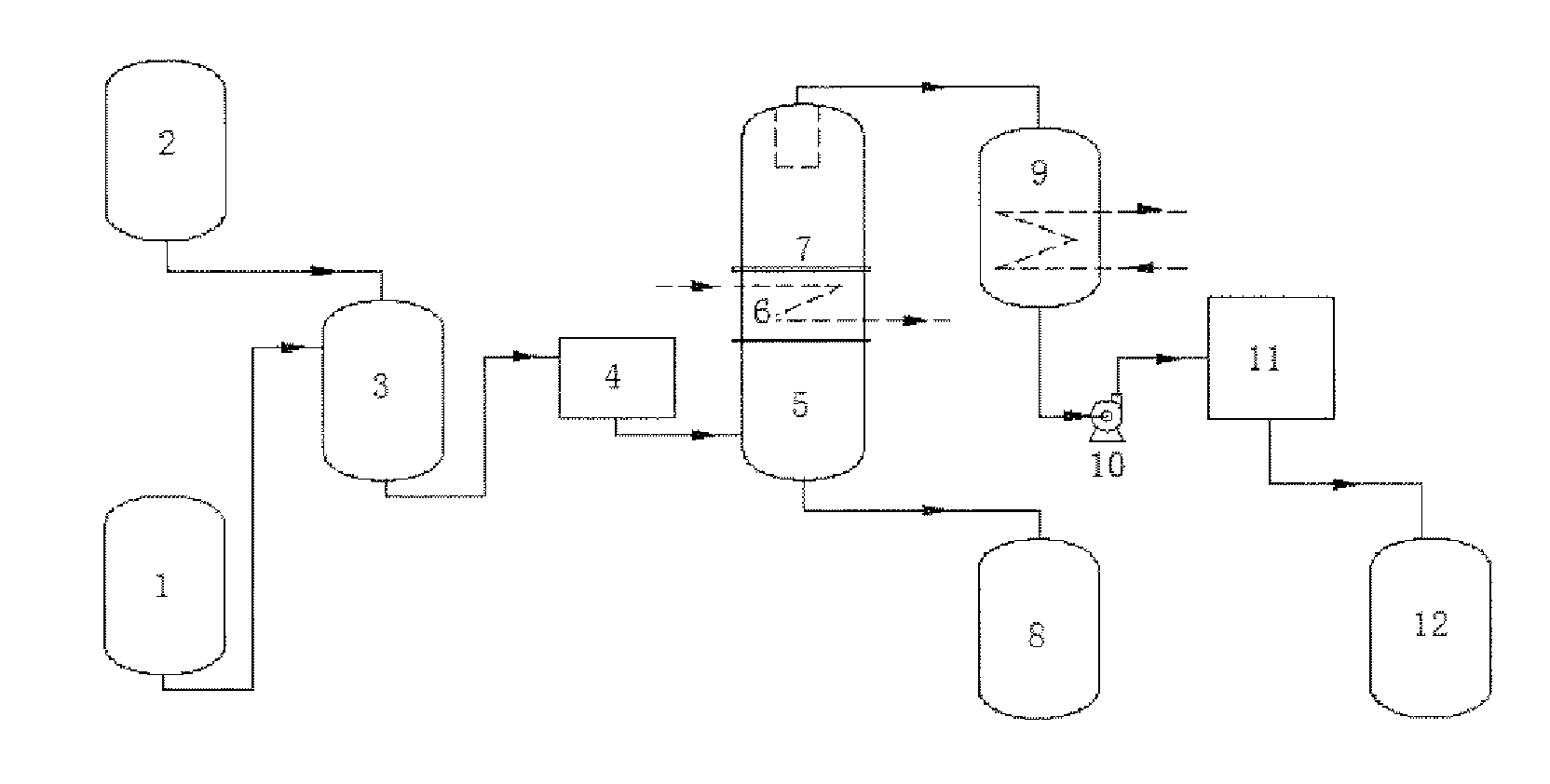

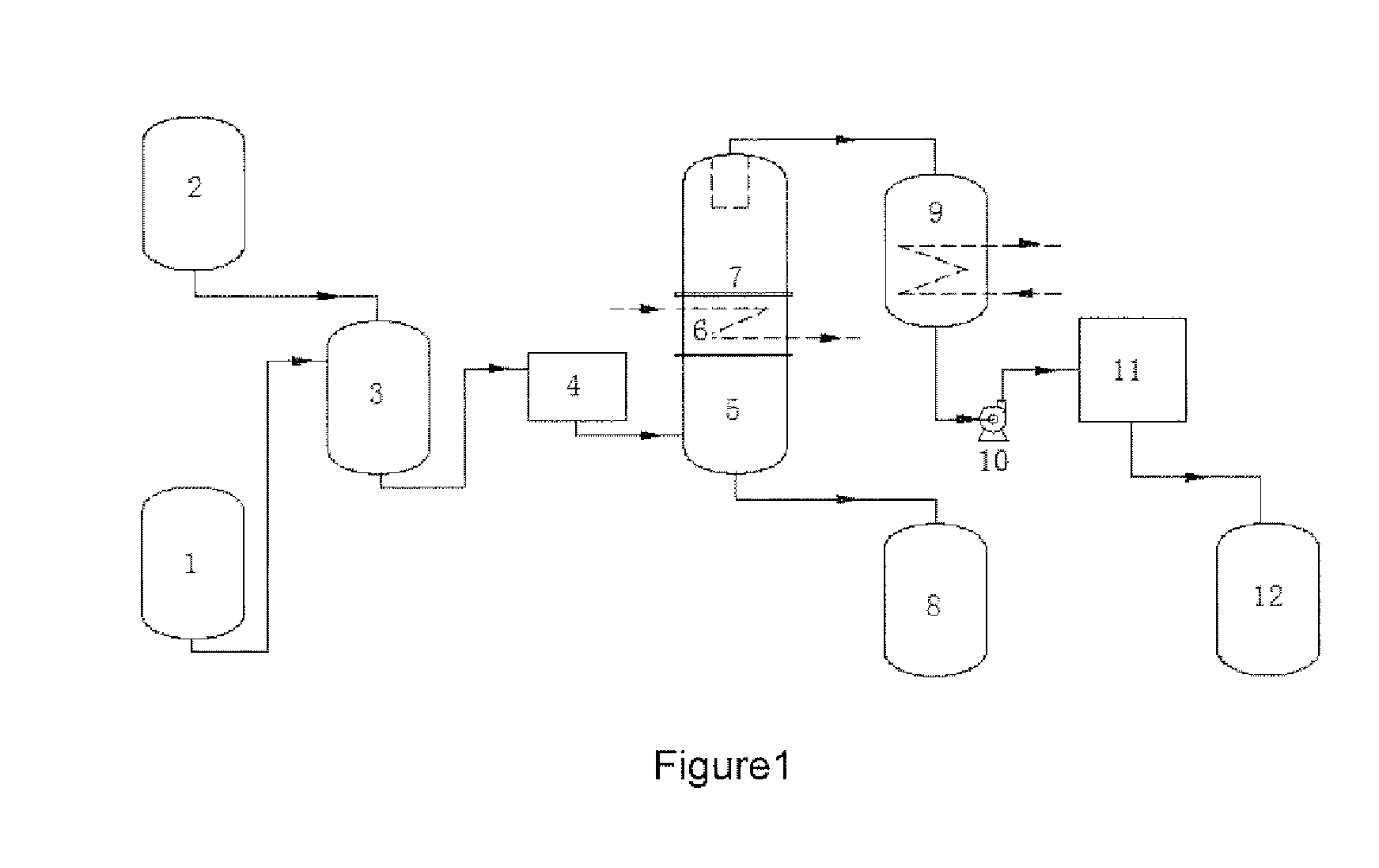

White mud/acetylene sludge slurry preparing device and process

ActiveCN102814138AHigh puritySmall granularityMixing methodsDispersed particle separationSludgeMegasonic cleaning

The invention discloses a white mud / acetylene sludge slurry preparing device and process. The device comprises an ultrasonic washing machine and further comprises a sedimentation separation pot and a homogenizer, wherein the sedimentation separation pot is communicated with the middle part of the ultrasonic washing machine through a pipeline with a pump; a feeding opening of the homogenizer is communicated with the lower part of the ultrasonic washing machine; a discharging opening of the homogenizer is communicated with the upper part of the ultrasonic washing machine; and the sedimentation separation pot and the ultrasonic washing machine are internally provided with agitators. According to the white mud / acetylene sludge slurry preparing device and process, white mud and acetylene sludge are treated and large grains can be circularly cut and crushed; and impurities in the grains are ultrasonically desorbed to improve the specific surface area and the purity of the white mud / acetylene sludge and the utilization rate is improved, so that the desulfuration efficiency and the gypsum quality are improved.

