Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341 results about "Reduced viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduced viscosity is equal to the ratio of the relative viscosity increment (ηᵢ) to the mass concentration of the species of interest. Reduced viscosity: ηᵢ/c . The unit must be specified; mL/g is recommended. Relative viscosity increment: ηᵢ=(η-ηₛ)/ηₛ (Where ηₛ is the specific viscosity.)

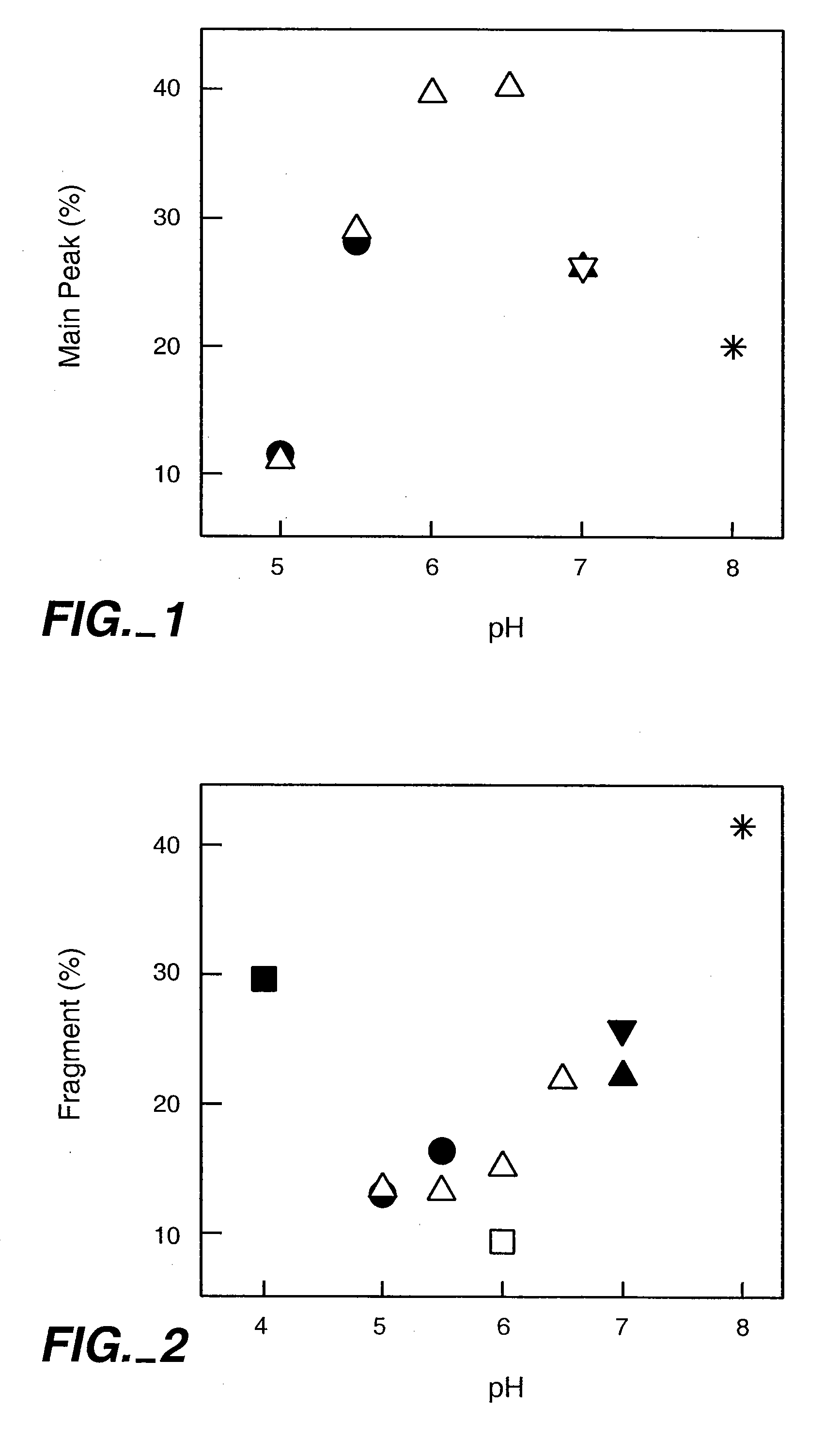

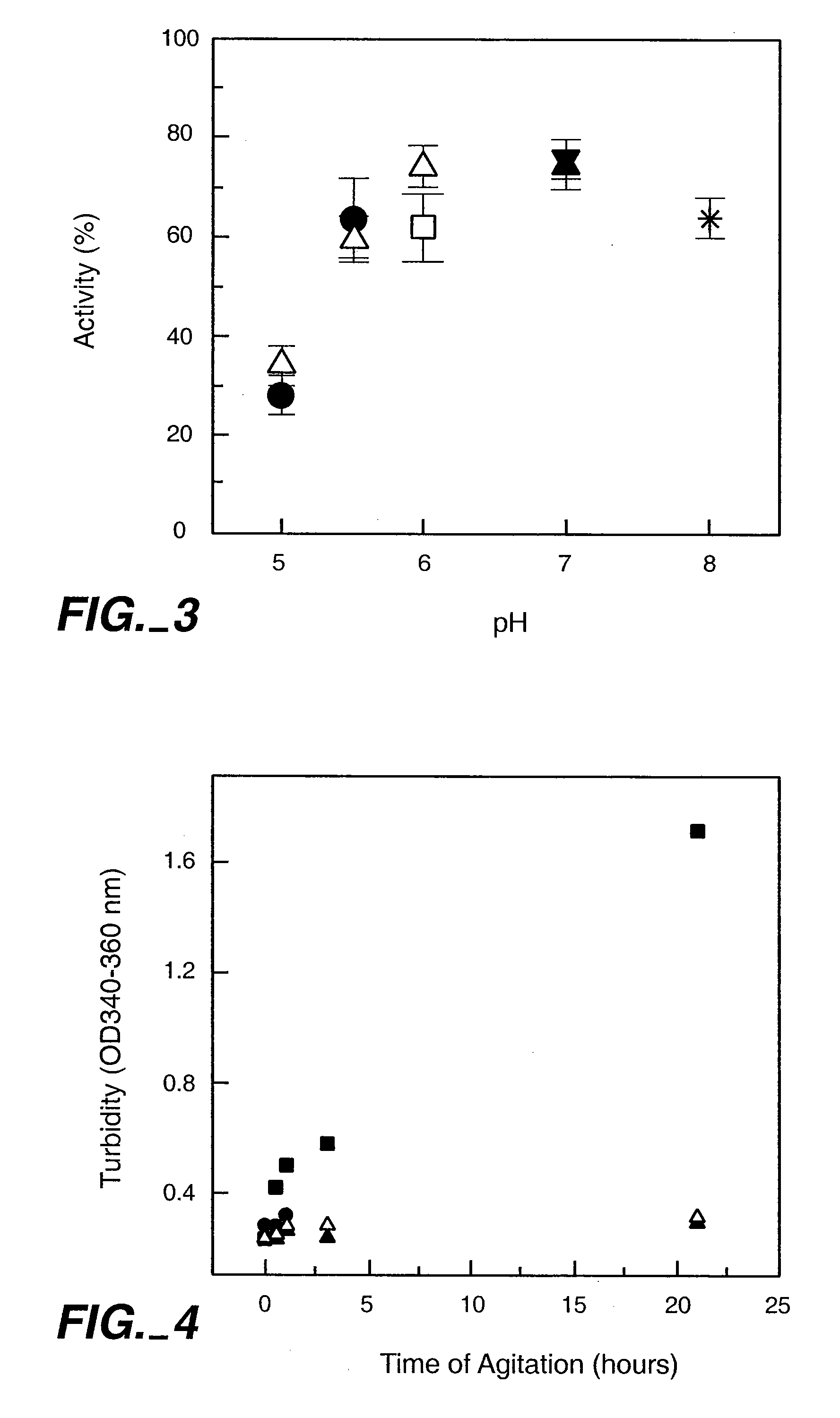

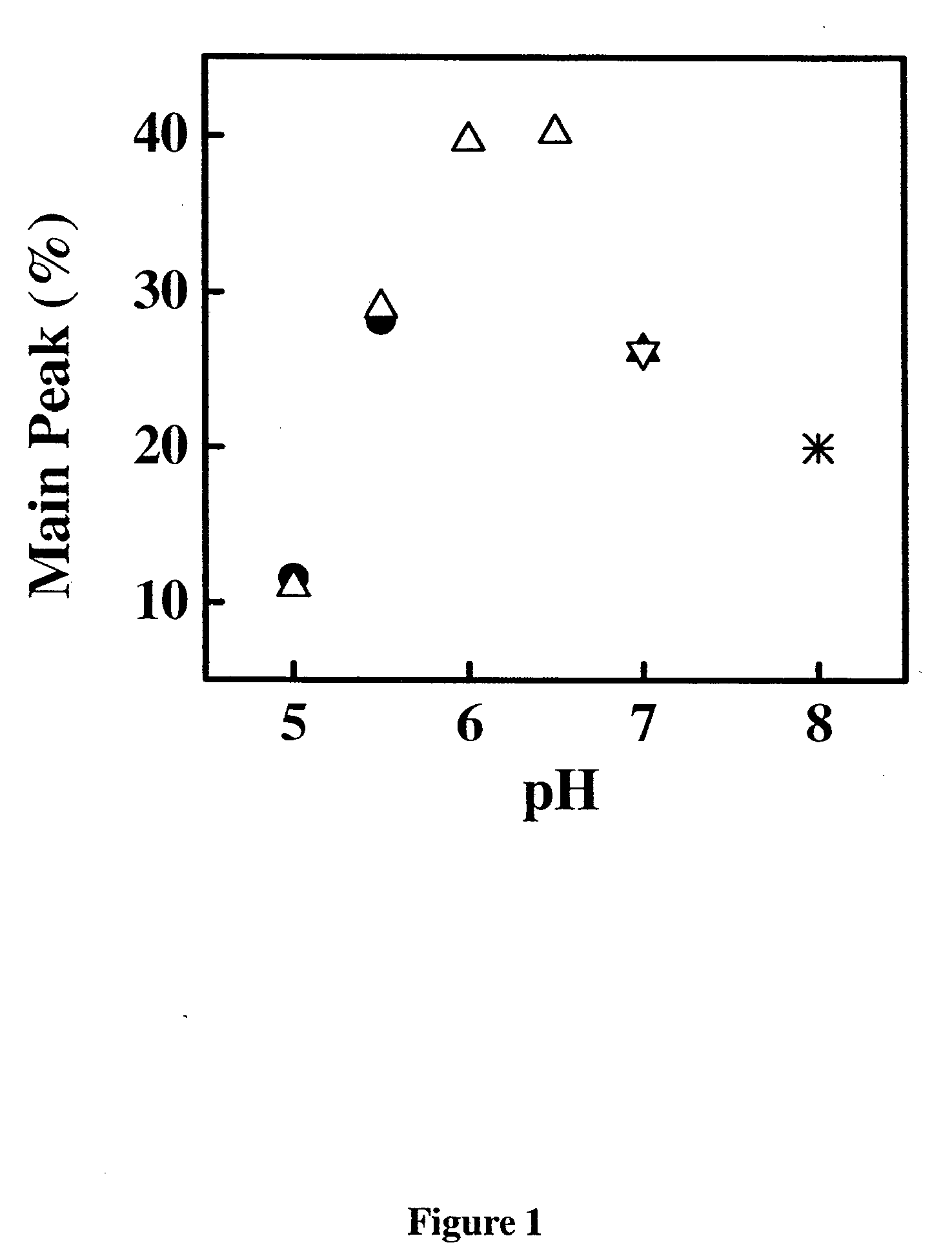

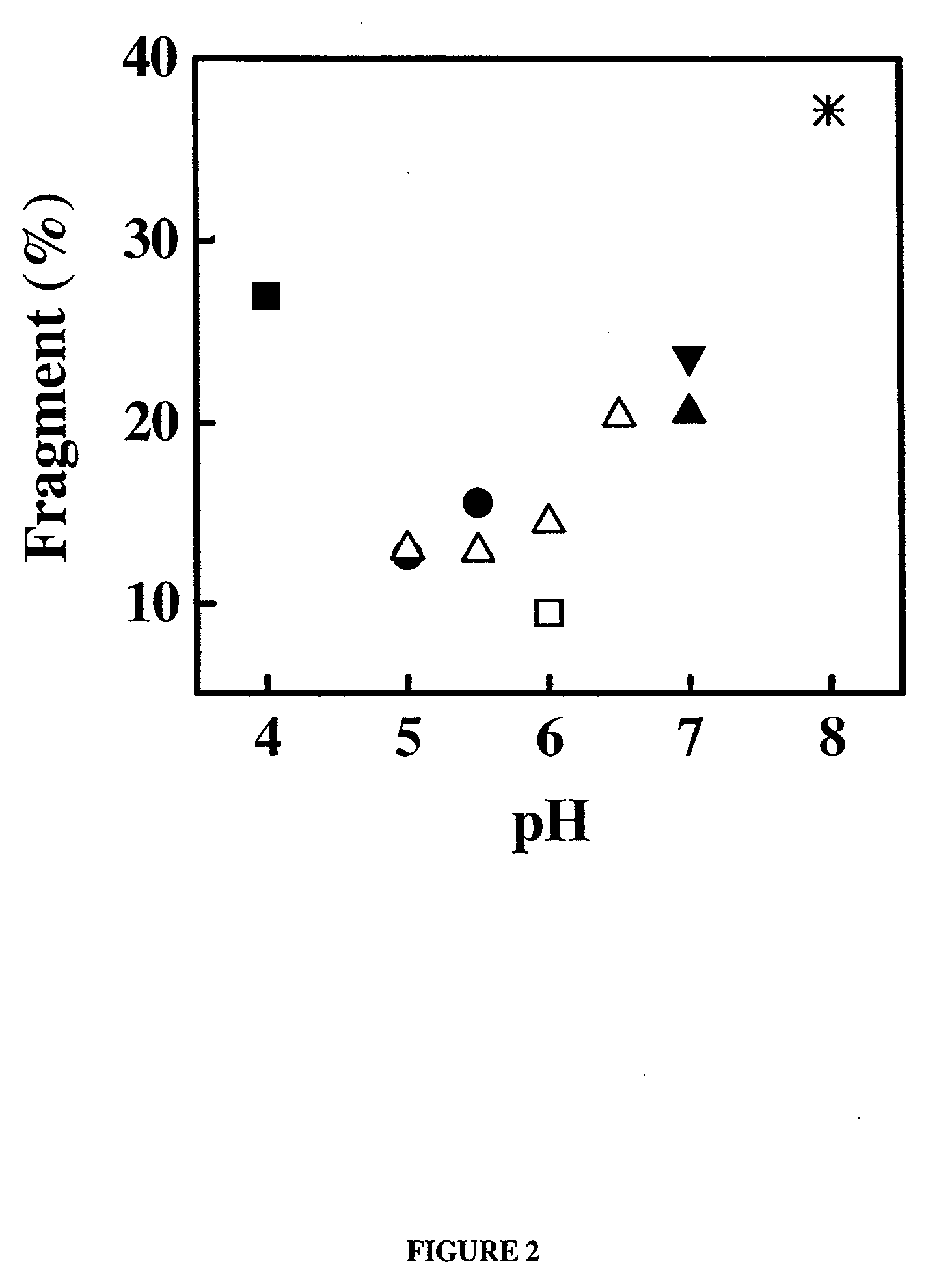

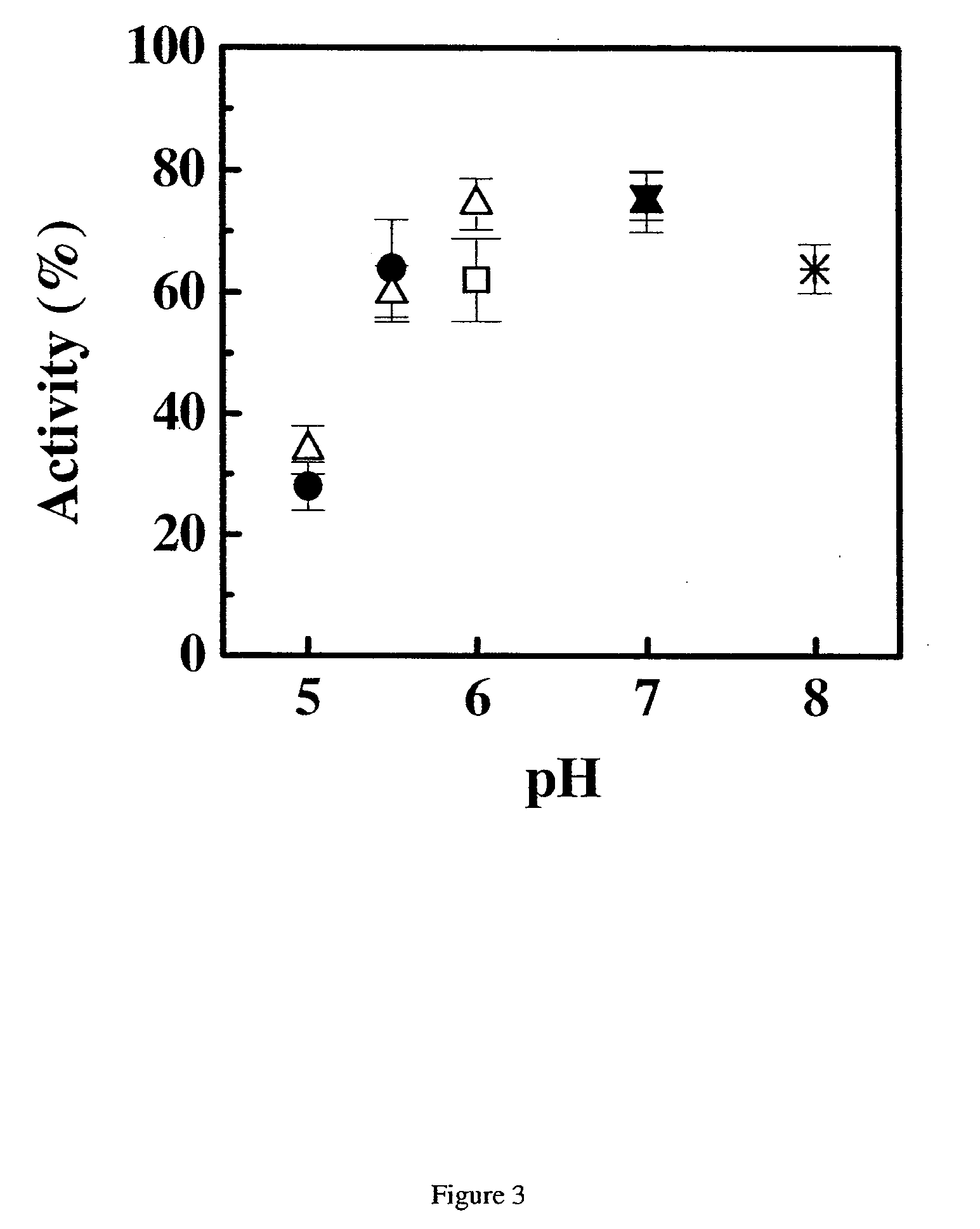

Reduced-viscosity concentrated protein formulations

InactiveUS6875432B2Low viscosityCompromising stability and biological activityPeptide/protein ingredientsInorganic non-active ingredientsConcentration proteinChemistry

