Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

350results about "Refining with metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sorbent composition, process for producing same and use in desulfurization

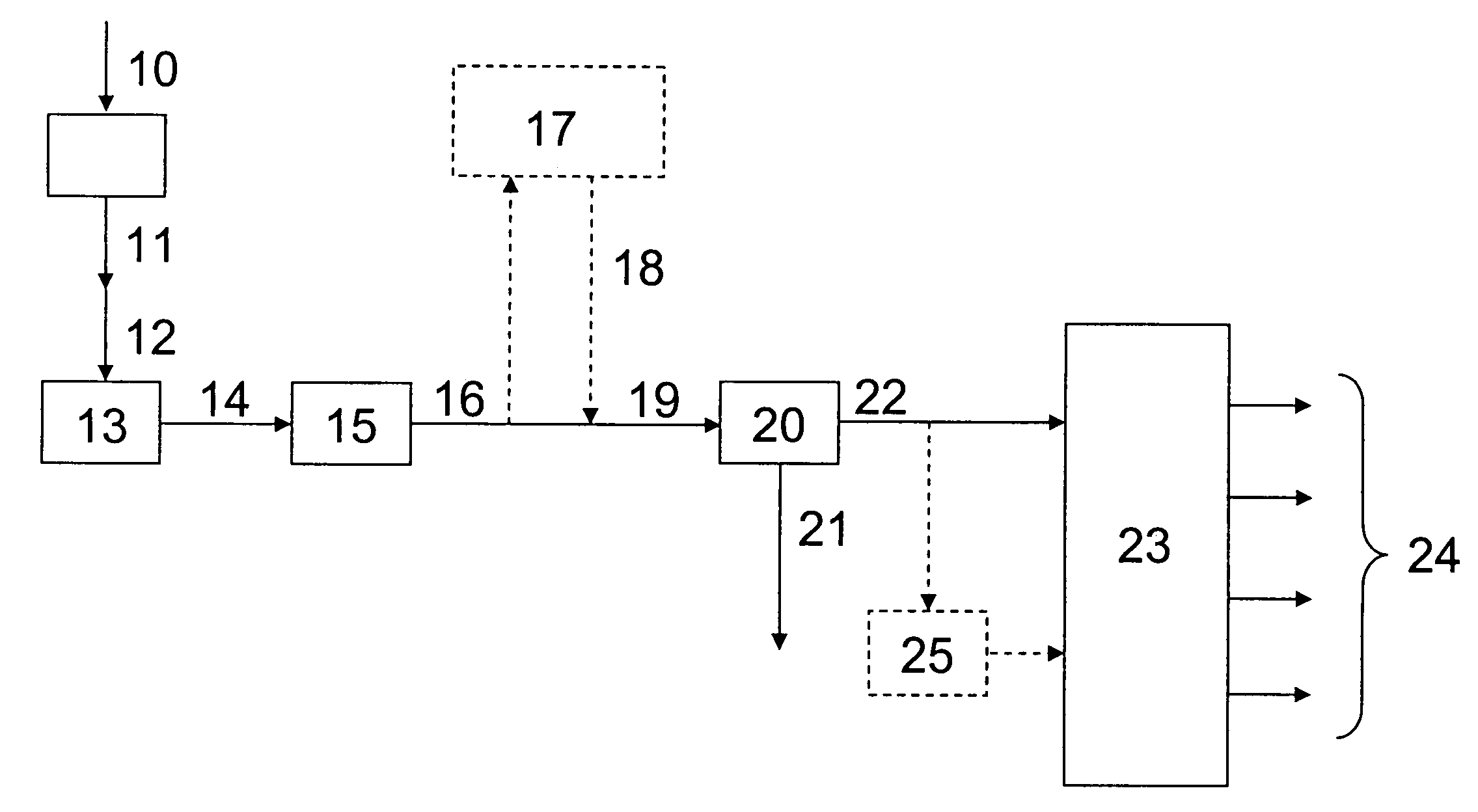

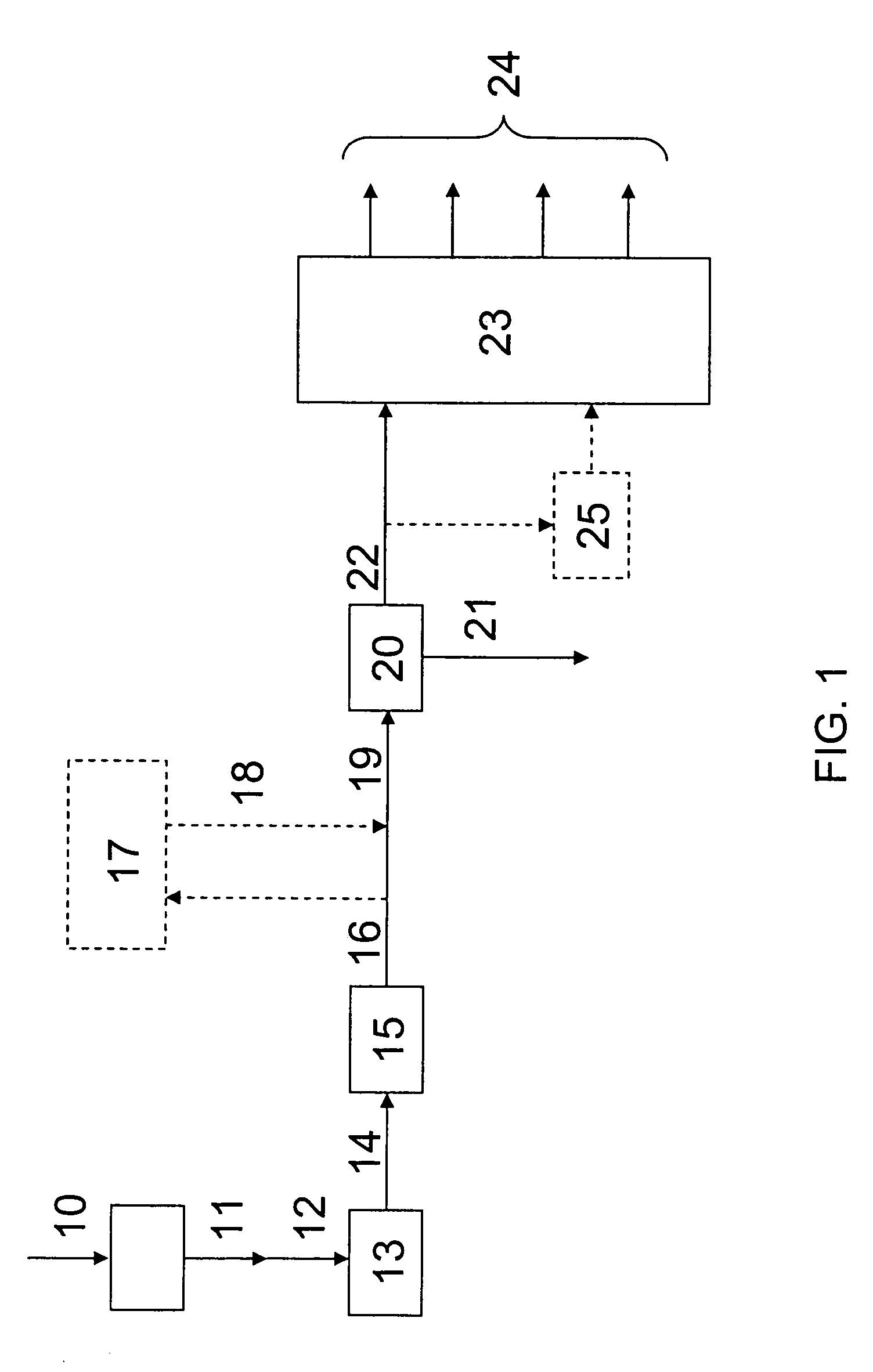

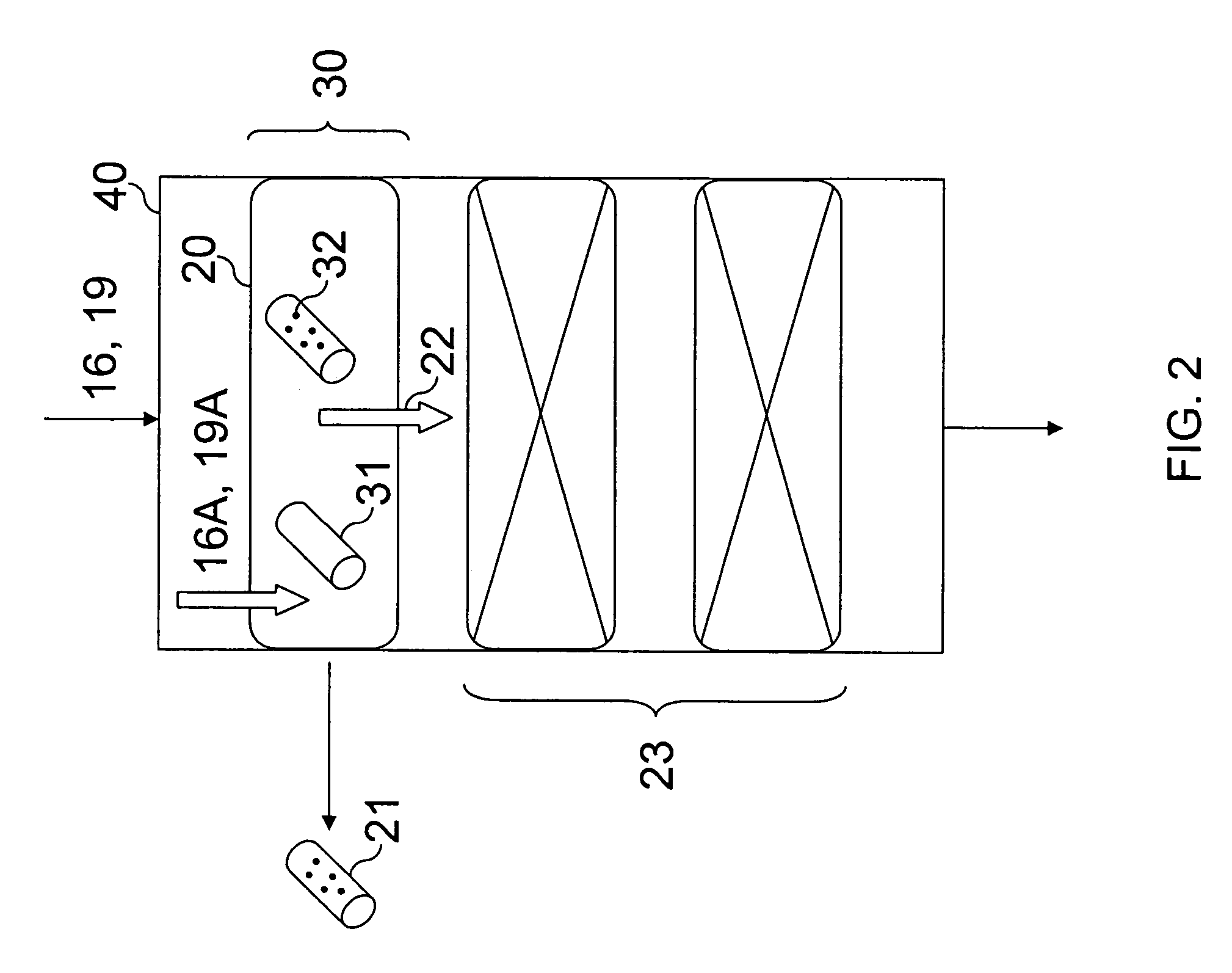

A particulate adsorbent composition comprising a mixture of zinc oxide, silica, alumina and substantially reduced valence cobalt for use in desulfurizing a cracked gasoline or diesel fuel feed stream in a desulfurization zone by: The desulfurization zone contacts the feed stream, then separates the resulting low sulfur content stream and the sulfurized adsorbent, regenerates and activates the separated adsorbent, and then returns to the desulfurization zone.

Owner:CHINA PETROLEUM & CHEM CORP

Systems, methods, and catalysts for producing a crude product

InactiveUS20060231465A1Reduce contentRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsChemistryCrude oil

