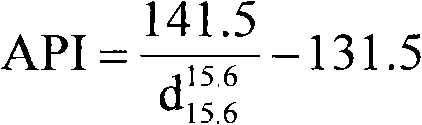

Heavy crude oil hydrocracking method

A technology for hydrocracking and heavy crude oil, used in hydrocarbon oil cracking, petroleum industry and other directions, can solve the problems of heavy crude oil difficulty, fast catalyst deactivation, etc., to protect the main catalyst, improve pipeline performance, and reduce viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] After the raw material oil E is mixed with hydrogen, it enters four hydrogenation reactors in turn for hydrogenation reaction. Among them, the first reactor (referred to as the first reactor, and the following analogy) is filled with hydrogenation protection agent A and hydrodemetallization agent B, and the second reactor is filled with Hydrodesulfurizing agent C, three reverse loading hydrocracking agent D, four reverse loading hydrodesulfurizing agent C. After cooling, the hydrogenation reaction product enters the high-pressure separator for gas-liquid separation to obtain hydrogen-rich gas and liquid products. The hydrogen-rich gas is recycled back to the hydrogenation reactor, and the liquid product is crude oil after hydrocracking. The loading ratios of catalysts and hydrogenation reaction conditions in this example are shown in Table 3; the properties of the obtained hydrogenated crude oil are shown in Table 4 after the above-mentioned flow process was continuously...

Embodiment 2

[0040] The raw material oil F is mixed with hydrogen and then enters four hydrogenation reactors for hydrogenation reaction. The first reactor (first reactor) is filled with hydrogenation protection agent A and hydrodemetallization agent B, and the second reactor is filled with hydrodesulfurization agent. C, three reverse loading hydrocracking agent D, four reverse loading hydrodesulfurization agent C. After cooling, the hydrogenation reaction product enters the high-pressure separator for gas-liquid separation to obtain hydrogen-rich gas and liquid products. The hydrogen-rich gas is recycled back to the hydrogenation reactor, and the liquid product is crude oil after hydrocracking. The loading proportions and reaction conditions of the catalysts in this example are shown in Table 3. The properties of the obtained hydrogenated crude oil were shown in Table 4 after the above-mentioned process was continuously operated for 500 hours.

[0041] It can be seen from Table 4 that aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com