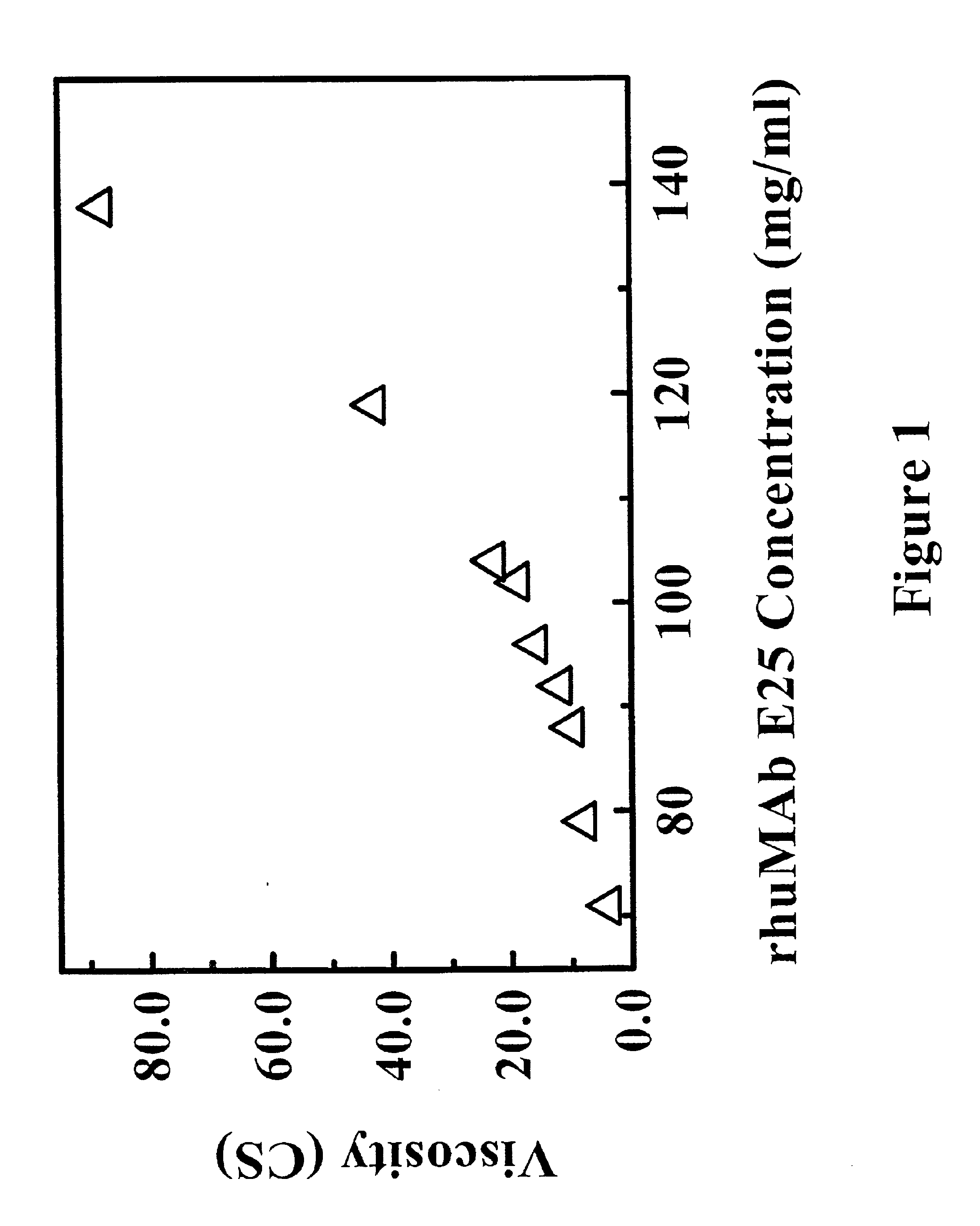

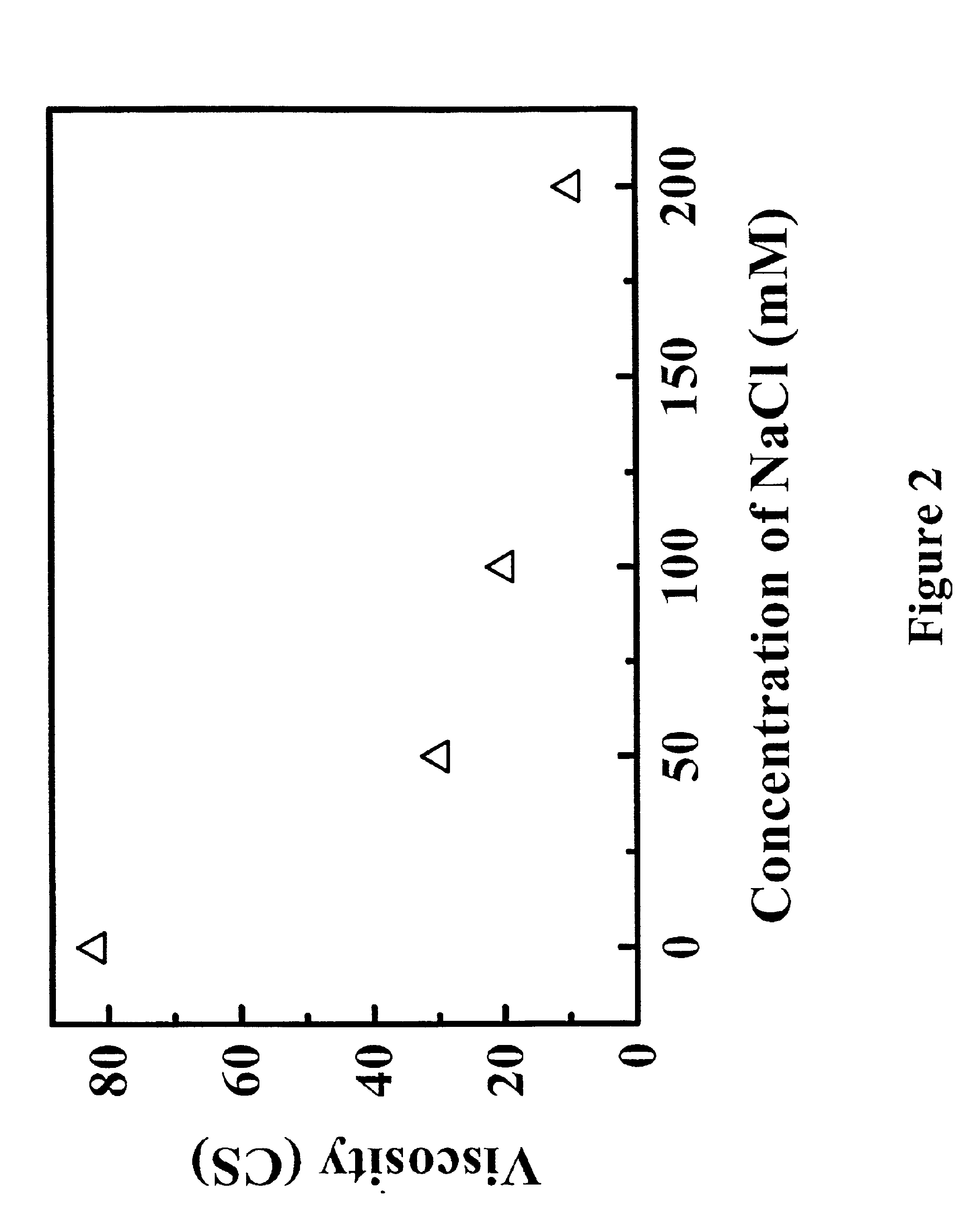

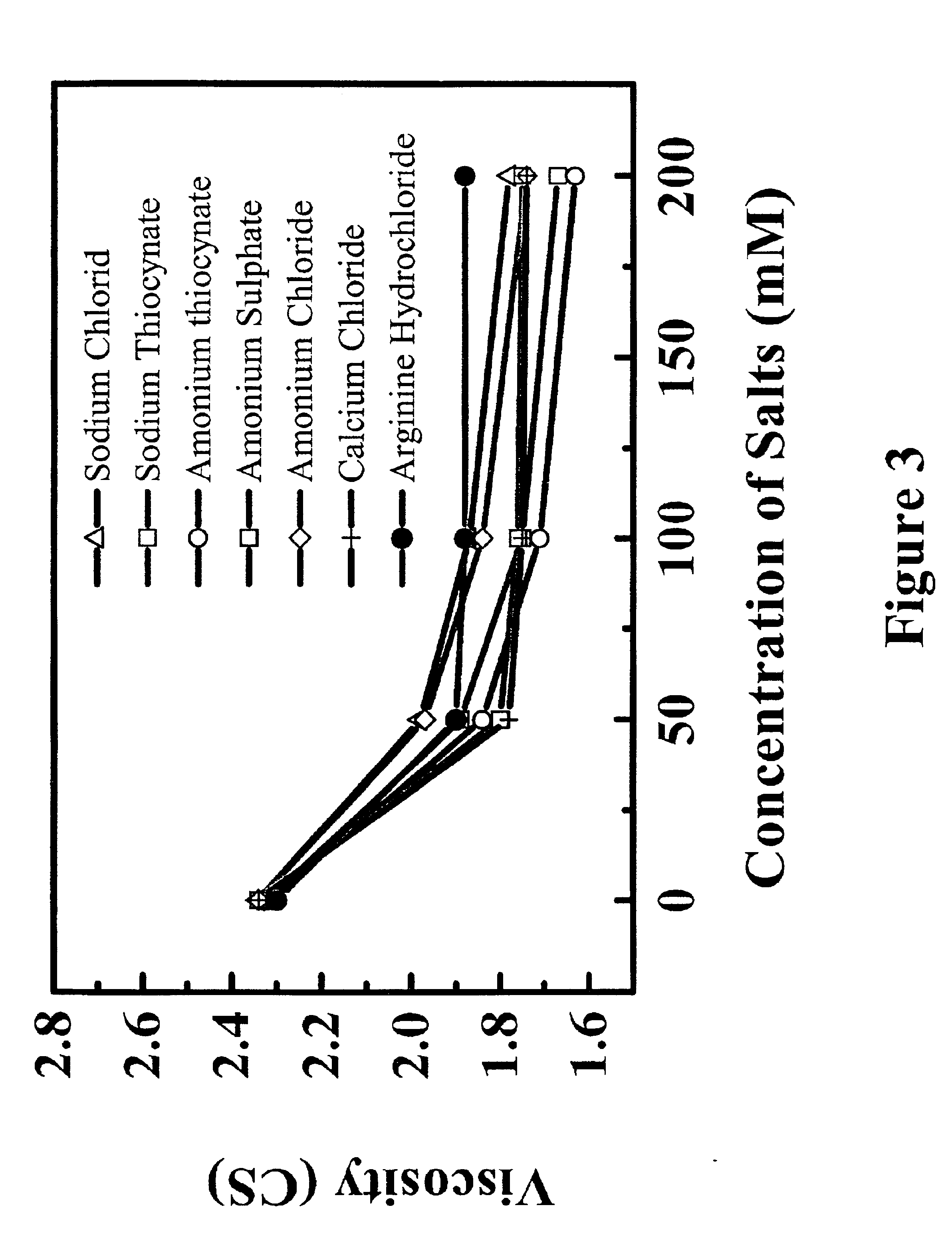

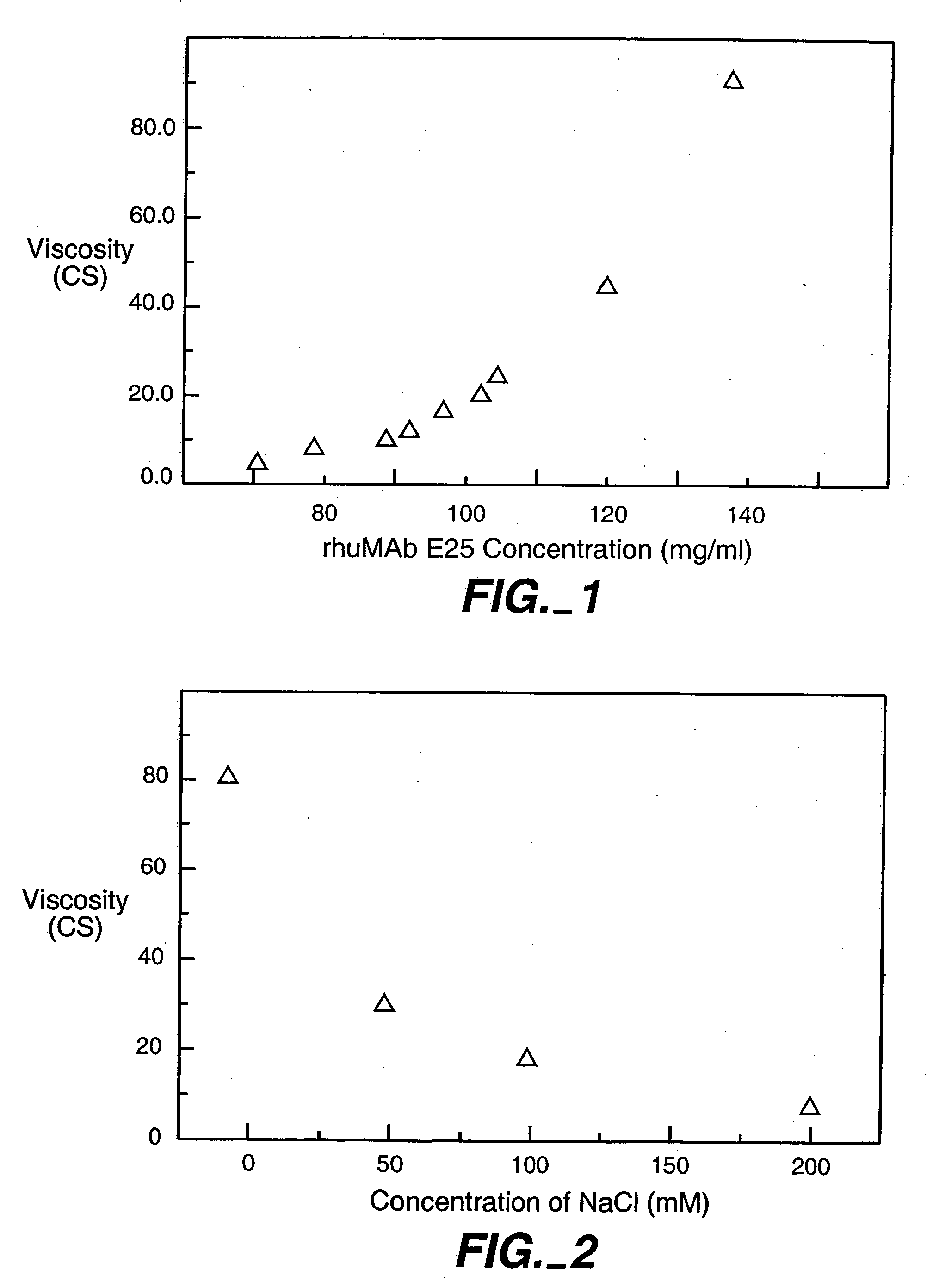

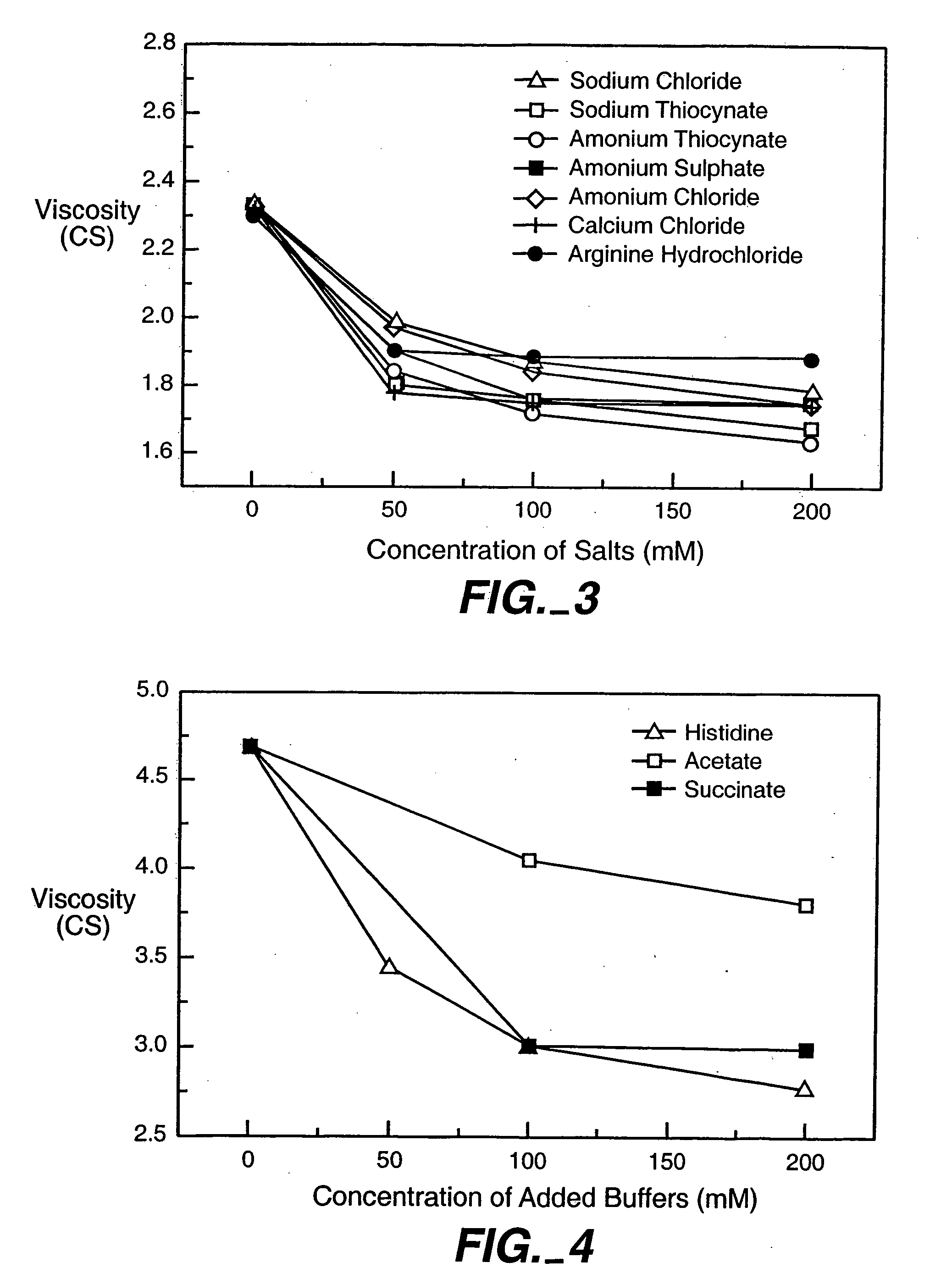

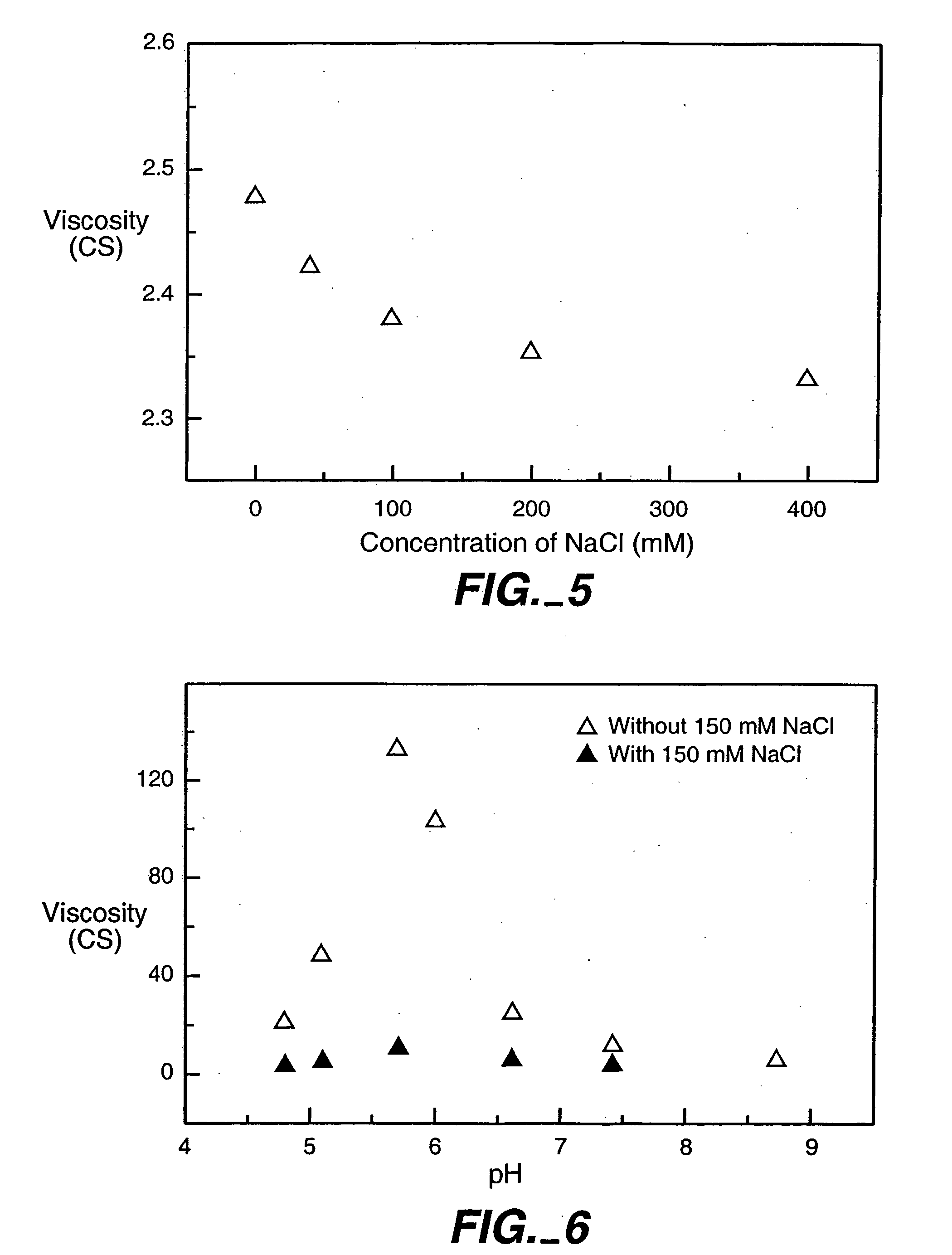

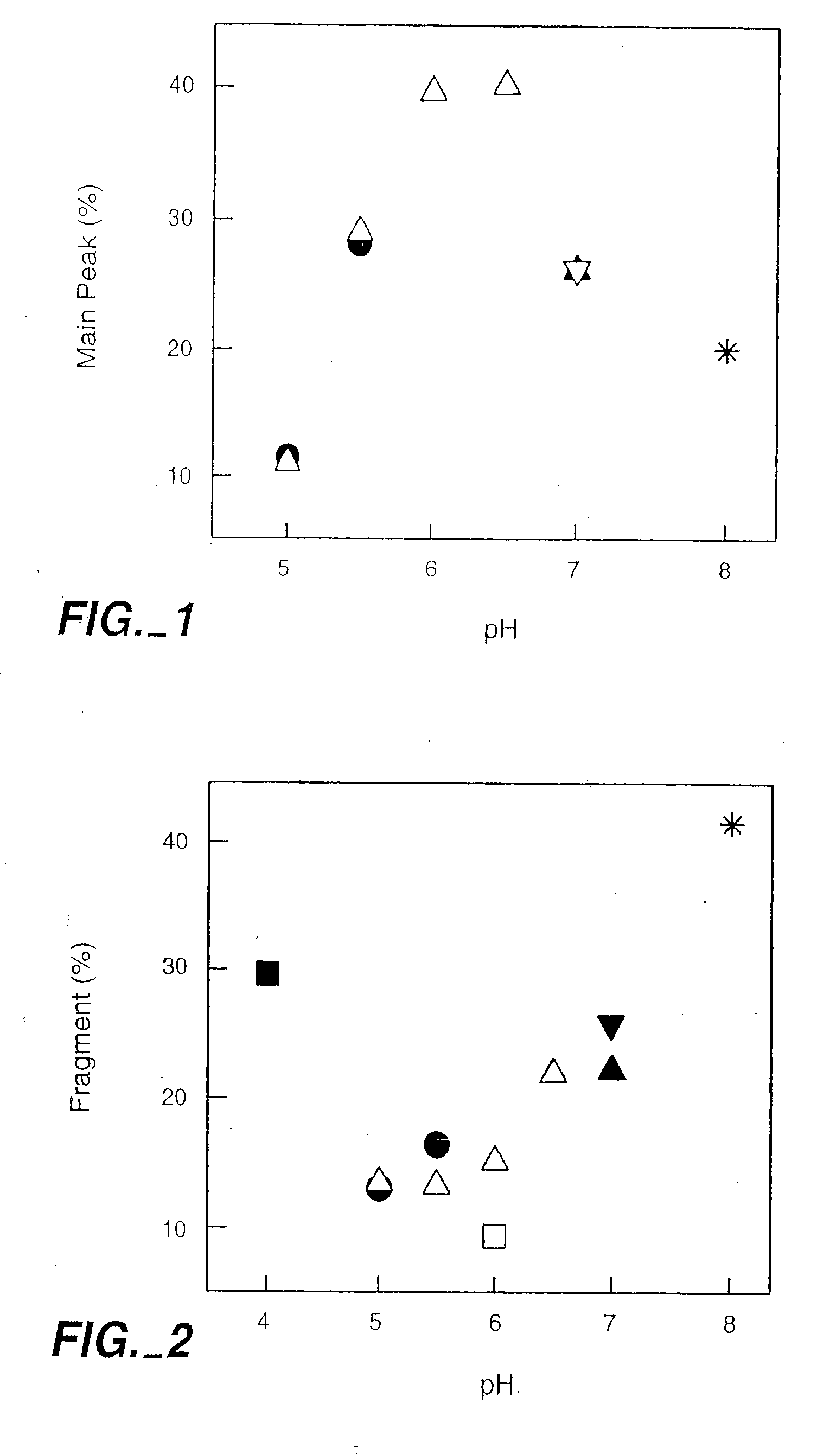

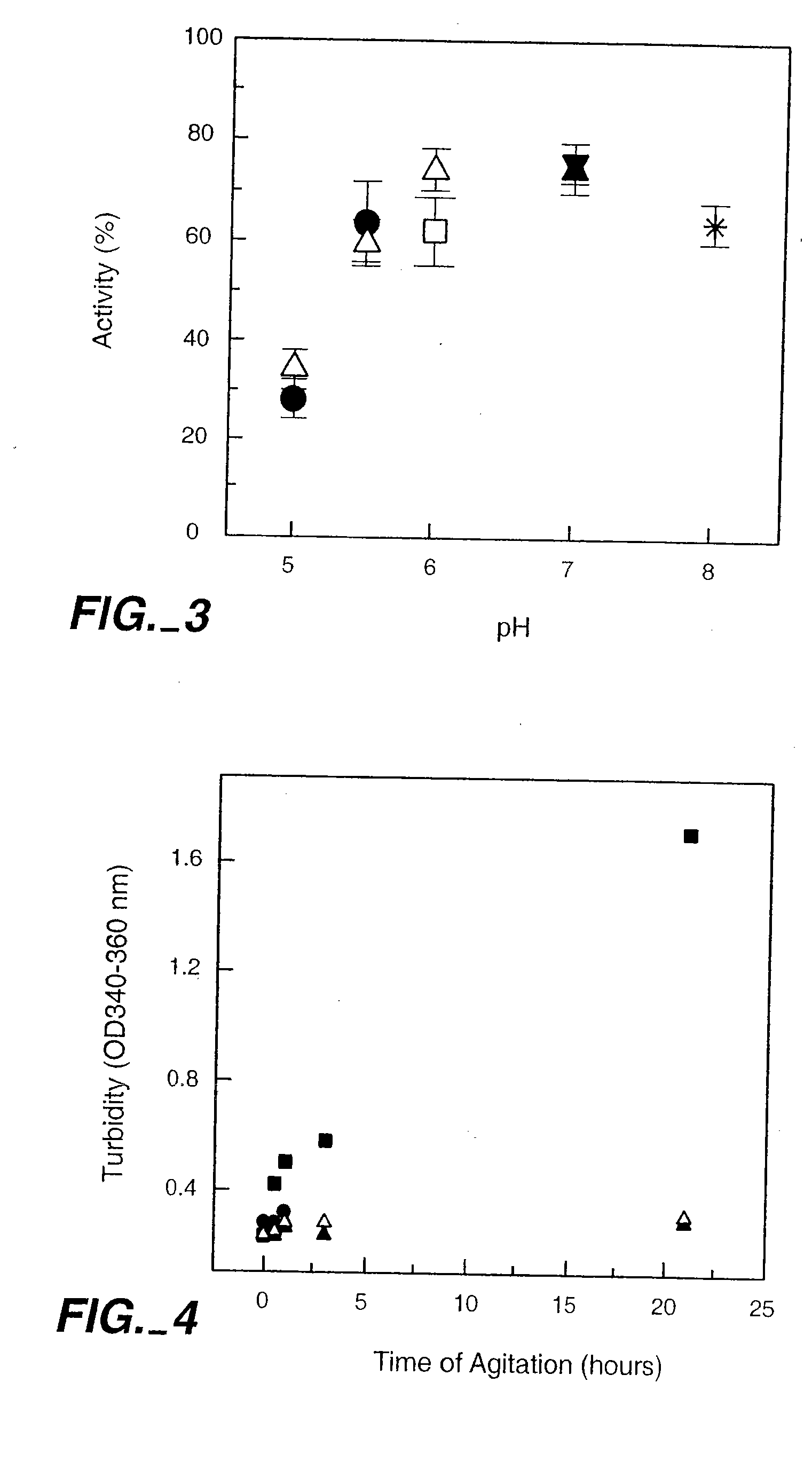

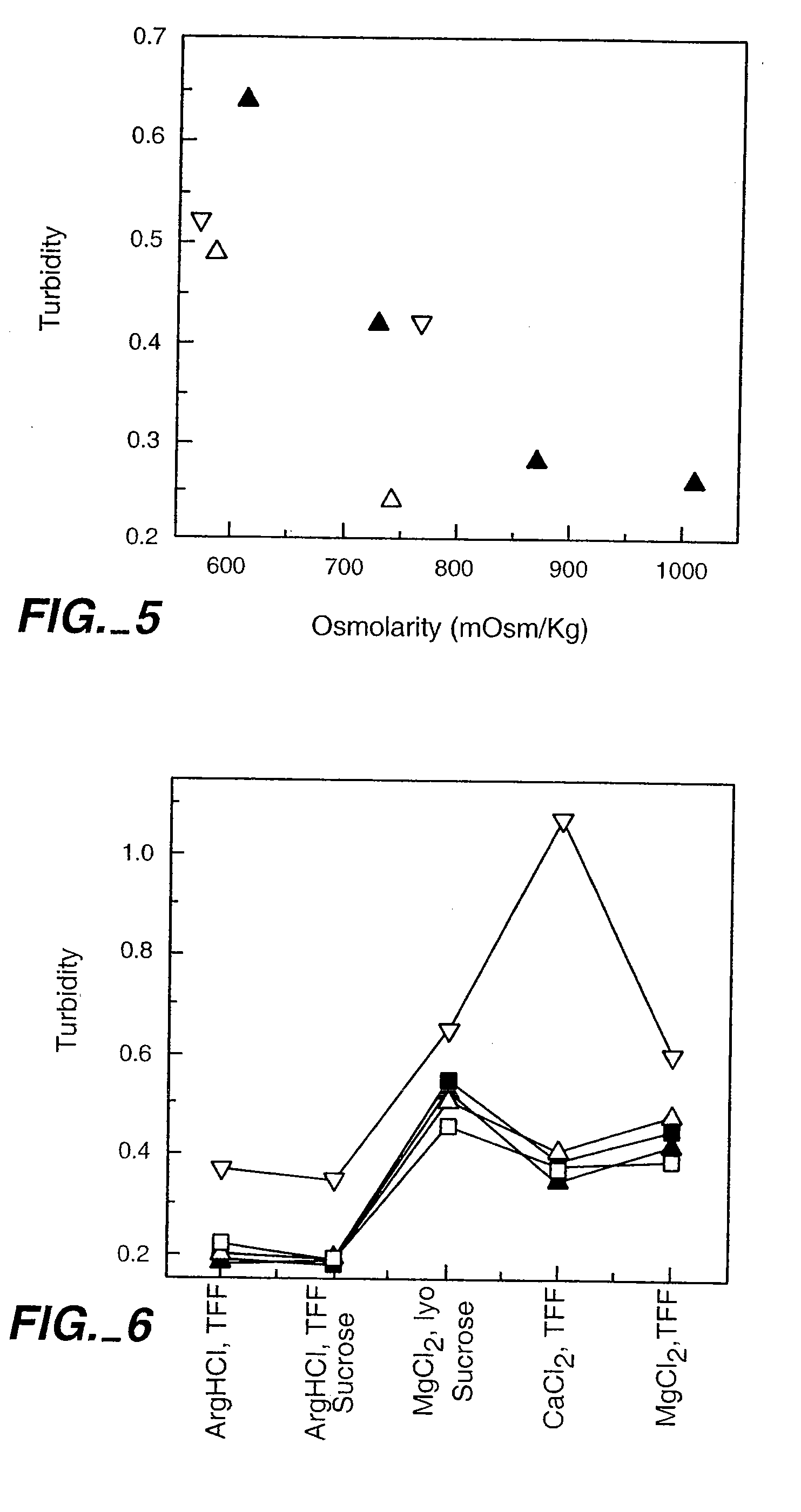