Owner:SHELL OIL CO

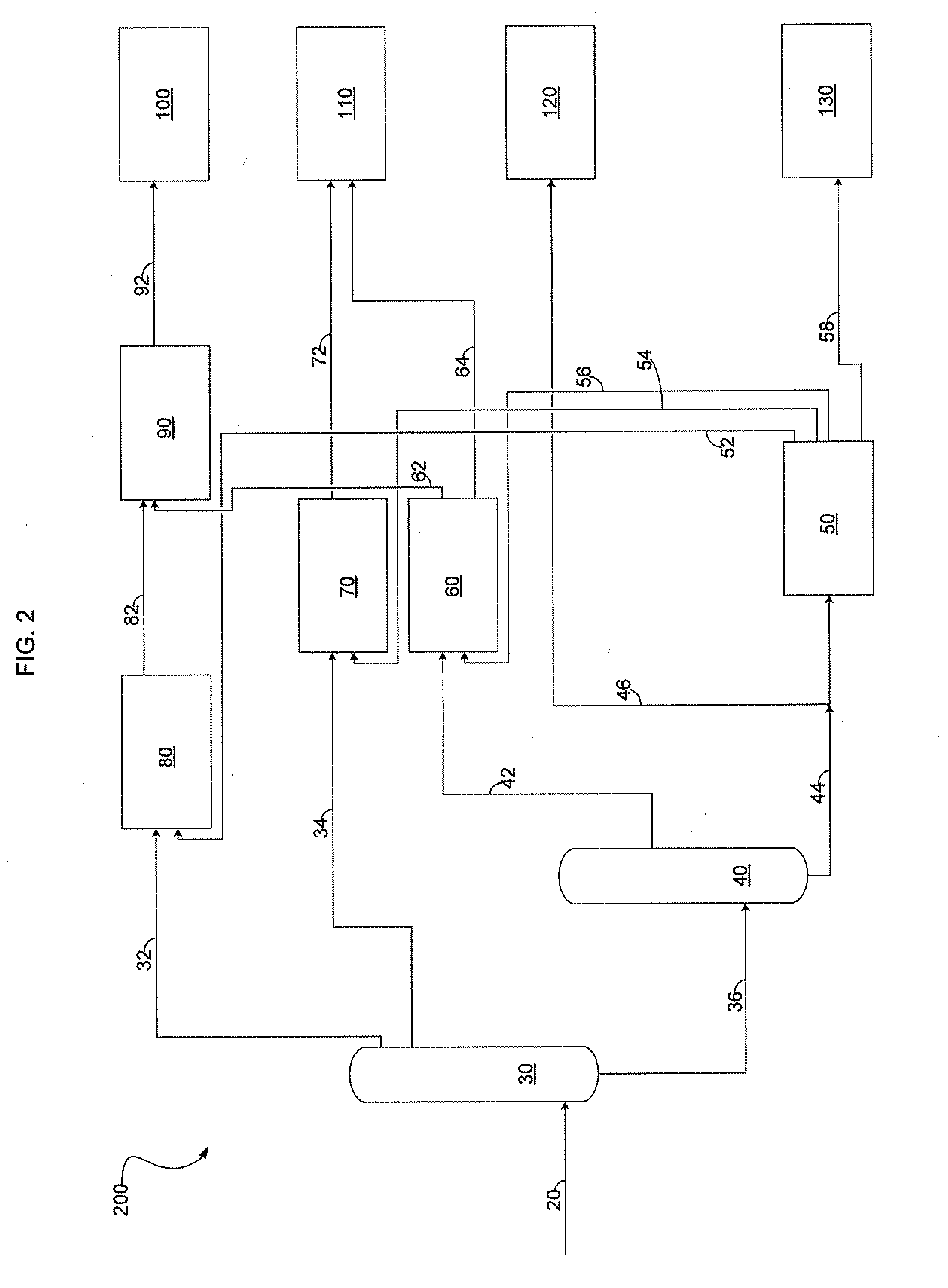

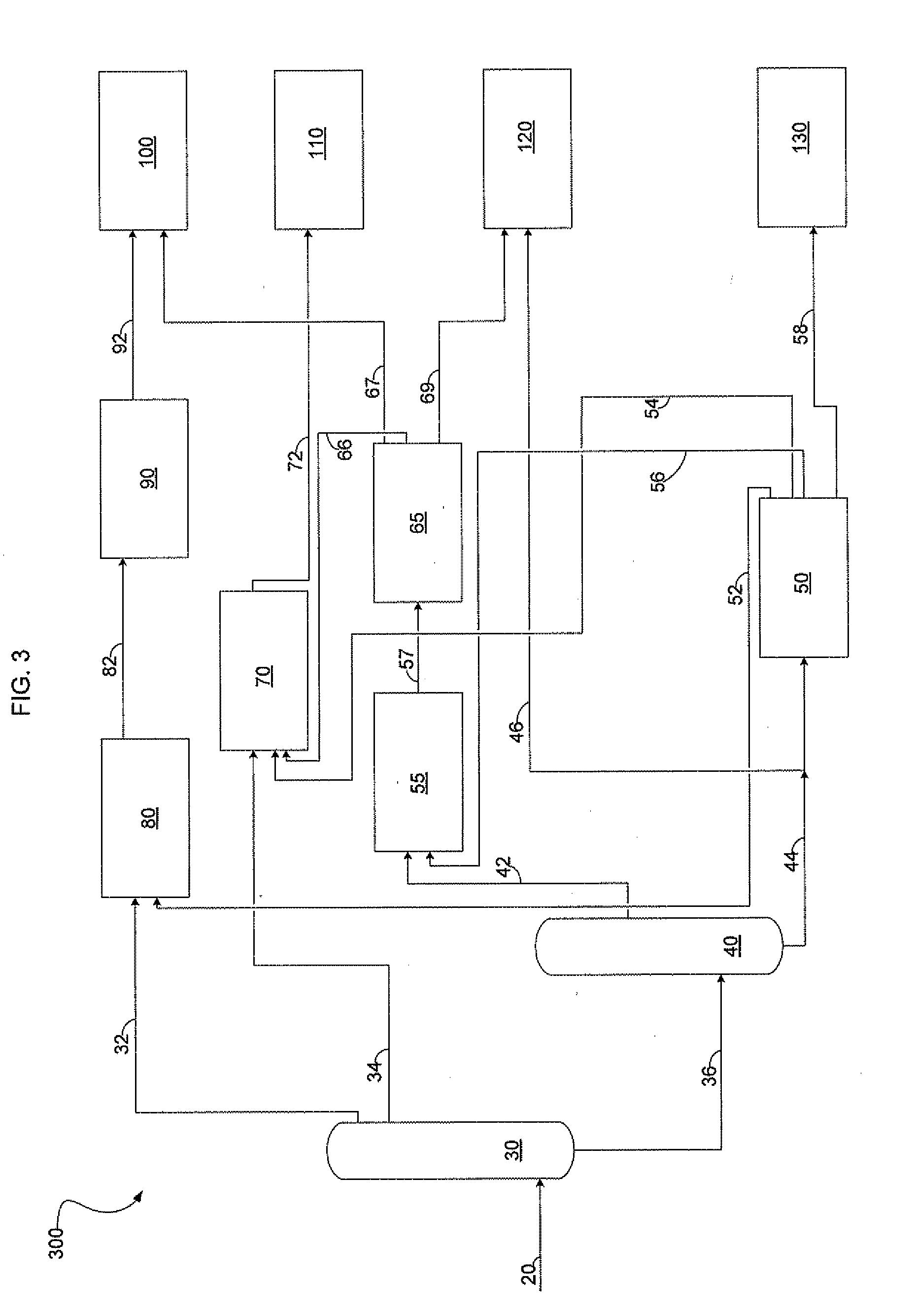

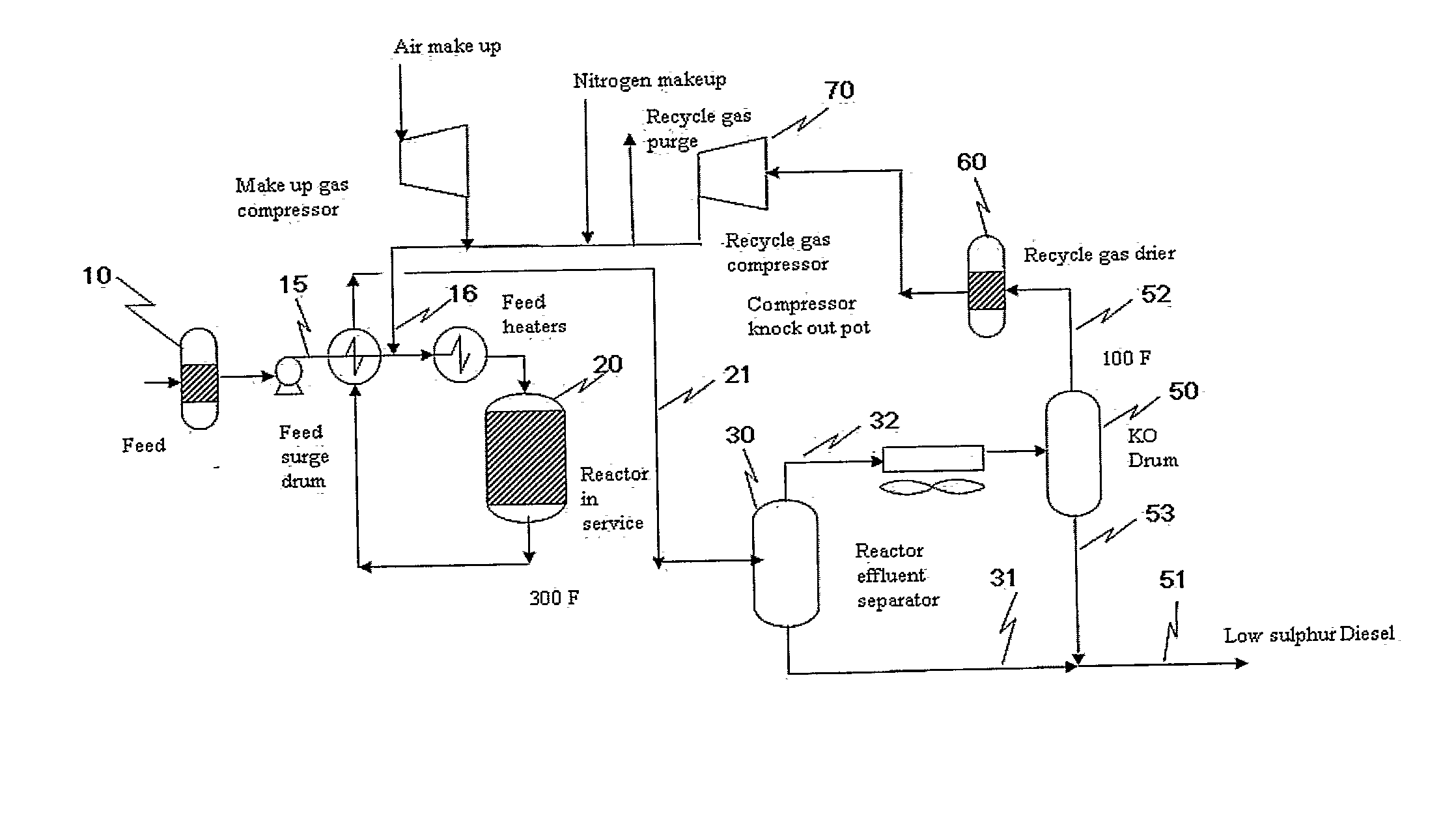

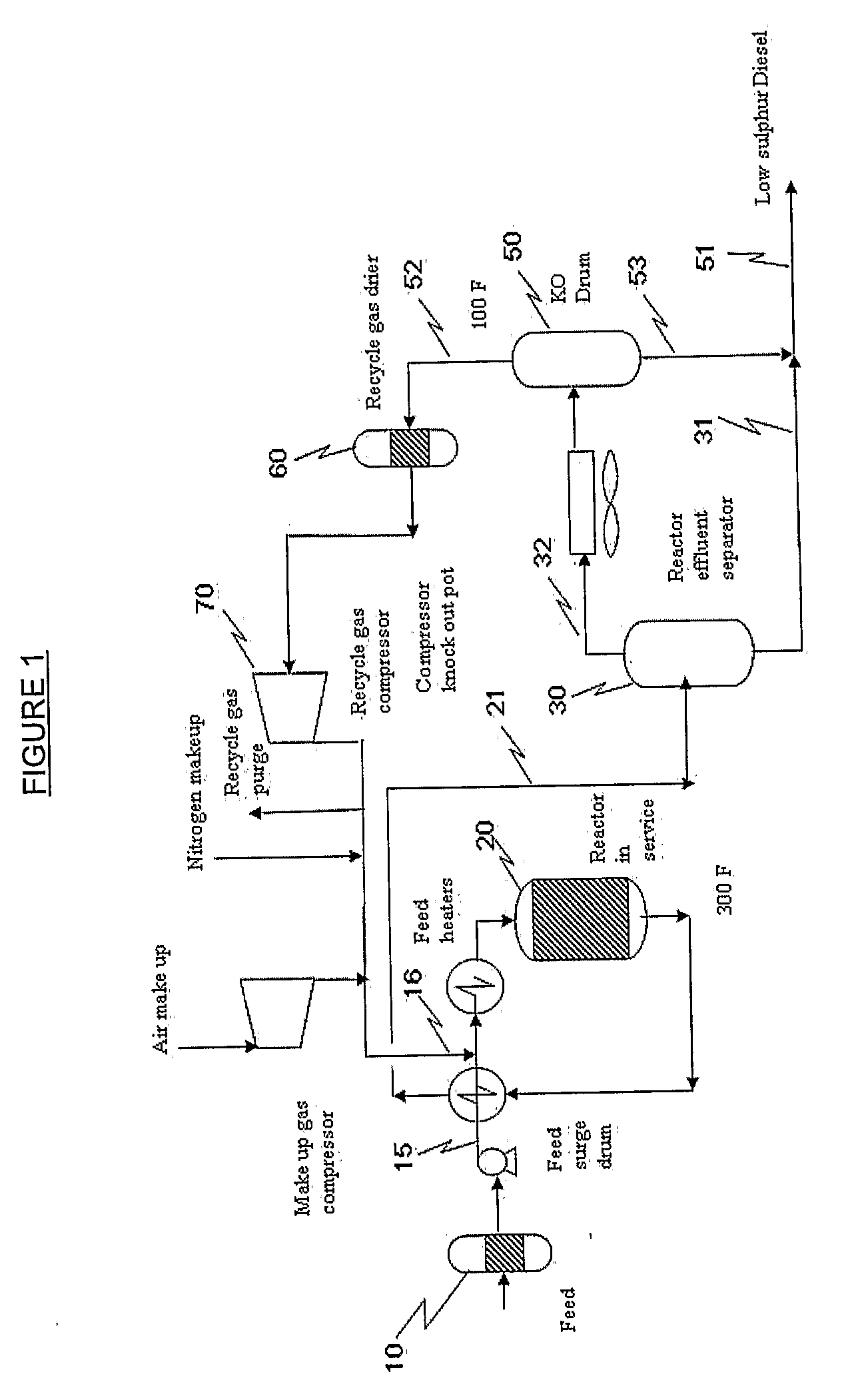

