Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298 results about "Heavy crude oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

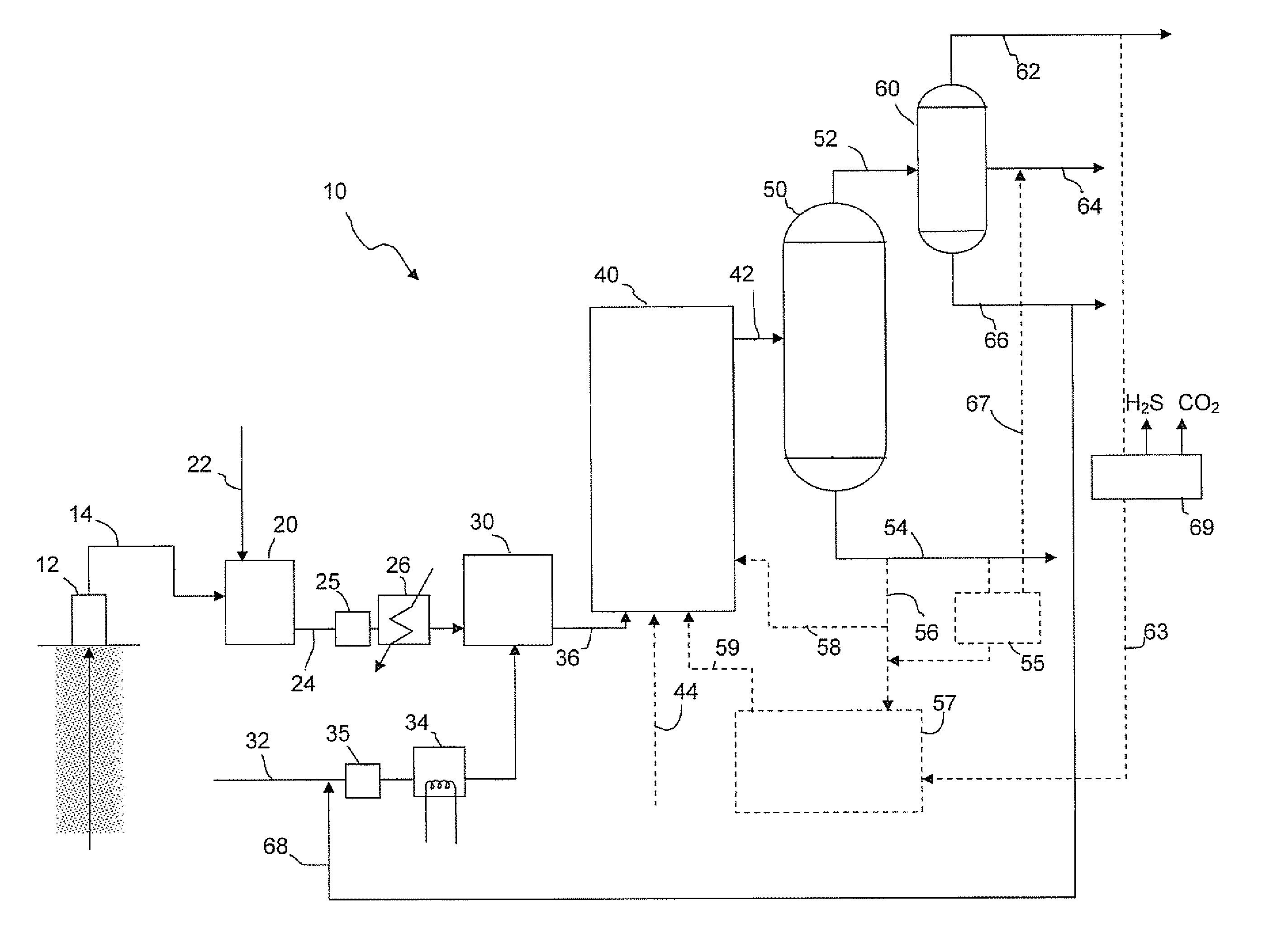

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

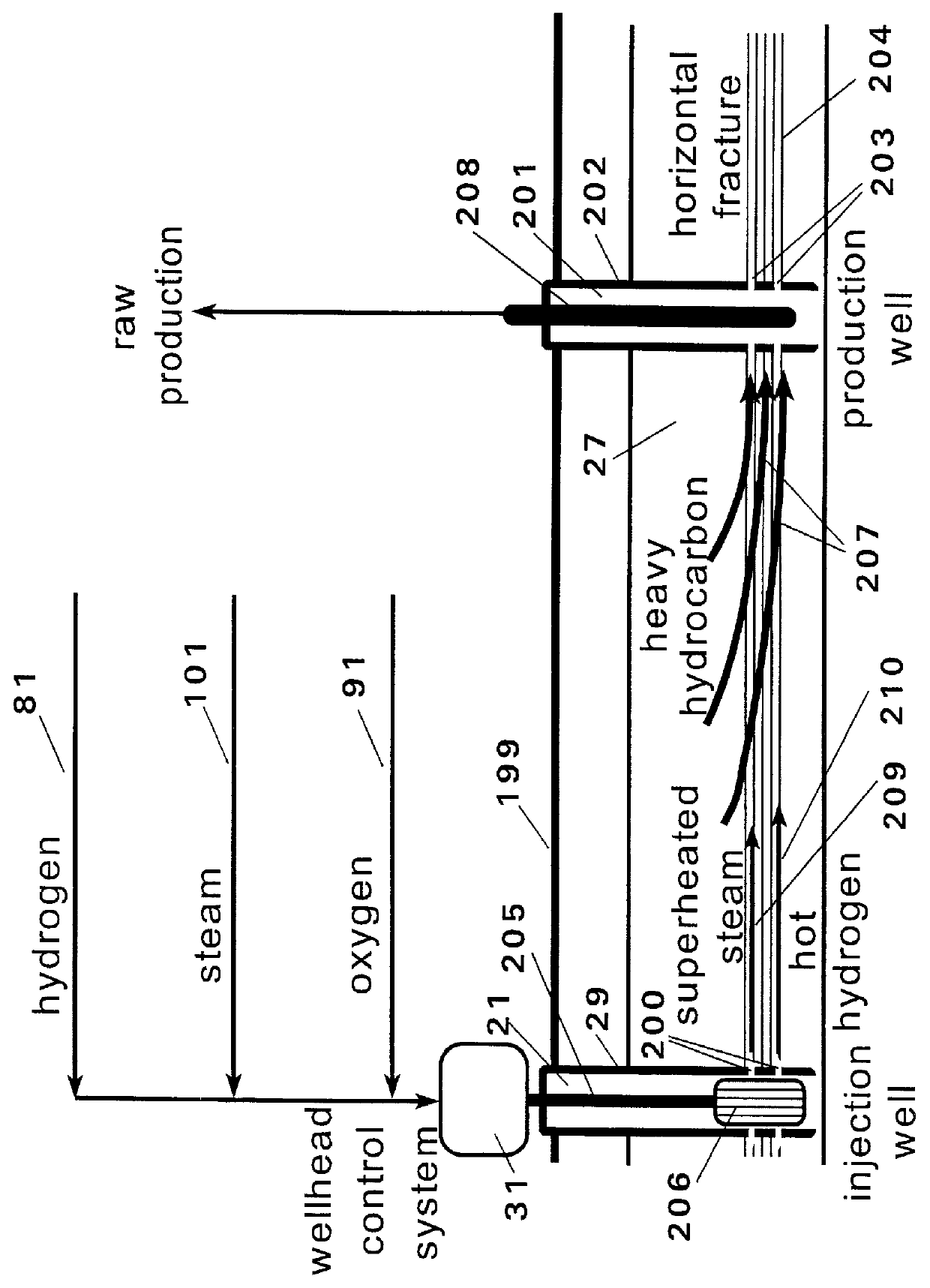

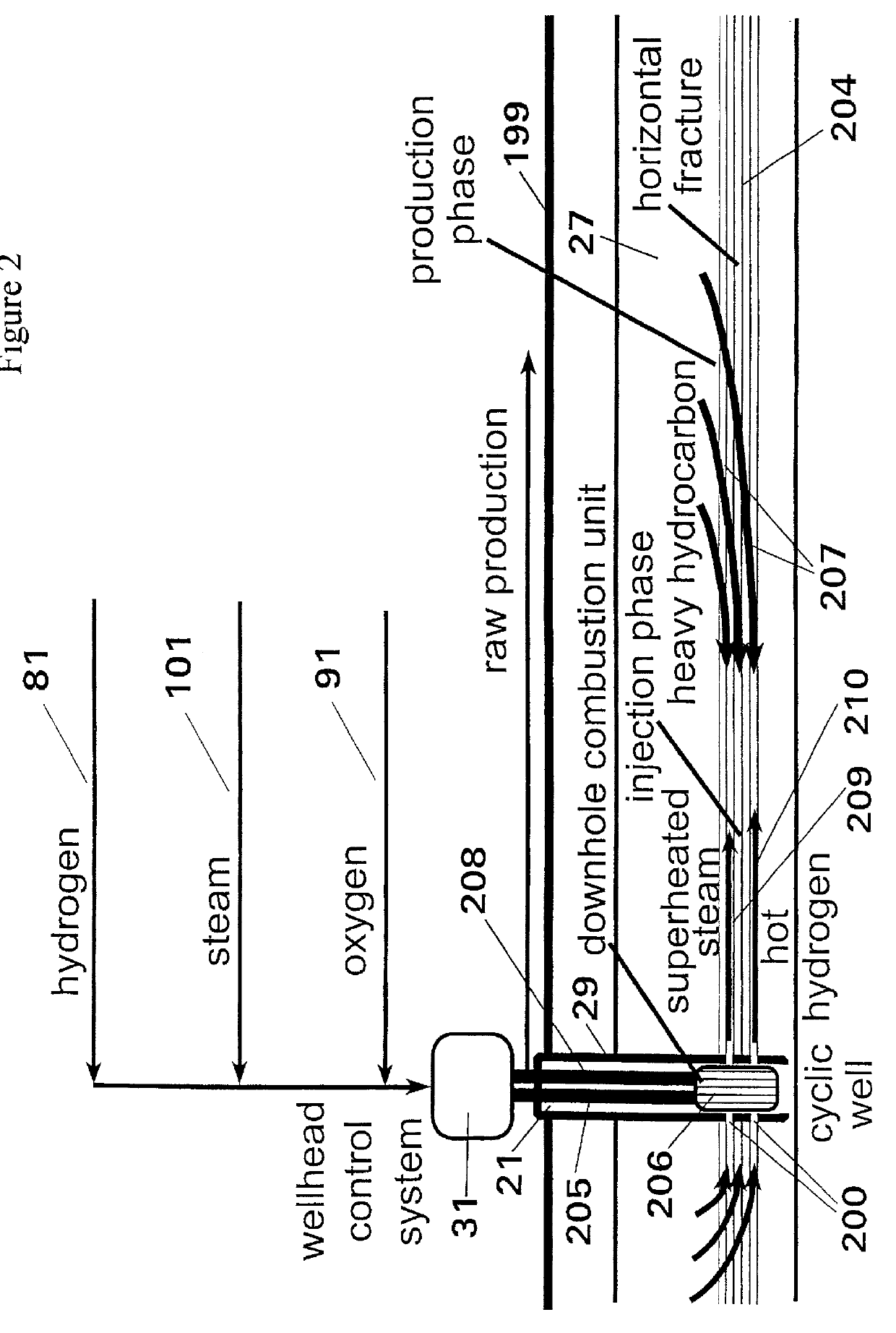

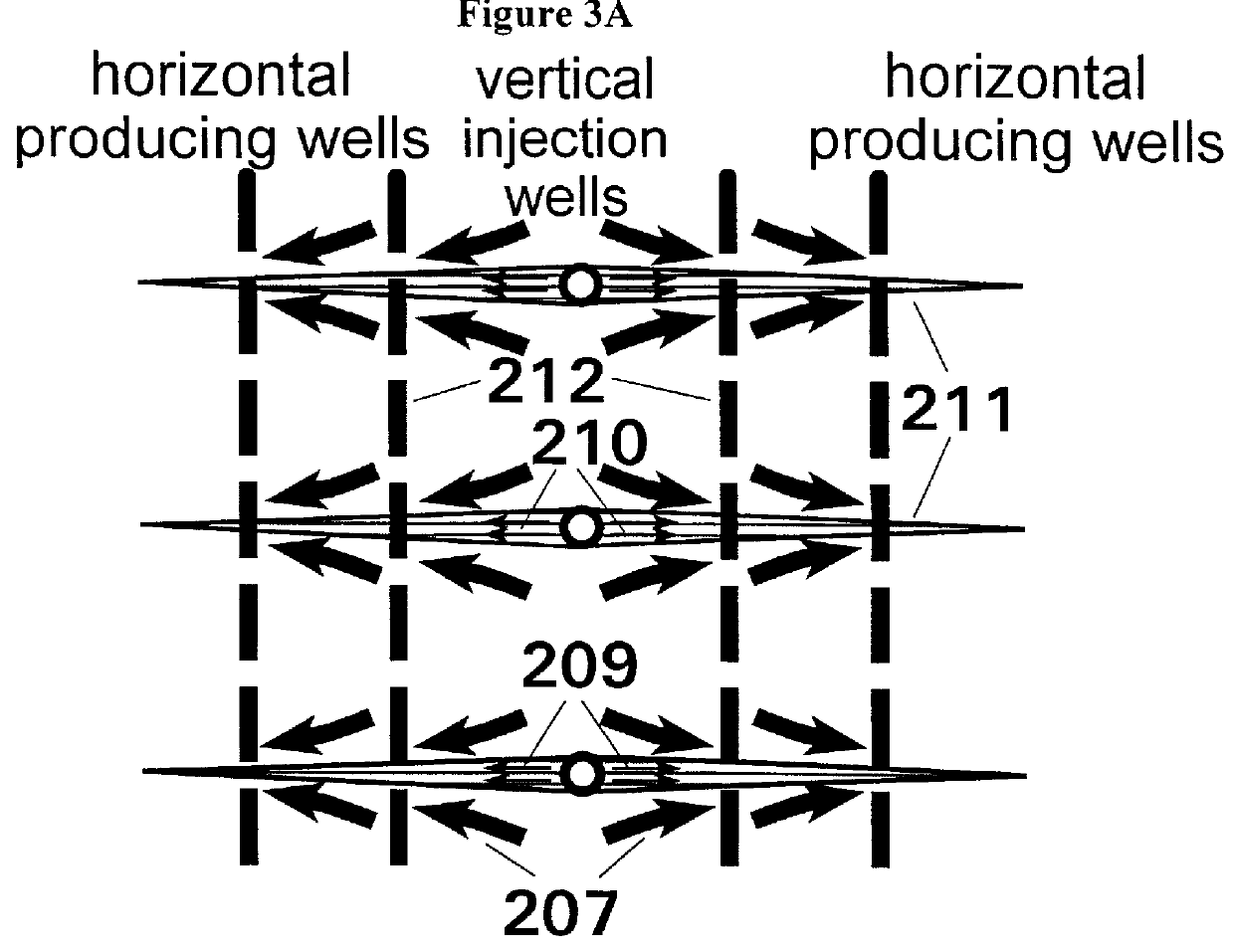

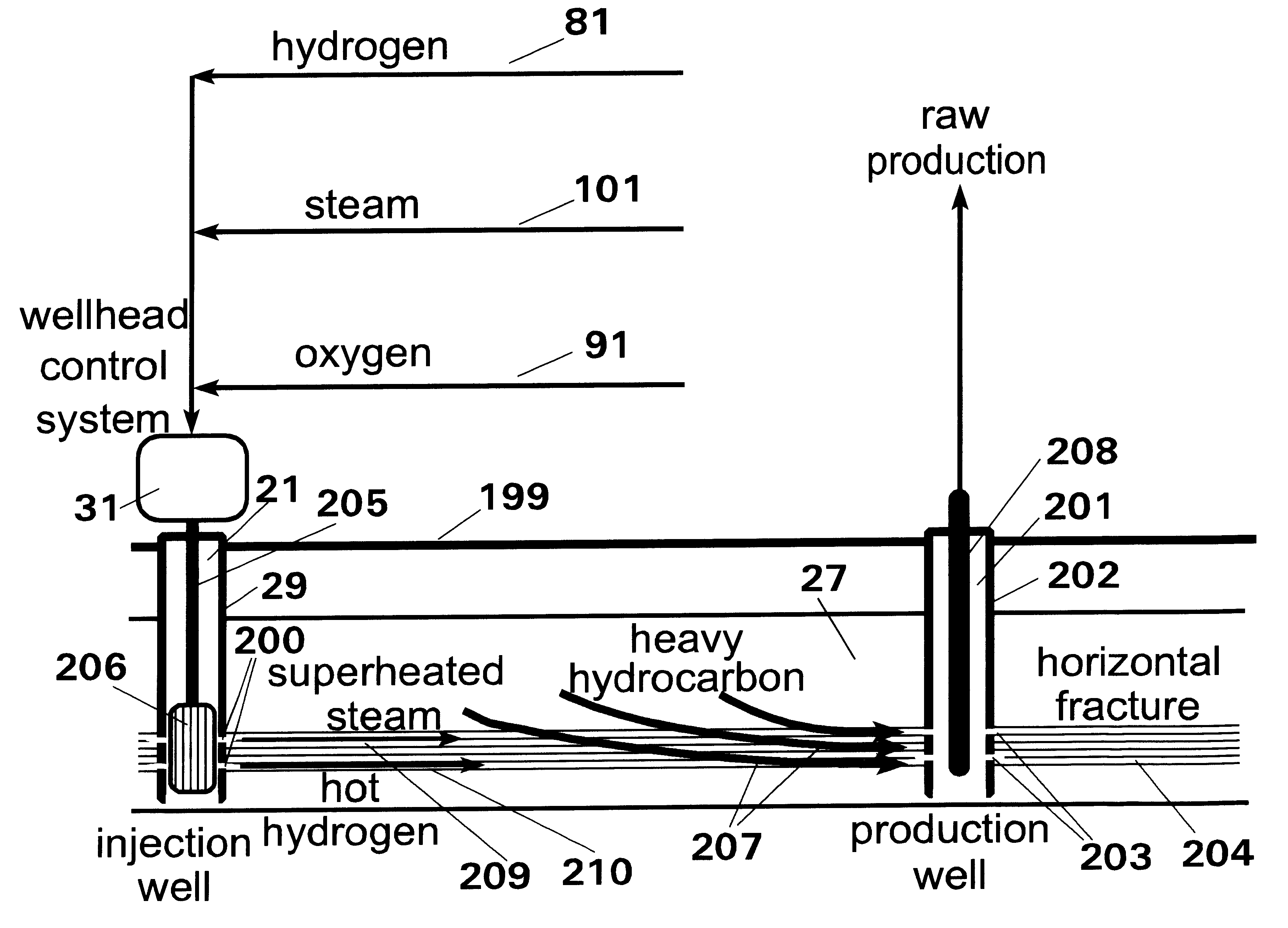

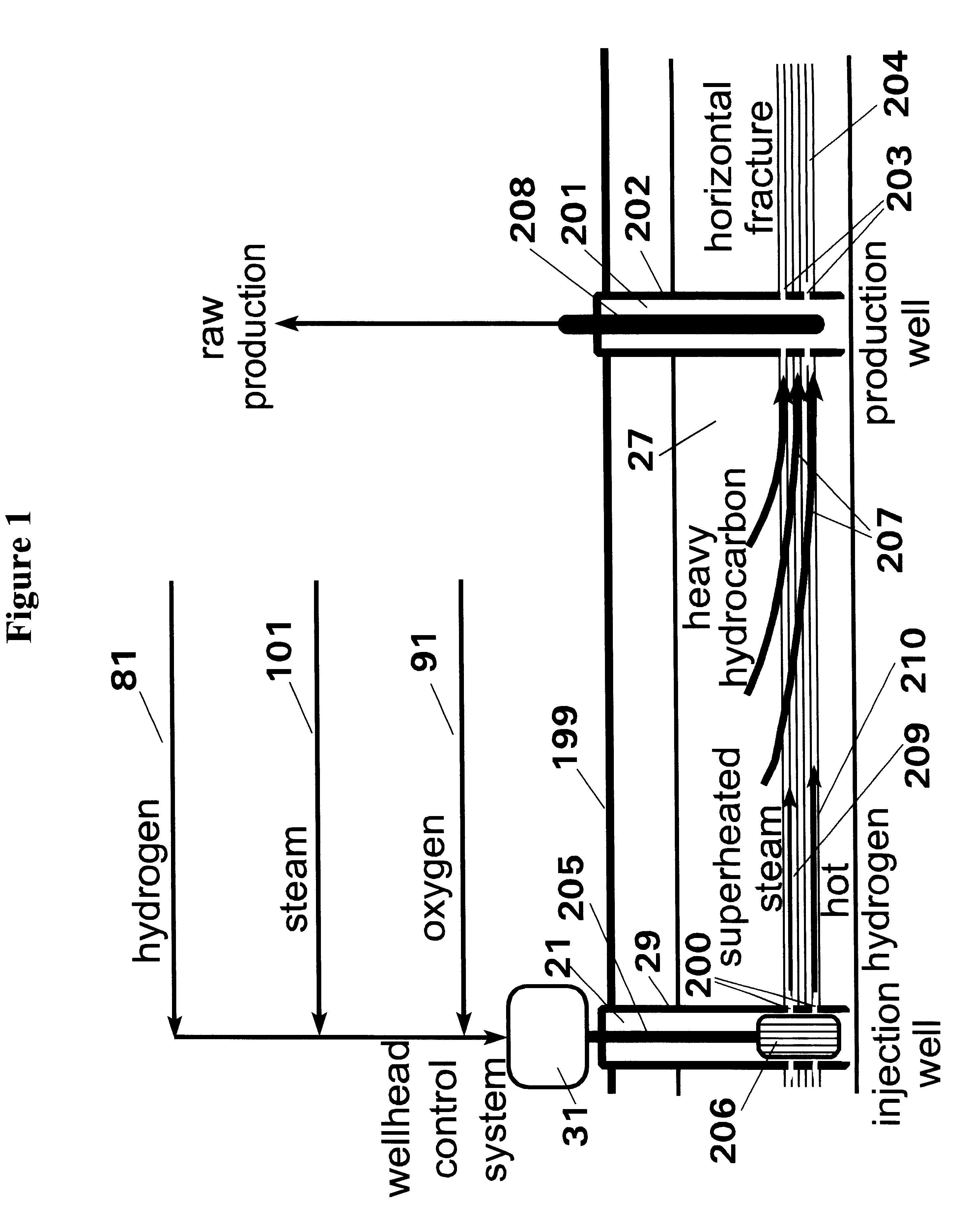

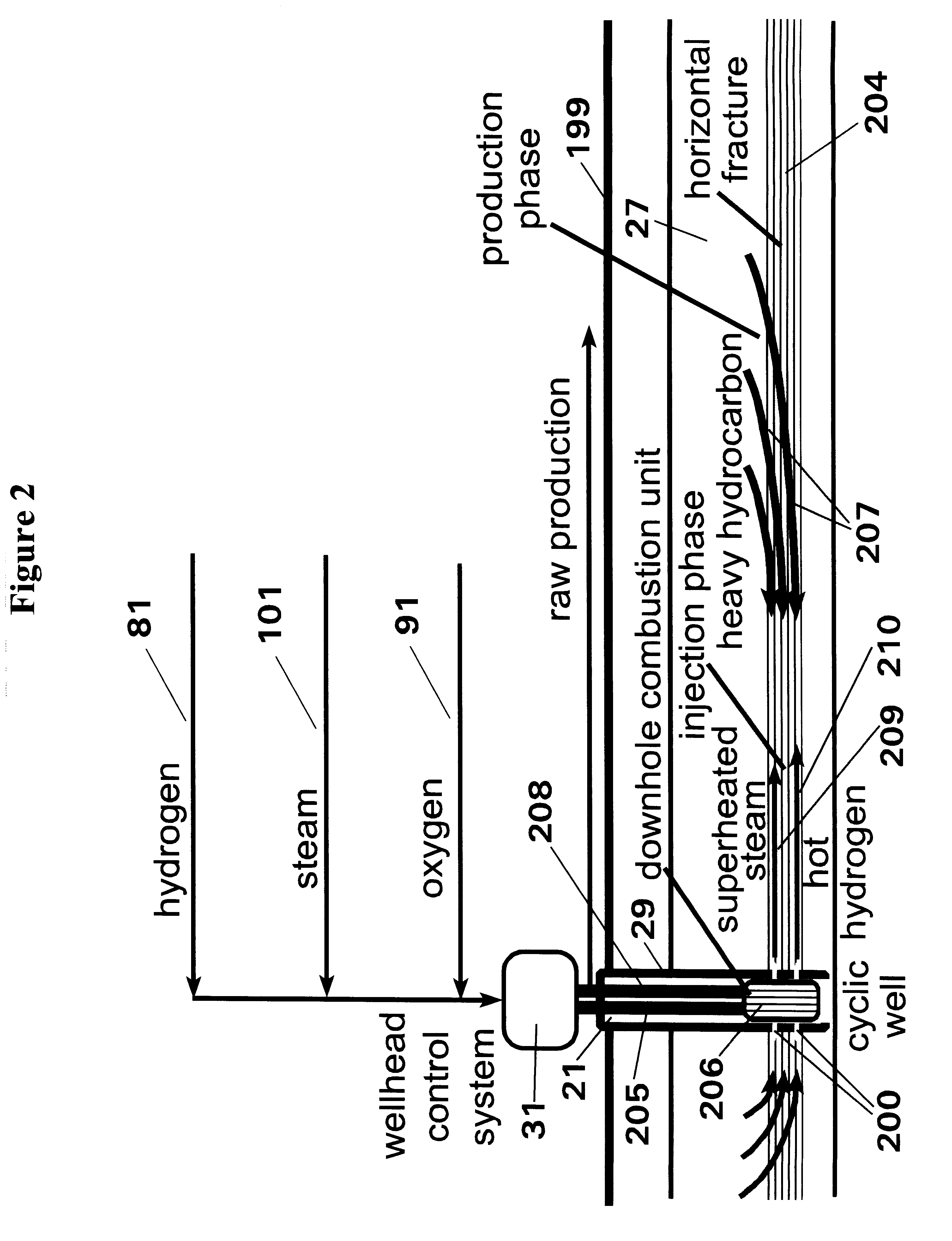

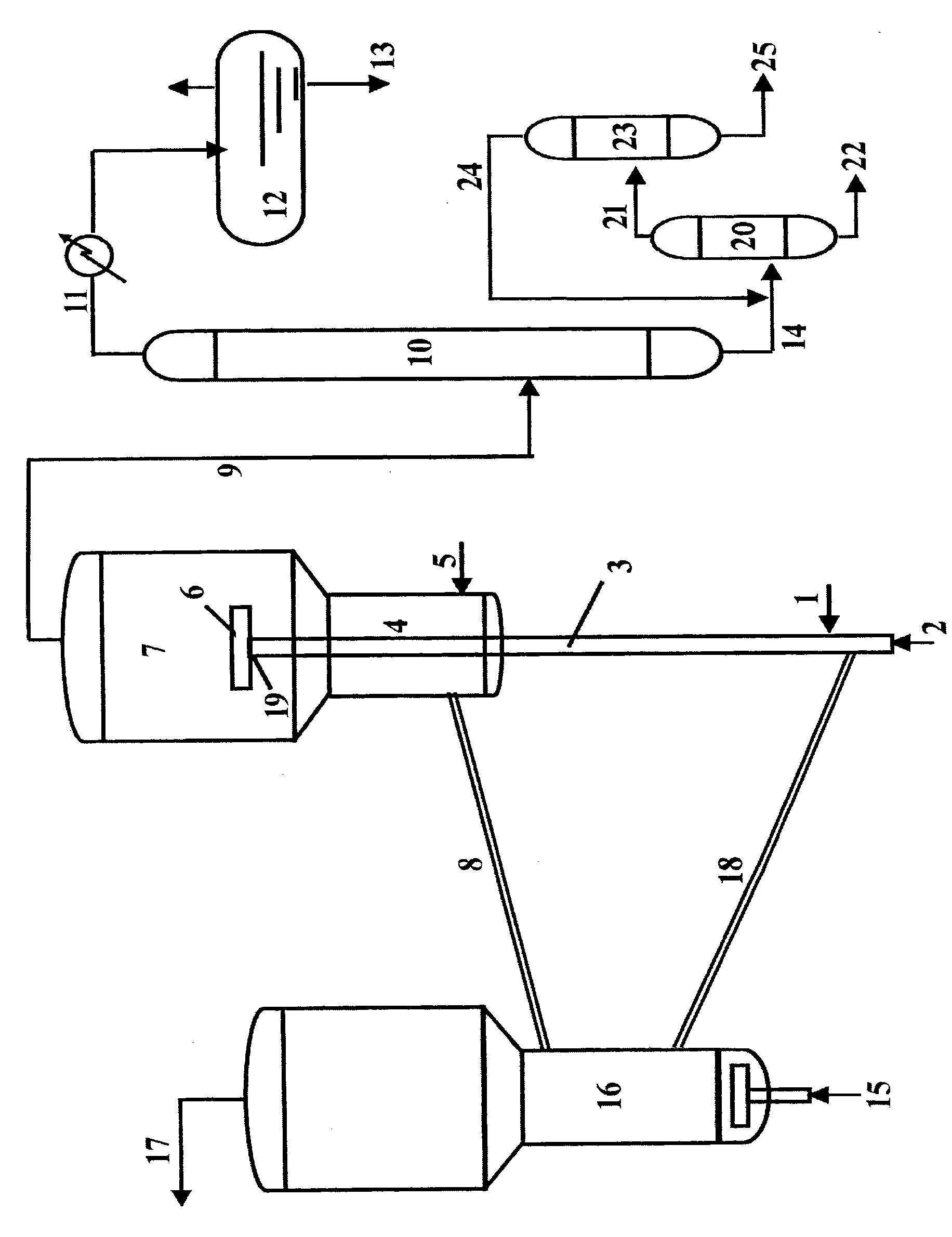

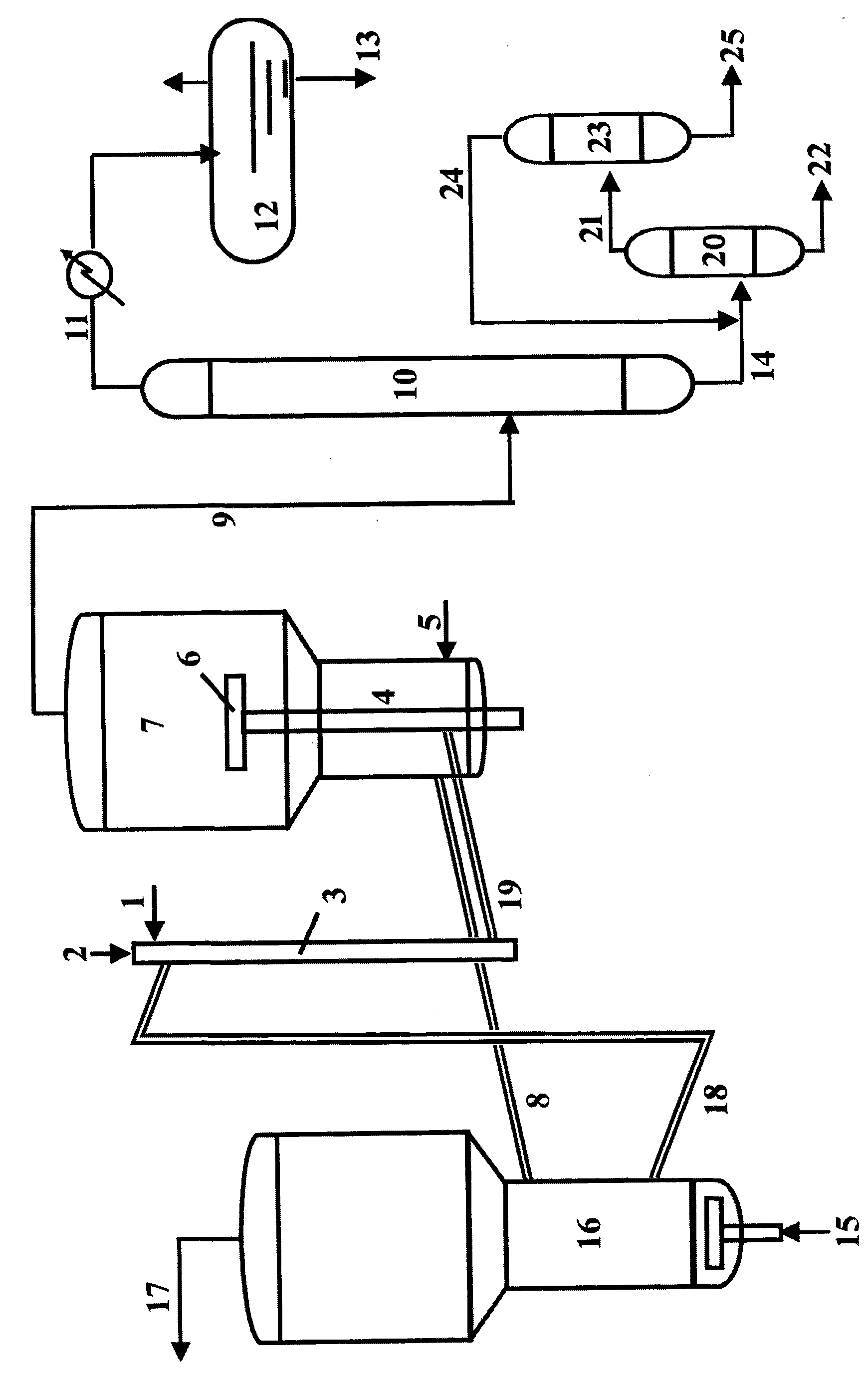

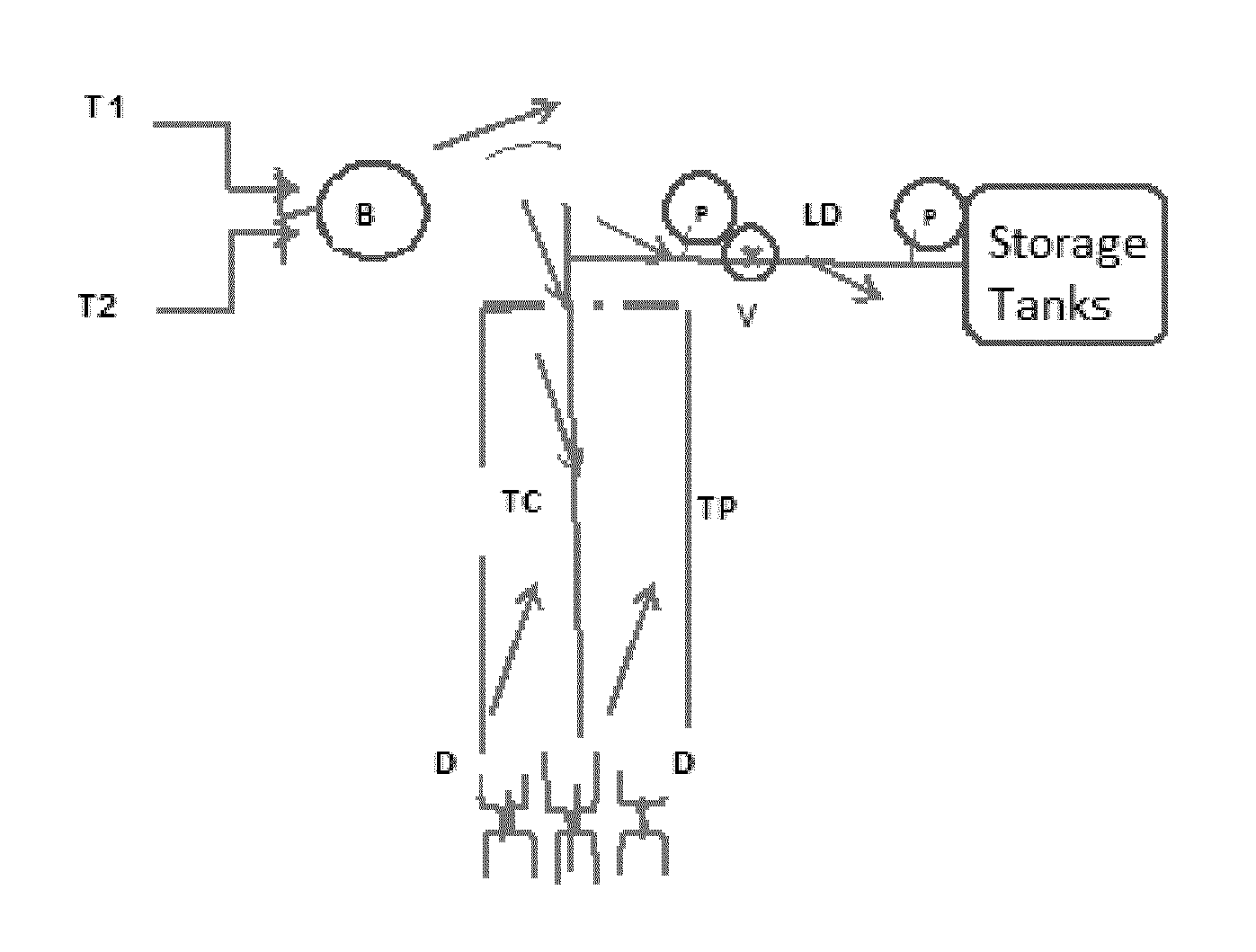

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more injection and production boreholes, which may include horizontal boreholes, or a cyclic operation whereby both injection and production occur in the same boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing or related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

Upgrading and recovery of heavy crude oils and natural bitumens by in situ hydrovisbreaking

A process is disclosed for the in situ conversion and recovery of heavy crude oils and natural bitumens from subsurface formations using either a continuous operation with one or more vertical injection boreholes and one or more vertical production boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes, or a cyclic operation whereby both injection and production occur in the same vertical boreholes in which multiple, uncased, horizontal boreholes may extend from the vertical boreholes. A mixture of reducing gases, oxidizing gases, and steam are fed to downhole combustion devices located in the injection boreholes. Combustion of the reducing gas-oxidizing gas mixture is carried out to produce superheated steam and hot reducing gases for injection into the formation to convert and upgrade the heavy crude or bitumen into lighter hydrocarbons. Communication between the injection and production boreholes in the continuous operation and fluid mobility within the formation in the cyclic operation is induced by fracturing, multiple horizontal boreholes extending from vertical boreholes, or other related methods. In the continuous mode, the injected steam and reducing gases drive upgraded hydrocarbons and virgin hydrocarbons to the production boreholes for recovery. In the cyclic operation, wellhead pressure is reduced after a period of injection causing injected fluids, upgraded hydrocarbons, and virgin hydrocarbons in the vicinity of the boreholes to be produced. Injection and production are then repeated for additional cycles. In both operations, the hydrocarbons produced are collected at the surface for further processing.