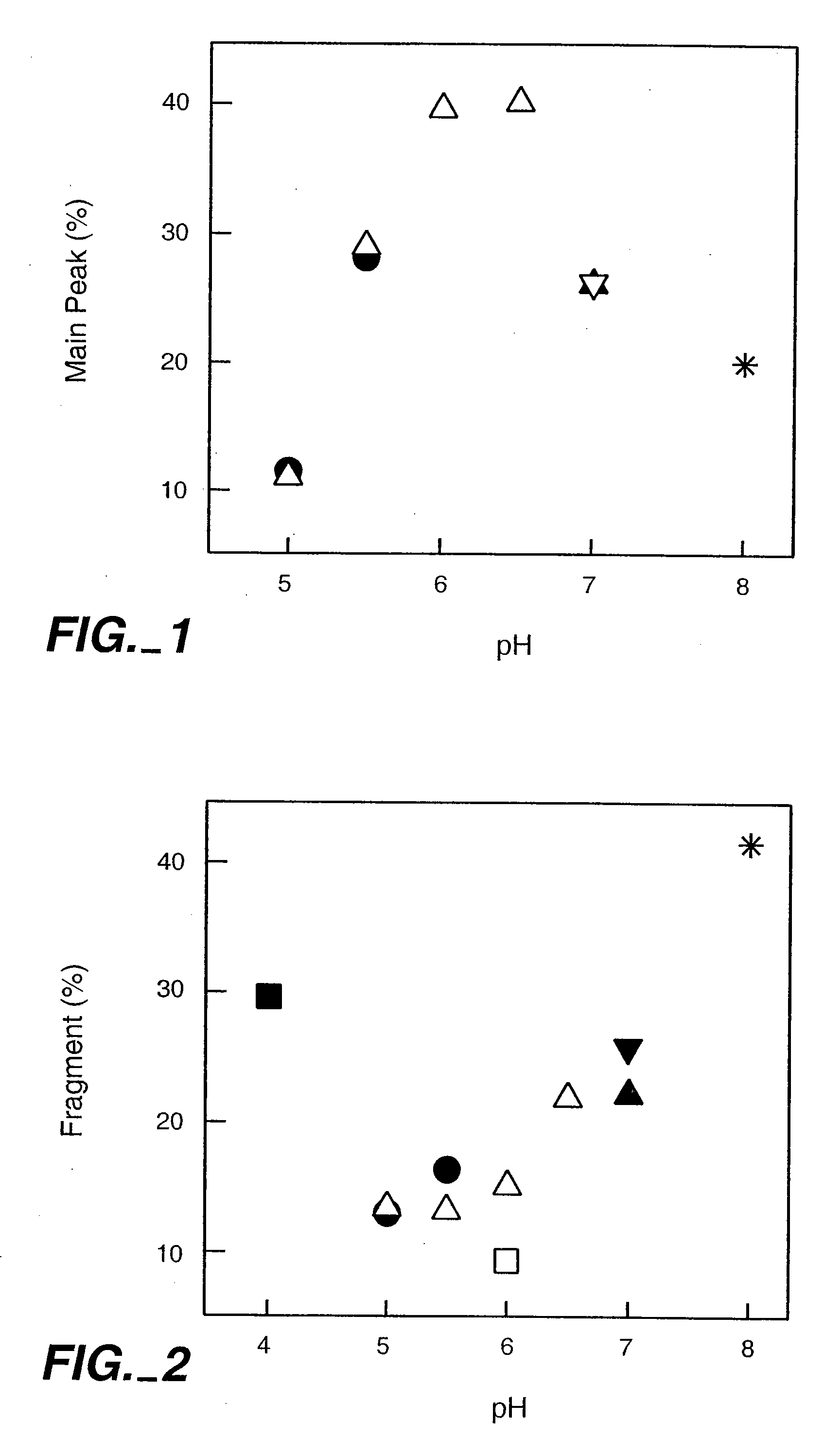

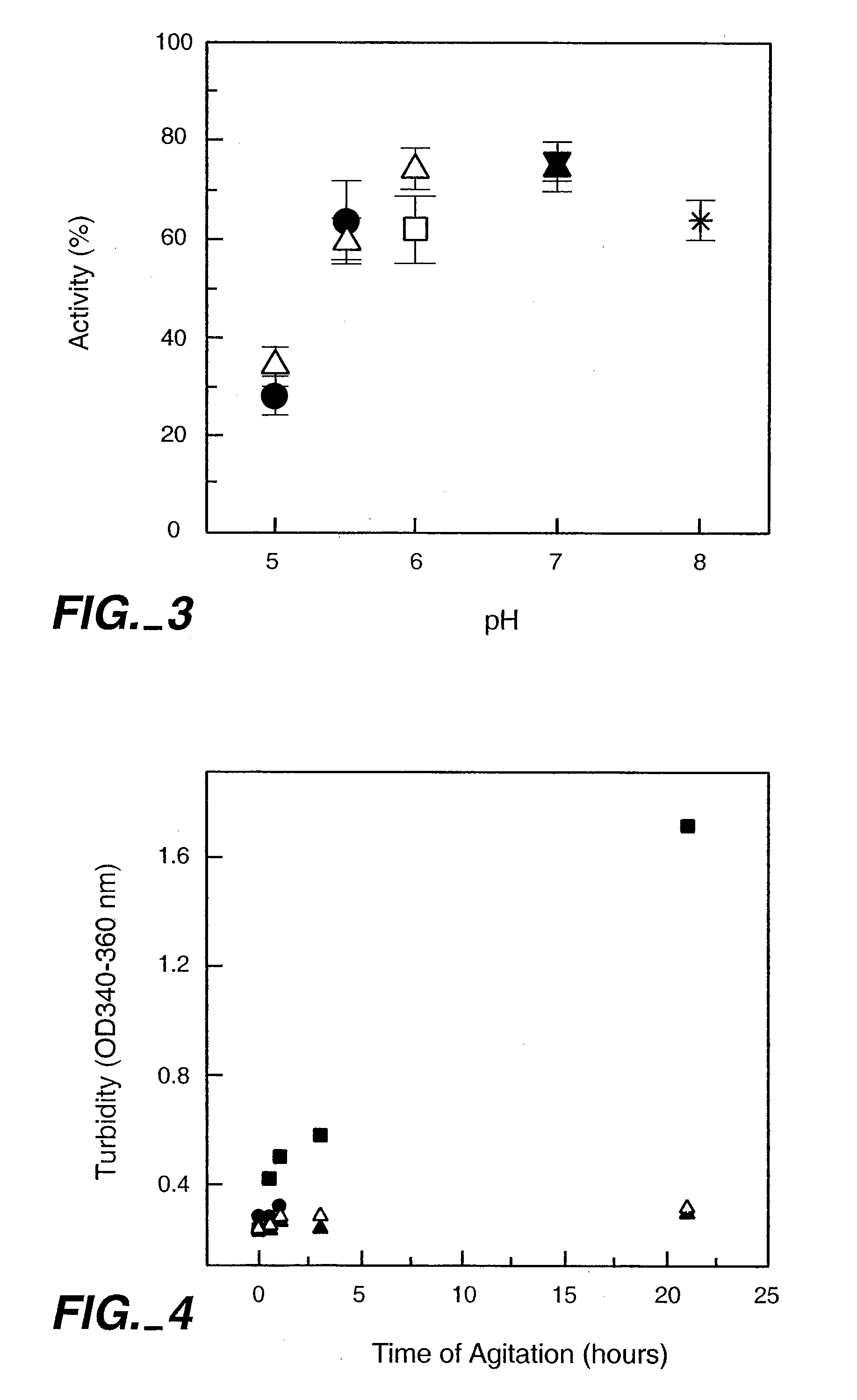

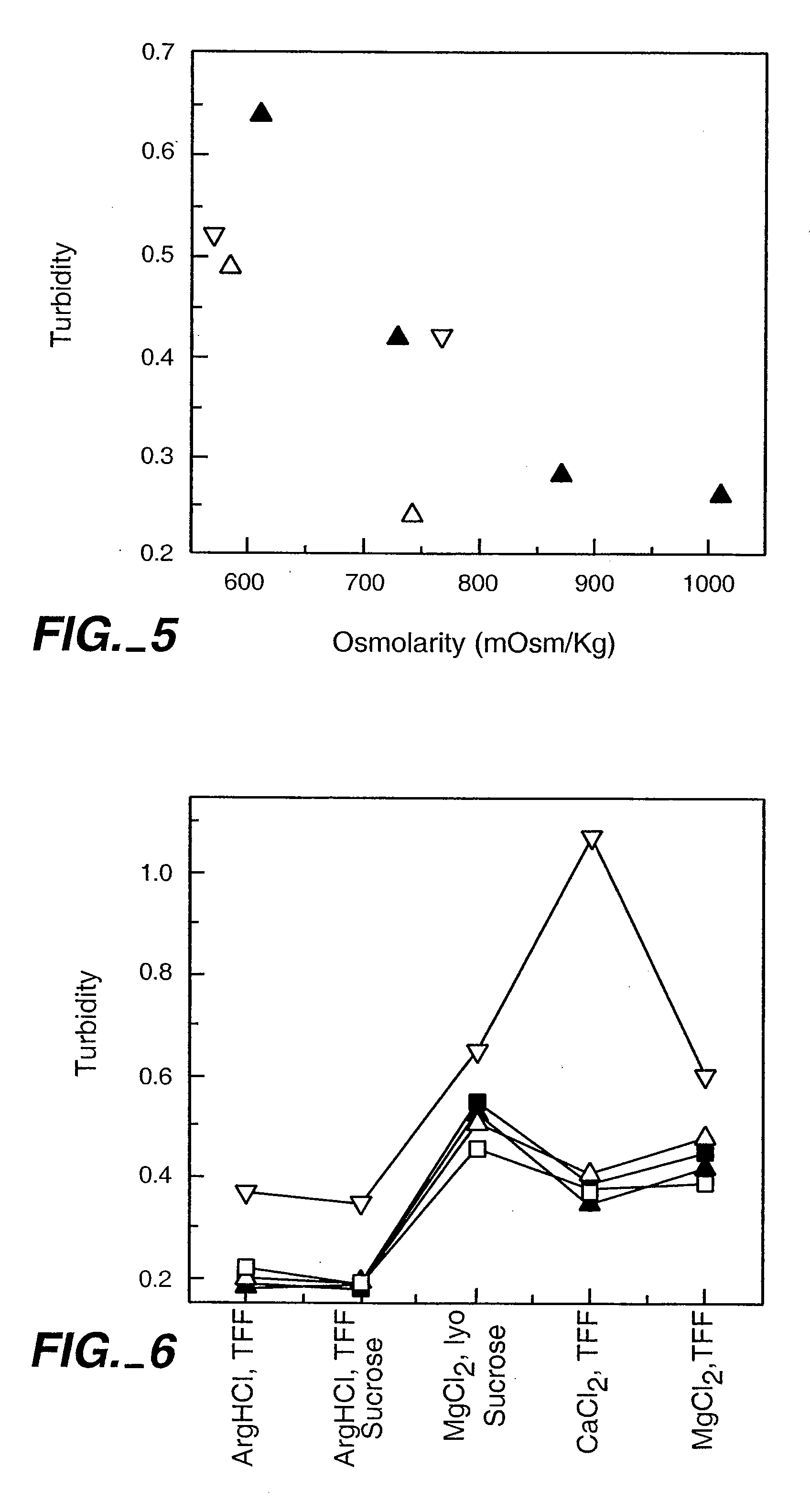

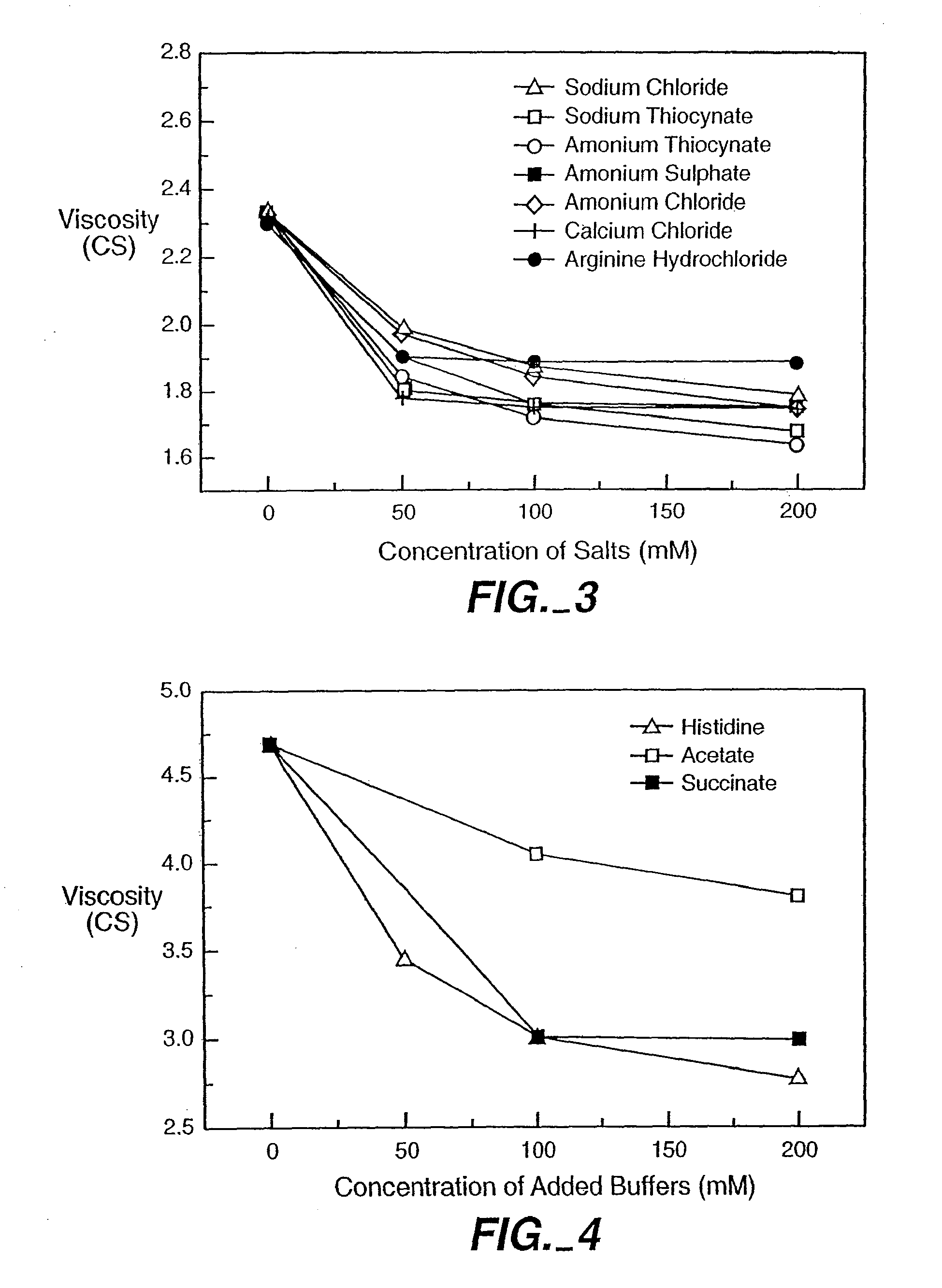

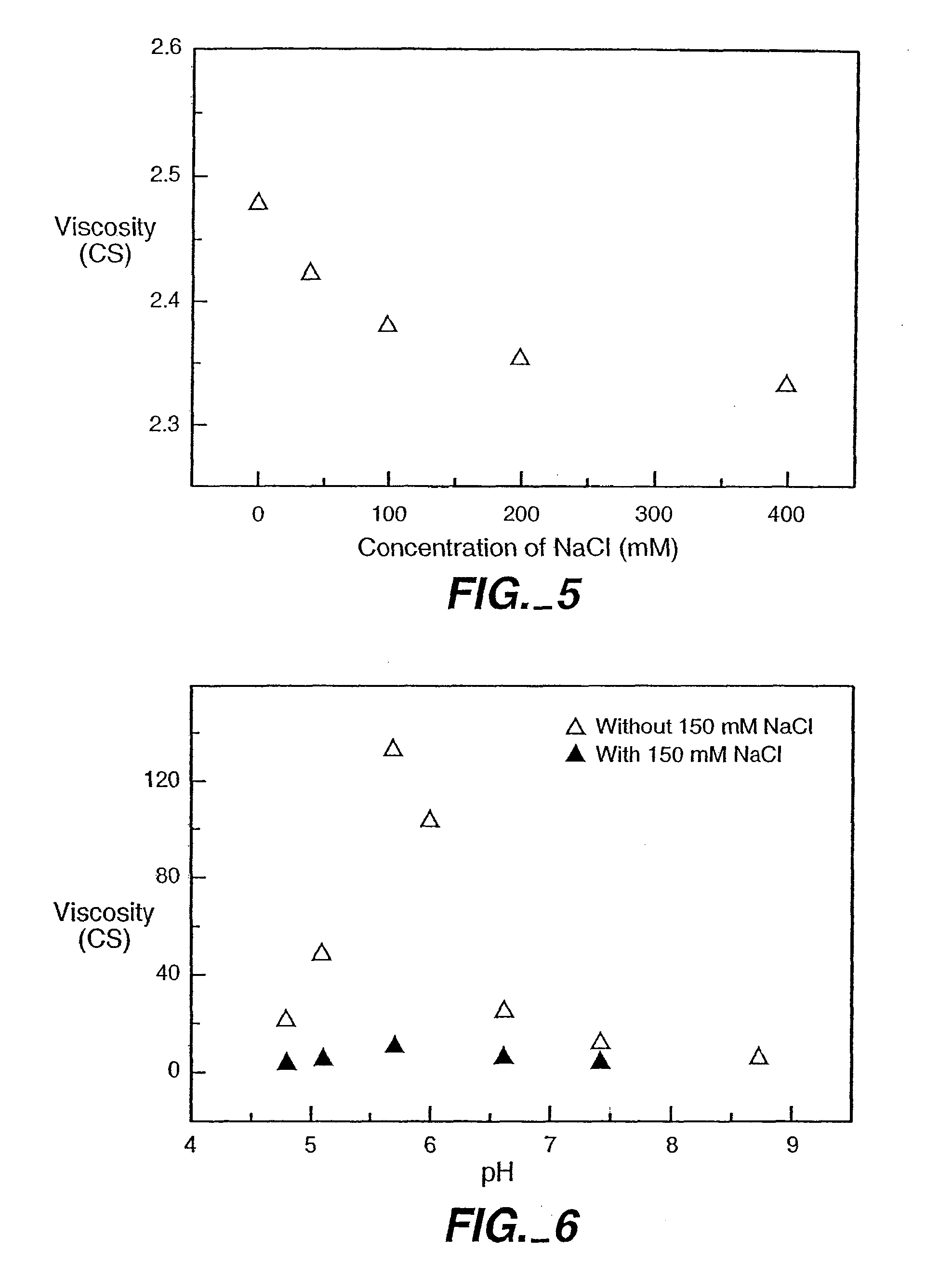

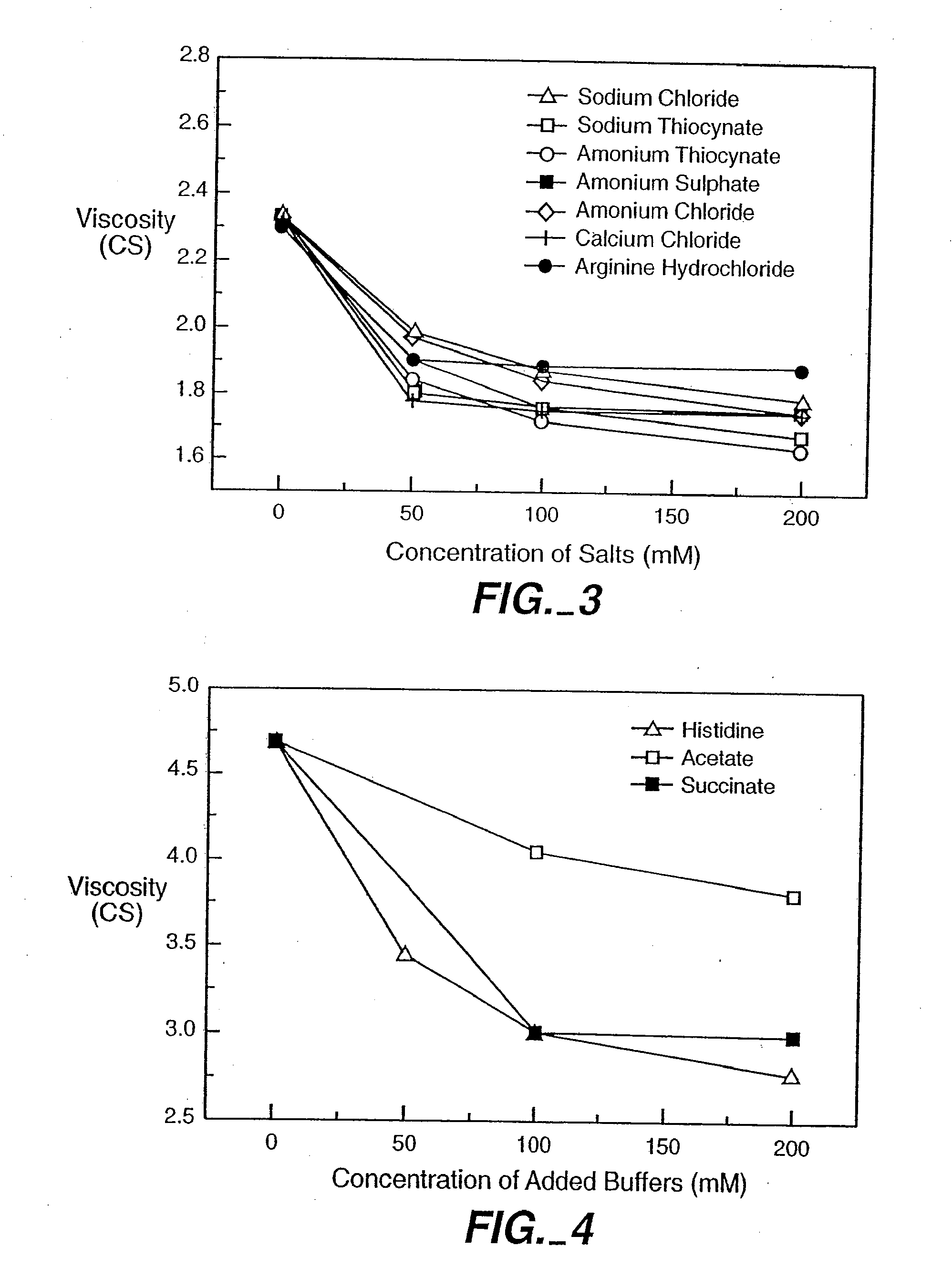

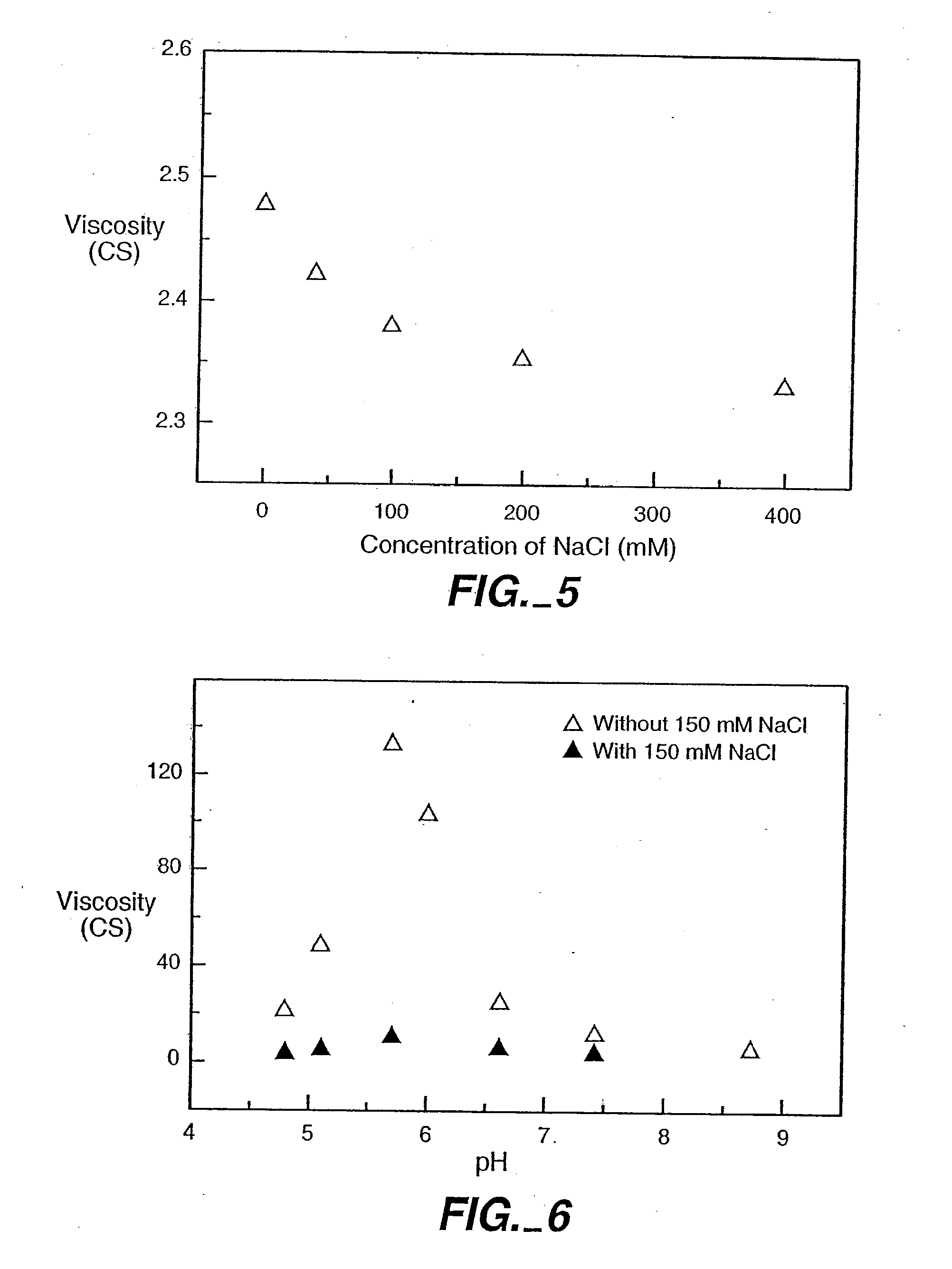

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

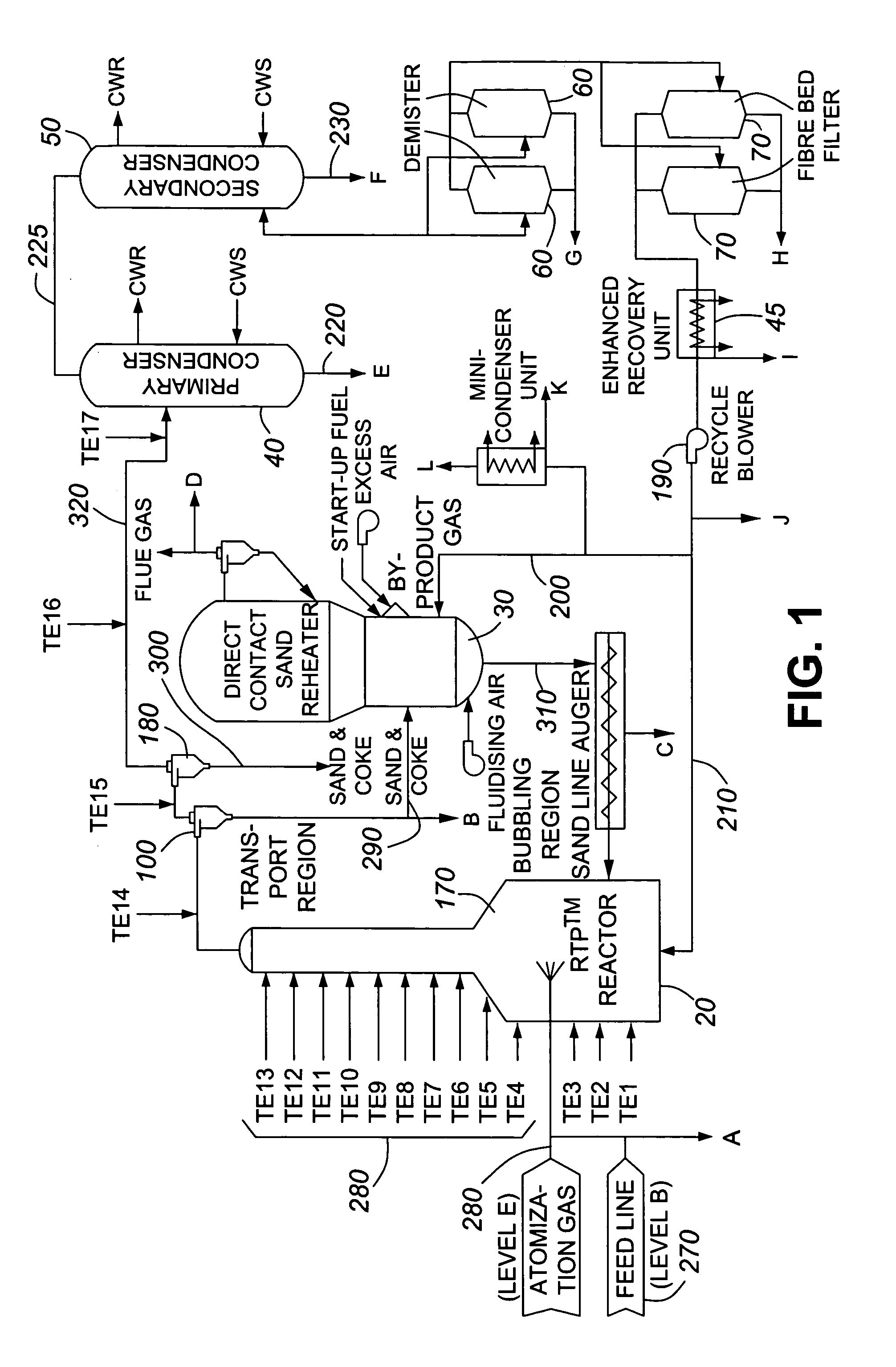