Owner:HANGZHOU TIANLAN ENVIRONMENTAL PROTECTION ENG DESIGN

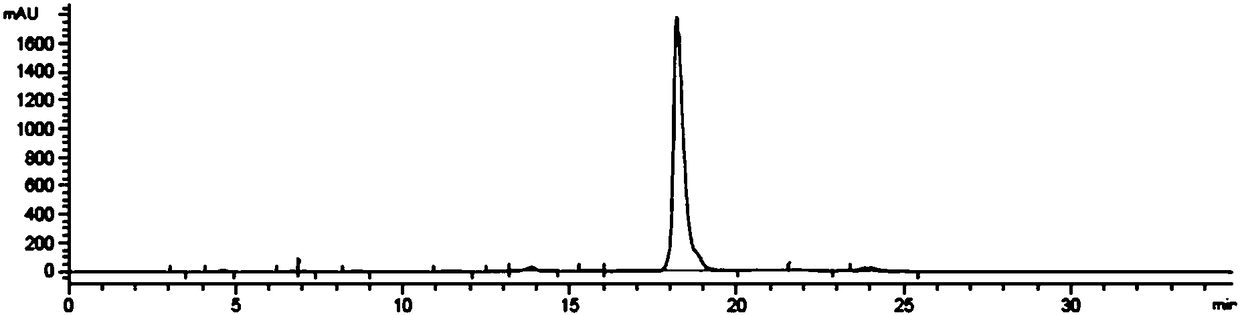

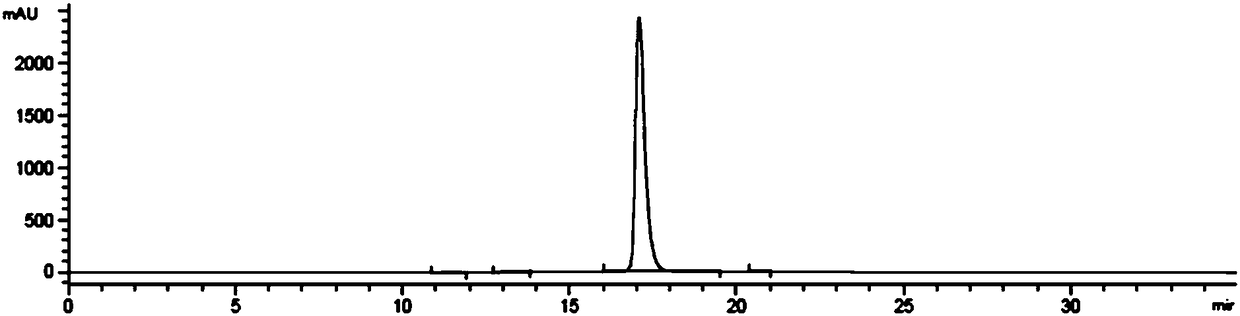

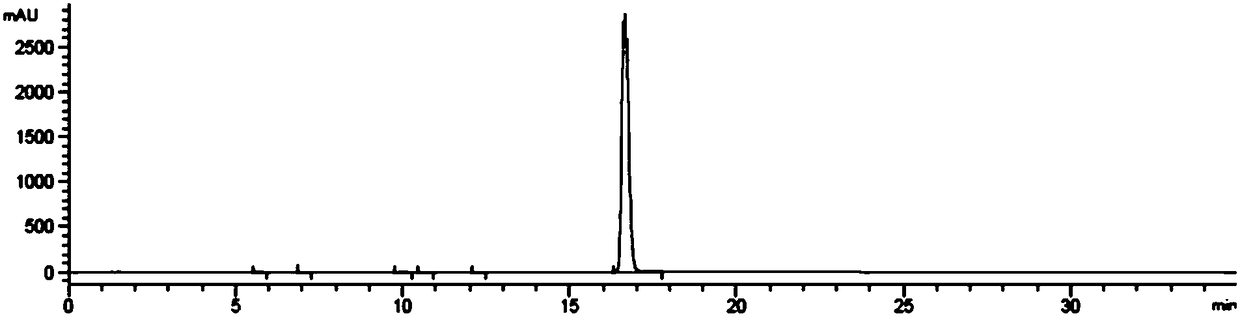

Preparation technology of high-purity flomoxef sodium

The invention discloses a preparation technology of high-purity flomoxef sodium. The preparation technology includes following steps: on the basis of a flomoxef intermediate, performing an acidifying reaction to obtain a reaction liquid; performing a water washing process, an extraction process, an aseptic filtration process and the like to the reaction liquid; and performing a solventing-out crystallization step through a one-step crystallization process to obtain a flomoxef sodium product with a purity being higher than 99.90%, wherein key points in the solventing-out crystallization step are selection and proportion of a solventing agent and dropwise addition of a salifying agent and the solventing agent at the same time with crystal growing. The preparation technology overcomes problems which are difficult to control during the solventing-out crystallization step of the flomoxef sodium. The flomoxef sodium is prepared in one step with the flomoxef intermediate as a raw material and the purity of the product of the flomoxef sodium reaches higher than 99.90% just through one crystallization step, which is cannot be achieved through a freeze-drying method or a common solventing-out crystallization process in the prior art. Quality of the product is in conformity with or even exceeds a standard in japanese pharmacopoeia JP16. The preparation technology has a more wide application prospect.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

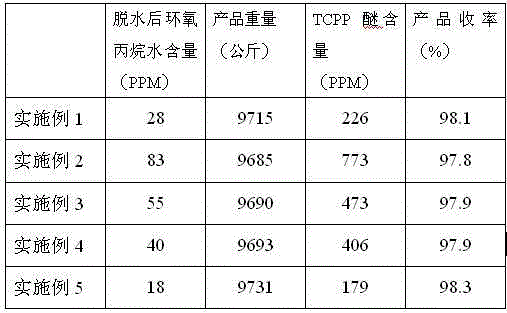

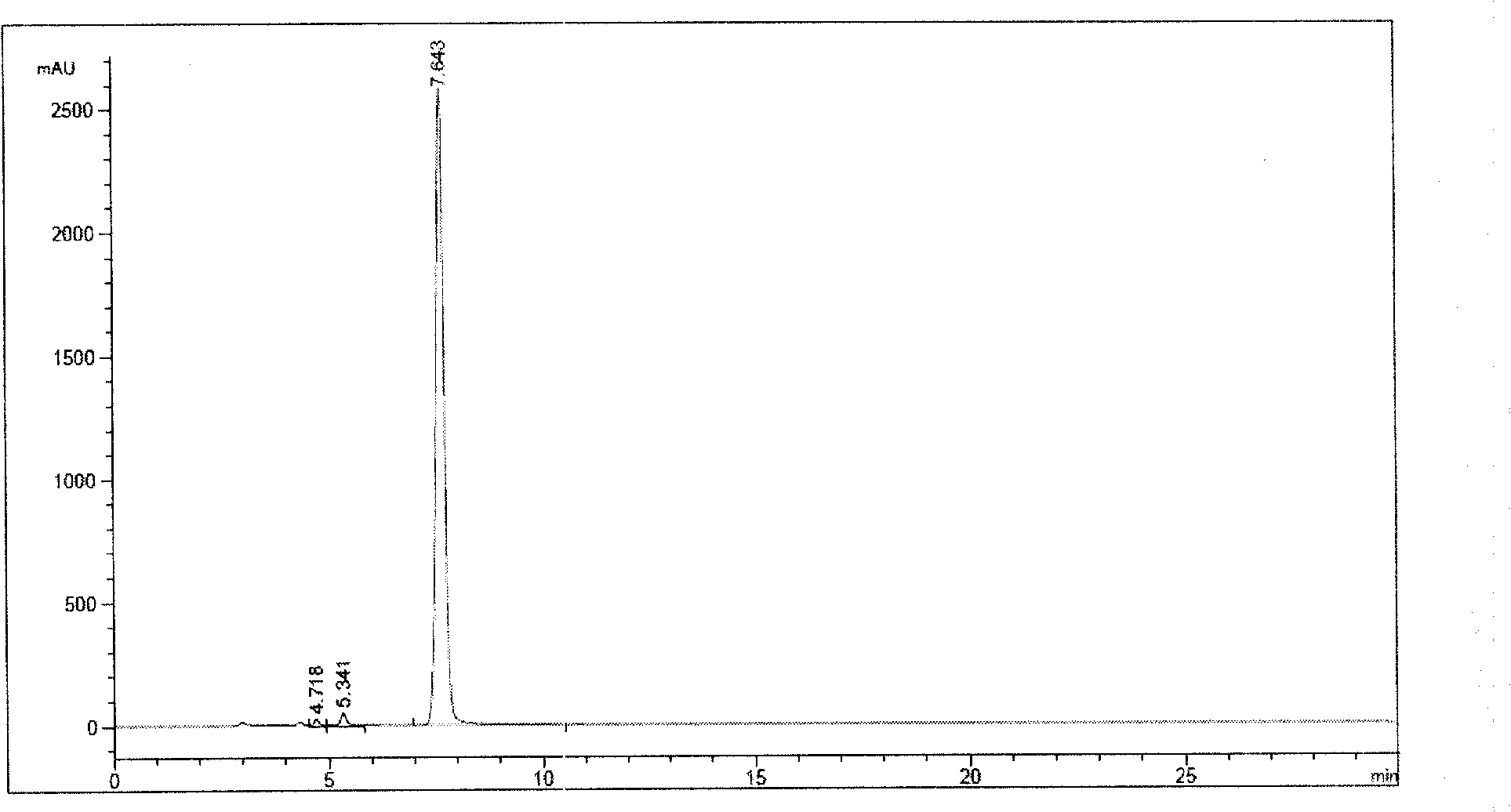

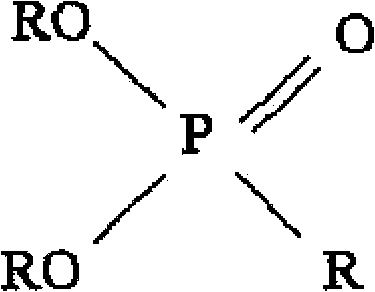

Preparation method of tri(2-chloroisopropyl)phosphate (TCPP)

The invention relates to a preparation method of tri(2-chloroisopropyl)phosphate (TCPP). The TCPP is prepared by reacting dehydrated epoxypropane and phosphorus oxychloride. The invention particularly relates to a preparation method of TCPP with low TCPP ether impurity content and high product yield. The method comprises the following steps: before adding the epoxypropane to react, adding a dehydrating agent into the epoxypropane or passing the epoxypropane through a dehydrating-agent-filled dehydration tower to perform deep dehydration on the epoxypropane until the water content in the epoxypropane is less than 100 ppm, and reacting with the phosphorus oxychloride to obtain the TCPP. The TCPP ether content in the TCPP product is less than 1000 ppm. Compared with the TCPP obtained in the prior art, the method greatly lowers the TCPP ether content in the product and enhances the product yield.

Owner:ZHEJIANG WANSHENG

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Production method of large-size graphite electrode

The invention relates to a production method of a large-size graphite electrode which comprises the components in percentage by weight: 76-79 percent of calcined petroleum coke, 21-24 percent of medium-high temperature modified asphalt and the balance of filling material with the diameter of 0.075-2 mm, wherein the calcined petroleum coke comprises the following components in percentage by weight: not more than 4 percent of granules with the diameter of more than 12 mm, 6-10 percent of granules with the diameter of 8-13 mm, 13-17 percent of granules with the diameter of 4-8 mm, 9-13 percent of granules with the diameter of 2-4 mm and 30-32 percent of powder with the diameter of not more than 0.075 mm according to the particle size distribution; and the coking value of the modified asphalt is over 55 percent and the softening point is 95-100 DEG C. After the raw materials are mixed according to the proportion, the large-size graphite electrode is produced by adopting a conventional process, wherein the mixing temperature is 160-165 DEG C and the thicker lumpiness during the die-filling is less than 40 mm. A huge-size electrode with the diameter of over 960 mm can be produced by adopting the production method of the large-size graphite electrode; meanwhile, the electrode has low resistivity and good conduction property and can bear strong current, thereby enabling the unit consumption and the electricity consumption to be greatly lowered and saving the production cost.