Owner:WORLD ENERGY SYST

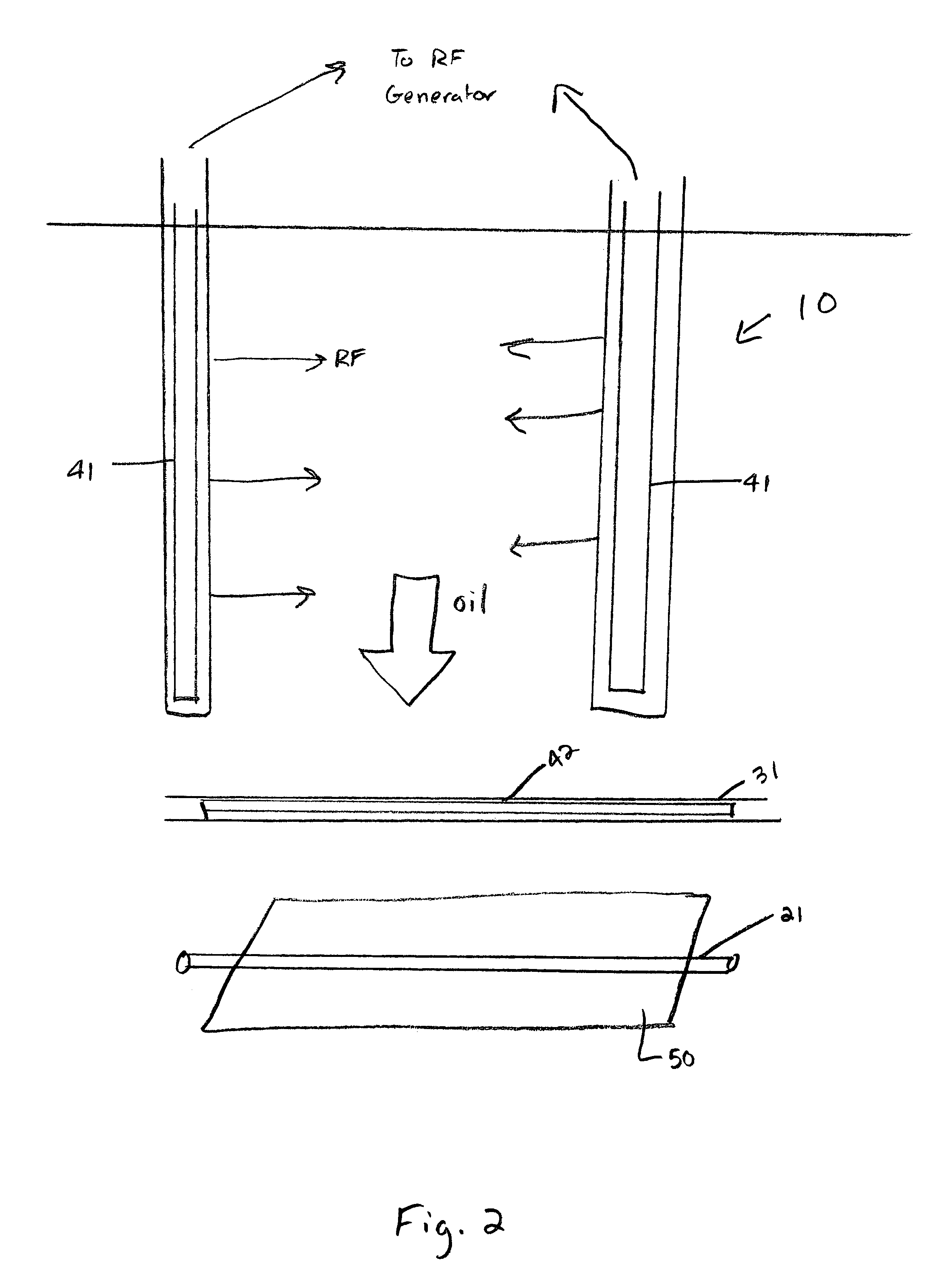

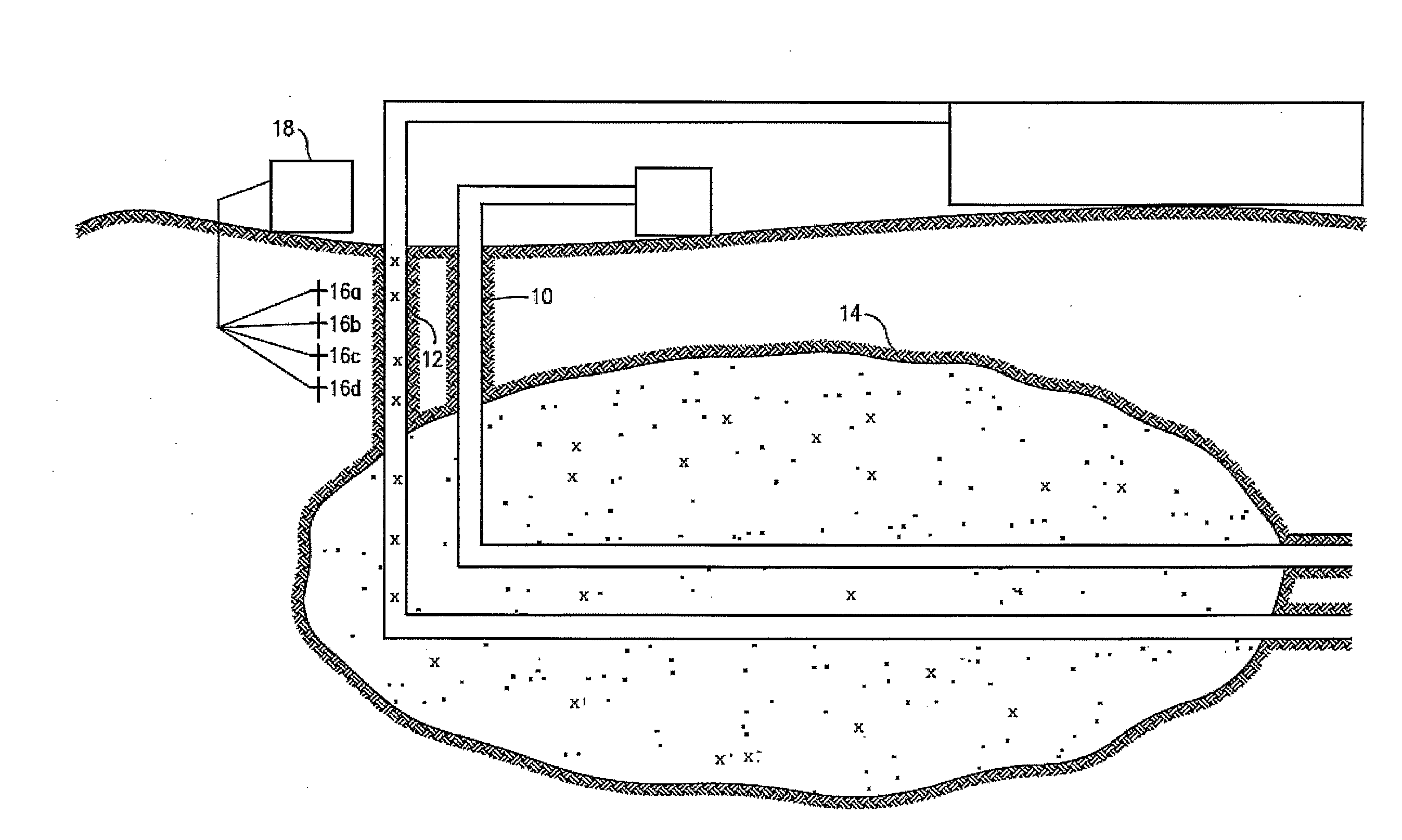

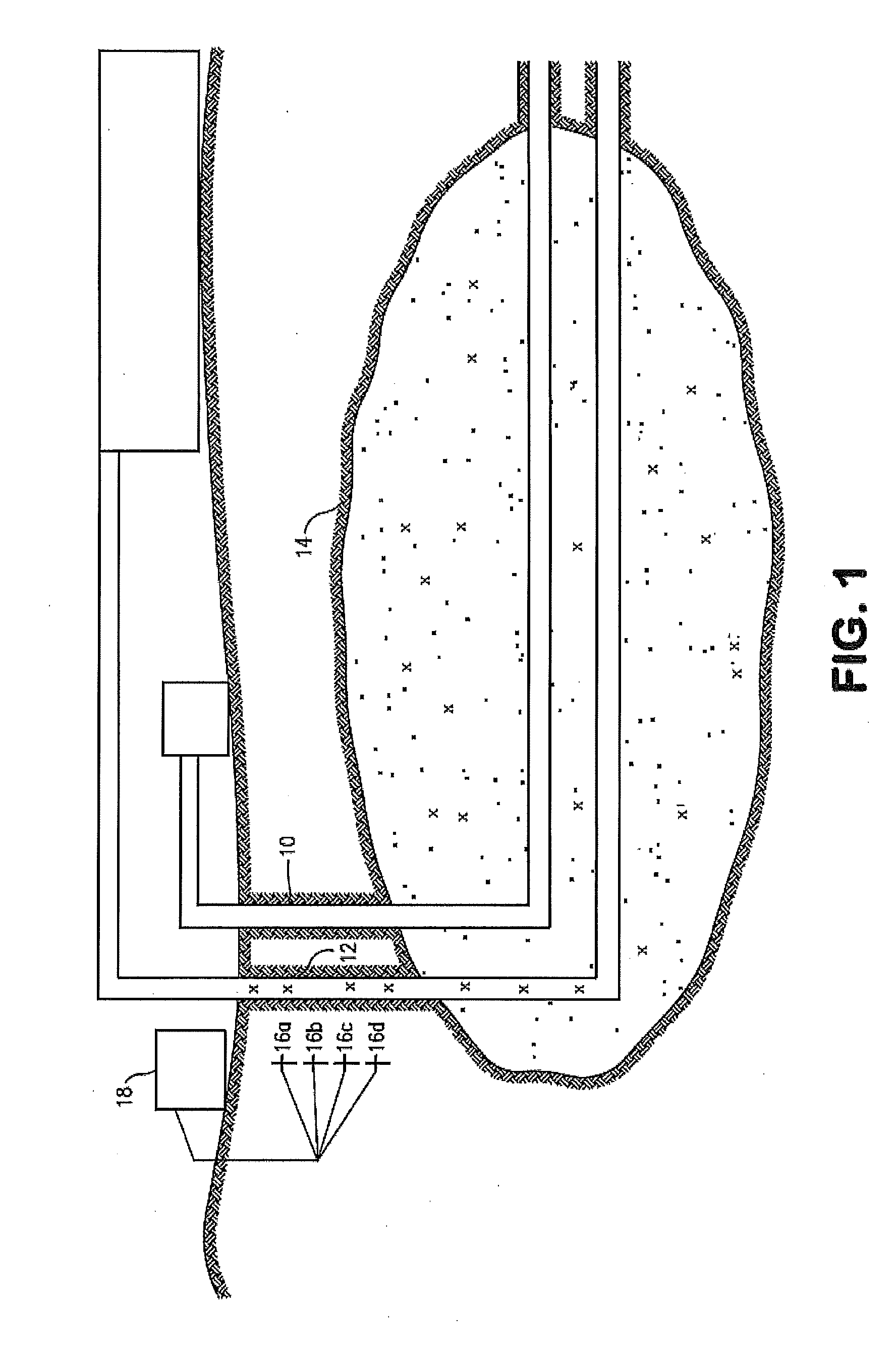

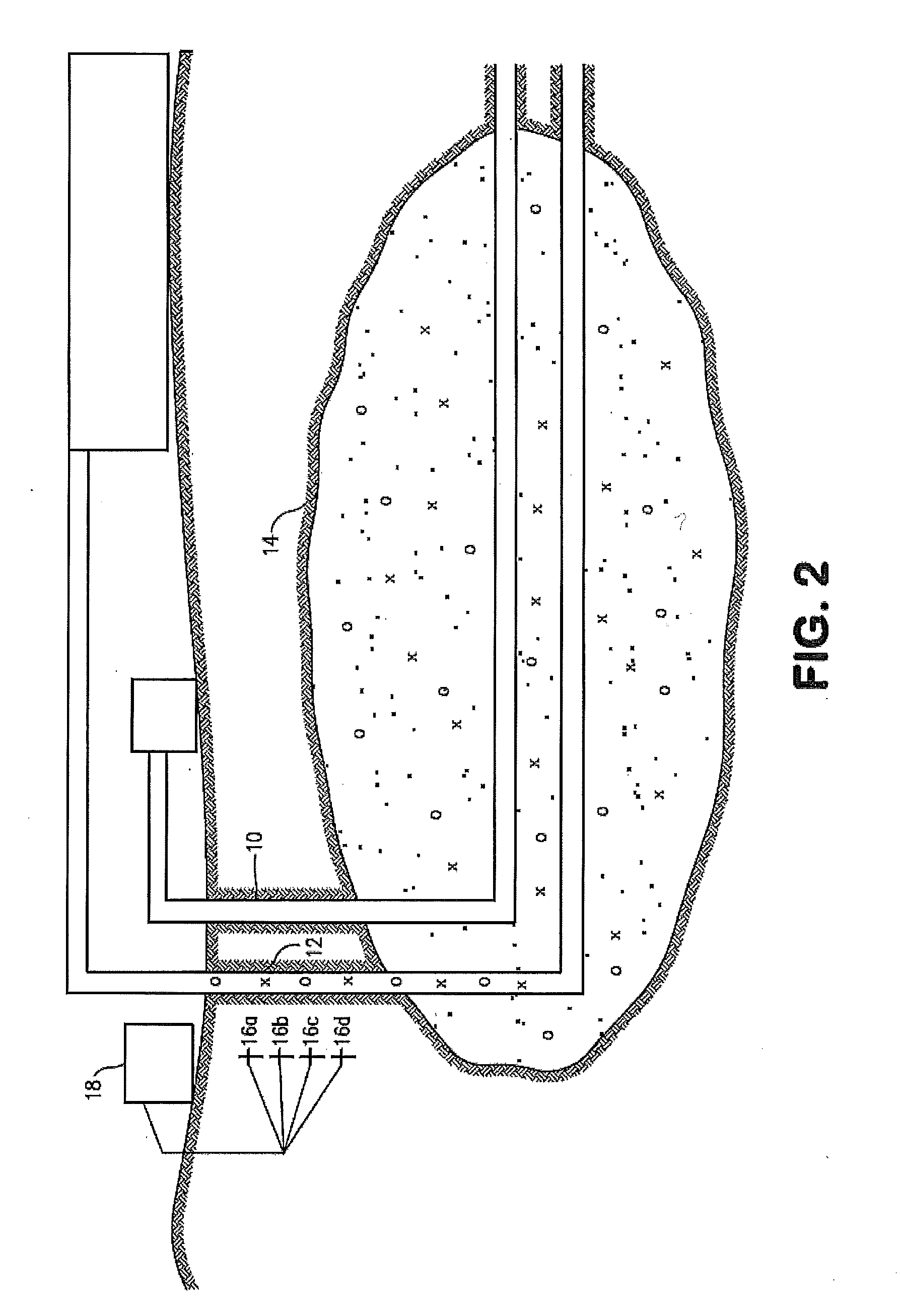

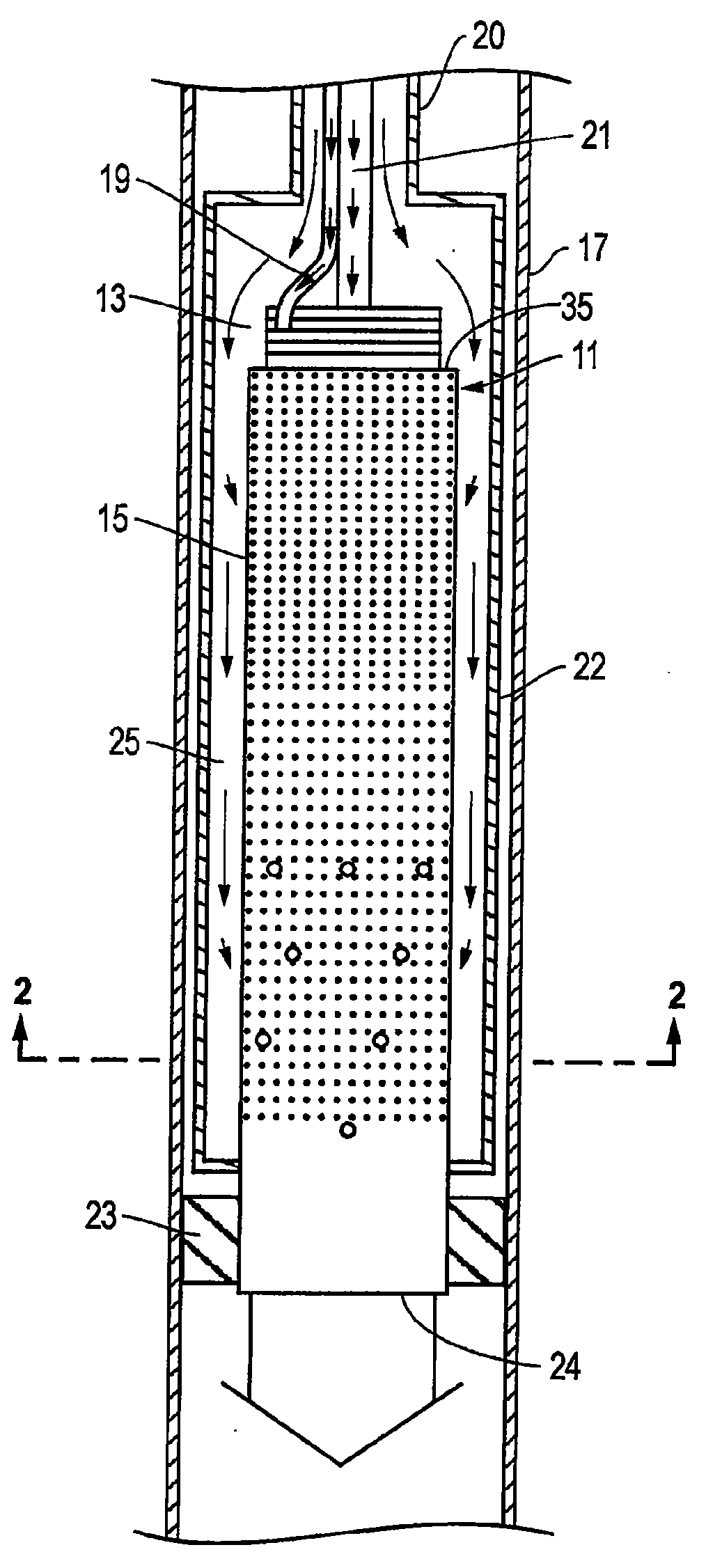

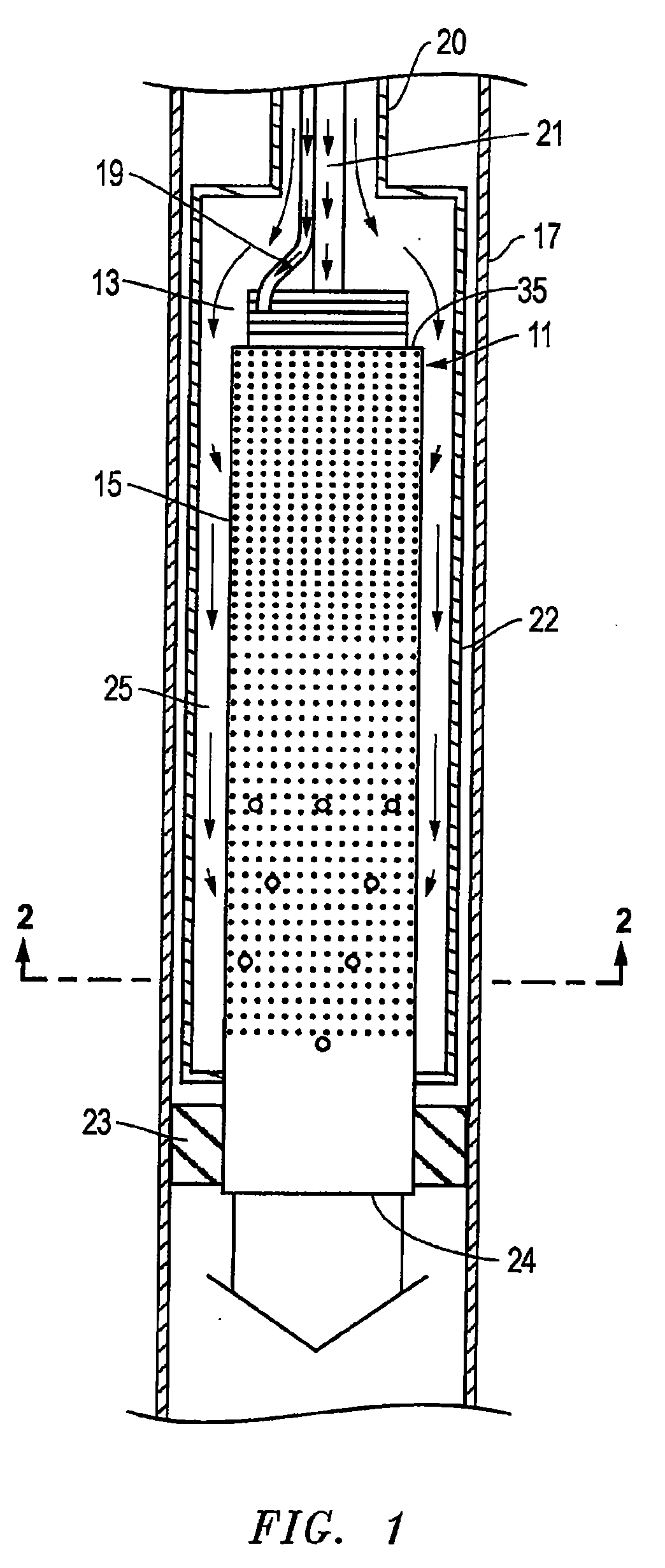

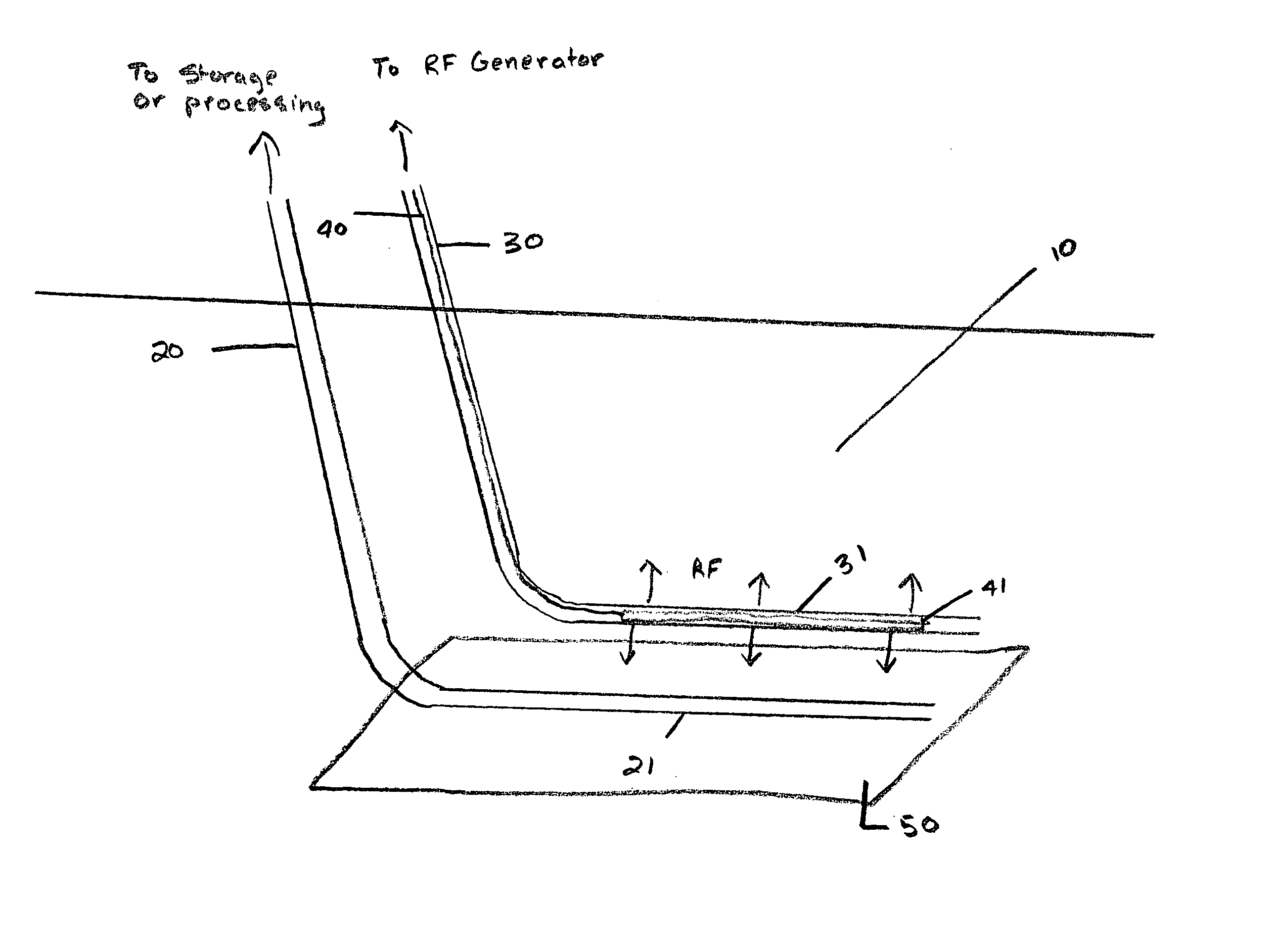

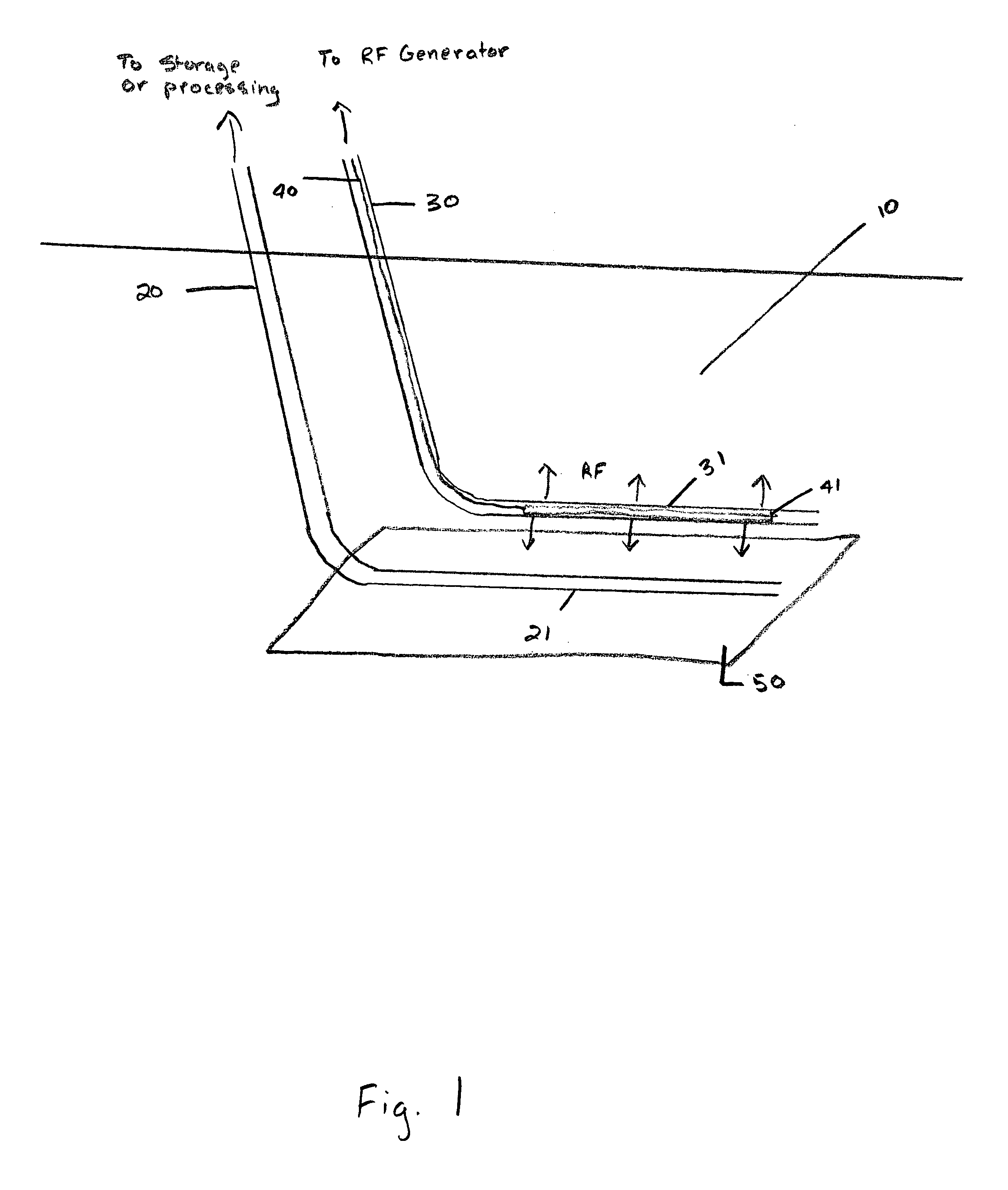

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS7441597B2Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

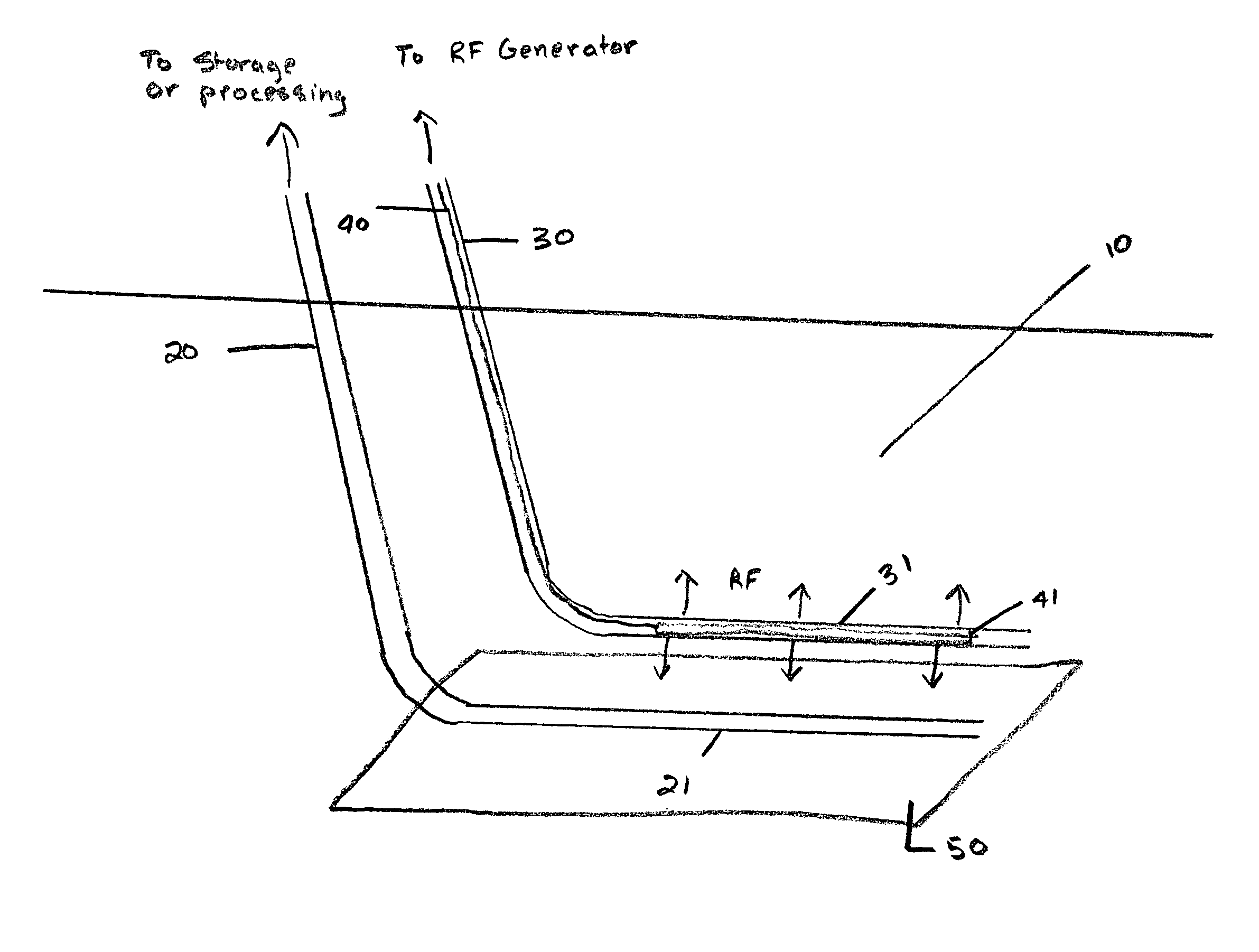

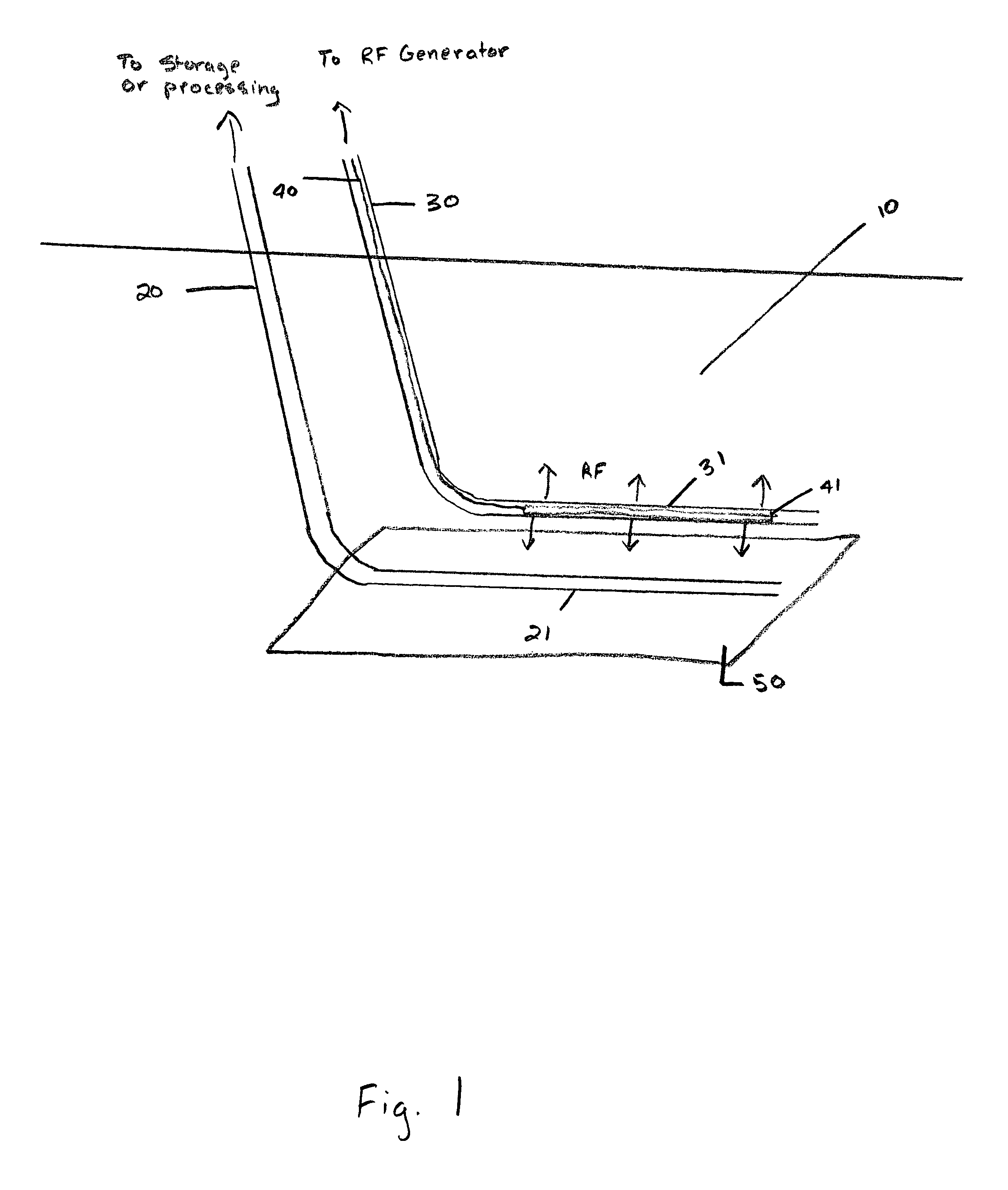

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

In-situ upgrading of heavy crude oil in a production well using radio frequency or microwave radiation and a catalyst

A method for heating heavy oil inside a production well. The method raises the subsurface temperature of heavy oil by utilizing an activator that has been injected below the surface. The activator is then excited with a generated microwave frequency such that the excited activator heats the heavy oil.

Owner:CONOCOPHILLIPS CO

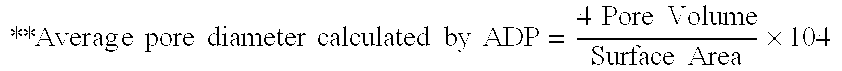

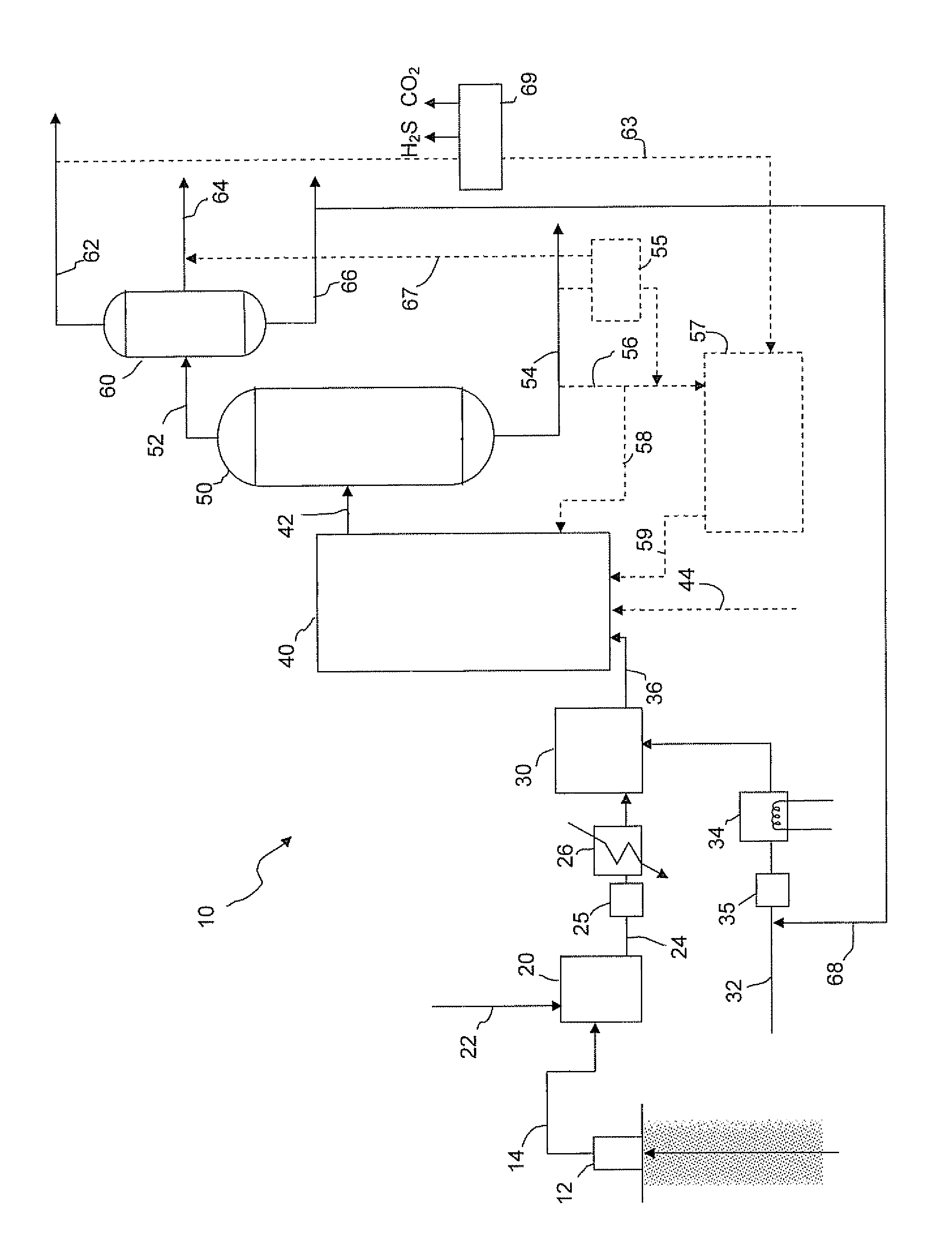

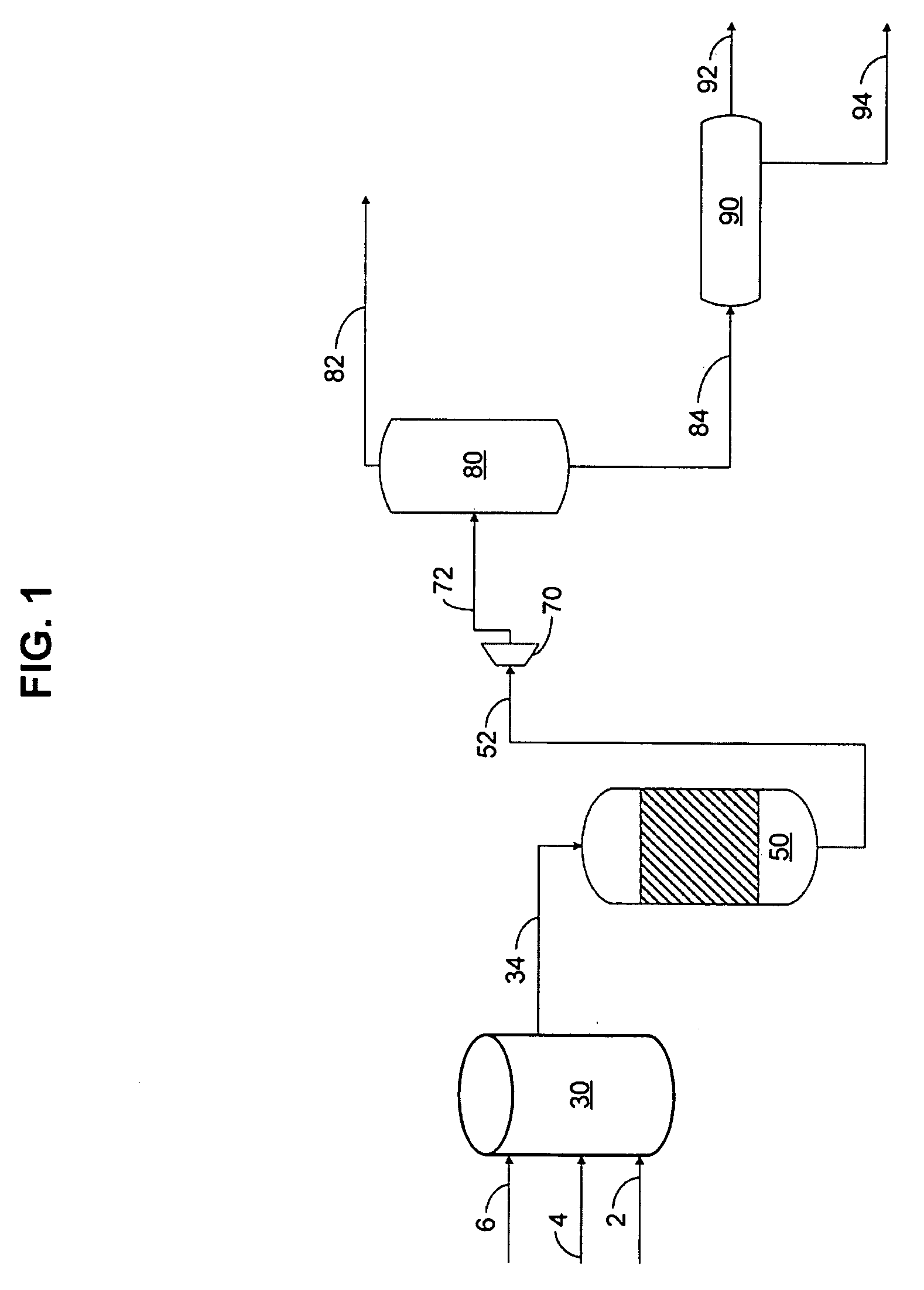

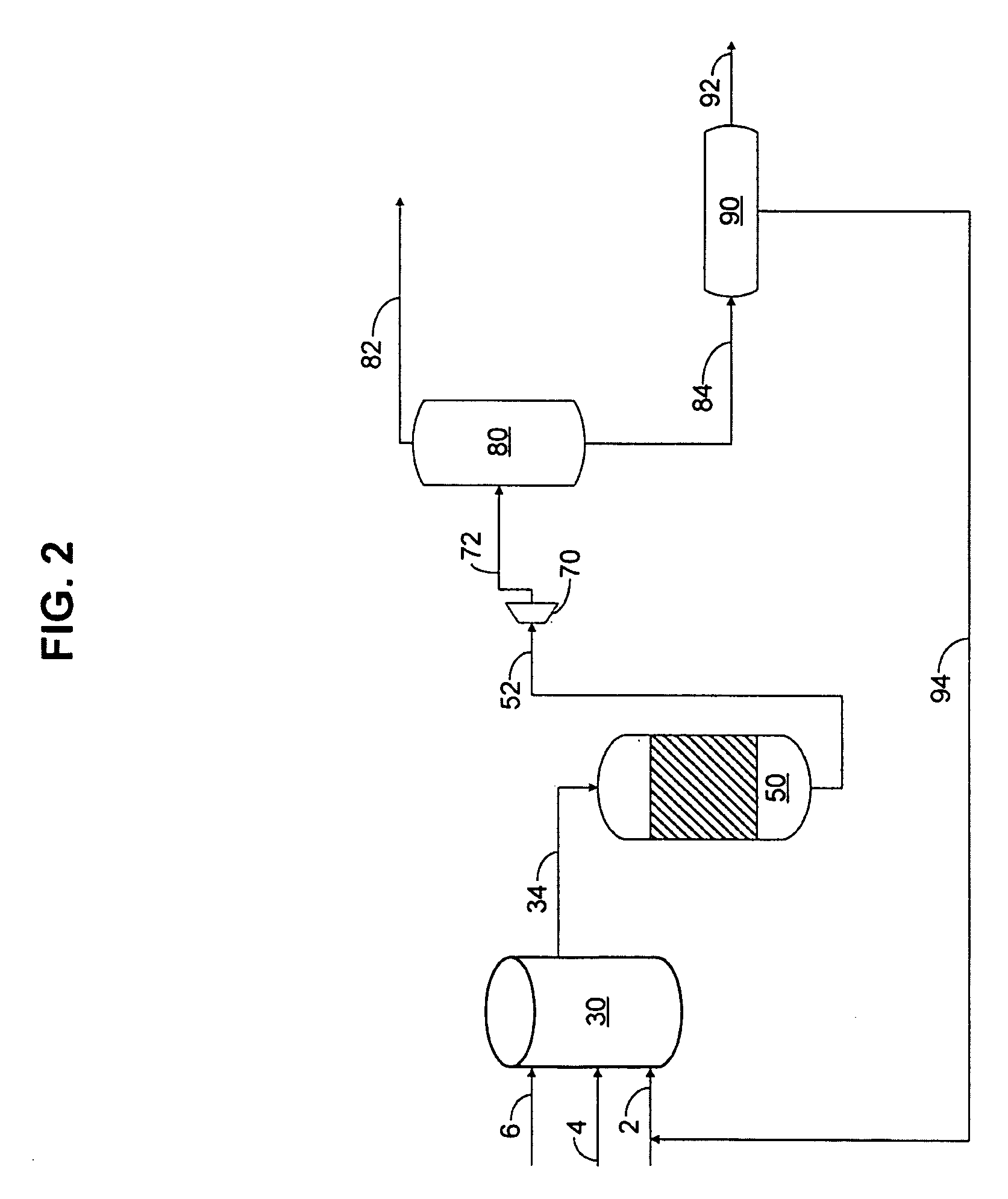