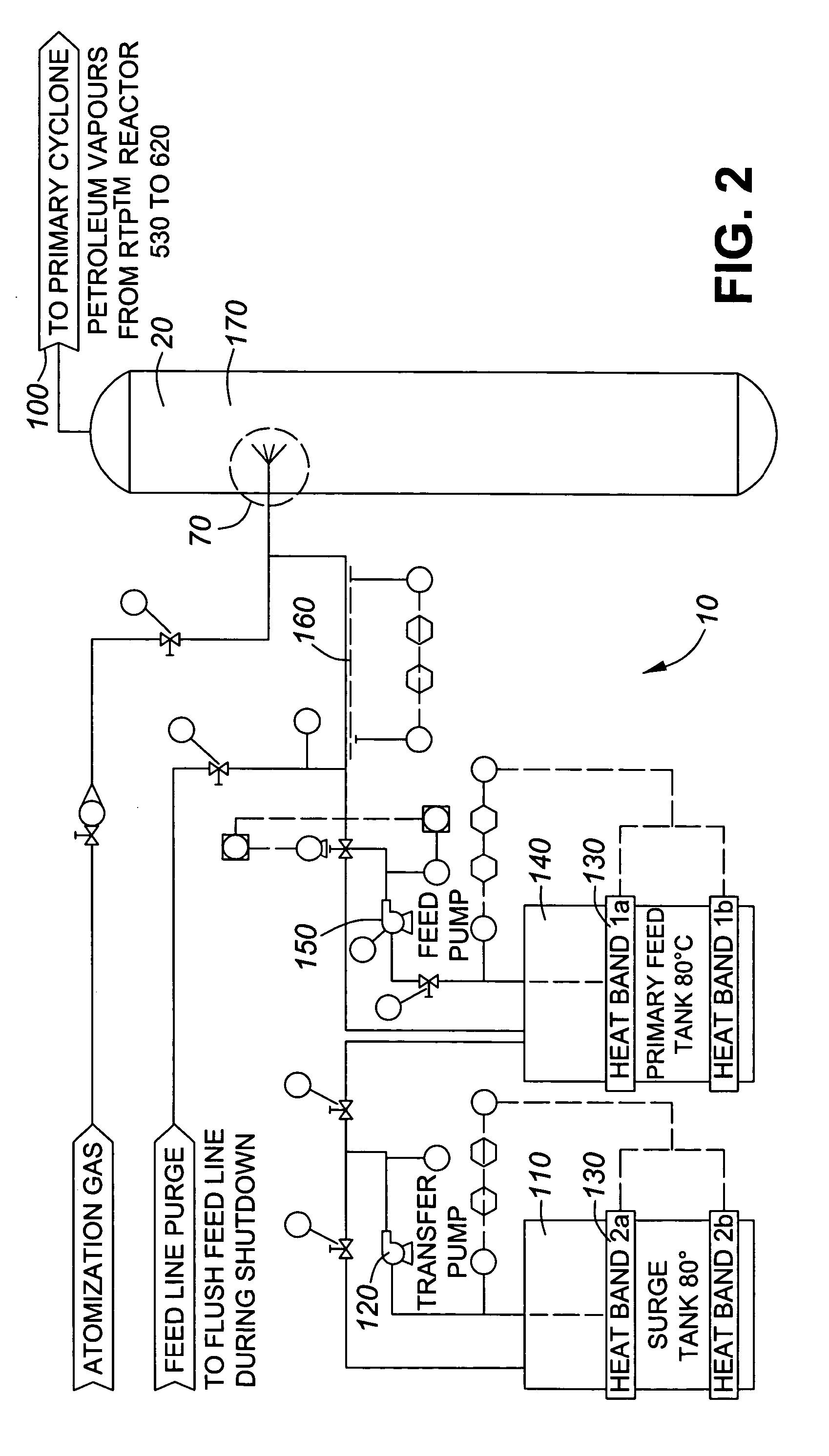

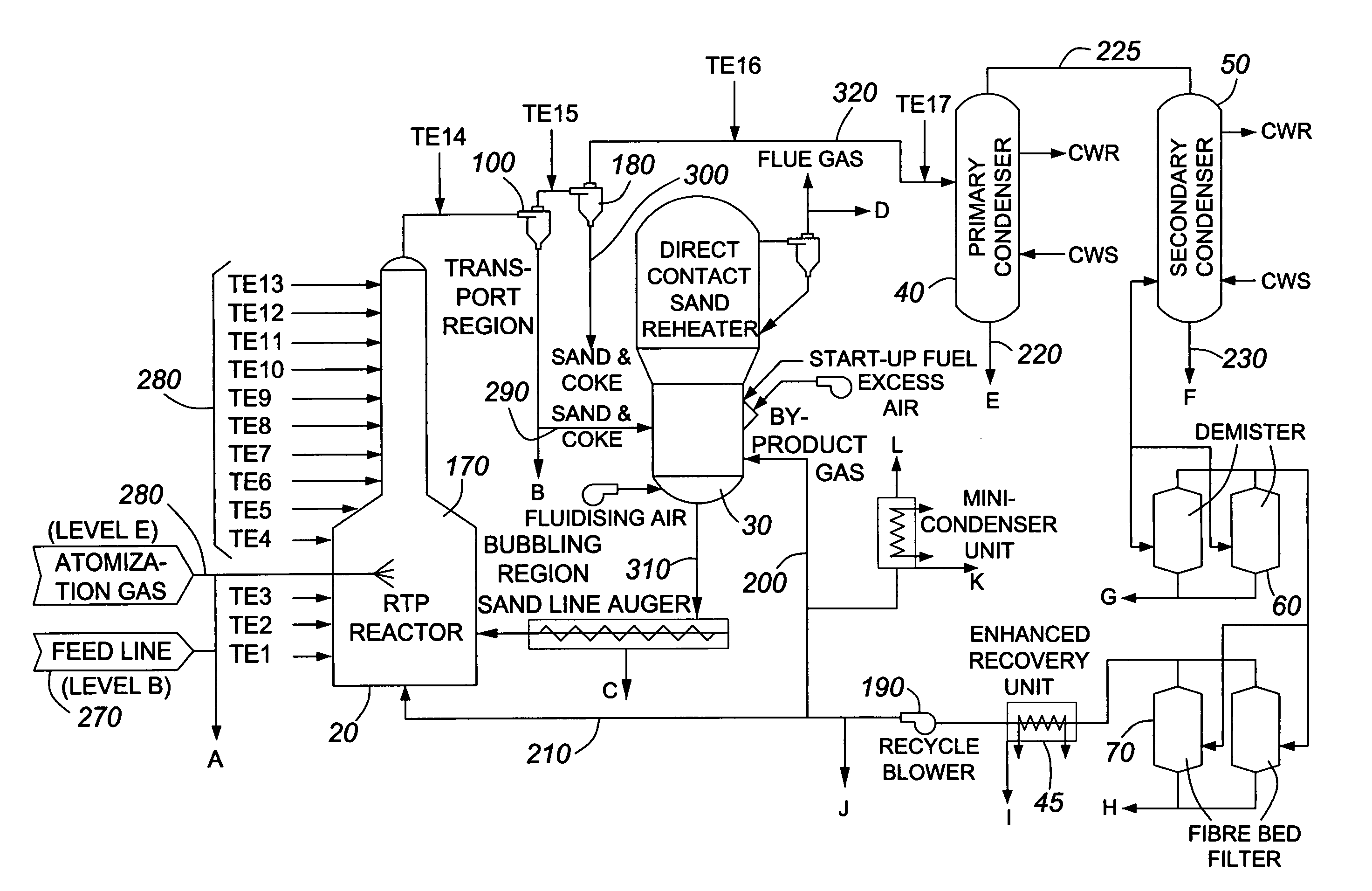

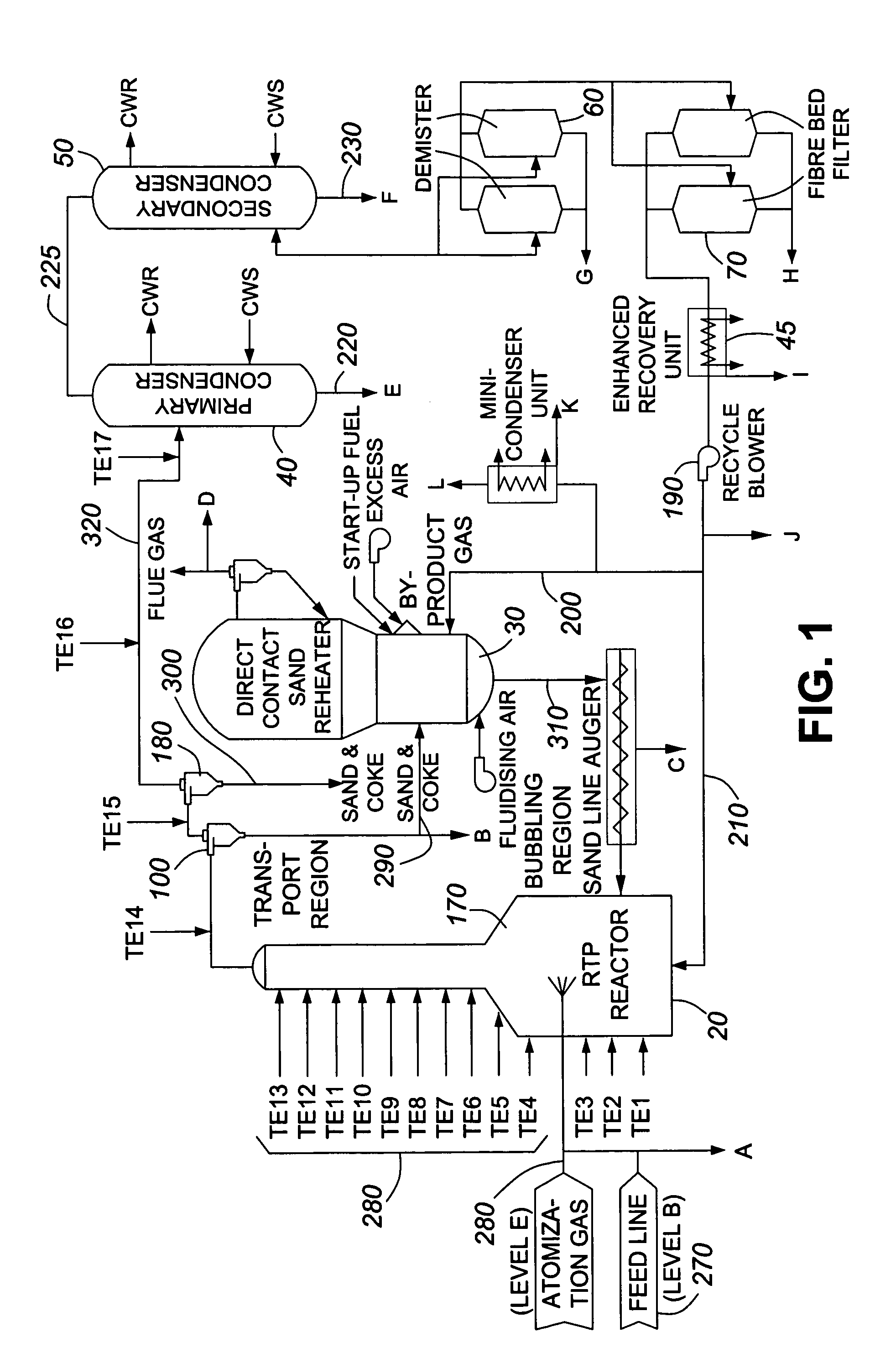

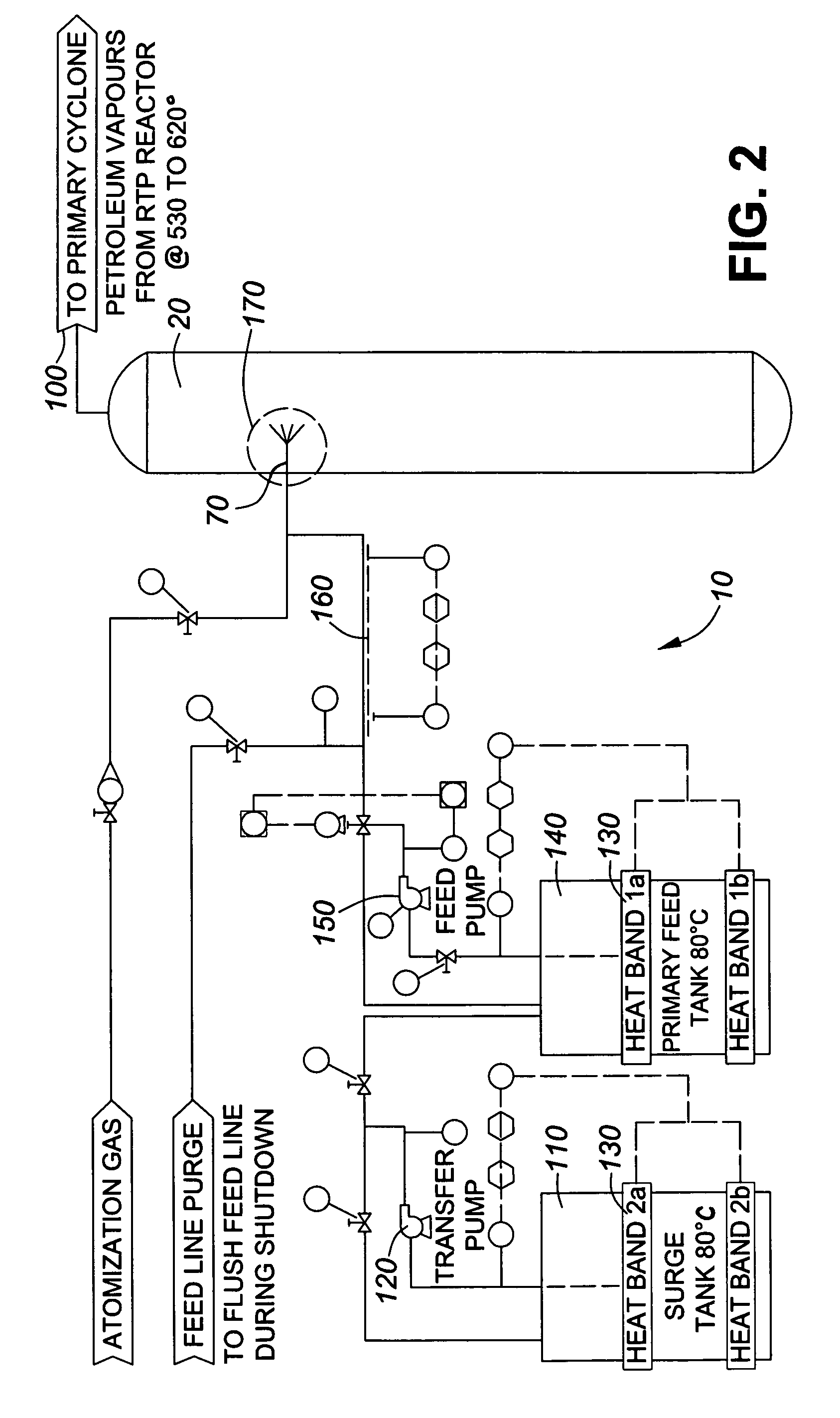

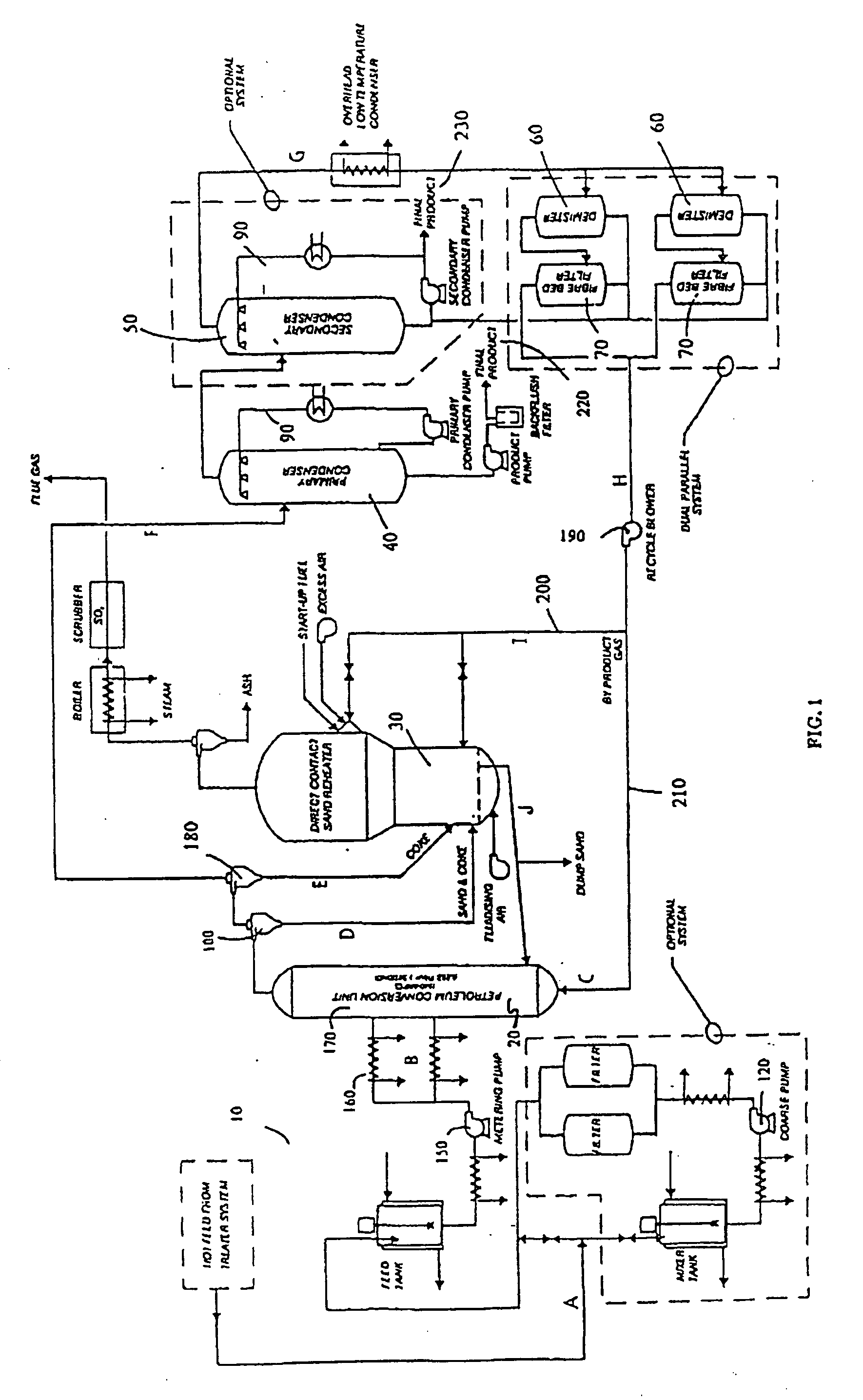

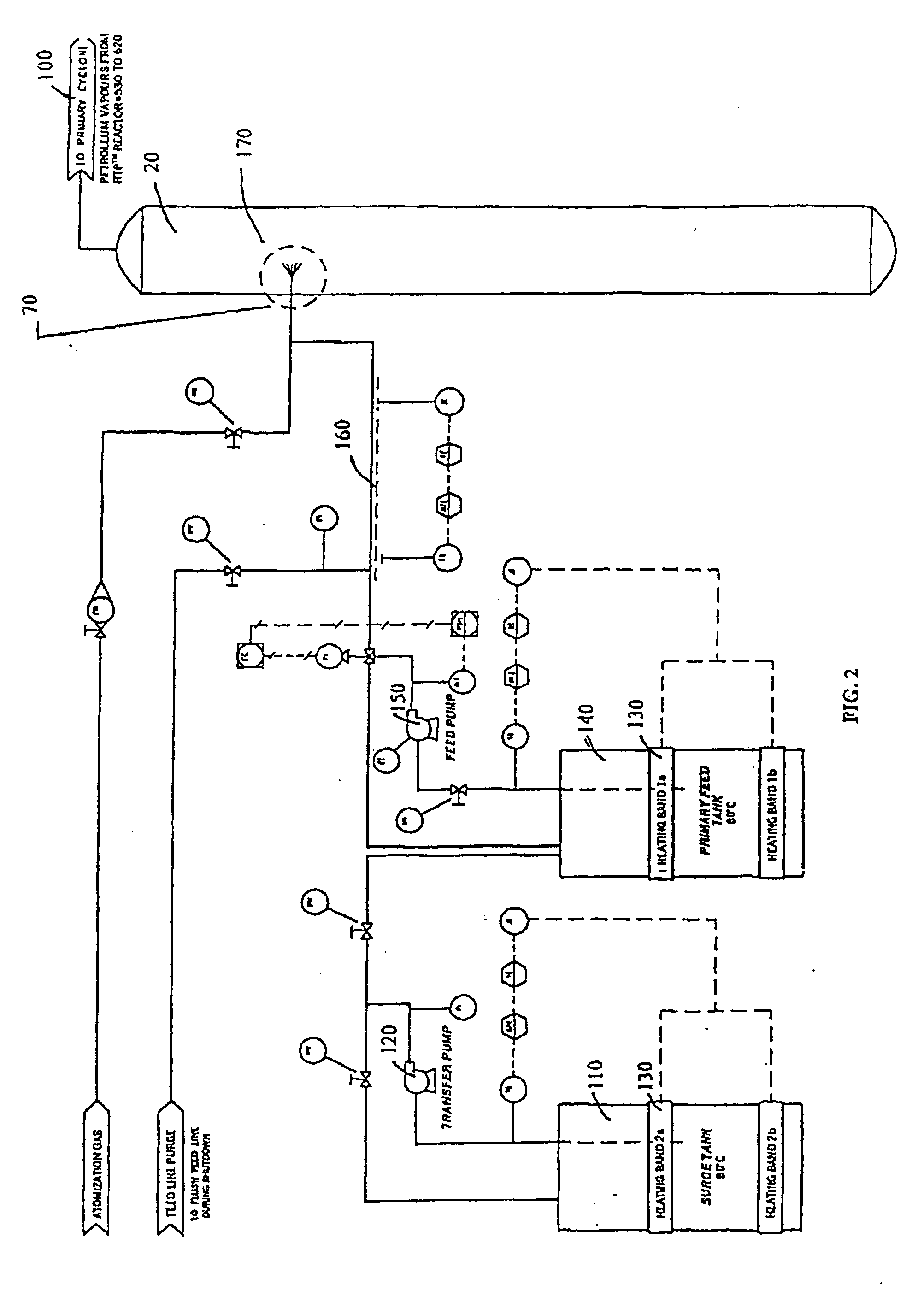

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572362B2Quick upgradeReducing H2S contentThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