Owner:JIEXIU JUYUAN & COALY

Ornithine aspartate injection and preparation method thereof

ActiveCN101987094AHigh content of main impuritiesLow main impurity contentOrganic active ingredientsNervous disorderActivated carbonHepatic encephalopathy

The invention relates to an ornithine aspartate injection and a preparation method thereof. The injection contains ornithine aspartate, water for injection and acid-base adjusting agent, and has the pH value of 5.2-6.0 and the concentration of 0.01-1g / mL. The ornithine aspartate injection is prepared by dissolving the ornithine aspartate by the water for injection, adjusting the pH value by the acid-base adjusting agent, discoloring by activated carbon, leading the volume to be constant, split charging and sterilizing. The injection can be used for treating hepatic encephalopathy. The injection provided by the invention has the characteristics of being less in impurity content, easy in control of quality, safer in clinical application and the like.

Owner:SHANGHAI CHENPON PHARM TECH CO LTD

Preparation method for titanium-aluminium alloy

The invention relates to a preparation method for titanium-aluminium alloy, belongs to the field of alloys and aims to solve the technical problem of providing the preparation method for the titanium-aluminium alloy. The preparation method comprises the following steps: titanium serves as an anode and liquid aluminium serves as a cathode and then titanium and liquid aluminium are electrolyzed in a fused salt electrolyte to prepare the titanium-aluminium alloy, wherein the fused salt electrolyte comprises the main body fused salt NaCl-KCl and soluble titanium salt; the mass ratio of the NaCl-KCl to the soluble titanium salt in the fused salt electrolyte is 100 to 1-10; the weight of the soluble titanium salt is measured by the weight of titanium. According to the preparation method for the titanium-aluminium alloy, as liquid aluminium is adopted to serve as the cathode and is alloyed in a smelting state, the alloyed titanium aluminium alloy sinks at the bottom of a crucible and is easy to separate; the obtained titanium-aluminium alloy products are spongy and easy to wash, the impurity content is less and the follow-up processing is facilitated.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