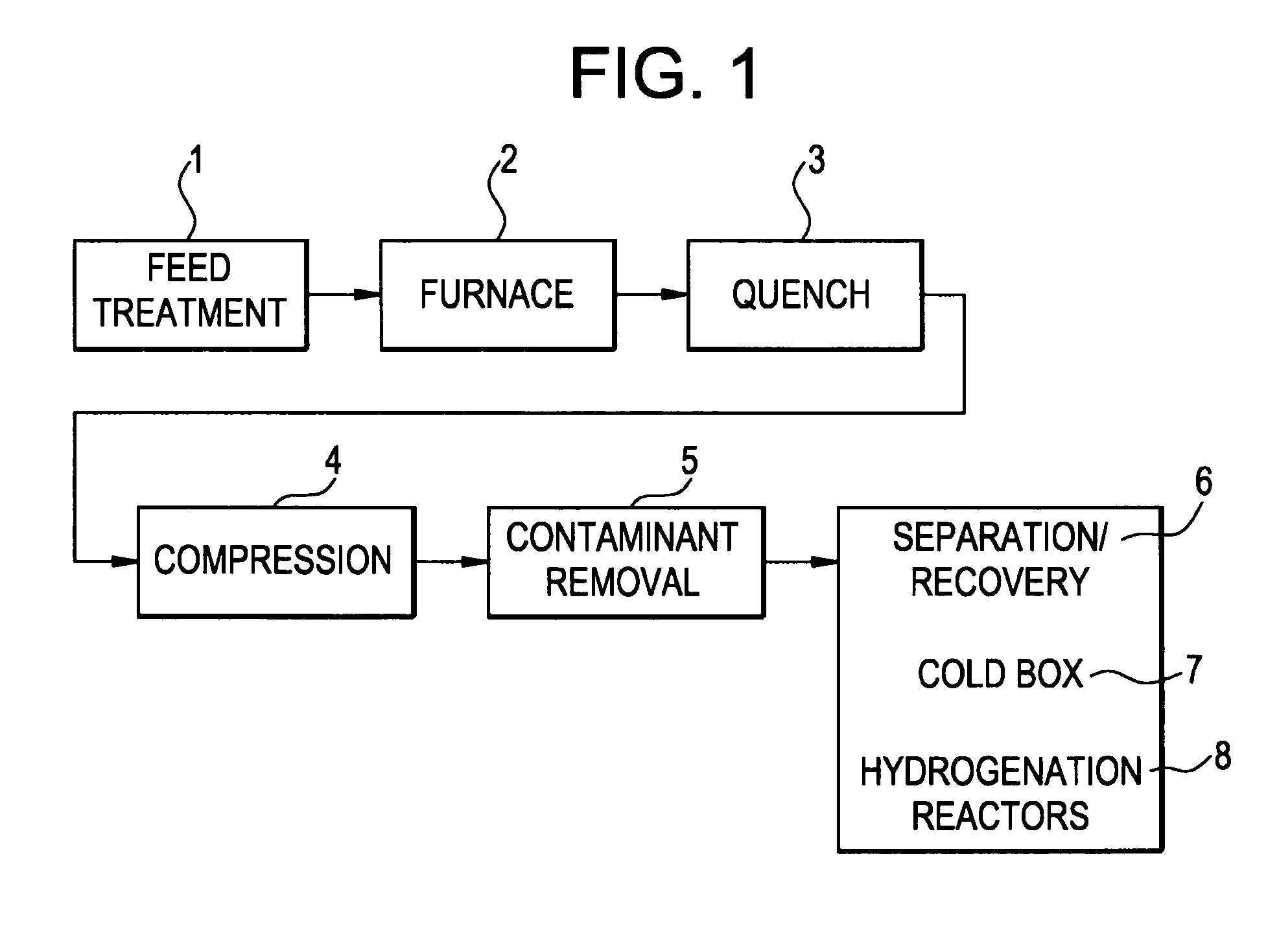

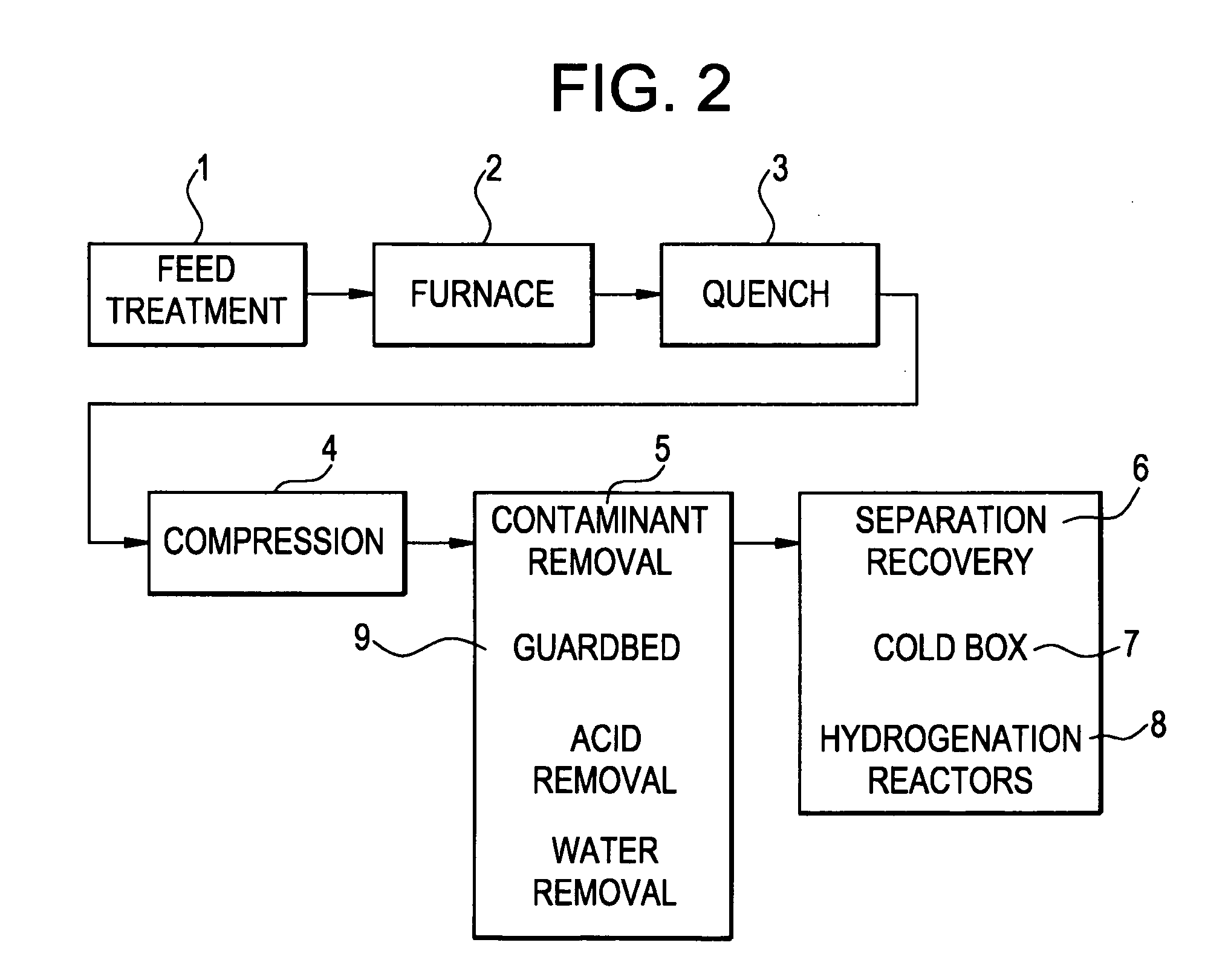

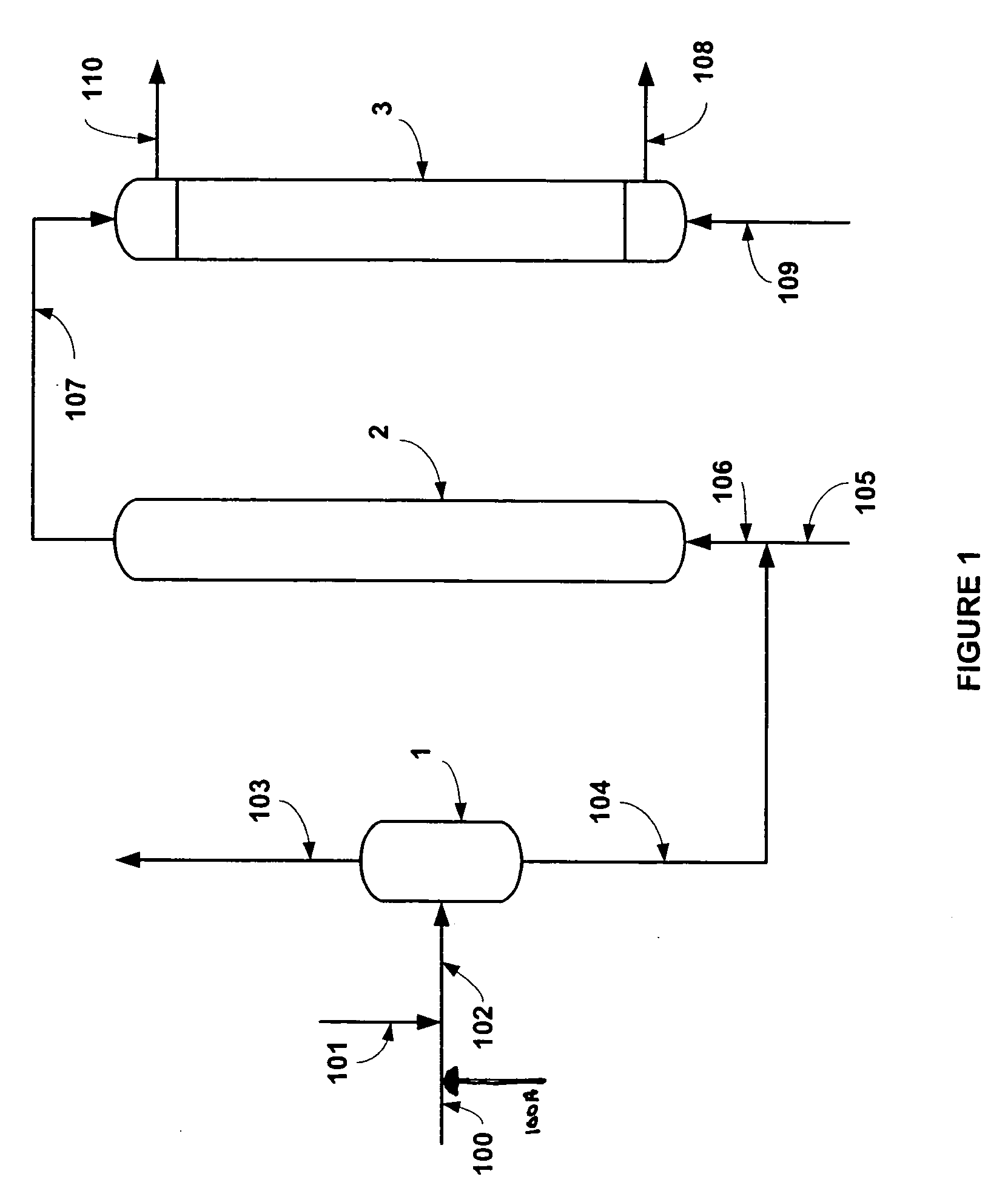

Alternative Process for Treatment of Heavy Crudes in a Coking Refinery

ActiveUS20110083996A1Increasing API gravityReduce the amount of metalThermal non-catalytic crackingRefining with metalsFuel oilPre treatment