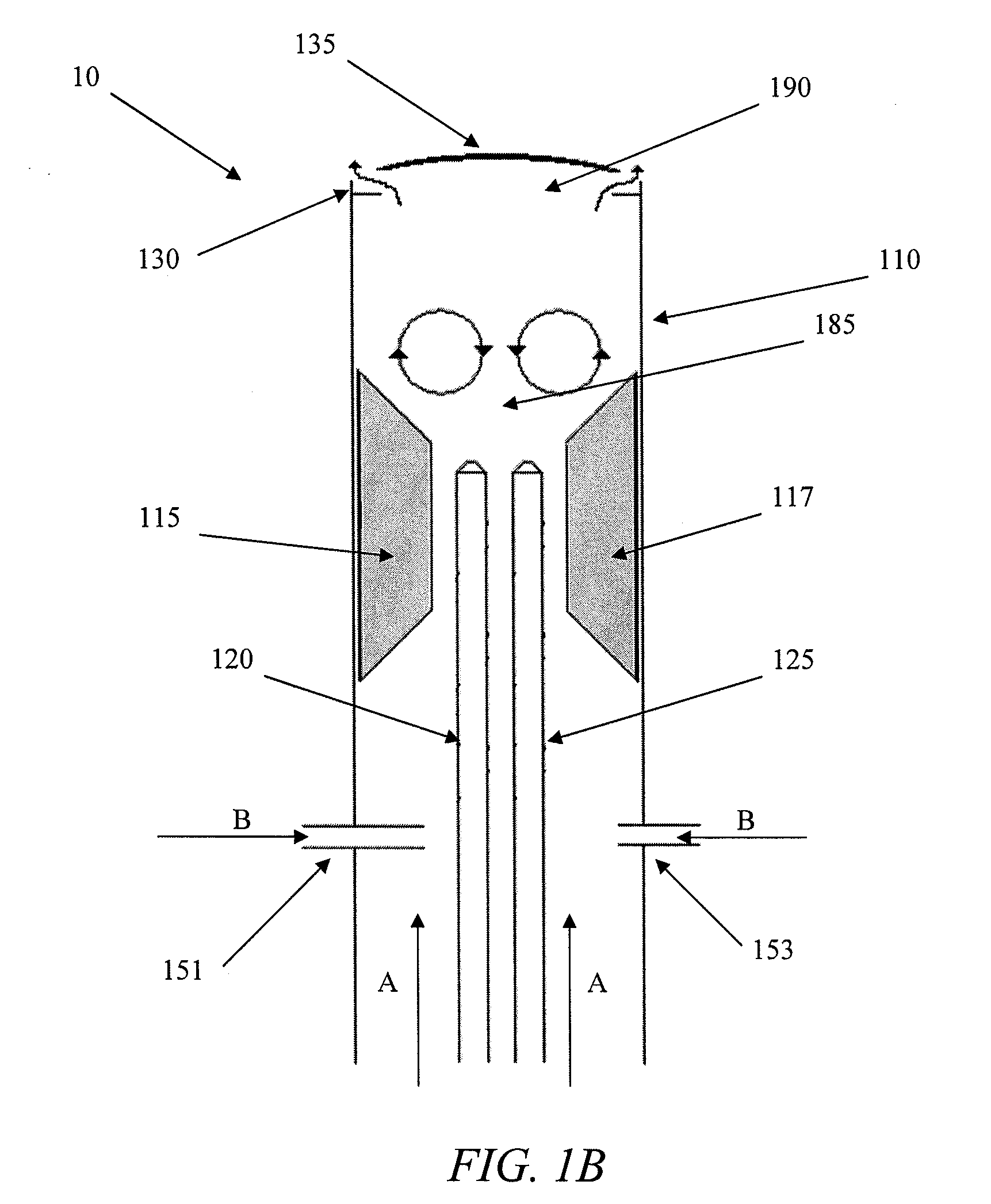

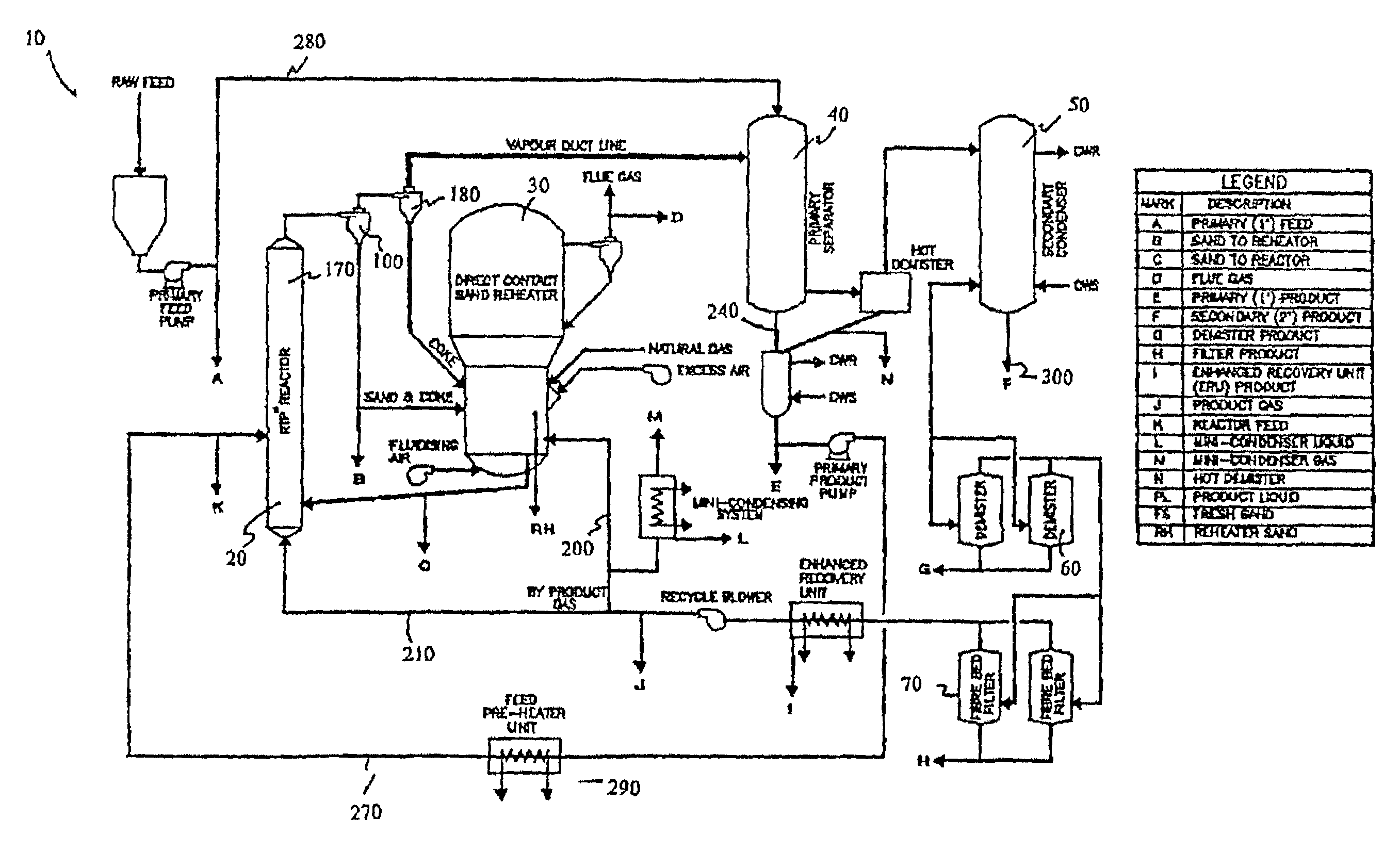

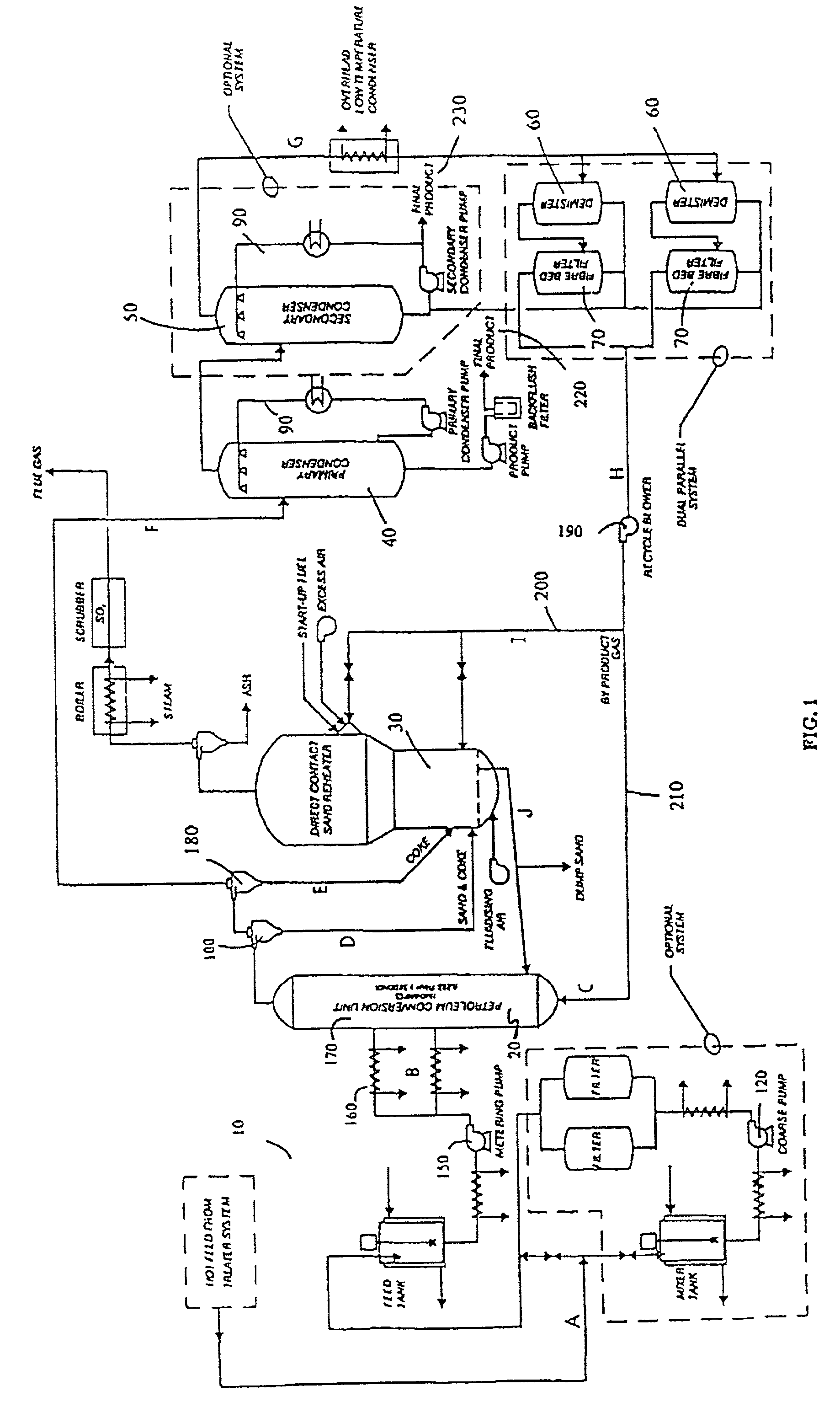

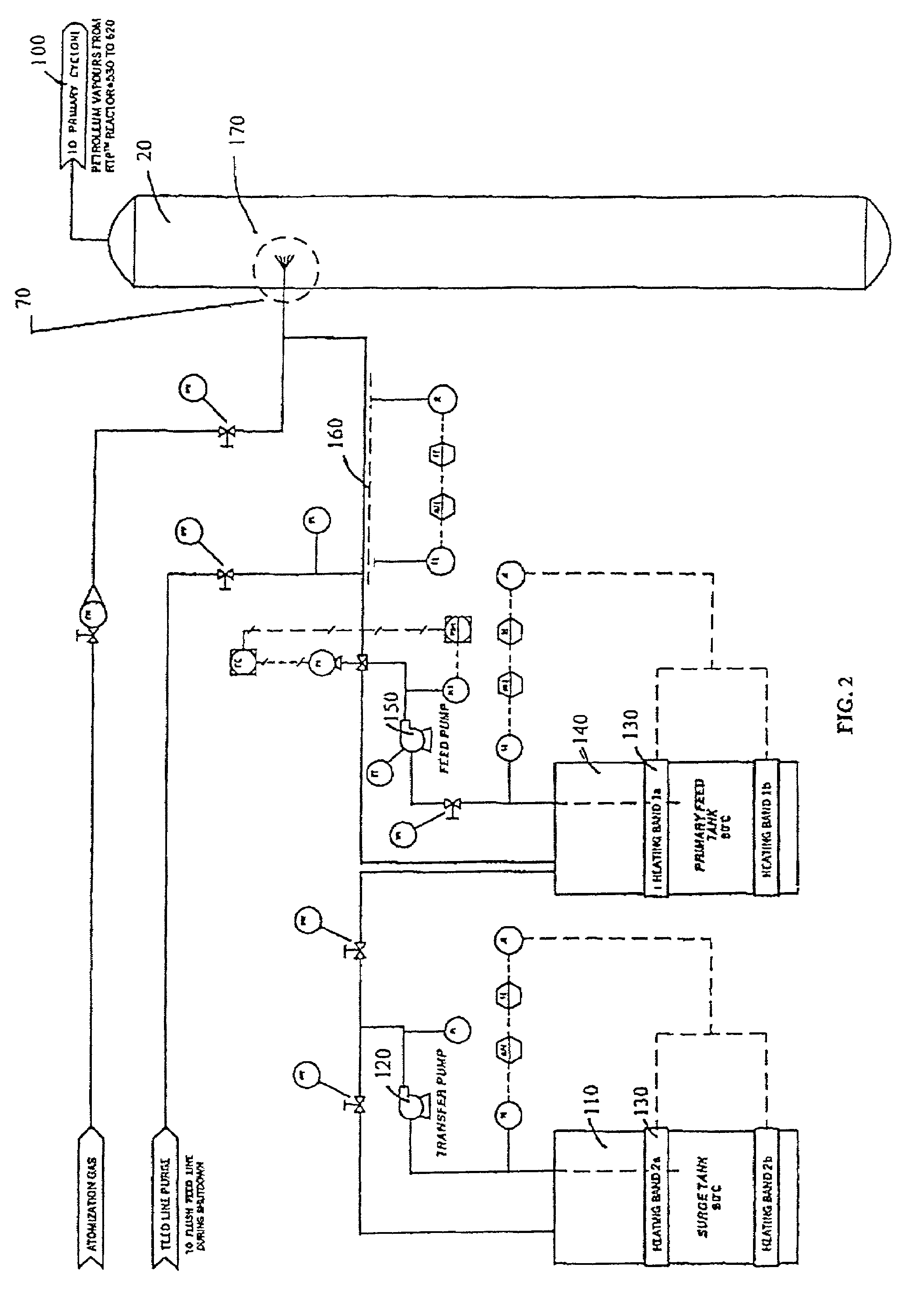

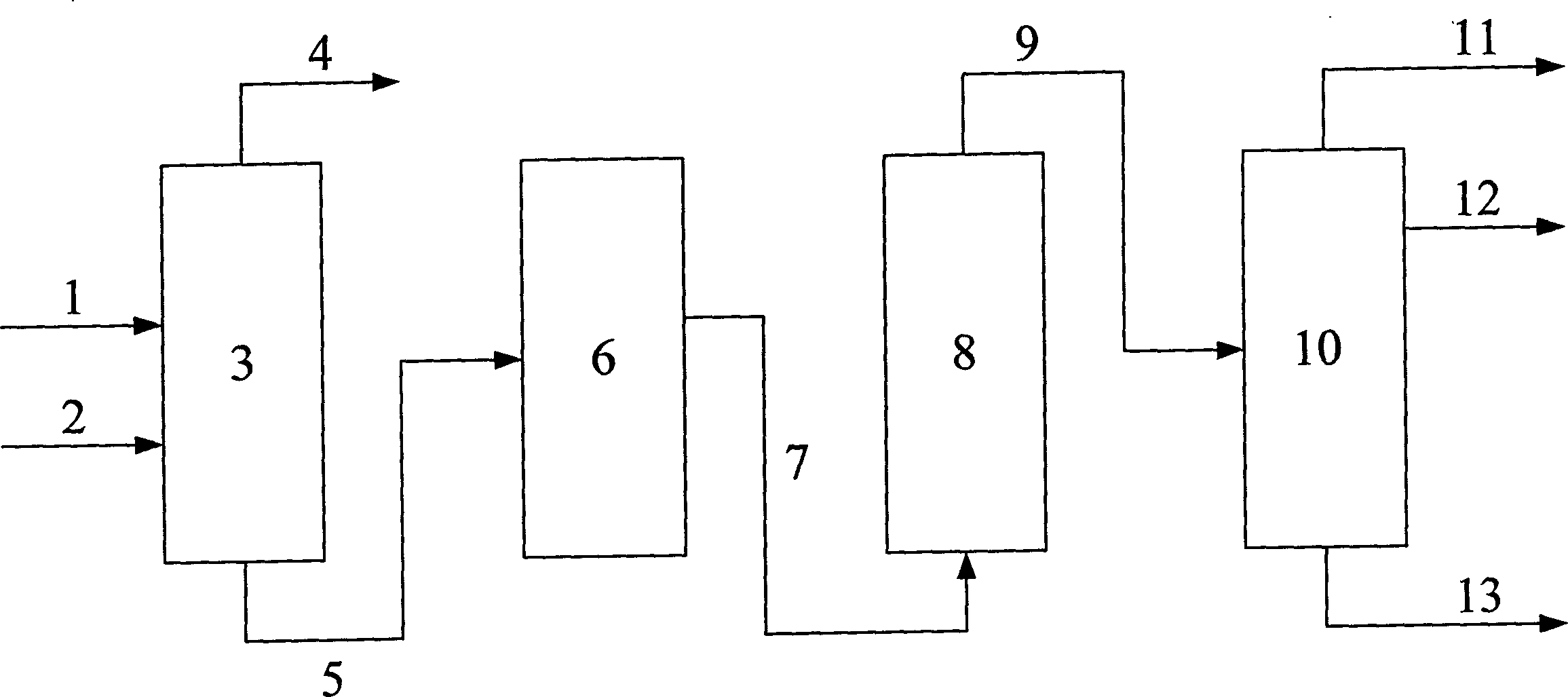

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas), to reducing the total acid number (TAN) of the liquid product, and to reducing the hydrogen sulfide content of one, or more than one component of the product stream. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

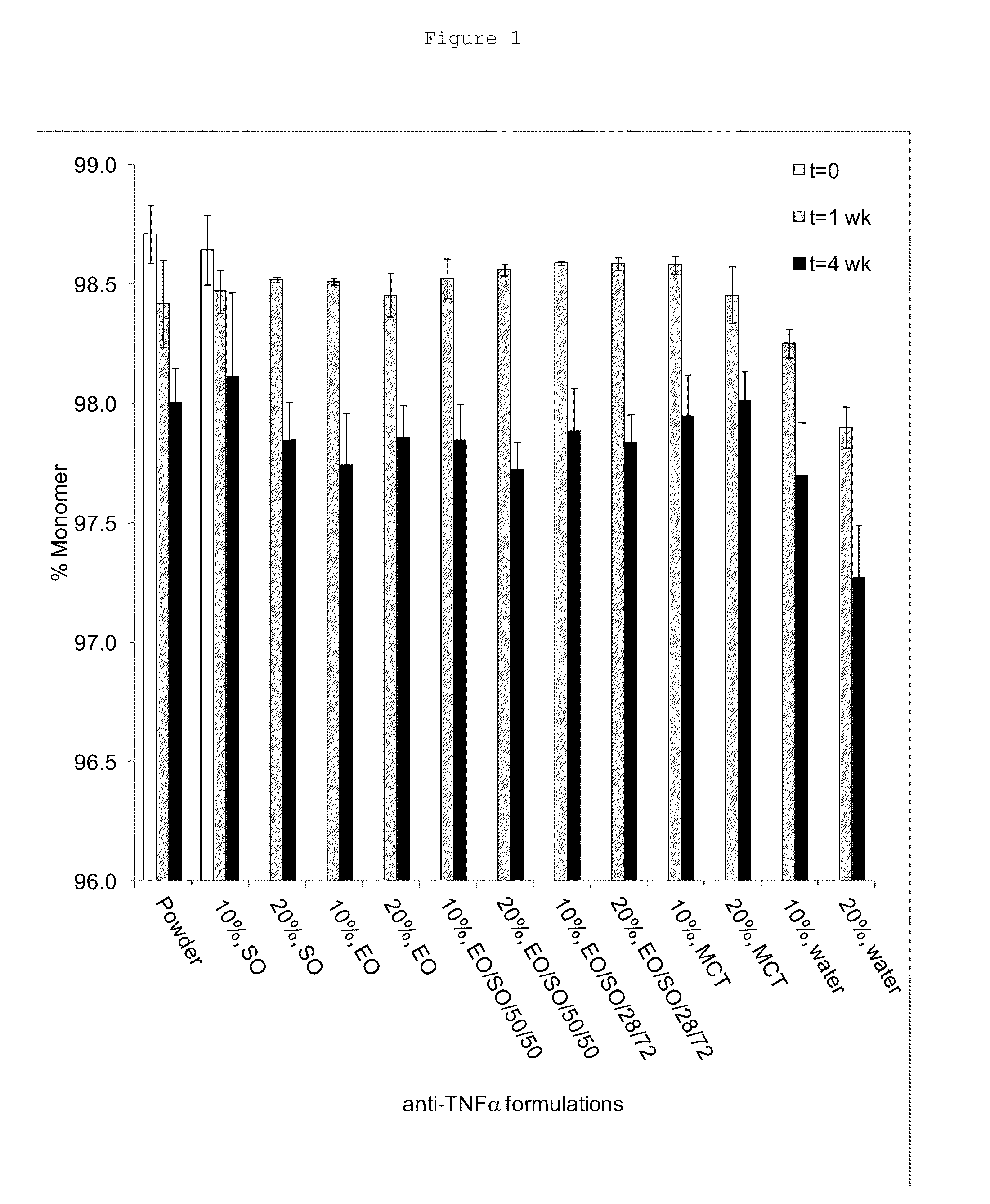

High concentration antibody and protein formulations

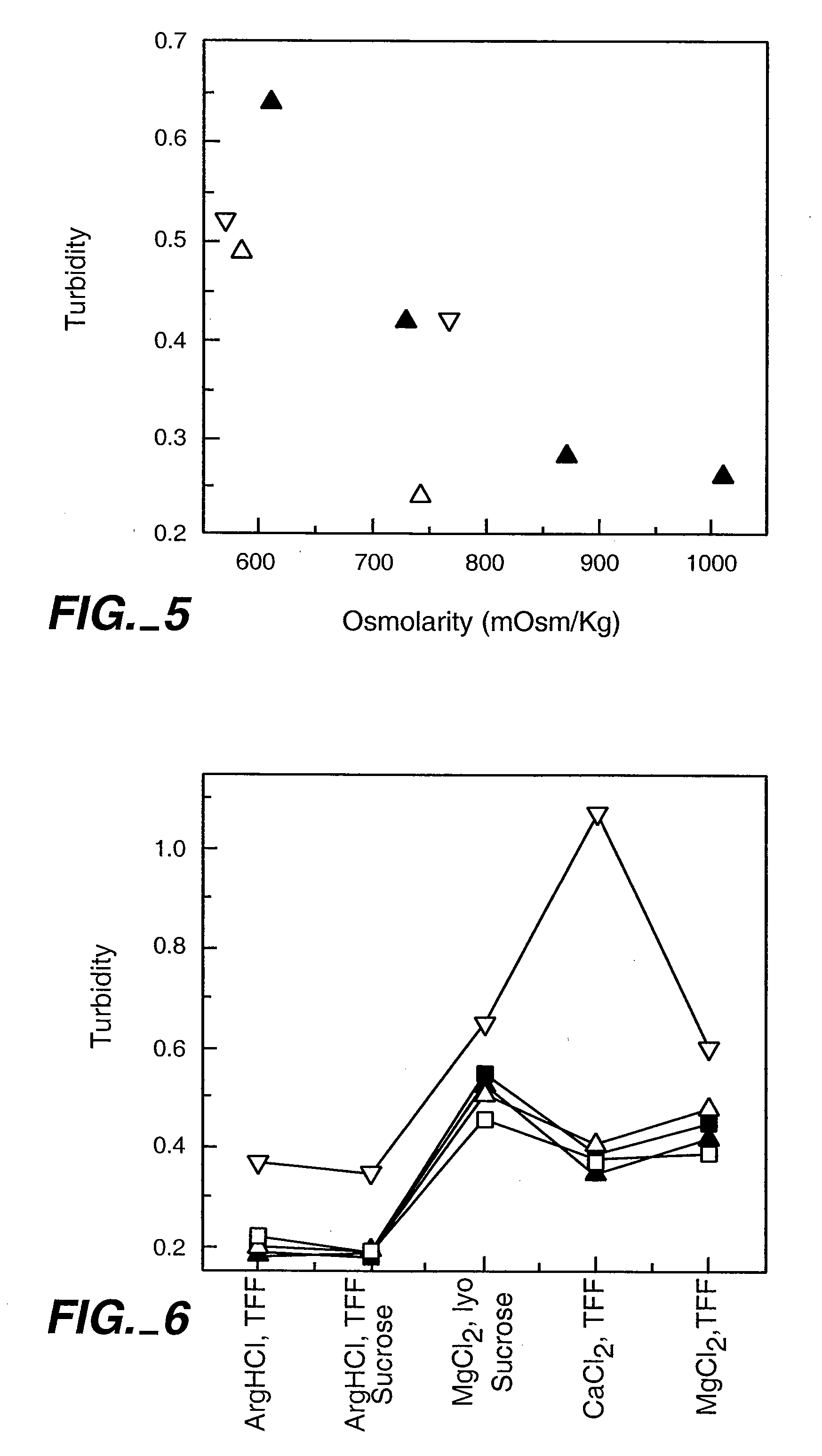

InactiveUS20070053900A1Speed up concentrationReduce turbidityAntipyreticAutomatic syringesDiseaseAntiendomysial antibodies

The present application relates to highly concentrated antibody and protein formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration. The application further describes articles of manufacture containing such formulations and method for using them to treat disorders treatable by the formulated antibody or protein.

Owner:GENENTECH INC

Reduced-viscosity concentrated protein formulations

InactiveUS20050175603A1Low viscosityCompromising stability and biological activityPeptide/protein ingredientsInorganic non-active ingredientsConcentration proteinChemistry

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

High concentration antibody and protein formulations

The present application relates to highly concentrated antibody and protein formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration. The application further describes articles of manufacture containing such formulations and method for using them to treat disorders treatable by the formulated antibody or protein.

Owner:GENENTECH INC +1

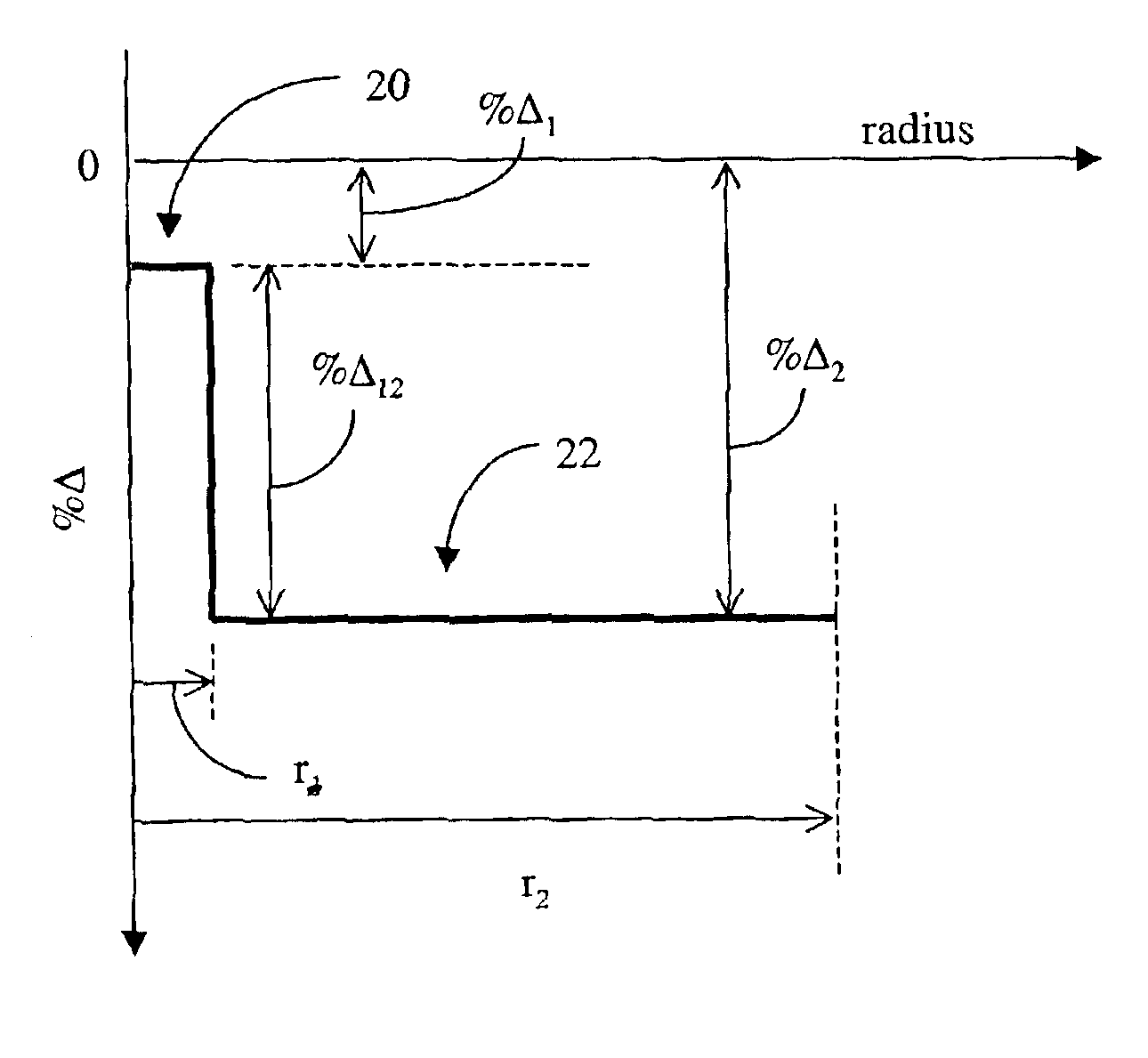

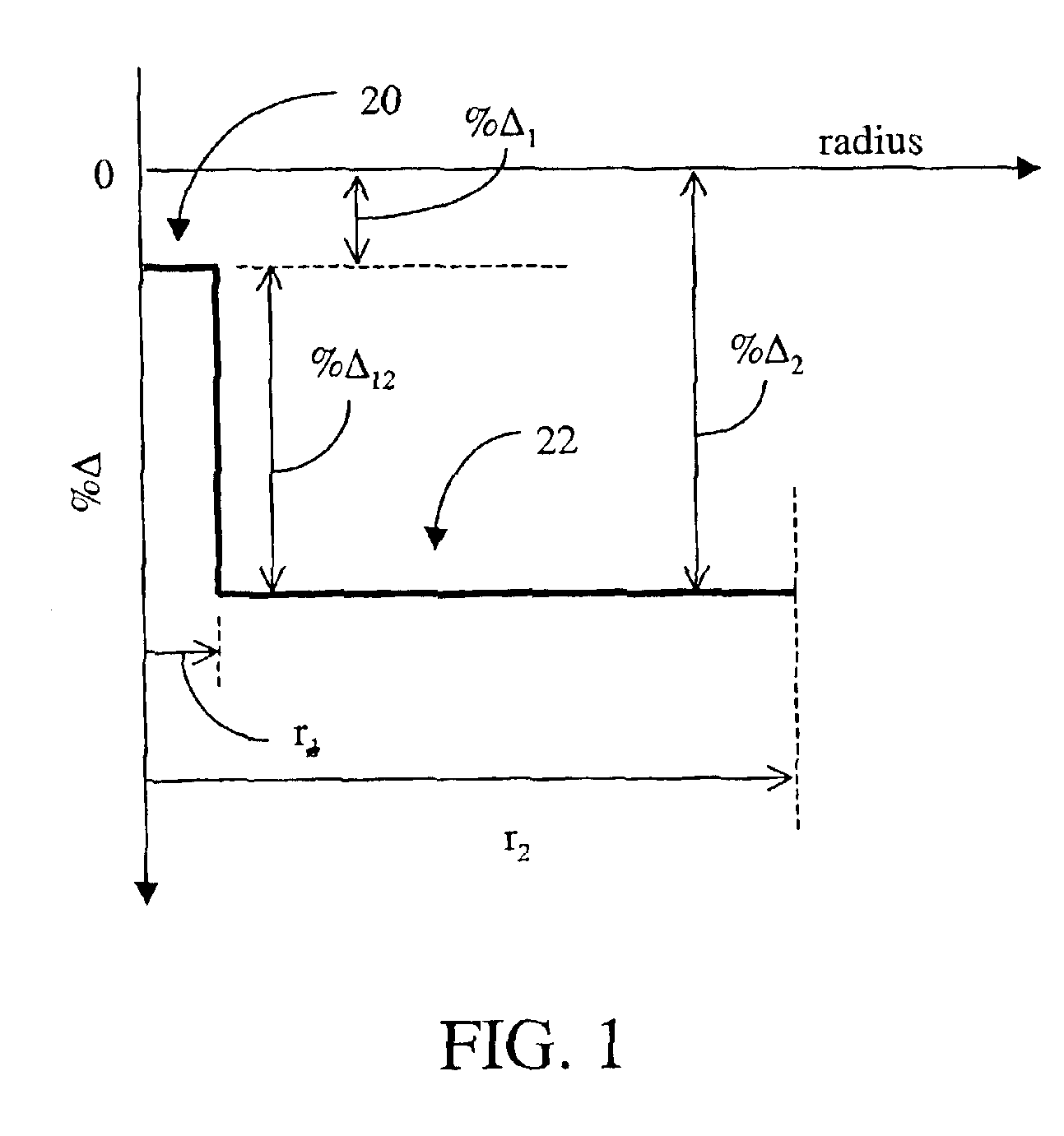

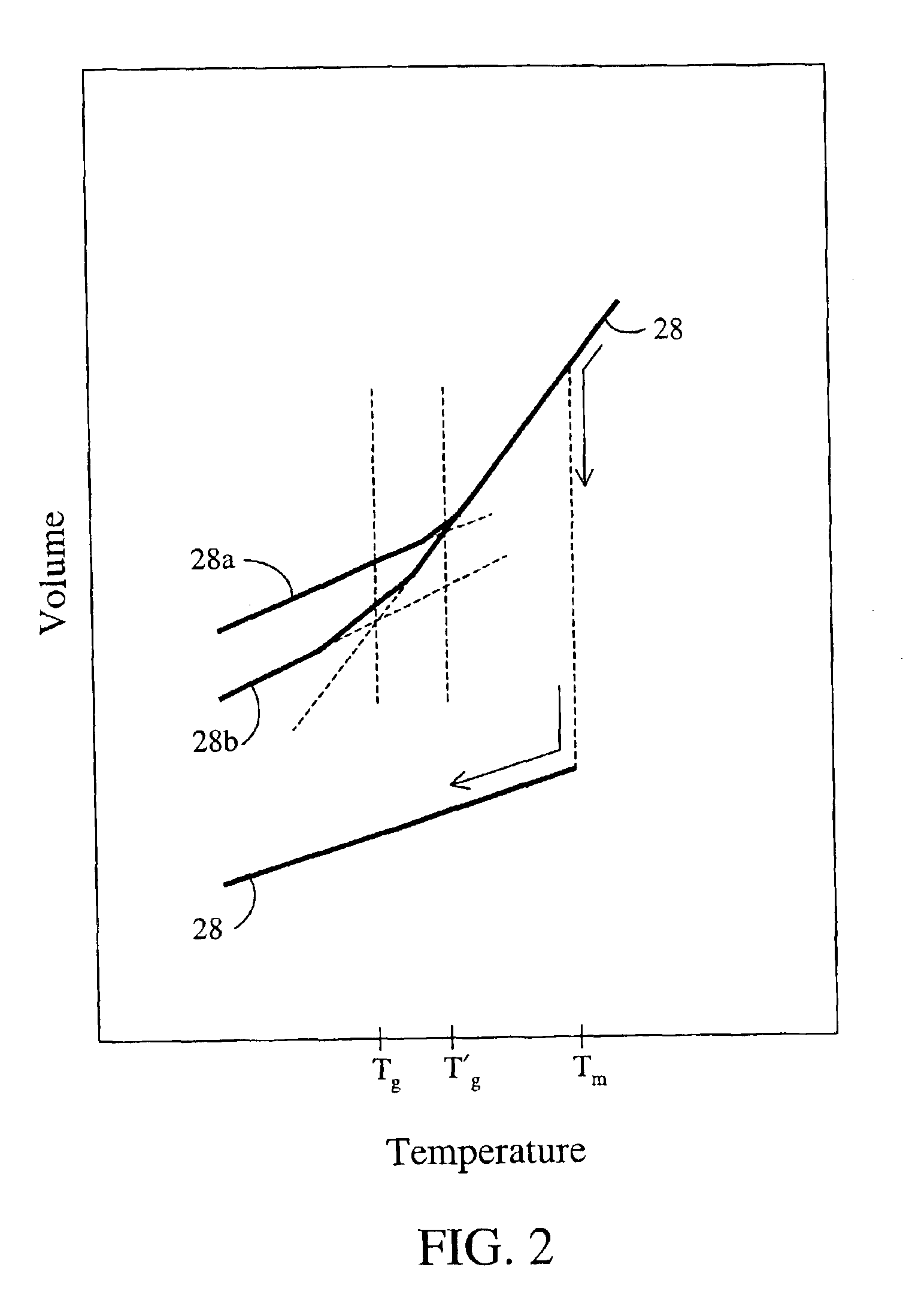

Optical fiber having reduced viscosity mismatch

InactiveUS6917740B2Glass making apparatusOptical fibre with multilayer core/claddingVitrificationRefractive index

An optical fiber is disclosed in which the core region of the optical fiber is doped with Cl and F in order to reduce the viscosity mismatch between the core region and the adjacent cladding region. In one embodiment of the invention, the optical fiber is a single-mode step index optical fiber having a core region doped with Cl and F in an amount effective to produce a difference in temperature between the glass transition temperature of the core region and the glass transition temperature of the adjacent cladding region of less than about 200° C.

Owner:CORNING INC

Acidic, protein-containing drinks with improved sensory and functional characteristics

InactiveUS20070014909A1Enhance sensoryImproved functional characteristicHydrolasesFood preparationOrganolepticPlant protein

Processes for producing acidic, protein-containing drinks are disclosed. Specifically, the processes comprise producing acidic, protein-containing drinks comprising plant protein material. The acidic, protein-containing drinks have improved sensory and functional characteristics such as reduced viscosity, improved sedimentation rate, and improved mouthfeel.

Owner:MAI JIMBIN +8

Modified thermal processing of heavy hydrocarbon feedstocks

InactiveUS7572365B2Quick upgradeReduce sulfur emissionsThermal non-catalytic crackingTreatment with plural serial cracking stages onlyLiquid productParticulates

The present invention is directed to the upgrading of heavy petroleum oils of high viscosity and low API gravity that are typically not suitable for pipelining without the use of diluents. It utilizes a short residence-time pyrolytic reactor operating under conditions that result in a rapid pyrolytic distillation with coke formation. Both physical and chemical changes taking place lead to an overall molecular weight reduction in the liquid product and rejection of certain components with the byproduct coke. The liquid product is upgraded primarily because of its substantially reduced viscosity, increased API gravity, and the content of middle and light distillate fractions. While maximizing the overall liquid yield, the improvements in viscosity and API gravity can render the liquid product suitable for pipelining without the use of diluents. This invention particularly relates to reducing sulfur emissions during the combustion of byproduct coke (or coke and gas) and to reducing the total acid number (TAN) of the liquid product. The method comprises introducing a particulate heat carrier into an up-flow reactor, introducing the feedstock at a location above the entry of the particulate heat carrier, allowing the heavy hydrocarbon feedstock to interact with the heat carrier for a short time, separating the vapors of the product stream from the particulate heat carrier and liquid and byproduct solid matter, regenerating the particulate heat carrier in the presence of the calcium compound, and collecting a gaseous and liquid product from the product stream.

Owner:IVANHOE HTL GASOLINEEUM

Positive photosensitive polyimide resin composition

InactiveUS6875554B2Low viscosityDiazo compound compositionsPhotosensitive materials for photomechanical apparatusOrganic groupPolyamic acid

A positive photosensitive polyimide resin composition comprising:(a) a solvent-soluble polyimide comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one solvent solubilizing functional group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g,(b) a photosensitive orthoquinonediazide compound, and(c) from 0.1 to 50 wt %, based on the total weight of all polymers of the composition, of a component (c1) or (c2), wherein:component (c1) is a solvent-soluble polyimide comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one functional group selected from the group consisting of a long chain alkyl group having at least 6 carbon atoms and a fluorinated alkyl group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g, andcomponent (c2) is a polyamic acid comprised of from 1 to 100 mol % of a bivalent organic group derived from a diamine, that has at least one functional group selected from the group consisting of a long chain alkyl group having at least 6 carbon atoms and a fluorinated alkyl group, the polyimide having a reduced viscosity ranging from 0.05 to 5.0 dl / g.

Owner:NISSAN CHEM IND LTD

Methods of treating IgE-mediated disorders comprising the administration of high concentration anti-IgE antibody formulations

The present application relates to methods of treating IgE-mediated disorders comprising the administration of highly concentrated anti-IgE antibody formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration.

Owner:GENENTECH INC

Reduced-viscosity concentrated protein formulations

InactiveUS8703126B2Low viscosityCompromising stability and biological activityInorganic non-active ingredientsAntibody ingredientsConcentration proteinReduced viscosity

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

Process for combustion of high viscosity low heating value liquid fuels

ActiveUS20080305445A1Easy to cleanHigh viscosityBurnersSpace heating and ventilationCombustion chamberGlycerol

The present invention is directed to a process for the clean and convenient combustion of high viscosity liquid fuels, such as glycerol, as well as an apparatus useful for carrying such processes. In certain embodiments, the invention provides a process for glycerol combustion comprising providing a combustion apparatus with a glycerol combustion chamber that facilitates reflective heating, pre-heating the glycerol combustion chamber, atomizing the reduced viscosity glycerol, and combining the atomized glycerol with air in the glycerol combustion chamber to thereby completely combust the glycerol. In one embodiment, such as when using a pressure-atomizing nozzle, the inventive method may further comprise treating the glycerol to reduce the glycerol viscosity.