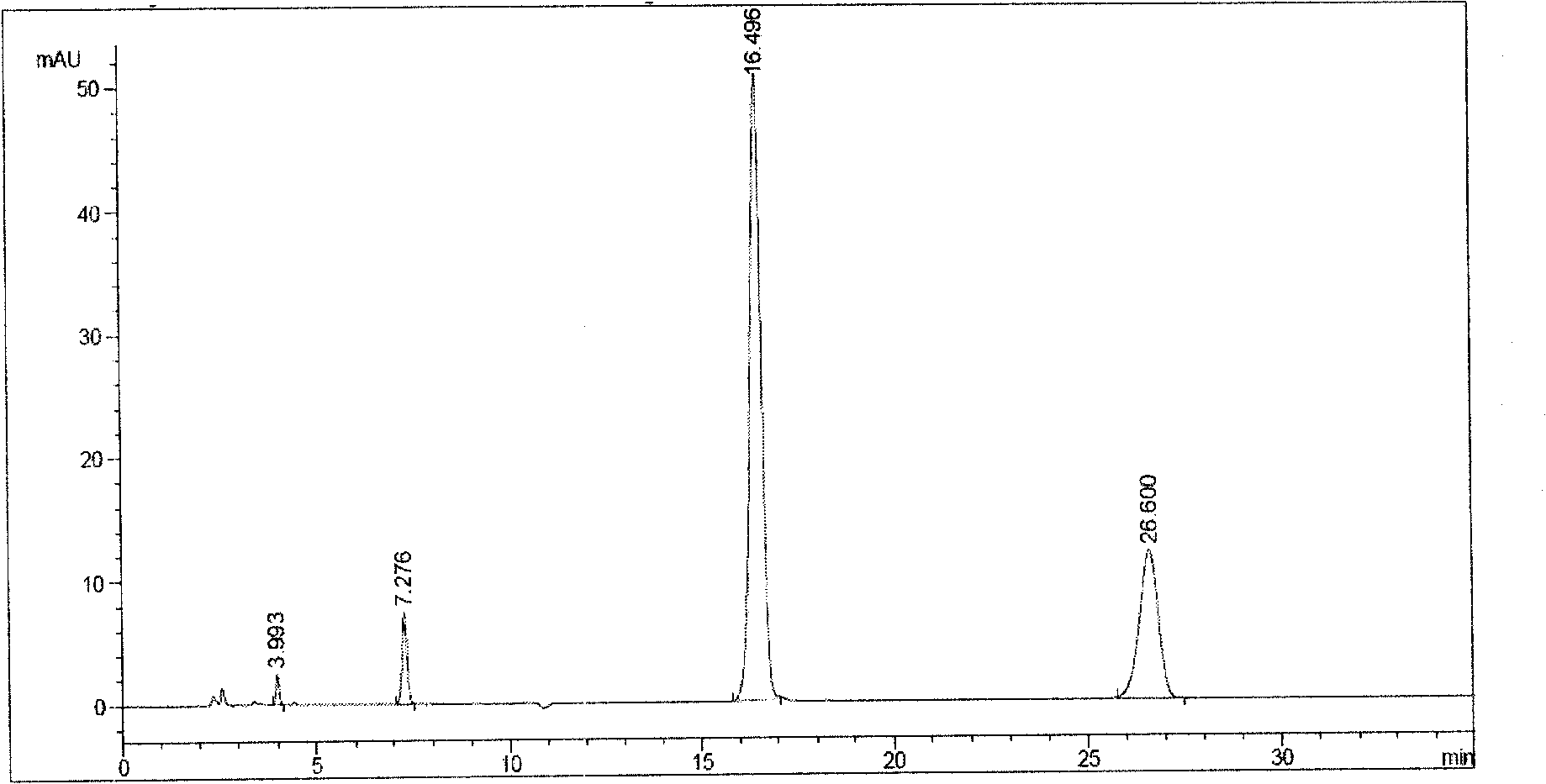

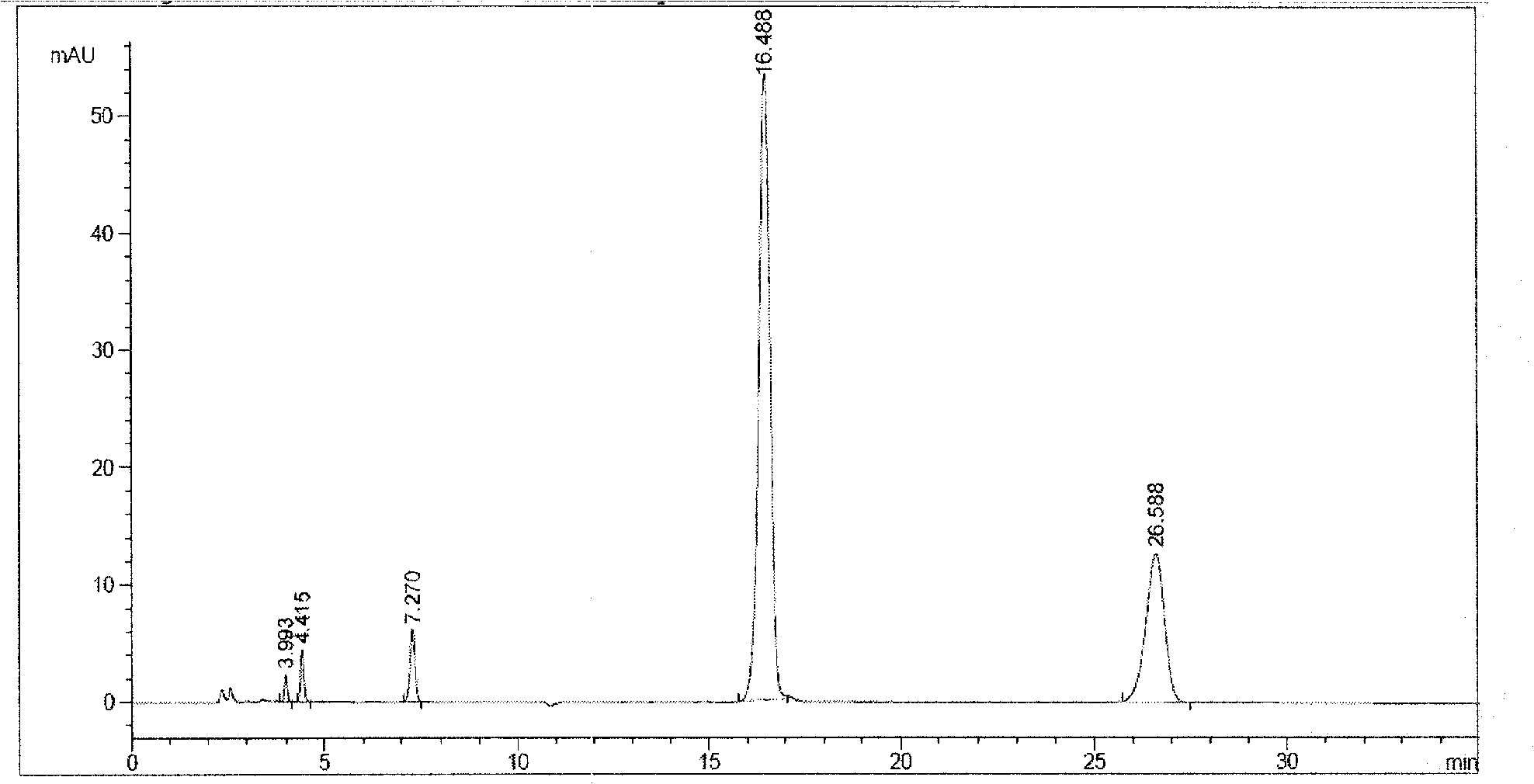

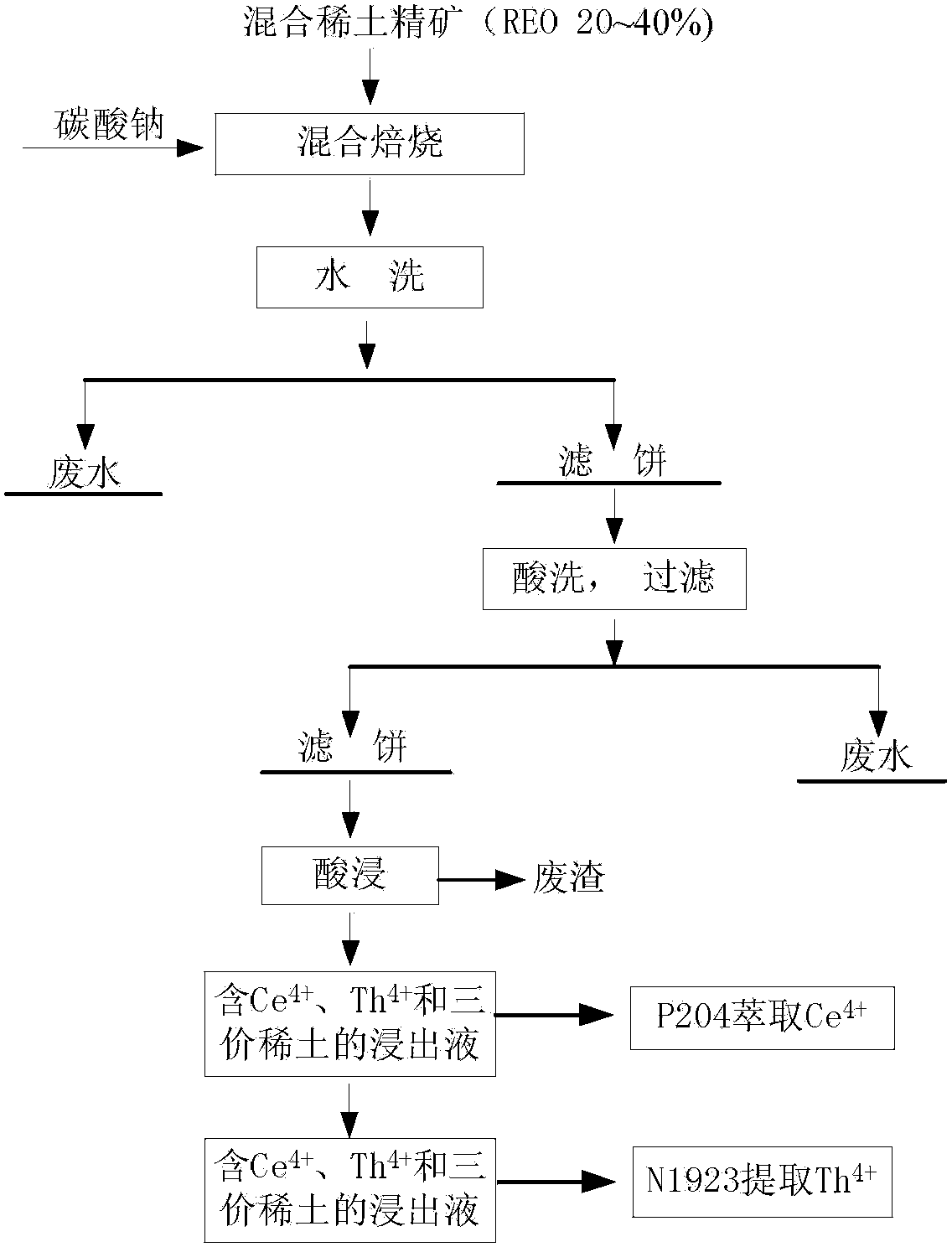

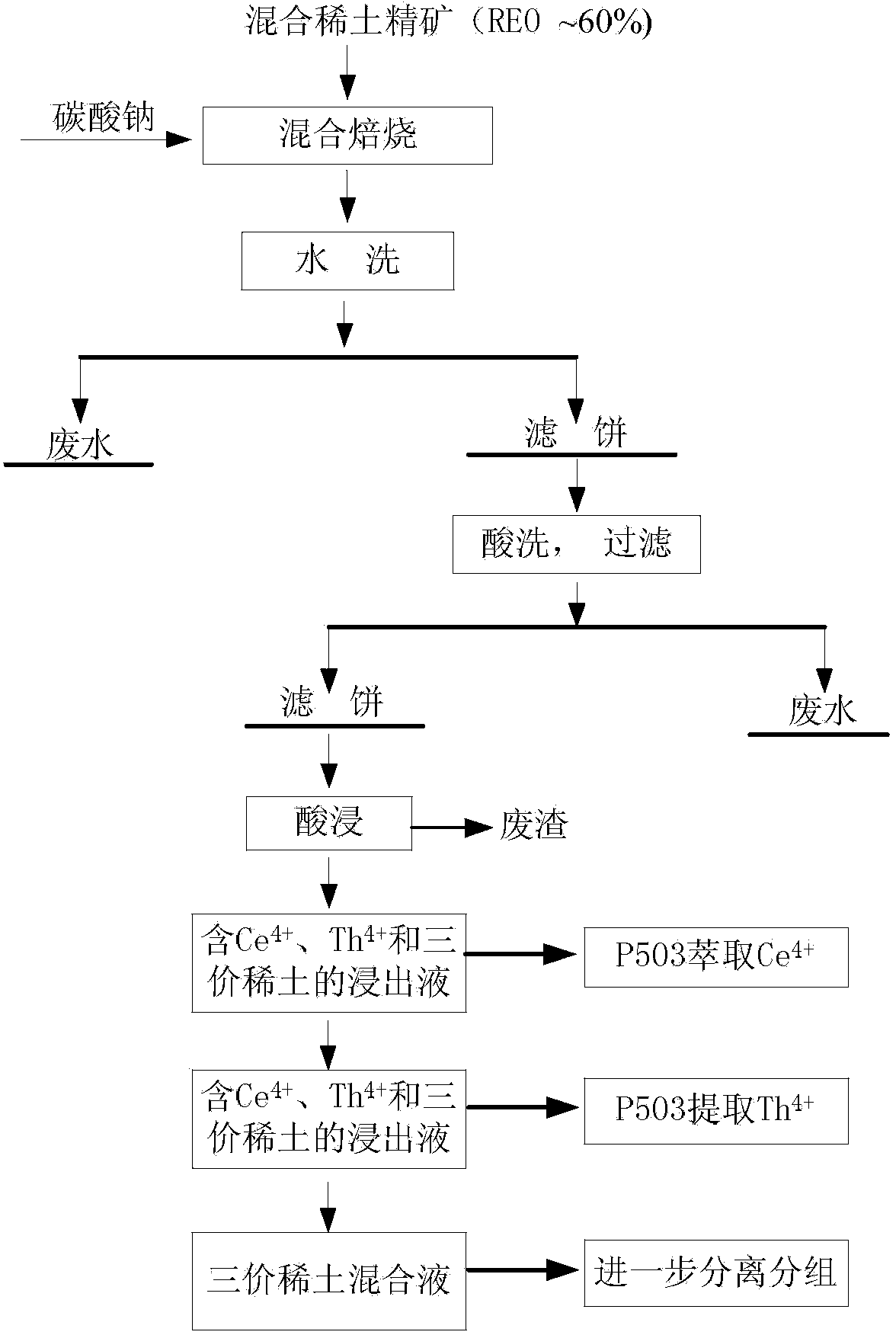

Clean separating method of Baotou rare-earth ore concentrate

InactiveCN103540740AReduce pollutionReduce contentProcess efficiency improvementRare-earth elementSeparation coefficient

The invention relates to a clean separating method of Baotou rare-earth ore concentrate. The method comprises the following steps: roasting the rare-earth ore concentrate by using sodium carbonate; carrying out acid leaching by adopting a nitric acid after washing and pickling by a dilute acid, so as to obtain a leach liquor containing Ce4<+>, Th4<+> and trivalent rare-earth elements; respectively extracting the Ce4<+> and Th4<+> by adopting a P503 extracting agent, and then carrying out separation of light rare earth. By adopting the same extracting agent, selective separation of cerium, thorium and other trivalent rare earth can be achieved; the clean separating method is economical to a factory, small in equipment pressure, and easy to operate; only separation of lanthanum, praseodymium and neodymium exists in separation of the trivalent rare earth; the extraction technology is mature. Interference of an adjacent element trivalent cerium is not generated, so that the separation coefficient of lanthanum, praseodymium and neodymium is large; corresponding extraction and separation flows are greatly simplified and shortened.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