Effective integration of solvent deasphalting and ebullated-bed processing

InactiveUS7214308B2Reduced light gas yieldImprove hydrogen efficiencyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyReactor systemHeavy crude oil

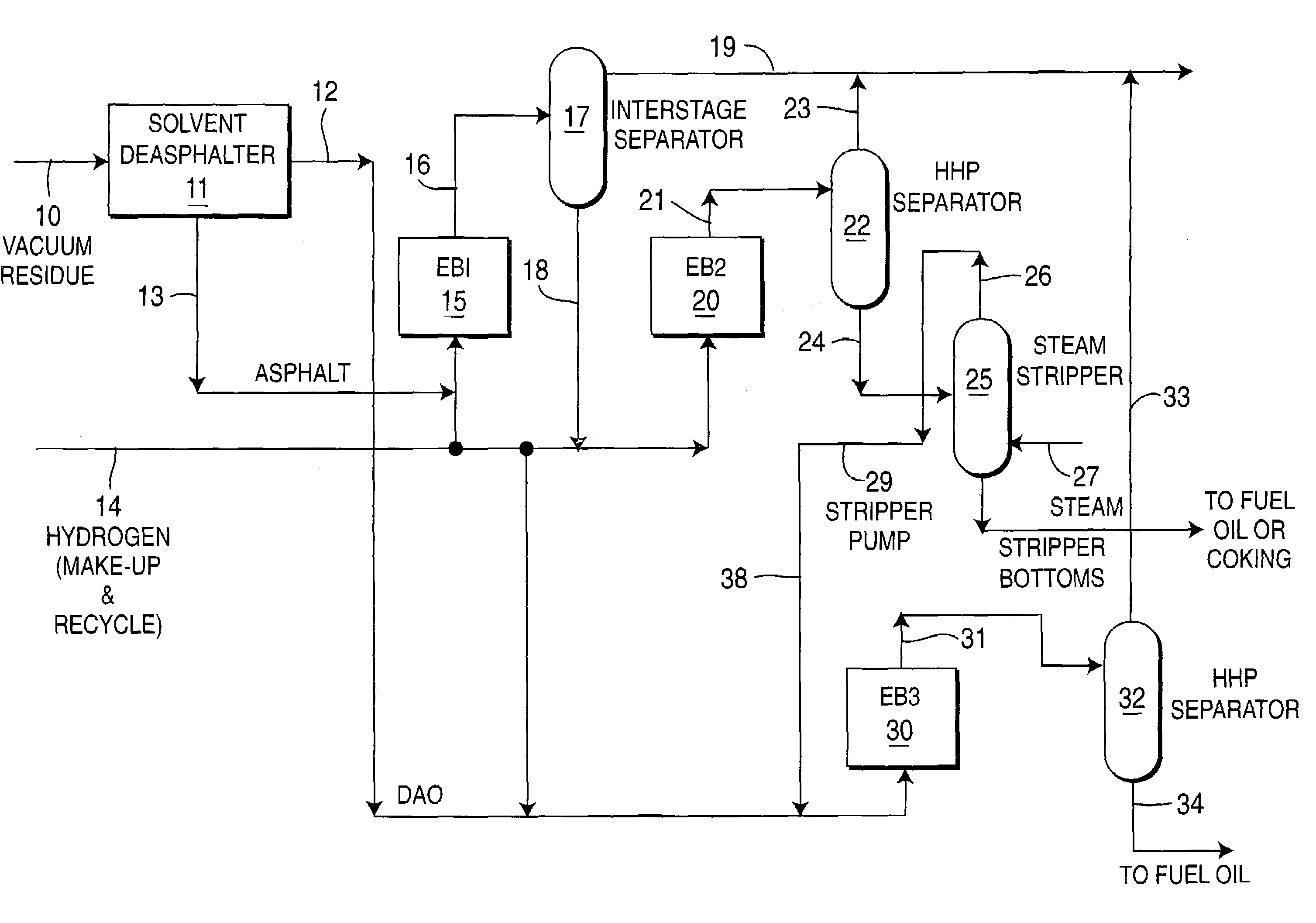

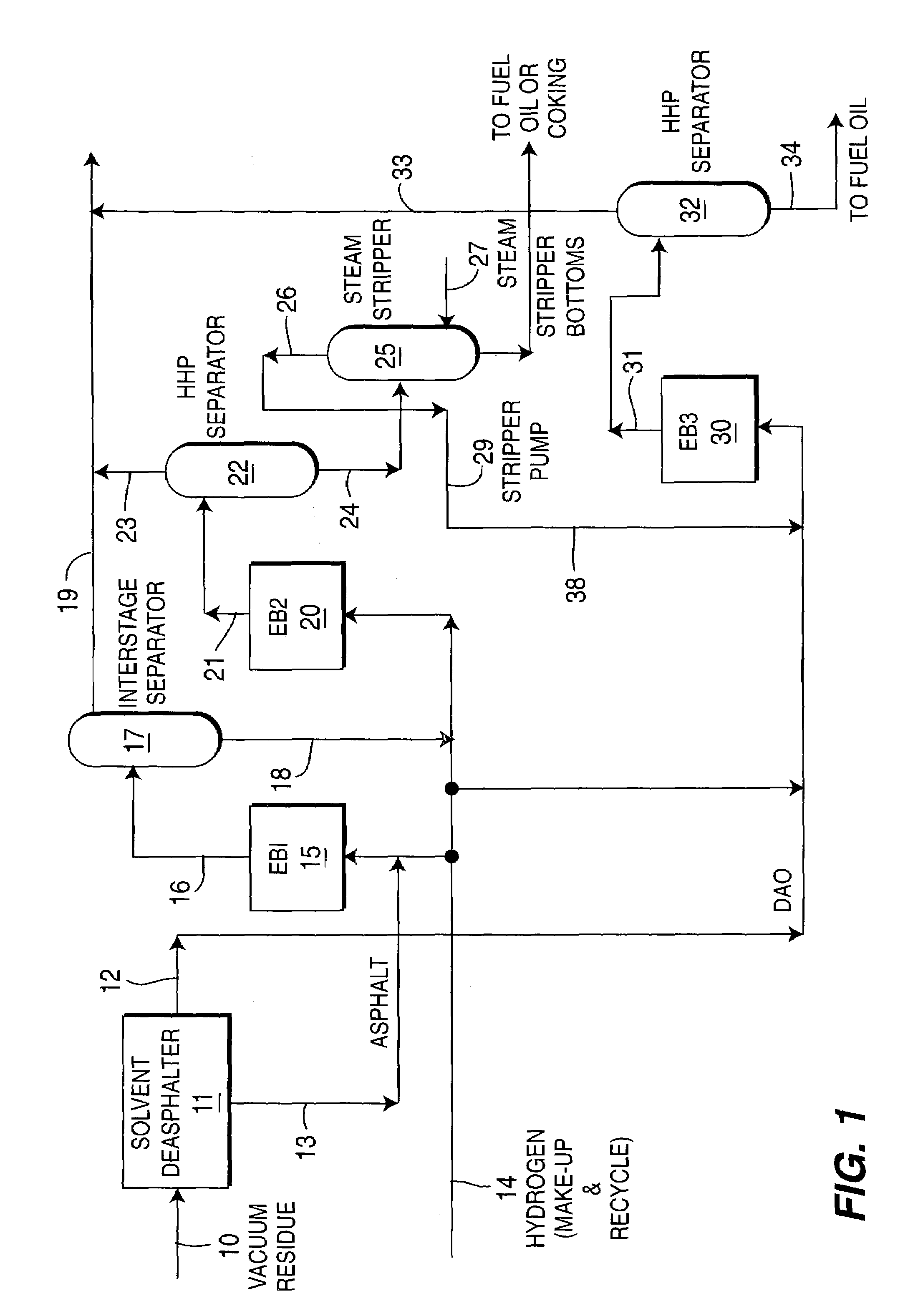

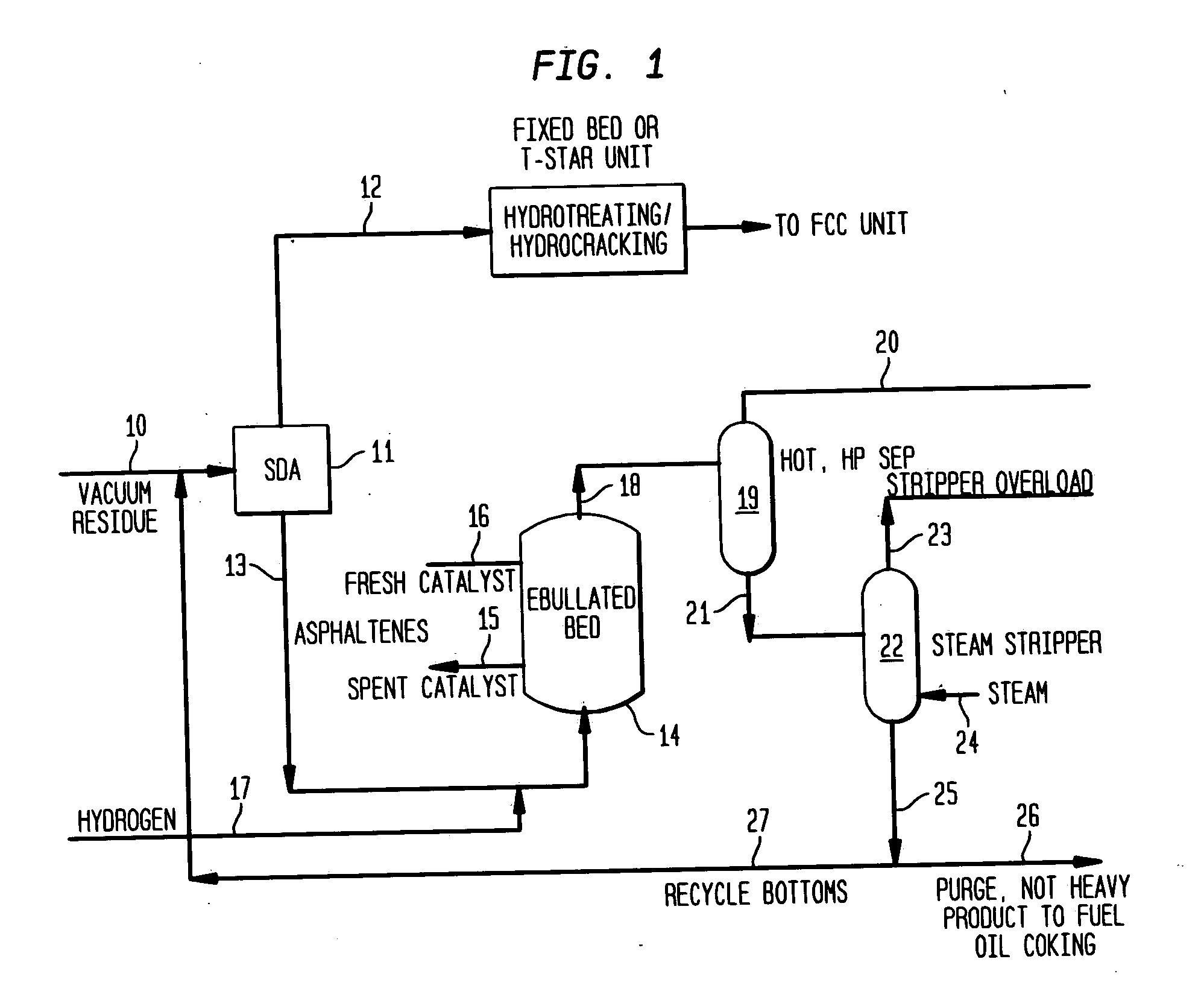

This invention relates to a novel method for economically processing vacuum residue from heavy crude oils by selectively processing the difficult and easy components in reactors whose design and operating conditions are optimized for the specific feed. The process utilizes an integrated solvent deasphalting (SDA) / ebullated-bed design wherein the heavy vacuum residue feedstock is initially sent to an SDA unit operated with C4 / C5 solvent to achieve a high deasphalted oil (DAO) yield. The resulting SDA products, namely asphaltenes and DAO are separately treated in ebullated-bed reactor(s) systems whose design and operating conditions are optimized for a particular feedstock. The resulting net conversion, associated distillate yield and product qualities are greatly improved relative to treatment of the entire residue feedstock in a common ebullated-bed reactor system.

