Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

263 results about "Concentration protein" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Protein Concentration is an important step in protein extraction and purification. The large amount of starting material used to acquire an adequate quantity of a protein of interest results in large volumes of dilute protein. Following protein extraction, the purified proteins need to be concentrated.

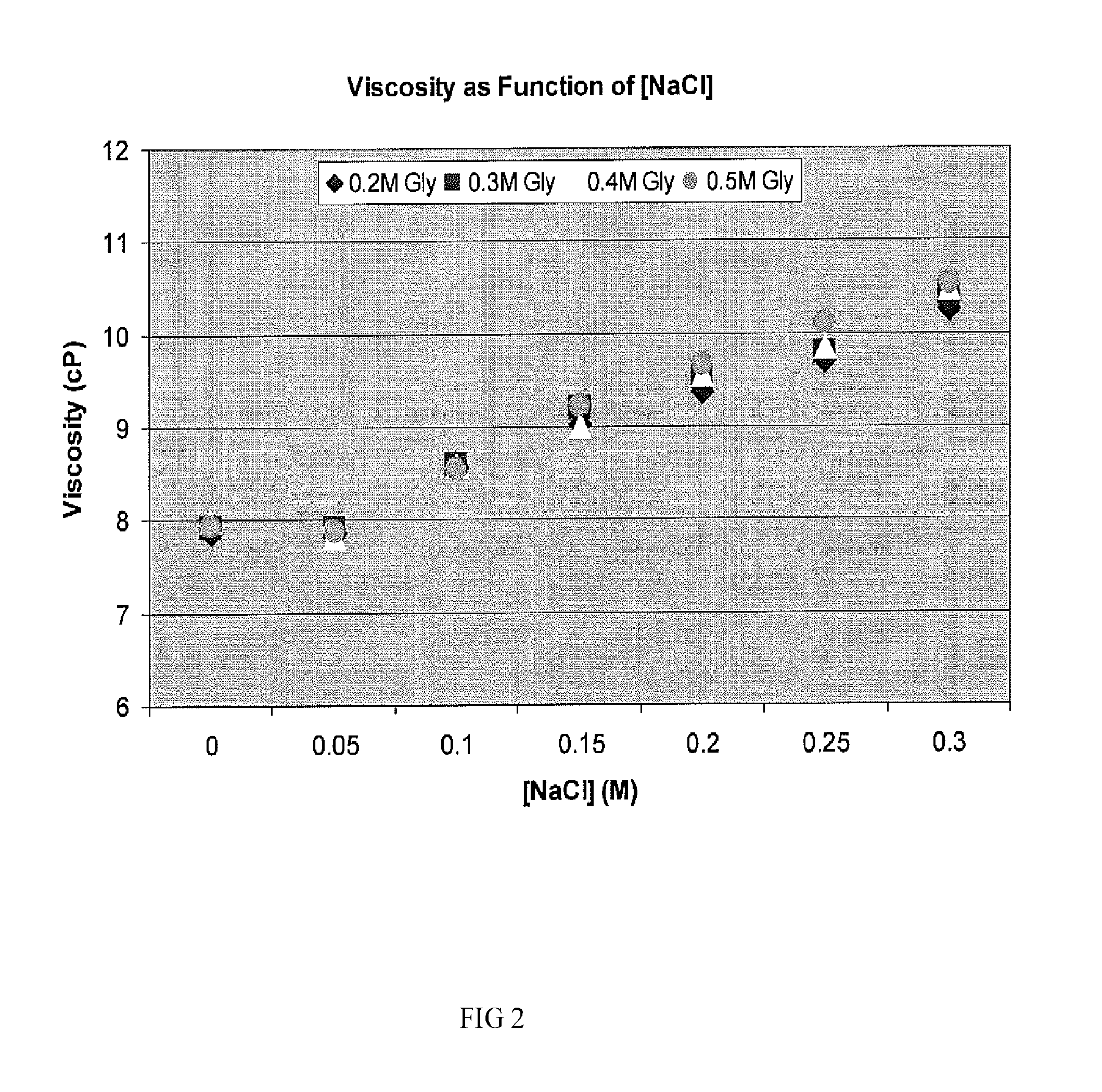

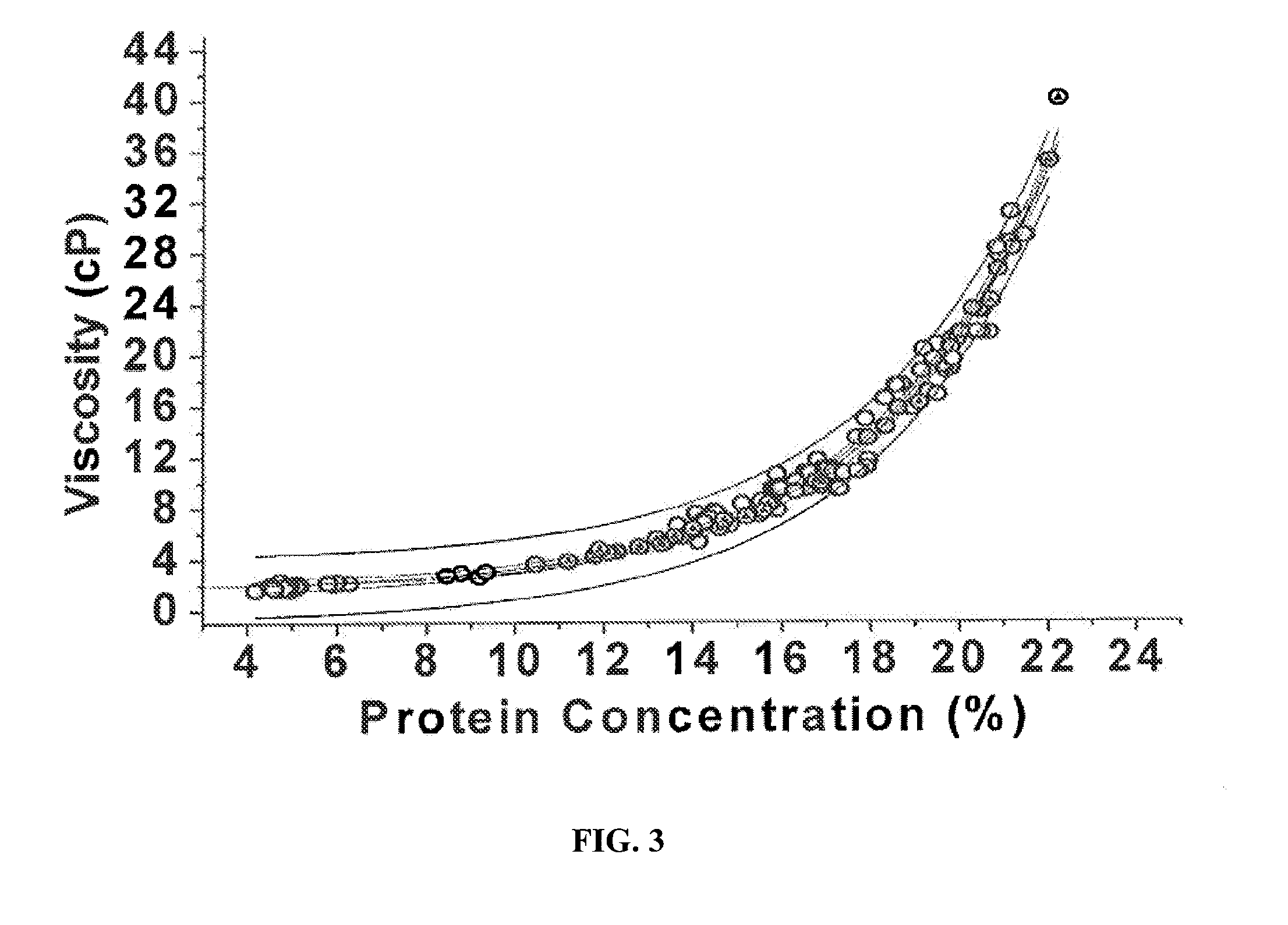

Reduced-viscosity concentrated protein formulations

InactiveUS6875432B2Low viscosityCompromising stability and biological activityPeptide/protein ingredientsInorganic non-active ingredientsConcentration proteinChemistry