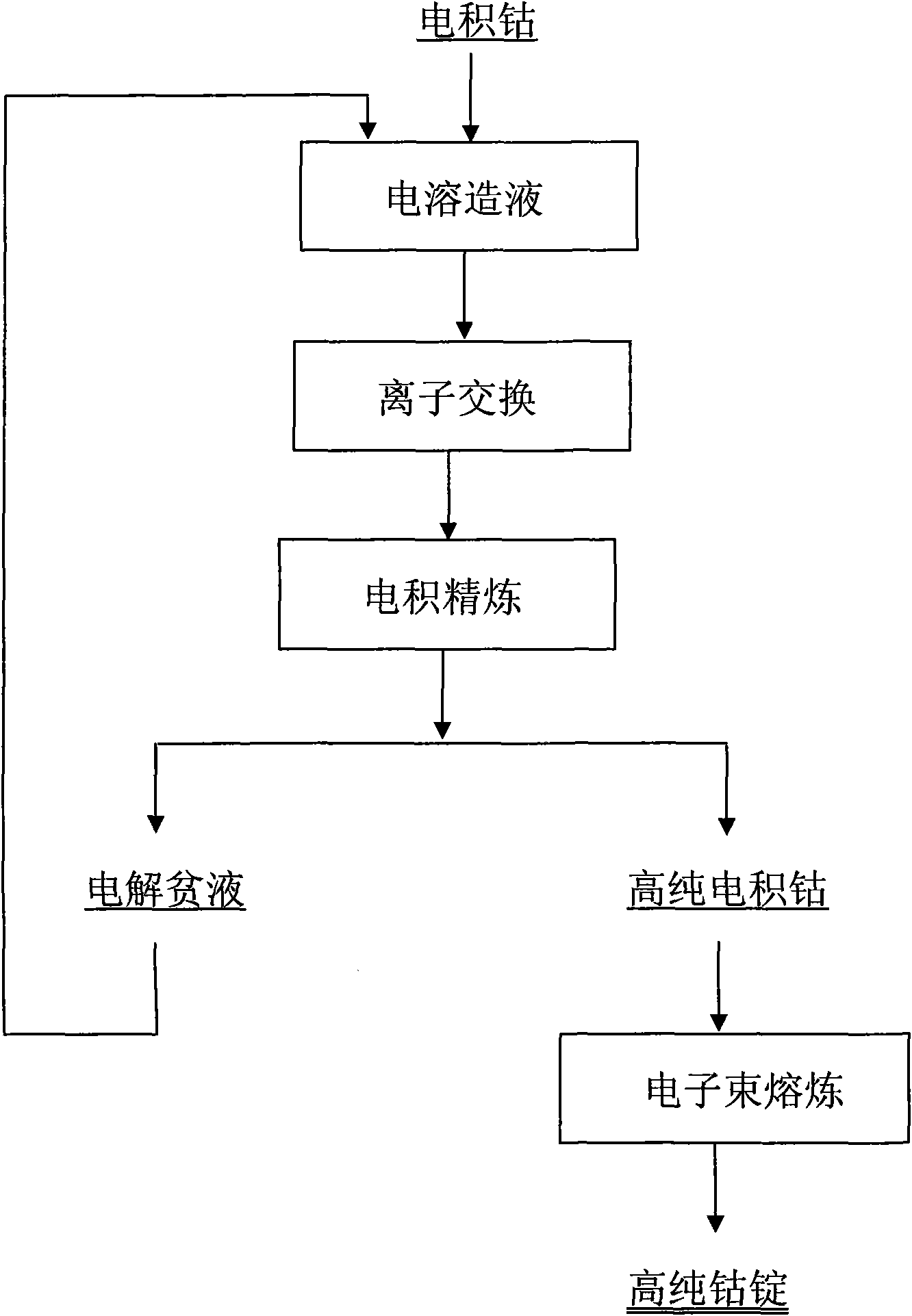

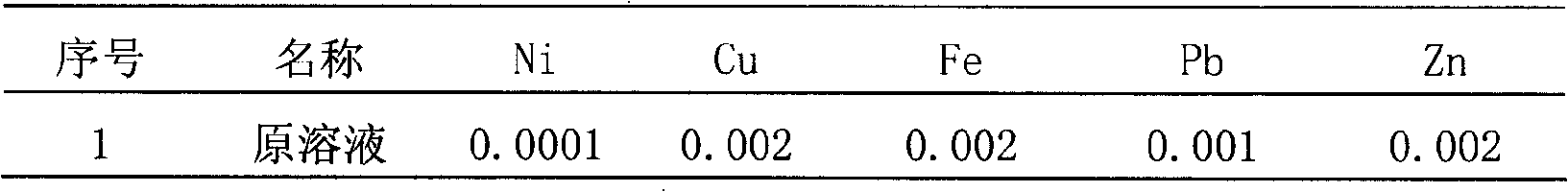

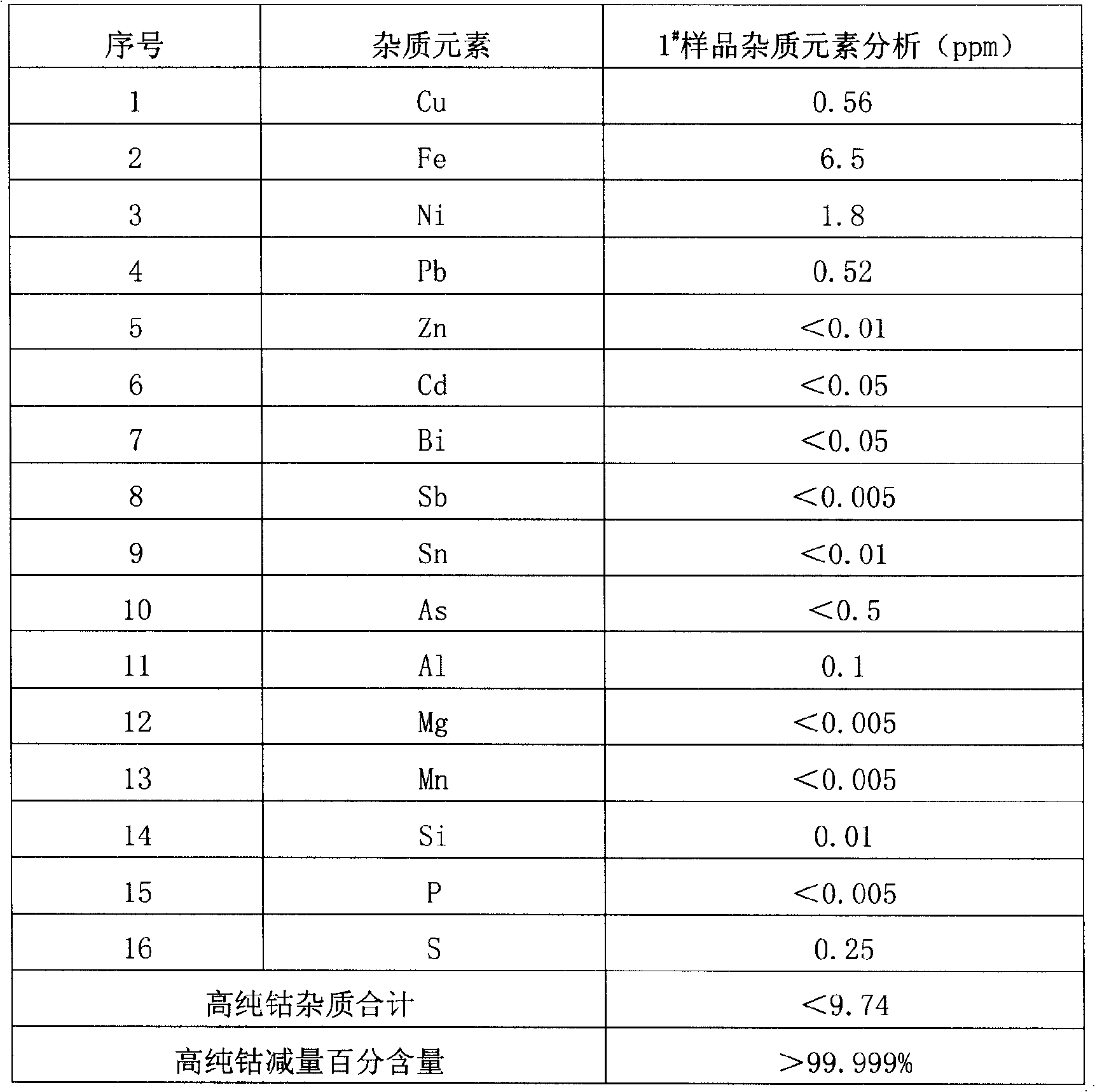

Method for preparing high-purity cobalt

InactiveCN101538721ASolving High Acid ProblemsAvoid mutual contaminationPhotography auxillary processesIon exchangePhysical chemistry

The invention relates to a method for preparing high-purity cobalt by adopting hydrochloric acid solution system electrodeposition. The method is characterized in that the technical process is sequentially as follows: hydrochloric acid solution system is adopted and 99.95% of electrodeposition cobalt is taken as an anode; a CoCI2 solution with ph of 3-3.5 is prepared by an electrolytic solution; the regular electrolytic solution is sequentially led into anion exchange resin for ion exchange deep clarification, and finally led into an electrobath for electrodeposition; the solution amount prossed by ion exchange clarification is equal to extracted and electrodeposited solution; the high-purity cobalt is obtained by electrodeposition. The electronic torch melting is carried out on high-purity cobalt to prepare high-purity cobalt ingot which can meet the requirements of different users. The high-purity electrodepositing cobalt of 5N or more than 5 N and high purity ingot are reached by high-purity cobalt prepared by the method processed by glow discharge mass spectrography-GDMS analyzing.