Owner:INST FR DU PETROLE

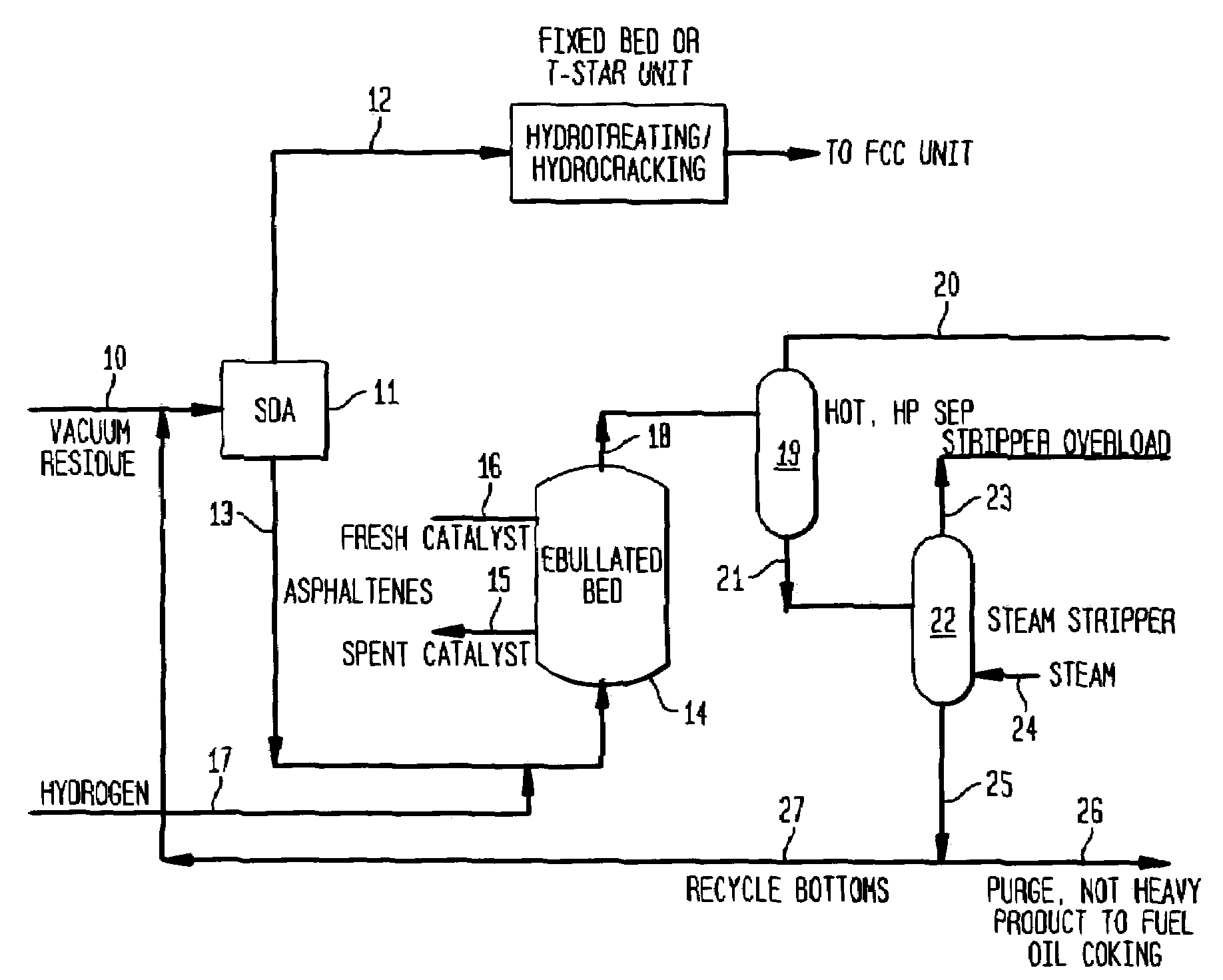

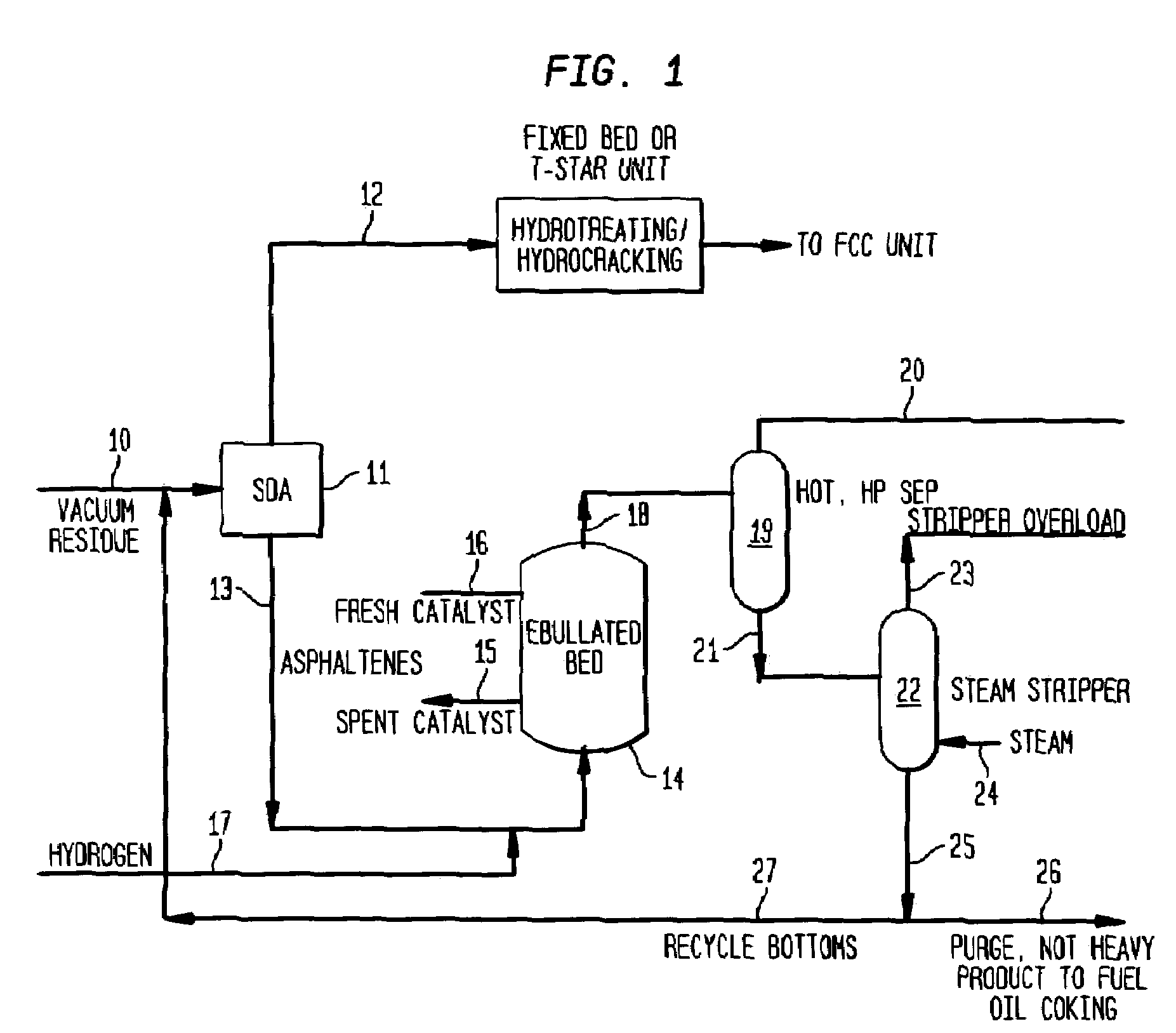

Integrated SDA and ebullated-bed process

ActiveUS20060118463A1Most efficientMinimizing chanceTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

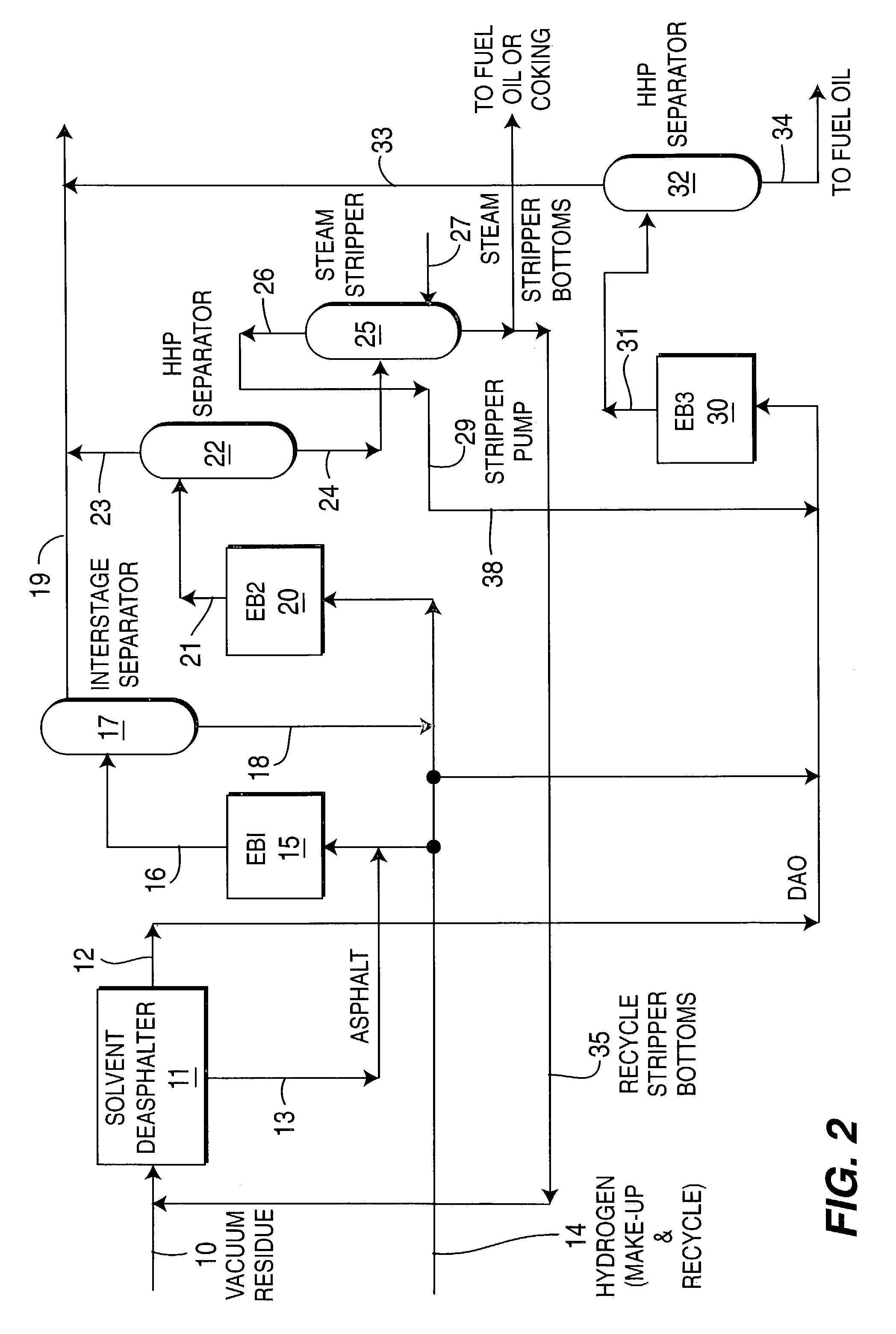

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit. The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

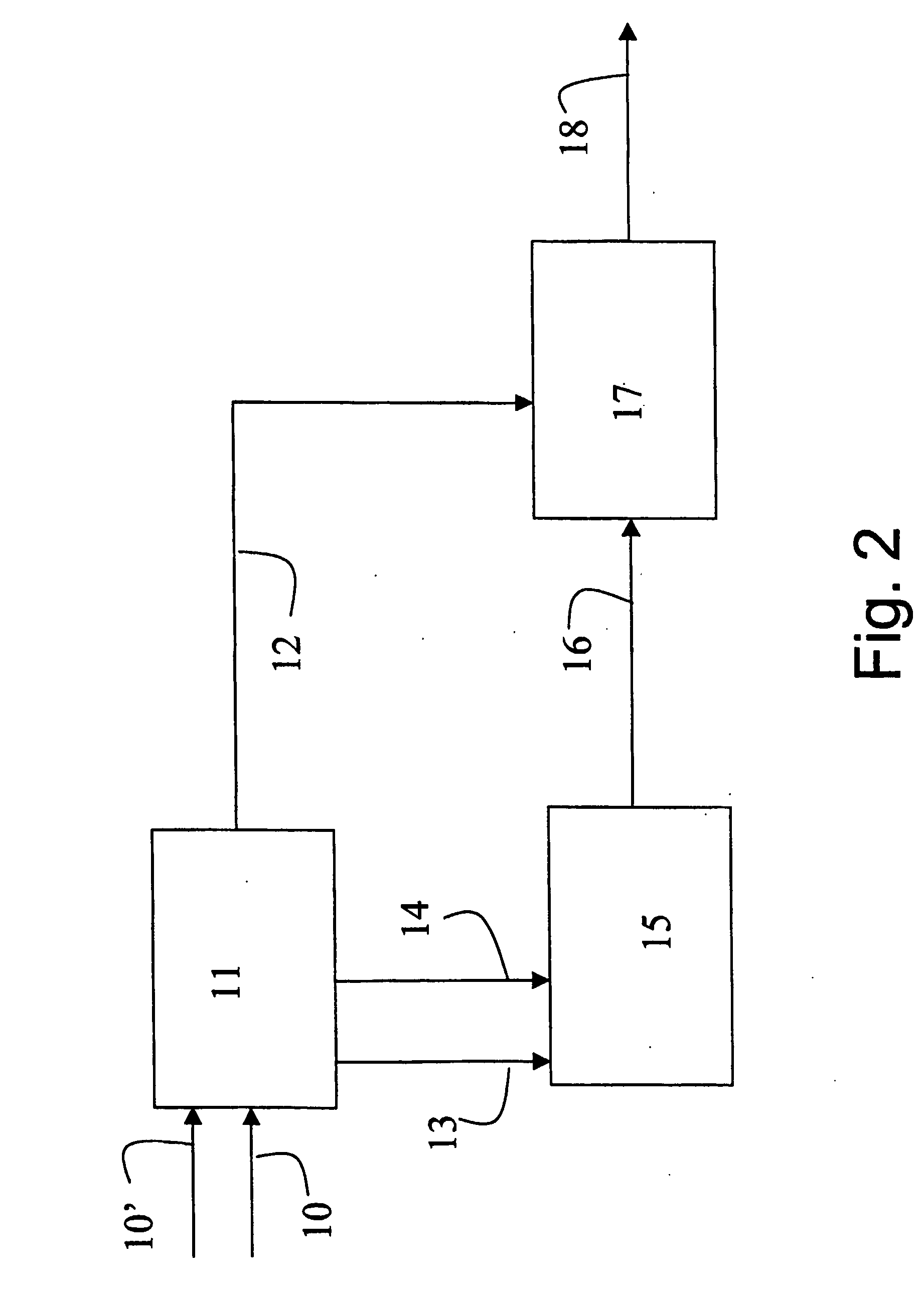

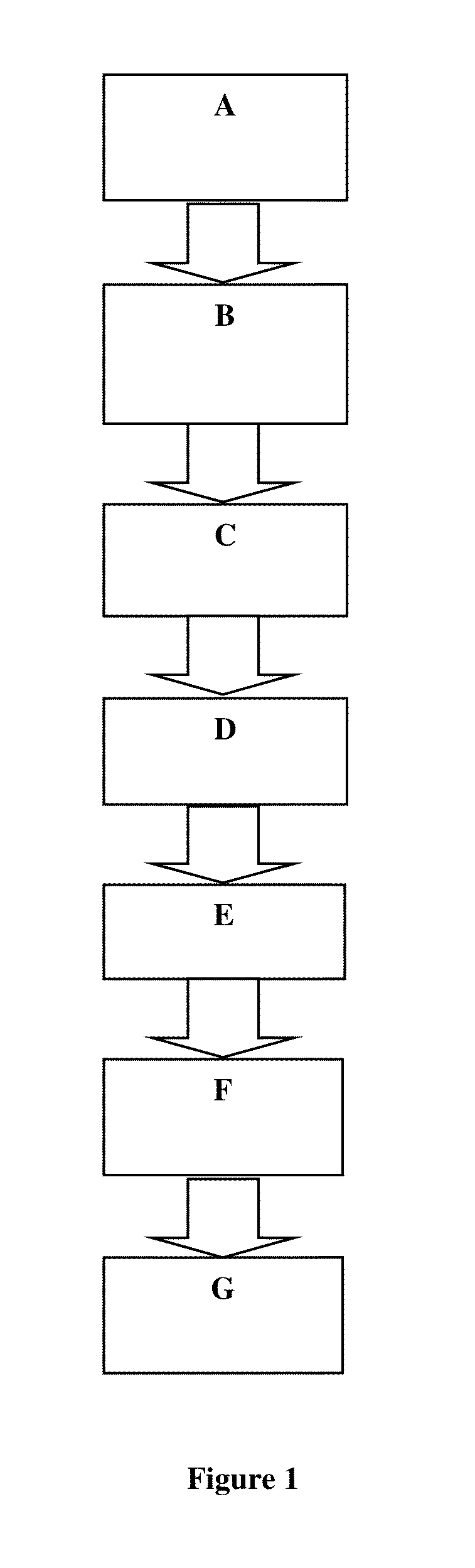

Method for production and upgrading of oil

An integrated process for production and upgrading of heavy and extra-heavy crude oil, comprising (a) reforming of hydrocarbons such as natural gas to produce hydrogen, CO2 and steam (b) separating the produced hydrogen from the CO2, steam and any other gases to give a hydrogen rich fraction and a CO2 rich fraction and steam, (c) injecting the steam alone or in combination with the CO2 rich fraction into a reservoir containing heavy or extra heavy oil to increase the oil recovery, and (d) upgrading / refining of the heavy or extra heavy oil to finished products by extensive hydroprocessing, comprising several steps of hydrocracking and hydrotreating (sulfur, nitrogen and metals removal as well as hydrogenation of olefins and aromatics), using the hydrogen rich fraction.

Owner:STATOIL ASA PETRO SA (NO)

Process for dispersing nanocatalysts into petroleum-bearing formations

Owner:WORLD ENERGY SYST

Integrated SDA and ebullated-bed process

ActiveUS7279090B2Wide pore catalystMost efficientTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit.The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

Process for dispersing nanocatalysts into petroleum-bearing formations

Embodiments of the invention provide methods for recovering petroleum products from a formation by distributing nanocatalysts into the formation and heating the heavy crude oil therein. In one embodiment, a method is provided which includes flowing a catalytic material containing the nanocatalyst into the formation containing the heavy crude oil, exposing the heavy crude oil and the catalytic material to a reducing agent (e.g., H2), positioning a steam generator within the formation, generating and releasing steam from the steam generator to heat the heavy crude oil containing the catalytic material, forming lighter oil products within the formation, and extracting the lighter oil products from the formation. In another embodiment, a method is provided which includes exposing the heavy crude oil and the catalytic material to an oxidizing agent (e.g., O2). The nanocatalyst may contain cobalt, iron, nickel, molybdenum, chromium, tungsten, titanium, oxides thereof, alloys thereof, derivatives thereof, or combinations thereof.

Owner:WORLD ENERGY SYST

Recovery and transportation of heavy crude oils

InactiveUS6402934B1Low viscosityWorking-up pitch/asphalt/bitumen by chemical meansLiquid carbonaceous fuelsHeavy crude oilSequestering Agent

Owner:ROHM & HAAS CO

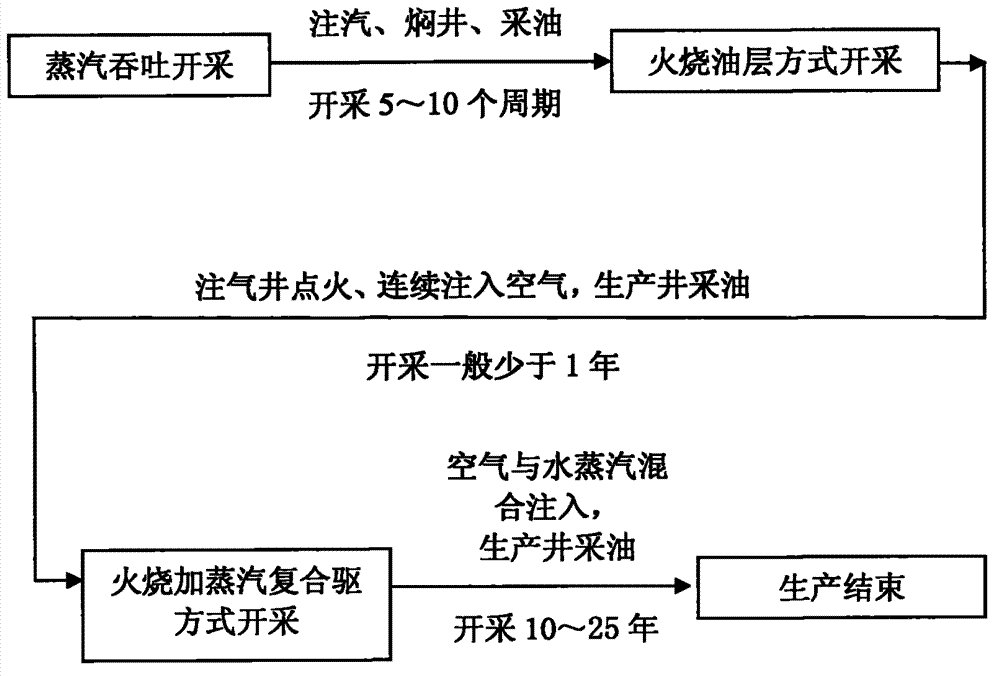

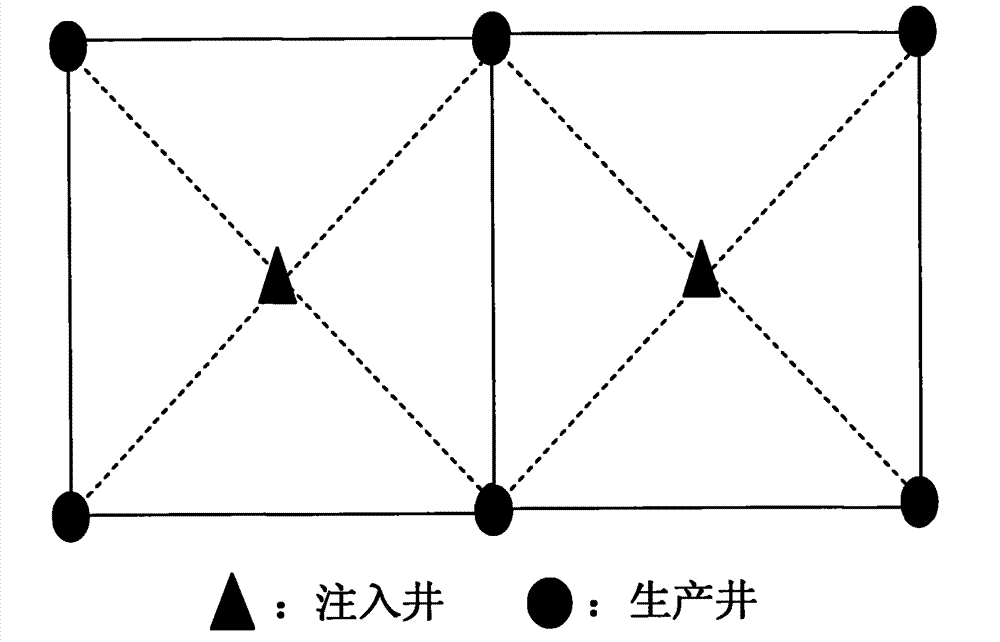

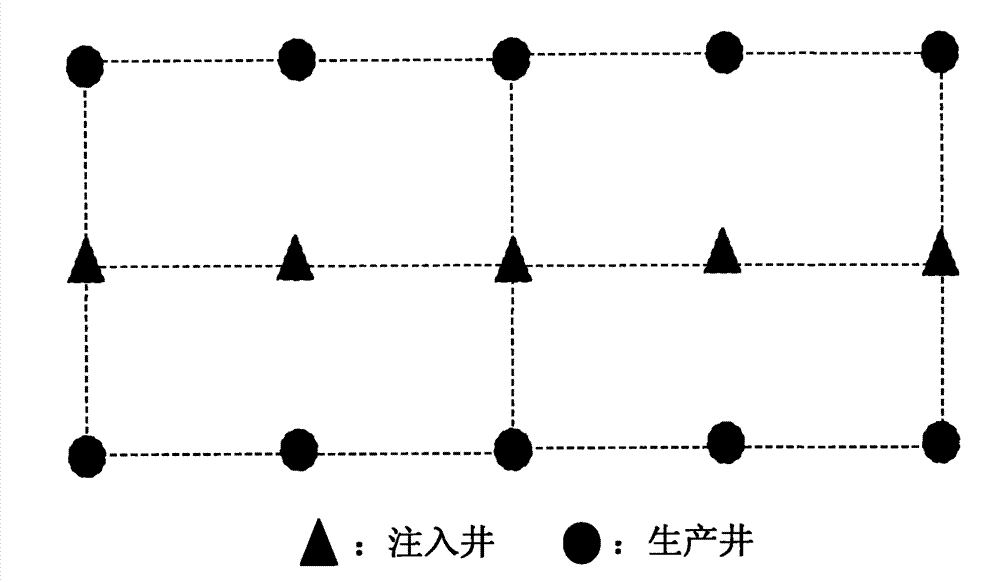

Method for using combustion and vapor combination flooding to exploit thick oil

The invention discloses a method for using combustion and stream combination flooding to exploit thick oil. The method comprises the following steps of: carrying out vapor huff and puff exploitation in a heavy crude oil reservoir; carrying out in-situ combustion exploitation after forming thermal linkage; and changing single air charging to be simultaneous charging of air and water vapor in certain proportion to carry out combination flooding exploitation. A proper optimal configuration relationship of air / vapour charging speed is selected, so as to improve combustion wave and volume of the oil reservoir and improve exploitation effects of in-situ combustion and the ultimate recovery factor.

Owner:PETROCHINA CO LTD

Process of hydrotreating heavy hydrocarbon oil

ActiveUS7651605B2Increase deactivation rateImprove throughputCoke ovensHydrocarbon distillationReaction temperatureHeavy crude oil

When a heavy fuel oil with a sulfur content of 1 percent by mass or lower is produced from a feedstock consisting of a heavy hydrocarbon oil derived from a heavy crude oil having an API degree of 30 or less and containing sulfur and metal components in amounts larger than those of ordinary crude oil, the conventional processes requires higher reaction temperature and was accompanied with a remarkably enhanced deactivation rate of the catalyst which results in a remarkable shortened lifetime thereof. Therefore, it is regarded as substantially impossible to treat the feedstock. However, the present invention makes it possible to produce a low sulfur heavy fuel oil with a sulfur content of 1 percent by mass or less by hydrotreating a mix oil of 100 parts by volume of a heavy hydrocarbon oil derived from a heavy crude oil with an API degree of 30 or less and 30 to 1000 parts by volume of a heavy hydrocarbon oil derived from a light crude oil with an API degree of 35 or greater, without lowering the degree of demetallization while retarding the deactivation rate of the catalyst.