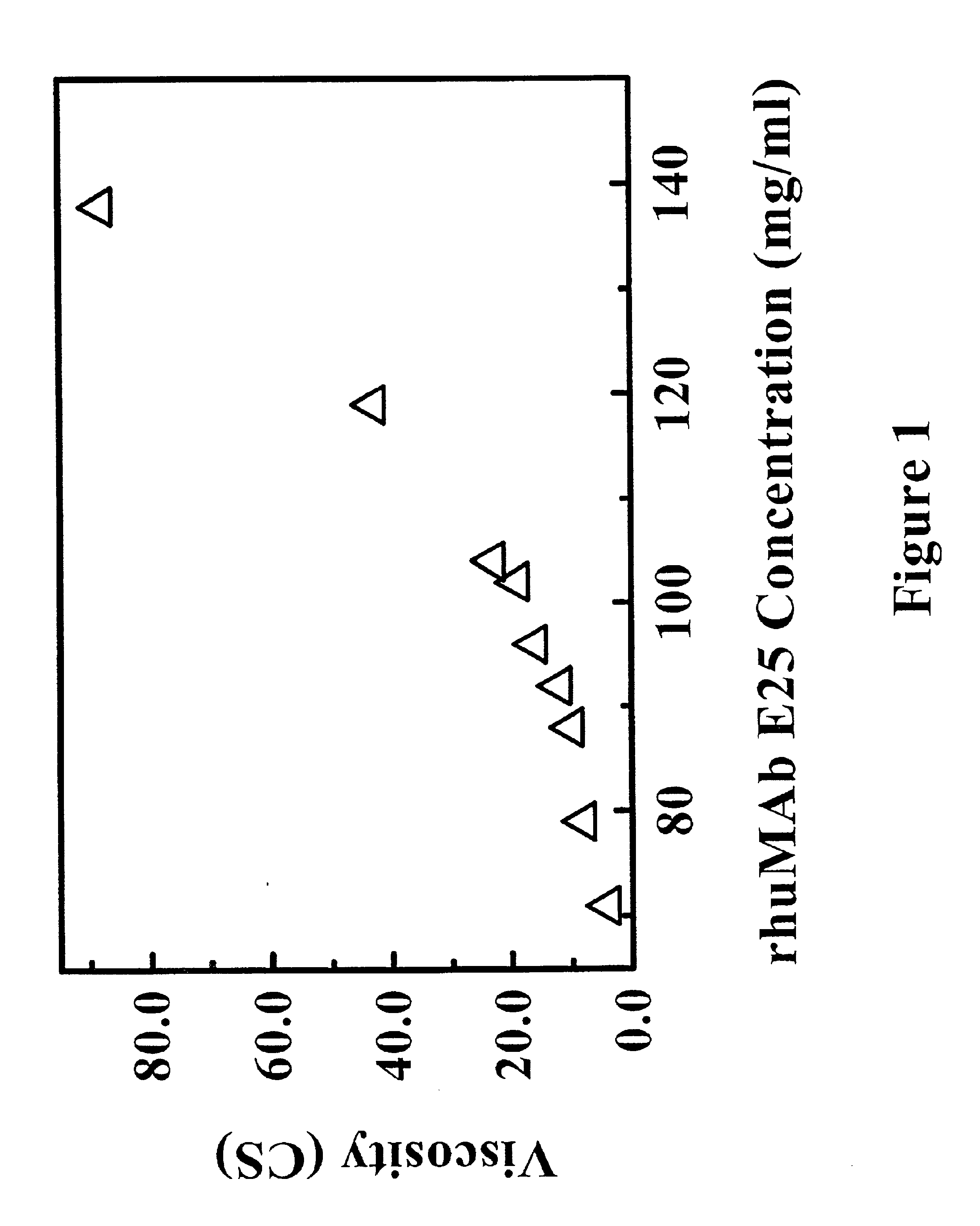

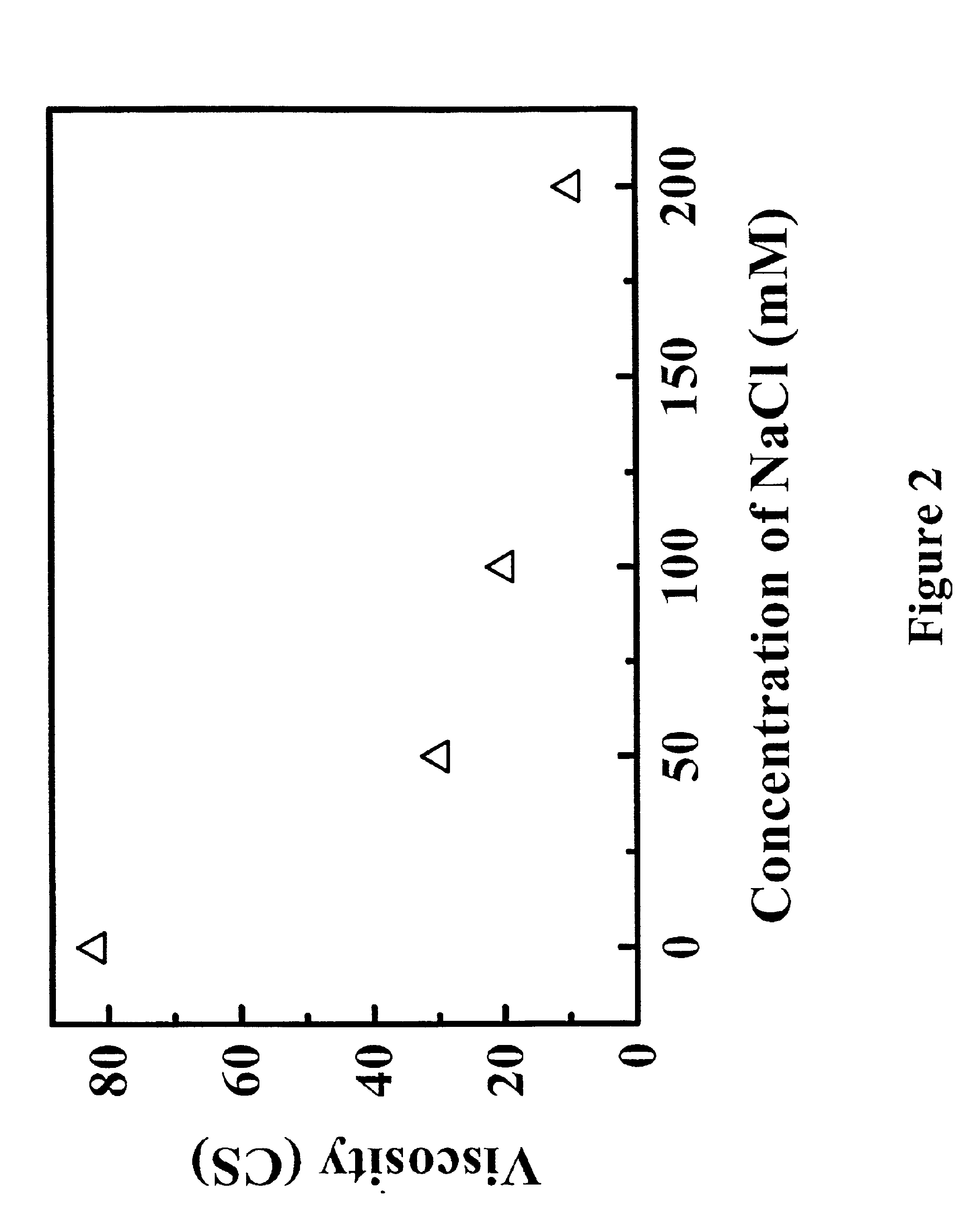

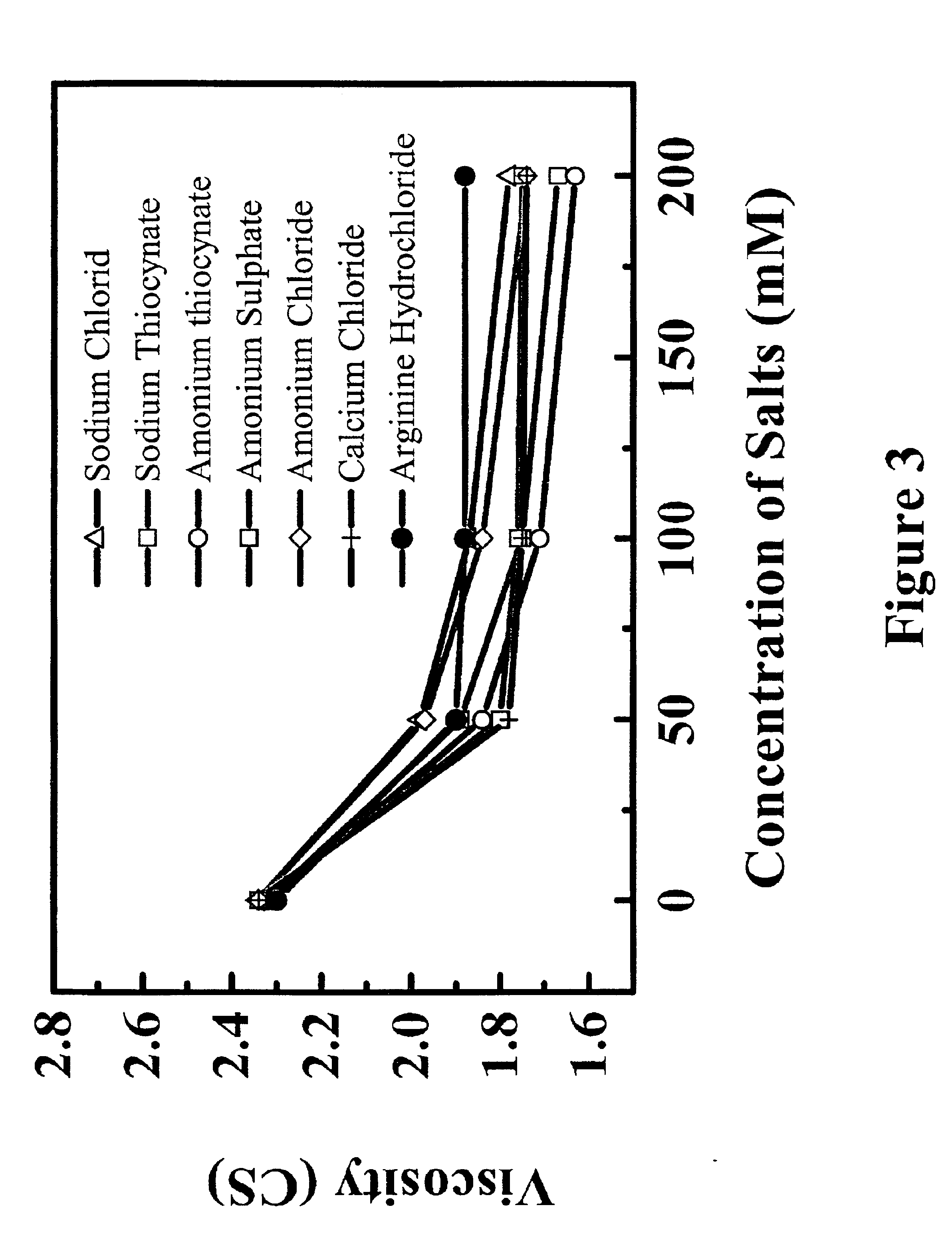

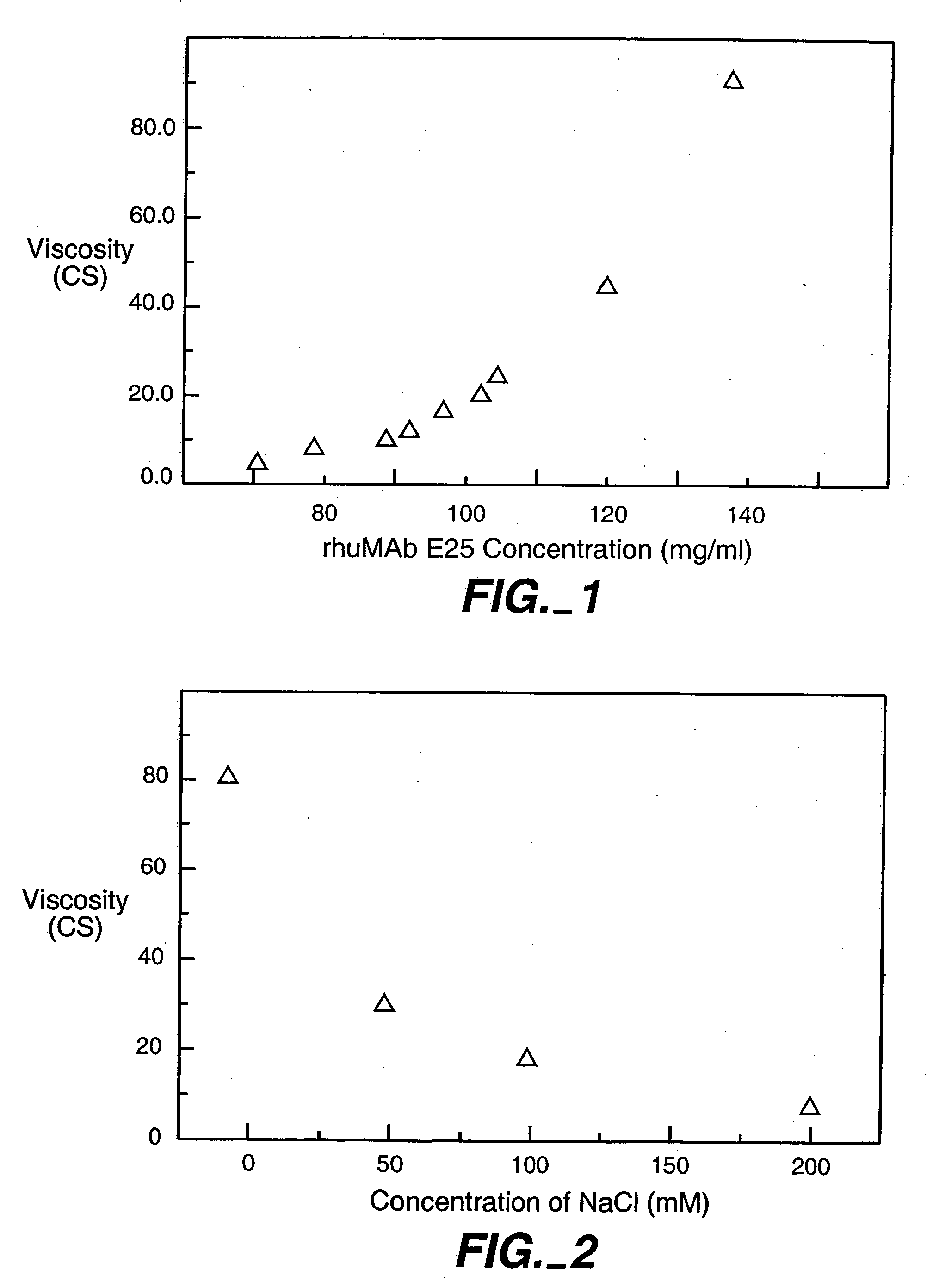

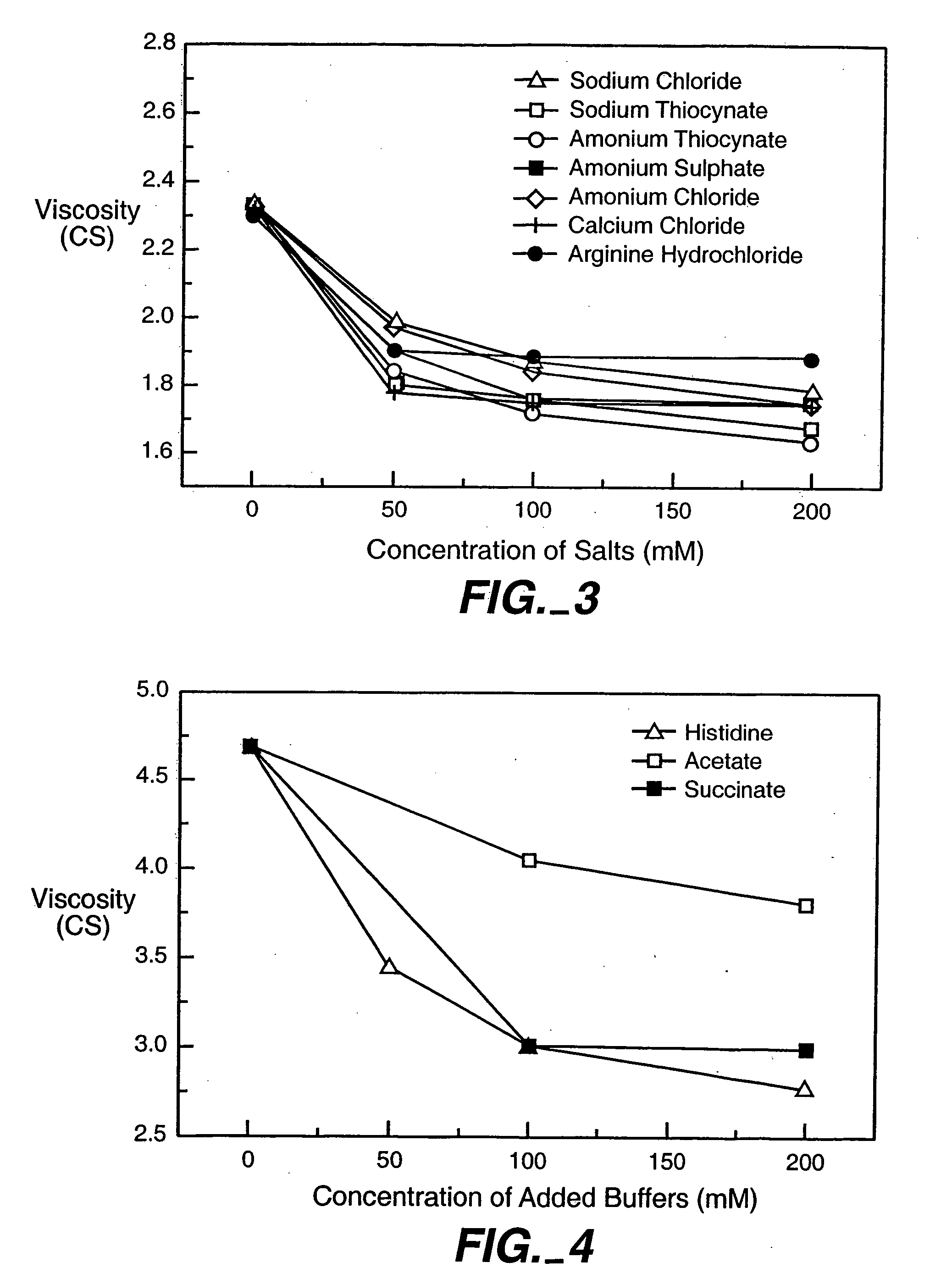

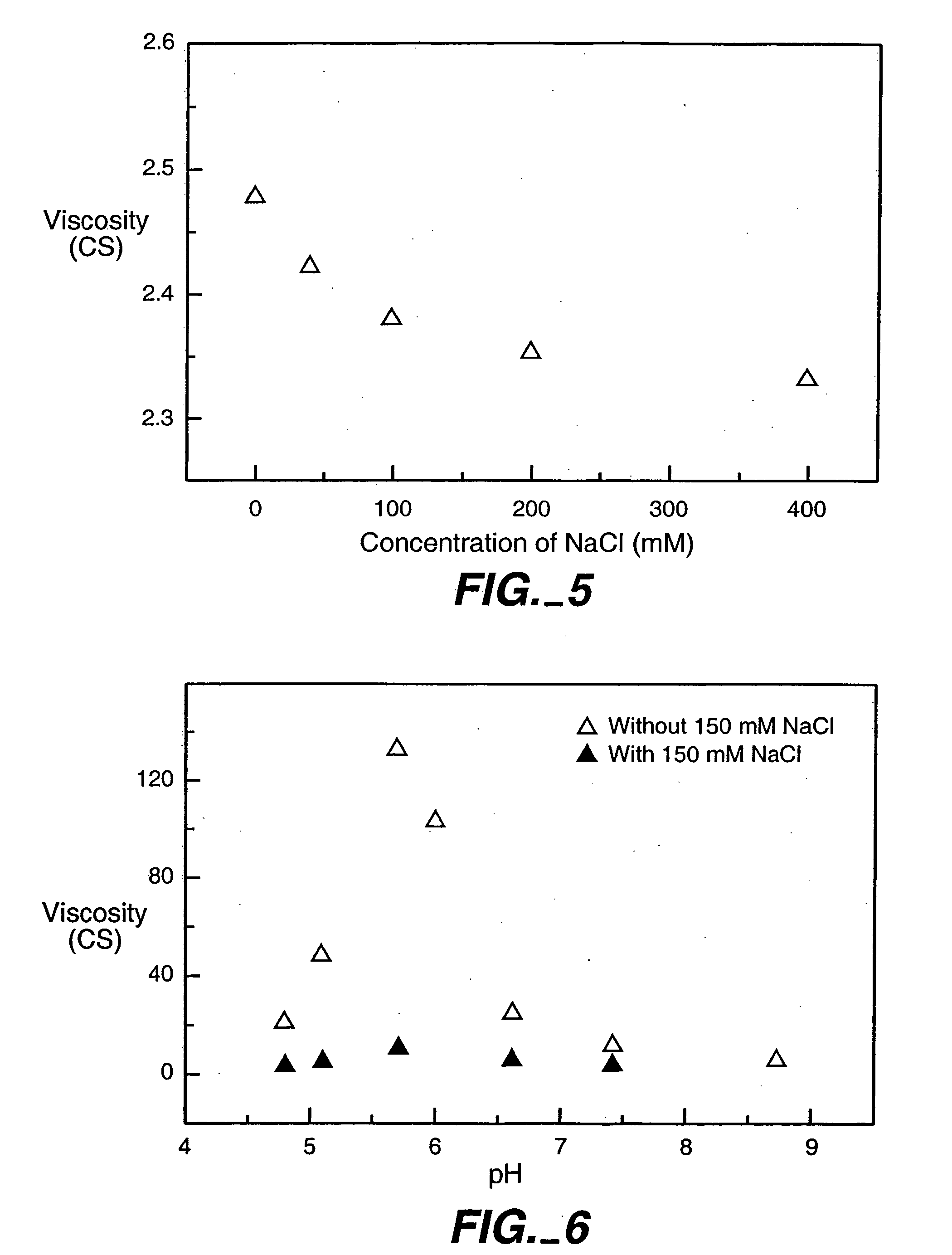

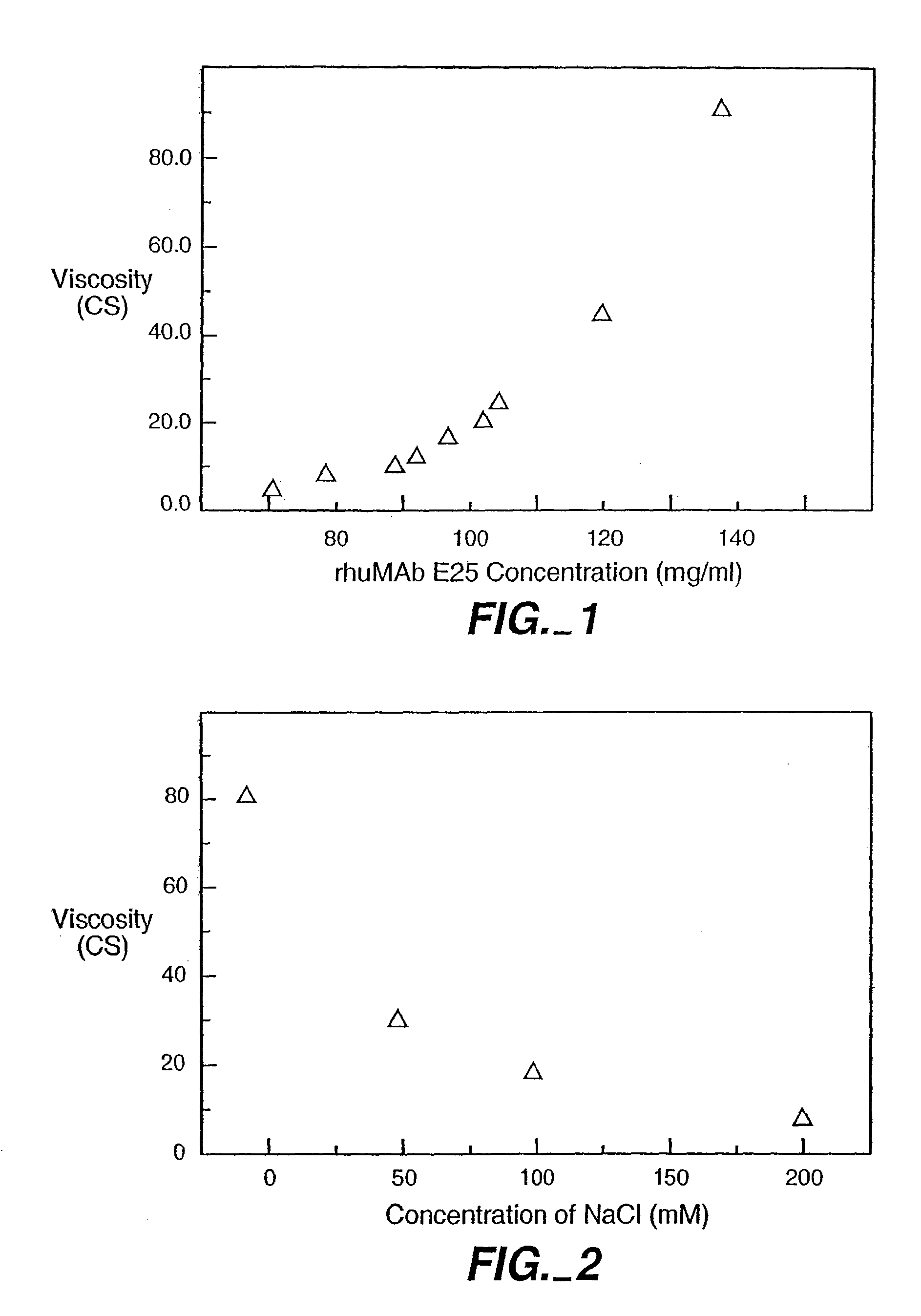

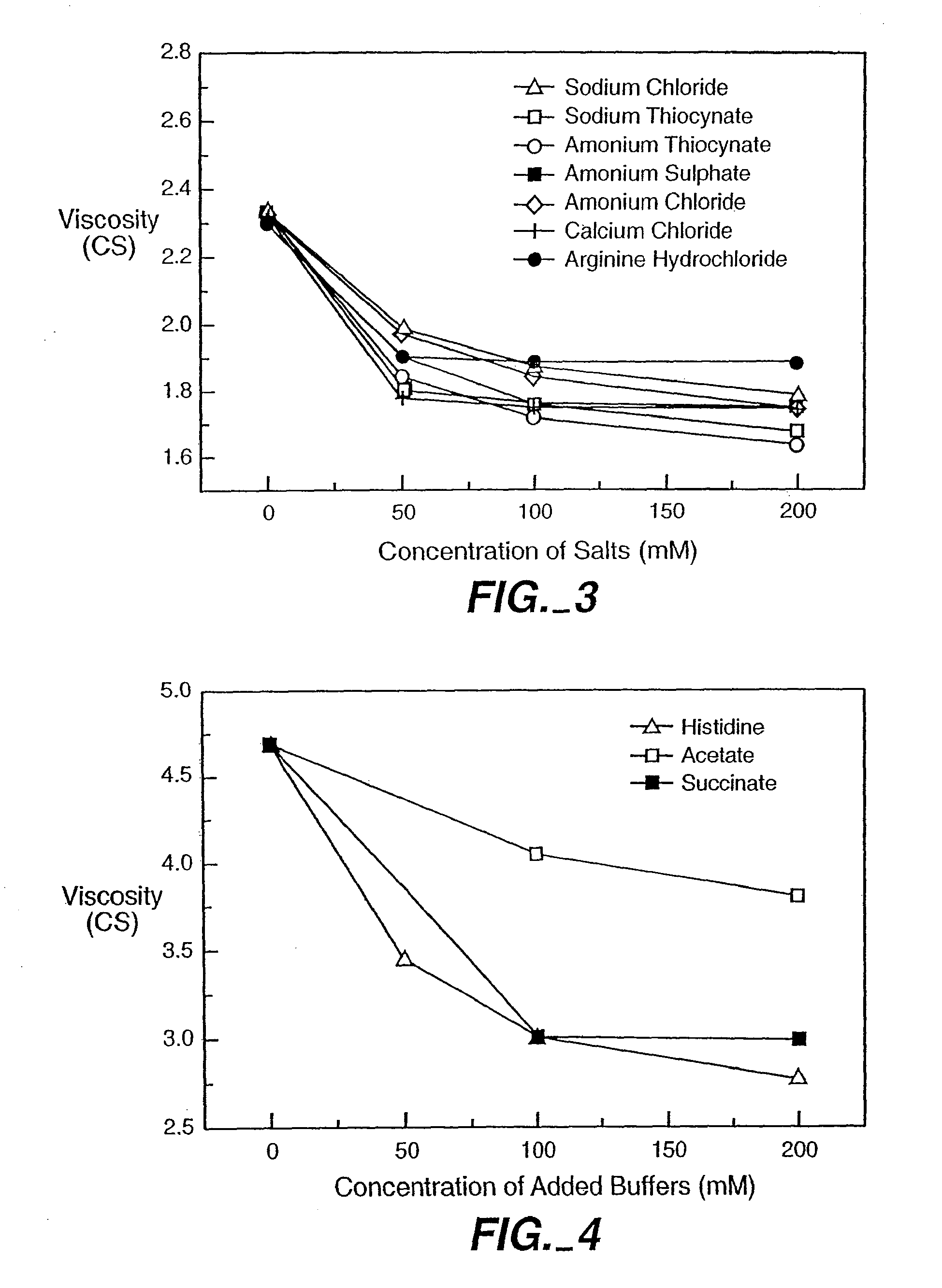

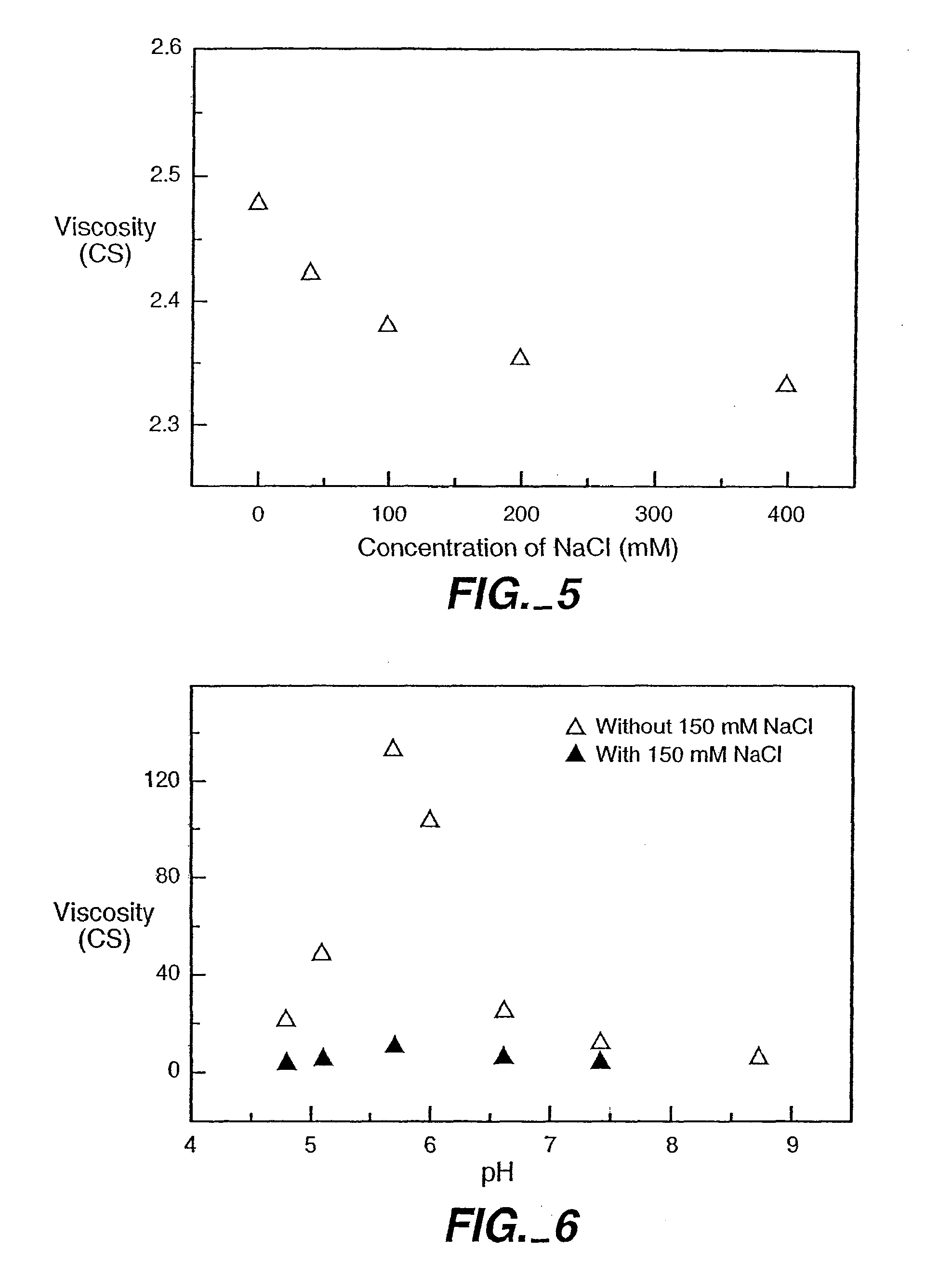

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

Reduced-viscosity concentrated protein formulations

InactiveUS20050175603A1Low viscosityCompromising stability and biological activityPeptide/protein ingredientsInorganic non-active ingredientsConcentration proteinChemistry

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

Reduced-viscosity concentrated protein formulations

InactiveUS8703126B2Low viscosityCompromising stability and biological activityInorganic non-active ingredientsAntibody ingredientsConcentration proteinReduced viscosity

The present application concerns concentrated protein formulations with reduced viscosity, which are particularly suitable for subcutaneous administration. The application further concerns a method for reducing the viscosity of concentrated protein formulations.

Owner:GENENTECH INC +1

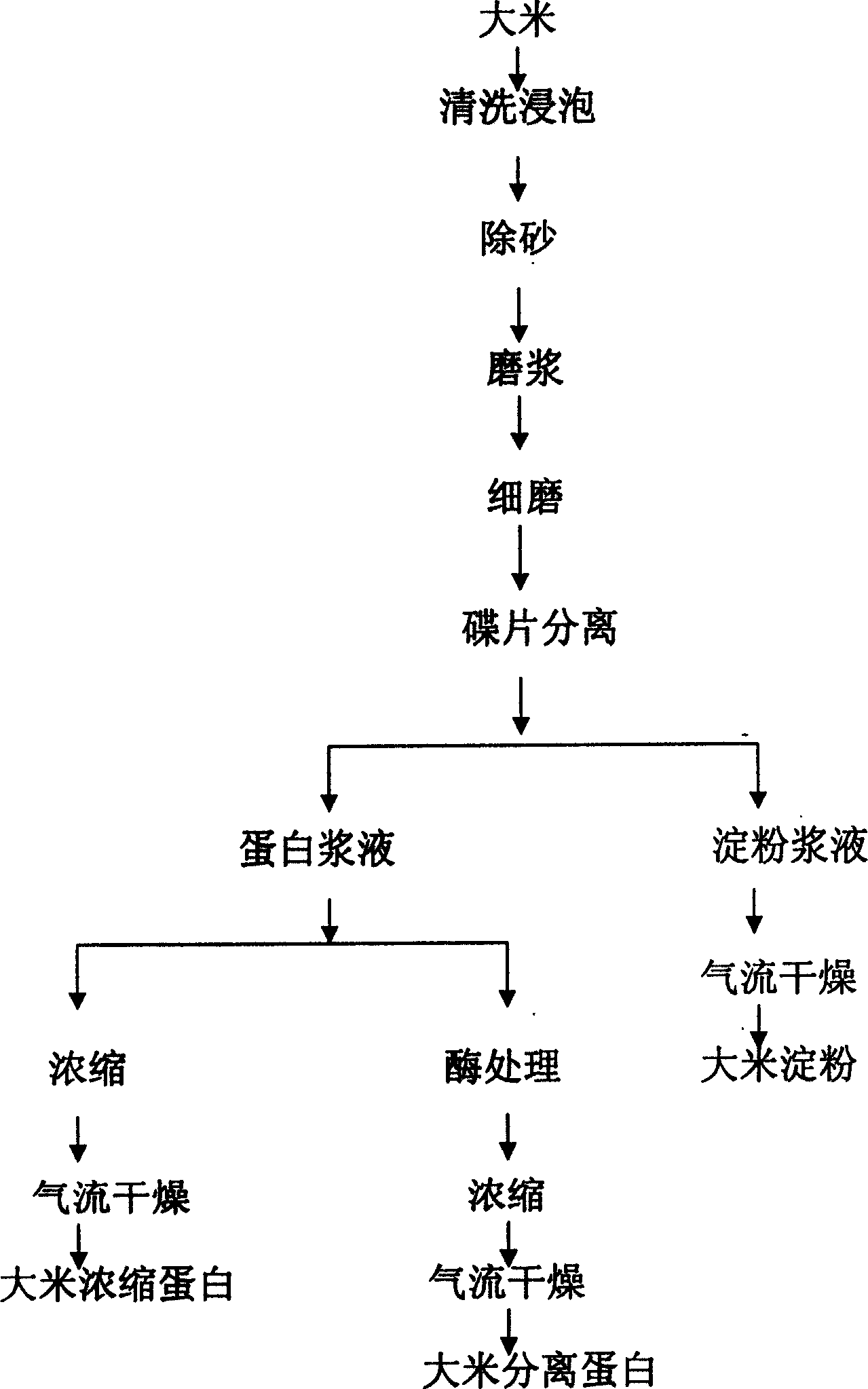

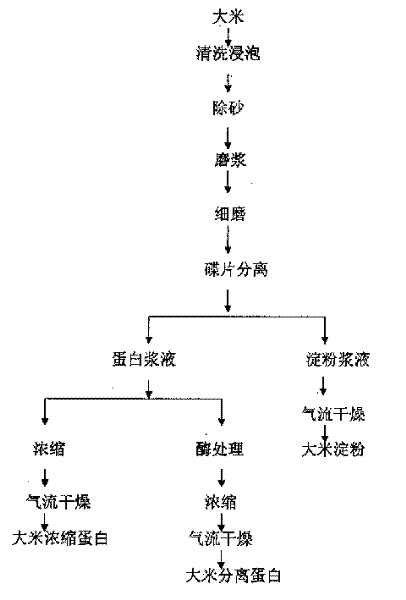

Method for extracting rice protein from rice

The present invention discloses a method for extracting rice protein from rice. Said method includes the following steps: cleaning rice, soaking, removing sand, grinding to make pulp, concentrating and drying rice protein; also includes the steps of fine-grinding rice pulp, adopting dished separating machine to make multistage separation and making the protein pulp undergo the process of enzyme treatment. The described enzyme treatment is characterized by that in the multistage separated and combined rice protein pulp the following enzymes are successively added to make reaction: adding 0.05%-0.2% of amylase, temp. is 60-70 deg.C and time is 40-60 min; adding 0.05%-0.2% of cellulase, temp. is 40-50 deg.C and time is 2-3 hr; and adding 0.1%-1% of lipase, temp. is 40-60 deg.C and time is 2-3 hr. Said method can implement industrial production of rice protein.