Owner:JINCHUAN GROUP LIMITED

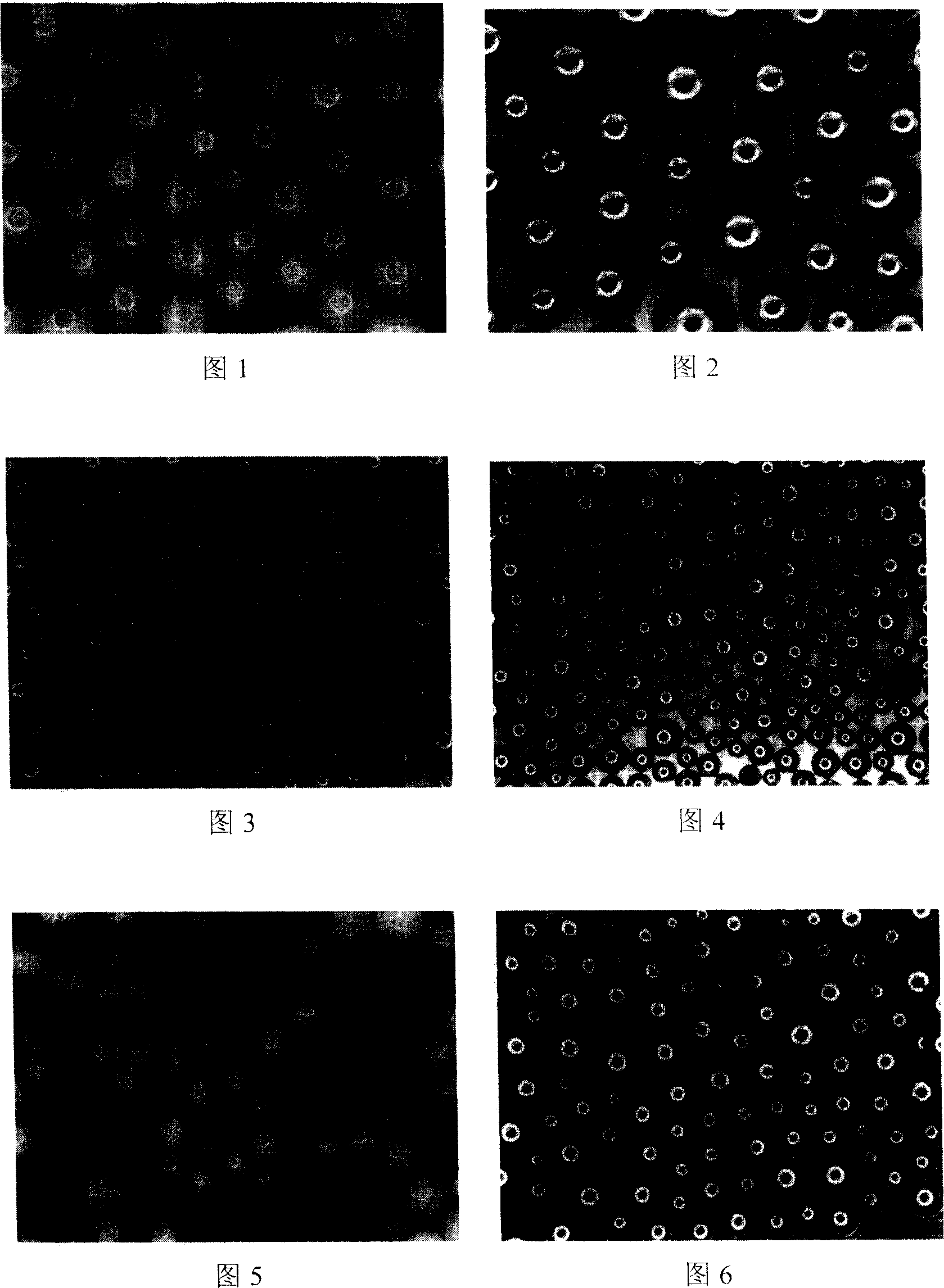

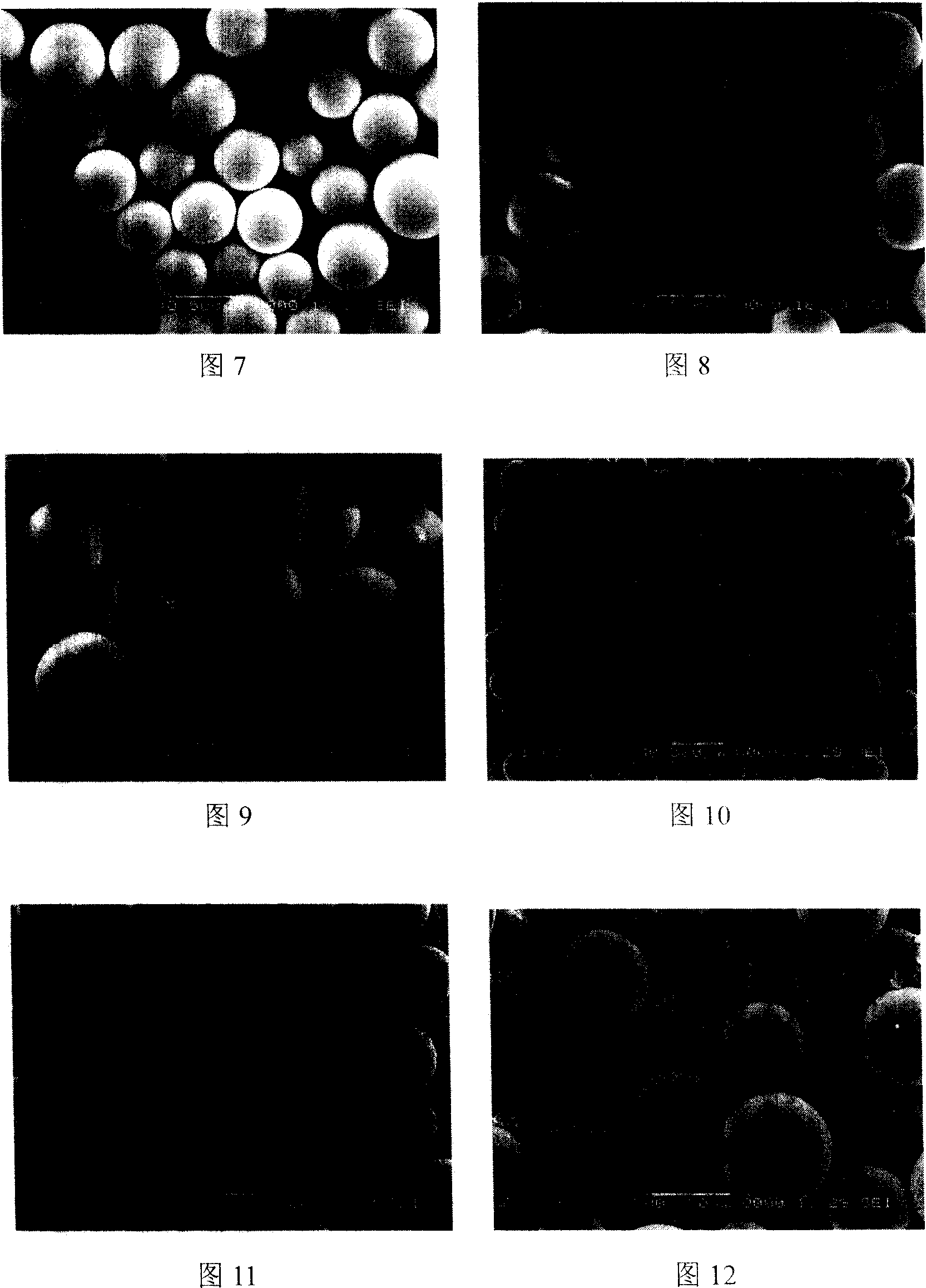

Preparation methods of spherical lithium manganate for lithium-ion power battery and precursor of spherical lithium manganate

ActiveCN103326012ALow impurity contentHigh discharge platformCell electrodesManganates/permanganatesWater bathsPower battery

The invention discloses preparation methods of a spherical lithium manganate for a lithium-ion power battery and a precursor of the spherical lithium manganate. The preparation method for the precursor is carried out as the following steps: (1) preparing a manganese salt water solution; (2) preparing a precipitant water solution; (3) injecting the prepared solutions in the step (1) and the step (2) to a reaction kettle with a stirrer and a constant-temperature water bath; (4) mixing the obtained MnCO3 and a compound containing an element M based on a mol ratio of M to Mn described in the invention, sintering and obtaining the precursor. The preparation method of the spherical lithium manganate is carried out as the following steps: mixing the precursor and Li2CO3, sintering and obtaining an M-doped spherical spinel lithium manganate. Compared with the prior art, the method of the invention has the advantages that: (1) impurity content is low, discharge plateau is high, specific capacity is high, cycle performance is good, high-temperature performance is good and tap density is high; and (2) raw material price and production cost are low, powder particle size can be controlled, microscale additive disperses uniformly, particle size distribution is concentrate, and microscopic morphology is spherical or spheroidic.

Owner:QINGDAO HUAGUAN HENGYUAN LI TECH

Method for producing of ultra-clean and high-purity electronic grade reagents

InactiveUS20110094872A1Quality improvementHigh yieldChlorine/hydrogen-chloride purificationUsing liquid separation agentParticulatesTechnical grade

A method for producing of ultra-clean and High-purity electronic grade reagents is disclosed. The industrial grade reagents are chemically pretreated and filtered, and the colature is rectified. Heating the steam during the rectification to overheated steam, and filtering the overheated steam used the microporous membrane to remove the solid particulates. Condensing the overheated steam and the secondarily filter to remove the dust in the product. Due to the adoption of the technical scheme, the ultra-clean and High-purity isopropanol produced is in conformity with standard SEMI-C12 and the hydrochloric acid to standard SEMI-C8. And the method is applicable for the large-scale continuous production.

Owner:SHANGHAI CHEM REAGENT RES INST

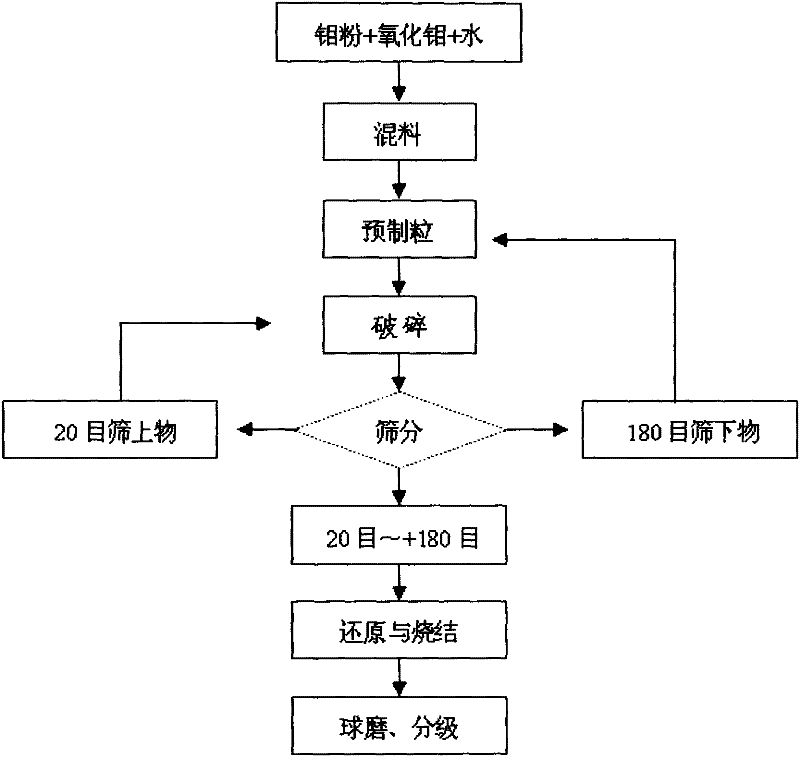

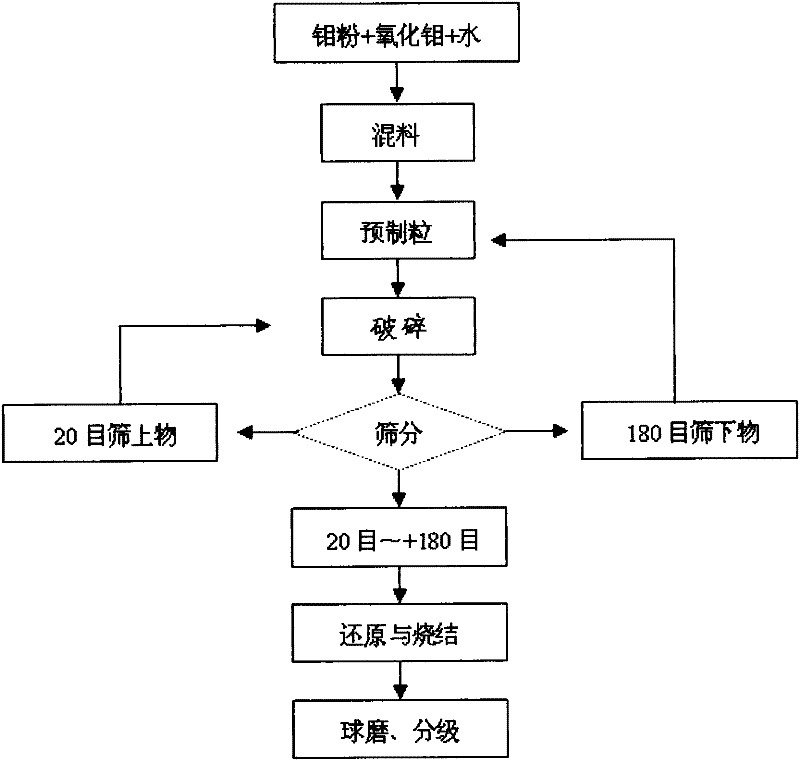

A kind of method for preparing coarse molybdenum powder

The invention discloses a method for preparing coarse molybdenum powder. After mixing molybdenum powder:molybdenum oxide powder in a weight ratio of (4-0.67):1, the mixed powder is mixed according to the ratio of (4ml-8ml) / 100g mixed powder. Spray deionized water on the mixed powder, mix well and then mix for 30-60 minutes; press the mixture into a billet by isostatic pressing; the pressed billet is crushed and screened to obtain a prefabricated powder (-20 mesh, +180 mesh); the prefabricated powder is subjected to hydrogen Reduction, the reduction temperature is 750°C~970°C; the reduction time is 10h~12h, the hydrogen flow rate: 20L / h-30L / h; according to the ball-to-material volume ratio of 1.1~2.0, after ball milling the prepared molybdenum powder for 30min~60min, Sieve to get the desired product. The method of the invention has low production cost and simple process, and the prepared molybdenum powder has good performance.