Owner:NORTH CAROLINA STATE UNIV

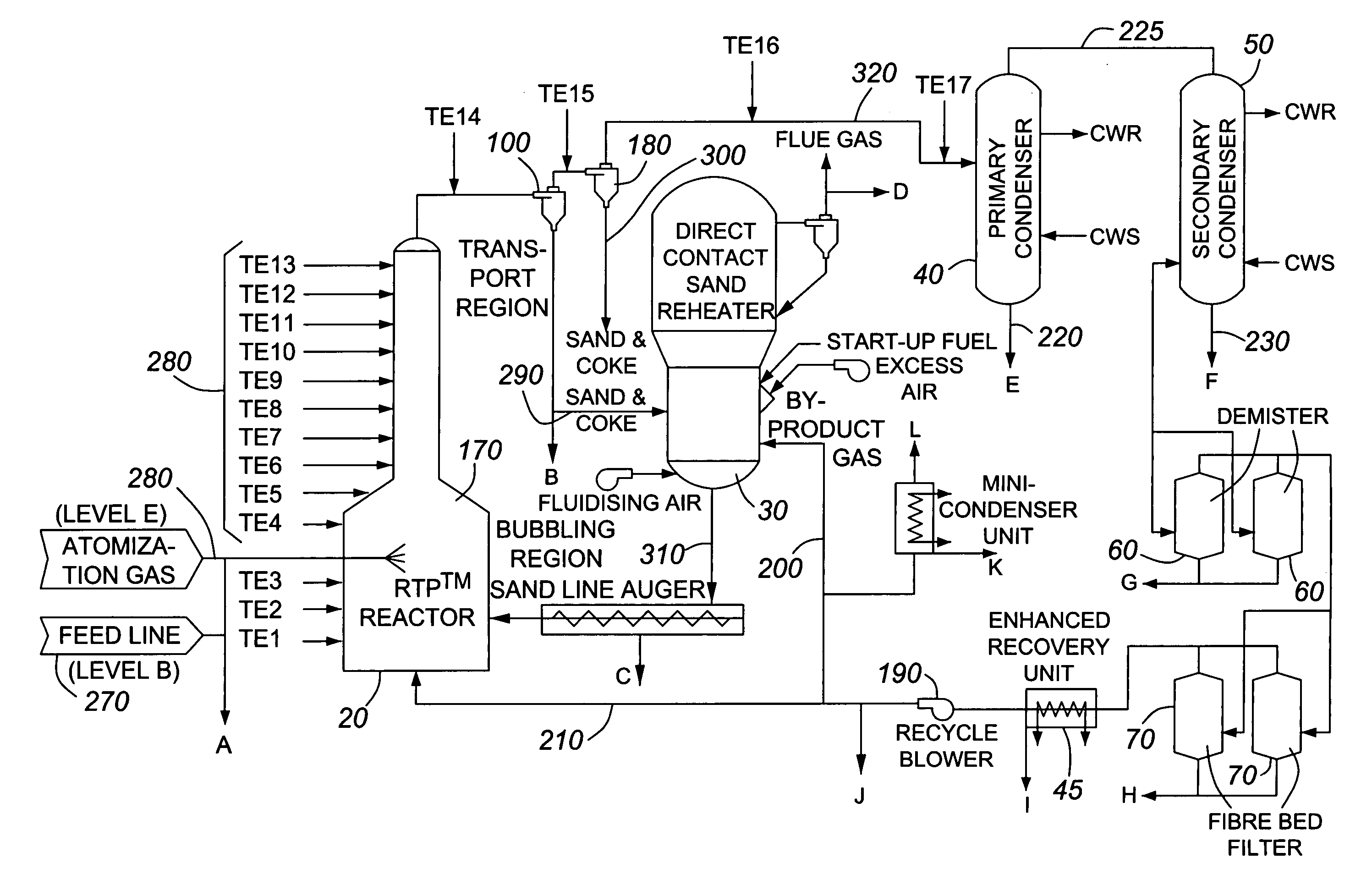

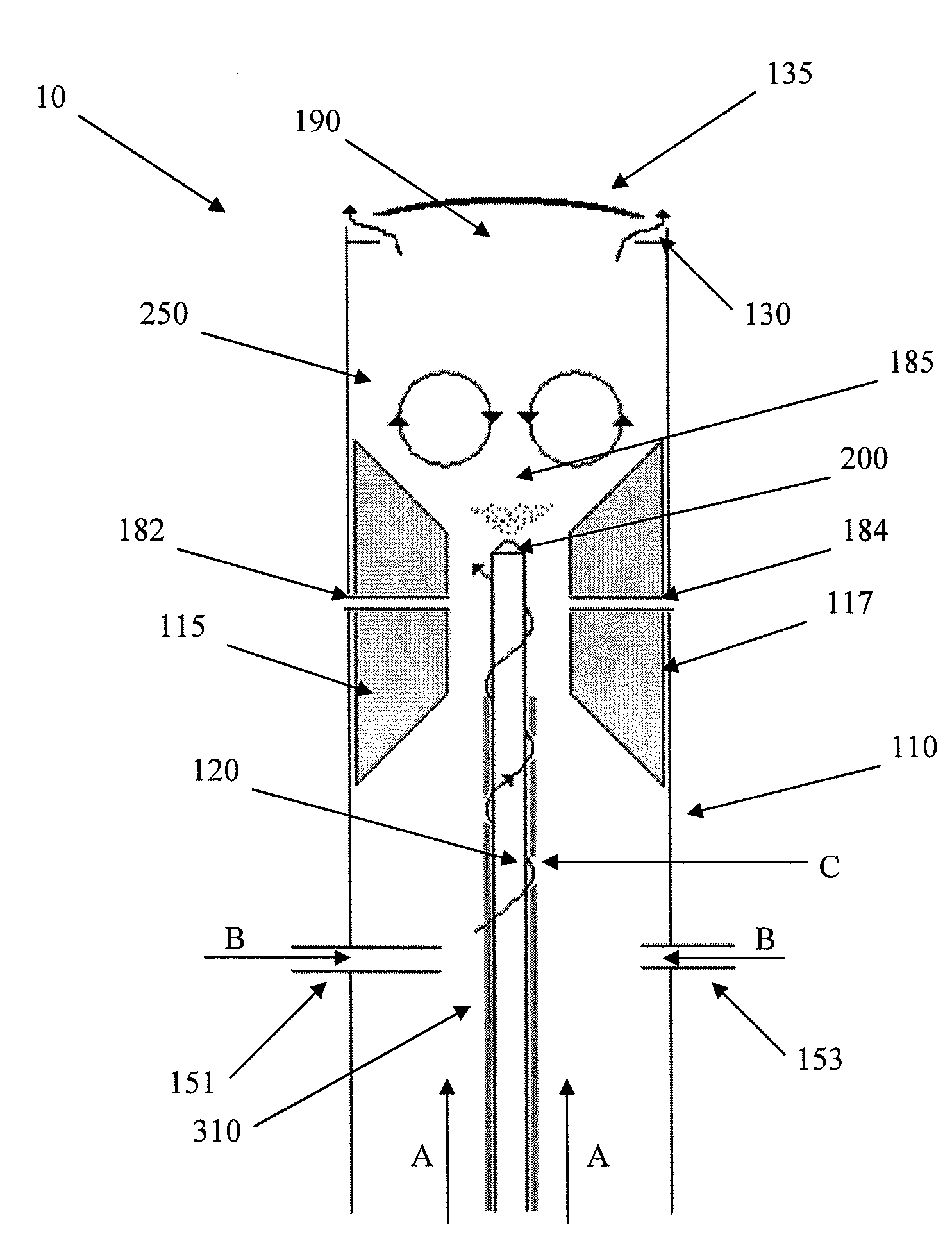

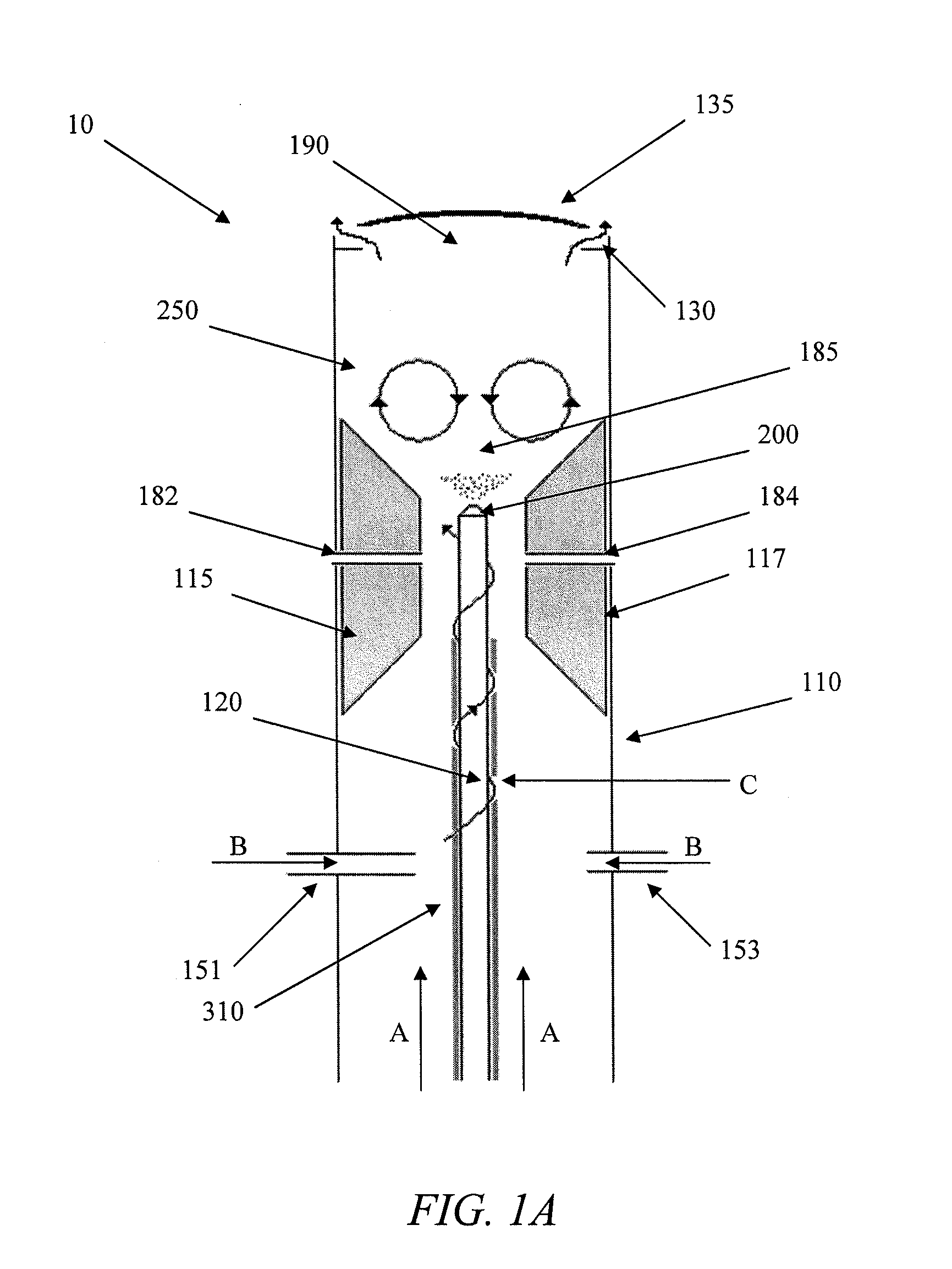

Products produced form rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS7270743B2Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

Reduced-viscosity concentrated protein formulations

InactiveUS20120076783A1Preventing self-associationLow viscosityInorganic non-active ingredientsAntibody ingredientsChemistryReduced viscosity

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

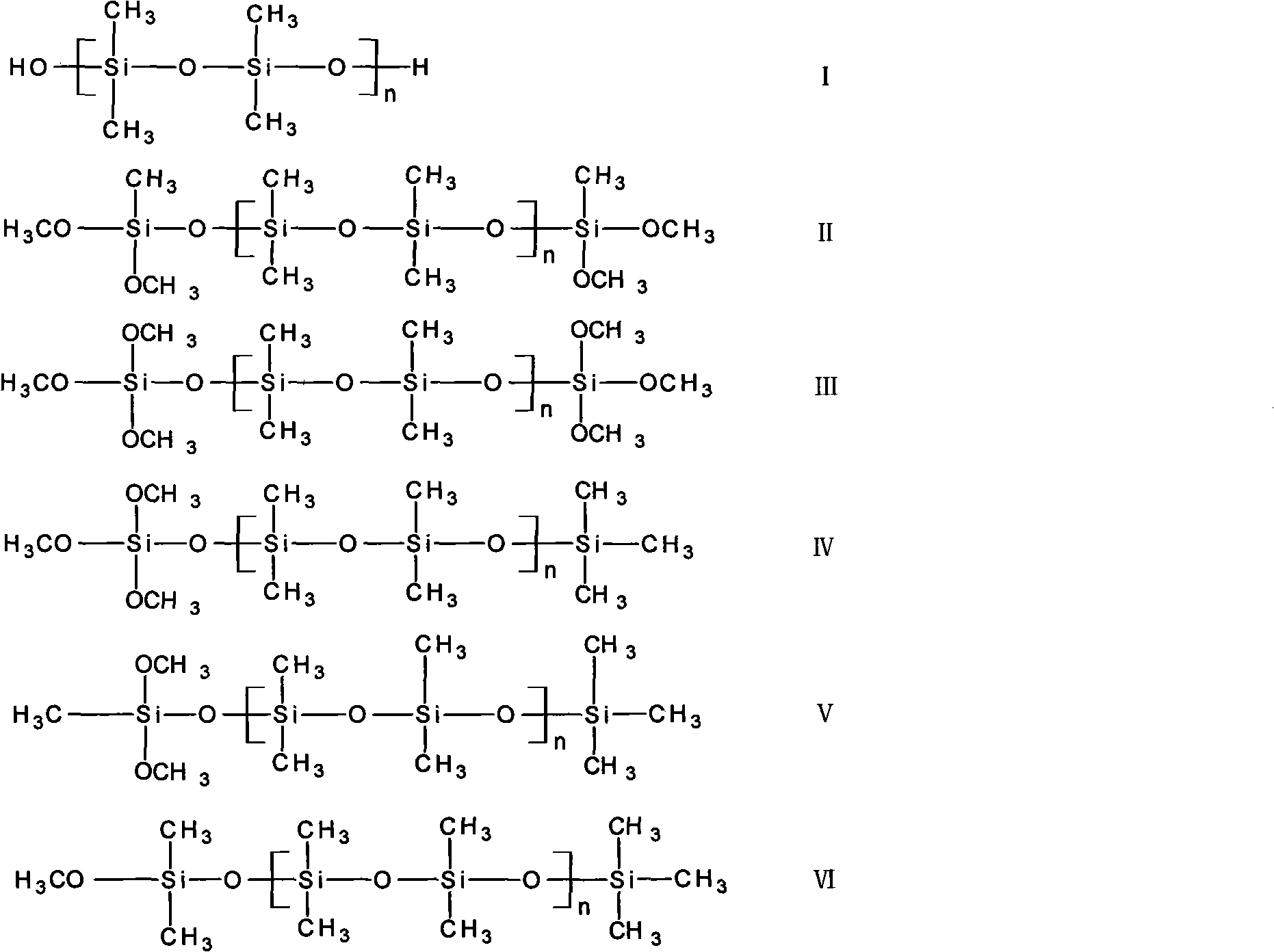

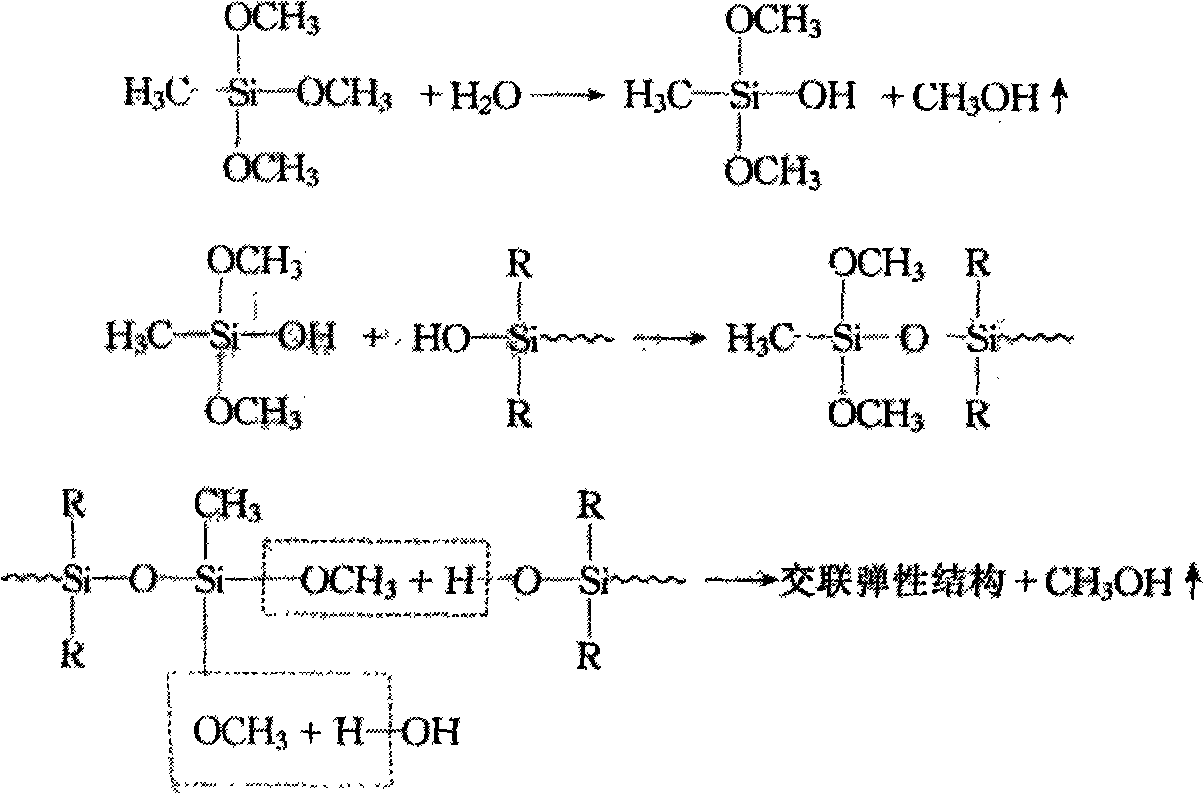

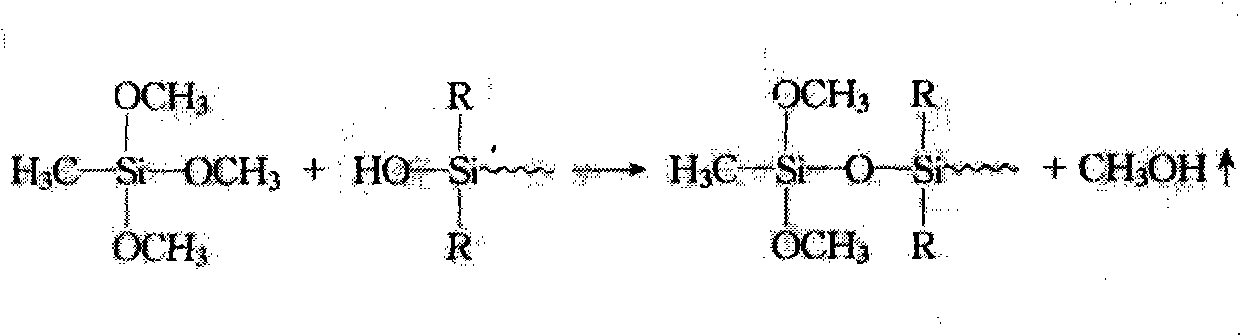

Neutral silicone weather resistant glue formula and technique for preparing the same

The invention relates to a weather resistant glue, especially a neutral silicone weather resistant glue formula and a technique for preparing the same. The formula includes the following components: basic polymer, plasticizer, stuffing, cross linker, anchoring agent and catalyst, which are prepared as follow: basic polymer: 10-100 parts; plasticizer 1-50 parts; stuffing 1-150 parts; cross linker 0.5-10 parts; anchoring agent 0.5-10 parts; catalyst 0.001-15 parts. The neutral silicone weather resistant glue produced by the invention has the advantages of pollution-free, improved product storage time, adjusted modulus, reduced viscosity peak, easy production without tin catalyst or the like.

Owner:深圳市百丽春粘胶实业有限公司

Methods and compositions for treating subterranean zones using environmentally safe polymer breakers

Methods and compositions for treating subterranean zones penetrated by well bores utilizing environmentally safe viscous fluids including a solubility increasing boron complex or ester forming compound. A method of the invention comprises the following steps. A viscous treating fluid composition is provided comprising water, a viscosity increasing polymer and a water soluble delayed polymer breaker that comprises a mixture of sodium perborate tetrahydrate and a solubility increasing boron complex or ester forming compound. The viscous treating fluid composition is introduced into the subterranean zone wherein the viscous treating fluid is allowed to break into a thin fluid of reduced viscosity.

Owner:HALLIBURTON ENERGY SERVICES INC

METHODS OF TREATING IgE-MEDIATED DISORDERS COMPRISING THE ADMINISTRATION OF HIGH CONCENTRATION ANTI-IgE ANTIBODY FORMULATIONS

The present application relates to methods of treating IgE-mediated disorders comprising the administration of highly concentrated anti-IgE antibody formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration.

Owner:GENENTECH INC +1

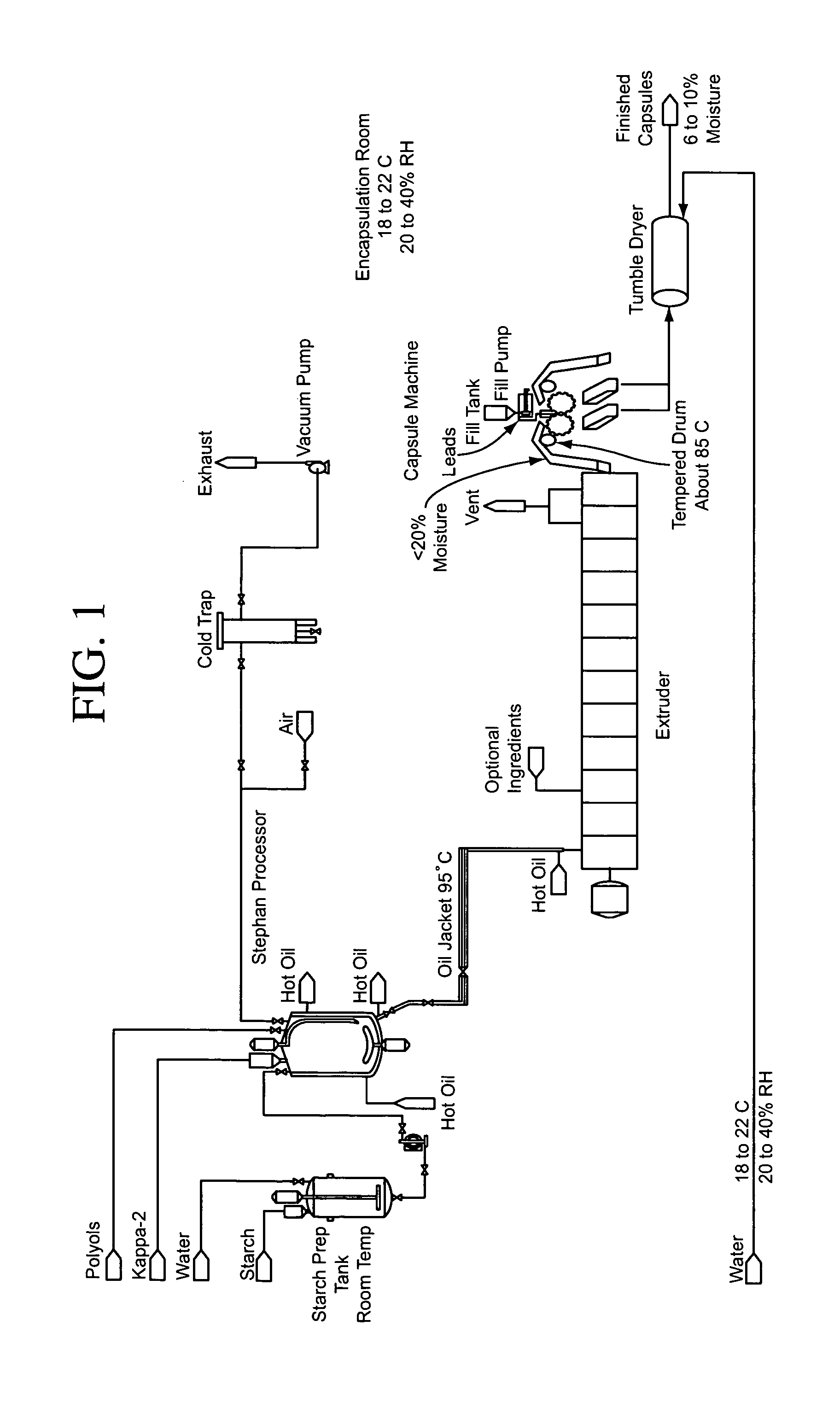

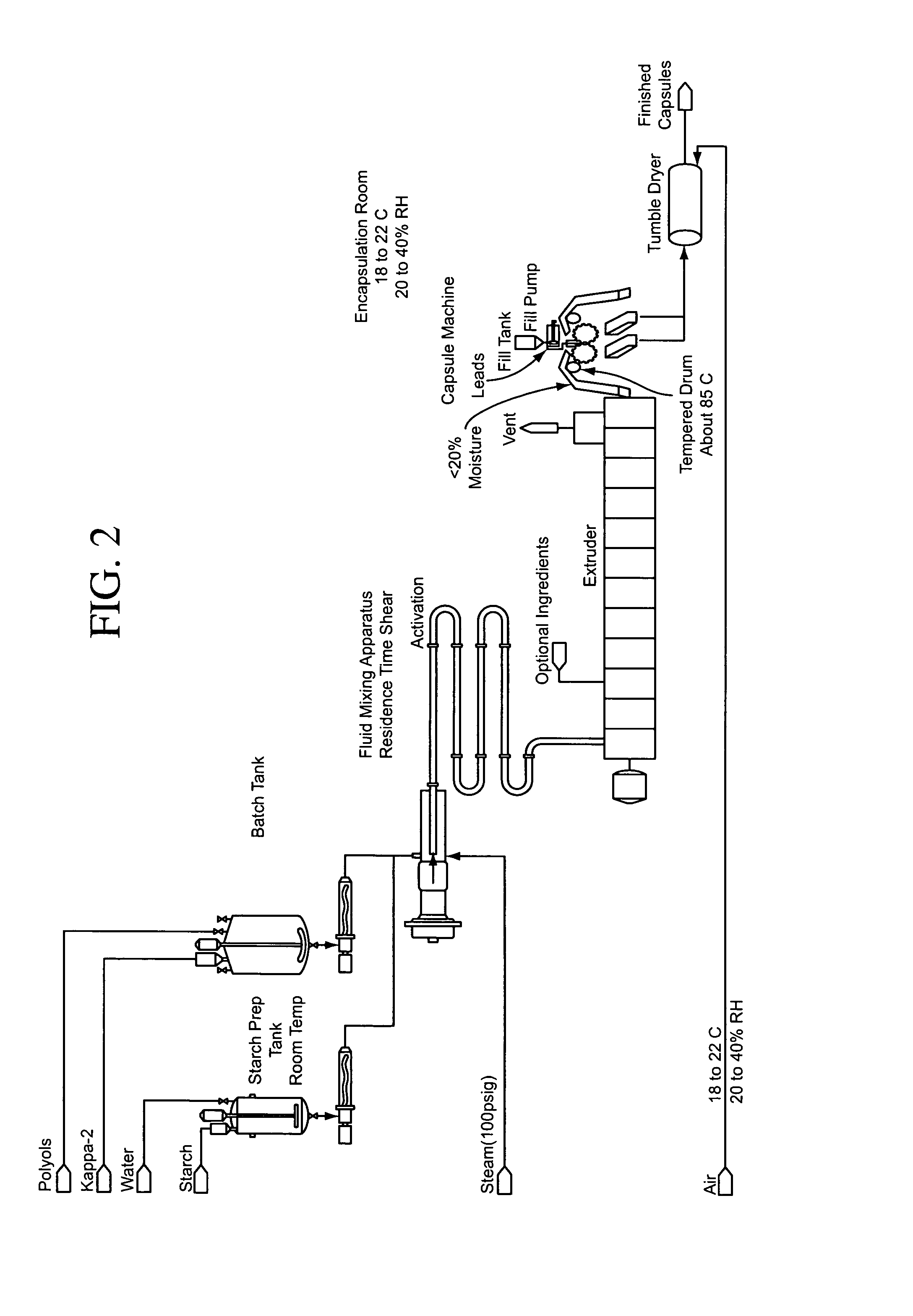

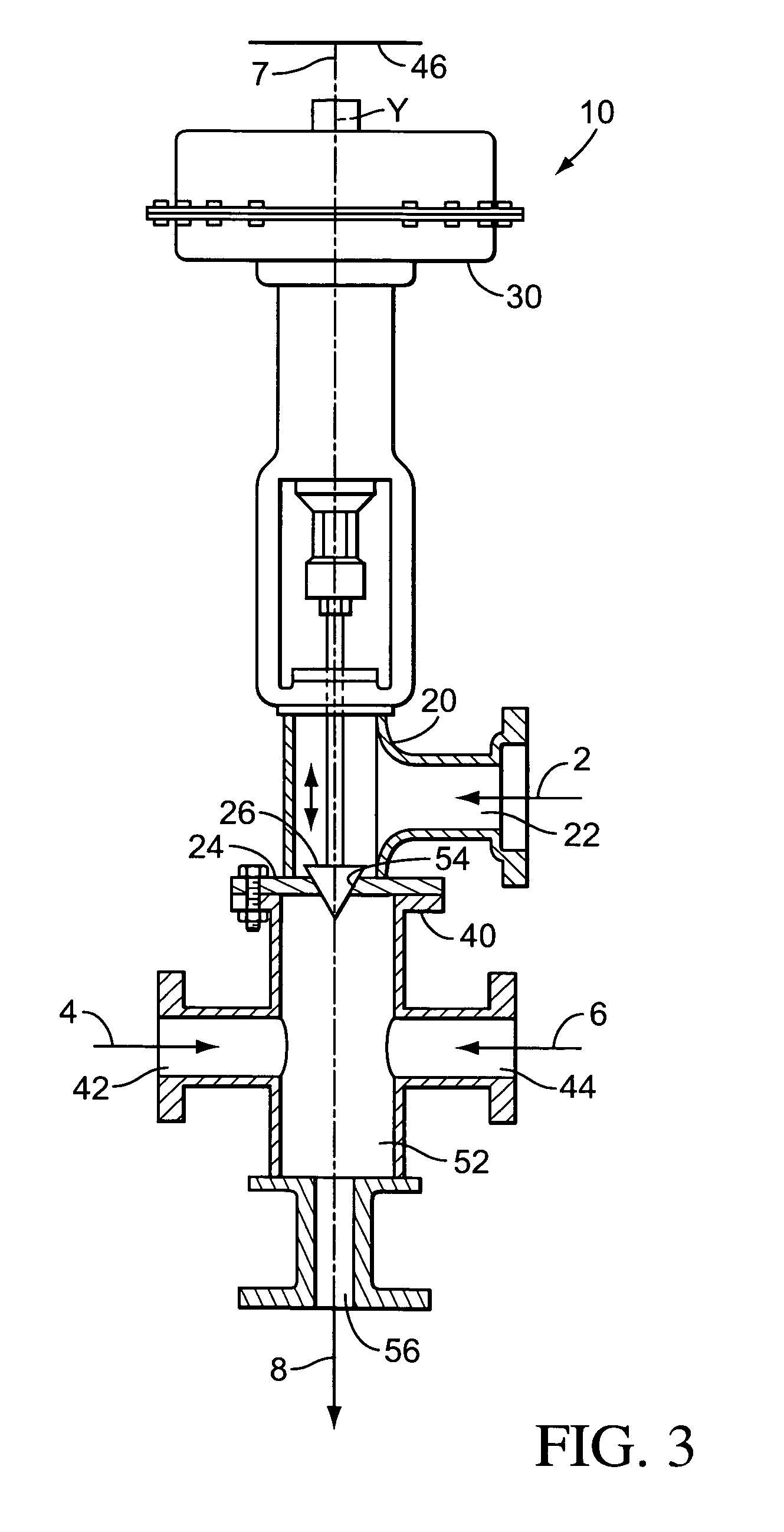

Homogeneous, thermoreversible gel containing reduced viscosity carrageenan and products made therefrom

The present invention is directed to a homogeneous, thermoreversible gel comprising carrageenan wherein the carrageenan has a viscosity of less than 10 cP at 75° C. when measured in a 0.10 molar aqueous sodium chloride solution containing 1.5% by weight of the carrageenan based on the weight of all components in the solution, and optionally at least one of a plasticizer, a second film former, a bulking agent, and a pH controlling agent, wherein the gel has a solids content of at least 40%. The present invention is also directed to processes for the preparation thereof, as well as to variety of products containing the gel including edible products, soft capsules, hard capsules and solid forms encapsulating powders, tablets, caplets, etc.