Owner:GAEA GEM RICE

Concentrated-protein food product and process

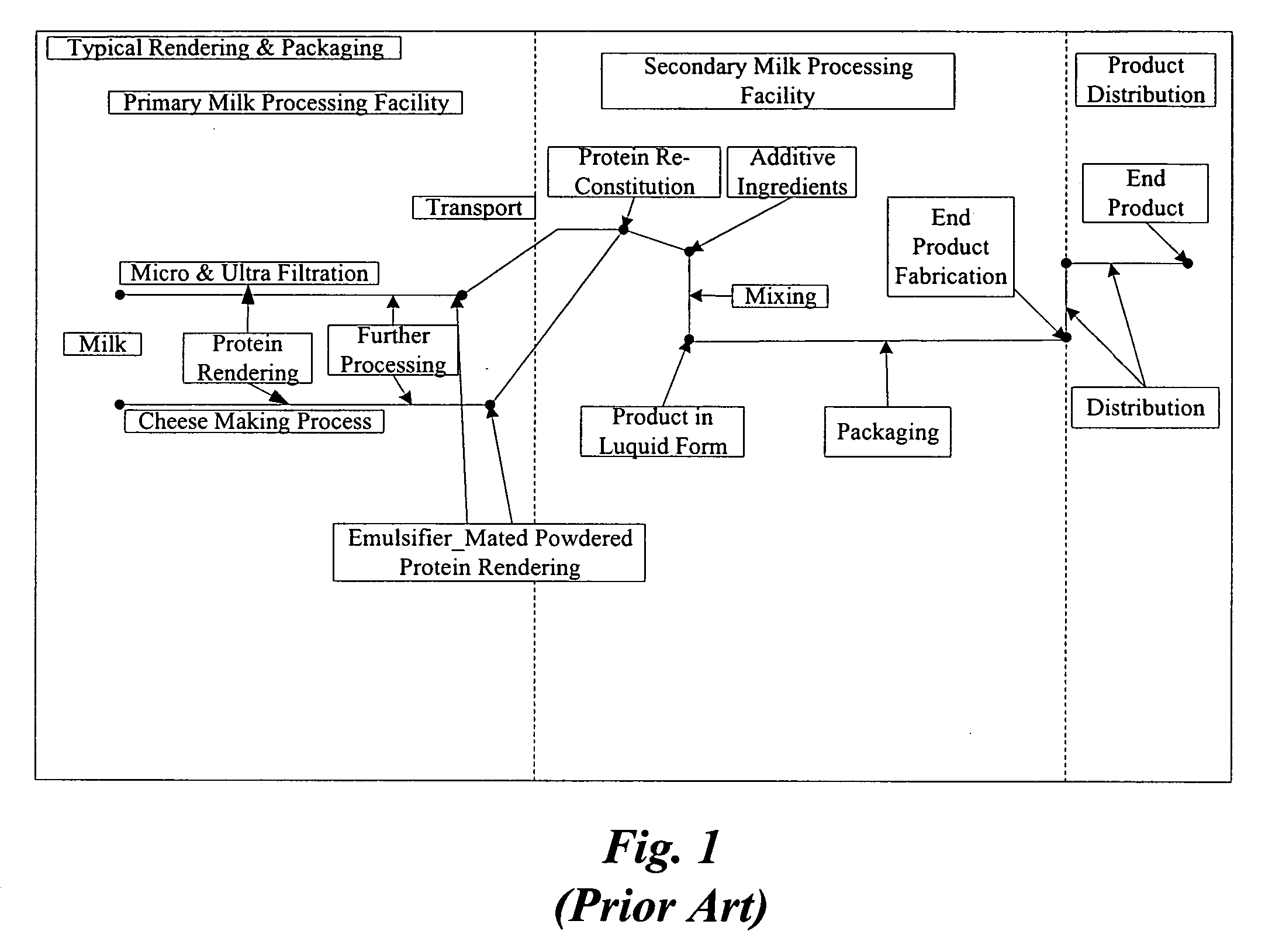

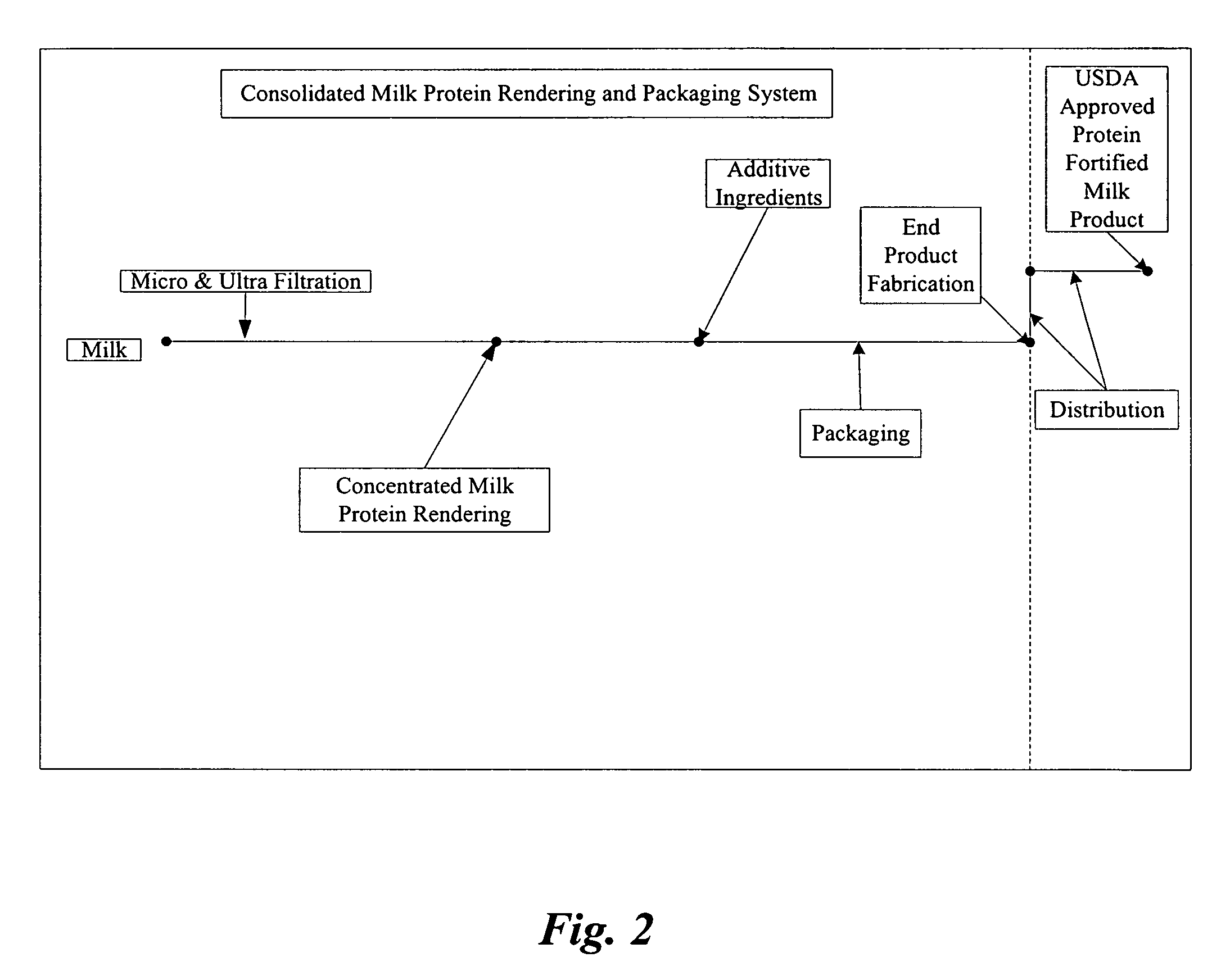

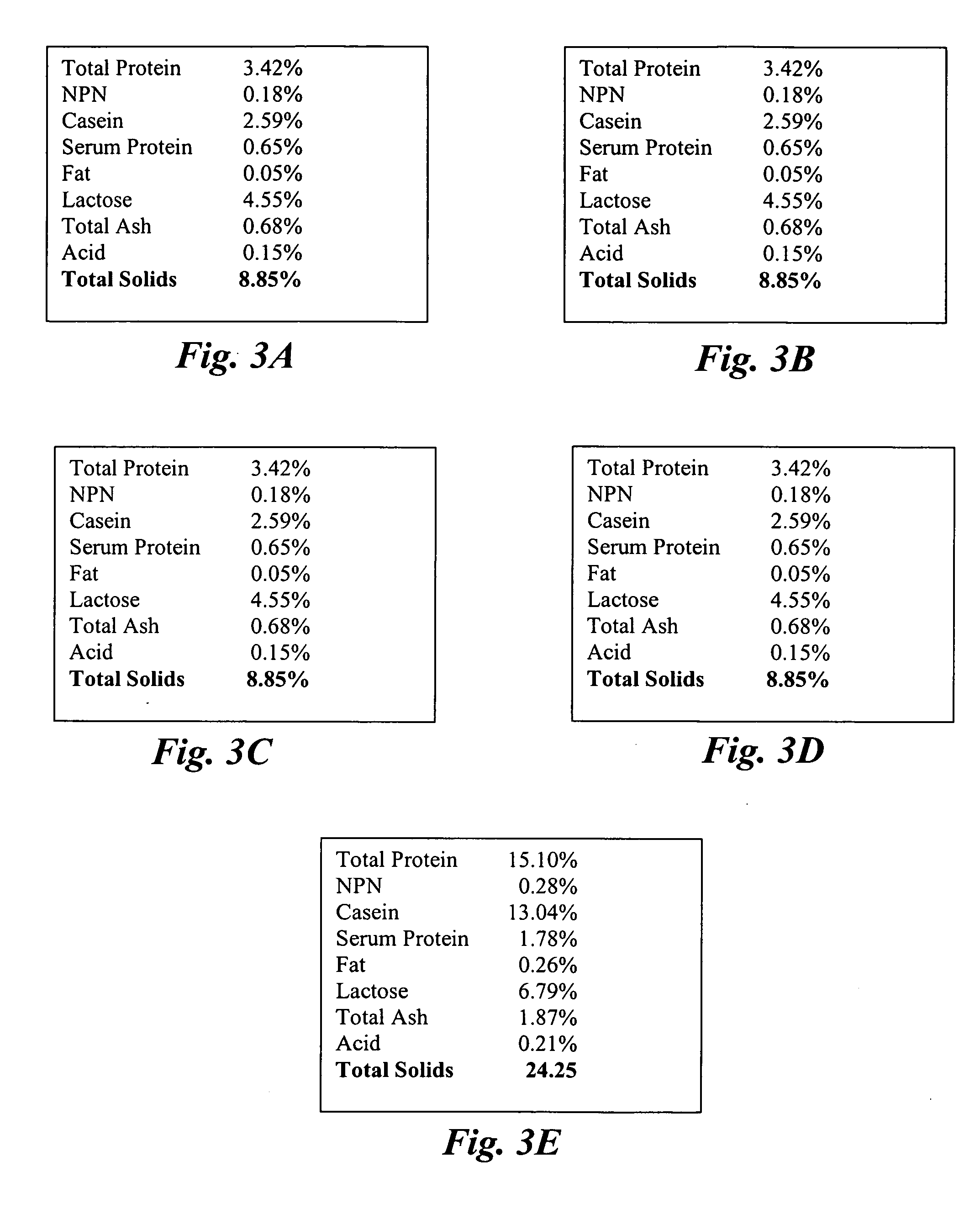

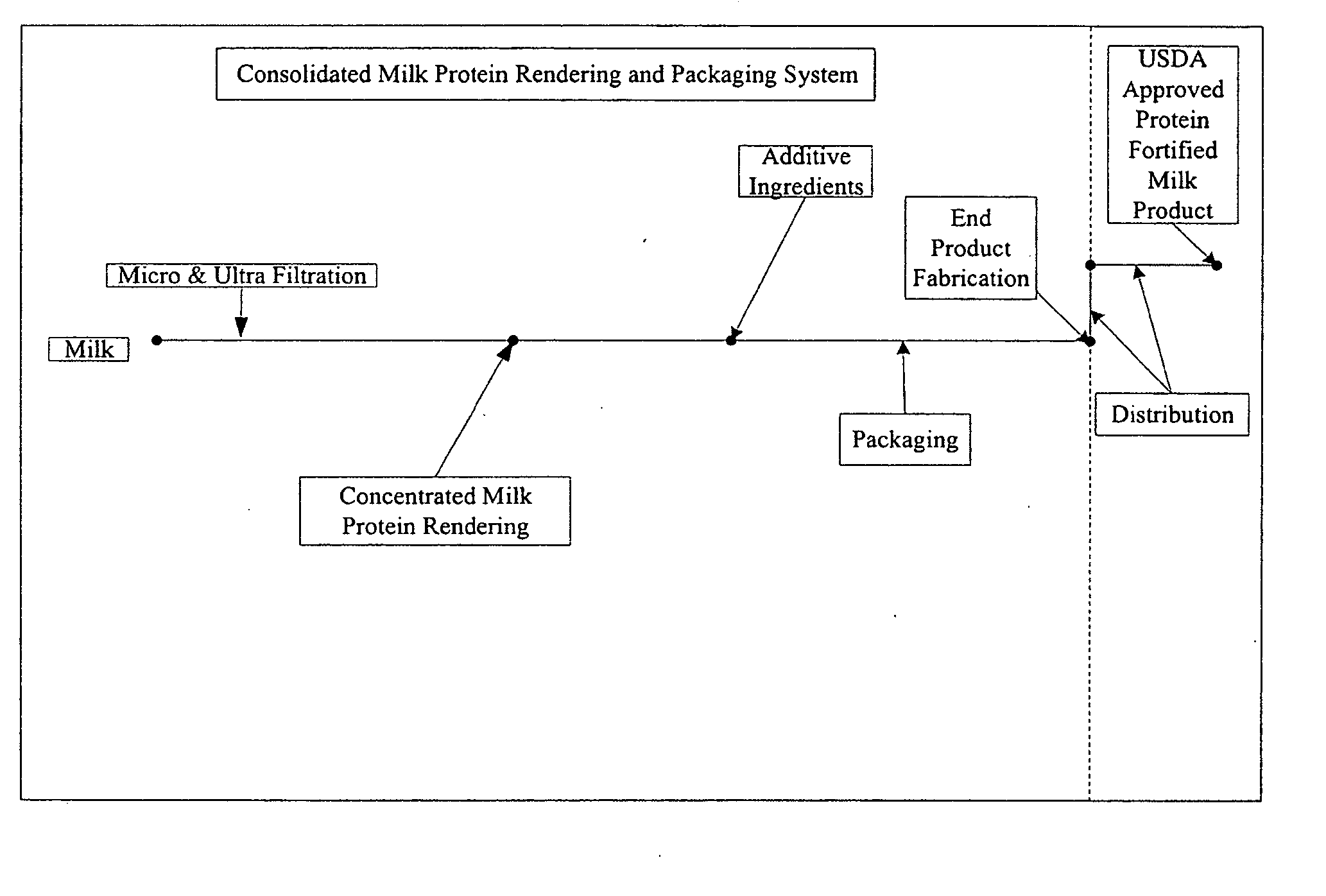

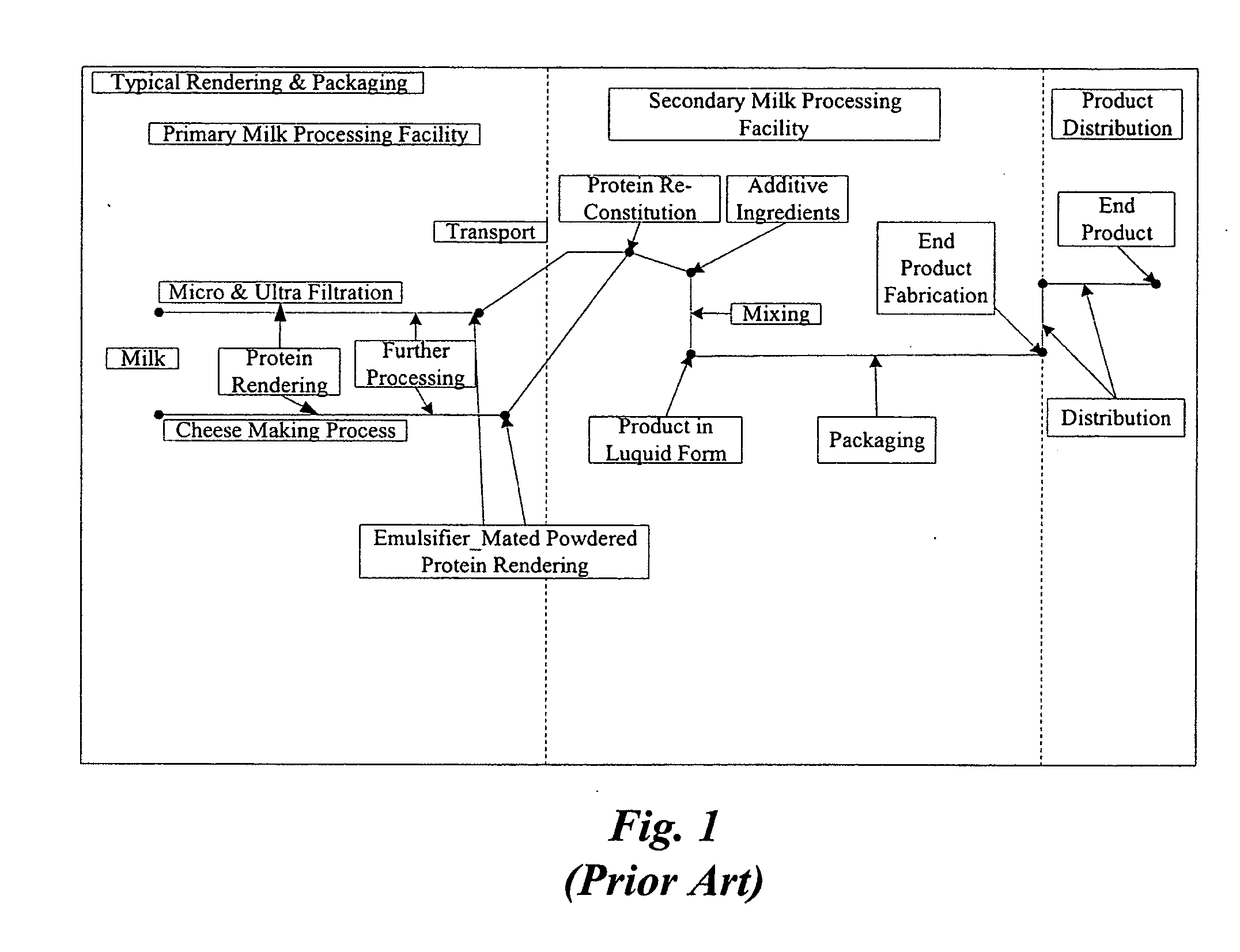

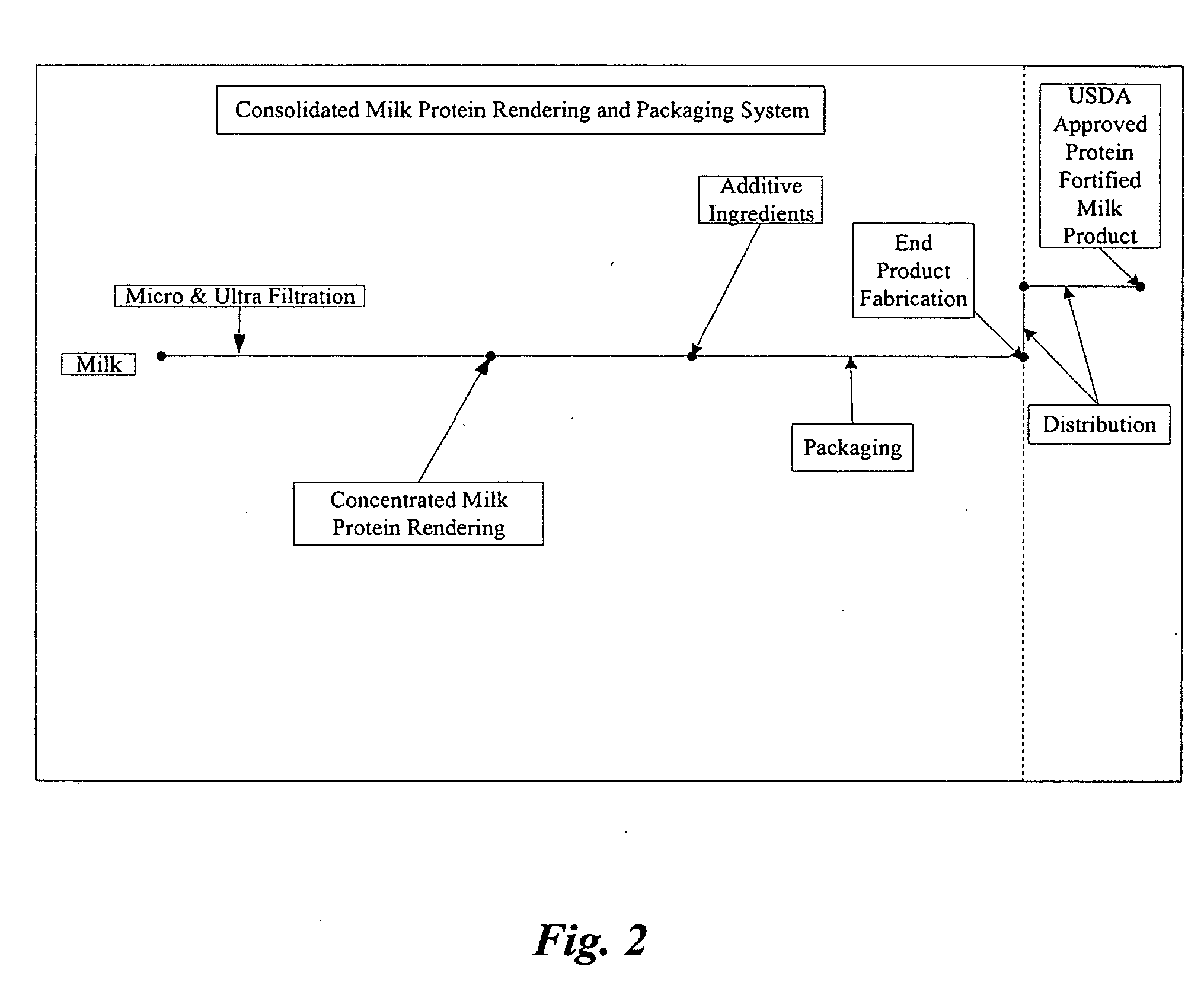

InactiveUS20050181095A1Ultra-low fatHigh in proteinMilk preparationProtein composition from milkConcentration proteinMicrofiltration

A system, processes, and milk-based food products made from the system and processes, in which cream is separated from milk to produce an ultra-low fat milk product. The milk product is microfiltered to produce a retentate that is ready to drink and is high in protein and has no or substantially no fat. The permeate from the microfiltration process is ultrafiltered to produce a retentate that is high in protein with few other solids. The permeate may be used to provide protein fortification to other food and beverage products, and is especially useful in its liquid form for such fortification.

Owner:DOMINION NUTRITION

Production process of solidified brown yogurt, and product of process

ActiveCN103141572AEnhances gel strength and water holding capacityThick and smoothMilk preparationFlavorChemistry

The invention relates to a production process of solidified brown yogurt and a product of the process, which belong to the technical field of liquid milk processing. The production process comprises the following steps of: uniformly mixing 87.5%-90.5% of raw milk, 7.5%-8.5% of edible sugar, 1.5%-2.5% of whey protein and 0.5%-1.5% of milk protein concentrate in percentage by weight, and performing homogenization, sterilization for browning, cooling, inoculation, bottling, fermentation and cold storage on the mixture to obtain the yogurt. The process can be used for producing the solidified brown yogurt having the characteristics that the curd is firm, no whey is separated out, the color is brown, the mouthfeel is thick and smooth, and the yogurt has a pleasant Maillard flavor. By virtue of the process, under the condition that no additive needs to be used, the jelly strength and the water retention property of the yogurt can be improved, so that the solidified brown yogurt is thick and smooth in mouthfeel and has the pleasant Maillard flavor; and in logistic and sale links, the mechanical disruption resistance of the yogurt is high, and no whey is separated out in the shelf life of the yogurt.

Owner:HANGZHOU NEW HOPE BIMODAL DAIRY CO LTD

Method for extracting and preparing protein powder and enzymolysis product thereof from almond meal

InactiveCN102174071AKeep aliveIncrease added valuePeptide preparation methodsFermentationProtein solutionFood additive

The invention discloses a method for continuously extracting and preparing concentrated protein, separated protein and proteolysis products from almond meal. The method comprises the following steps of: degreasing and debitterizing residual oil meal obtained after almond oil is mechanically and coldly pressed, and then extracting with a low-concentration NaCl phosphate buffer solution to obtain the concentrated protein; preparing almond separated protein from the concentrated protein solution by applying an ultrafiltration membrane technology; preparing a proteolysis-almond polypeptide mixed solution from the separated protein solution by applying an enzymolysis technology; and ultrafiltering the polypeptide mixed solution by applying a membrane technology to obtain multifunctional active almond peptide with different class level molecular weights in sequence. The method has the advantages of simple process, strong operability and easiness in control of extracting conditions and can finish the extraction and preparation of the almond concentrated protein, the separated protein and the proteolysis products in sequence; and the obtained products have high purity and wide application and can be directly used as food additives, nutrition reinforcers, health care products, medicaments, and the like needed by the protein foods and different processing foods.