Owner:NIPPON OIL CORP

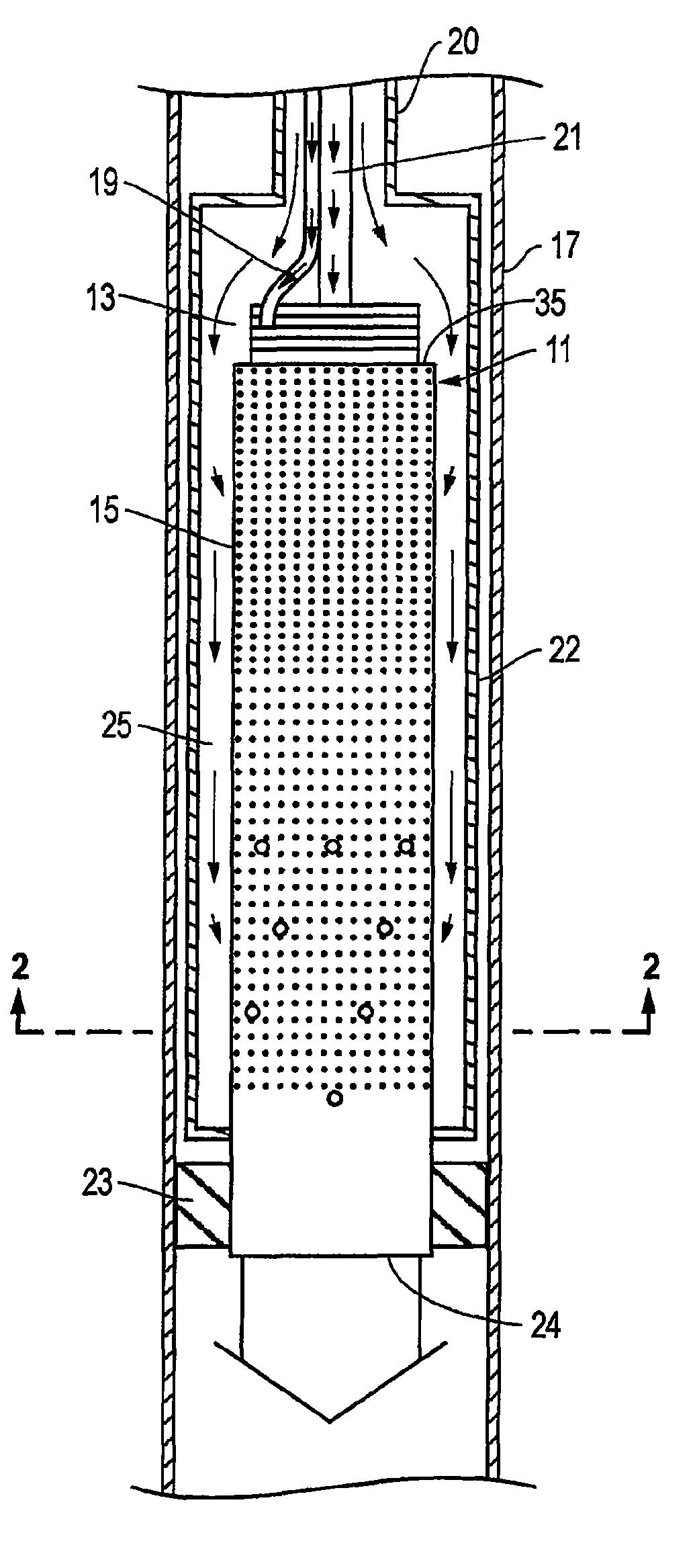

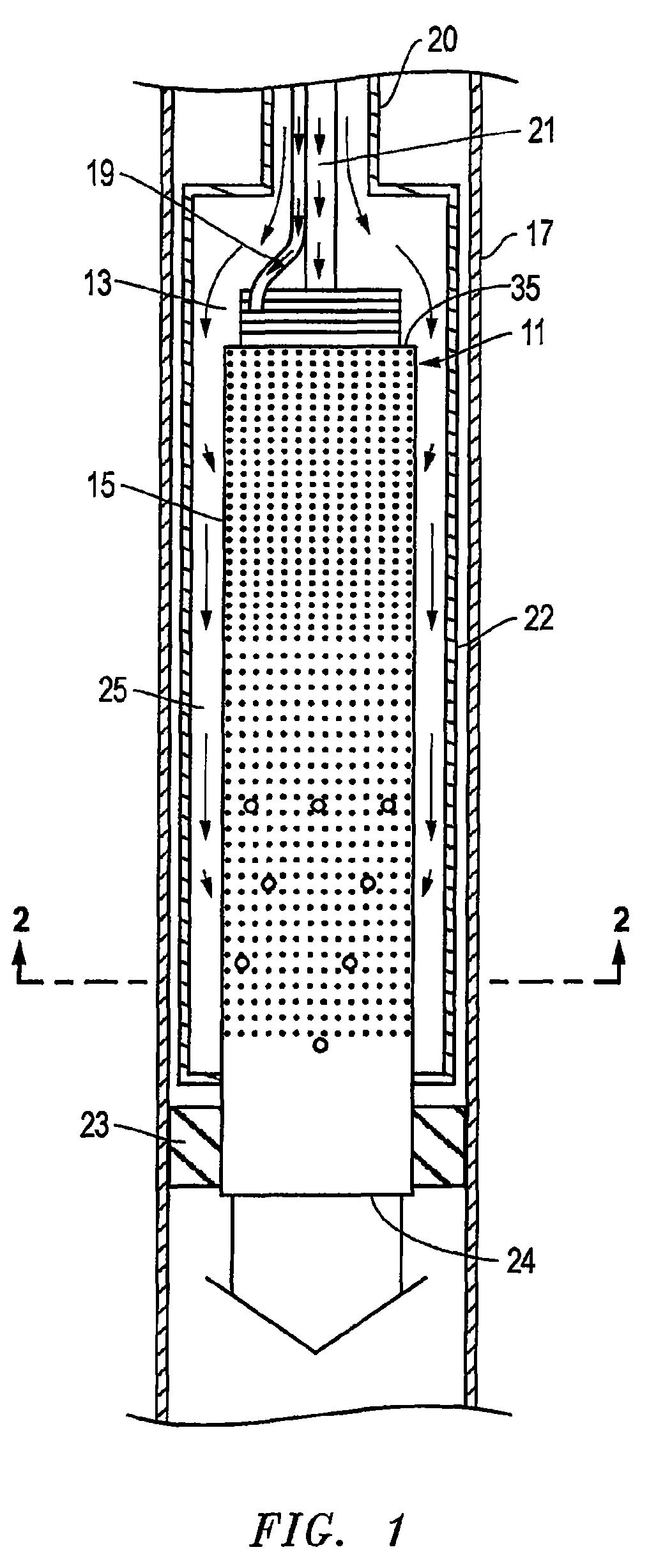

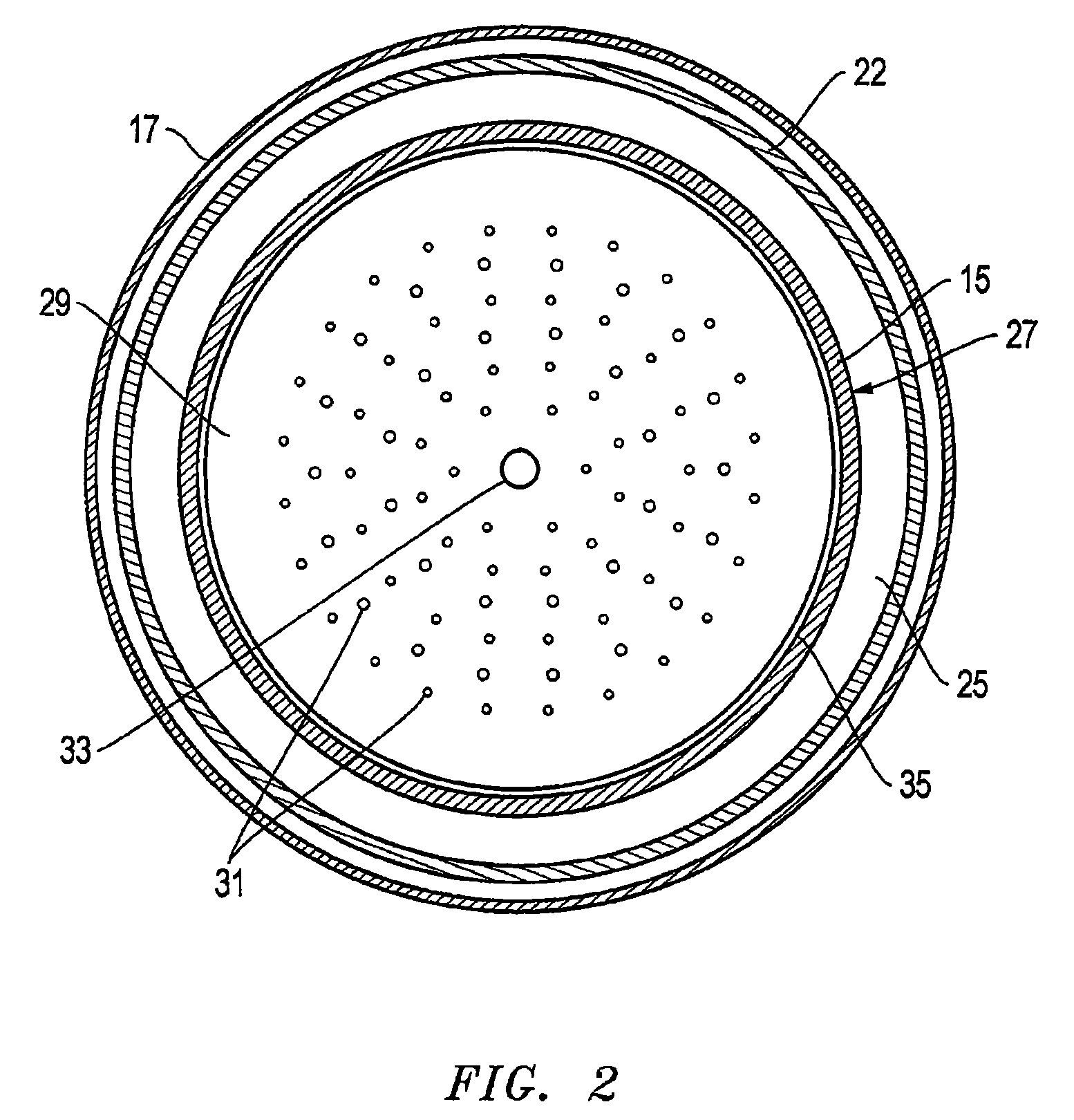

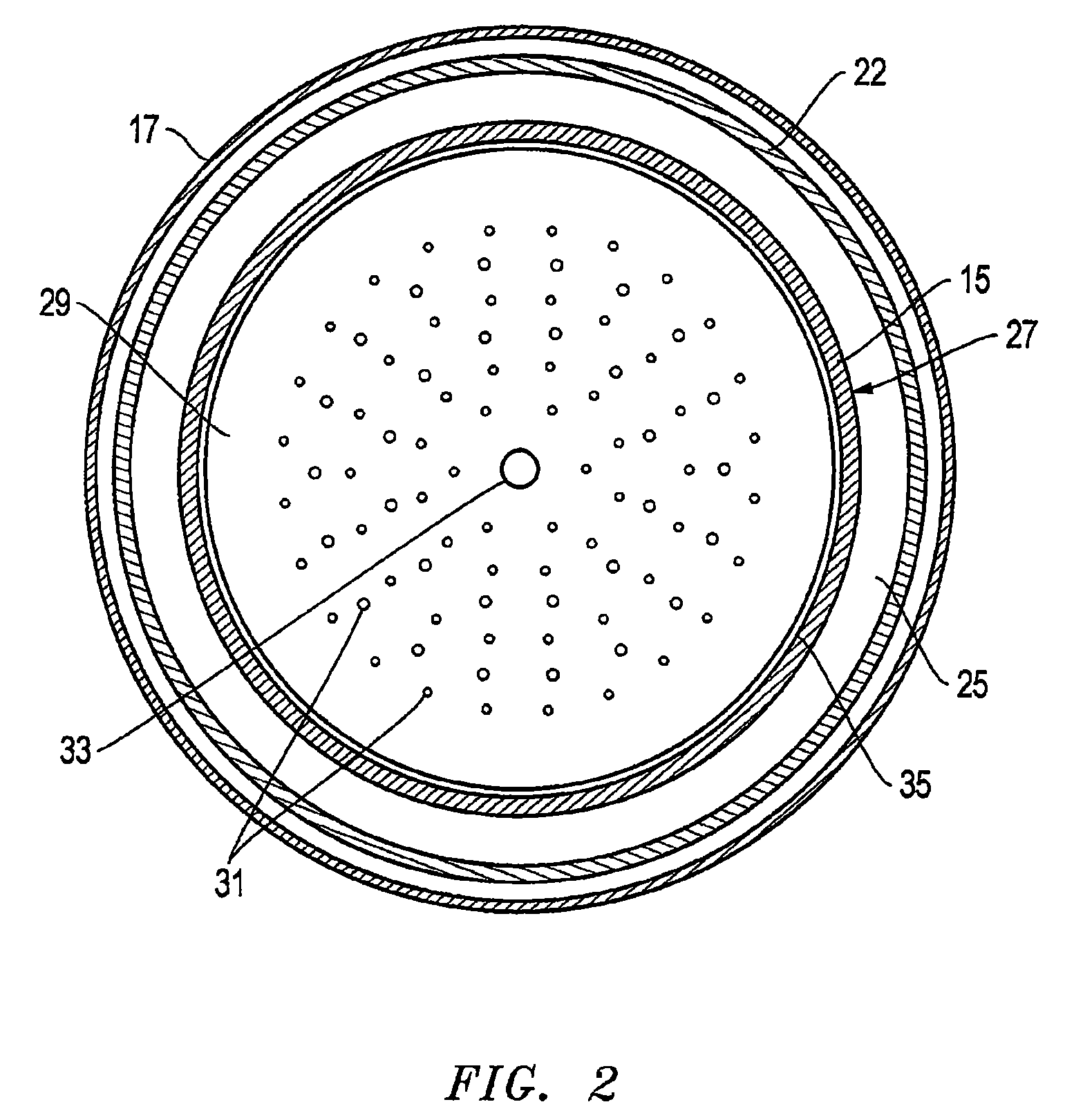

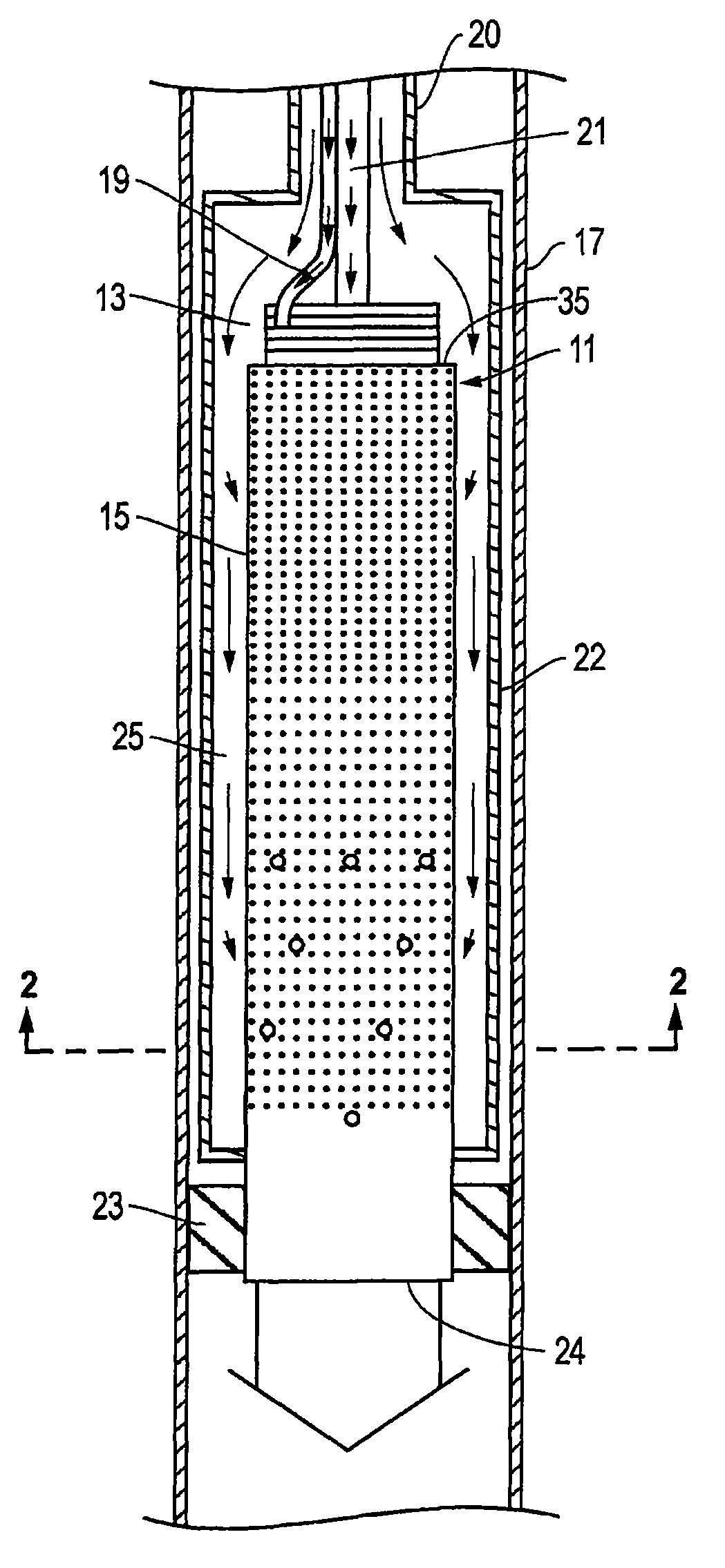

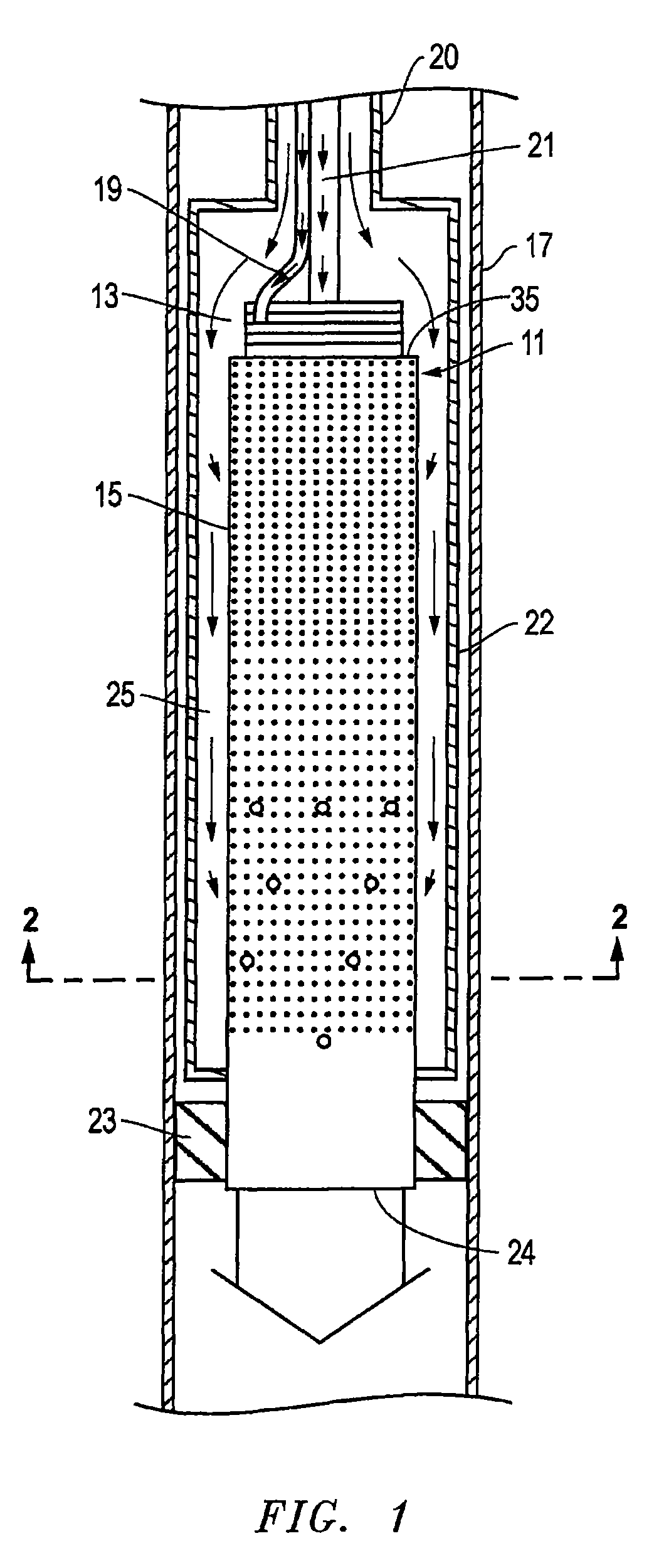

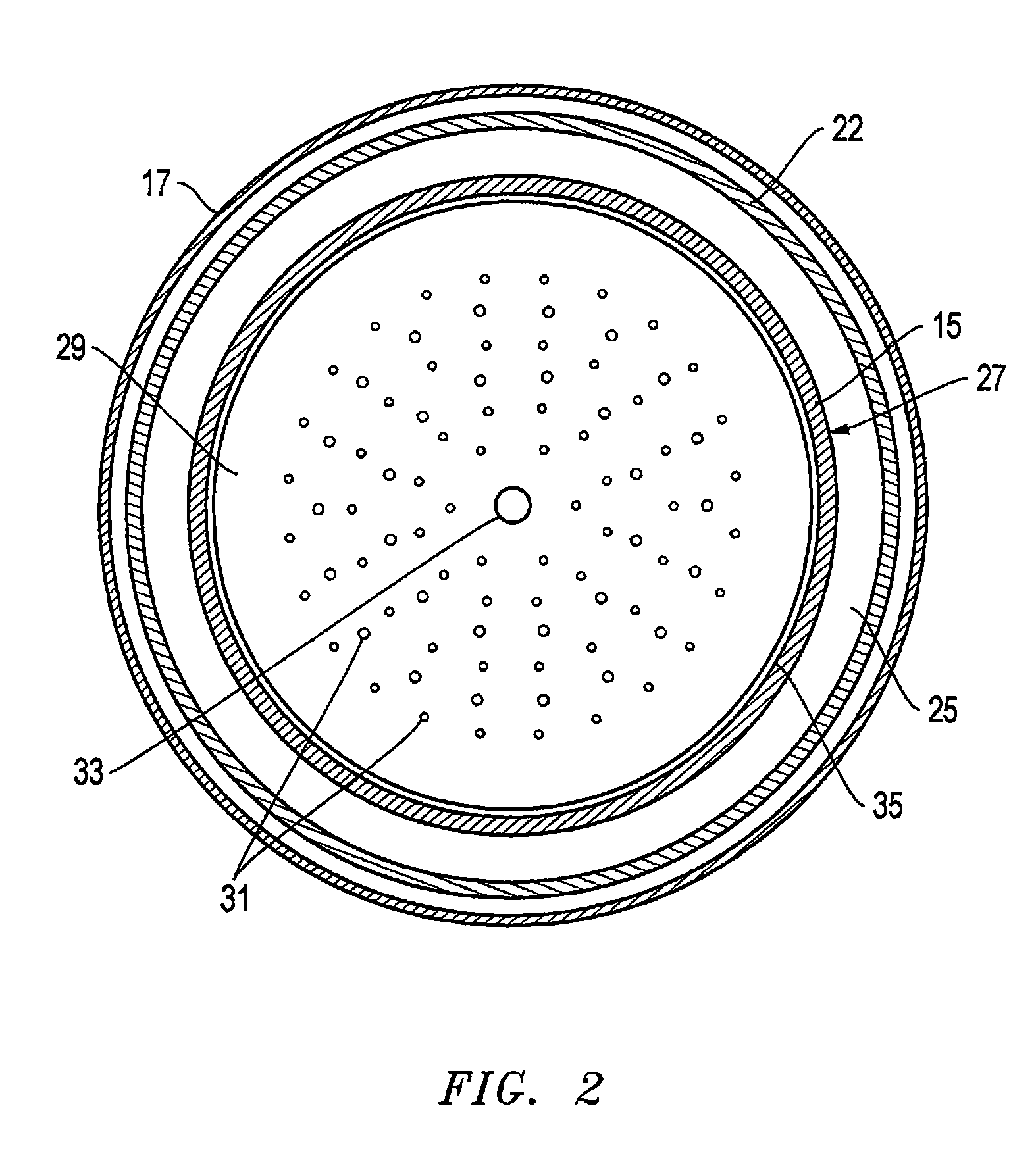

System, method and apparatus for hydrogen-oxygen burner in downhole steam generator

A downhole burner for a steam generator includes an injector and a cooling liner. Steam enters the burner through holes in the cooling liner. Combustion occurring within the cooling liner heats the steam and increases its quality and may superheat it. The heated, high-quality steam and combustion products exit the burner and enter an oil-bearing formation to upgrade and improve the mobility of heavy crude oils held in the formation. The injector includes a face plate, a cover plate, an oxidizer distribution manifold plate, and a fuel distribution manifold plate. The cooling liner has an effusion cooling section and effusion cooling and jet mixing section. The effusion cooling section includes effusion holes for injecting steam along the cooling liner surface to protect the liner. The effusion cooling and jet mixing section has both effusion holes and mixing holes for injecting steam further toward central portions of the burner.