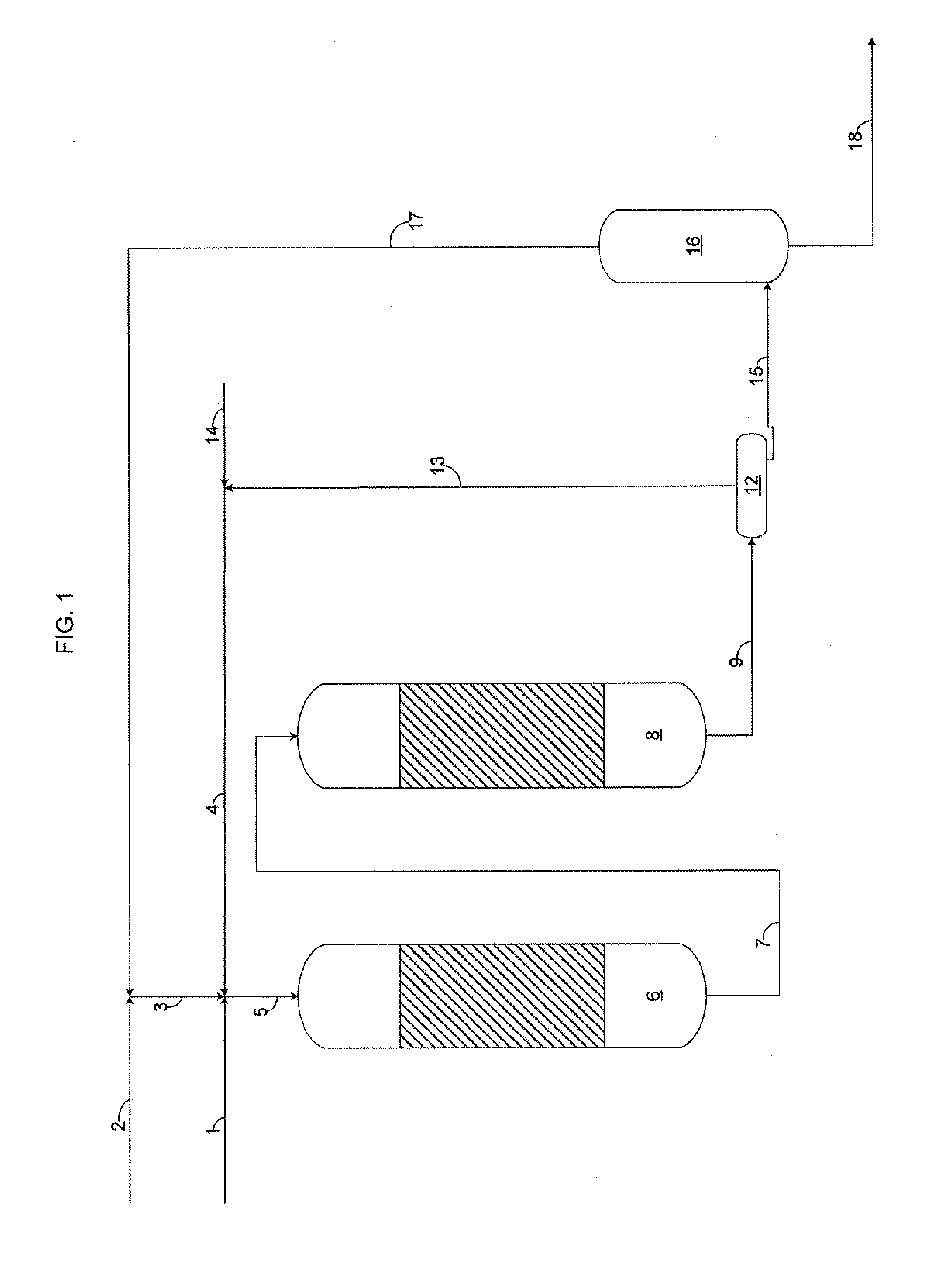

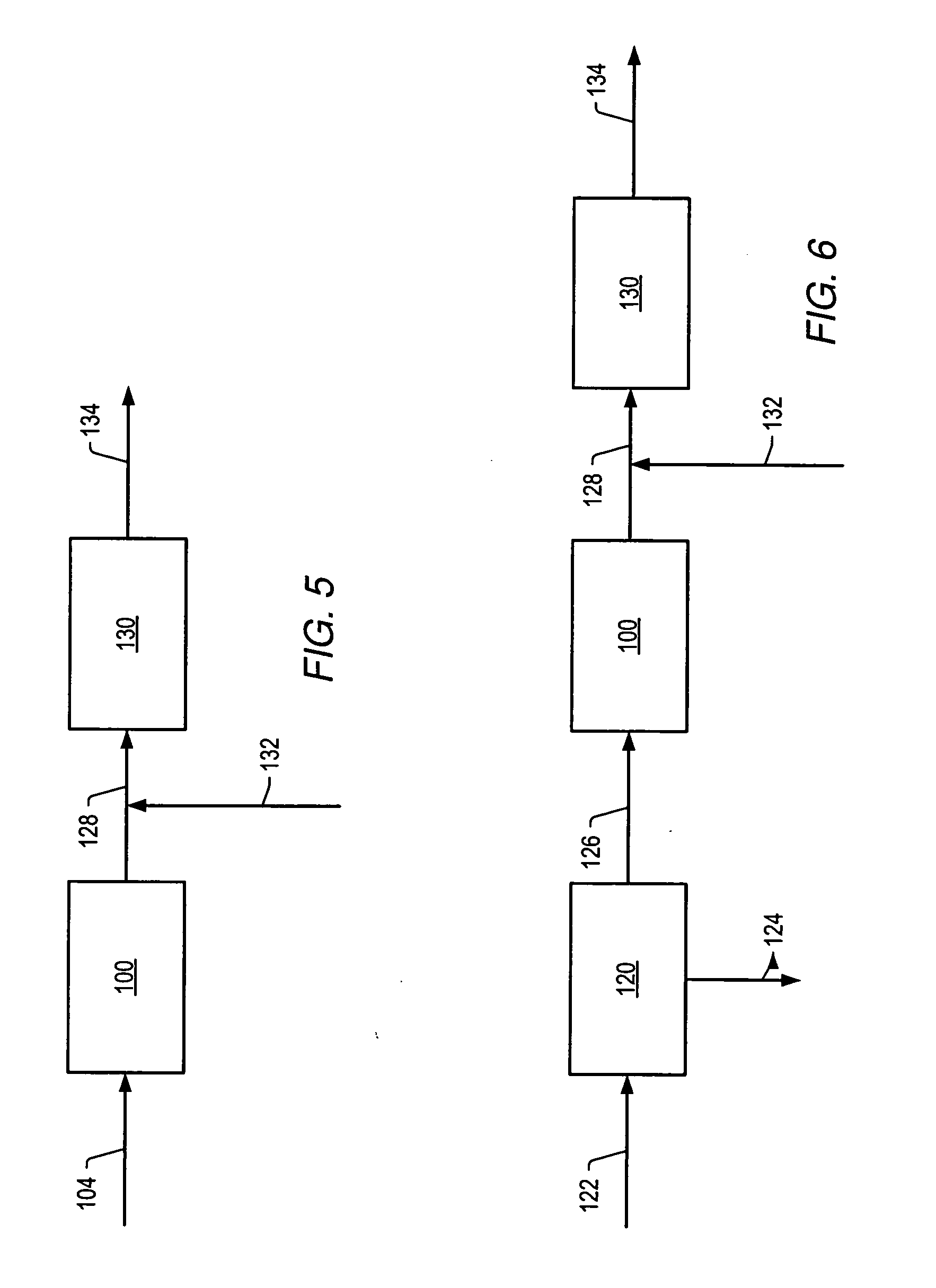

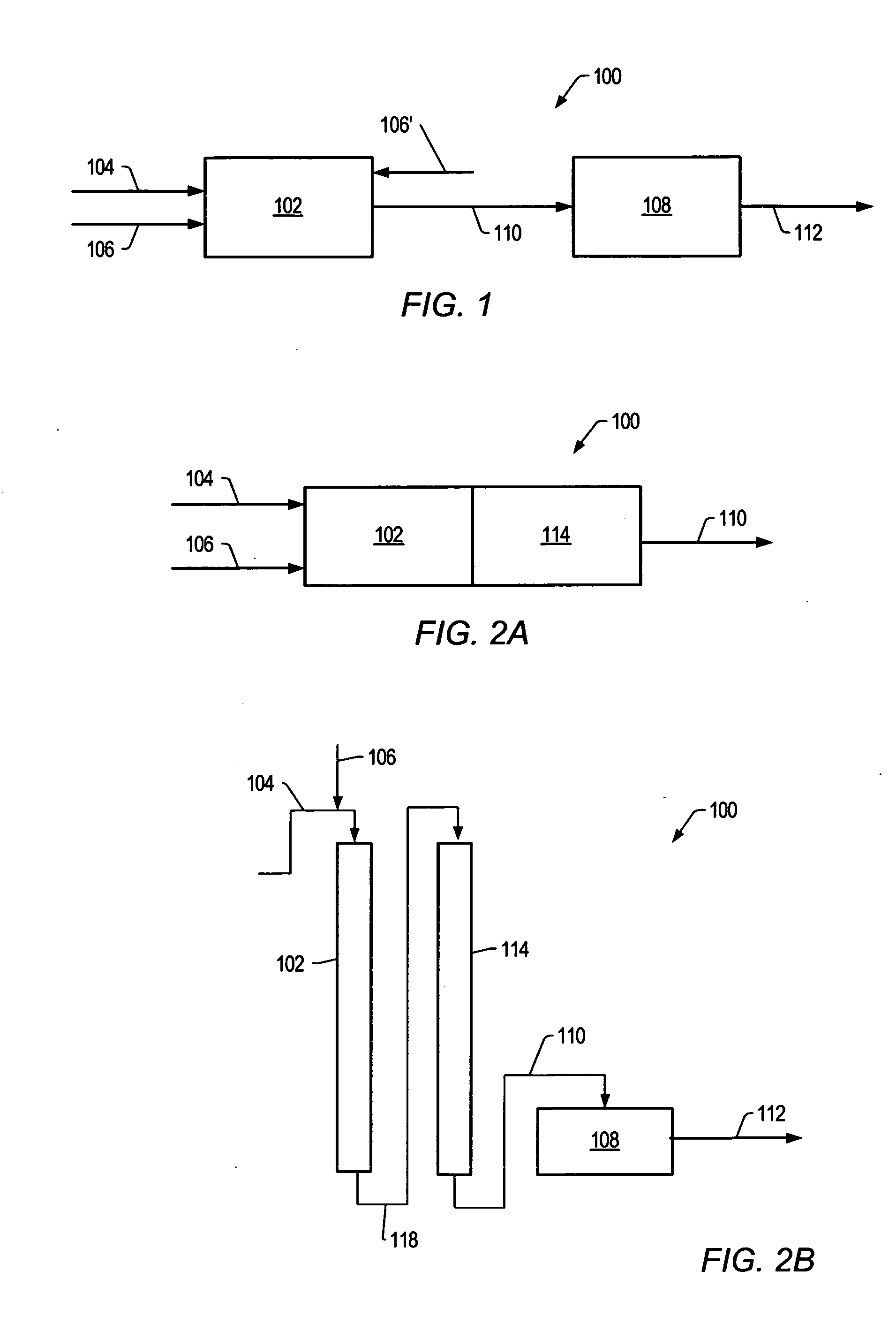

The present invention relates to a process for the pretreatment of heavy oils using a catalytic hydrotreating process prior to introduction to a refinery. More specifically, the invention relates to the use of an HDM reactor and an HDS reactor in order to improve the characteristics of the heavy oil, such that when the oil is introduced into the refinery, the refinery can achieve improved throughputs, increased catalysts life, increased life cycles, and a reduction in overall operation costs.