Owner:NORTHWEST A & F UNIV

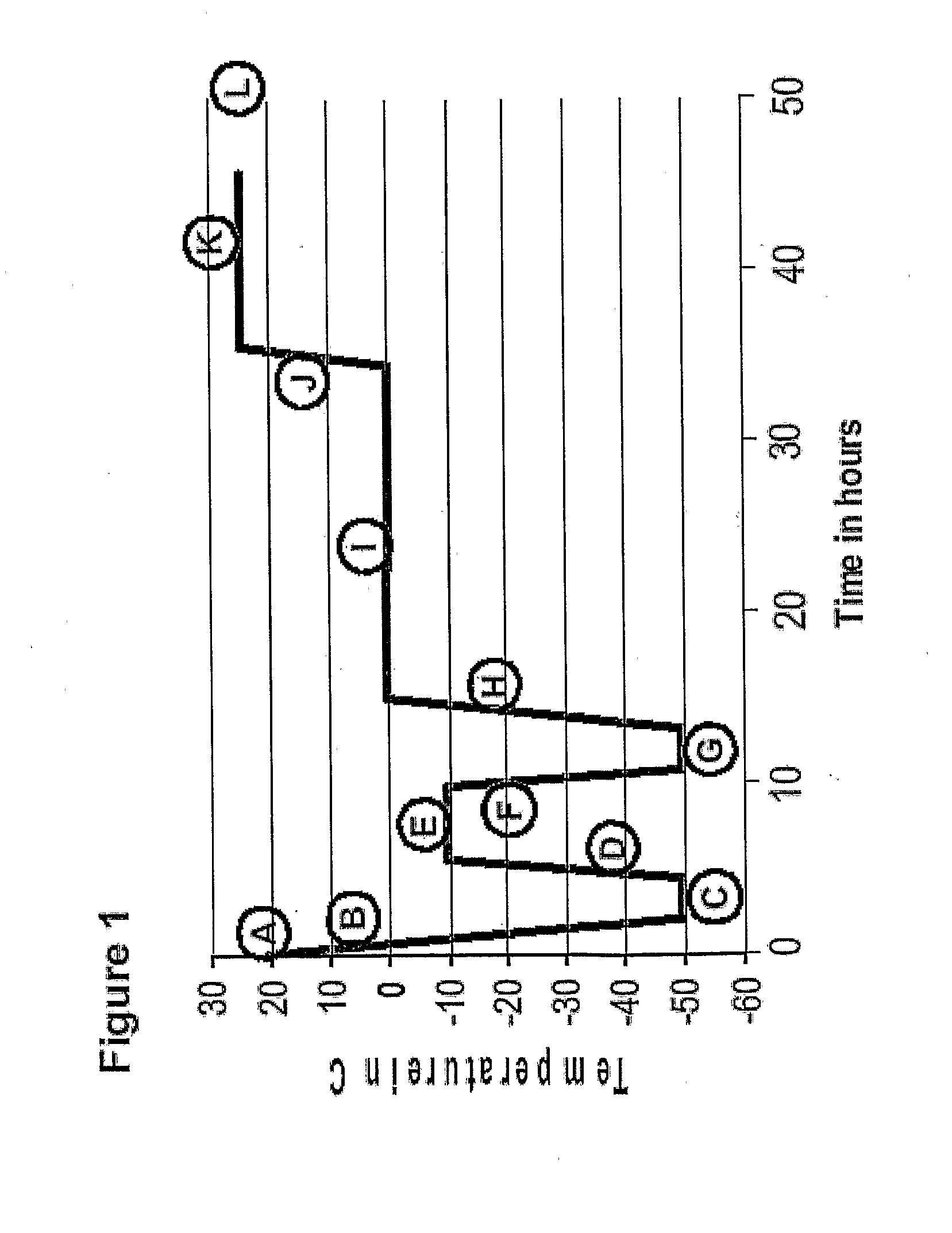

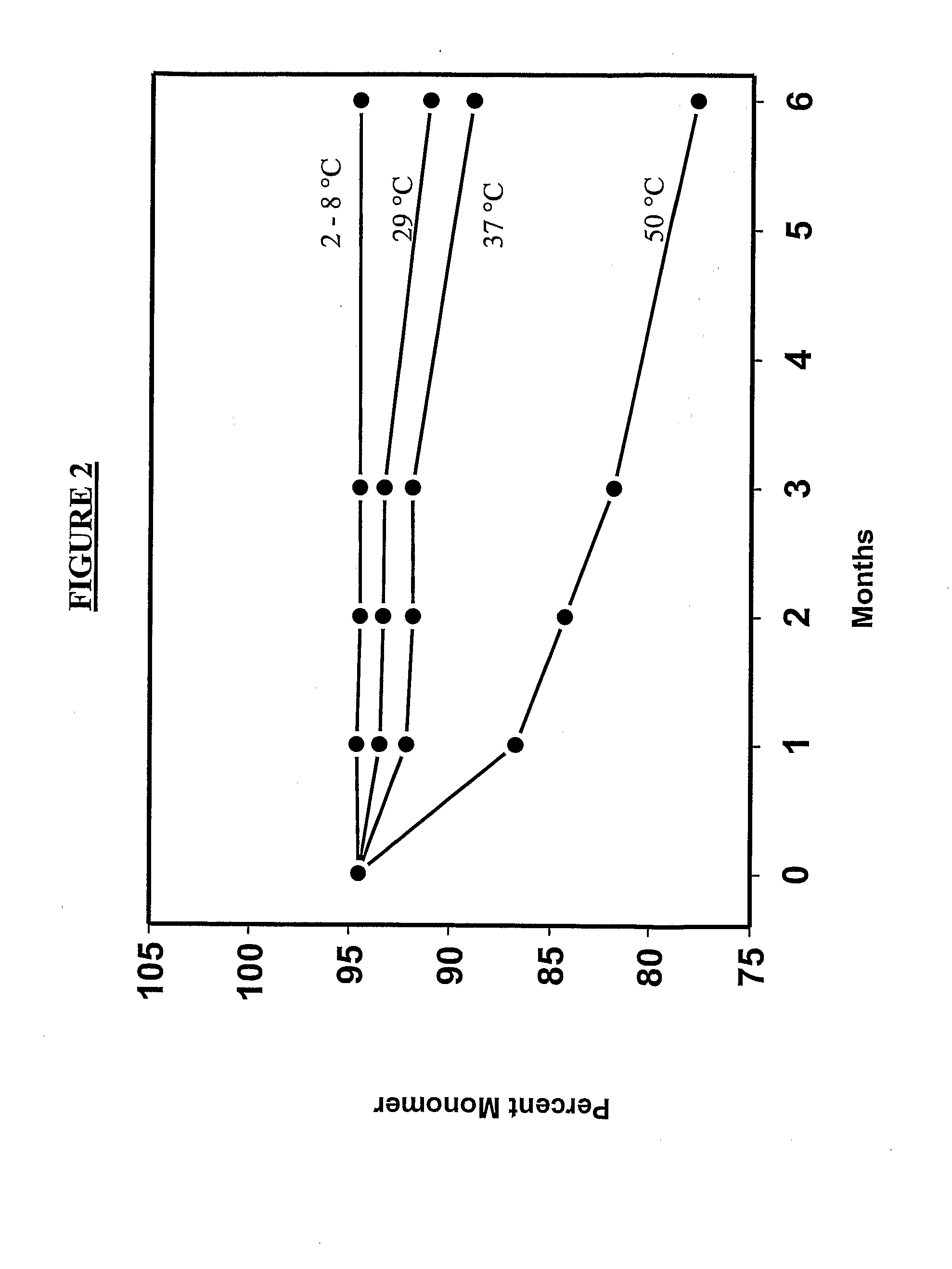

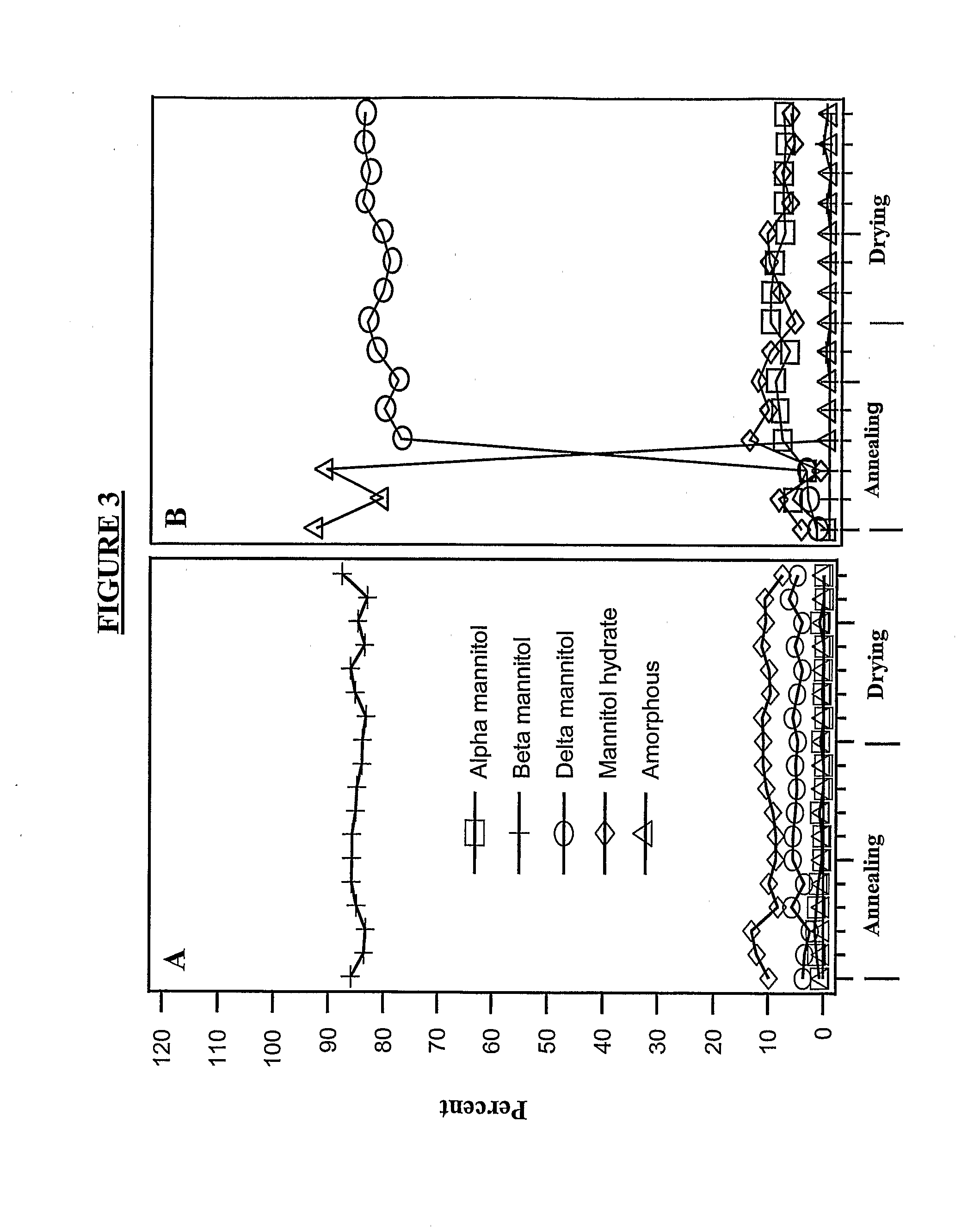

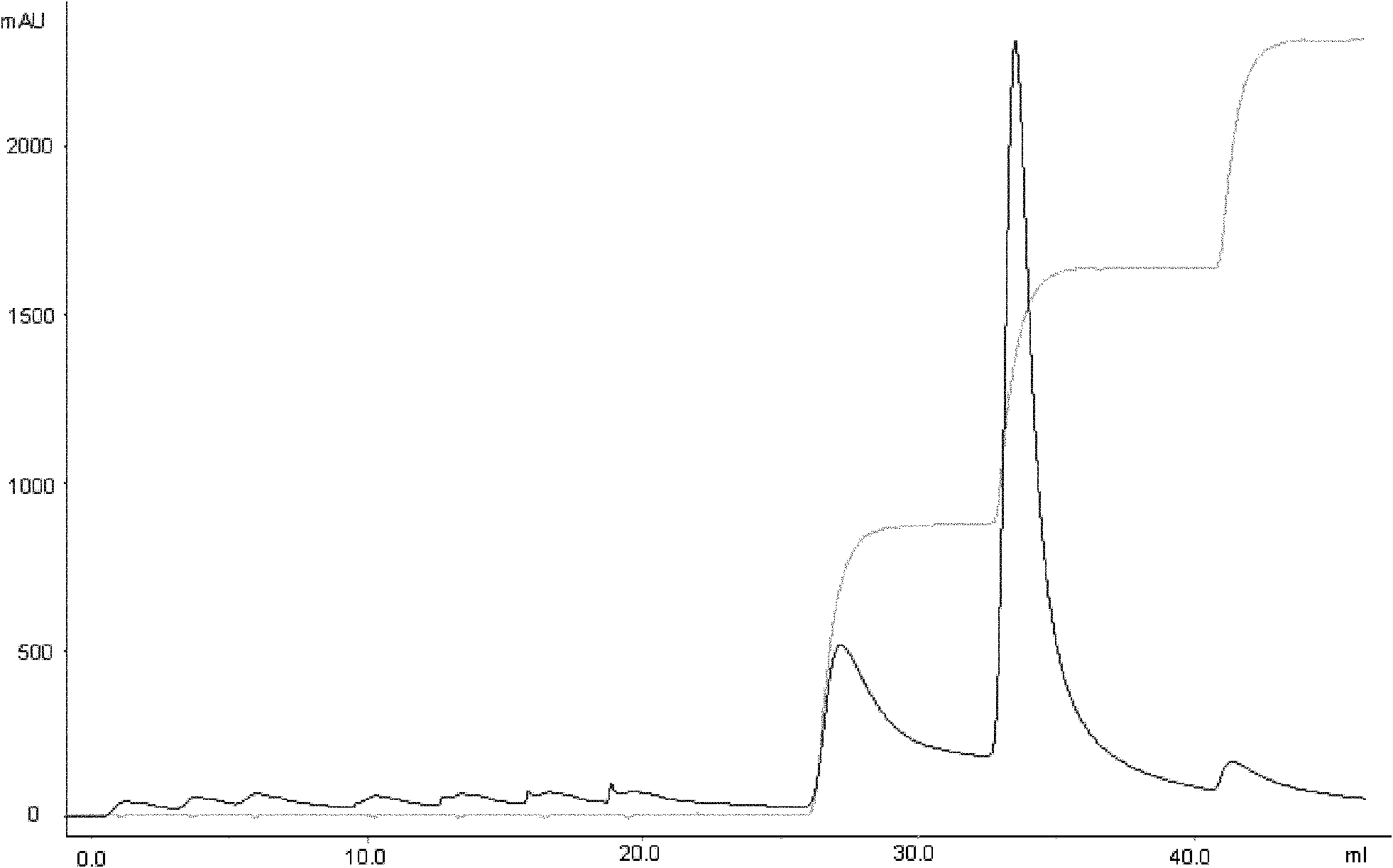

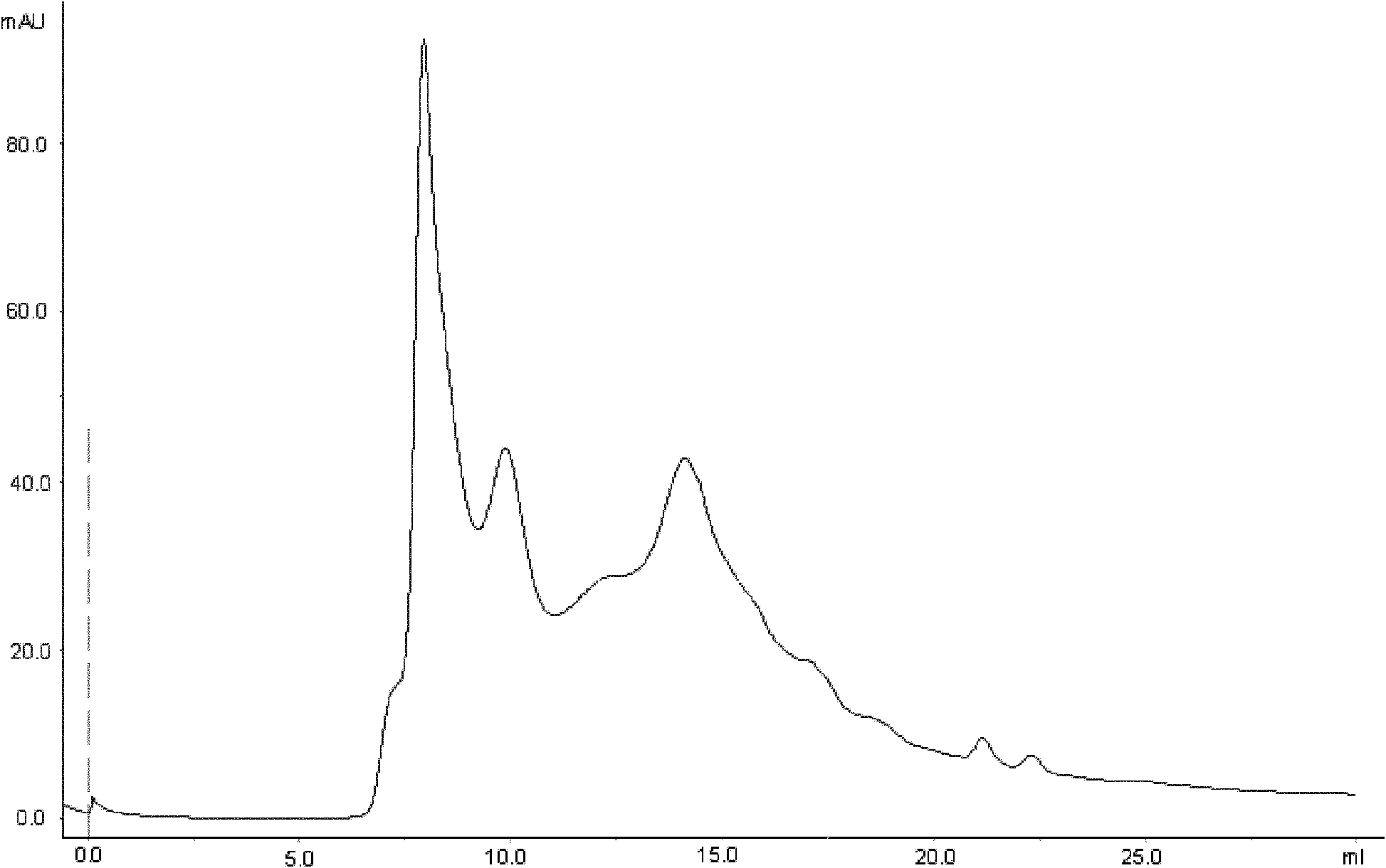

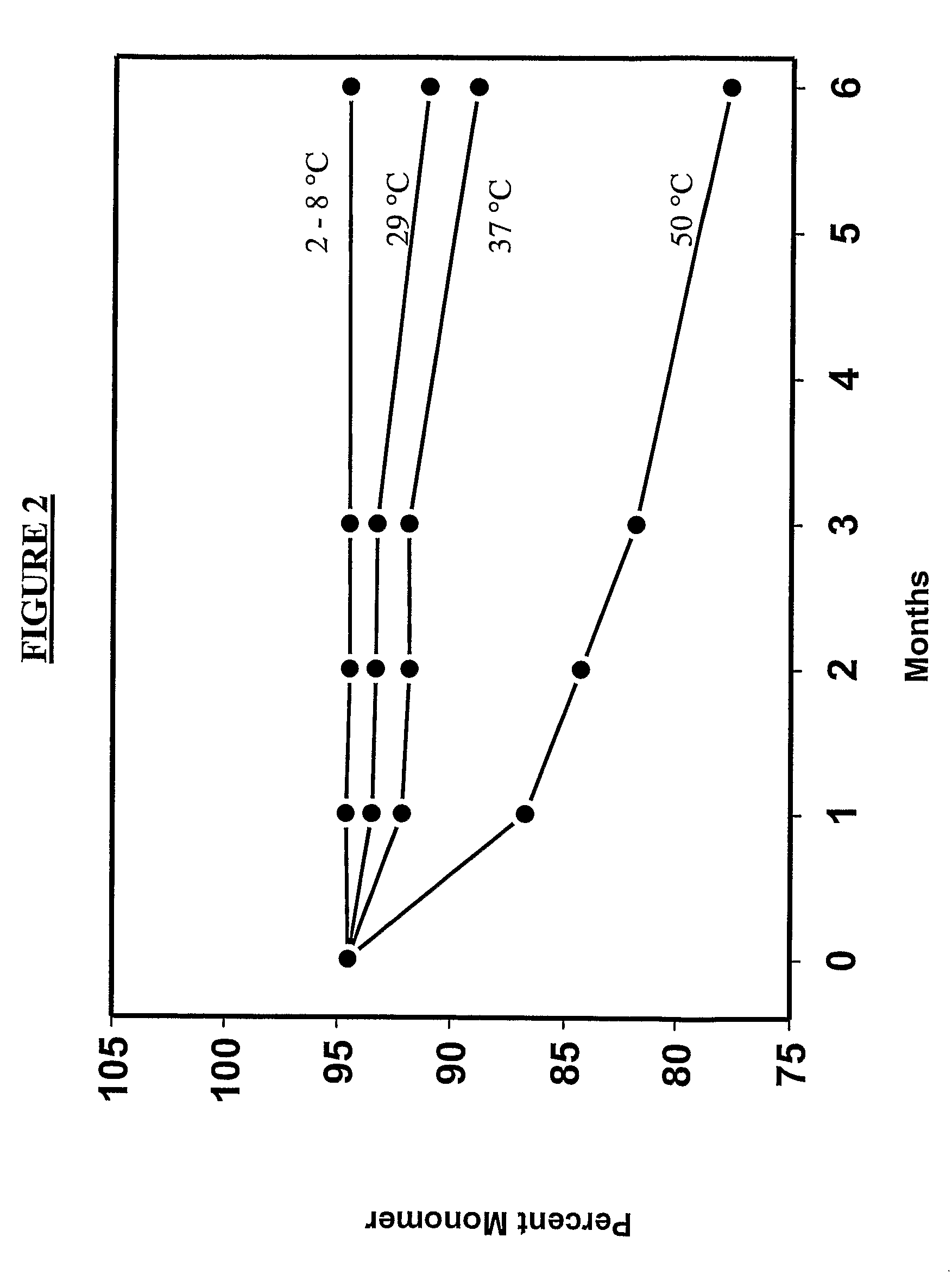

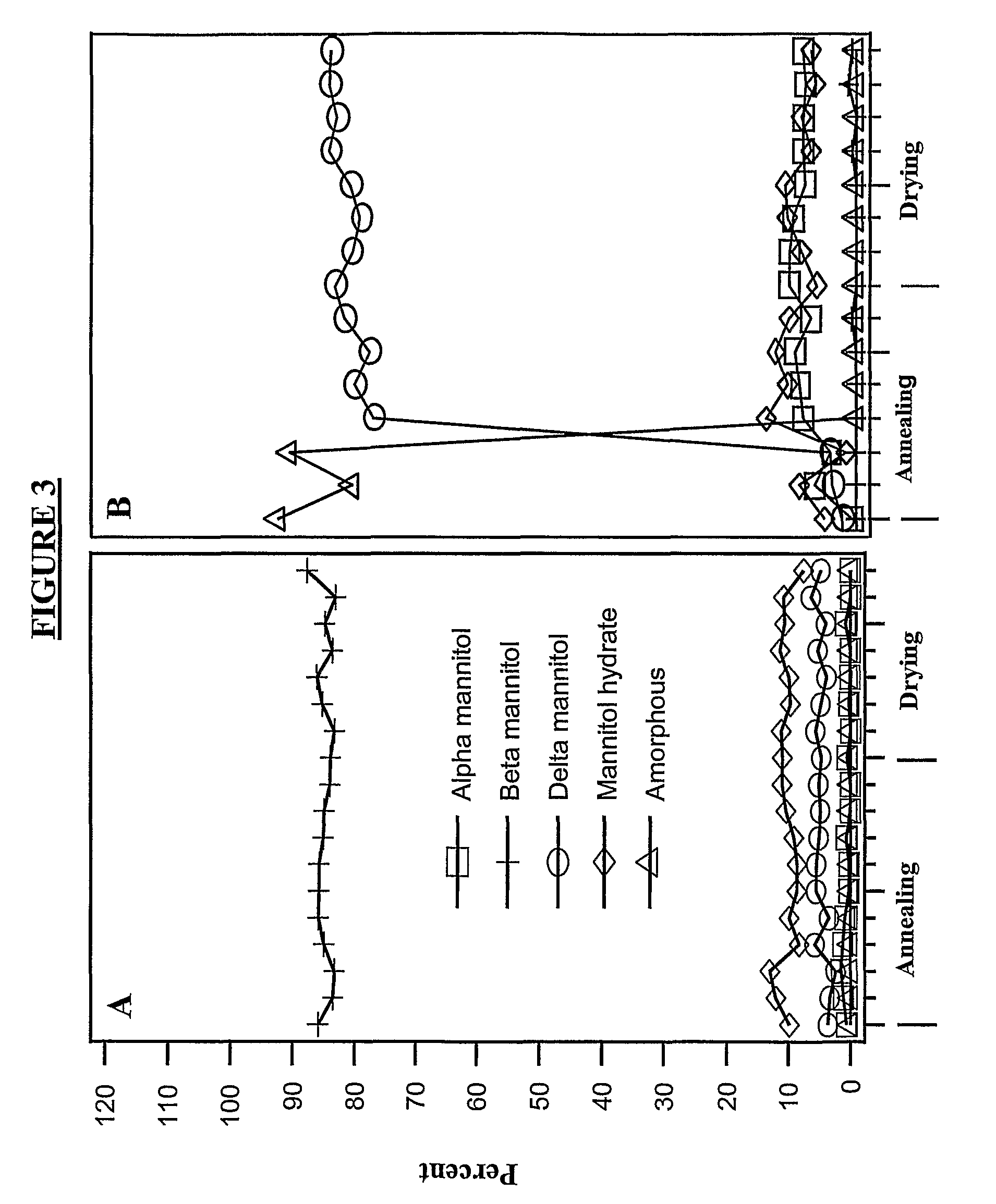

Concentrated Protein Lyophilates, Methods, and Uses

InactiveUS20080213215A1Reduce moisture contentSpeed up the flowRadiation pyrometryPeptide/protein ingredientsRaman imagingReal time analysis

The invention provides, among other things, lyophilized compositions of high surface area that comprise a protein and that reconstitute quickly and efficiently to solution of high protein concentration with minimal formation, if any, of foam, effervescence, bubbles, turbidity, or particulates that might be deleterious. The invention also provides, among other things, methods for making the lyophilized compositions. The invention in additional aspects also provides Raman Imaging Spectrographic methods for real time analyses of polymorphs in a sample using PLS algorithms. By way of particular example, the use of the method for the analysis of mannitol polymorphs is described, and the use of the analysis to determine optimum compositions and lyophilization methods for producing lyophilates of pharmaceutical proteins having a predefined distribution of mannitol polymorphs and having the aforementioned reconstitution properties is also described.