Owner:FMC CORP

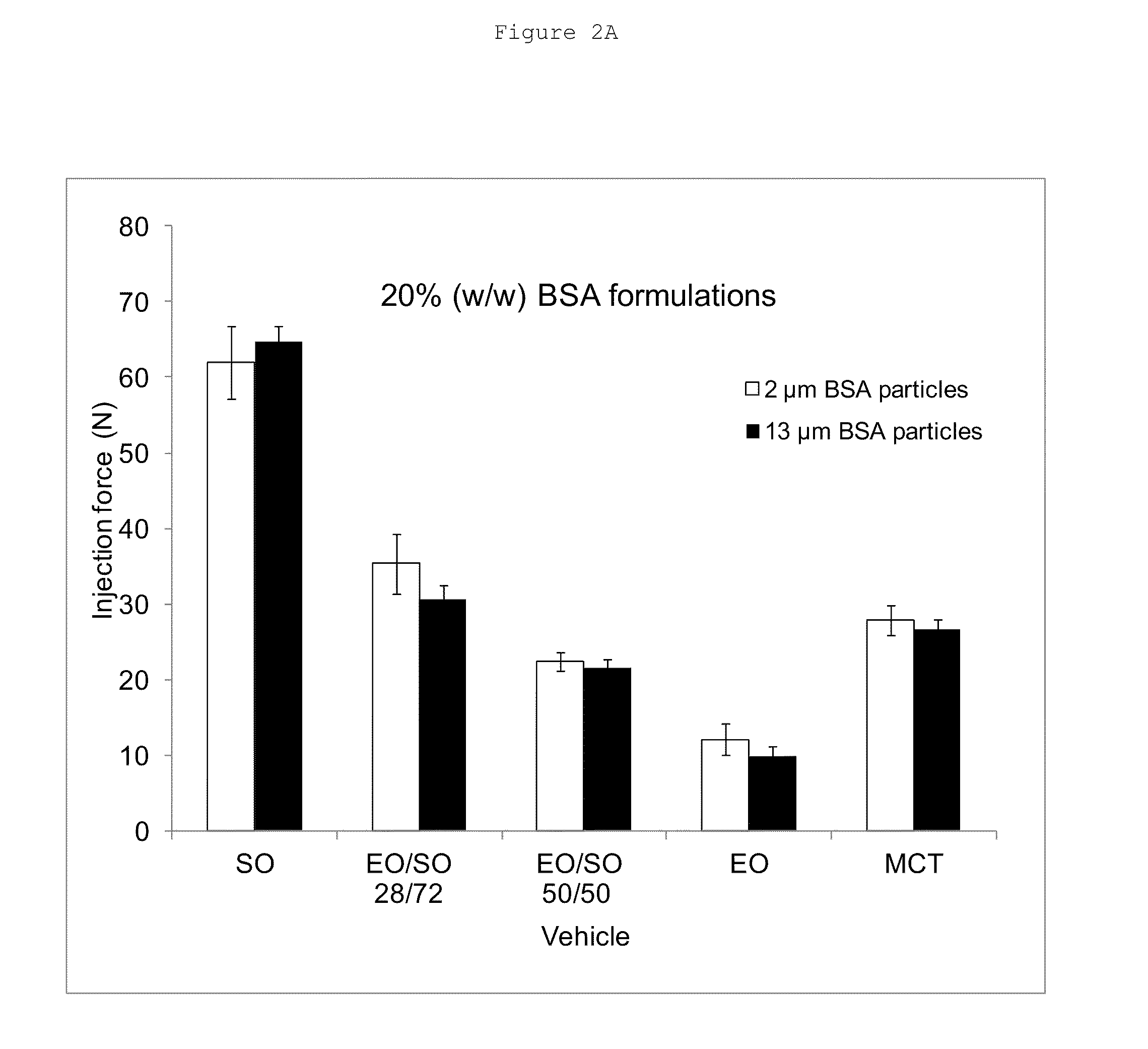

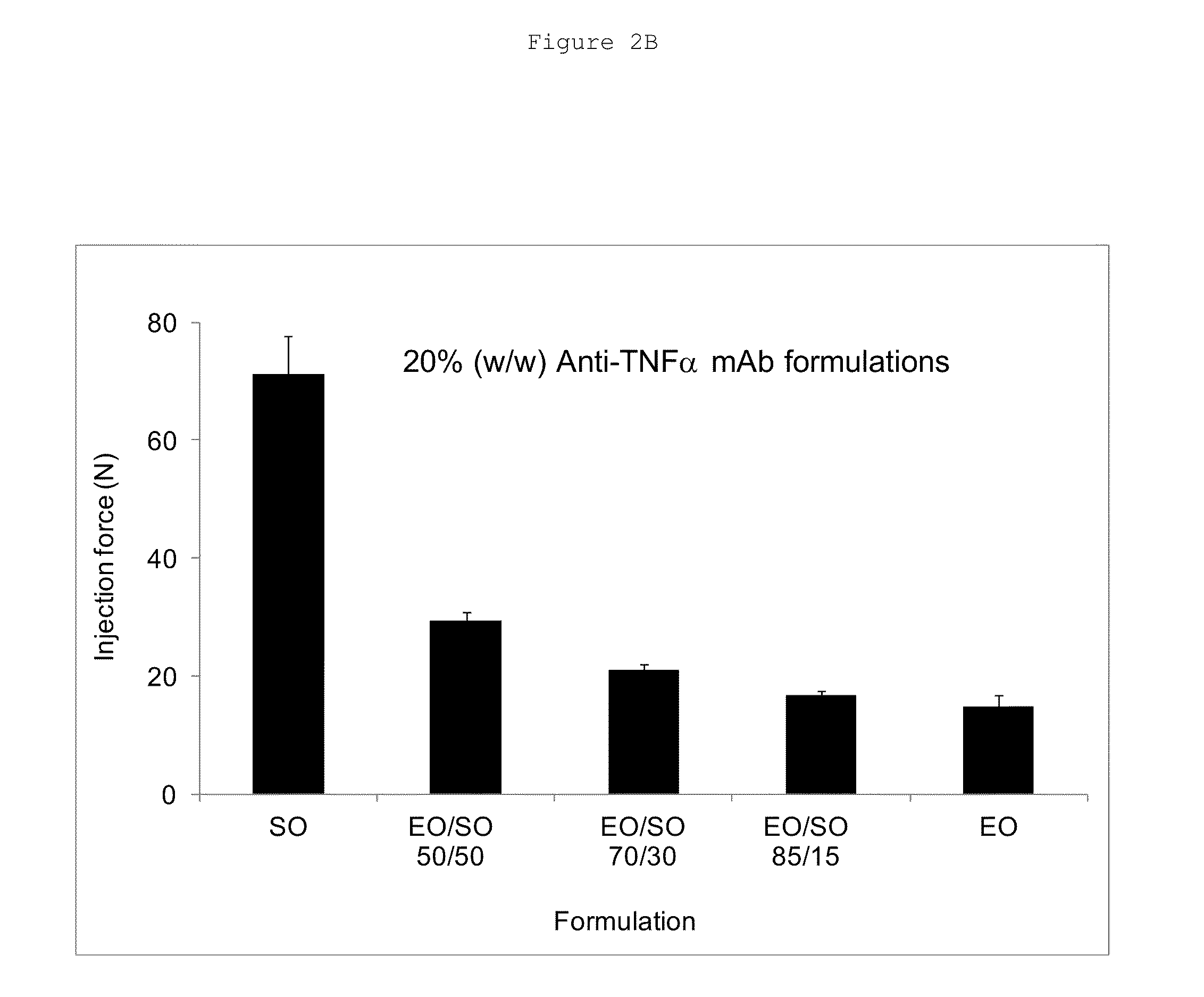

Non-Aqueous High Concentration Reduced Viscosity Suspension Formulations

The present invention relates to non-aqueous high concentration reduced viscosity suspension formulations and methods of making and using them.

Owner:JANSSEN BIOTECH INC

Chewy products and methods for making the same

InactiveUS20080008742A1Low viscosityPharmaceutical non-active ingredientsPill deliveryEmulsionActive agent

Methods for producing chewable emulsion compositions and compositions produced from such methods are disclosed. The emulsion base may be prepared by contacting an aqueous phase and a nonaqueous phase in the presence of an emulsifier. The aqueous phase is prepared under conditions that permit no substantial moisture loss and reduced viscosity. The methods permit preparing chewable compositions for delivering confectionary items, nutriceuticals, vitamins, minerals and therapeutically active agents. The compositions may be sugar-free or sugar-containing. The active agent may be added to the emulsion base at a lower temperature compared to the temperature at which either the aqueous or nonaqueous phase is formed. The compositions may be further coated with taste-masking materials, enteric coating materials, or slow-release materials. The compositions may be formed into compressible tablets, beads, granules, or otherwise generally known dosage forms.

Owner:CAPRICORN PHARMA INC

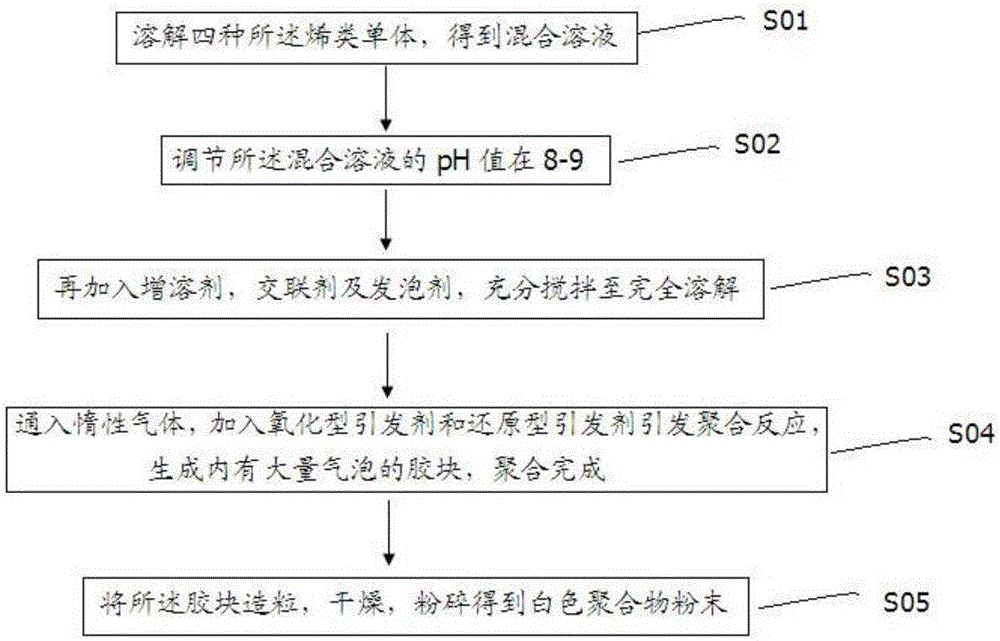

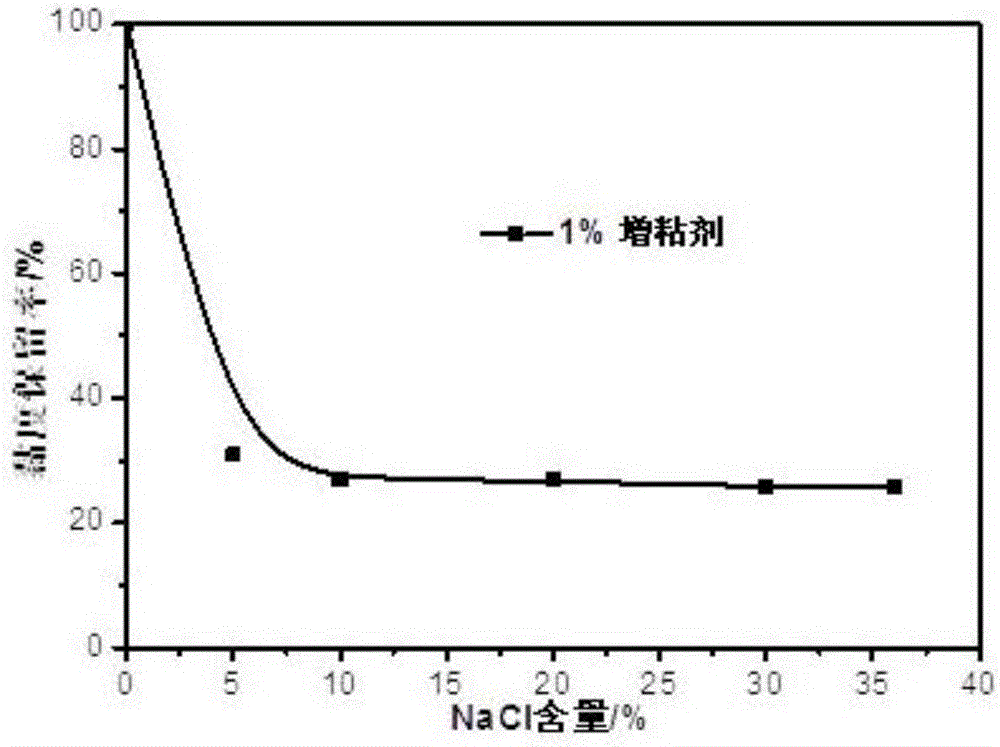

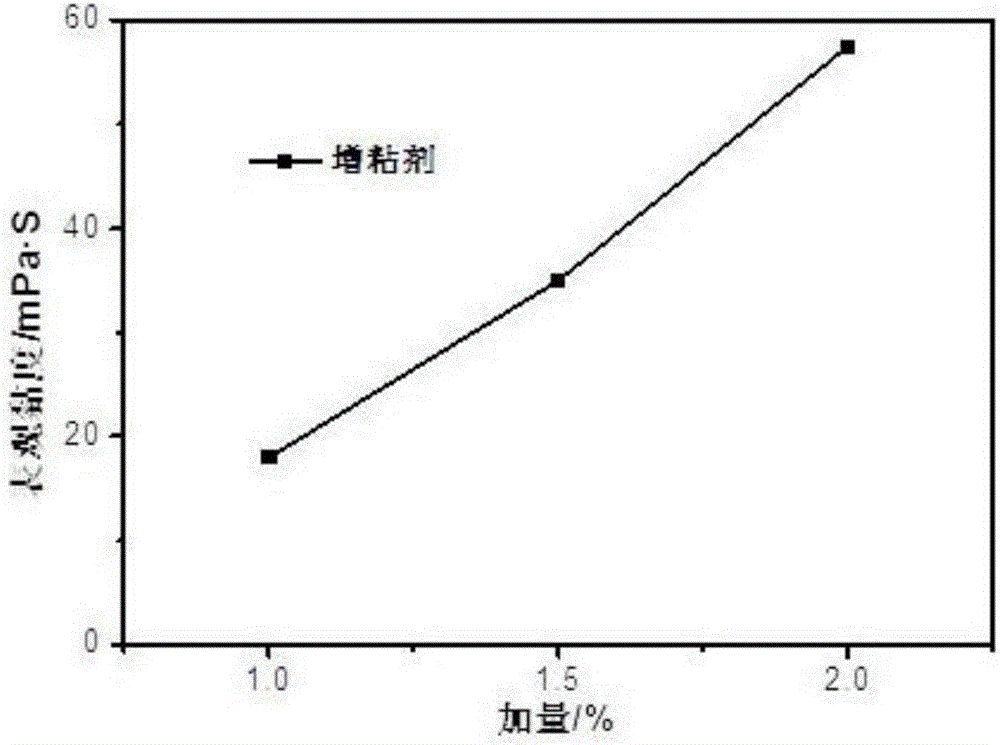

Tackifier for drilling fluid, and preparation method and application thereof

ActiveCN106243266AGood temperature and salt resistancePromote hydrationDrilling compositionAlkaneDouble bond

The invention provides a tackifier for a drilling fluid, and a preparation method and application thereof. The tackifier is a quadripolymer formed by polymerization of four alkene monomers, wherein the four alkene monomers are selected from a temperature-resistant salt-tolerant monomer, a hydrated monomer and an adsorptive monomer; the temperature-resistant salt-tolerant monomer is selected from an alkenyl sulfonic acid monomer; the hydrated monomer is selected from alkenyl carboxylic acid, alkenyl alkane ketone and double-bond-containing quaternary ammonium salt compounds; and the adsorptive monomer is selected from an alkenyl amide monomer. The tackifier provided by the invention can resist a high temperature of no less than 180 DEG C, is resistant to saturated salt, has remarkable tackifying effect, is low in toxicity and environmentally friendly, and can obviously improve the dehydration and wall building capability of the drilling fluid, thereby effectively reducing the dehydration. The invention solves the downhole complexity possibly caused by the fact that the drilling fluid system can not carry and suspend rock debris and thus can not clear boreholes in time due to reduced viscosity shearing force as a result of poor temperature resistance and salt tolerance of the tackifier in deep well, ultradeep well, horizontal well and extended reach well operations.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

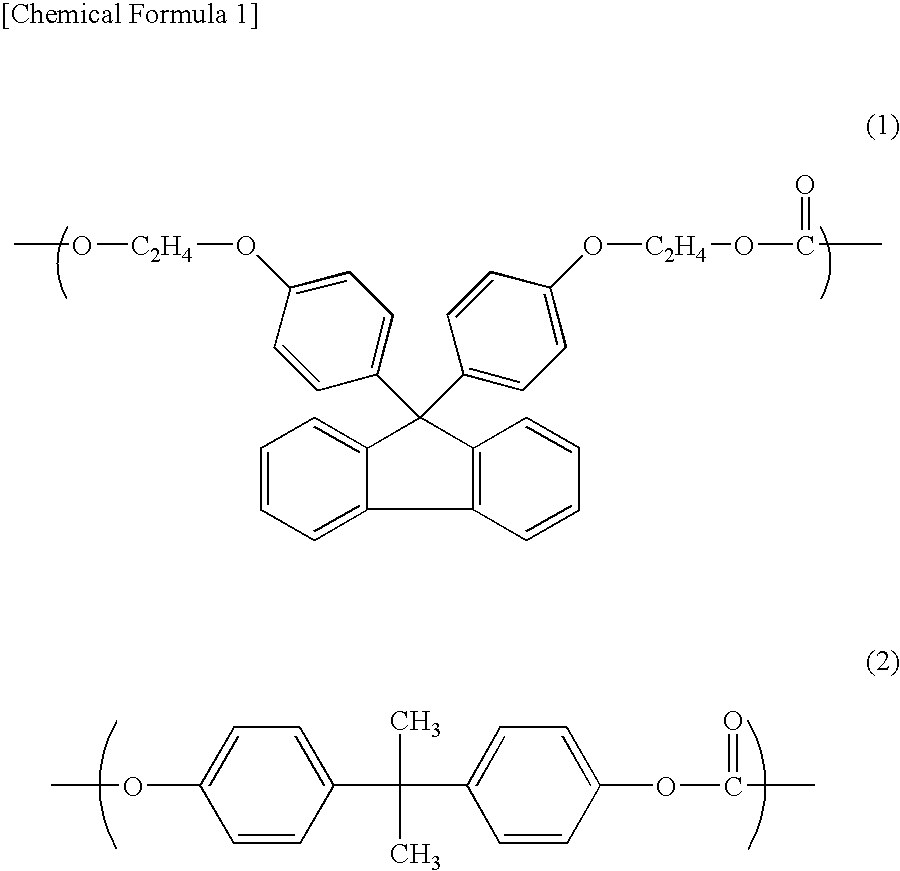

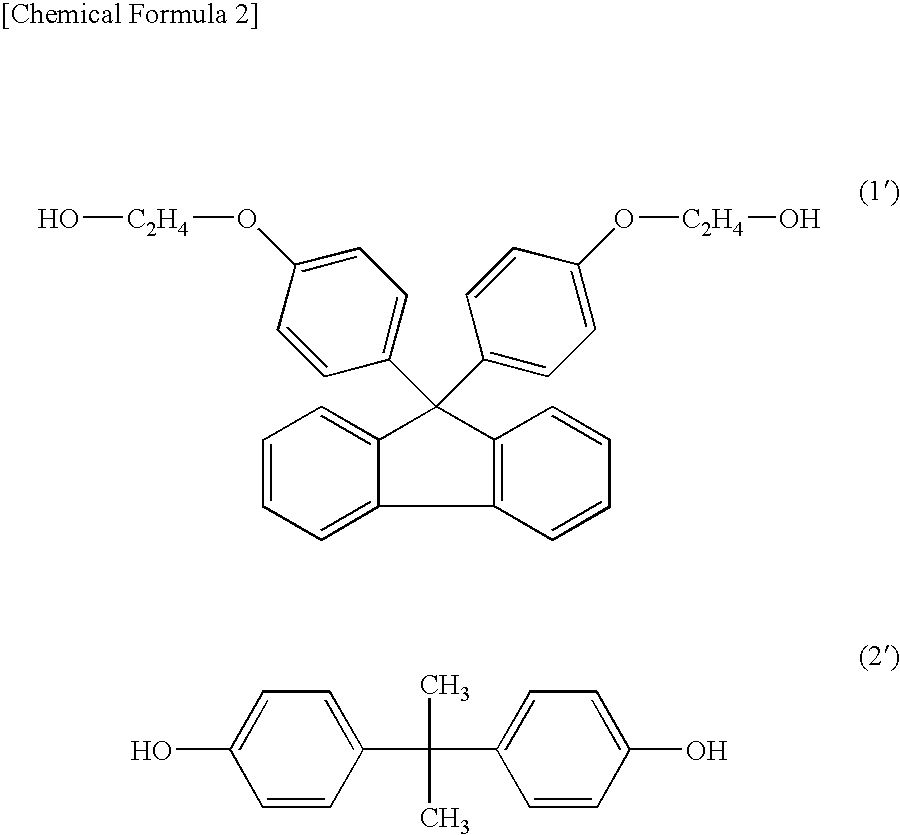

Optical Lens

ActiveUS20100048855A1Reduce light transmittanceHigh glass transition temperatureSynthetic resin layered productsMountingsCamera lensPolymer science

Disclosed is an optical lens which can be produced by injection molding on an industrial scale and which has a high refractive index, a low Abbe's number, a low birefringence index, a high transparency and a high glass transition temperature. The optical lens can be produced by injection molding of a polycarbonate resin (preferably having a reduced viscosity of 0.2 dl / g or higher and a glass transition temperature of 120 to 160° C.), wherein the polycarbonate resin is produced by reacting a diol component comprising 99 to 51 mol % of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene and 1 to 49 mol % of bisphenol A with a carbonate diester. It becomes possible to produce an optical lens preferably having a refractive index of 1.60 to 1.65, an Abbe's number of 30 or smaller, a birefringence index of 300 nm or lower and an all light transmittance of 85.0% or higher.

Owner:MITSUBISHI GAS CHEM CO INC

Combined technologic process for manufacturing petroleum residue

InactiveCN1485412AReduce cokingIncrease line speedTreatment with plural serial stages onlyGasolineResidual oil

A method of processing residual oil. It comprises: after preheating, introducing the raw material into the upper portion of a solvent deasphalting extraction tower, the solvent is introduced into thelower portion of the extraction tower at the predetermined proportion, residual oil and the solvent contacting refluently and extracting, recycling solvent from deasphalted oil containing a great amount of the solvent, deasphalted oil containing a small quality of the solvent is discharged from the bottom of the tower without recycling solvent and enters the heating oven for heating, then entering a fractionating tower, fractionating gases, gasoline and residual oil with reduced viscosity.

Owner:CHINA PETROLEUM & CHEM CORP +1

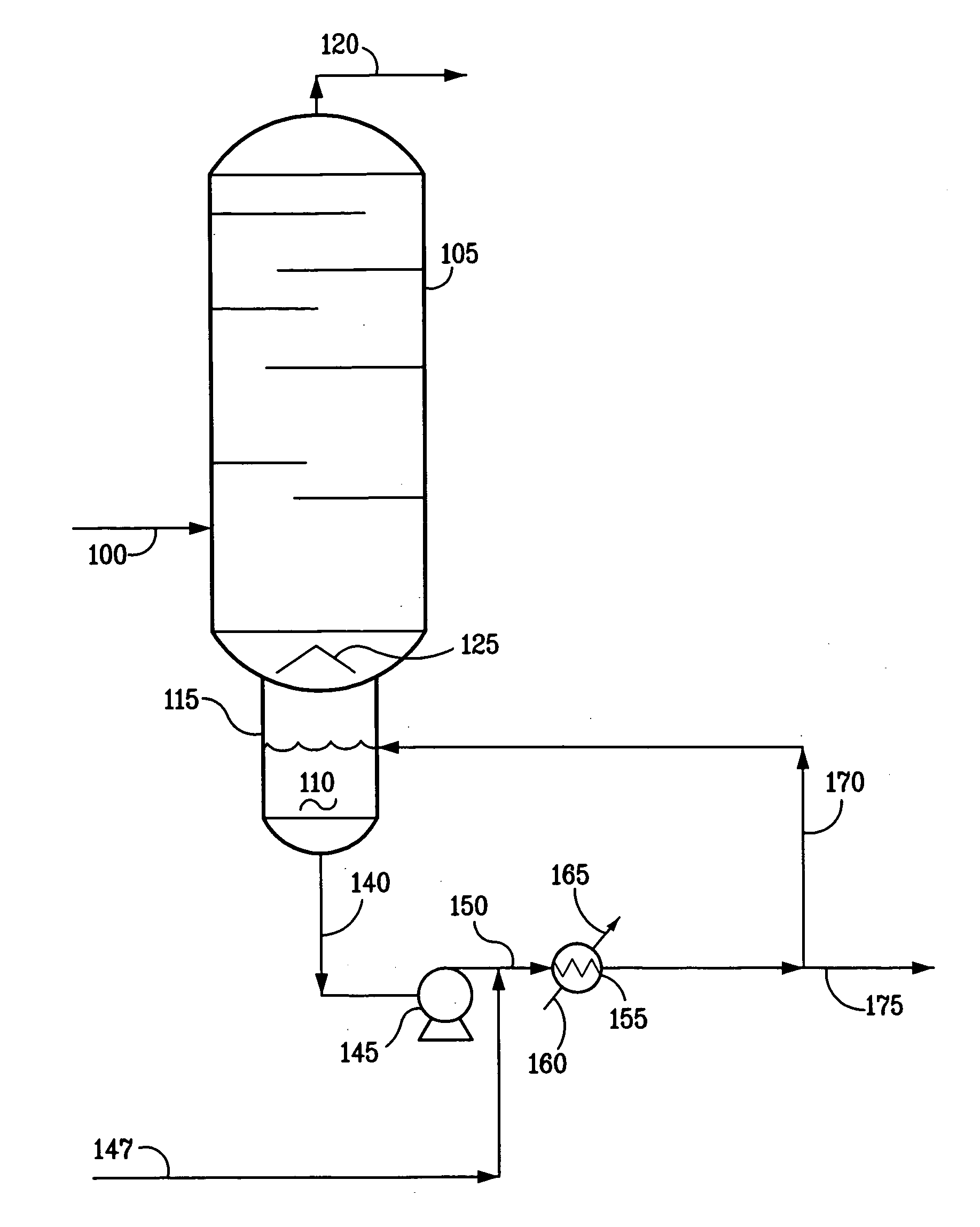

Method for processing hydrocarbon pyrolysis effluent

ActiveUS20070007170A1Tar temperatureLow viscosityThermal non-catalytic crackingCombination devicesTarToluene

A method is disclosed for treating gaseous effluent from a hydrocarbon pyrolysis unit to provide steam cracked tar of reduced asphaltene and toluene insolubles content. The method is suitable for preparing reduced viscosity tar useful as a fuel blending stock, or feedstock for producing carbon black, while reducing or eliminating the need for externally sourced lighter aromatics additives to meet viscosity specifications. The method comprises drawing steam cracked tar from a separation vessel, e.g., a primary fractionator or tar knock-out drum, cooling the tar, and returning it to the separation vessel to effect lower overall tar temperatures within the separation vessel, in order to reduce viscosity increasing condensation reactions. An apparatus for carrying out the method is also provided.