Owner:SAUDI ARABIAN OIL CO

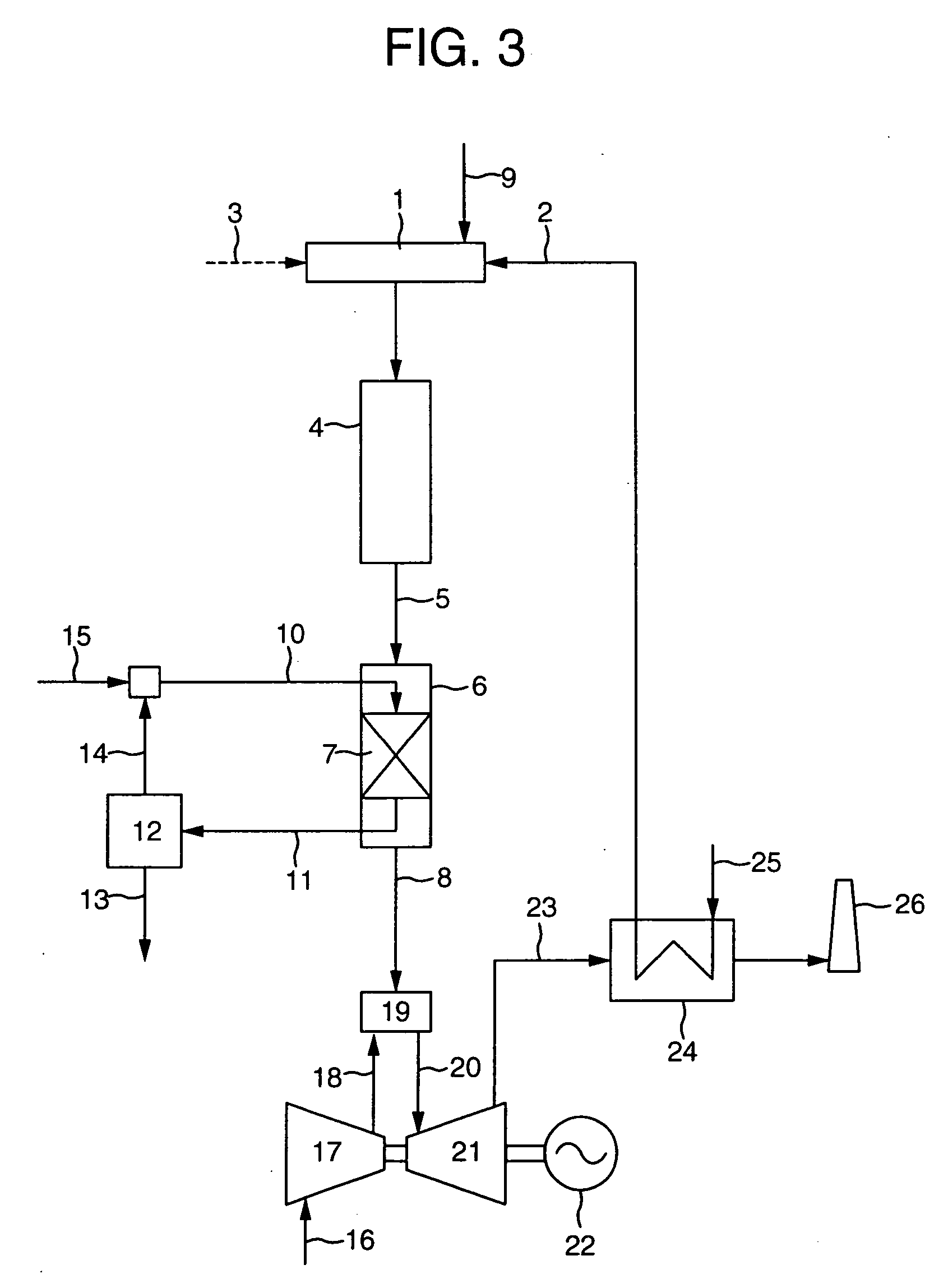

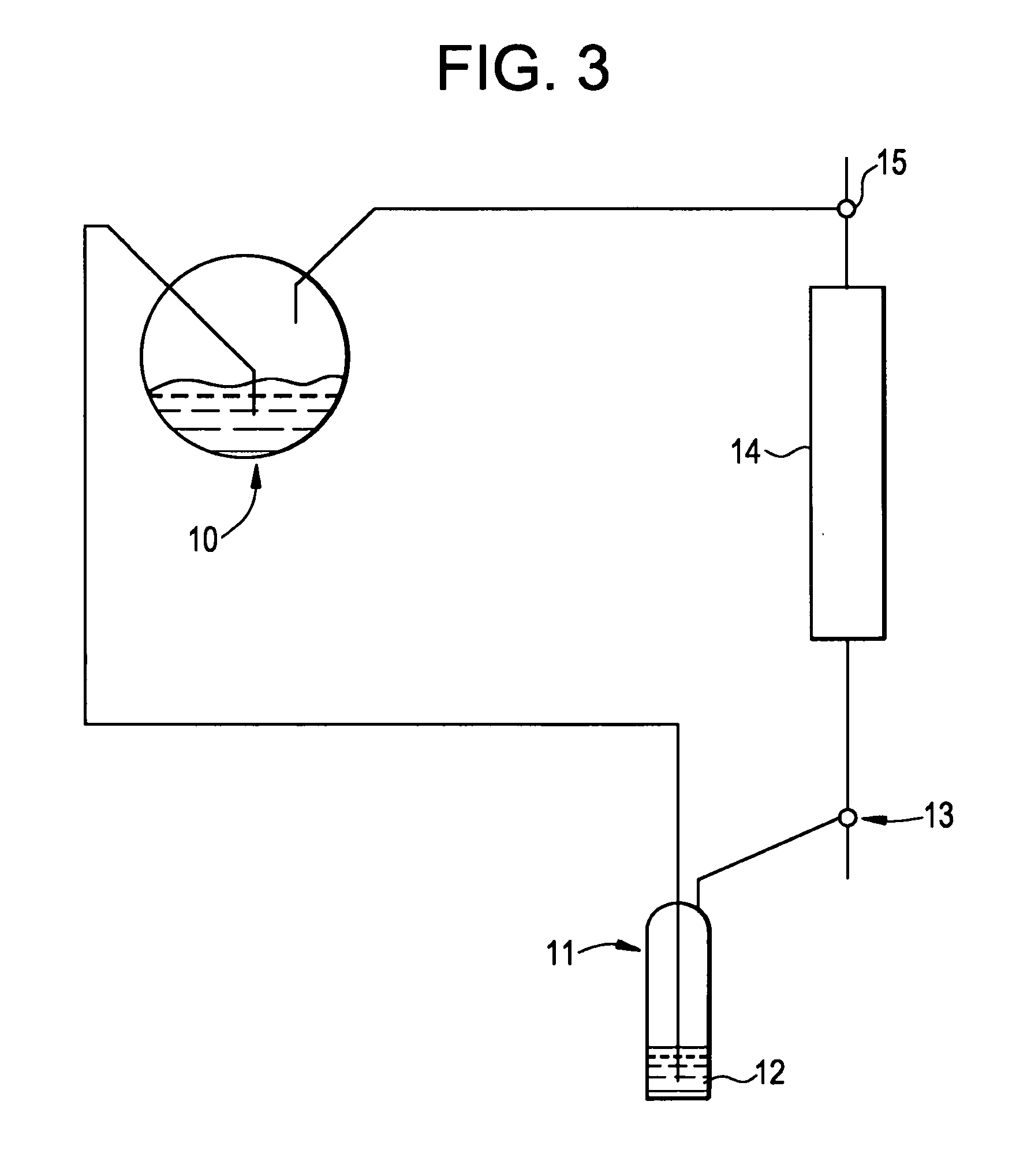

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

InactiveUS20060011511A1Reduce equipment costsReduce runningThermal non-catalytic crackingHydrogenScavengerCombustor