Owner:AMGEN INC

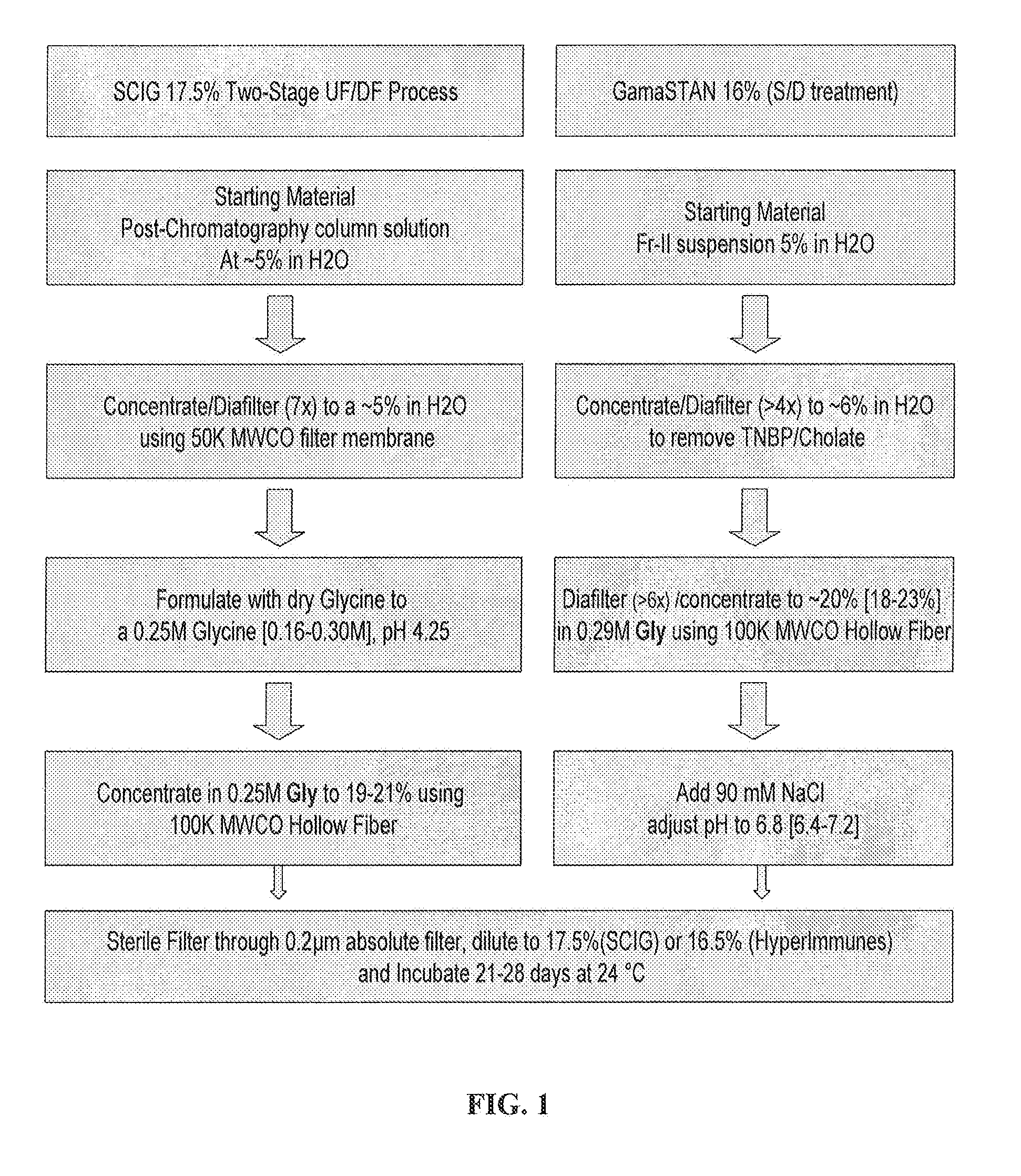

Two-stage ultrafiltration/diafiltration

The present invention provides a method for concentrating a protein, in particular a method for concentrating a plasma product, in particular IgG, using glycine in a (two-stage ultrafiltration / diafiltration approach.

Owner:GRIFOLS THERAPEUTICS LLC

Process method for quickly preparing soybean antioxidant peptide

The invention discloses a process method for quickly preparing a soybean antioxidant peptide, belonging to the technical fields of deep processing of agricultural and sideline products and comprehensive utilization of byproducts thereof, and relating to the process method for quickly preparing the soybean antioxidant peptide by using a microwave technology. According to the process method, soybean protein concentrate powder with protein content of 70 percent is used as a raw material, the material passes through a microwave extractor through processes of preparing the soybean protein concentrate powder, pretreating soybean protein concentrate powder emulsion, performing microwave auxiliary enzymatic treatment on the soybean protein concentrate powder emulsion, deactivating enzymatic hydrolysate, centrifuging, performing ultrafiltration treatment and performing vacuum freeze drying treatment by using the microwave auxiliary enzymatic hydrolysis technology; the enzymatic hydrolysis time is shortened to 35-38 minutes; and compared with the conventional enzymatic hydrolysis, the efficiency is increased by 3-4 times, and the ABTS (2, 2'-azino-bis (3-ethylbenzthiazoline-6-sulfonic acid)) free radical clear rate is over 72 percent and is equivalent to that of the conventional enzyme. According to the process method, a new idea is provided for technical research for quickly preparing the soybean antioxidant peptide, and a new approach is provided for development and application of soybean series products of high antioxidant activity.

Owner:JILIN UNIV

Concentrated-protein food product and process

InactiveUS20060172058A1Protein composition from fishMilk preparationConcentration proteinMicrofiltration

A system, processes, and milk-based food products made from the system and processes, in which cream is separated from milk to produce an ultra-low fat milk product. The milk product is microfiltered to produce a retentate that is ready to drink and is high in protein and has no or substantially no fat. The permeate from the microfiltration process is ultrafiltered to produce a retentate that is high in protein with few other solids. The permeate of the ultrafiltration step, or other milk salt containing fluid may be used to perform diafiltration on the retentate of the microfiltration process. The permeate may also be used to provide protein fortification to other food and beverage products, and is especially useful in its liquid form for such fortification.

Owner:DOMINION NUTRITION

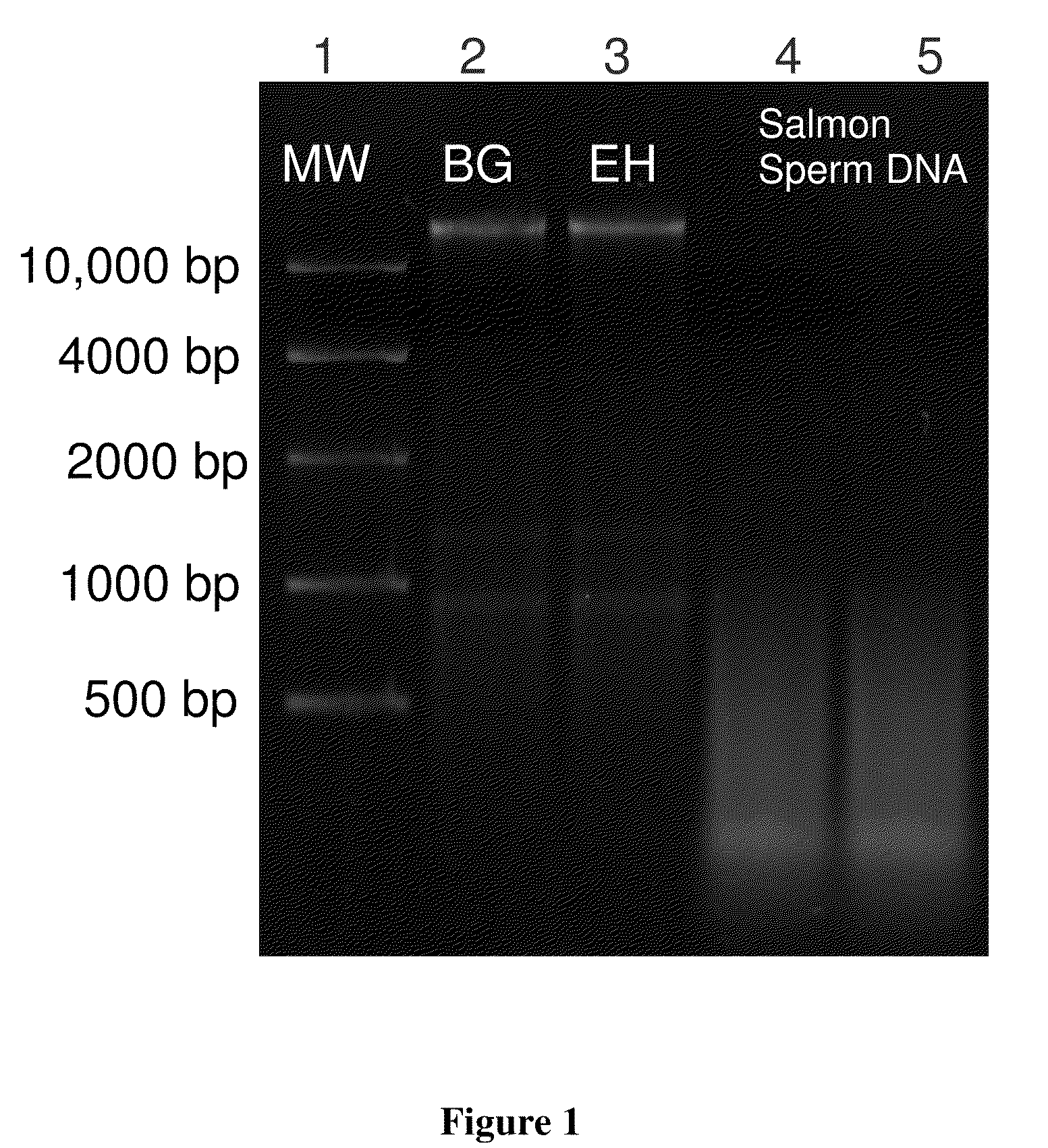

Purification and Concentration of Proteins and DNA from a Complex Sample Using Isotachophoresis and a Device to Perform the Purification

A method of simultaneously co-purifying and concentrating nucleic acid and protein targets is described. The method includes automation of the entire sample preparation process, performed by having an analyst add a sample into a device that performs all of the steps necessary to prepare a sample for analysis. The method provides for samples that are not split during the sample preparation process and where common purification methods can be used for purifying multiple analytes.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

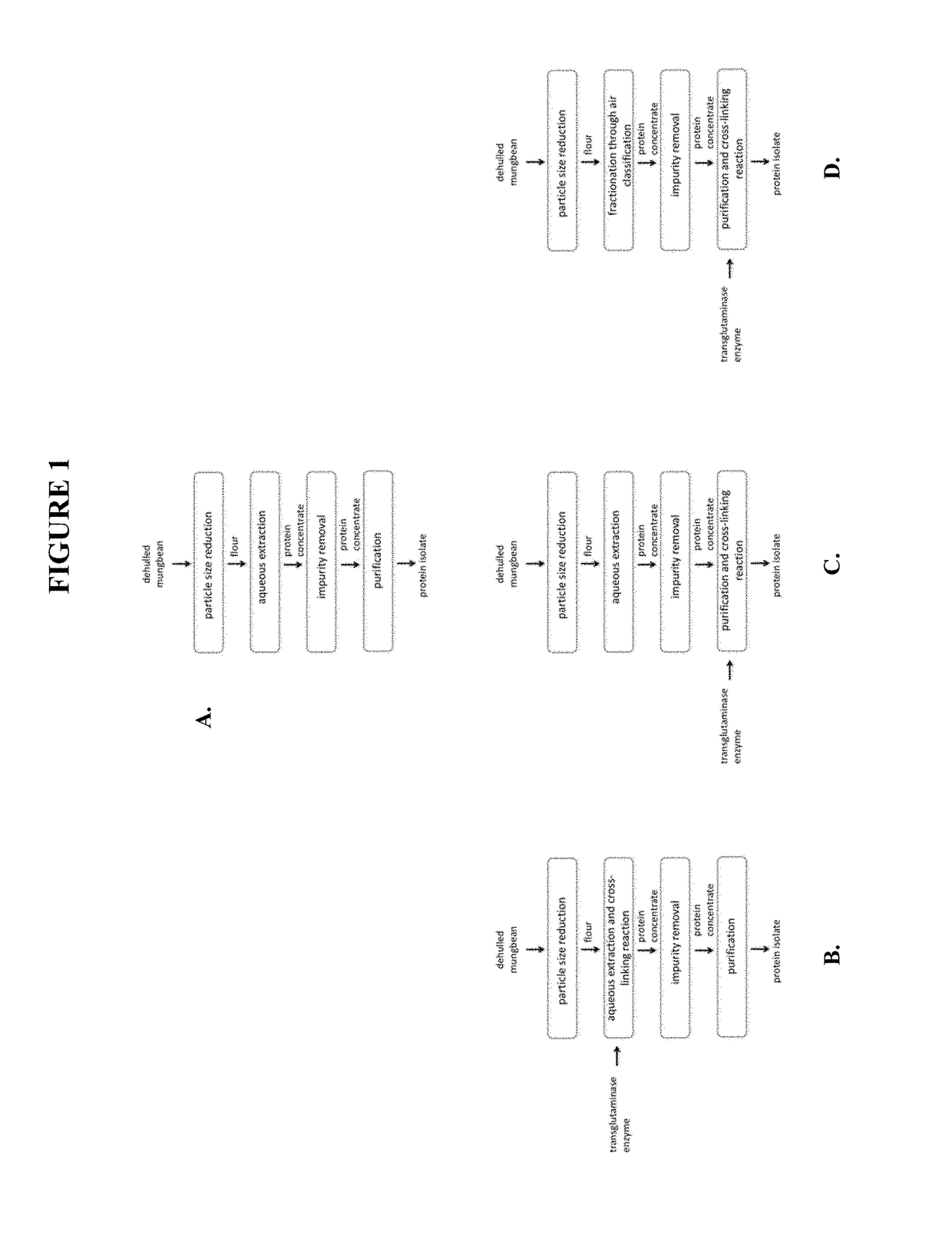

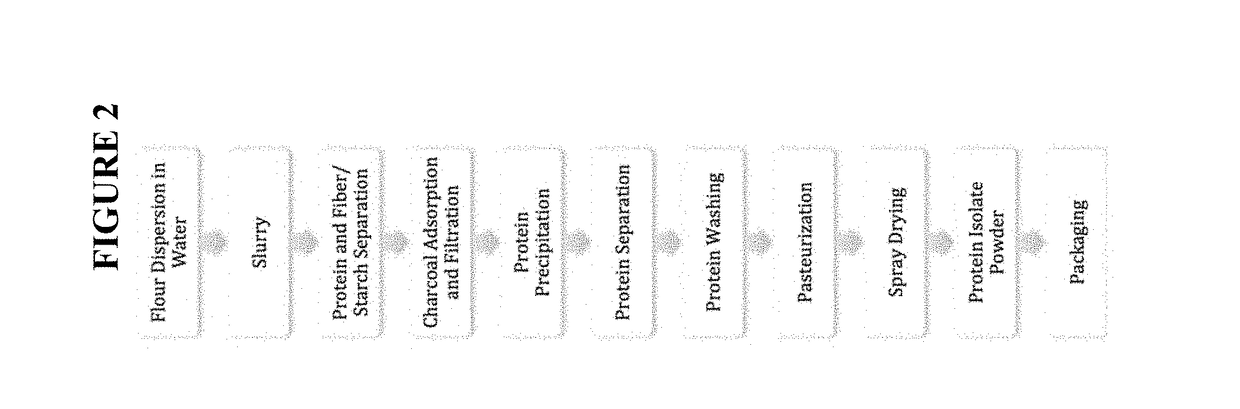

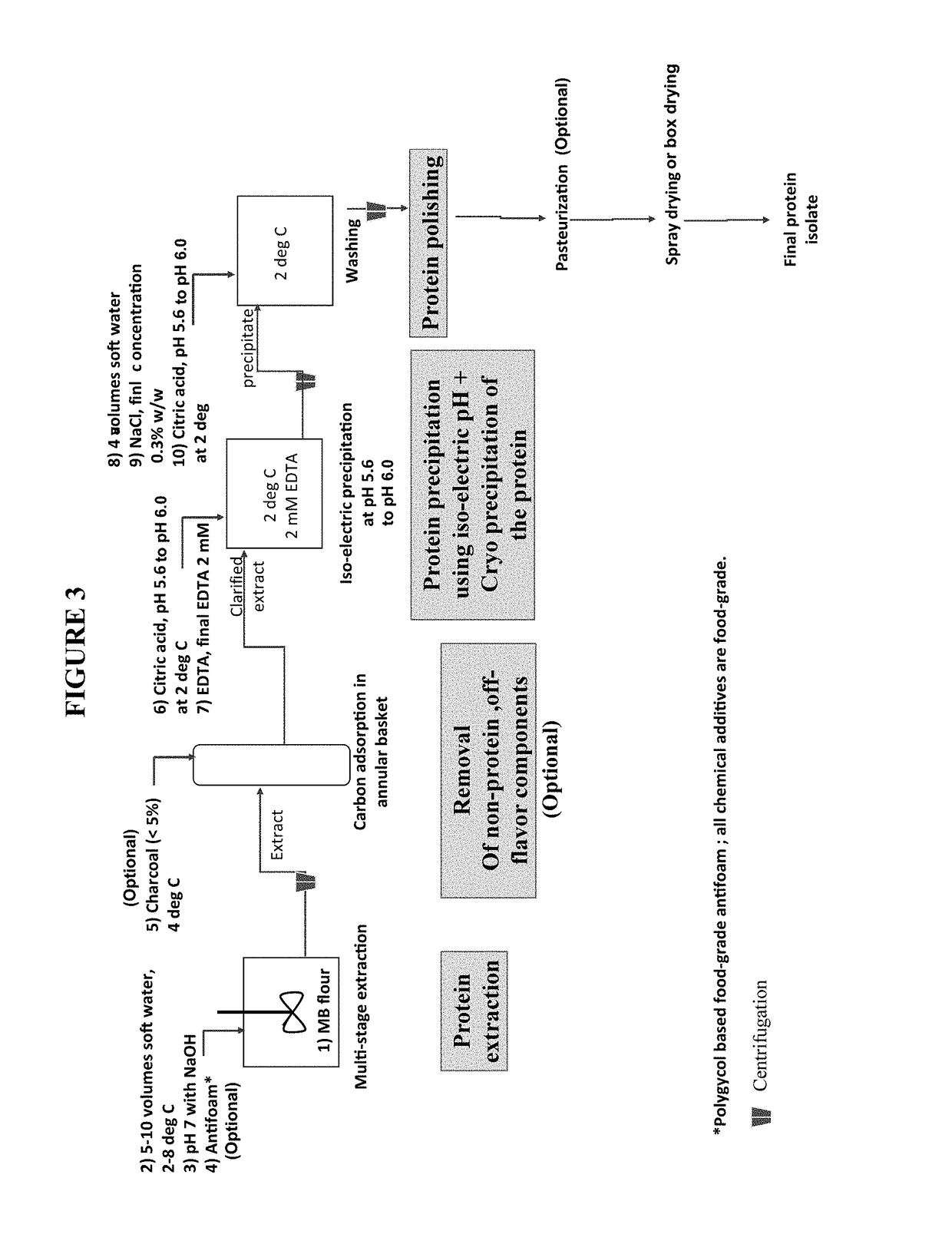

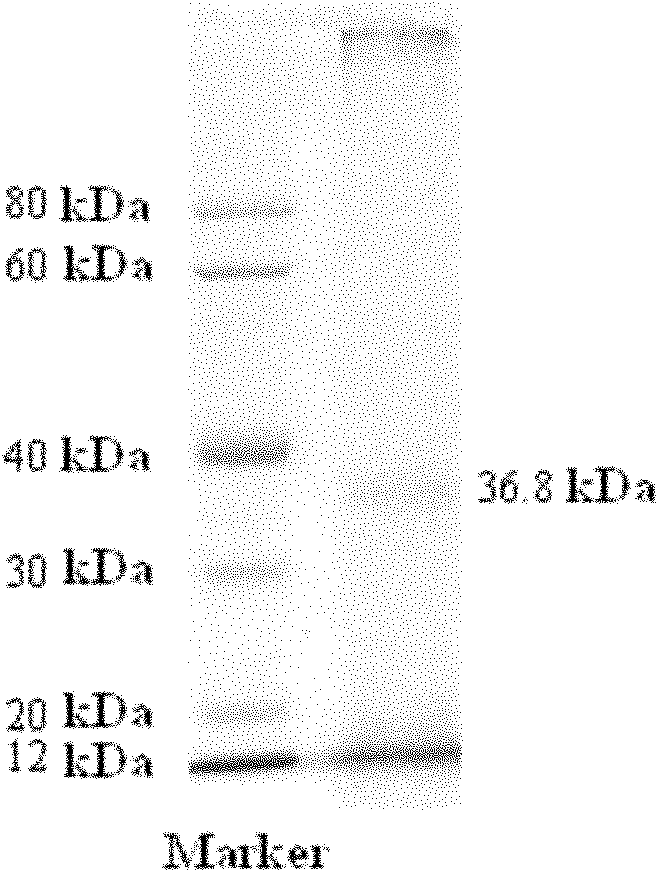

Functional mung bean-derived compositions

ActiveUS20170238590A1Reduced enzymatic activityReduced activityDough treatmentFrozen sweetsProtein isolateFiltration

Provided herein are methods for producing a mung bean protein isolate having high functionality for a broad range of food applications. In some embodiments, the methods for producing the isolate comprise one or more steps selected from: (a) extracting one or more mung bean proteins from a mung bean protein source in an aqueous solution, for example, at a pH between about 6.5-10.0; (b) purifying protein from the extract using at least one of two methods: (i) precipitating protein from the extract at a pH near the isoelectric point of a globulin-rich fraction, for example a pH between about 5.0-6.0; and / or (ii) fractionating and concentrating protein from the extract using filtration such as microfiltration, ultrafiltration or ion-exchange chromatography; and (c) recovering purified protein isolate.

Owner:JUST INC

Modification method of soybean protein concentrate

InactiveCN1689430ANSI improvedIncrease nutritionProtein composition from vegetable seedsSolubilityWater insoluble

The present invention is concentrated soybean protein modifying method and features that water insoluble protein obtained through low temperature separation of defatted soybean residue is produced into concentrated protein powder in high water solubility through water dilution, pH regulation, heating, homogenization, drying and other steps. The concentrated protein powder has water solubility as high as 70-80 %, protein content of 67-70 %, processing performance of being emulsified, thickened, gelatinized, etc. and expanded use range. In addition, the process of the present invention has low cost, less pollution and good product taste.

Owner:夏中军

Separation and purification method of bacillus amyloliquefaciens antimicrobial proteins

InactiveCN102153618AHigh purityHigh antibacterial activityPeptide preparation methodsPurification methodsAntibiotic resistance

The invention discloses a separation and purification method of bacillus amyloliquefaciens antimicrobial proteins, relating to a separation and purification method of bacillus antimicrobial proteins. The method solves the problems that the existing separation and purification method of proteins can not acquire bacillus amyloliquefaciens TF28 antimicrobial proteins with high purity, generates various impurity proteins and is low in the yield of antimicrobial proteins. The method includes the following steps: I. obtaining the crude extract of antimicrobial proteins; II. obtaining protein concentrate by anion exchange chromatography; and III. performing gel filtration chromatography through a molecular sieve to obtain bacillus amyloliquefaciens antimicrobial proteins. The separation and purification method is used for the separation and purification of bacillus amyloliquefaciens antimicrobial proteins.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

Concentrated protein lyophilates, methods, and uses

InactiveUS7956160B2Speed up the flowReduce moisture contentBiocidePeptide/protein ingredientsRaman imagingParticulates

The invention provides, among other things, lyophilized compositions of high surface area that comprise a protein and that reconstitute quickly and efficiently to solution of high protein concentration with minimal formation, if any, of foam, effervescence, bubbles, turbidity, or particulates that might be deleterious. The invention also provides, among other things, methods for making the lyophilized compositions. The invention in additional aspects also provides Raman Imaging Spectrographic methods for real time analyses of polymorphs in a sample using PLS algorithms. By way of particular example, the use of the method for the analysis of mannitol polymorphs is described, and the use of the analysis to determine optimum compositions and lyophilization methods for producing lyophilates of pharmaceutical proteins having a predefined distribution of mannitol polymorphs and having the aforementioned reconstitution properties is also described.