Owner:EXXONMOBIL CHEM PAT INC

Heavy crude oil hydrocracking method

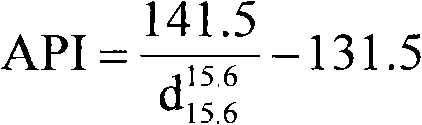

The invention relates to a heavy crude oil hydrocracking method. In the method, heavy crude oil is sequentially subjected to the steps of a hydrogenation protective agent, a hydrodemetallization agent, a hydrodesulfurization agent I, a hydrocracking agent and a hydrodesulfurization II in the presence of hydrogen, wherein the filling weight percentage of the hydrogenation protective agent, the hydrodemetallization agent, the hydrodesulfurization agent I, the hydrocracking agent and the hydrodesulfurization agent II are respectively 2-20%, 10-78%, 10-78%, 5-50% and 5-50% by taking an integral catalyst as a reference. According to the method provided by the invention, the heavy crude oil with the API (American Petroleum Institute) degree smaller than 20 can be processed to obtain hydrogenated crude oil with enhanced API and reduced viscosity, and moreover, the operating period of a hydrogenation processing device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

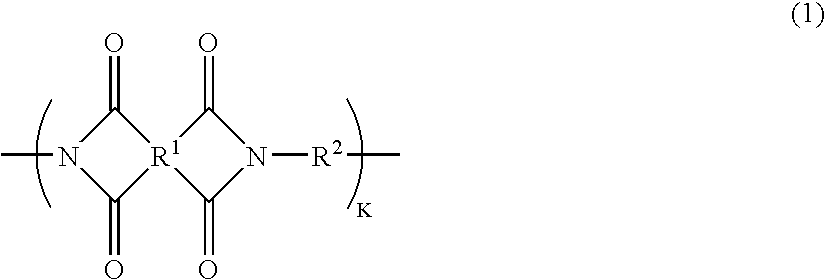

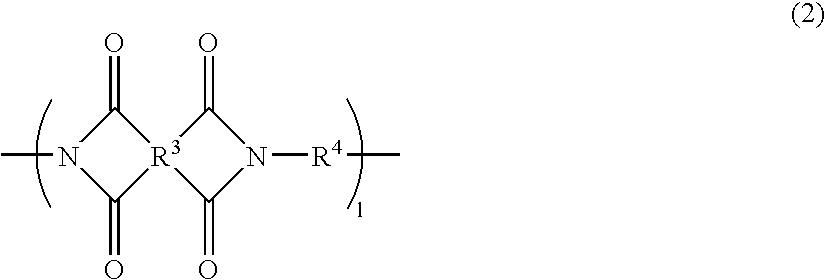

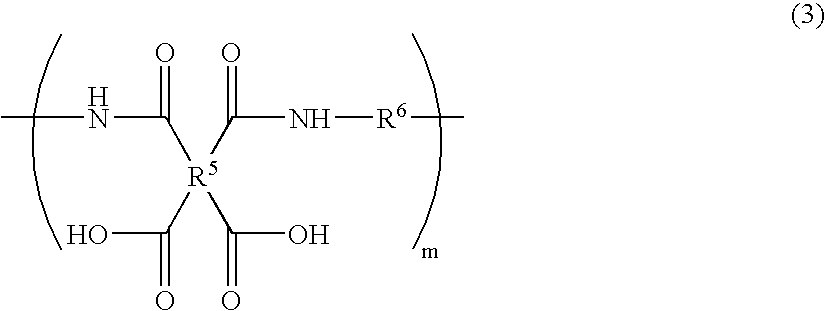

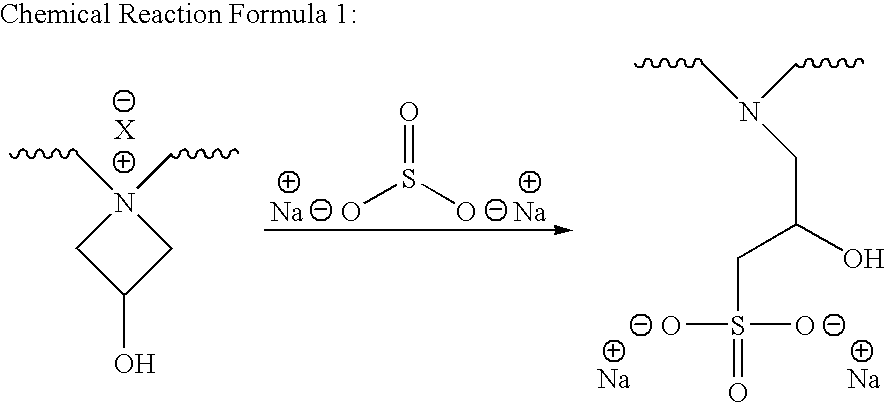

Protein/Cationic Polymer Compositions Having Reduced Viscosity

The present invention discloses an adhesive composition comprising a protein component, an azetidinium functionalized polymer component and a viscosity modifying component. The preferred protein is a soy protein and the viscosity modifying component is preferably a sulfite reducing agent, a thiol, or combinations thereof. The invention provides for a high solids, lower viscosity adhesive formulation. The present invention also relates to a composite and a method of making a composite comprising a substrate and the adhesive composition of the present invention.

Owner:HERCULES INC

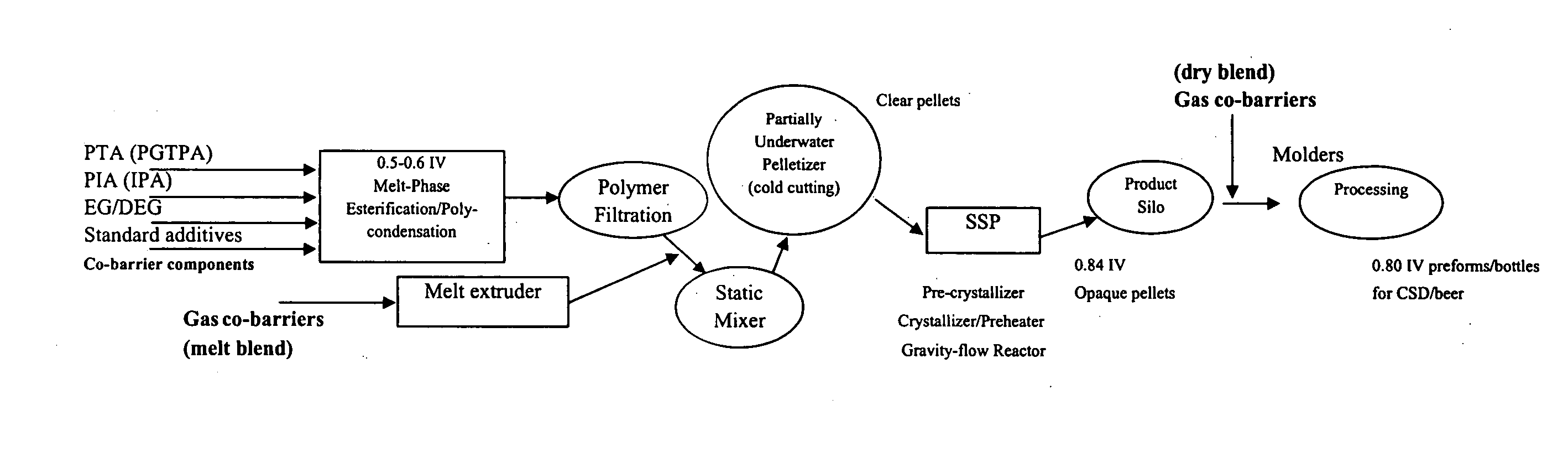

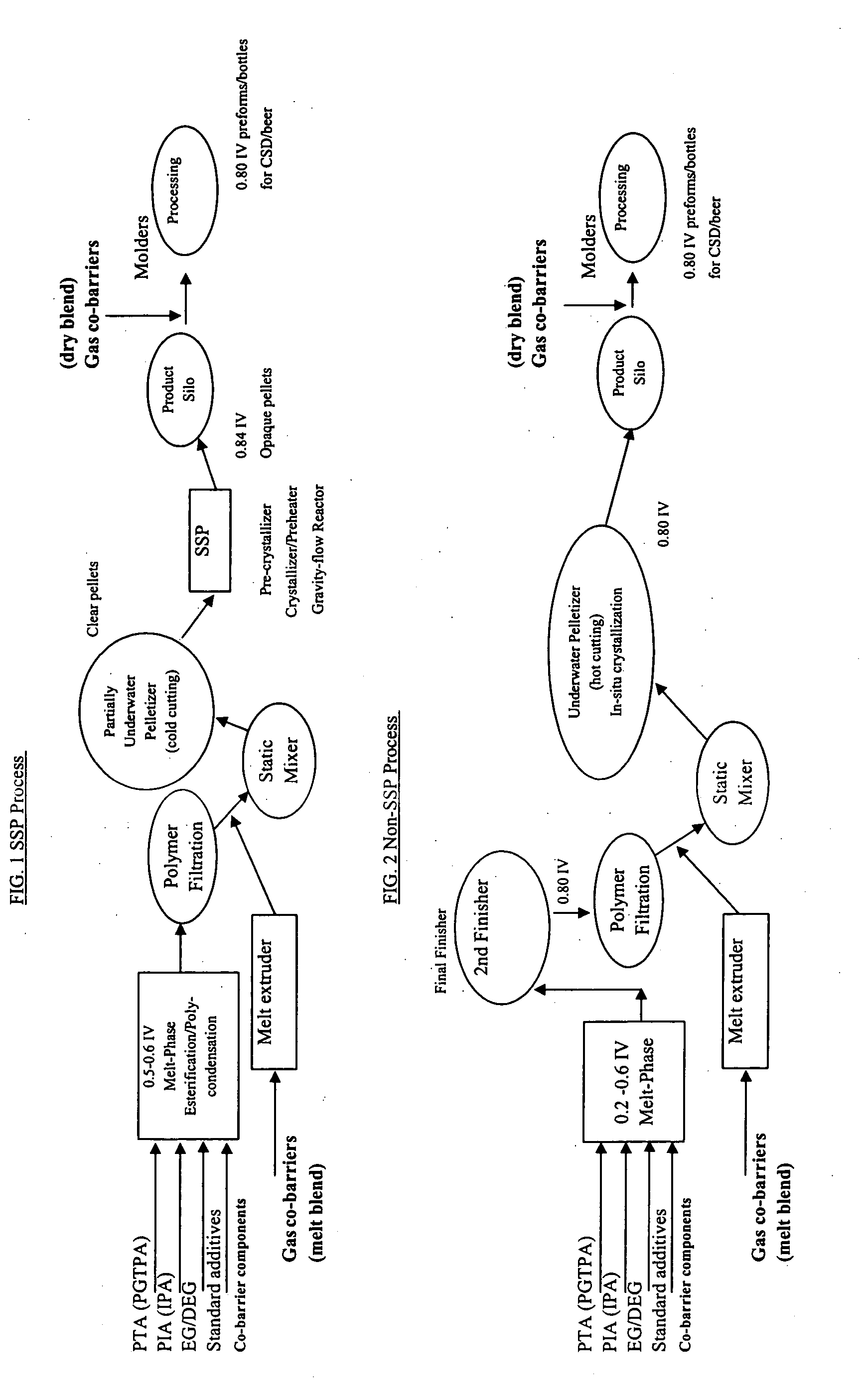

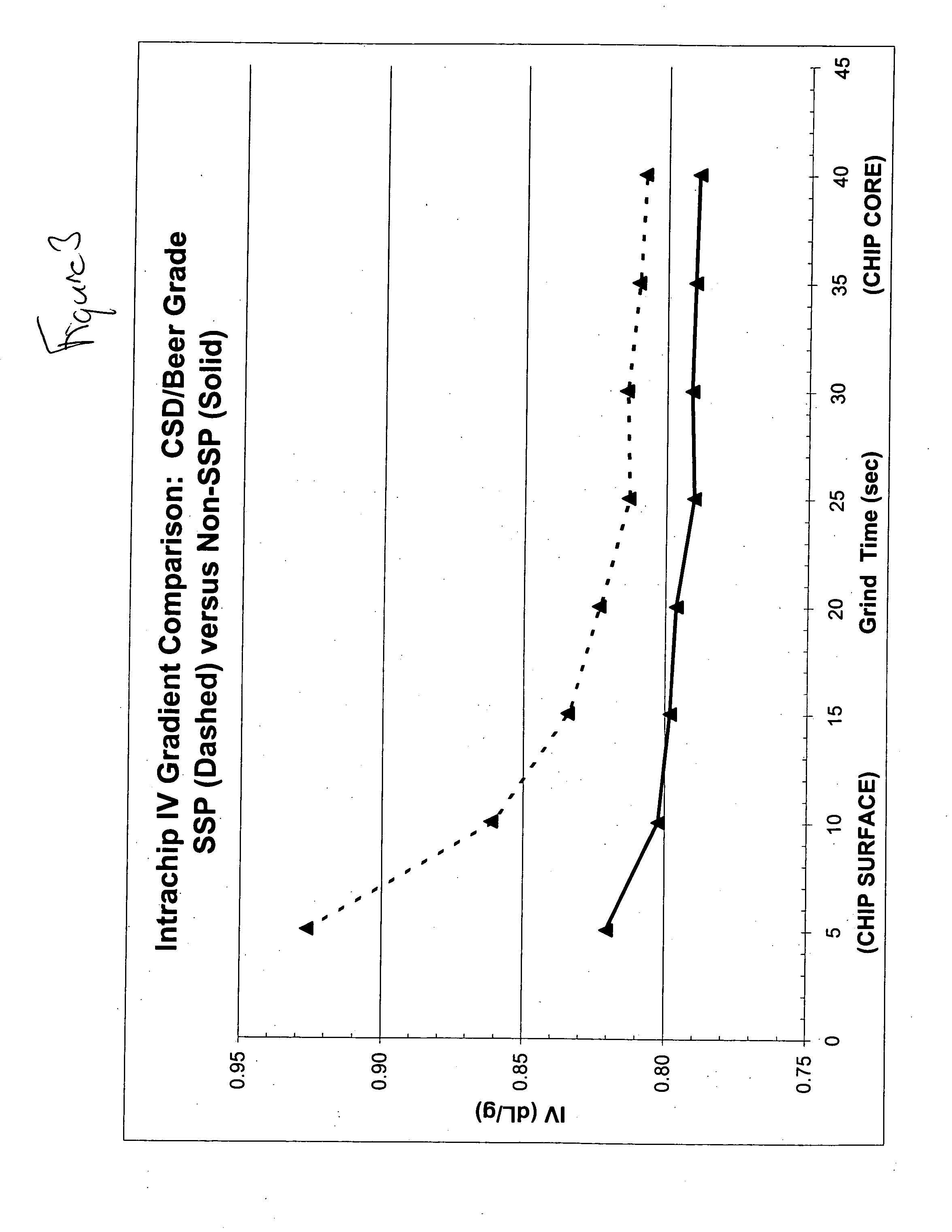

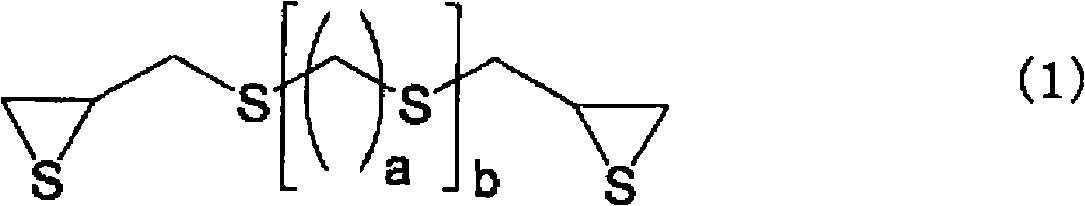

Co-polyester packaging resins prepared without solid-state polymerization, a method for processing the co-polyester resins with reduced viscosity change and containers and other articles prepared by the process

ActiveUS20070248778A1Without reducing IVReduce degradationSynthetic resin layered productsDomestic articlesBlow moldingPolyester resin

A method of processing a polyester composition without changing the intrinsic viscosity of the polyester polymer by more than 0.025 dL / g such as injection molding a PET resin to form a bottle perform and blow molding a container from the bottle preform.

Owner:DAK AMERICAS LLC

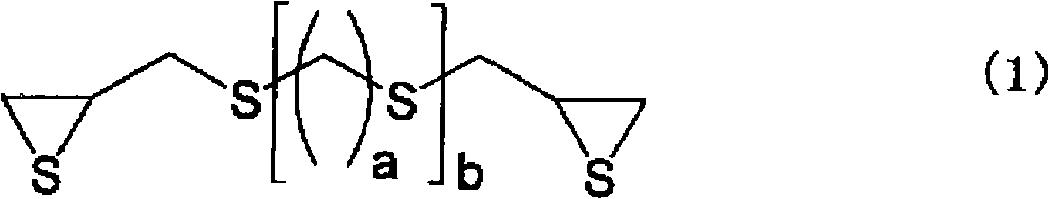

Composition for resin and optical lens obtained therefrom

ActiveCN101932630AHigh refractive indexLow viscosityOptical partsOptical elementsSulfurInorganic compound

Owner:MITSUBISHI GAS CHEM CO INC

Products produced from rapid thermal processing of heavy hydrocarbon feedstocks

InactiveUS20070170095A1Upgrade and reduce viscosityRapid heat treatmentThermal non-catalytic crackingLiquid organic insulatorsParticulatesLiquid product

The present invention is directed to the upgrading of heavy hydrocarbon feedstock that utilizes a short residence pyrolytic reactor operating under conditions that cracks and chemically upgrades the feedstock. The process of the present invention provides for the preparation of a partially upgraded feedstock exhibiting reduced viscosity and increased API gravity. This process selectively removes metals, salts, water and nitrogen from the feedstock, while at the same time maximizes the yield of the liquid product, and minimizes coke and gas production. Furthermore, this process reduces the viscosity of the feedstock in order to permit pipeline transport, if desired, of the upgraded feedstock with little or no addition of diluents. The method for upgrading a heavy hydrocarbon feedstock comprises introducing a particulate heat carrier into an upflow reactor, introducing the heavy hydrocarbon feedstock into the upflow reactor at a location above that of the particulate heat carrier so that a loading ratio of the particulate heat carrier to feedstock is from about 15:1 to about 200:1, allowing the heavy hydrocarbon feedstock to interact with the heat carrier with a residence time of less than about 1 second, to produce a product stream, separating the product stream from the particulate heat carrier, regenerating the particulate heat carrier, and collecting a gaseous and liquid product from the product stream. This invention also pertains to the products produced by the method.

Owner:IVANHOE HTL GASOLINEEUM

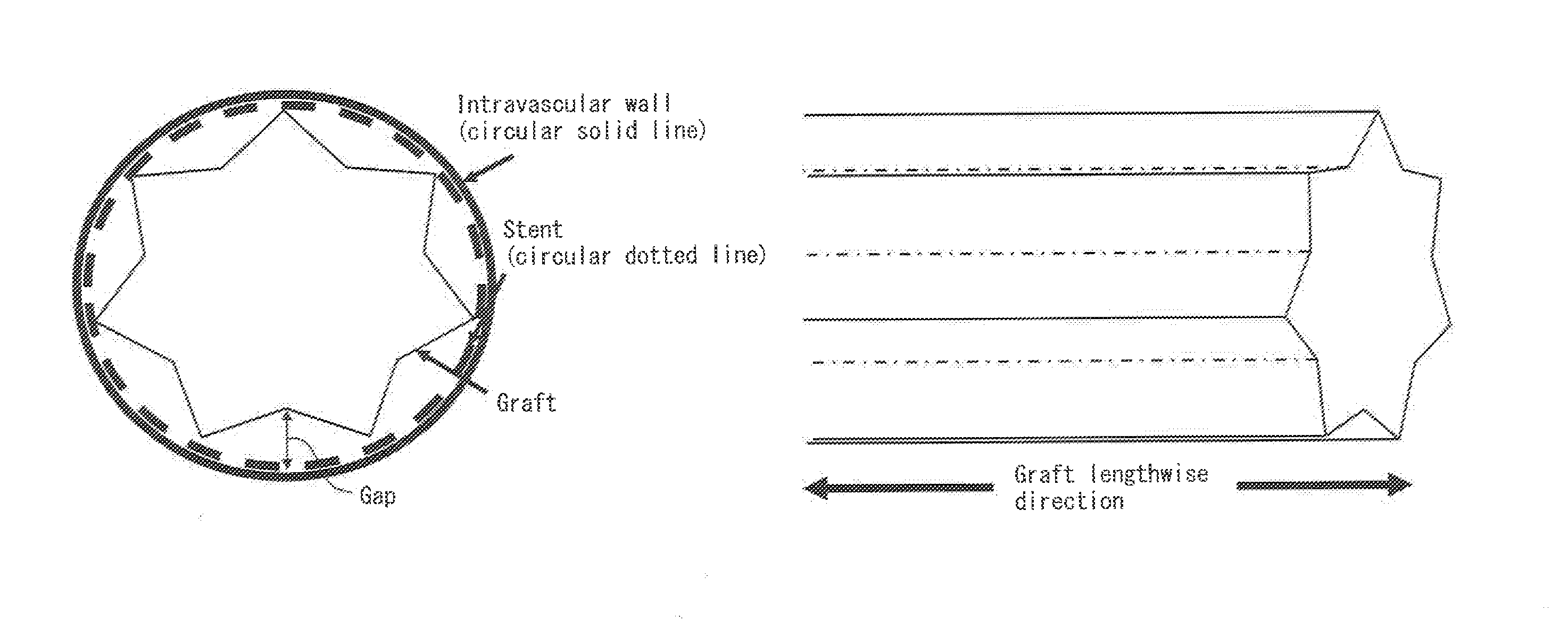

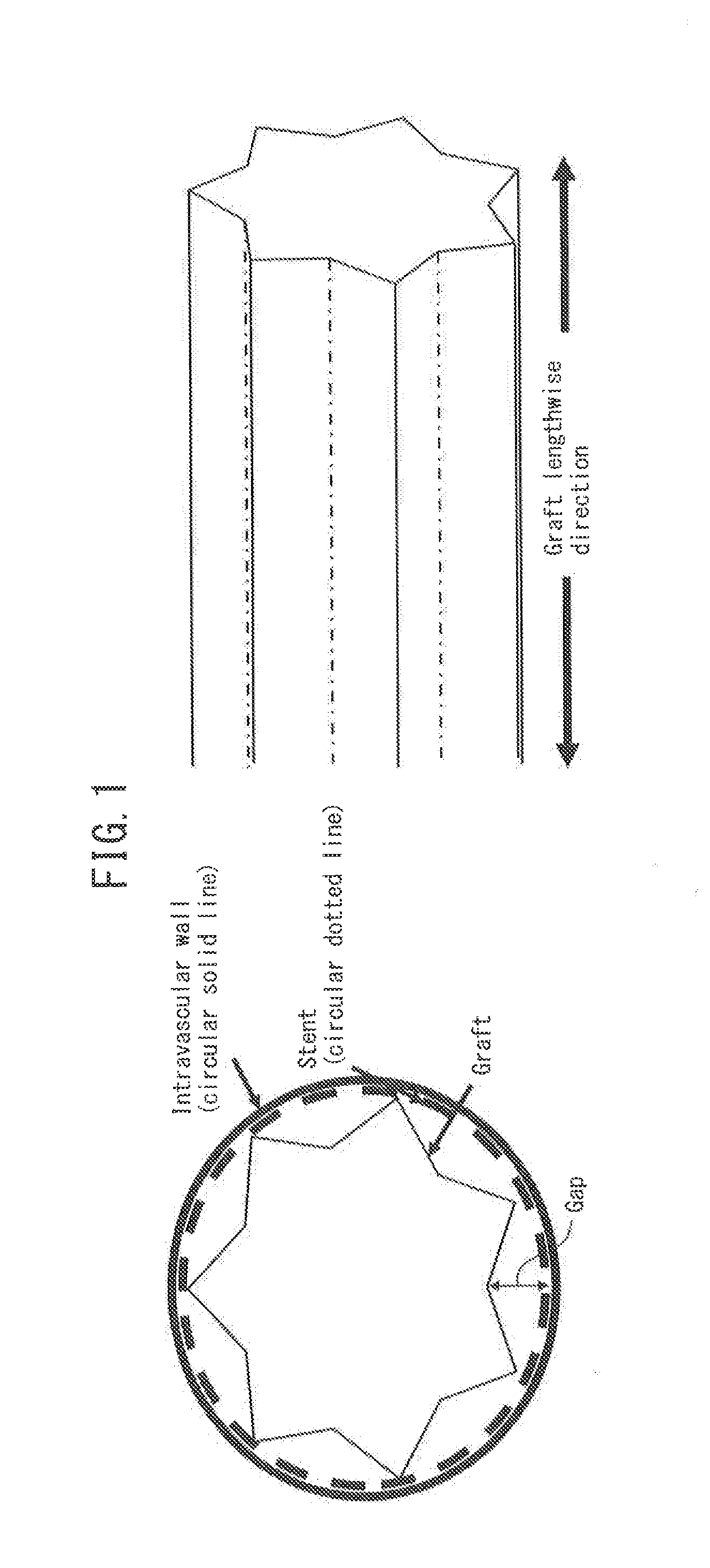

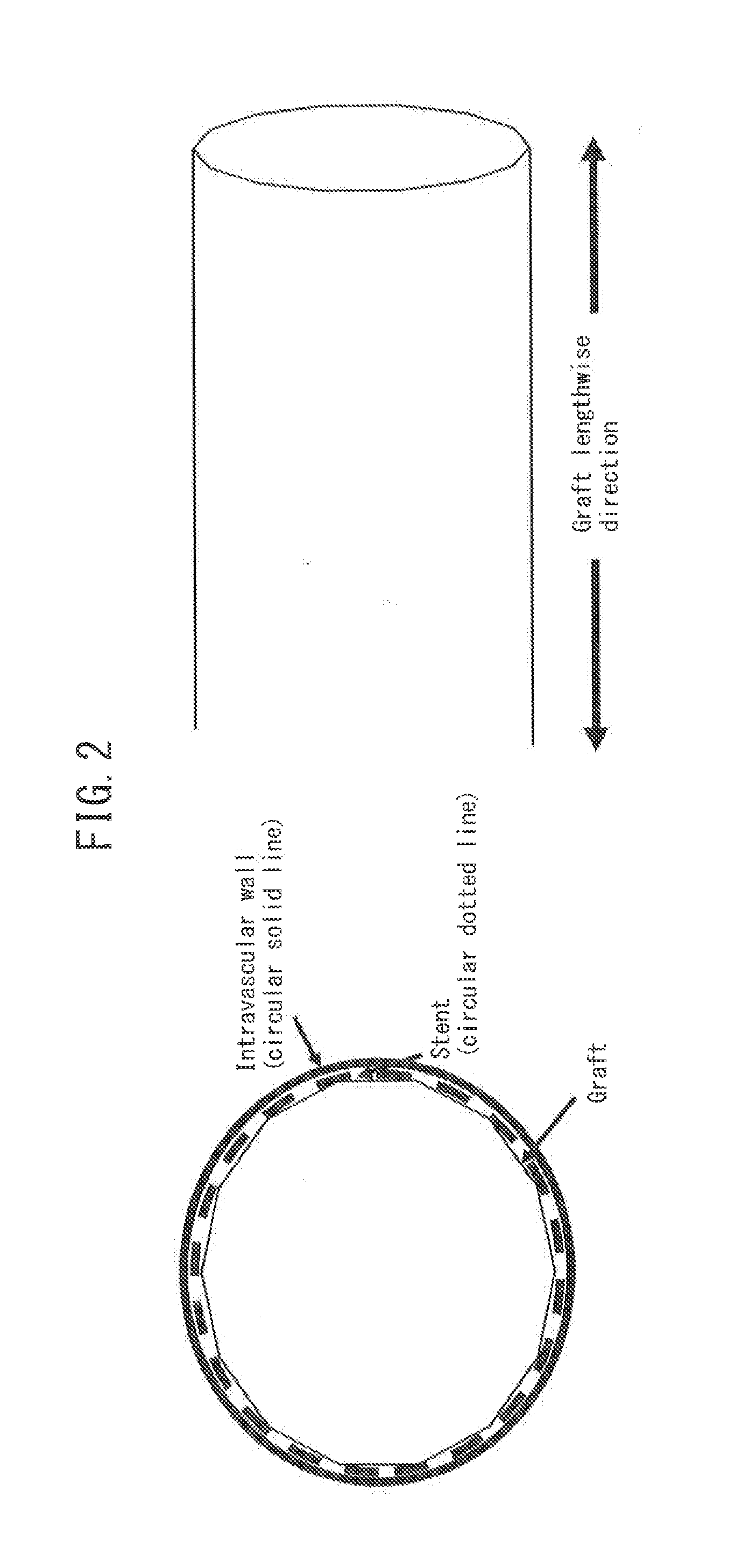

Ultrafine polyester fiber

InactiveUS20160184488A1Highly integratedEnsure long-term stabilityStentsSurgeryPolyesterPolyethylene terephthalate glycol

Provided is an ultrafine polyester fiber which is useful as a constituent material for a cloth for a stent graft or other medical device that is to be implanted in the body and which can simultaneously solve both a clinical need (diameter reduction) and a clinical challenge (integration of a stent with a stent graft). An ultrafine polyester fiber which has a polyethylene terephthalate content of 98 wt % or more, characterized by: having (1) a reduced viscosity (ηsp / c) of 0.80 dl / g or higher and (2) a total fineness of 7 to 120 dtex and a single-fiber fineness of 0.5 dtex or less; and exhibiting (3) a maximum thermal shrinkage stress of 0.05 cN / dtex or more in a temperature range of 80 to 200° C. or (4) a degree of crystallinity of 35% or more in a region spreading from the surface of the fiber to a depth of 0.1 μm.

Owner:ASAHI KASEI FIBERS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com