Method for synchronously preparing peanut oil and peanut peptides through aqueous enzymatic extraction

A peanut peptide and peanut oil technology, applied in the direction of fat production, fat oil/fat production, fermentation, etc., can solve the problems of inapplicable purification of peanut hydrolyzed protein, technical difficulties, etc., and achieve increased added value, simple equipment and process route, and solubility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

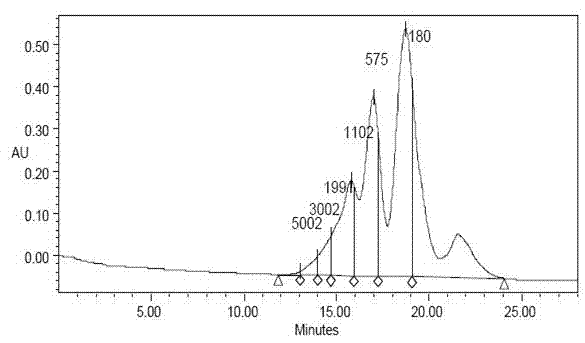

[0035] After the peanut kernels are screened to remove impurities, they are roasted with a roasting machine at a roasting temperature of 190°C and a roasting time of 20 minutes. After the roasting, the peanuts are cooled and the peanuts are peeled. After peeling, use a crusher to coarsely crush the peanut kernels, and then use a sand disc mill to further grind the peanuts into a slurry. Disperse the peanut pulp in 3 times the weight of water, adjust the pH of the system to 4.5, the temperature is 40°C, and the acid leaching time is 20 minutes. After acid leaching, use a three-phase decanter centrifuge to separate the system to obtain an oily emulsion phase, aqueous phase I and concentrated protein. Combine the oil-containing emulsion phase and the concentrated protein and disperse them in 2 times the weight of water, adjust the pH of the system to 9.0, the temperature is 55°C, and the alkali dissolution time is 30 minutes. After the alkali dissolution, 2.0% (w / w) Protex 6L a...

Embodiment 2

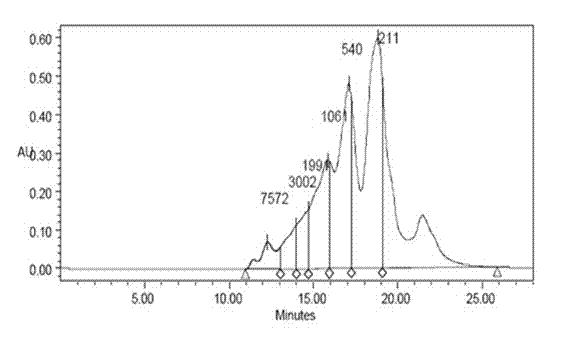

[0040] After the peanut kernels are screened to remove impurities, they are roasted with a roasting machine at a roasting temperature of 185°C and a roasting time of 20 minutes. After the roasting, the peanuts are cooled and the peanuts are peeled. After peeling, use a crusher to coarsely crush the peanut kernels, and then use a sand disc mill to further grind the peanuts into a slurry. Disperse the peanut pulp in 4 times the weight of water, adjust the pH of the system to 4.2, the temperature is 40°C, and the acid leaching time is 20 minutes. After acid leaching, use a three-phase decanter centrifuge to separate the system to obtain an oily emulsion phase, aqueous phase I and concentrated protein. Combine the oil-containing emulsion phase and concentrated protein and disperse them in 3 times the weight of water, adjust the pH of the system to 9.5, the temperature is 60°C, and the alkali dissolution time is 30 minutes. After the alkali dissolution, add 1.5% (w / w) Protex 6L a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com