Owner:AMGEN INC

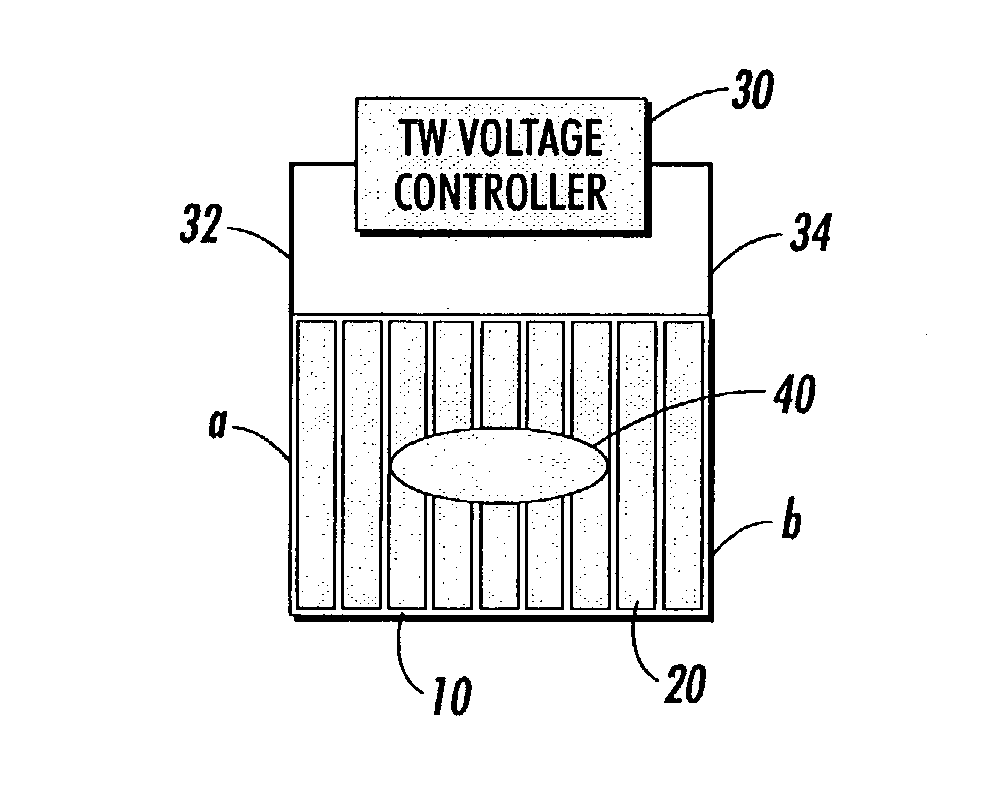

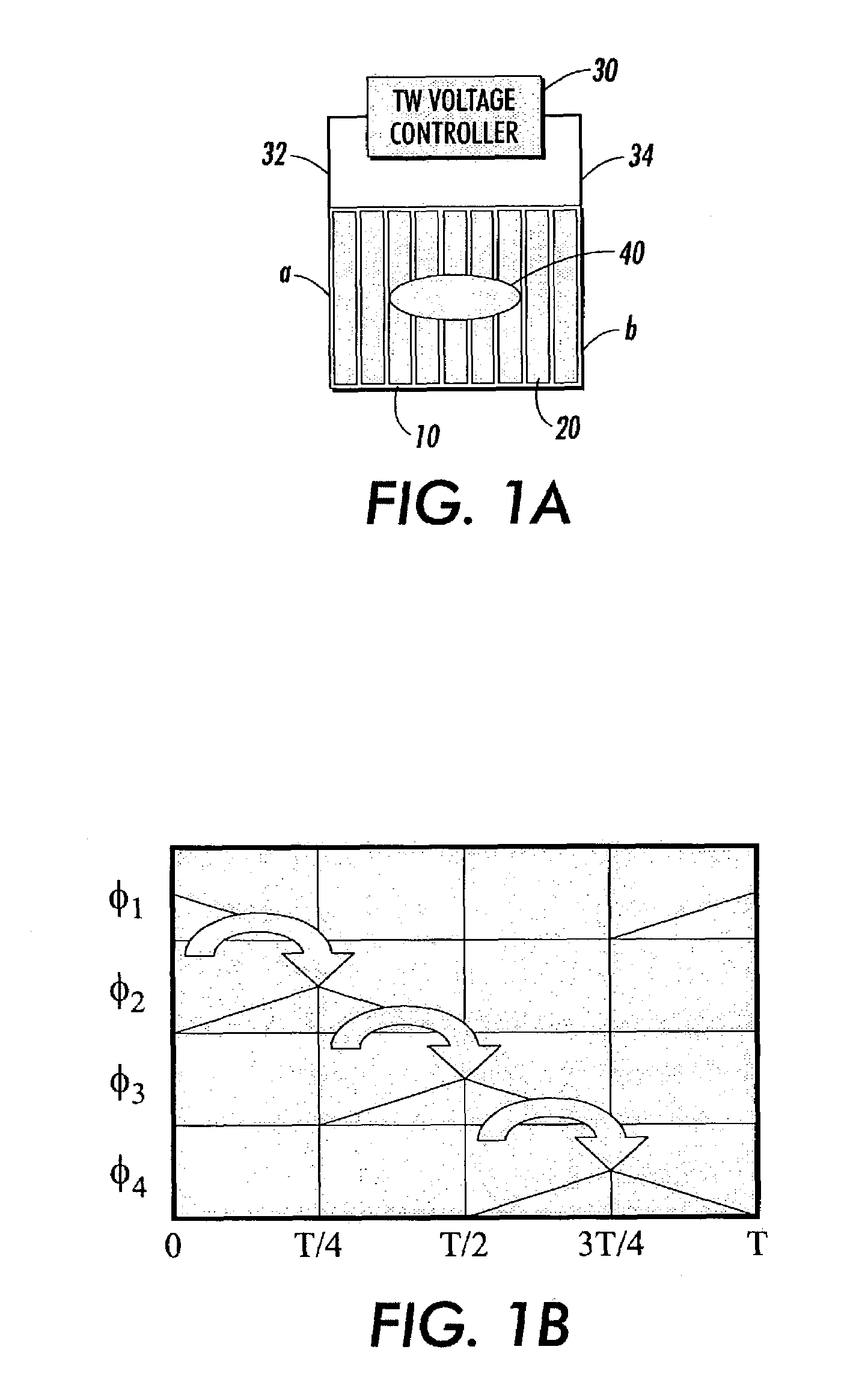

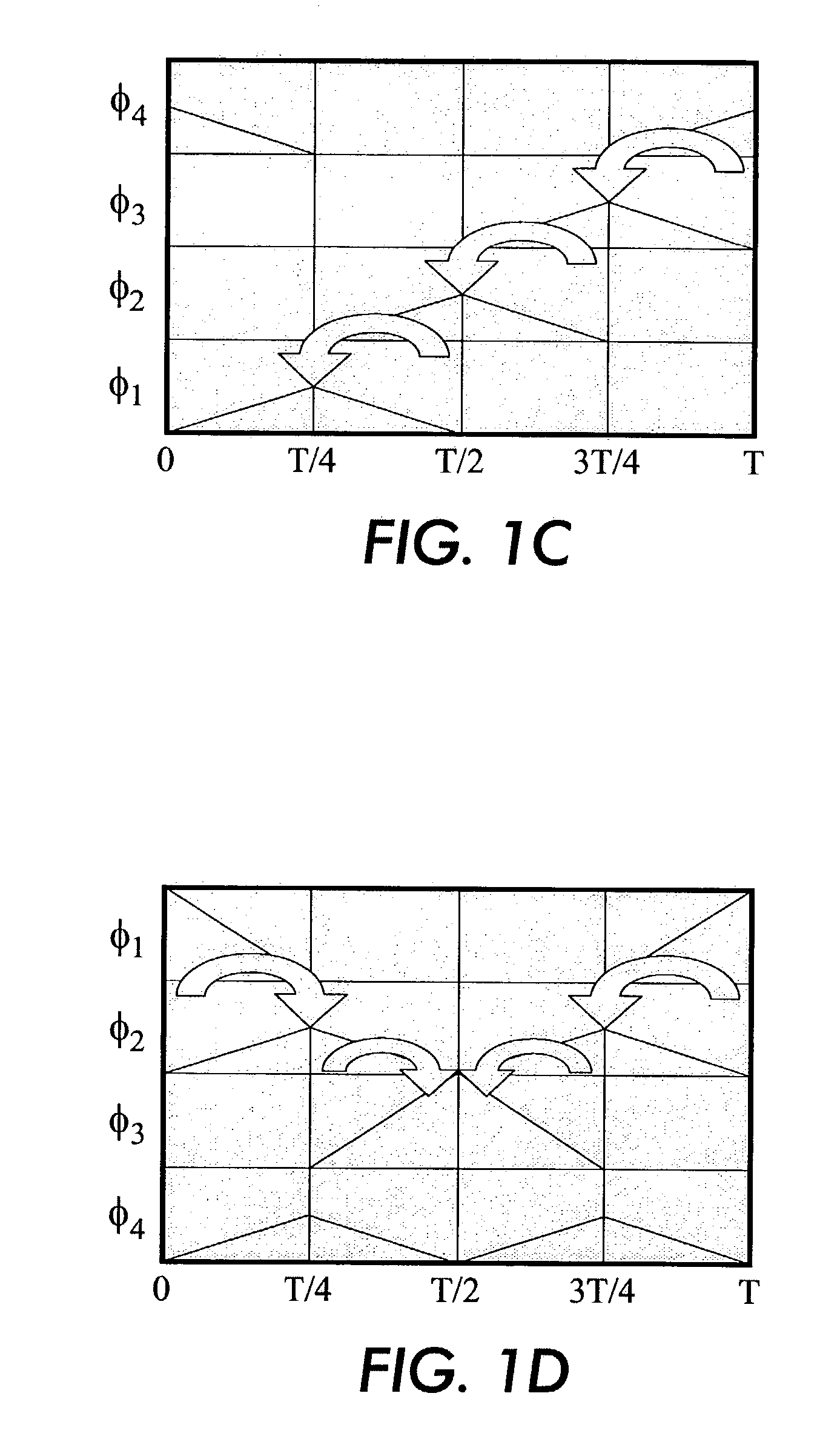

Traveling wave algorithms to focus and concentrate proteins in gel electrophoresis

InactiveUS7282129B2Short processing timeCompact patchElectrostatic separatorsSludge treatmentElectrophoresisGel electrophoresis

An electrophoretic cell configuration and related method are disclosed that employ oppositely directed traveling electrical waves. The waves travel across the cell and samples undergoing separation. Various strategies are used to selectively direct the movement and arrangement of the samples and resulting sample patterns.

Owner:PALO ALTO RES CENT INC

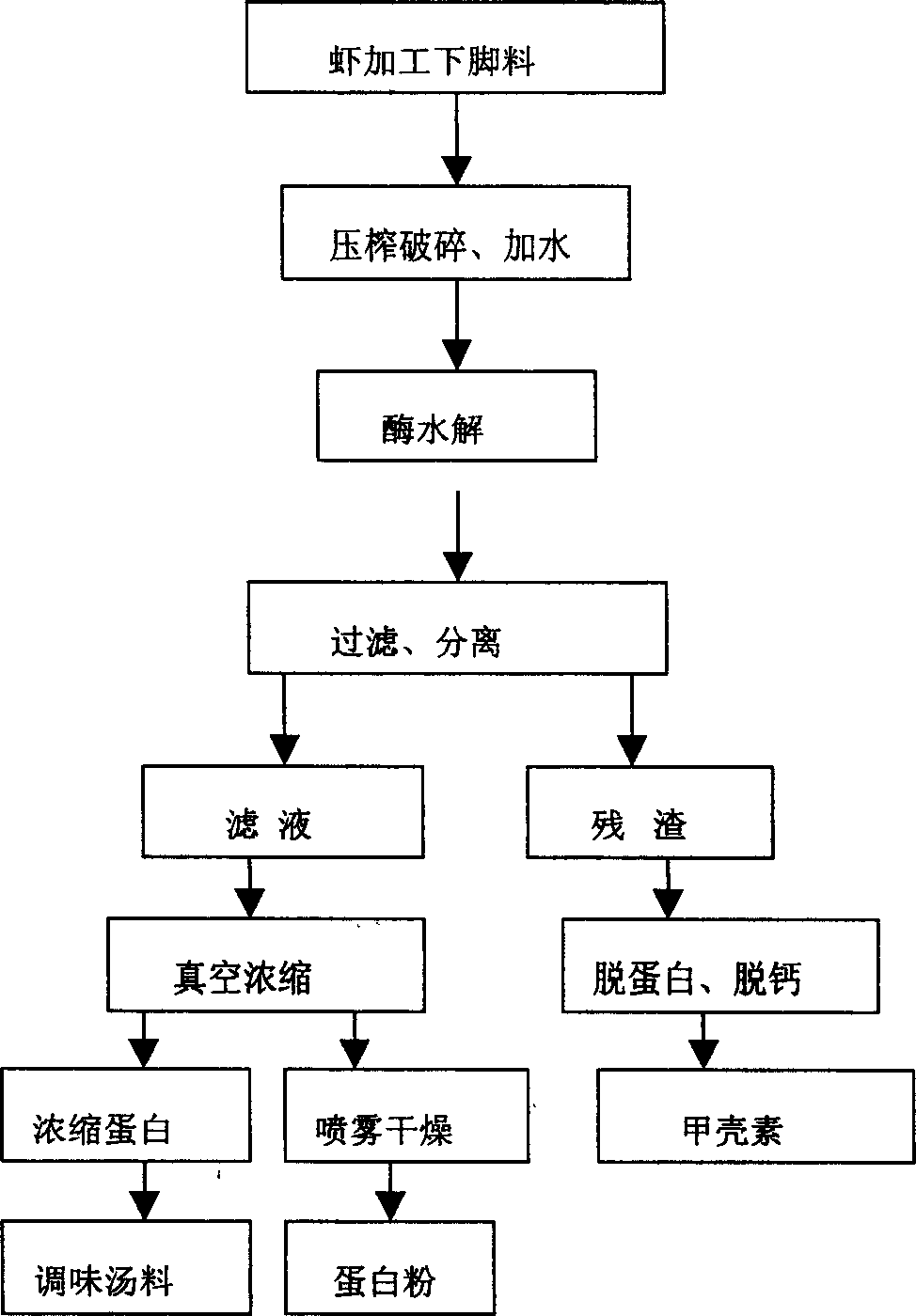

Method for processing fent by comprehensive utilizing shrimp by enzyme method

InactiveCN1644073AIncrease profitImprove utilizationAnimal proteins working-upAstaxanthinEnzyme method

A process for reclaiming the leftover of shrimp by enzyme method includes such steps as using the composite enzyme to hydrolyze the leftover of fresh shrimp, filtering, concentrating to obtain the concentrated protein rich in astaxanthin, and spray drying. Its product can be used to prepare the flavouring.

Owner:JIANGNAN UNIV

Method for synchronously preparing peanut oil and peanut peptides through aqueous enzymatic extraction

InactiveCN103113977AReduce pollutionAdd flavorFatty-oils/fats productionFermentationBiotechnologyEnzymatic hydrolysis

The invention provides a method for synchronously preparing peanut oil and peanut peptides through aqueous enzymatic extraction and belongs to the technical field of deep processing of agricultural products and comprehensive utilization of byproducts of the agricultural products, mainly solving the technical problems that protein products obtained according to a conventional technology for preparing oil from peanuts through aqueous enzymatic extraction have low purity and are imperfect in oil flavor and easy in generation of emulsion and the like. The method comprises the following steps of: baking peanut kernels, grinding, adding water so as to adjust acid for extraction, carrying out three phase centrifugation, combining oil bearing emulsion phase and protein concentrate, adjusting alkali, adding protease for enzymatic hydrolysis, carrying out high-temperature enzyme deactivation after the enzymatic hydrolysis is ended, and carrying out three phase centrifugation under a hot condition, thus directly obtaining the free oil and the peanut peptides. Peanuts are processed by adopting the method, so that the emulsion can be basically avoided, and the obtained oil has strong flavor and high quality; the peanut peptides have high purity (75% of protein content) and low relative molecular mass and can be used as a good functional additive to be widely applied to food processing.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Low-fat high-protein yoghourt and preparation method thereof

The invention provides a low-fat high-protein yoghourt and a preparation method thereof. The yoghourt is prepared from, by weight, the following raw materials: 80-90 parts of low-fat milk, 8-12 partsof composite protein powder, 0.2-8.5 parts of a sweetener and a proper amount of a leavening agent, wherein the total weight is 100 parts, and the use amount of the leavening agent per 100 kg of the raw materials is 10-25U, and the composite protein powder is selected from at least two of concentrated whey protein, isolated whey protein, milk concentrated protein, casein and skimmed milk powder. By screening raw milk indexes, strains, composite protein powder and other auxiliary materials and optimizing the proportion, the problem is effectively solved that high-protein yoghourt products are prone to serious particles and poor in taste. The protein content of the product is 8% or above, and the product has the characteristics of strong fragrance, smoothness and fine taste. In addition, theprocessing method is simple and feasible, devices such as centrifugation, filtration and the like are not needed, and the cost is saved.

Owner:黑龙江完达山林海液奶有限公司

No-antibiotic feed for piglet and preparation process thereof

InactiveCN104489332AImprove immunity against diseaseIncrease profitAnimal feeding stuffBiotechnologySucrose

The invention discloses no-antibiotic feed for a piglet. The no-antibiotic feed comprises the following materials: expanded corns, soybean meal, expanded soybeans, flour, whey powder, fish meal, soybean concentrated protein, plasma protein powder, soybean phospholipid, sucrose, glucose, sodium chloride, calcium lactate, calcium dihydrogen phoshate, special enzyme for a baby pig, a detoxication agent, citric acid, sodium butyrate, eucommia bark extract, xylooligosaccharide, lactobacillus, a phagostimulant and compound premix, wherein the phagostimulant contains calcined oyster shell powder, fiveleaf gynostemma herb, lalang grass rhizome, pine needle, denucleated wild jujubes, malic acid, radix glycyrrhizae preparata, royal jelly freeze-dried powder and peony cake meal. The no-antibiotic feed and the preparation process disclosed by the invention have the advantages that by the feed formula, the growth performance and the immunity of the piglet can be obviously improved; and by the mode of proportioned nutrition, the diarrhea and the death rate of the piglet are reduced, the effect of preventing and treating diseases is achieved and the feeding attraction and growth-promoting effects are obvious.

Owner:PINGDINGSHAN JIUZHOUTONGXIN FEED

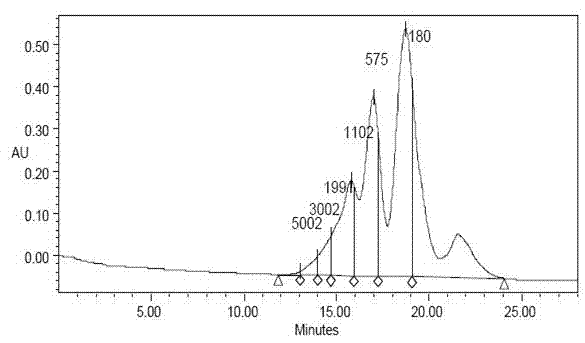

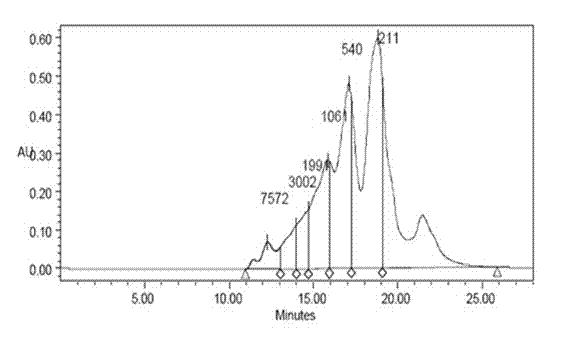

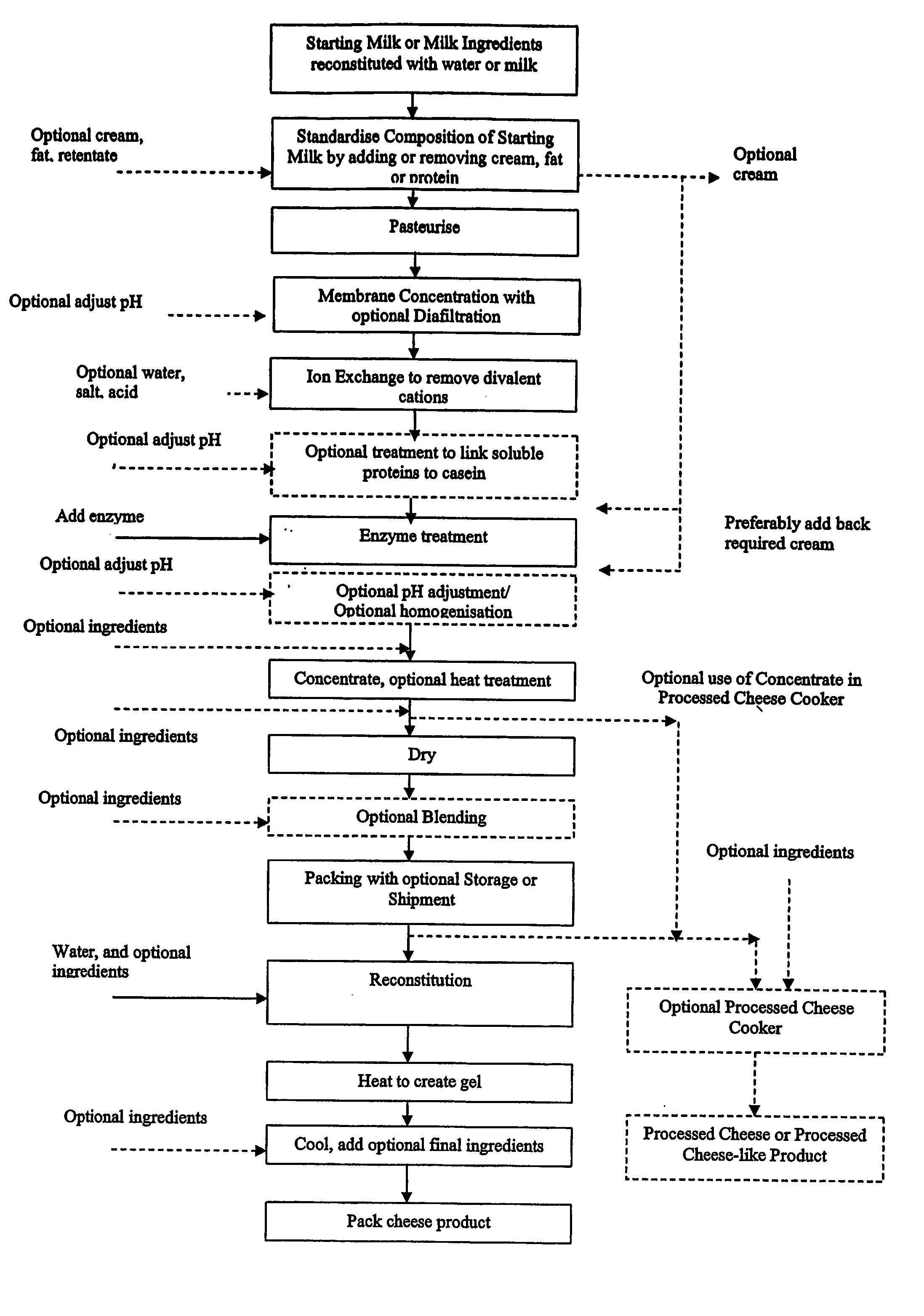

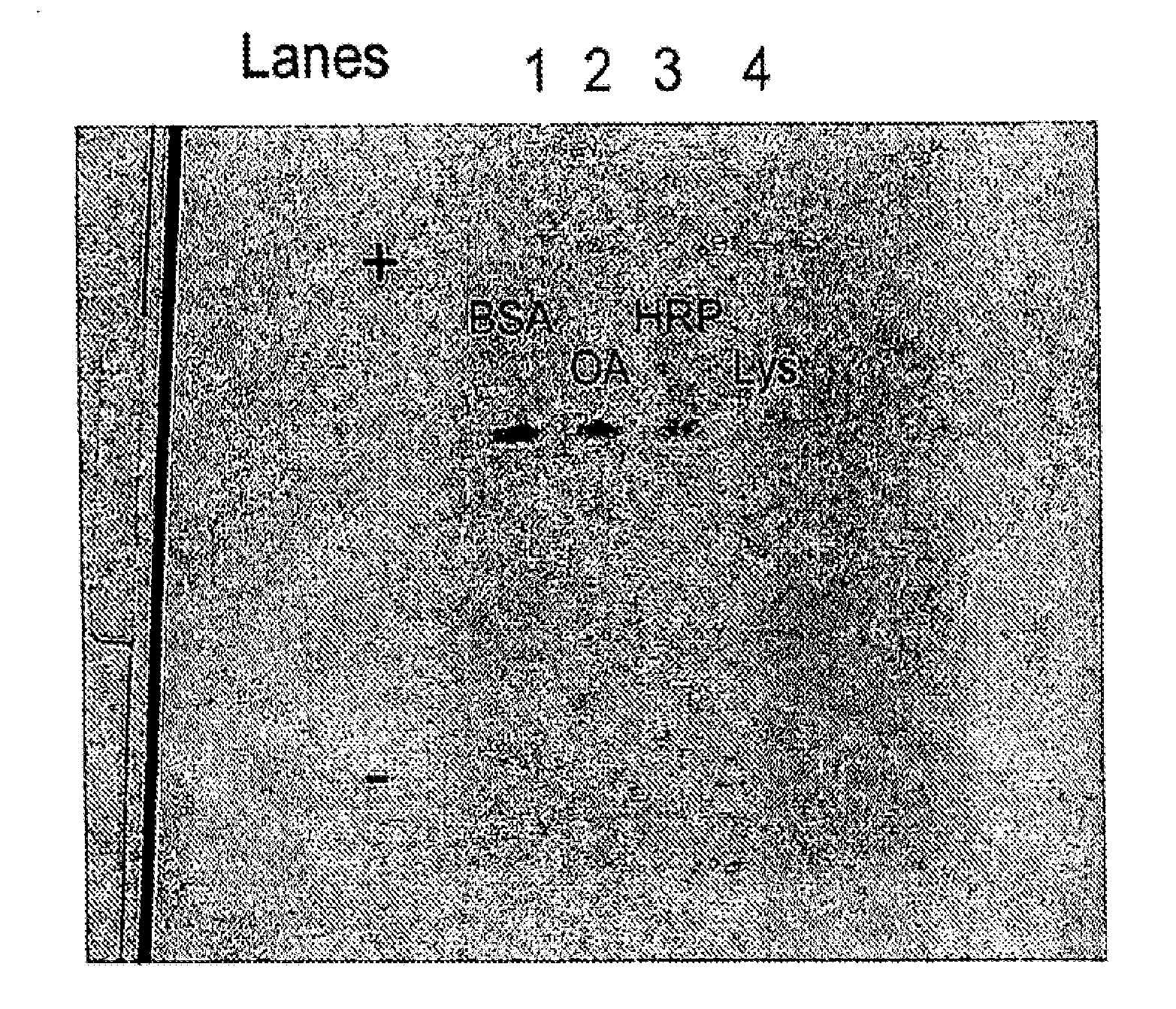

Process for preparing concentrated milk protein ingredient and processed cheese made thererfrom

Process for preparing a concentrated milk protein ingredient comprising the steps of: providing a membrane retentate solution having kappa-casein milk protein, adjusting the divalent ion content of said protein solution to a predetermined level at which no gel is formed after treatment with milk clotting enzyme, adding a food grade milk clotting enzyme under conditions where kappa-casein is converted to para-kappa casein while remaining in solution, terminating the conversion by removal or inactivation of the enzyme and concentrating said solution. The resultant milk protein concentrate ingredient is used in the production of cheese.