Owner:WORLD ENERGY SYST

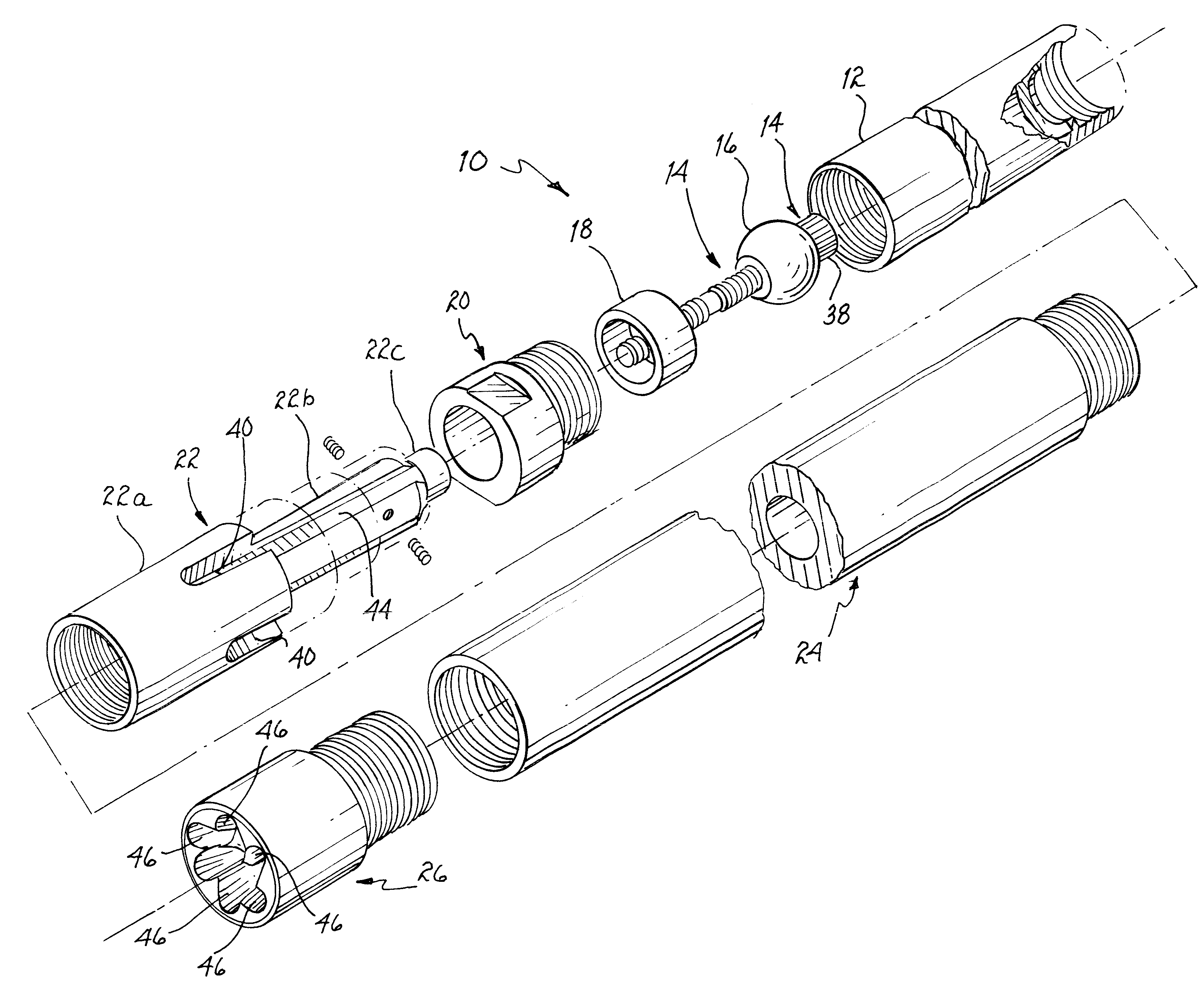

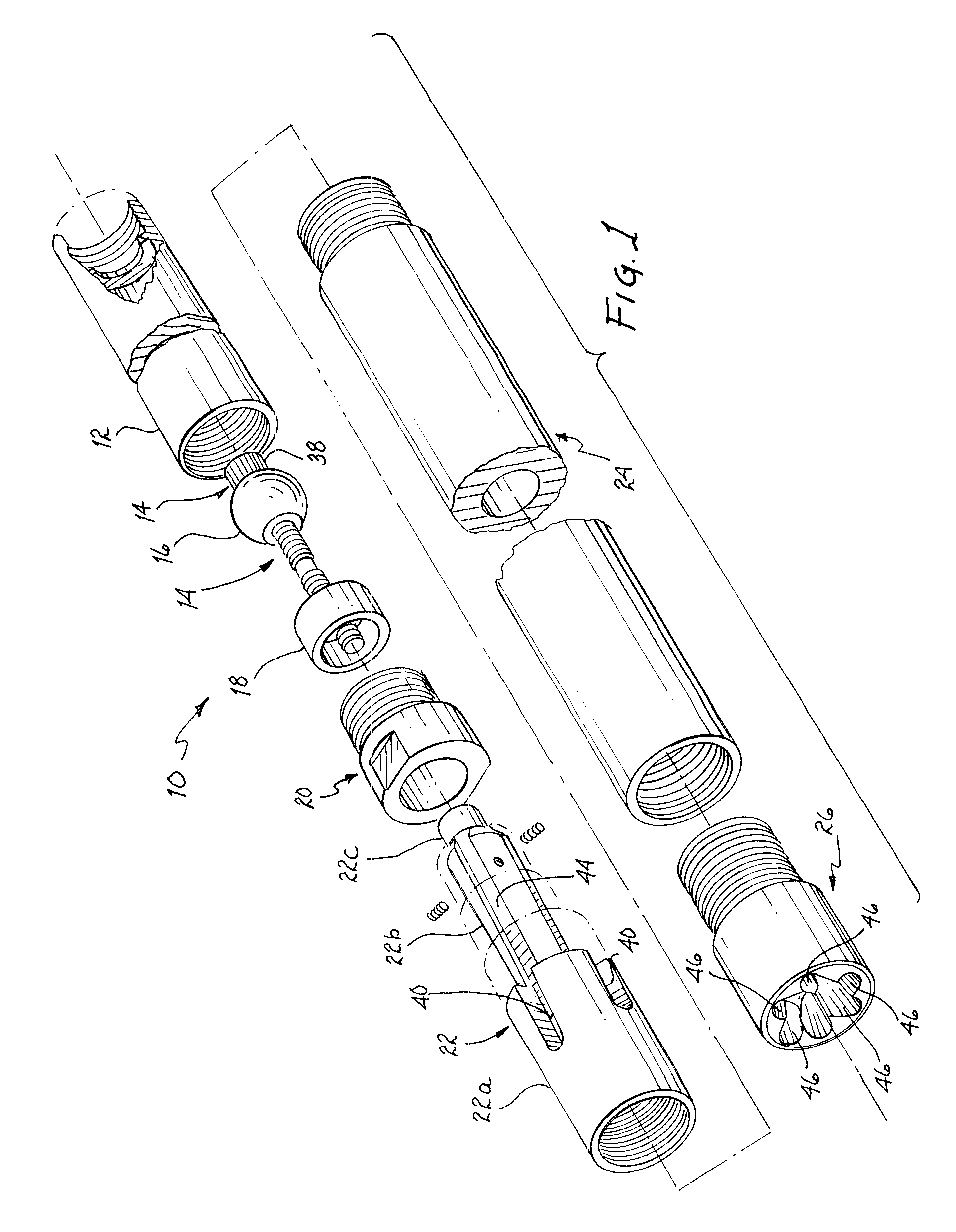

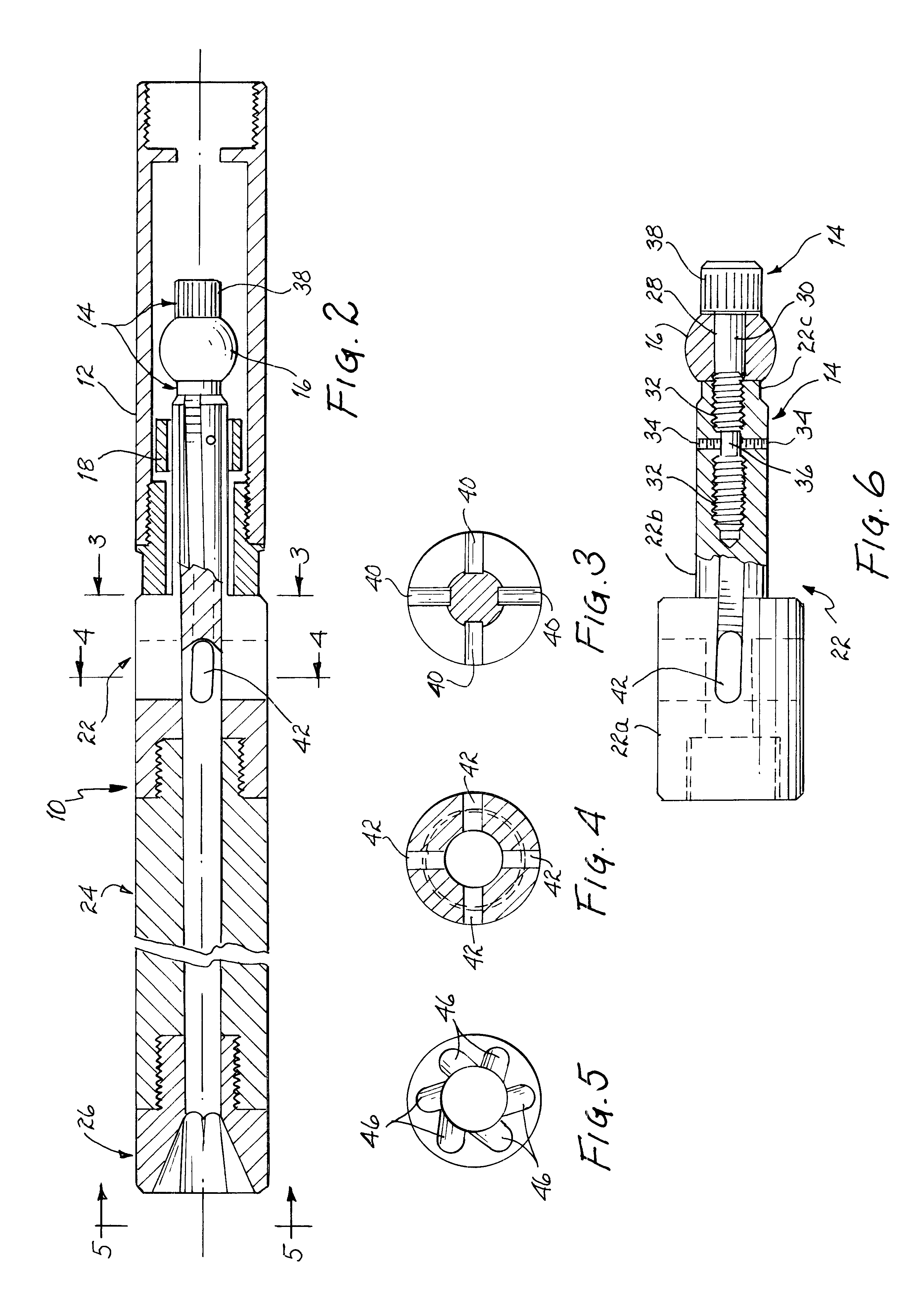

Travelling valve for a pumping apparatus

An improved travelling valve has a ball which is positioned on a seal stem, so that the ball is reliably centered when seated on the valve seat, reducing damage to the ball and seat from improper seating and providing increased efficiency for deviated or non-vertical pumping operations and the pumping of highly viscous fluids such as heavy crude. The improved travelling valve is constructed so that a lower portion of the valve rotates during pumping, and thereby imparts rotational movement to the fluid passed therethrough. Such rotational movement of the valve and fluid helps reduce gas lock, and reduces damage to the ball, seat, and valve exterior from impurities in the pumped fluid. Preferably, rotational movement is caused by angled channels in an interior portion of a vein rotator positioned at the bottom of the travelling valve, working in combination with angled channels in the seal stem.

Owner:FORD MICHAEL BRENT

Method and apparatus for in-situ radiofrequency assisted gravity drainage of oil (RAGD)

InactiveUS20060283598A1Promote recoveryEnhanced overall recoveryInsulationFluid removalHeavy crude oilFuel oil

The present invention relates generally to the use of radiofrequency energy to heat heavy crude oil or both heavy crude oil and subsurface water in situ, thereby enhancing the recovery and handling of such oil. The present invention further relates to methods for applying radiofrequency energy to heavy oils in the reservoir to promote in situ upgrading to facilitate recovery. This invention also relates to systems to apply radiofrequency energy to heavy oils in situ.

Owner:KSN ENERGIES

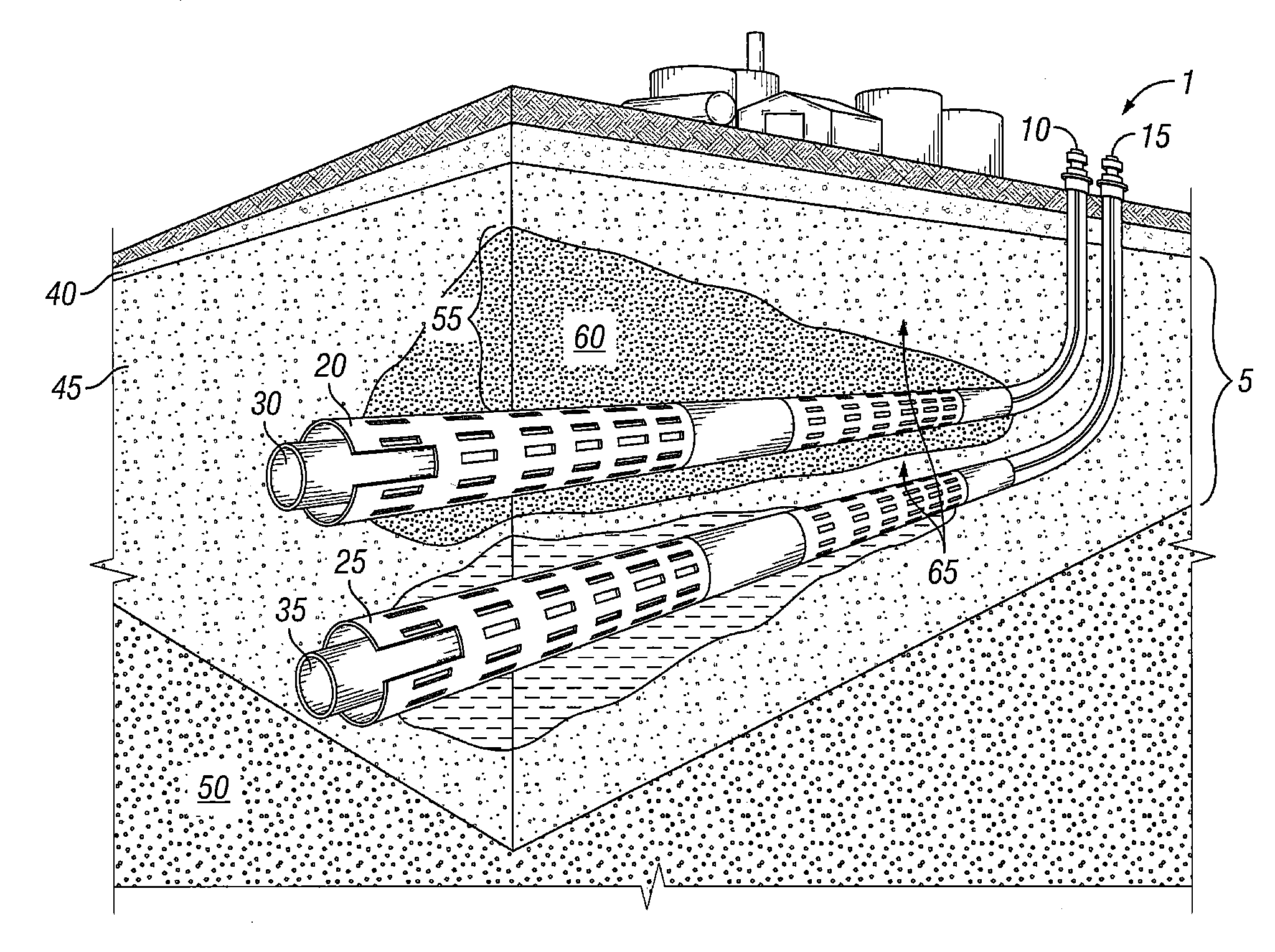

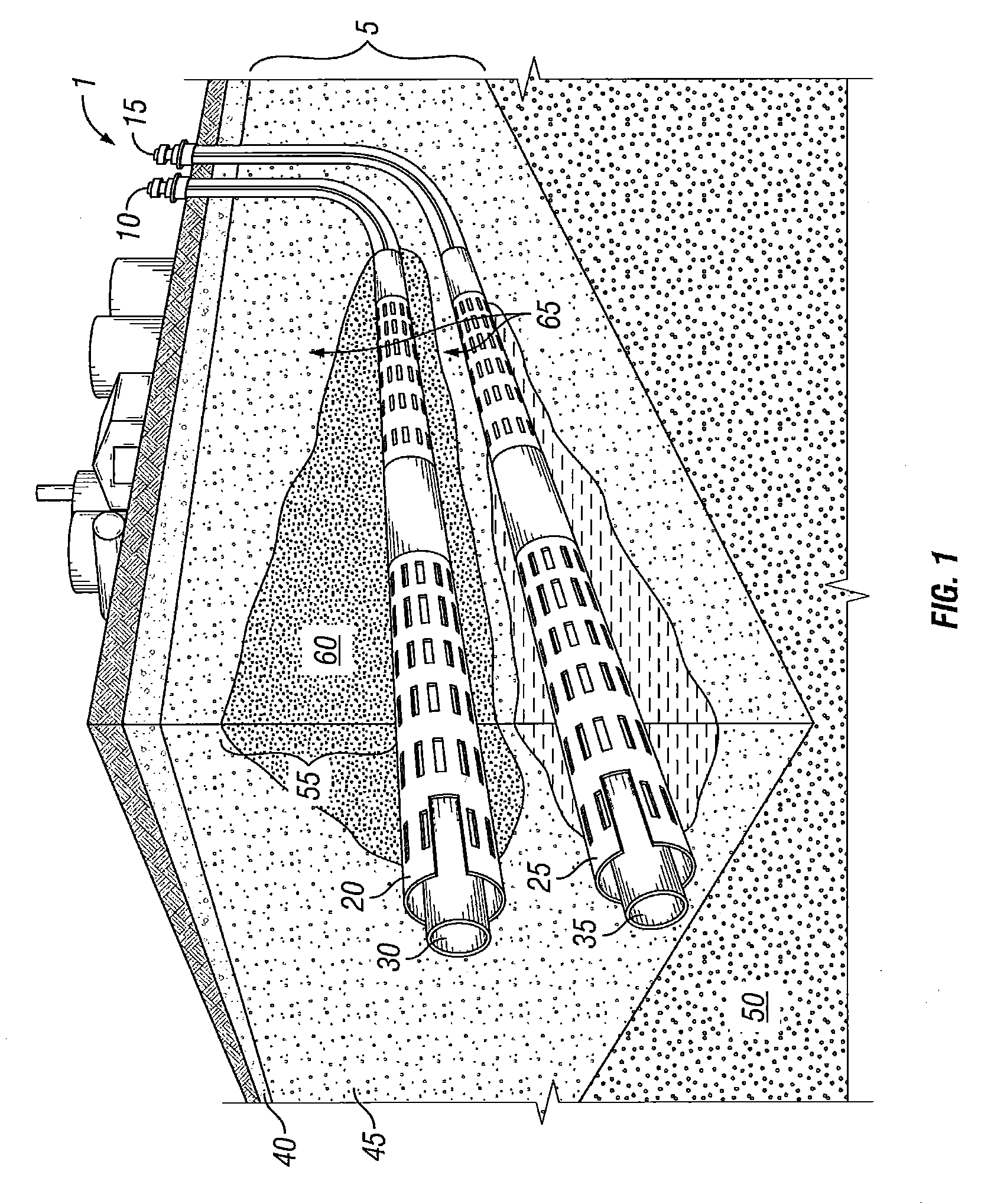

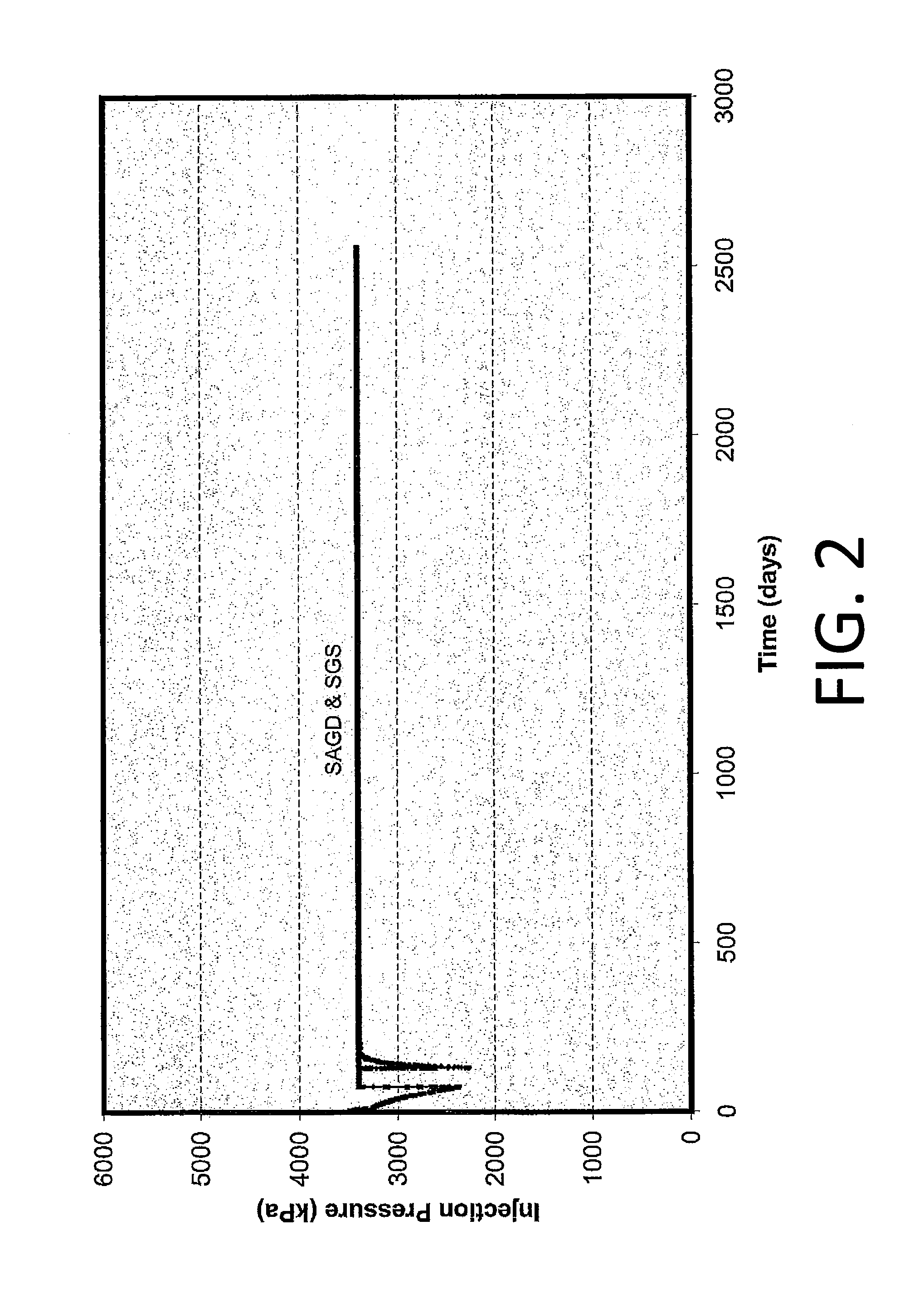

Steam-gas-solvent (SGS) process for recovery of heavy crude oil and bitumen

Methods relate to a steam-gas-solvent (SGS) process for recovery of heavy crude oil and bitumen. The methods include injecting a steam-gas-solvent mixture to mobilize hydrocarbons in a formation and producing from the formation the hydrocarbons that are mobilized. The steam-gas-solvent mixture includes steam, a gas non-condensable under reservoir operating conditions and a solvent condensable under reservoir operating conditions.

Owner:CONOCOPHILLIPS CO

Mesoporous composite of molecular sieves for hydrocracking of heavy crude oils and residues

ActiveUS20140124410A1High activityImprove stabilityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveBoiling point

A hydrocracking catalyst having a support of a composite of mesoporous materials, molecular sieves and alumina, is used in the last bed of a multi-bed system for treating heavy crude oils and residues and is designed to increase the production of intermediate distillates having boiling points in a temperature range of 204° C. to 538° C., decrease the production of the heavy fraction (>538° C.), and increase the production of gasoline fraction (<204° C.). The feedstock to be processed in the last bed contains low amounts of metals and is lighter than the feedstock that is fed to the first catalytic bed.

Owner:INST MEXICANO DEL GASOLINEEO

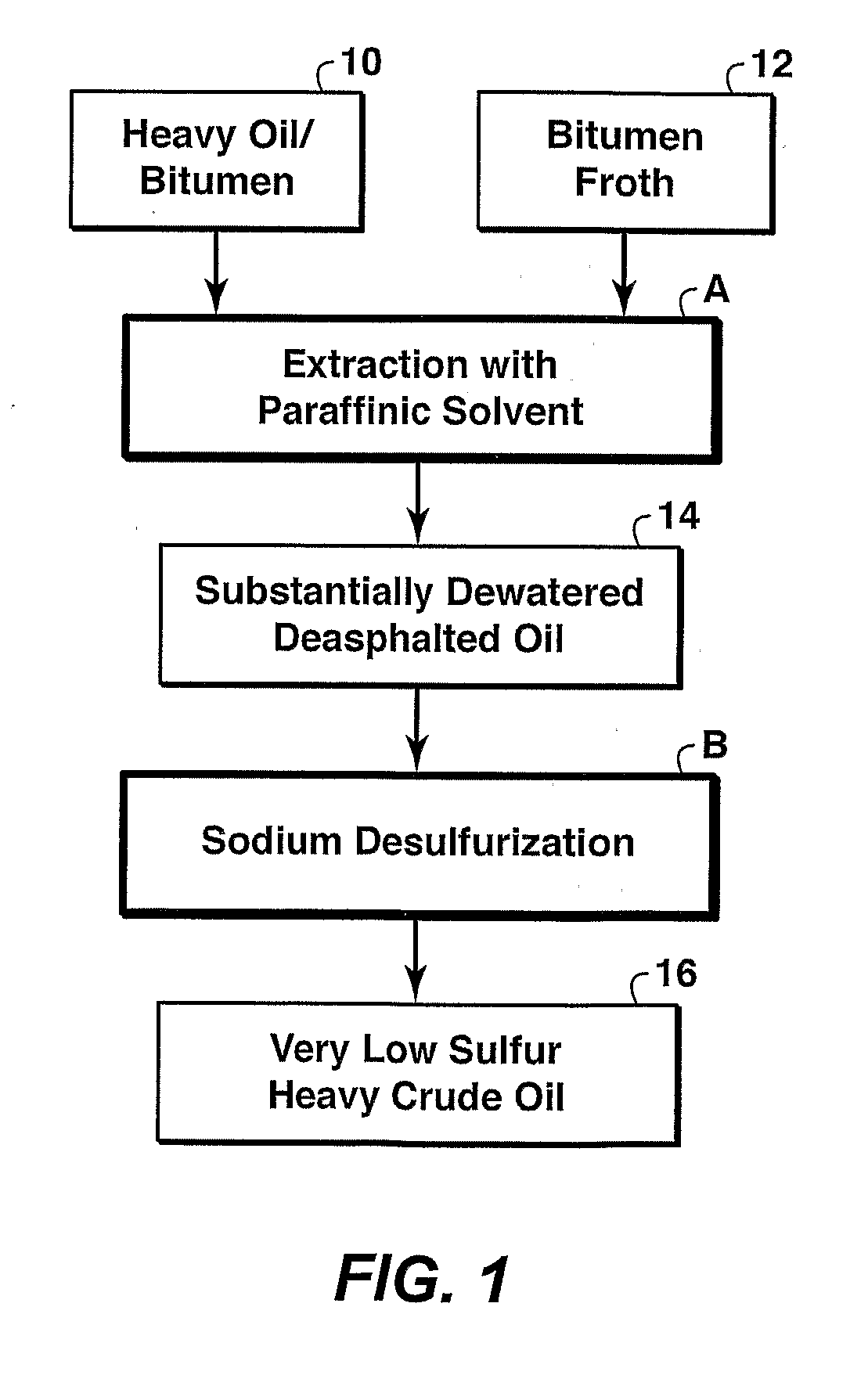

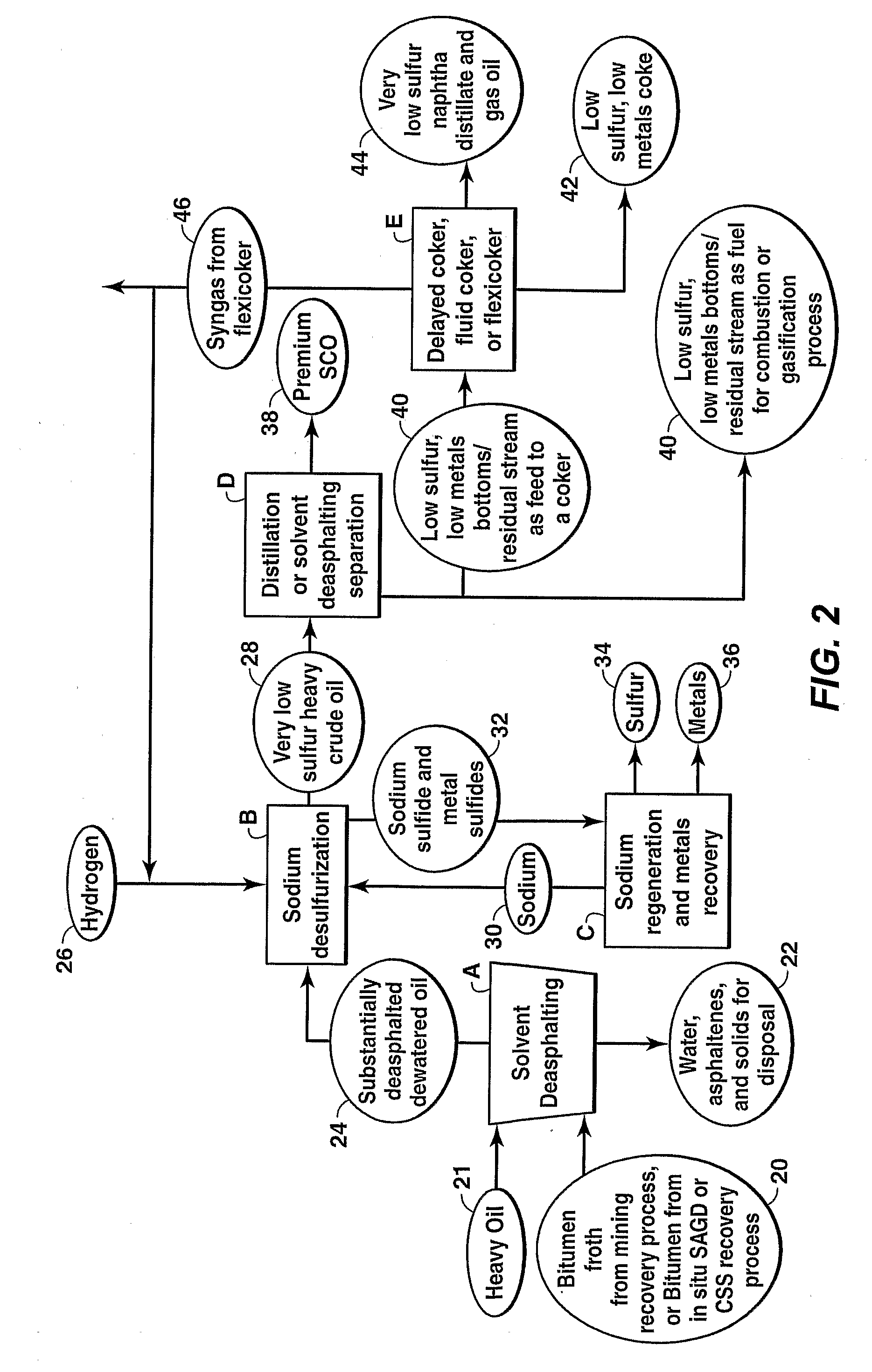

Very Low Sulfur Heavy Crude oil and Porcess for the Production thereof

A process for production of sweet heavy crude oil is disclosed. The process comprises the steps of: removing contaminants from heavy oil, bitumen or bitumen froth to form a substantially dewatered deasphalted oil; and subsequent desulfurization of the substantially dewatered deasphalted oil using sodium metal desulfurization to produce a sweet heavy crude oil. The step of removing contaminants is conducted using extraction with a paraffinic solvent.

Owner:EXXONMOBIL UPSTREAM RES CO

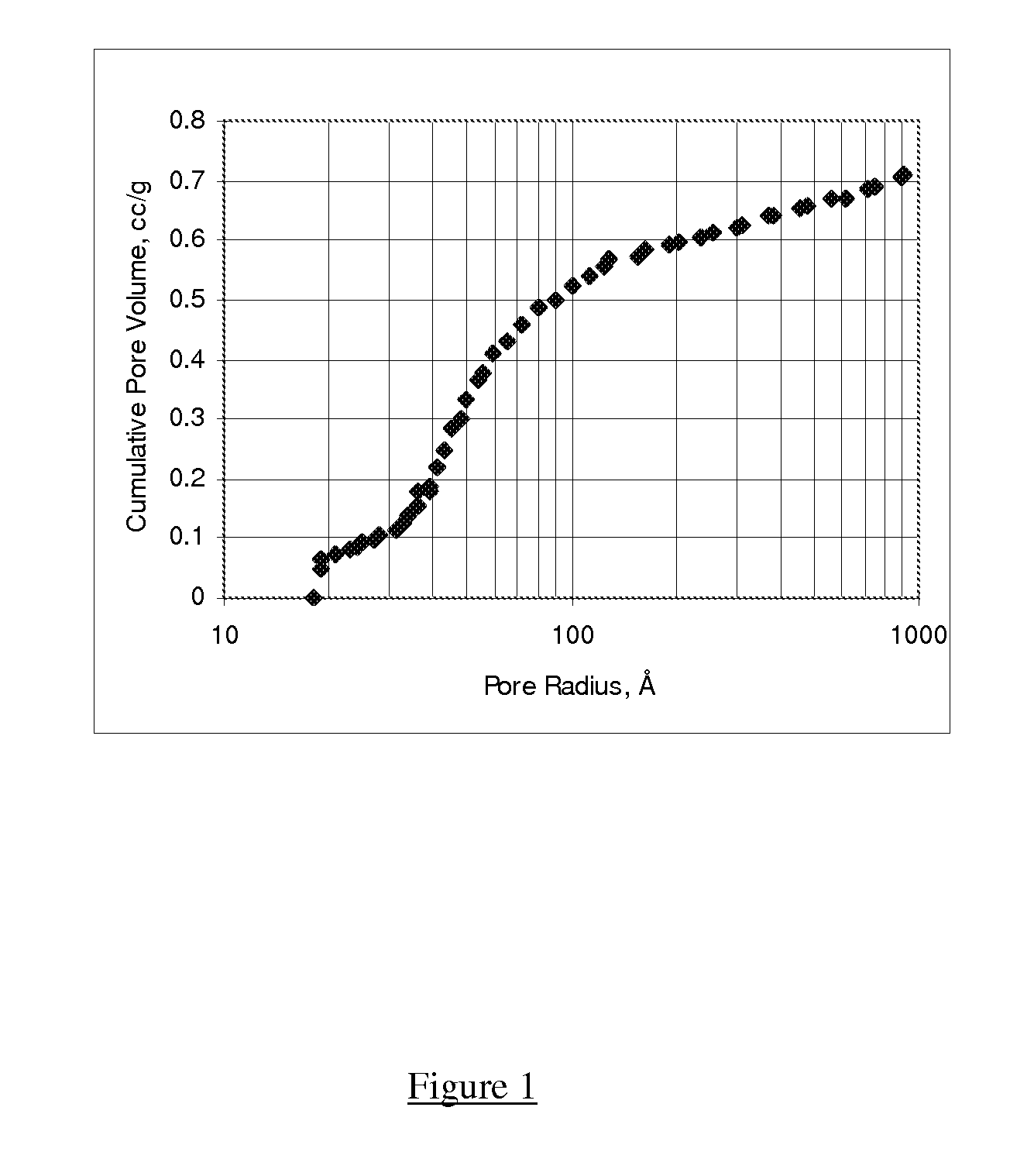

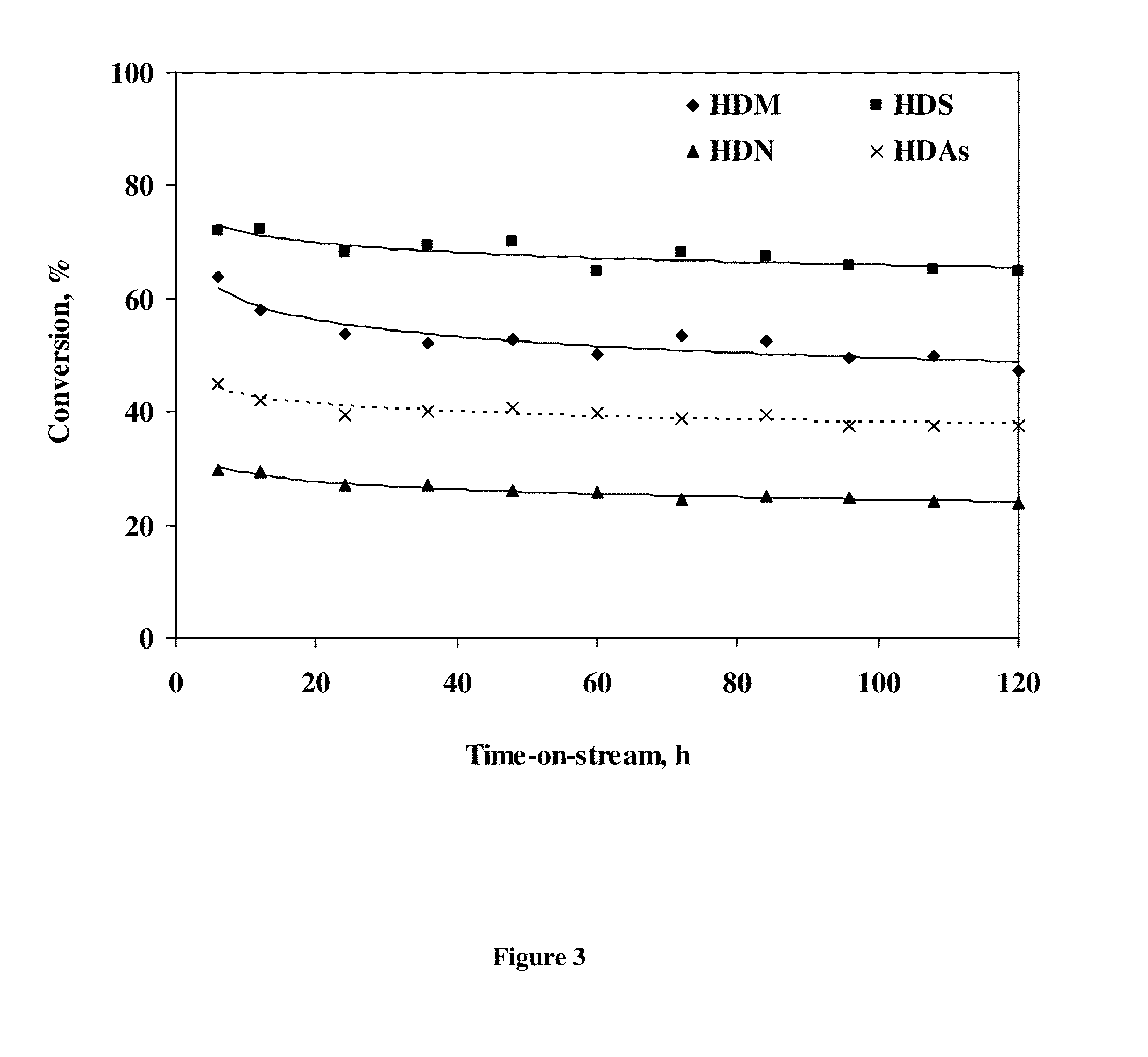

Carbon supported catalyst for demetallation of heavy crude oil and residue

ActiveUS20100224535A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrodesulfurizationCobalt

A supported carbon having high surface area, high pore volume containing (i) molybdenum (ii) a metal of non noble Group VIII, (iii) phosphorous, is used for hydrometallization of heavy crude oil and residue. The catalyst contains about 6 to 15 wt % molybdenum as MoO3, about 1 to 6 wt % cobalt or nickel as CoO or NiO and phosphorus as phosphorous oxide. One characteristic of the catalyst is the portion of pores having pore diameter in the range of 200 to 2000 Angstrom of 20 percent or more. The catalyst prepared by chelating agent has higher hydrodesulfurization activity assuming that more dispersed active metals are present on this catalyst. Long run activity studies show that catalyst having only molybdenum supported on activated carbon has good stability with time-on-stream and very high metal retention capacity.