Owner:CHENGDU HONGBO INDAL

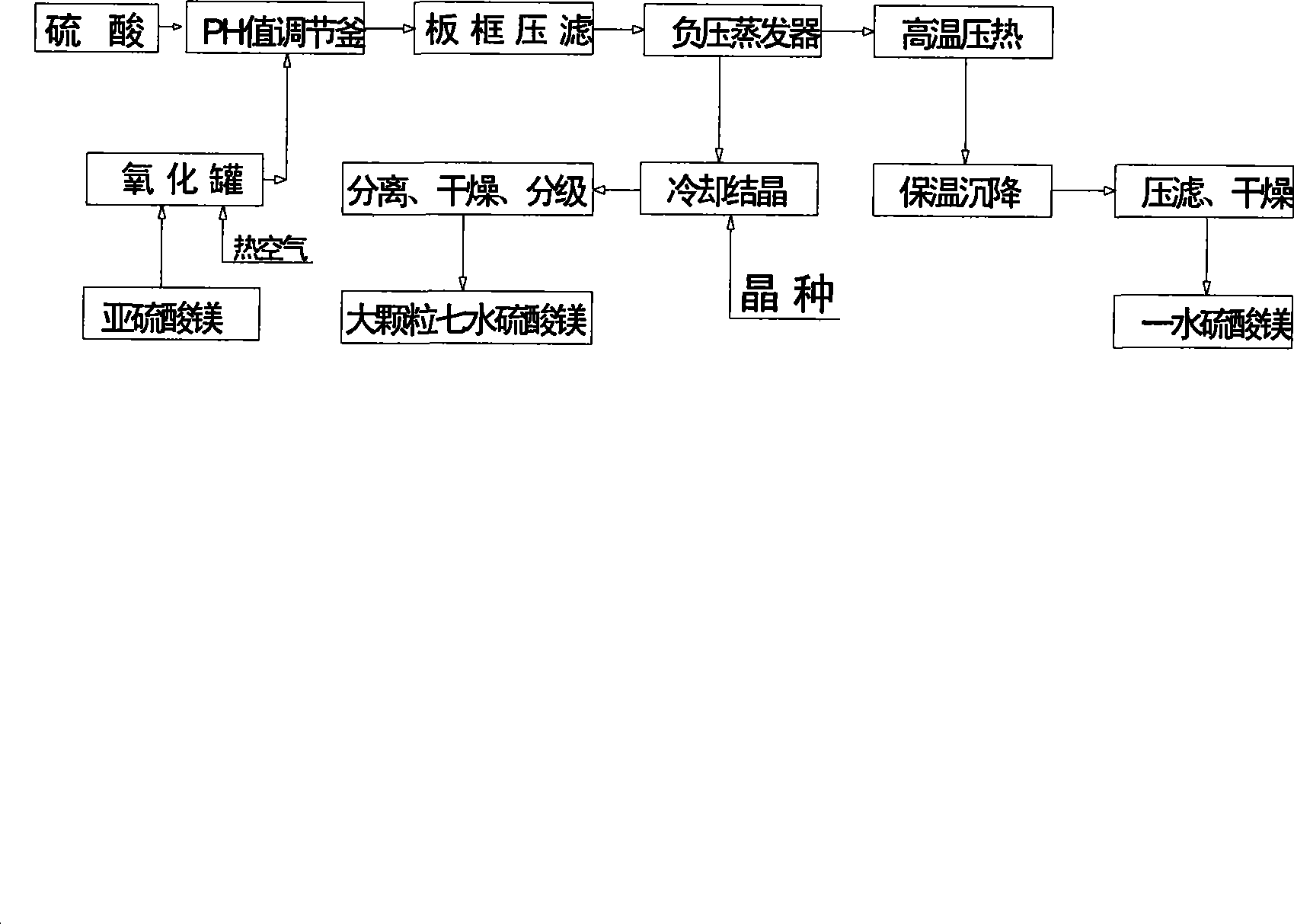

Method for producing large particles of heptahydrate magnesium sulfate and monohydrate magnesium sulfate from magnesium sulfate solution

InactiveCN101214980AImprove product qualityQuality improvementMagnesium sulfatesSocial benefitsPhysical chemistry

The invention discloses a method for producing magnesium sulfate, which is a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate from magnesium sulfate solution, in particular to a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate by employing solid containing magnesium sulfite (the chemical name is MgSO3) to obtain solution containing magnesium sulfate after oxidation treatment. The method of the invention comprises high temperature oxidizing magnesium sulfite, adding acid to adjust pH value, filtering solution, negative pressure evaporating and high temperature heating or seeding cooling for producing magnesium sulfate heptahydrate. The invention is simple in method and easy in operation. The product of magnesium sulfate produced by the method is high in product quality, and the selling price is increased. The method sufficiently employs byproduct of desulphurization process with magnesium as raw material, thereby decreasing the investment of environmental equipment in the desulphurization process with magnesium and operation cost, also decreasing the production cost of magnesium sulfate industry and achieving the win-win purpose of social benefit and economic benefit. The problems that in the existing method the product quality is low and macroaggregated magnesium sulfate heptahydrate can not be produced are resolved.

Owner:张荣阳 +2

High temperature-resistant de-molding paint as well as preparation method thereof

The invention discloses high temperature-resistant de-molding paint which is prepared from alkaline silica sol, graphite powder and a dispersing agent in a proportion of 100:(5-20):(0.1-1), wherein SiO2 content of the alkaline silica sol is 20%-40%; and grain size of the graphite powder is 30 meshes-100 meshes. According to the high temperature-resistant de-molding paint as well as the preparation method disclosed by the invention, conglutination of the paint can be greatly lowered by adding the graphite powder in the alkaline silica sol, a paint protective layer obtained by coating is uniform in thickness, flat and smooth, and bottom and sides are protected; moreover, dosage is a little, and a firm protective film can be formed by only spraying a thin layer of paint; besides, the graphite powder and the silica sol are uniformly fixed, and after forming the protective layer, the graphite powder is dispersed in the silica sol and not dispersed inside a cast ingot to affect product quality.

Owner:GANSU SANXIN SILICON IND CO LTD

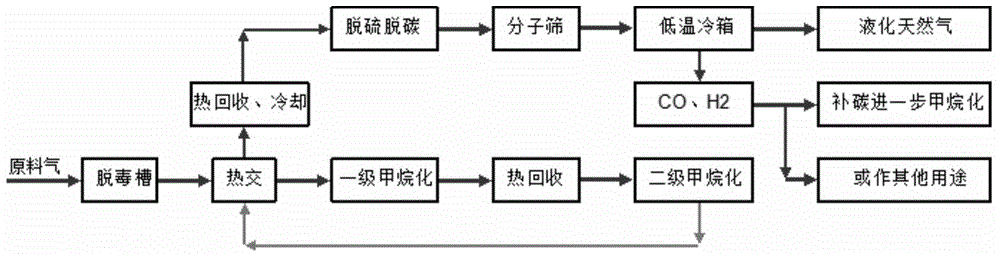

Production process of liquefied natural gas

The invention provides a production process of liquefied natural gas and particularly relates to a sulfur-resistance methanation production process for producing liquefied natural gas by taking coke-oven gas as a raw material. The production process at least comprises two stages of sulfur-resistant methanation processes. The volume content of dry-basis CO in outlet gas subjected to two-stage methanation is less than or equal to 1.0 percent, and the volume content of methane is more than or equal to 48 percent; gas discharged from a second reactor is subjected to high-pressure overheat steam through a spent pit, enters a desulfuration and decarburization device to remove H2S and CO2, then enters a low-temperature cold box and is subjected to methane liquefaction by the low-temperature cold box; gases, such as H2 and little CO can be further produced into more methane or used as other purposes in a carbon replenishing manner. Compared with a non-sulfur-resistant methanation process of coke-oven gas, the production process provided by the invention has the advantages of simple flow, remarkably low equipment cost and operation cost; after project implementation, the production cost of natural gas is further reduced; a relatively energy-saving production path is created for the coal gas making industry and coke-oven gas in China.