Owner:FONTERRA COOP GRP LTD

Extrusion of agro-food industry byproducts and protein concentrates into value-added foods

ActiveUS20150282507A1Quality improvementEffective preservationMilk preservationFood shapingFood industryWaste stream

The present invention relates to a process for preparing an edible foodstuff from food industry waste stream byproducts. This process involves the steps of: (i) combining, in an extruder, an extrusion formulation comprising a first food byproduct and at least one additional ingredient; (ii) introducing supercritical carbon dioxide (SC—CO2) into the extruder to mix with the first food byproduct and the at least one additional ingredient; and (iii) producing an edible foodstuff containing the first food byproduct and the at least one additional ingredient, where the edible foodstuff comprises an extrudate prepared under supercritical fluid extrusion (SCFX) conditions. The present invention also relates to a process for preparing an edible foodstuff from a protein concentrate. The present invention further relates to edible foodstuffs produced by the various processes disclosed herein.

Owner:CORNELL UNIVERSITY

Purification and Concentration of Proteins and DNA from a Complex Sample Using Isotachophoresis and a Device to Perform the Purification

ActiveUS20100261612A1Improve automationBioreactor/fermenter combinationsBiological substance pretreatmentsIsotachophoresisAnalyte

A method of simultaneously co-purifying and concentrating nucleic acid and protein targets into a single volume is described. The method includes automation of the entire sample preparation process, performed by having an analyst add a sample into a device that performs all of the steps necessary to prepare a sample for analysis. The method provides for samples are not split during the sample preparation process and where common purification methods can be used for purifying multiple analytes.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

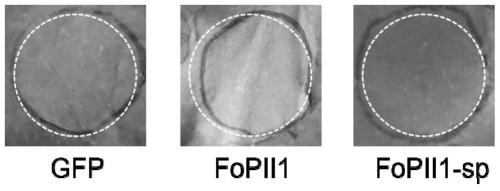

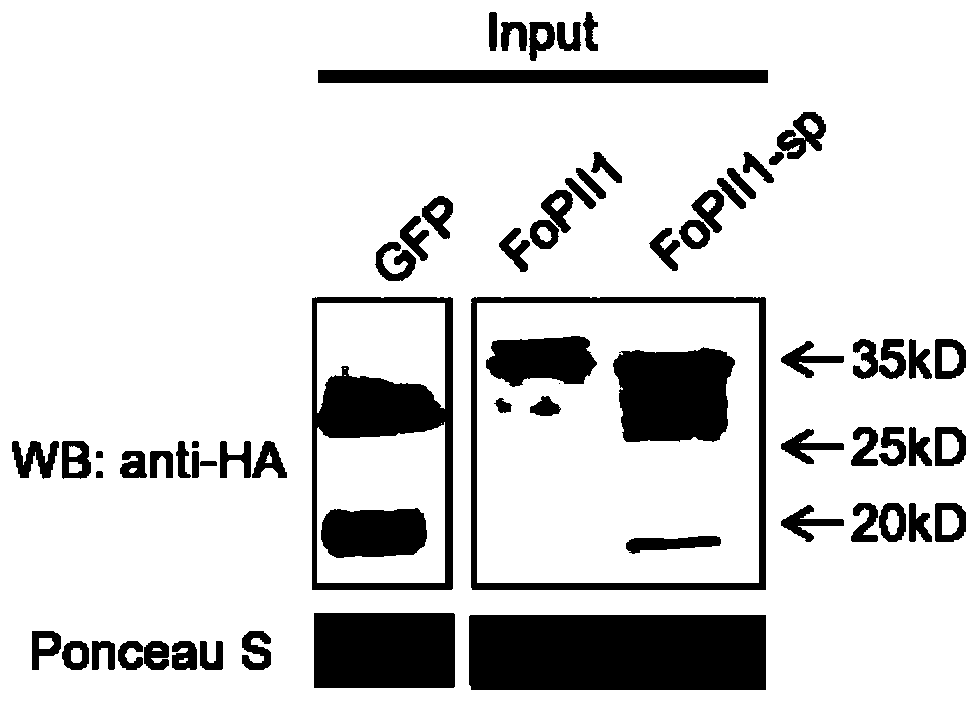

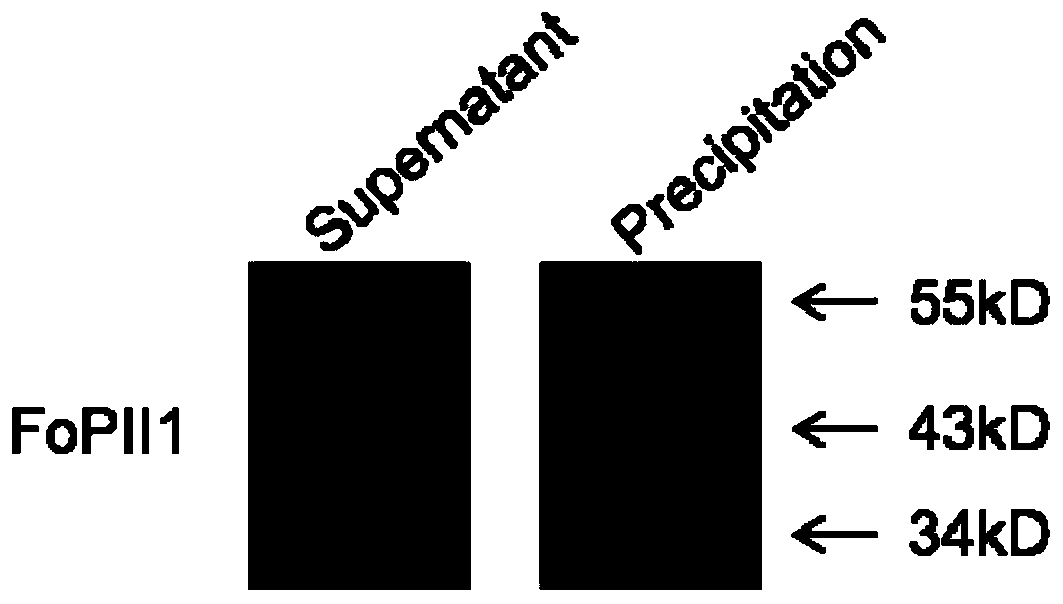

Plant immune activator protein FoPII1 secreted by fusarium oxysporum and its application

ActiveCN110194790AImprove disease resistanceUse low concentrationBacteriaMicroorganism based processesHigh concentrationFusarium oxysporum

The invention discloses a plant immune activator protein FoPII1 secreted by fusarium oxysporum and its application. The protein is capable of inducing plant resistance and can be applied as a plant immune activator to the field of plant disease control. An amino acid sequence of the protein is shown in SEQ ID NO: 2. The high-concentration protein can be obtained by using engineering strain expression, which can be used to improve the disease resistance of tobacco and soybean, and the involved plant diseases are tobacco mosaic disease and soybean root rot. The plant immune activator protein notonly can significantly improve plant disease resistance, but also has the advantages of low required concentration, quick effect and long acting time. The FoPII1 provides a novel way to improve plantdisease resistance and control plant diseases.

Owner:NANJING AGRICULTURAL UNIVERSITY

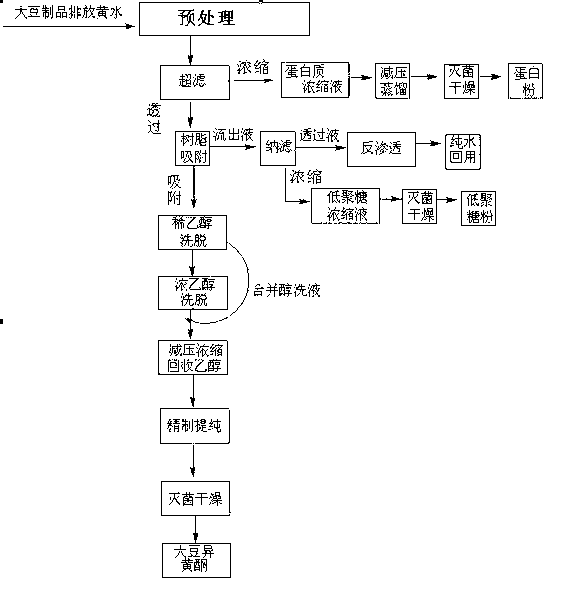

Method for extracting soy protein, oligosaccharide and isoflavone from soybean wastewater by one-step process

InactiveCN103265614ARealize comprehensive utilizationRealize the gap of zero emission in the true senseSugar derivativesPeptide preparation methodsSOY ISOFLAVONESUltrafiltration

The invention relates to a method for extracting soy protein, oligosaccharide and isoflavone from soybean wastewater by a one-step process. The method is characterized by comprising the steps of: obtaining protein concentrate and ultrafiltration membrane permeate liquid by an ultrafiltration membrane after wastewater pretreatment is carried out; preparing soy protein powder from the protein concentrate; eluting resin by ethanol after adsorbing the ultrafiltration membrane permeate liquid by the resin; preparing soy isoflavone from washing liquor; obtaining oligosaccharide concentrate and nanofiltration membrane permeate liquid after the resin effluent passes through a nanofiltration membrane; preparing oligosaccharide powder from the oligosaccharide concentrate; and obtaining the purified water after the nanofiltration membrane permeate liquid passes through a reverse osmosis membrane. The method has the beneficial effects that high-concentrate organic matters in bean product waste water can be thoroughly extracted. Thus, discharge water achieves grade 1 emission standard; the environment is effectively protected; and the method brings benefits to children. Meanwhile, the blank of extraction of the soy oligosaccharide, the soy protein and the soy isoflavone from the wastewater in bean product production industry in China can be filled by putting the project into production.

Owner:YIBIN UNIV

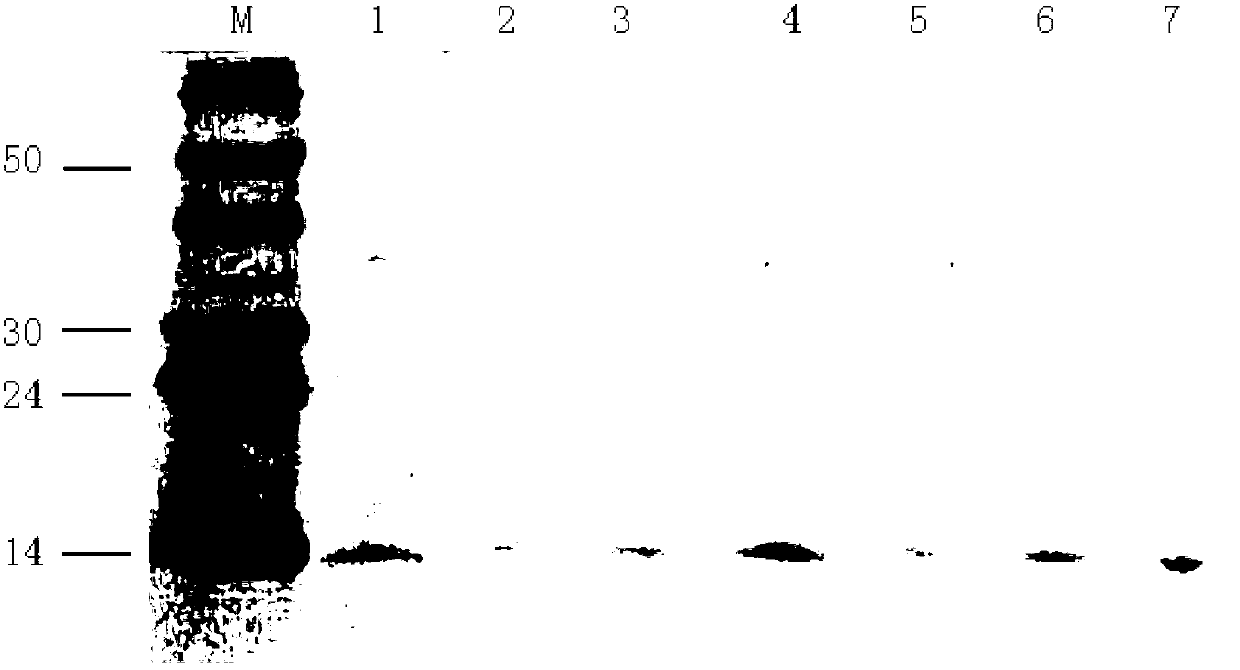

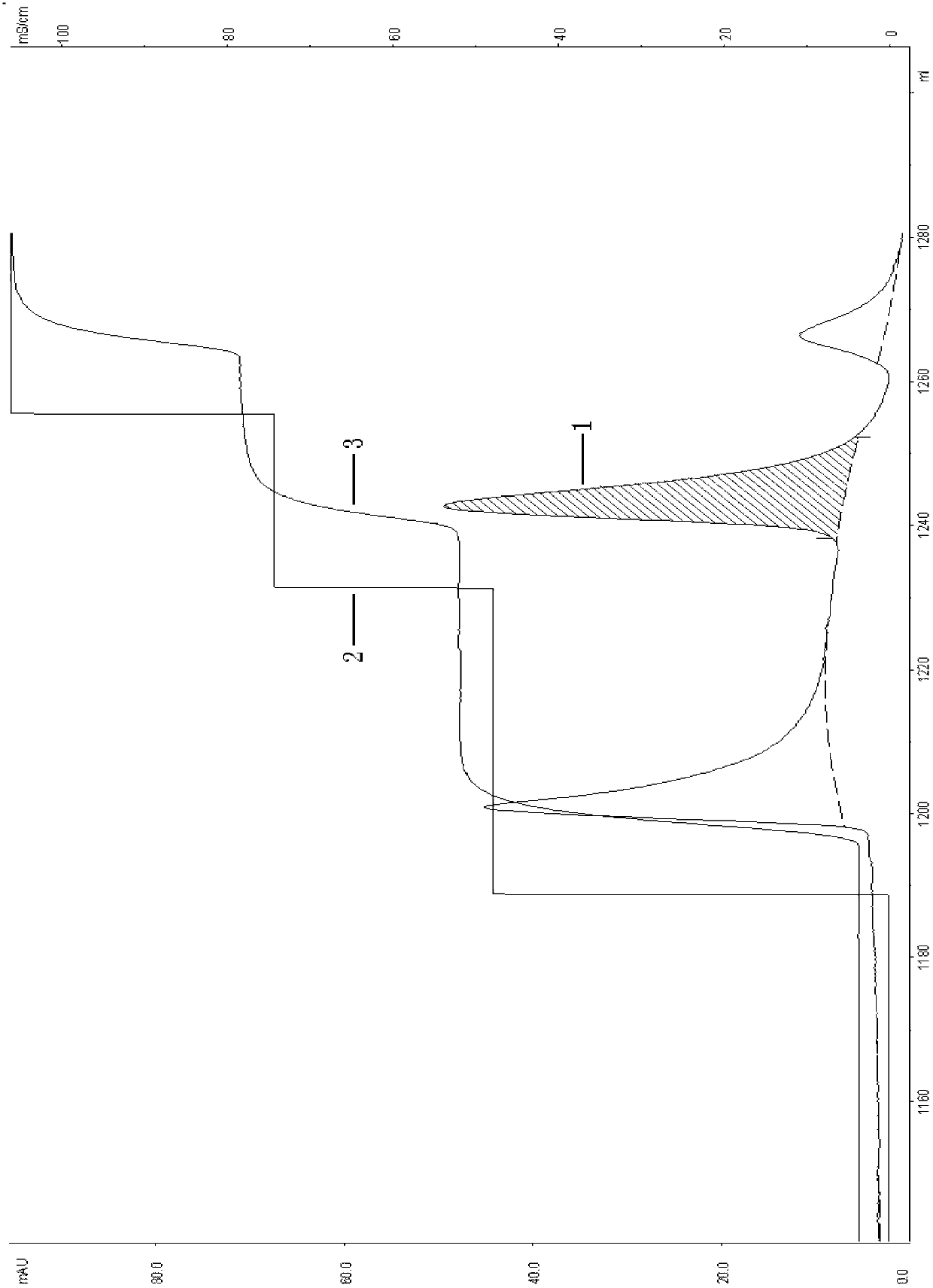

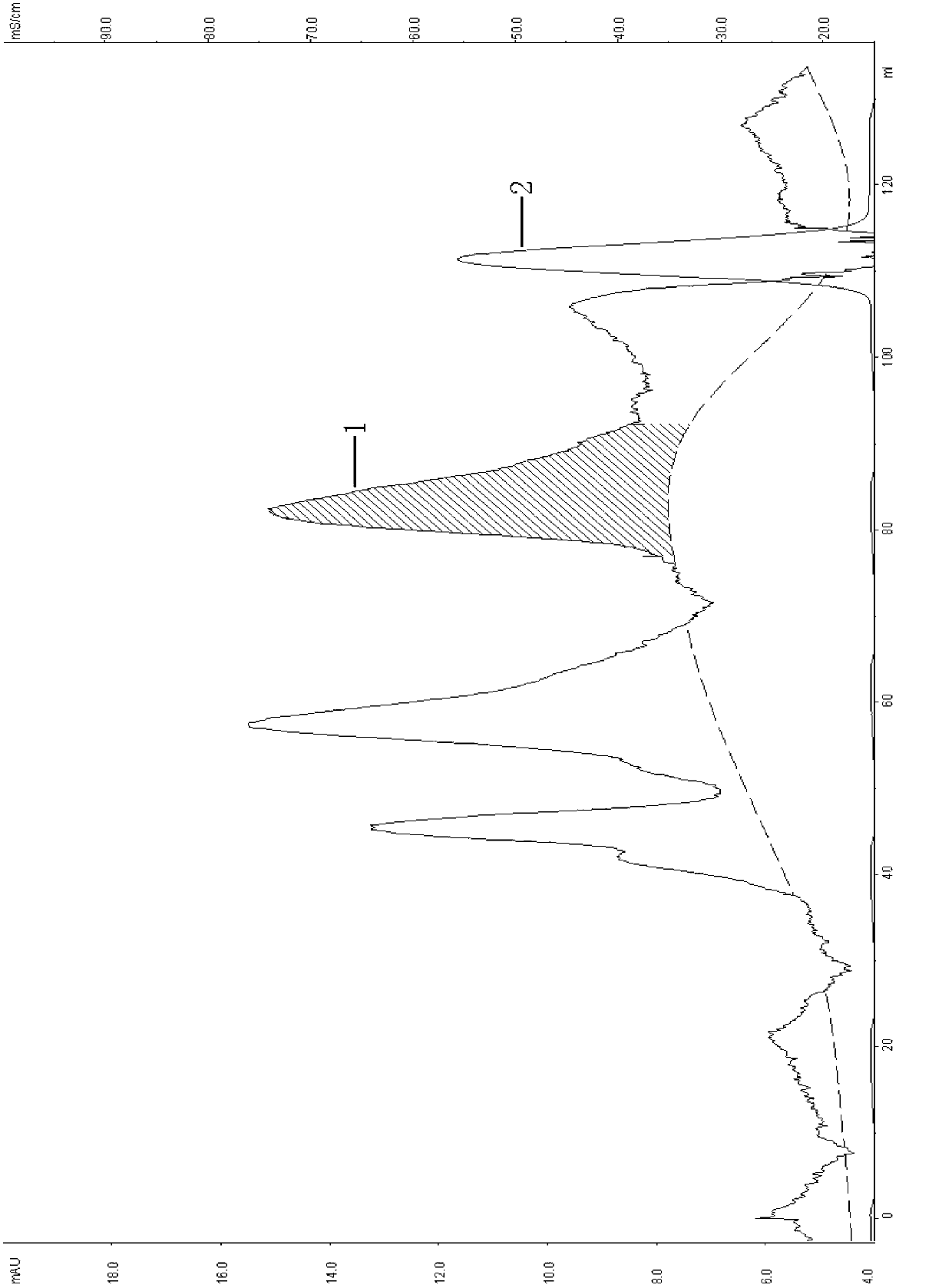

Recombinant human nerve growth factor purifying method based on CHO cell expression system

ActiveCN102702341AImprove bindingHigh purification yieldPeptide preparation methodsAnimals/human peptidesProtein targetChromatography column

The invention relates to a recombinant human nerve growth factor purifying method based on a CHO cell expression system. The recombinant human nerve growth factor purifying method based on the CHO cell expression system comprises the following steps: 1), centrifugating supernatant, successively removing living cells and cell fragments, and removing impurities and bacteria by filtering; 2), applying a supernatant sample to an EMD SO3-(M) chromatography column, rinsing unbound protein and impure protein, eluting and collecting a target protein peak; 3), concentrating the protein with ultrafiltration equipment with a molecular weight cutoff of 3K; and 4), applying the sample to Superdex 75-containing chromatography column and collecting the target protein peak, namely a recombinant human nerve growth factor stoste. According to the CHO cell expression system and the recombinant human nerve growth factor purifying method based on the CHO cell expression system, the recombinant human nerve growth factor with the purity greater than 98% and the specific activity higher than the 5* 10 to the power of 5 AU / mg can be prepared; compared with other methods, the recombinant human nerve growth factor purifying method based on the CHO cell expression system has the advantages that the steps are reduced, the production cycle is greatly shortened, and the processing capacity and the yield are improved; therefore, the recombinant human nerve growth factor purifying method based on the CHO cell expression system is application for large-scale production.