Owner:INST MEXICANO DEL GASOLINEEO +1

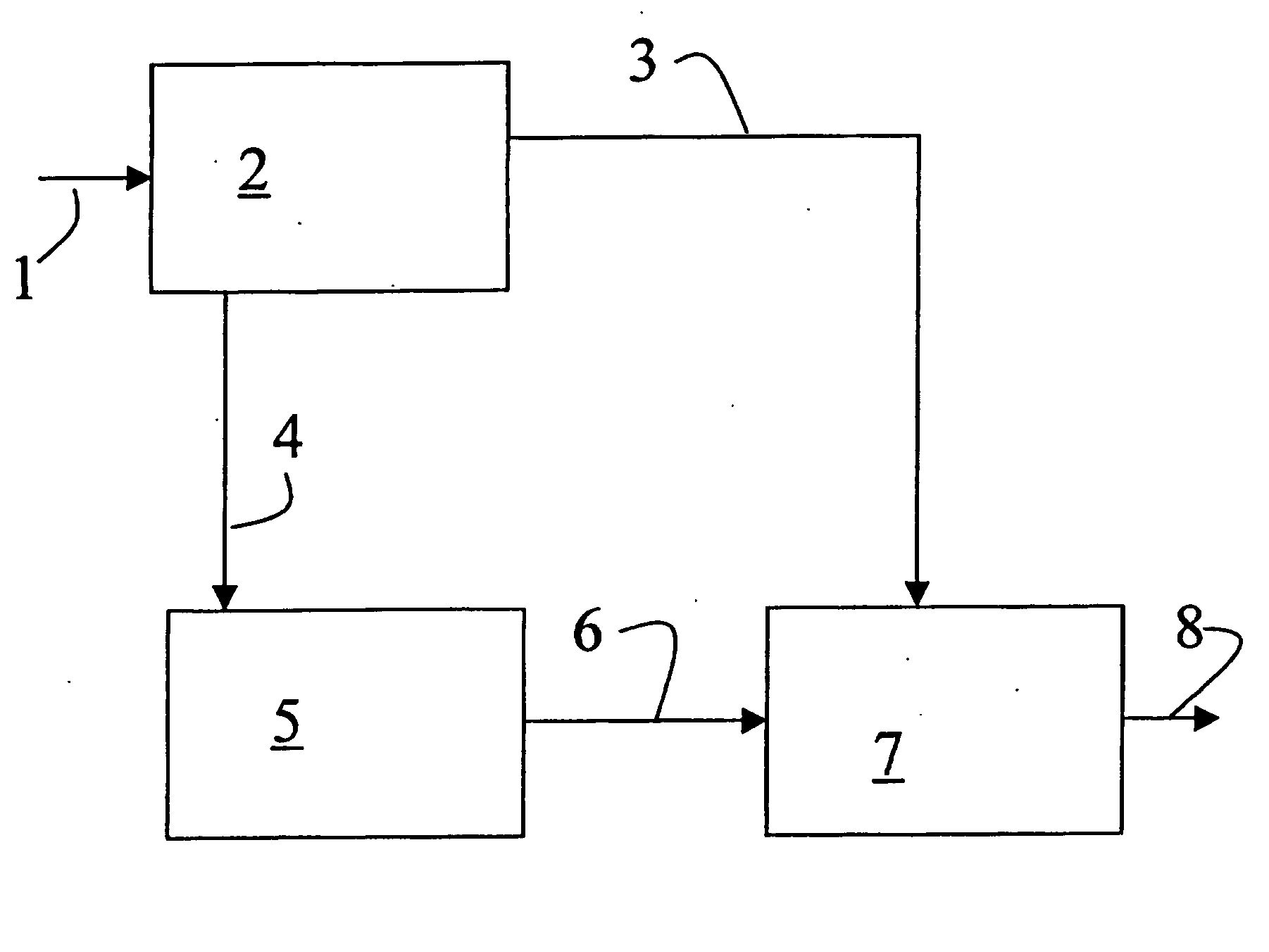

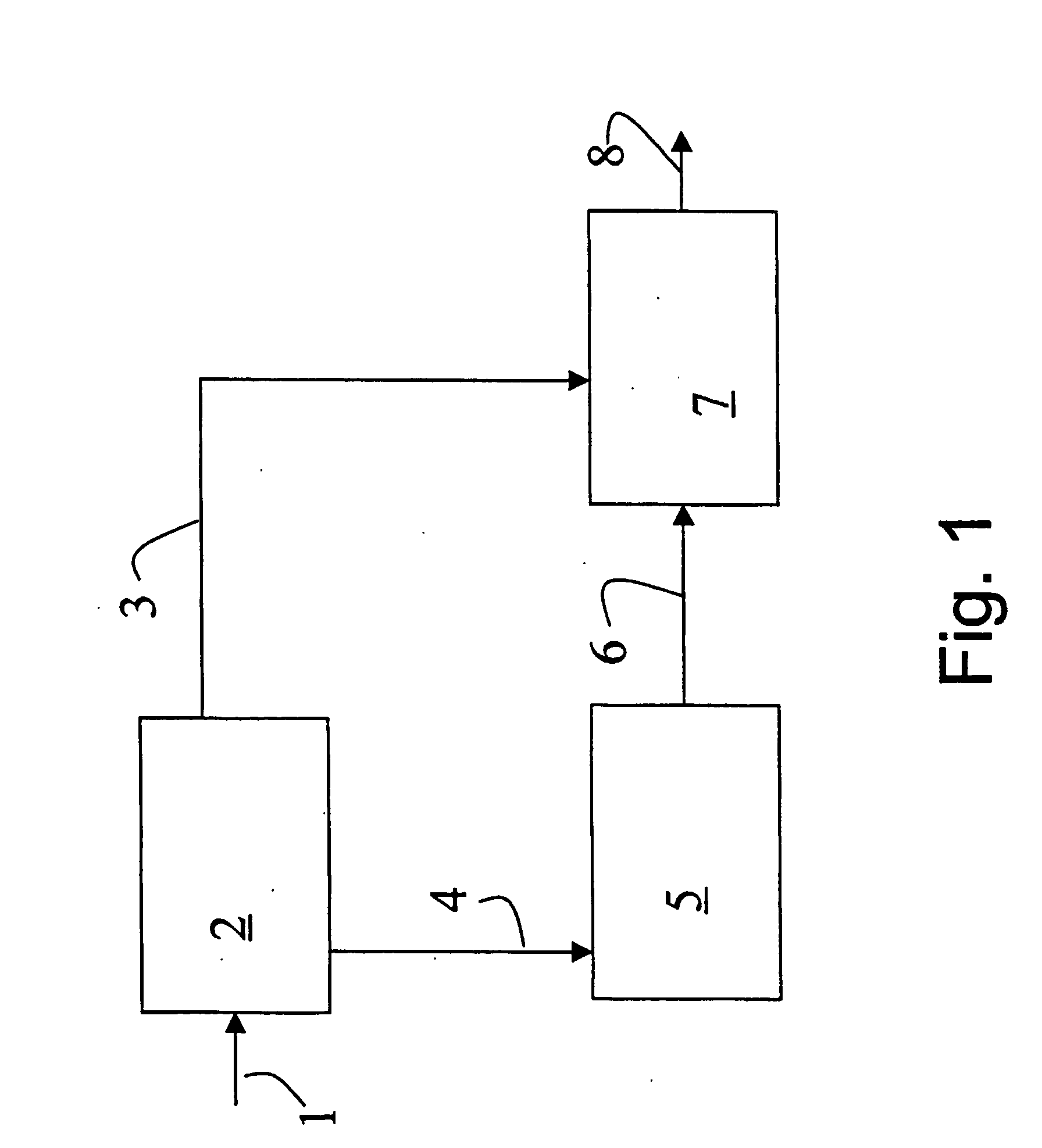

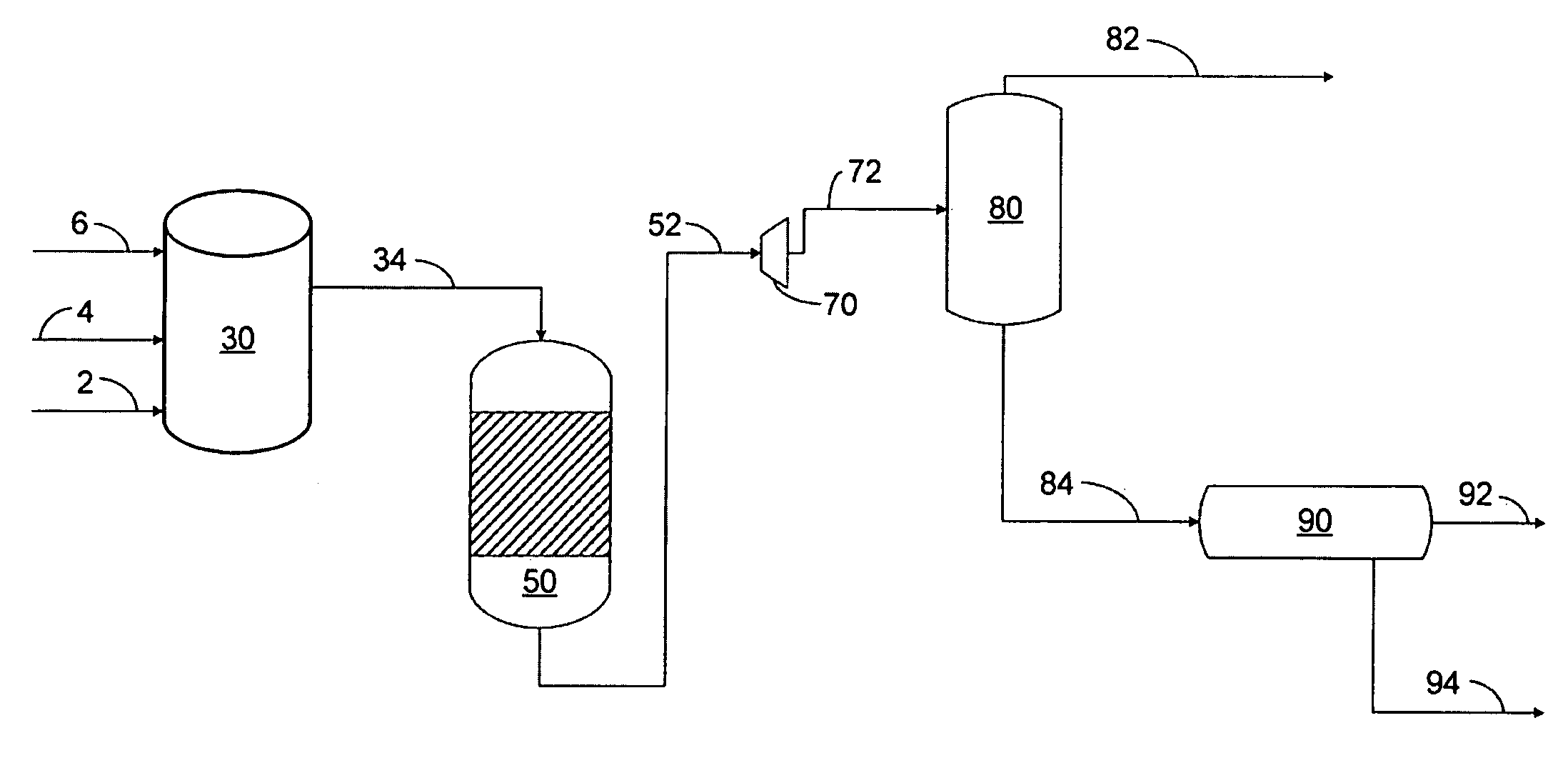

Supercritical Water Processing of Extra Heavy Crude in a Slurry-Phase Up-Flow Reactor System

InactiveUS20070289898A1Easy to usePromote recoveryCatalytic crackingHydrocarbon oils refiningReactor systemHydrogen

A system and method for upgrading heavy crude oil. The system comprises: a system for blending a catalyst with the heavy crude to produce a crude / catalyst slurry, a source of supercritical water, a system for blending the supercritical water with the crude / catalyst slurry, infecting the feed slurry into the bottom of an tip-flow reactor, carrying out a reaction between the water and the crude to produce treated hydrocarbons, and separating the treated hydrocarbons into a heavy stream and a light stream. The first separator is in fluid communication with the tipper half of the reactor. A second separator receives the light stream and separates it into gases, liquid hydrocarbons, and water. A system and method of generating hydrogen for the process through in situ shift reaction, generating carbon monoxide either in situ through the injection of air inside the reactor or externally by gasification of unreacted resid or produced gases.

Owner:CONOCOPHILLIPS CO

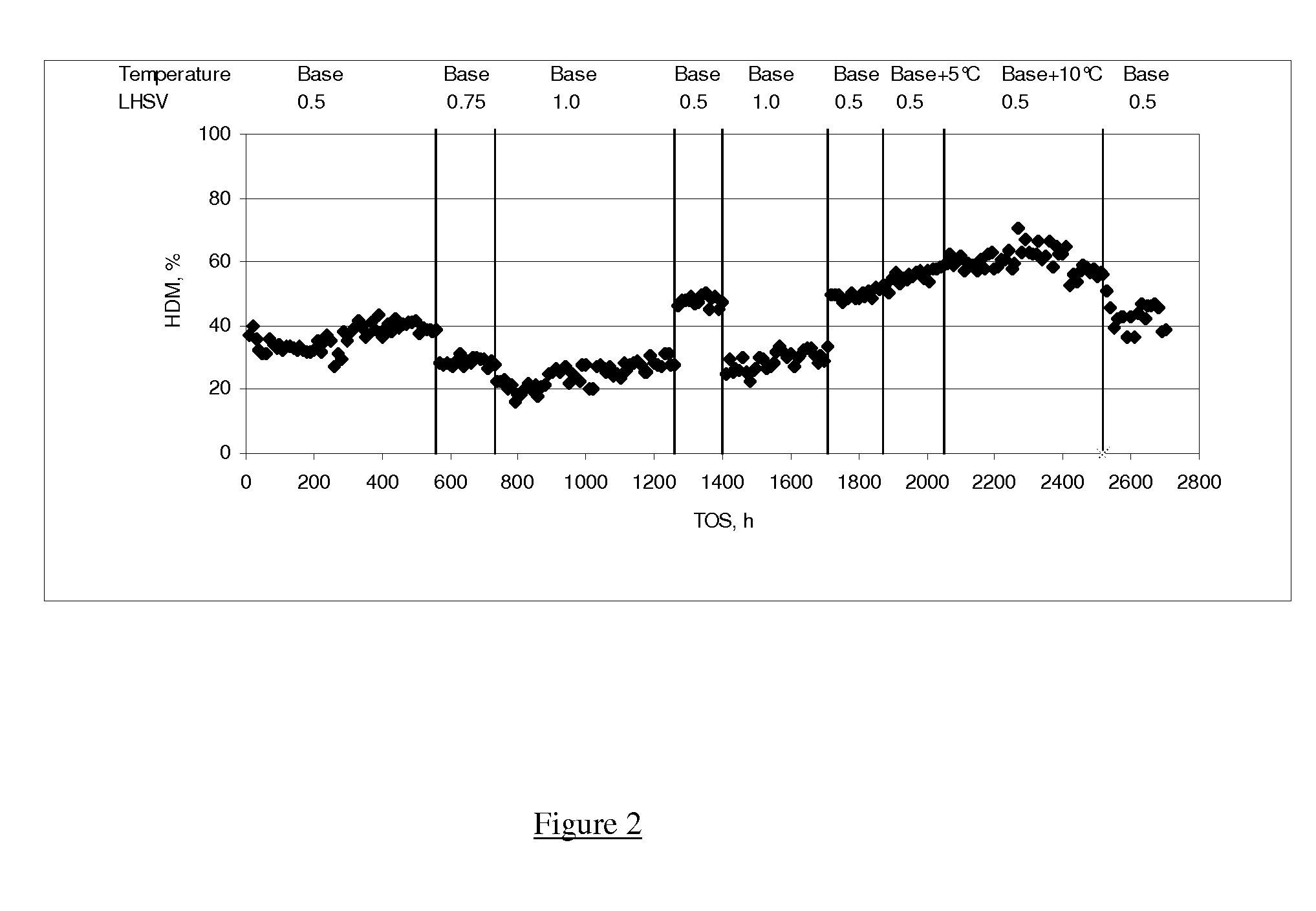

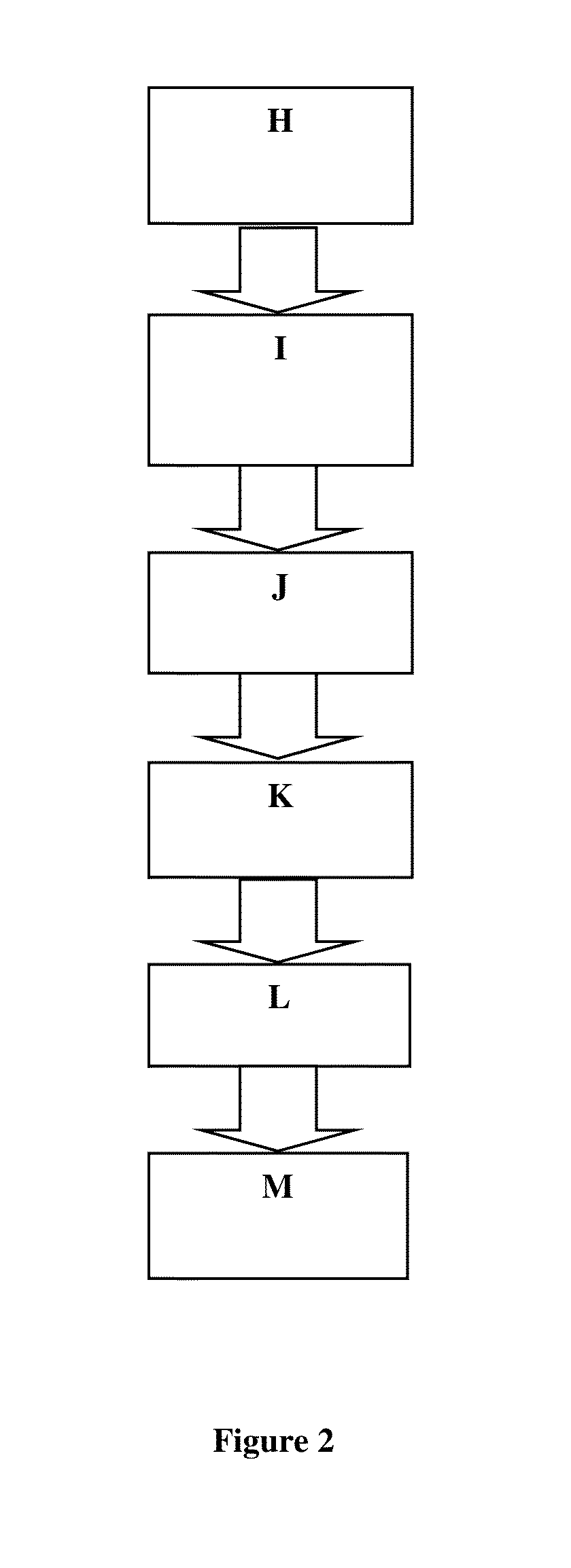

Catalyst for the first hydrodemetalization step in a hydroprocessing system with multiple reactors for the improvement of heavy and extra heavy crudes

ActiveUS20150321177A1High metal retention capacityExtended service lifeRefining with metalsCatalyst activation/preparationFixed bedHeavy crude oil

An improved catalyst for hydrodemetallization of heavy crude oils and residua is disclosed. The catalyst is adopted for fixed bed hydroprocessing units. The invention is characterized for having a large pore diameter catalyst principally for hydrodemetallization of heavy oil and residue in a first reactor of a multi-reactor process. The catalyst has high demetallizing activity and high metal deposition capacity which results in good stability with time on stream (TOS). The hydrorefining catalyst is obtained by kneading a porous starting powder principally composed of gamma-alumina and having a pore capacity of 0.3-0.6 ml / g or larger and a mean pore diameter of 10 to 26 nm, extrudating and calcining, and after that supported with active metals component of elements belonging to groups VIIIB and VIB of the periodic table.

Owner:INST MEXICANO DEL GASOLINEEO

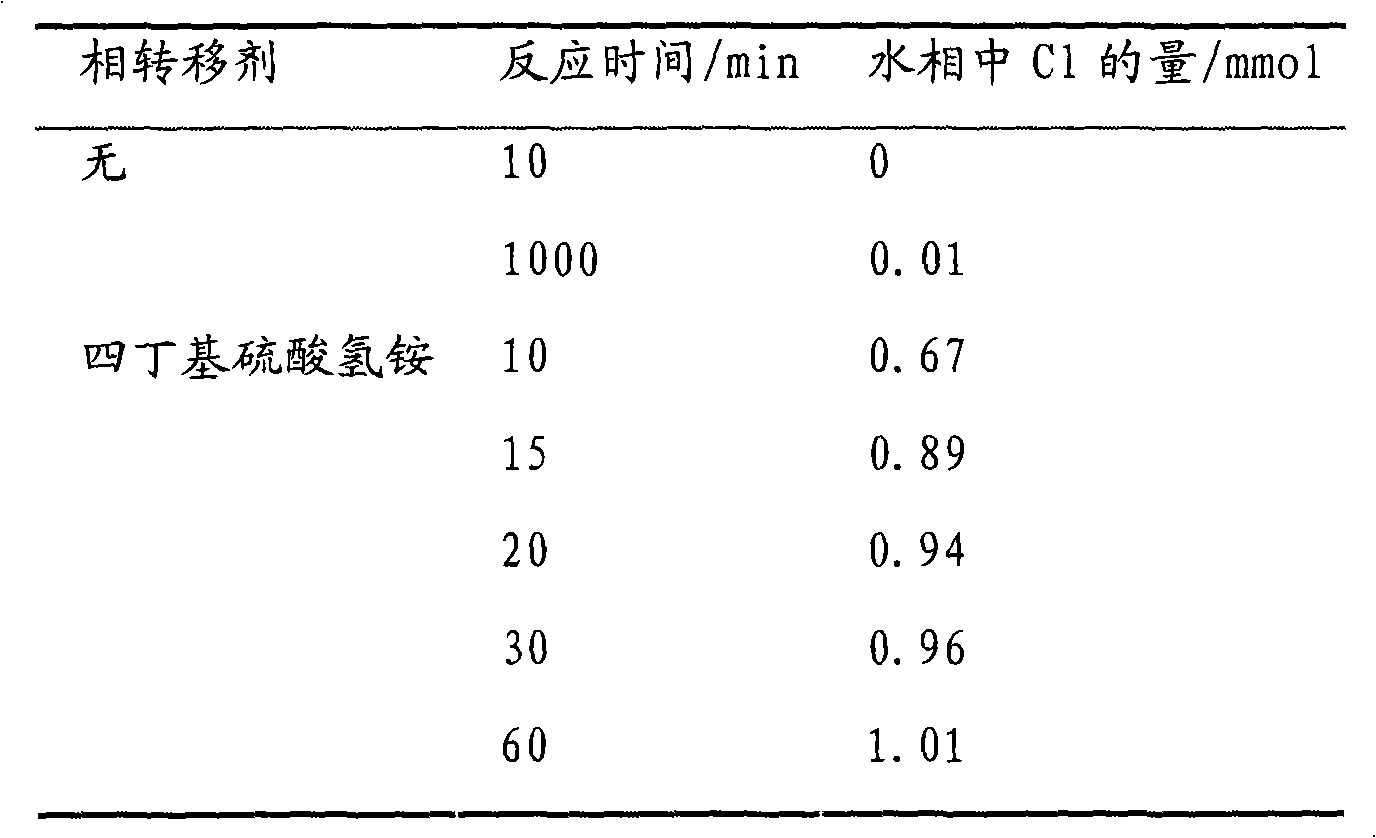

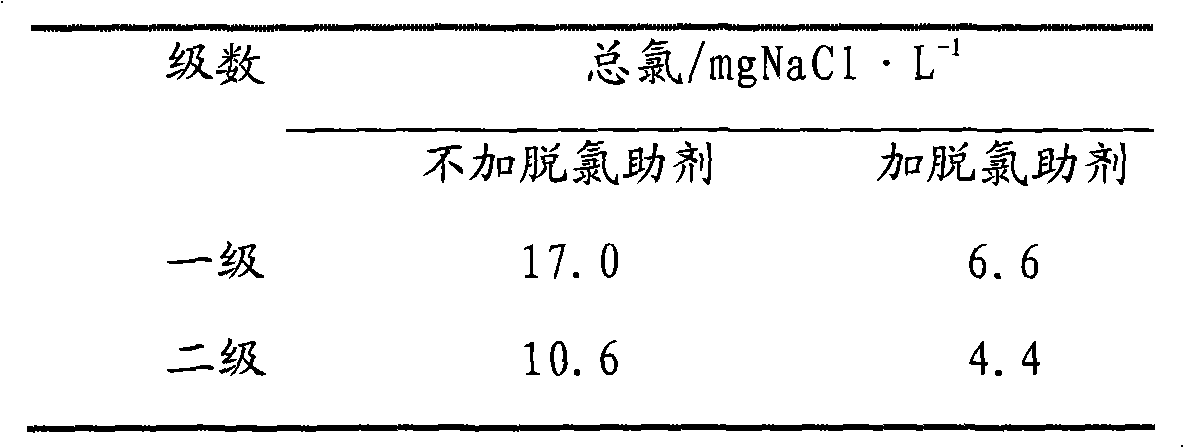

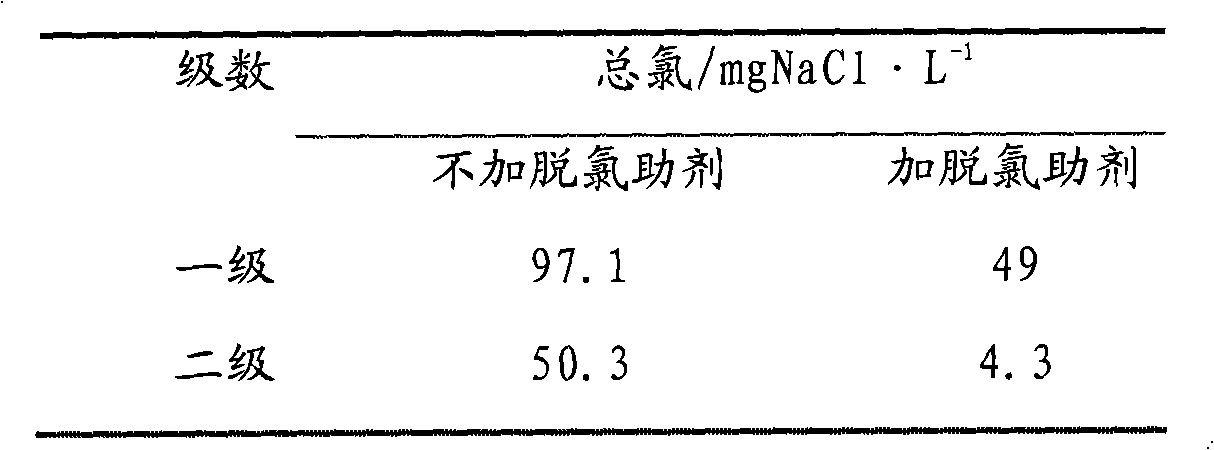

Method for removing organochlorine from hydrocarbon oil

ActiveCN102127464ADewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansDemulsifierOrganic chloride compound

The invention relates to a method for removing organochlorine from hydrocarbon oil. A demulsifier, an alkaline compound, a phase transfer agent, injected water and the hydrocarbon oil are mixed, oil-water separation is performed under the action of a thermal field and / or an electric field, organic chloride is transformed into inorganic chloride and the inorganic chloride is removed with a water phase, so that the aim of dechlorination is fulfilled. The method is suitable for organochlorine-containing conventional crude oil, heavy crude oil and distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for upgrading heavy and highly waxy crude oil without supply of hydrogen

ActiveUS20090145805A1Increase gravityReduce the amount requiredThermal non-catalytic crackingRefining by heating/coolingAlkaneHydrogen

A continuous process to upgrade heavy crude oil for producing more valuable crude feedstock having high API gravity, low asphaltene content, and high middle distillate yield, low sulfur content, low nitrogen content, and low metal co teat without external supply of hydrogen and / or catalyst. Heavy crude oil having substantial amount of asphaltene and heavy components is mixed with highly waxy crude oil having large amount of paraffinic components and water to decompose asphaltene compounds and remove sulfur, nitrogen, and metal containing substances under supercritical conditions. Product has higher API gravity, lower asphaltene content, high middle distillate yield, lower sulfur content, lower nitrogen content, and lower metal content to be suitable for conventional petroleum refining process.