Owner:青岛联信催化材料有限公司 +1

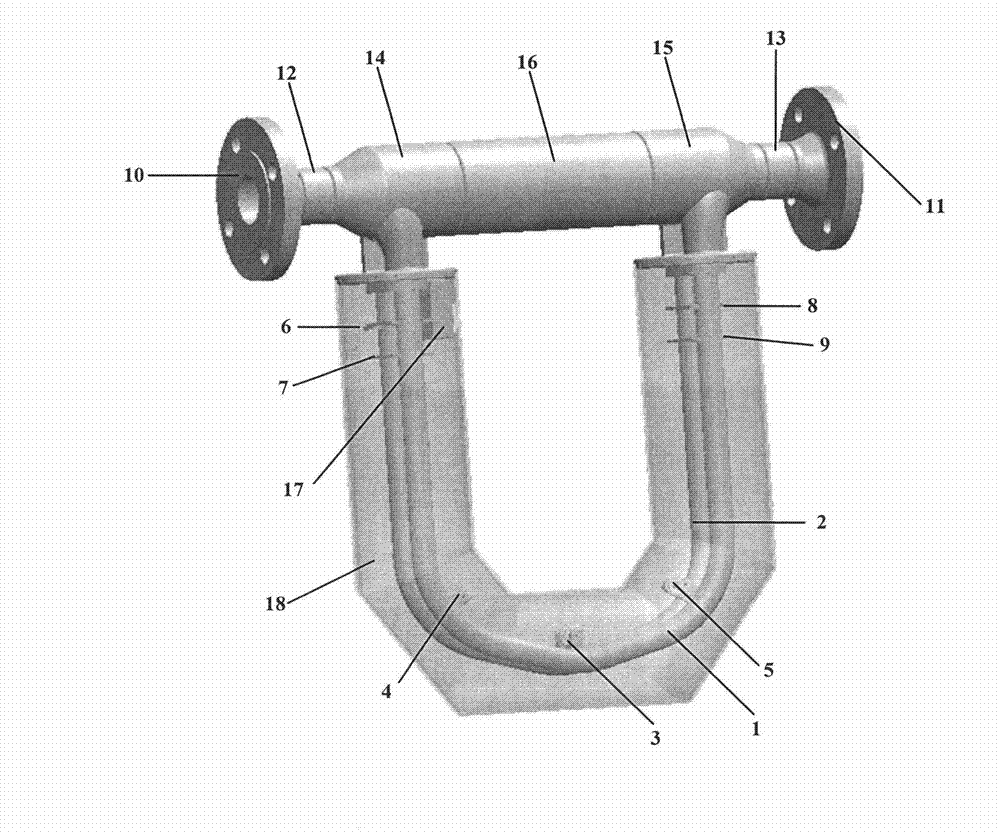

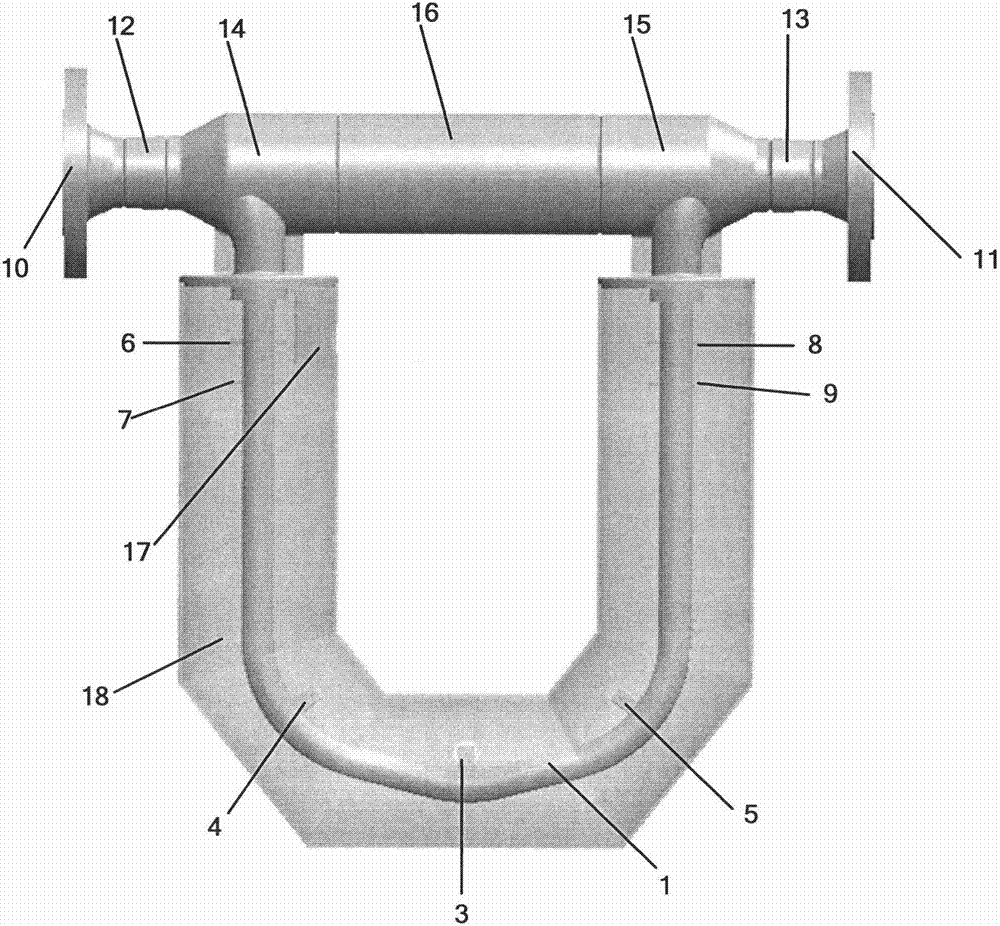

Mass flowmeter

ActiveCN103076053AImprove performanceImprove qualityVolume meteringDirect mass flowmetersFlow resistivityDynamic balance

The invention relates to a mass flowmeter for highly precisely measuring mass flow directly. The mass flowmeter comprises two parallel U-shaped measuring tubes with an identical structure, a vibration exciter, two detectors, four fixed distance plates, two flanges, two end connecting tubes, two splitters, a middle connecting tube and a casing. The mass flowmeter provided by the invention has the advantages that the performance and the mechanical quality factor of a resonant sensor are effectively improved, the influence of a flow field is greatly reduced, the mass flowmeter has small flow resistance and low pressure loss and is simple to install and process, the measuring tubes have excellent dynamic balance properties, the mass flow of liquid with high viscosity and high impurity content can be measured, the application range of the Coriolis mass flowmeter is further enlarged, and the requirement of industrial development on the accuracy and the range of flow measurement is met. The mass flowmeter has great promotion effects for saving raw materials, lowering the production cost, reducing environmental pollution, increasing the profit rate and improving the product quality.

Owner:微测工控设备(廊坊)有限公司

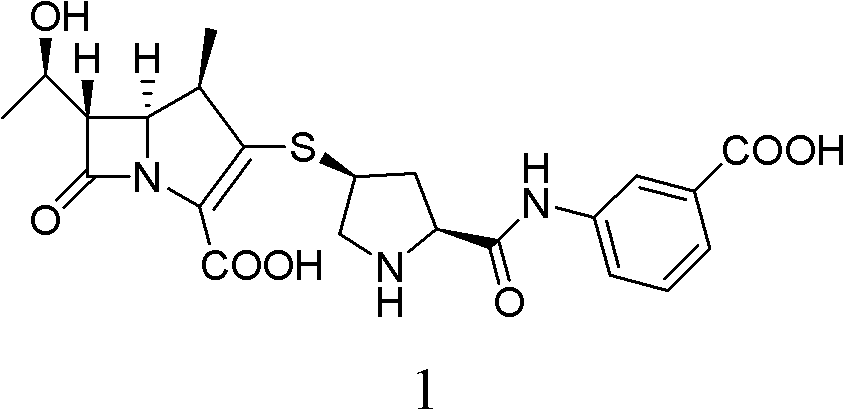

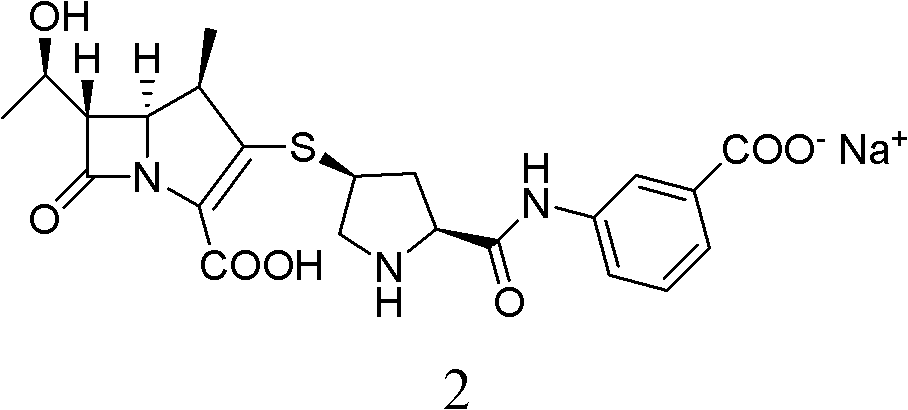

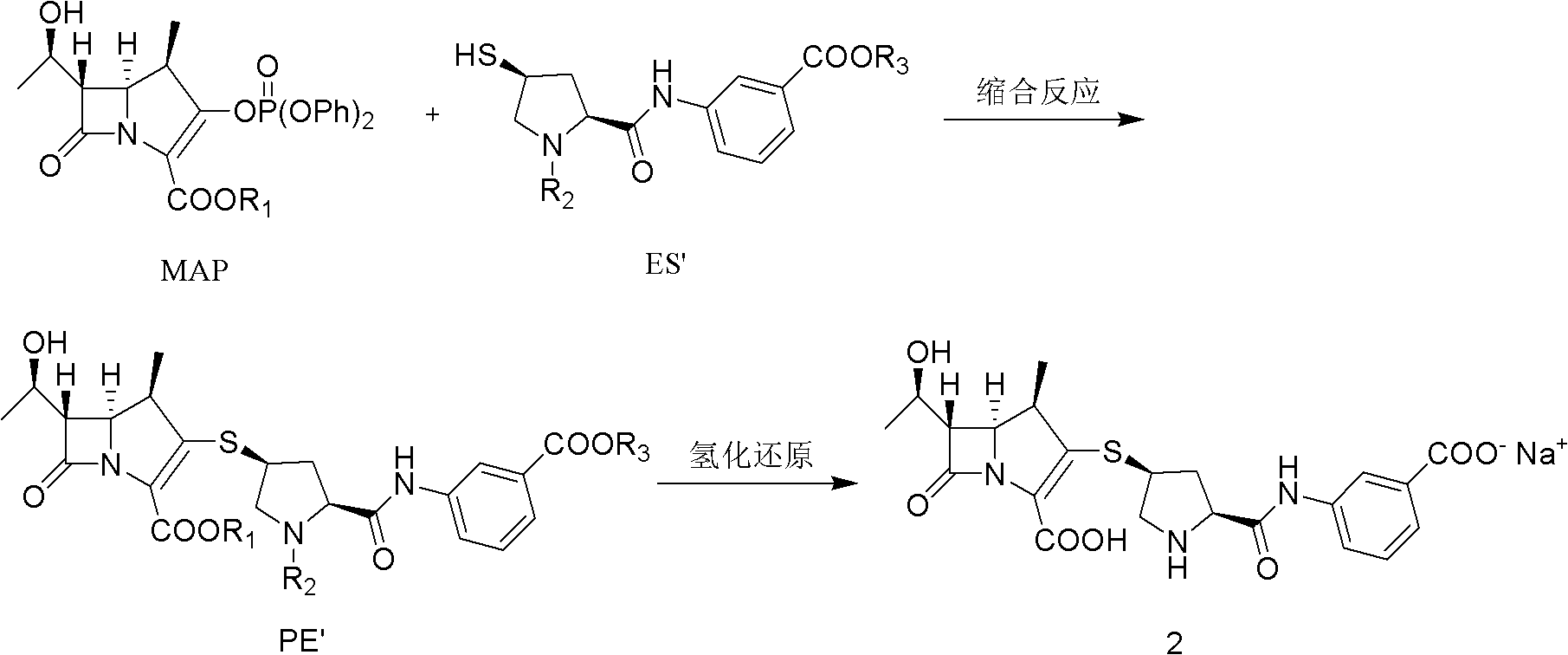

Method for preparing ertapenem sodium

ActiveCN102690266AQuality improvementLow impurity contentGroup 4/14 element organic compoundsErtapenem sodiumOrganic chemistry

The invention provides a method for preparing ertapenem sodium. In the method provided by the invention, an undried ertapenem intermediate is directly subjected to catalytic hydrogenation, or an ertapenem intermediate which is dried to a water content of 5-65% at 20-30 DEG C is subjected to catalytic hydrogenation, thereby preparing the ertapenem sodium. The method provided by the invention is beneficial to simply and efficiently preparing high-quality ertapenem sodium.

Owner:SHENZHEN HAIBIN PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com