Owner:北京福睿君安科技有限公司

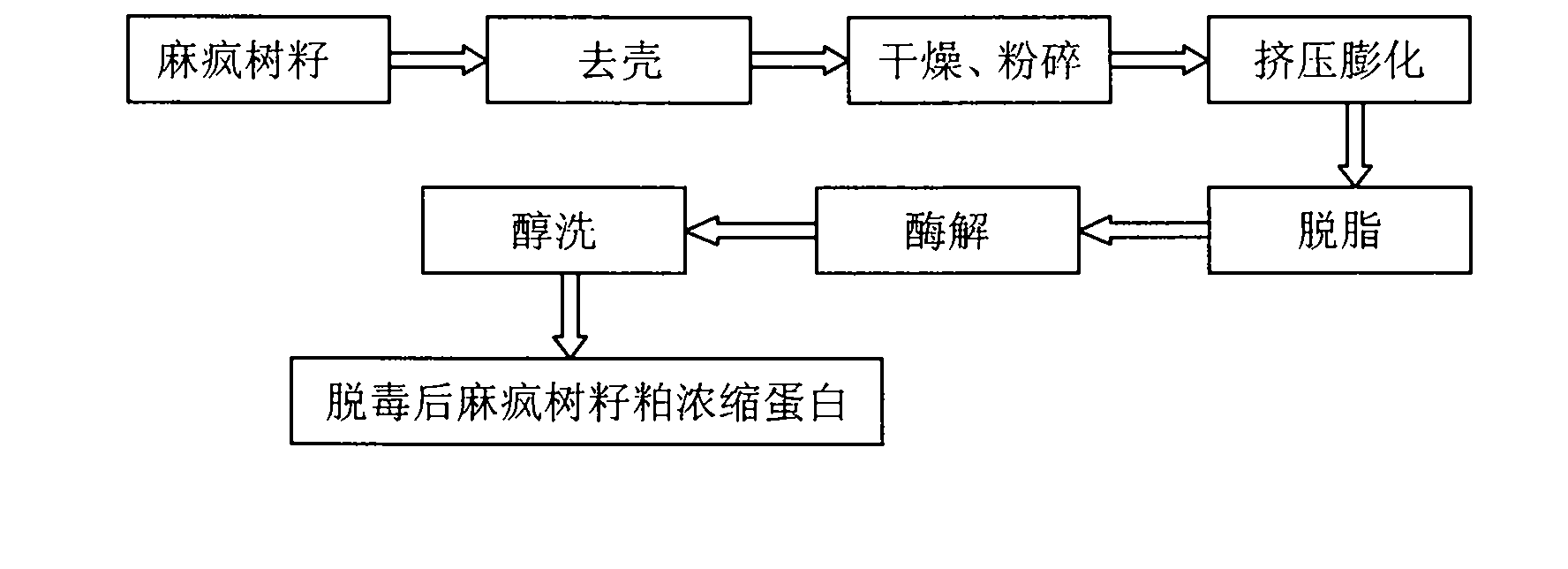

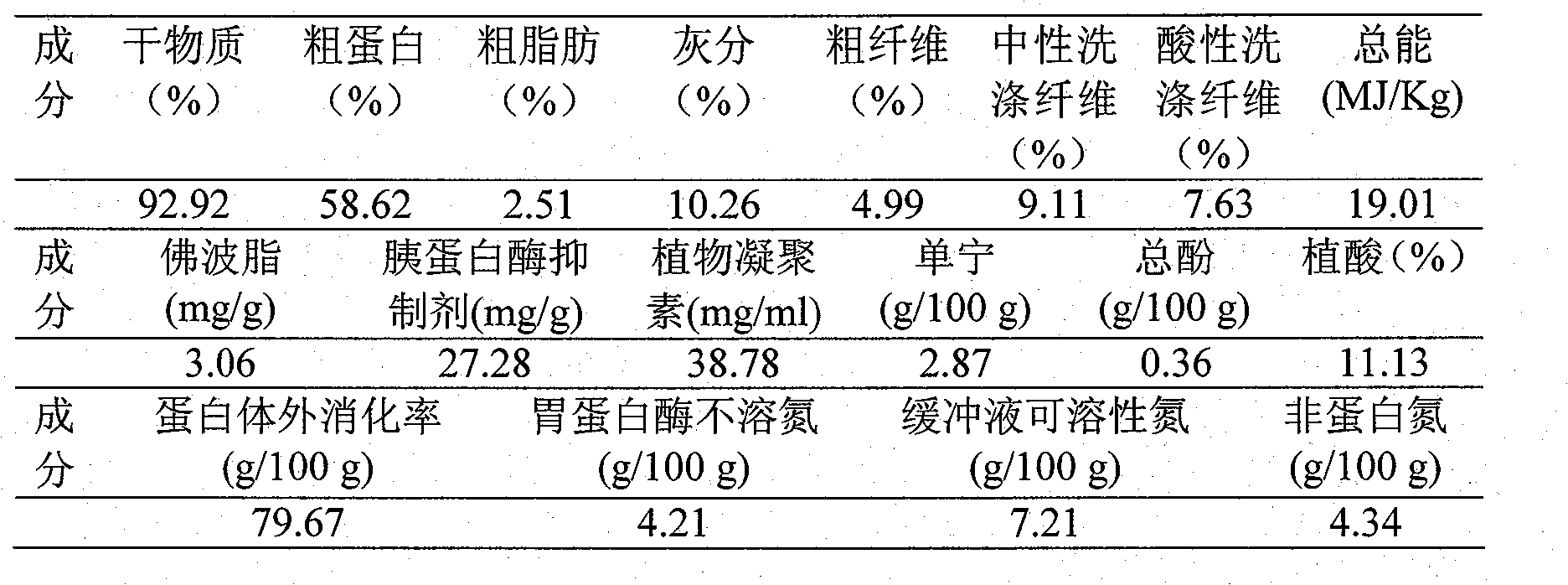

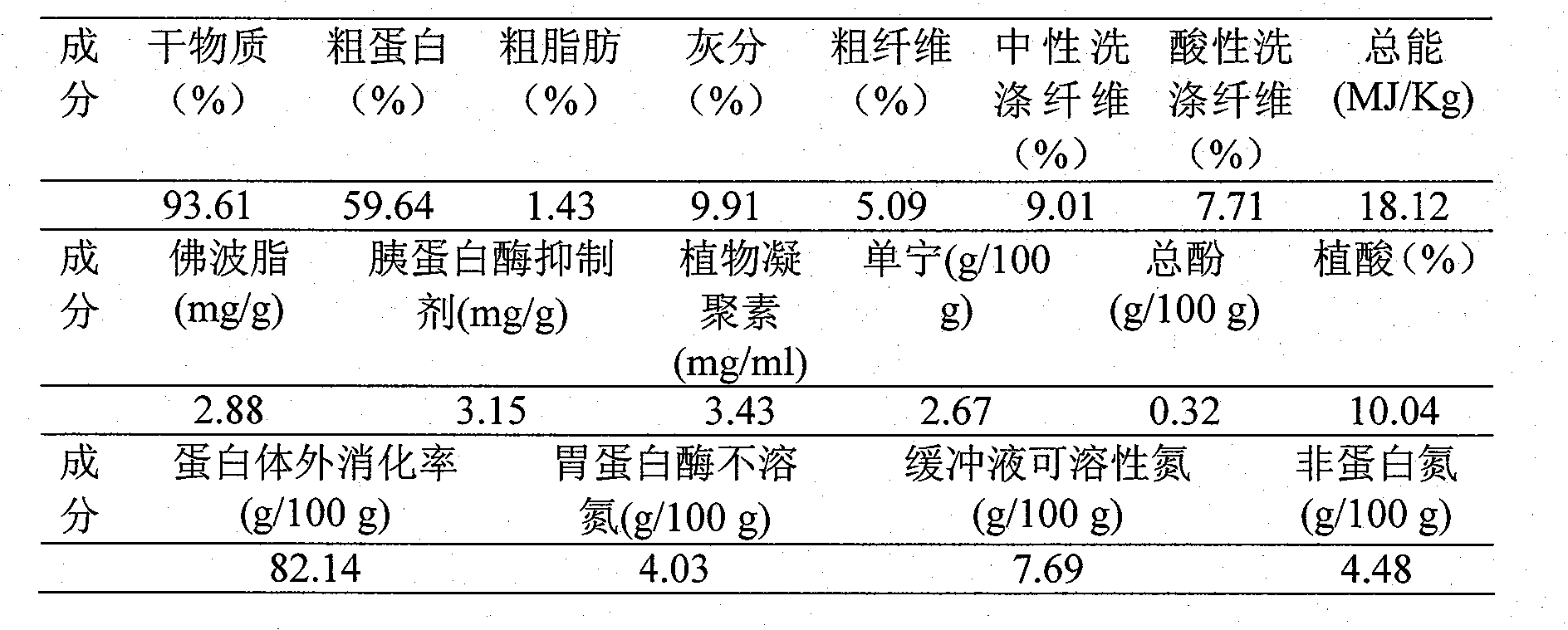

Method for detoxifying barbadosnut seed dregs and preparing protein concentrates

ActiveCN102090501ALow priceMeet the needs of the deep processing fieldProtein composition from vegetable seedsAnimal feeding stuffBiotechnologyTechnology development

The invention provides a method for detoxifying barbadosnut seed dregs and preparing protein concentrates, which belongs to the field of fine and further processing of barbadosnut seed dregs. The method comprises the following steps of: destroying plant cell walls by firstly using an extruding bulking machine as a reactor and then utilizing biological enzymolysis, then eluting by using alcohol with a proper concentration, thereby solving the problem of toxin residual of the barbadosnut seed dregs and simultaneously preparing the protein concentrates of the barbadosnut seed dregs; and finally, carrying out nutrition evaluation on the protein concentrates of the barbadosnut seed dregs. The method has the advantages of low requirement on equipment, simple production process, low production cost and environmental friendliness without using strong acid and strong base for treating the barbadosnut seed dregs, also has low cost of raw materials and low production cost and is suitable for large-scale industrial production. Meanwhile, the method also meets the requirements of fine and further processing field of agricultural products in the 'National Guideline on Medium- and Long-Term Program for Science and Technology Development' and has very obvious social and economic benefits and significance.

Owner:JIANGNAN UNIV

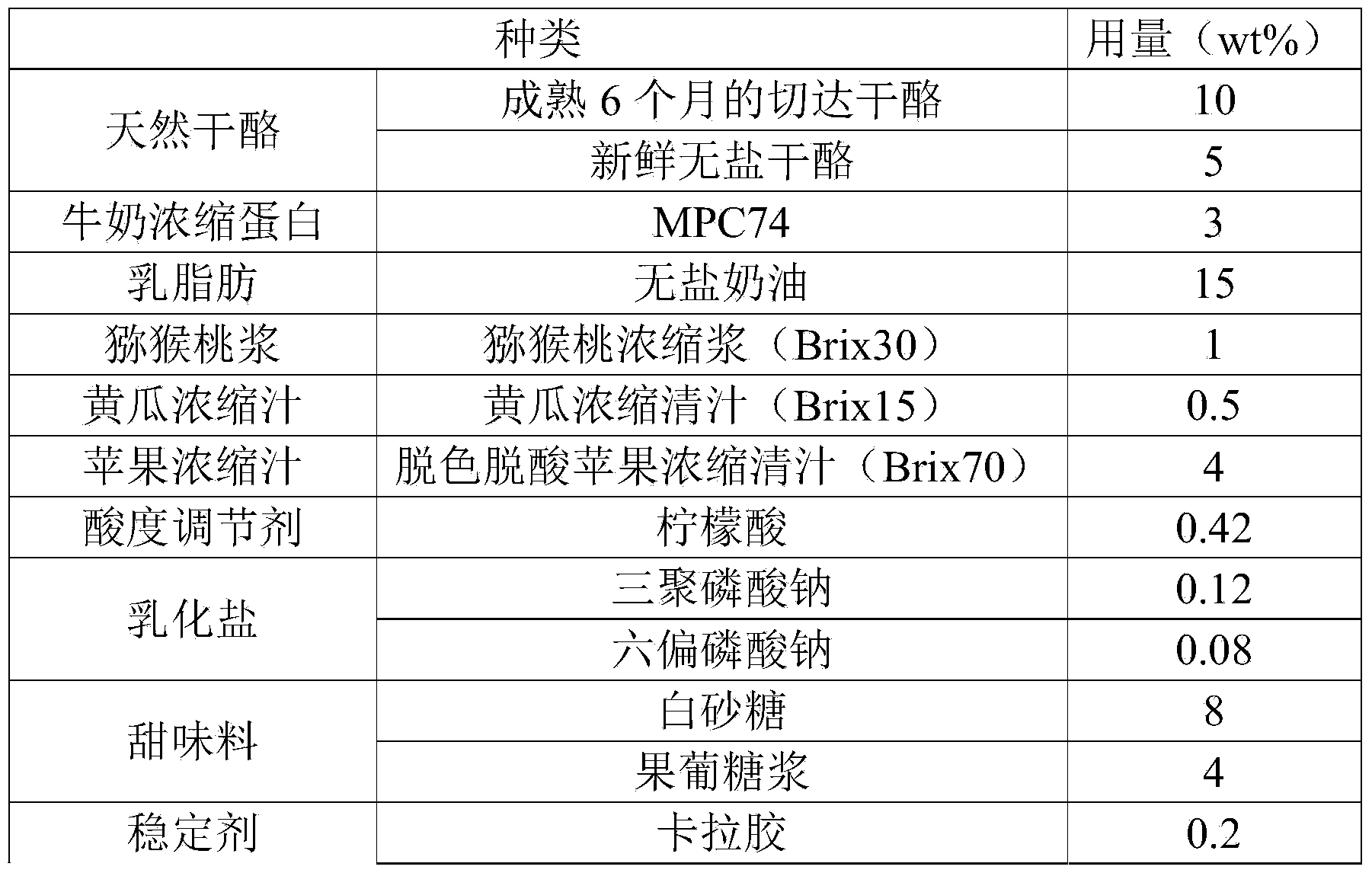

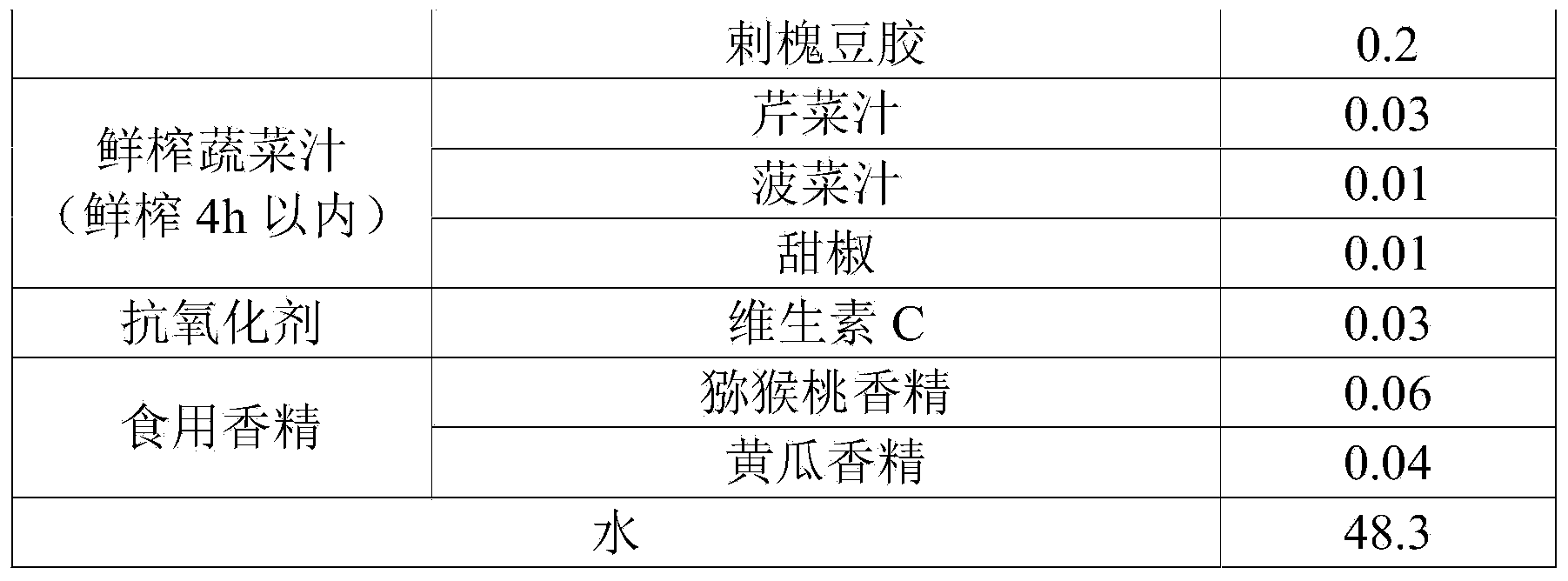

Processed cheese spread and preparation method thereof

The invention discloses a processed cheese spread and a preparation method thereof. The preparation method comprises the steps of (1) evenly mixing 15%-25% of natural cheese, 11%-30% of milk fat, 0.2%-0.5% of emulsifying salt, 1%-5% of milk protein concentrate, 8%-12% of a sweetener, and a stabilizer and water together, (2) further adding 1-15% of kiwi fruit pulp, 1-4% of apple concentrated juice, 0.5-1.2% of cucumber concentrated juice, 0.03-0.42% of an acidity regulator and 0.02%-0.04% of an antioxidant at a stirring speed ranging from 600rpm to 1200rpm, and stirring, (3) carrying out homogenizing at a temperature ranging from 82 DEG C to 90 DEG C and under pressure within the range from 15MPa to 20MPa, and pasteurizing, and (4) performing super-high pressure treatment on 0.05-0.2% of fresh vegetable juice, and then adding the fresh vegetable juice to the slurry obtained in the step (3), and carrying out hot filling and three-stage quick cooling and molding. The processed cheese prepared by the preparation method is high in nutritive value, naturally green, and good in sensory evaluation.

Owner:BRIGHT DAIRY & FOOD

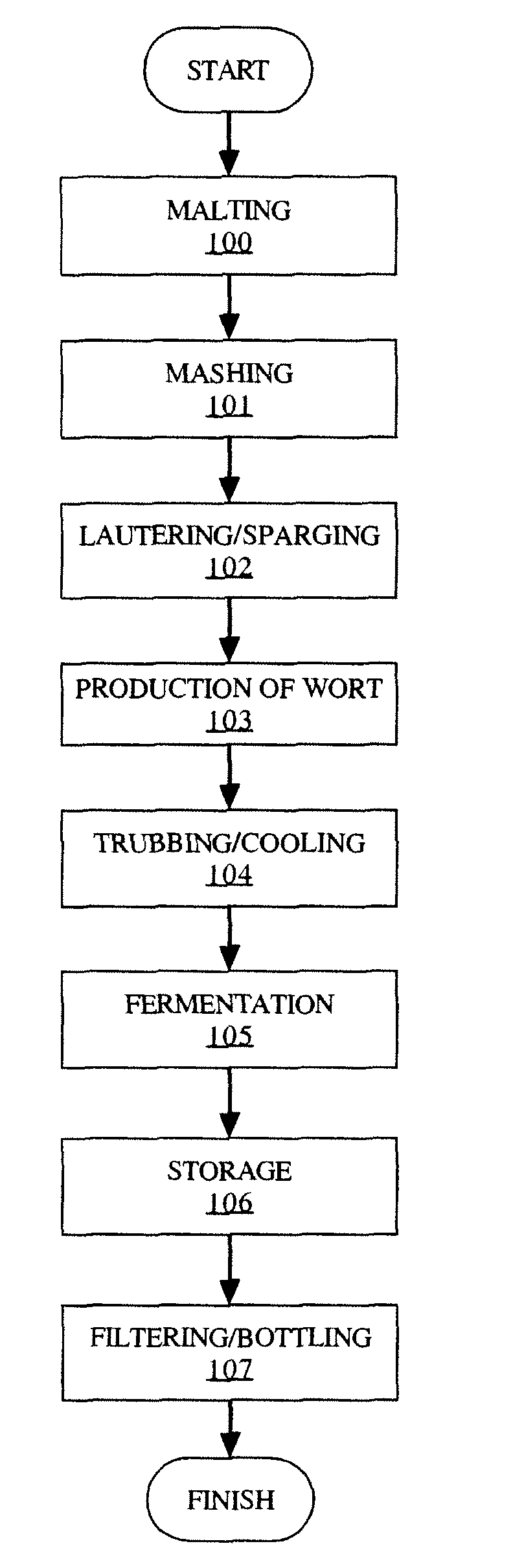

Novel Fermentation Process and Uses Therefore

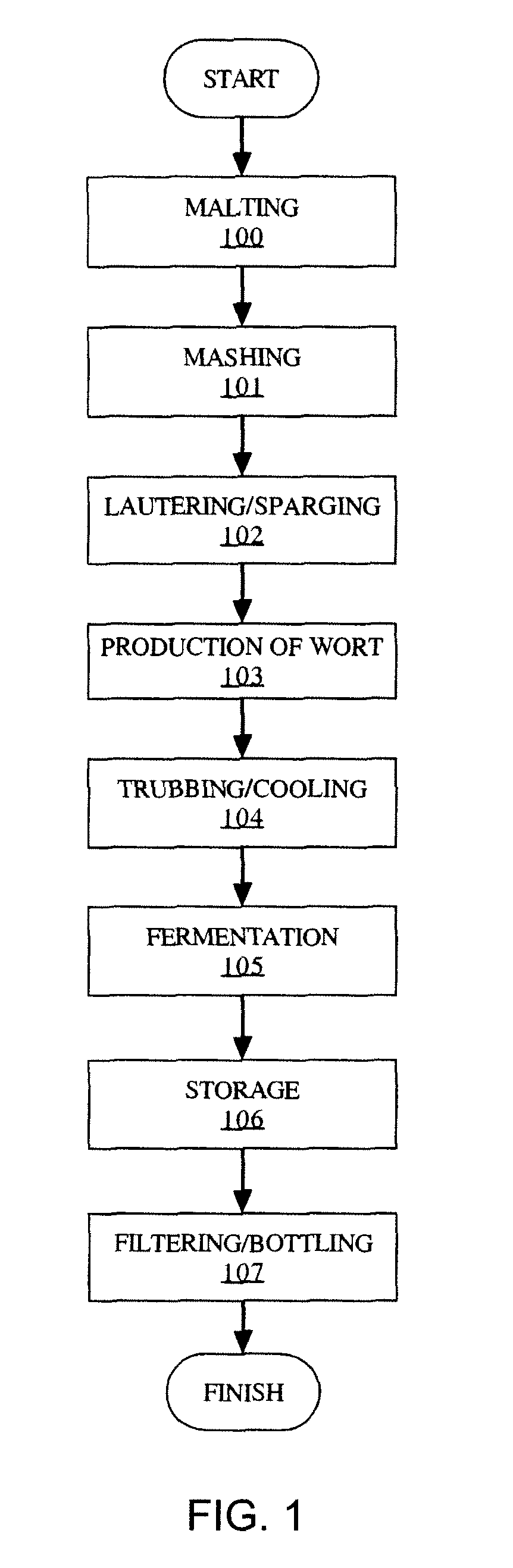

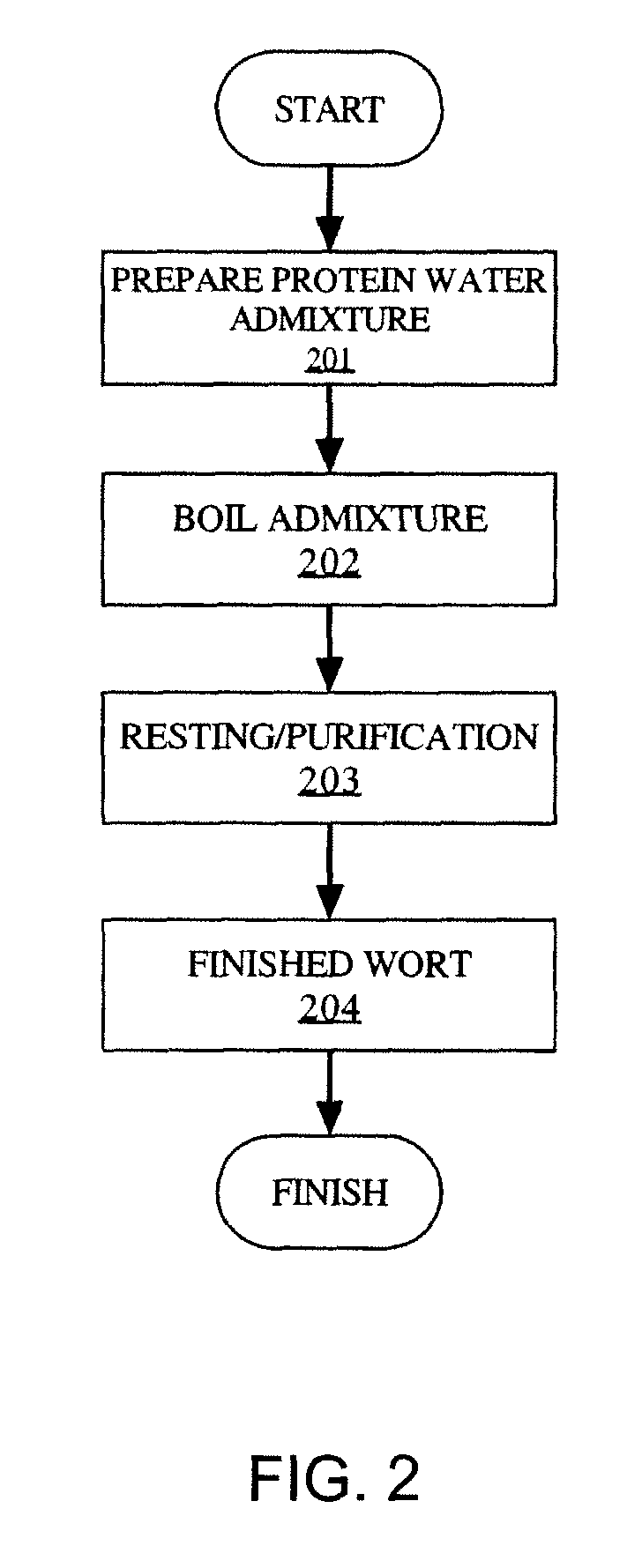

A method of producing a liquid fermentation product using a natural protein concentrate from a non-cereal grain source in place of protein derived from malted grains is provided. The natural protein concentrate can be directly used, in addition with a carbohydrate source, to produce a wort suitable for fermentation, thus avoiding the malting and mash mixing steps in traditional brewing methods. The wort requires less yeast to initiate the fermentation process than in similar alcohol fermentations, and does not require the addition of yeast nutrients. The resulting fermentation product can be processed for bottling without the need for an intervening storage period. The protein concentrate used in the method can be derived from non-cereal sources such as peas, soy, rice potatoes and other sources of natural protein. Using non-cereal sources also permits the simplified production of a gluten-free fermentation product that can be used in preparing beverages consumable by persons suffering from gluten intolerance.

Owner:FARMPURE BEVERAGES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com