Owner:SAUDI ARABIAN OIL CO

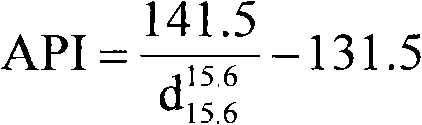

Heavy crude oil hydrocracking method

The invention relates to a heavy crude oil hydrocracking method. In the method, heavy crude oil is sequentially subjected to the steps of a hydrogenation protective agent, a hydrodemetallization agent, a hydrodesulfurization agent I, a hydrocracking agent and a hydrodesulfurization II in the presence of hydrogen, wherein the filling weight percentage of the hydrogenation protective agent, the hydrodemetallization agent, the hydrodesulfurization agent I, the hydrocracking agent and the hydrodesulfurization agent II are respectively 2-20%, 10-78%, 10-78%, 5-50% and 5-50% by taking an integral catalyst as a reference. According to the method provided by the invention, the heavy crude oil with the API (American Petroleum Institute) degree smaller than 20 can be processed to obtain hydrogenated crude oil with enhanced API and reduced viscosity, and moreover, the operating period of a hydrogenation processing device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

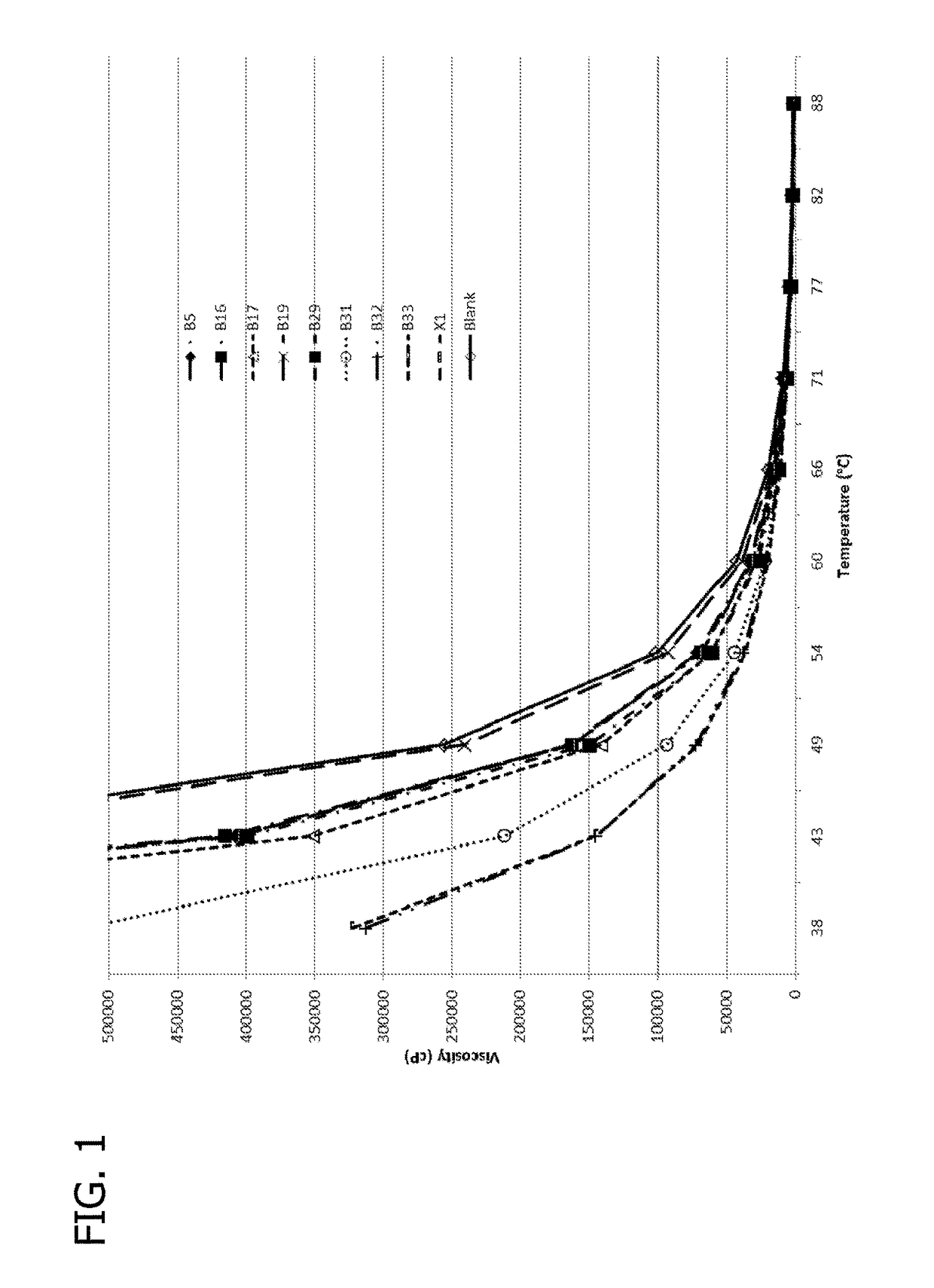

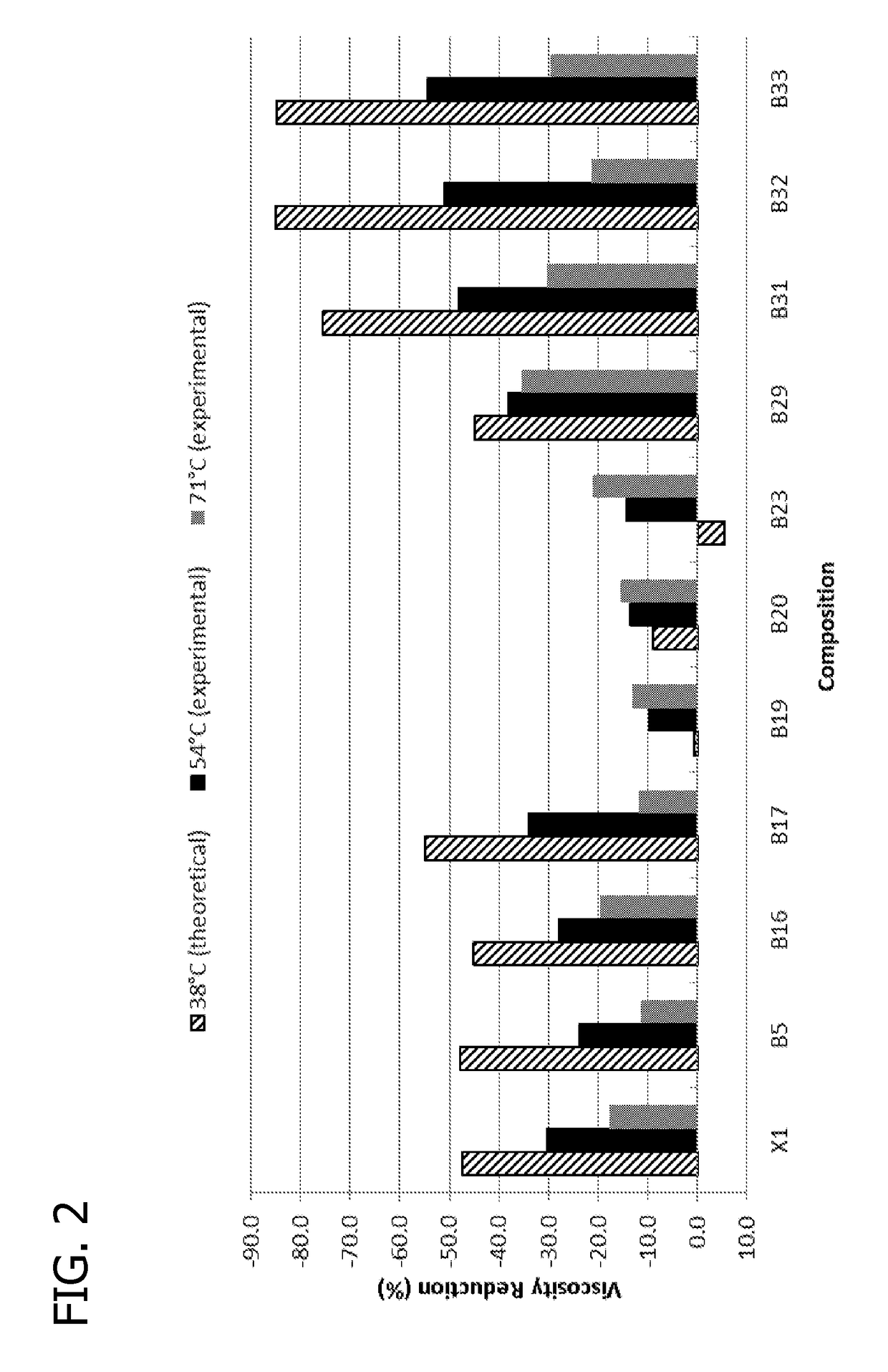

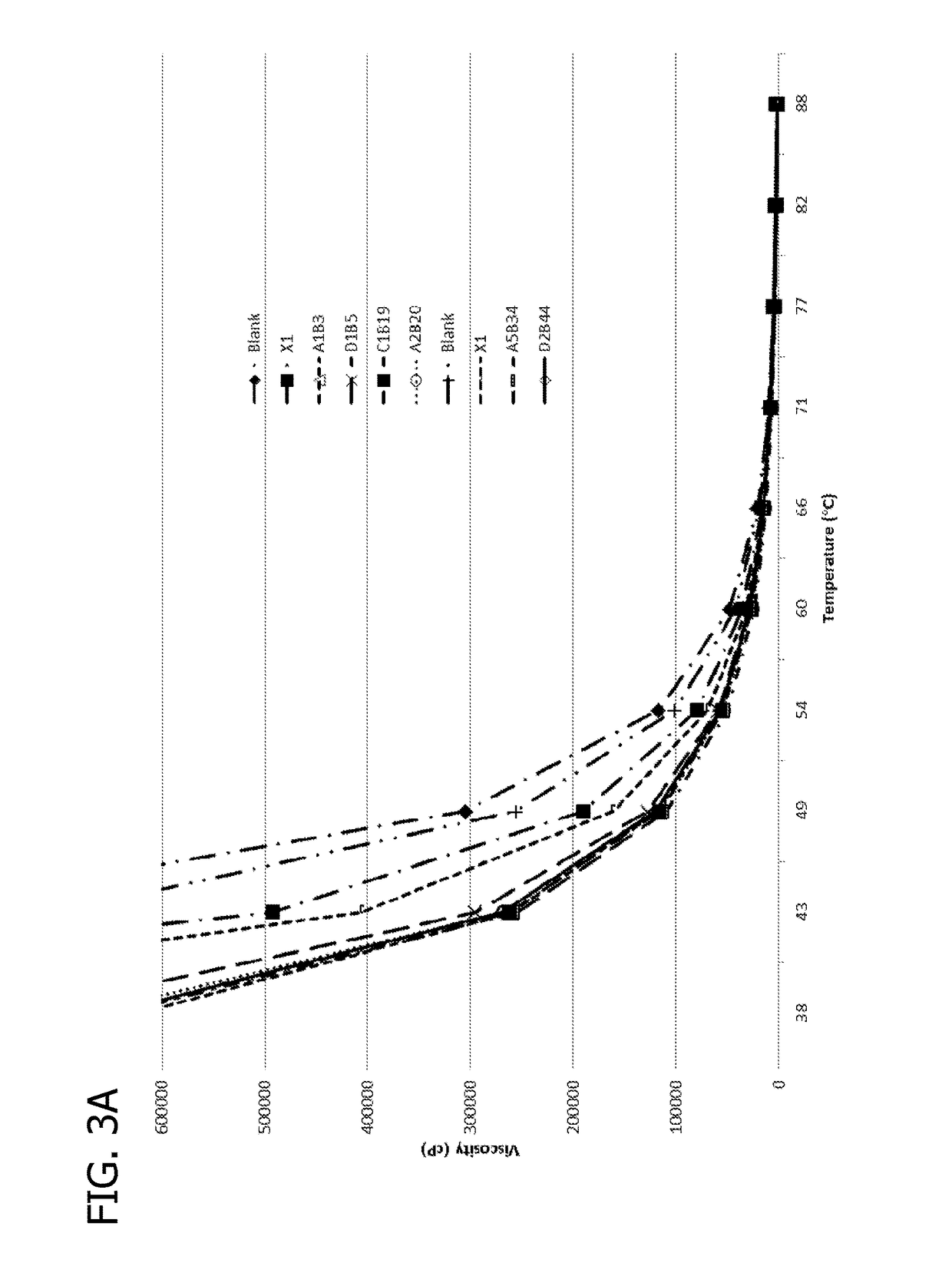

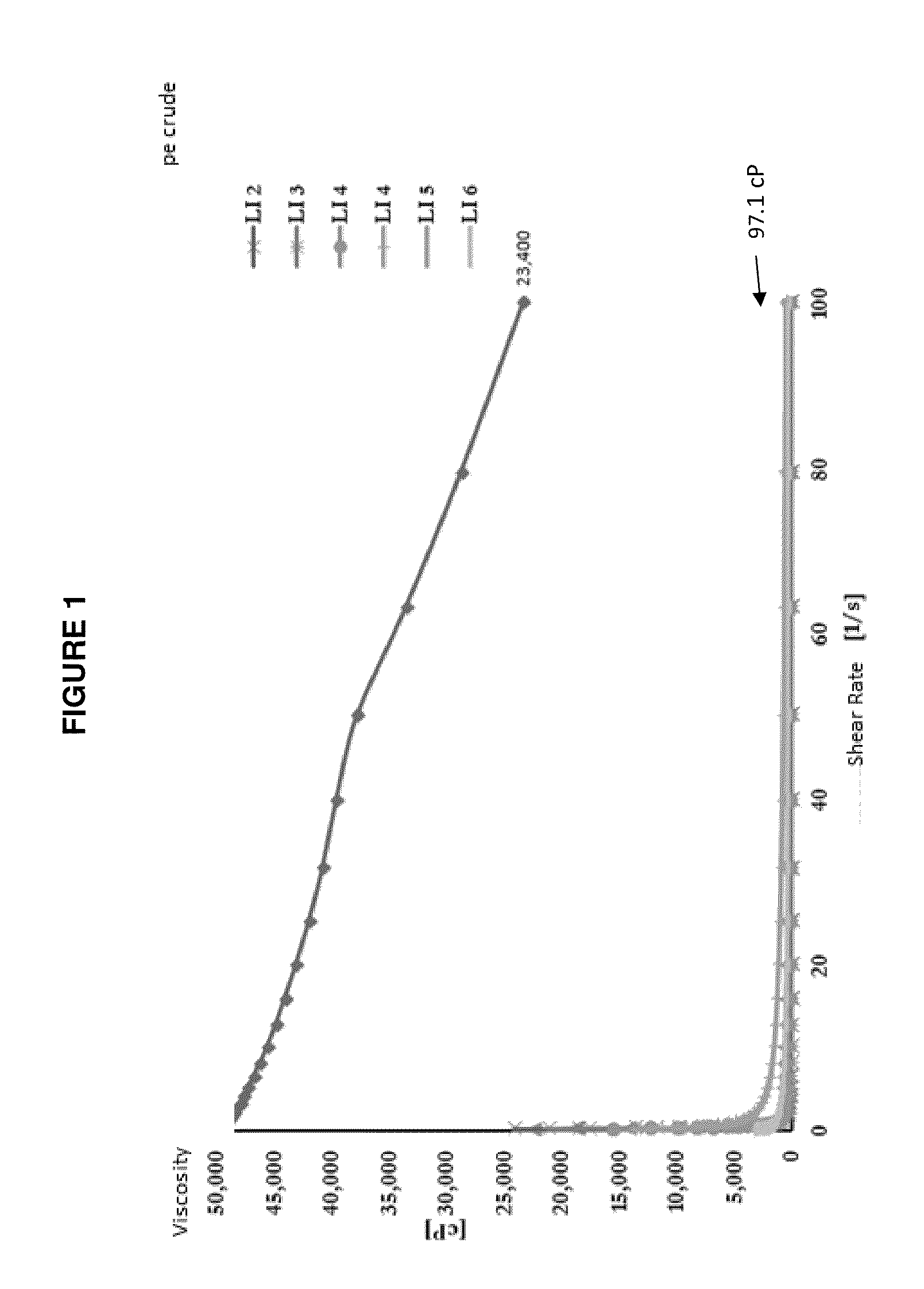

Heavy oil rheology modifiers for flow improvement during production and transportation operations

ActiveUS20170198204A1Low viscosityIncrease productionPipeline systemsDrilling compositionPentaerythritolAlkylphenol

The present invention generally relates to methods for enhancing production and transportation of heavy and extra-heavy crude oil and for reducing the growth of asphaltene flocculants or hindering their formation, the methods comprising contacting an oil-soluble composition that comprises polyetheramines, tallow amines, tallow diamines, alkylphenol-formaldehyde resins, reaction products of alpha-olefin, maleic anhydride and pentaerythritol, or a combination thereof, with the heavy or extra-heavy crude oil.

Owner:CHAMPIONX USA INC

Process method for modifying and processing extra-heavy crude oil

The invention relates to a method for modifying and processing extra-heavy crude oil. The method comprises the following steps: the extra-heavy crude oil is mixed with diluted oil, and the mixture is preheated to 250-350 DEG C and led into a catalytic cracking reactor to contact with a catalyst with the temperature of 670-760 DEG C for reaction; cracking gas, light-oil steam and water vapor are separated in a separating system; the rest catalytic cracking liquid residue, i.e. heavy components at a tower bottom and solvent enter an extraction tower for deasphalting the solvent so that the heavy components are separated into a heavy liquid phase rich in heave metals and asphaltine part and a light liquid phase containing deasphalted oil and solvent; and the light liquid phase enters a supercritical tower to carry out supercritical recovery of the solvent. The process method has the function of visbreaking, demetalization, desulfurization and decarburization in one step, ensures that theobtained modified oil has favorable stability with the fluidity satisfying the transportation requirement and provides high-quality raw materials with low sulphur, low metal and low residual carbon for processes of catalytic cracking, coking, and the like.

Owner:PETROCHINA CO LTD

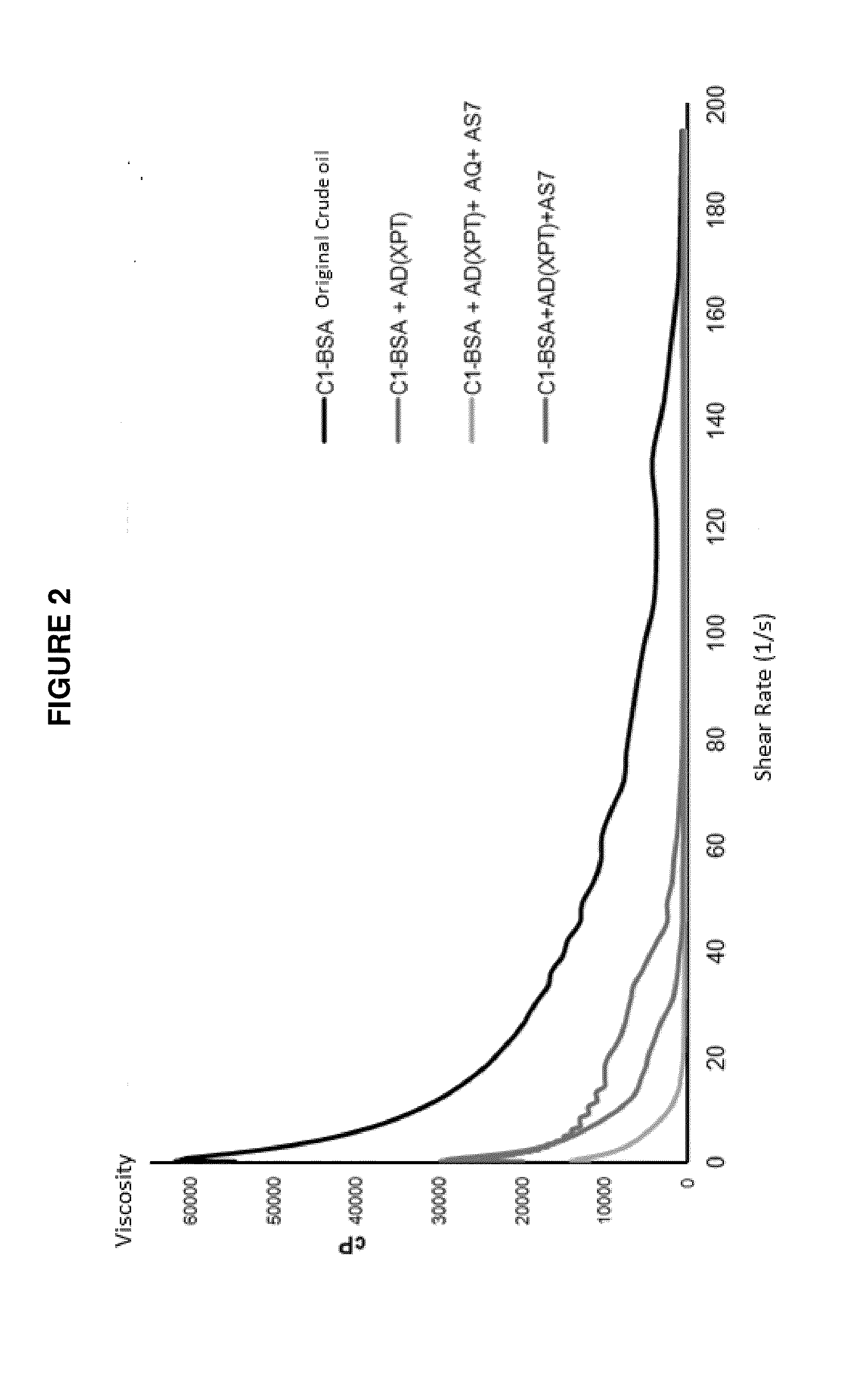

Application of a chemical composition for viscosity modification of heavy and extra-heavy crude oils

ActiveUS20150111799A1Low viscosityImprove liquidityDistillation purification/separationHydrocarbonsChemical compositionHeavy crude oil

The present invention relates to the use of a chemical composition to modify the physical properties (viscosity and interfacial tension) of heavy and extra-heavy crude oils, to increase their mobility. The chemical composition comprises or consists of a combination of systems based on ionic and non-ionic liquids, which may be pure or modified, mixed in an aqueous or organic medium as a dispersing agent, depending on the nature of the crude to be treated, together with a surfactant. The composition is mixed with the crude oil at a temperature between 5 and 100° C., at pressures from 1 atm (14.7 psi) up to about 680.2 atm (10,000 psi). The composition can be mixed with heavy crude oils, at the point of extraction from the well in the field, during the transport of crude oil in pipelines, or in the well discharge pipelines.

Owner:INST MEXICANO DEL GASOLINEEO +1

Water-Based Polymer Drilling Fluid and Method of Use

A water-based drilling fluid comprises a polymer which is a non-ionic polymer or an anionic polymer. The polymer can be a polyacrylamide. The fluid is used for drilling subterranean formations containing heavy crude oil and bitumen-rich oil sands, and may comprise additional fluid components.

Owner:CANADIAN ENERGY SERVICES

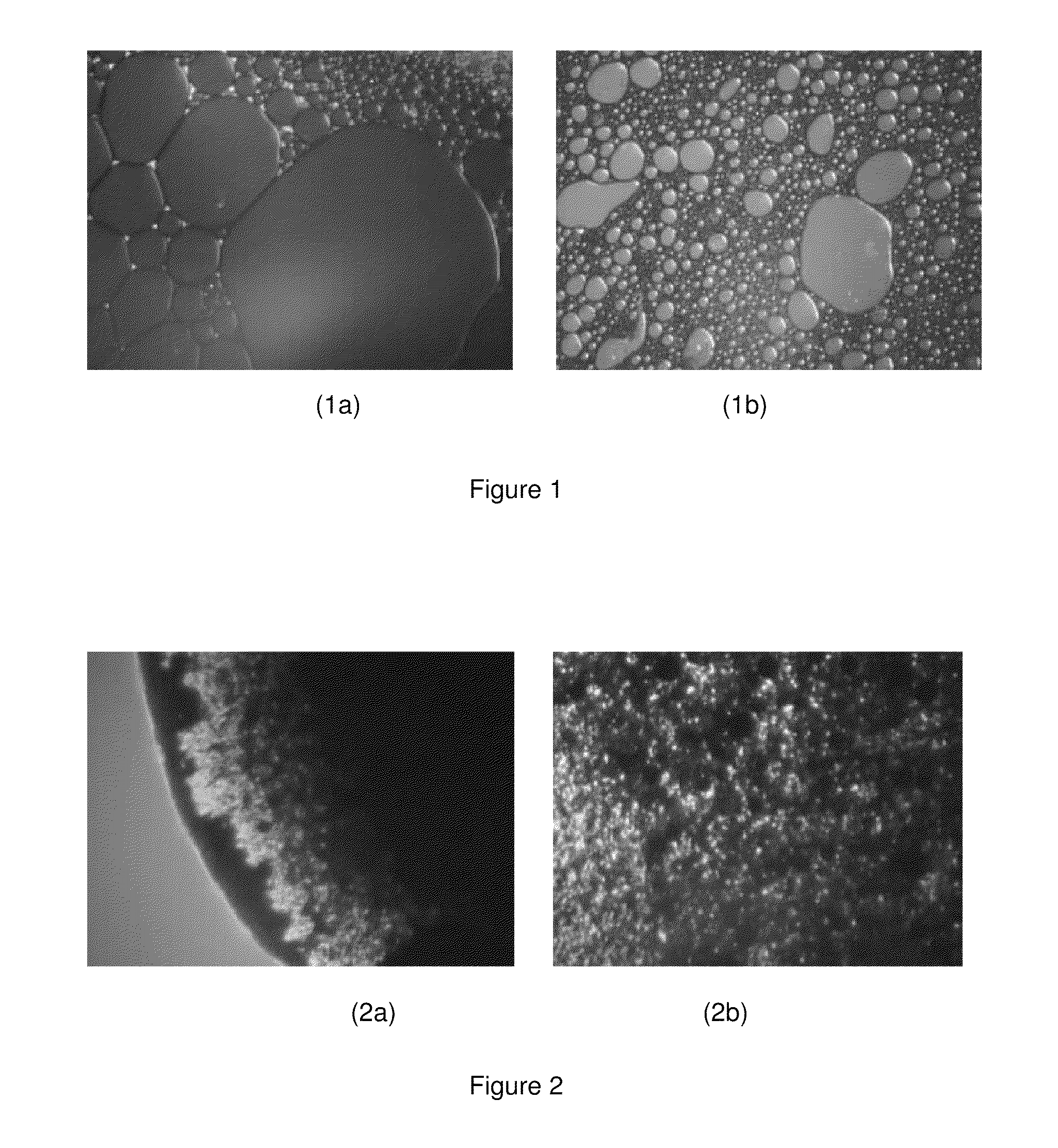

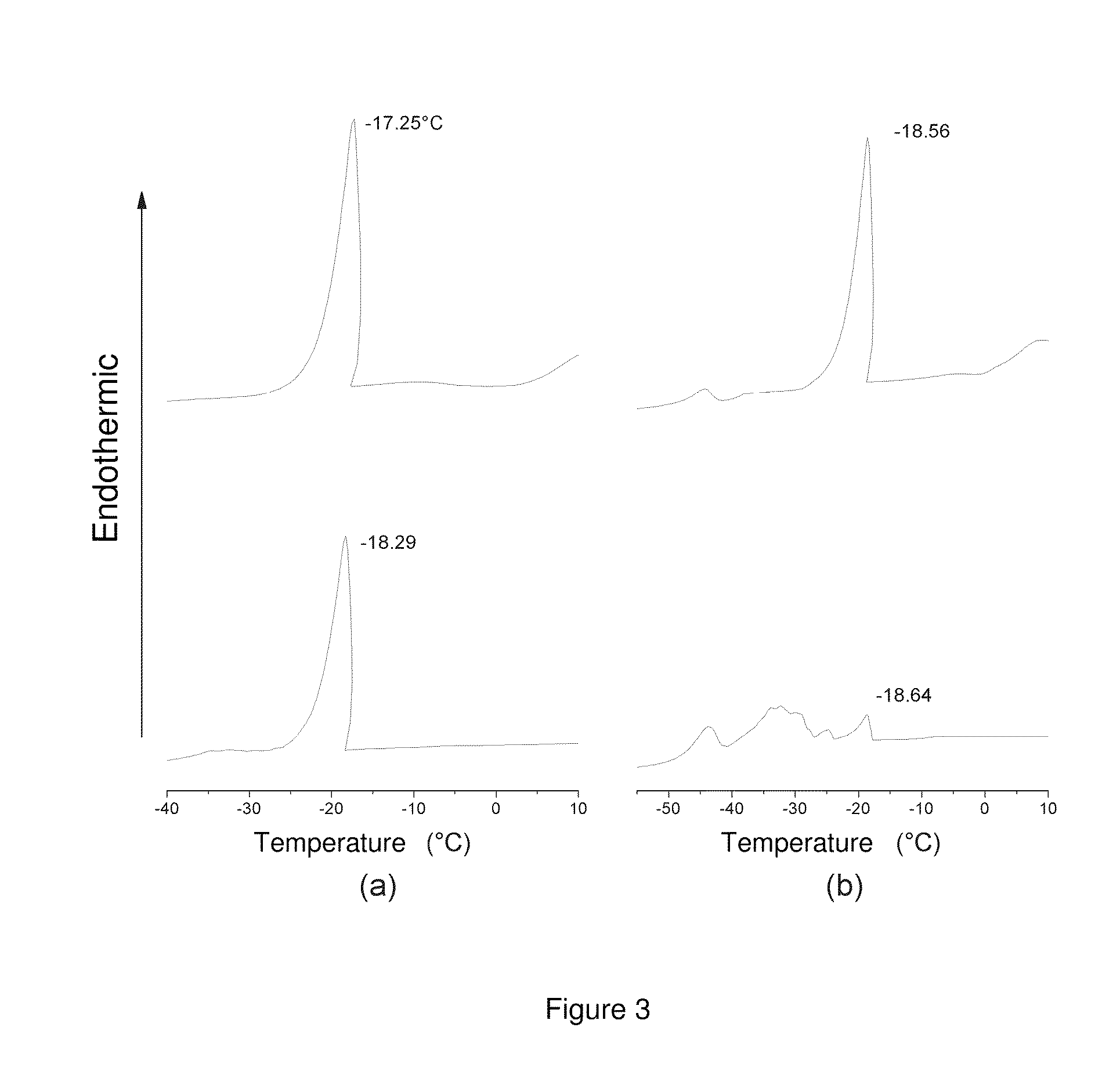

Process of preparing improved heavy and extra heavy crude oil emulsions by use of biosurfactants in water and product thereof

ActiveUS20110139262A1Increase capacityImprove stabilityLiquid carbonaceous fuelsPipeline systemsEmulsionHeavy crude oil

The present invention provides a process, which allows working with viscous petroleum referred to as “heavy and extra heavy crudes” by adding an appropriate biosurfactant to an aqueous phase containing a biosurfactant active compound. The result is the formation of a stable crude / water emulsion even with salt present therein.

Owner:INST MEXICANO DEL GASOLINEEO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com