Owner:HOKARI NOBUYUKI +4

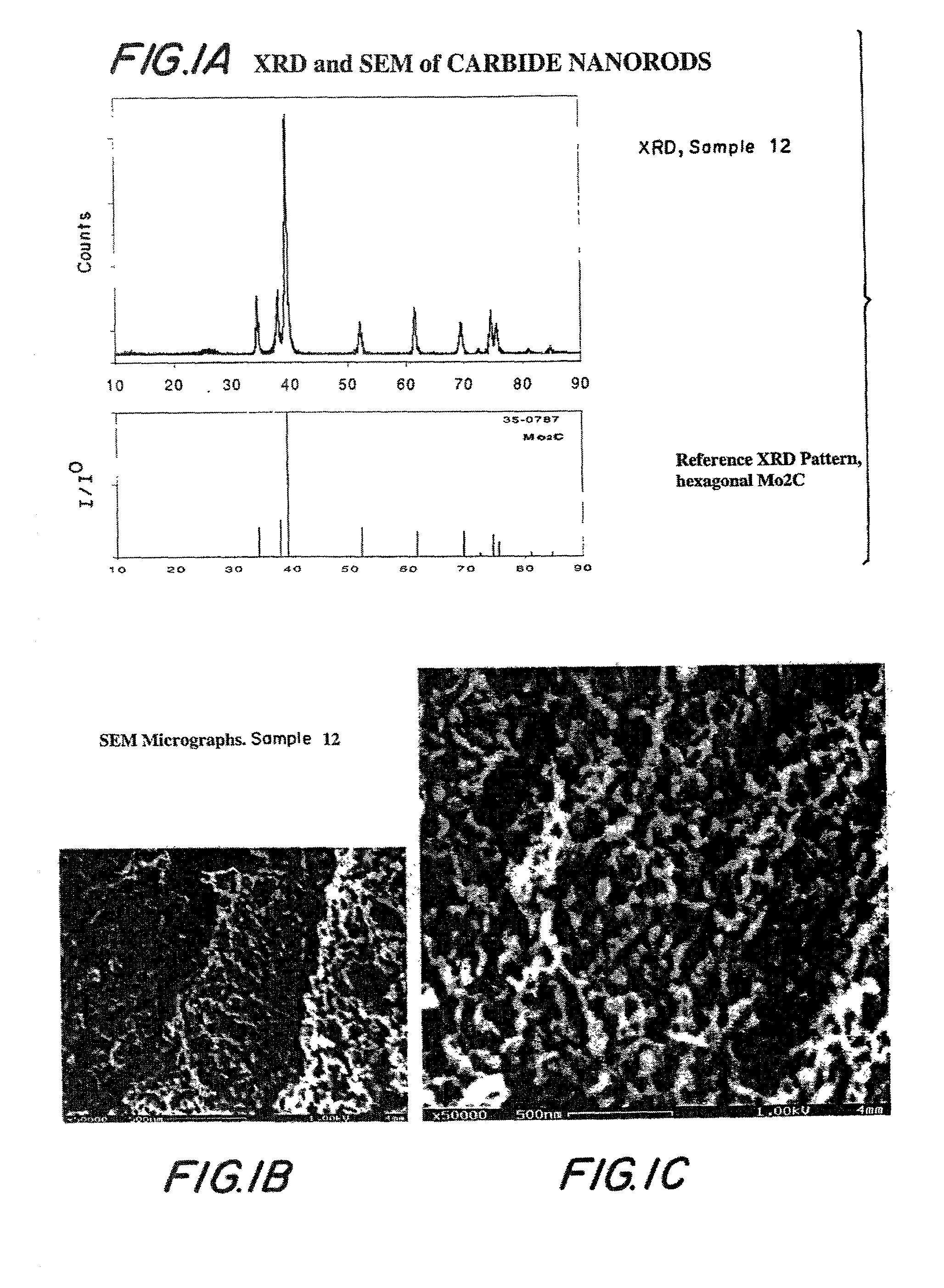

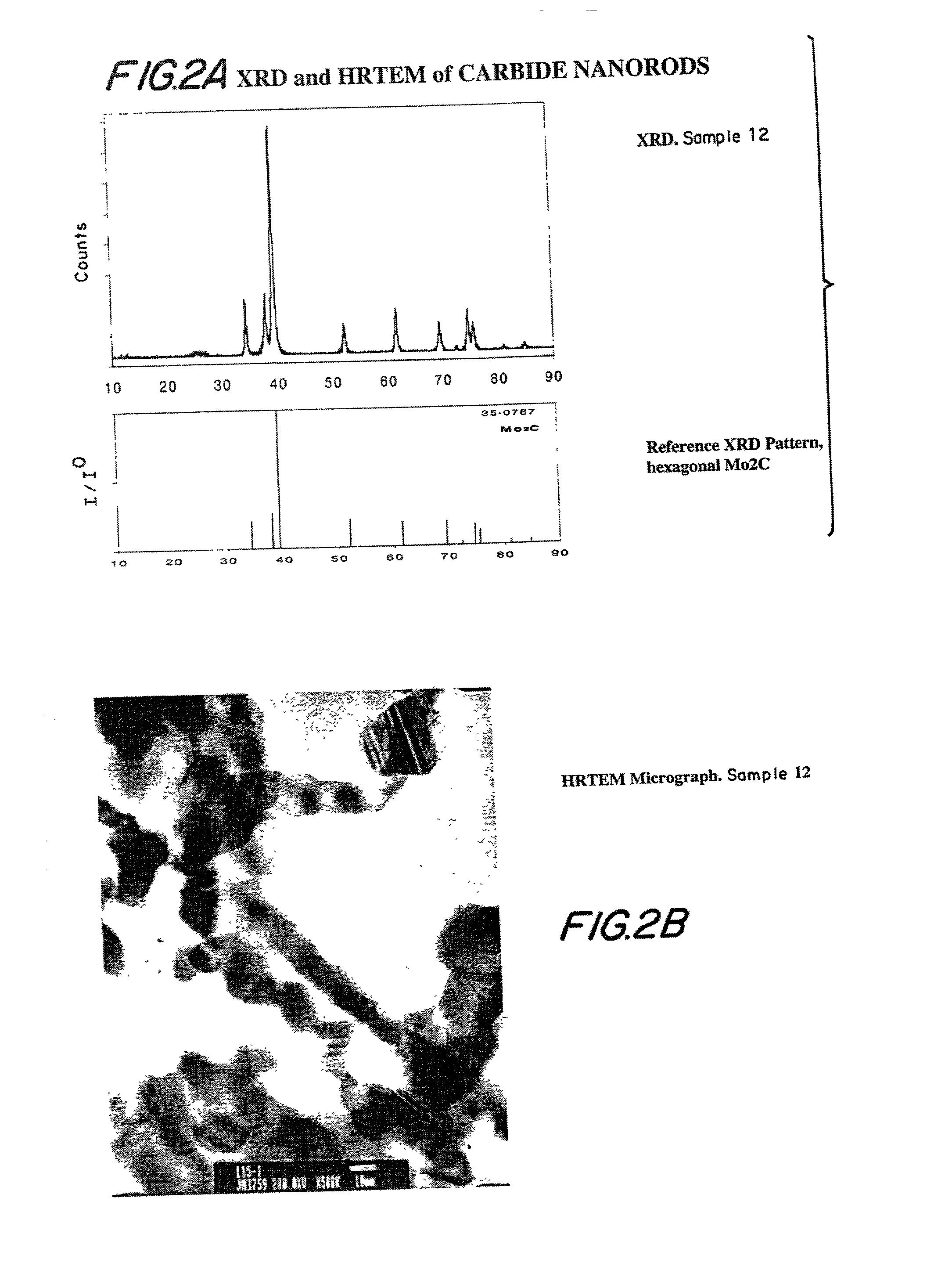

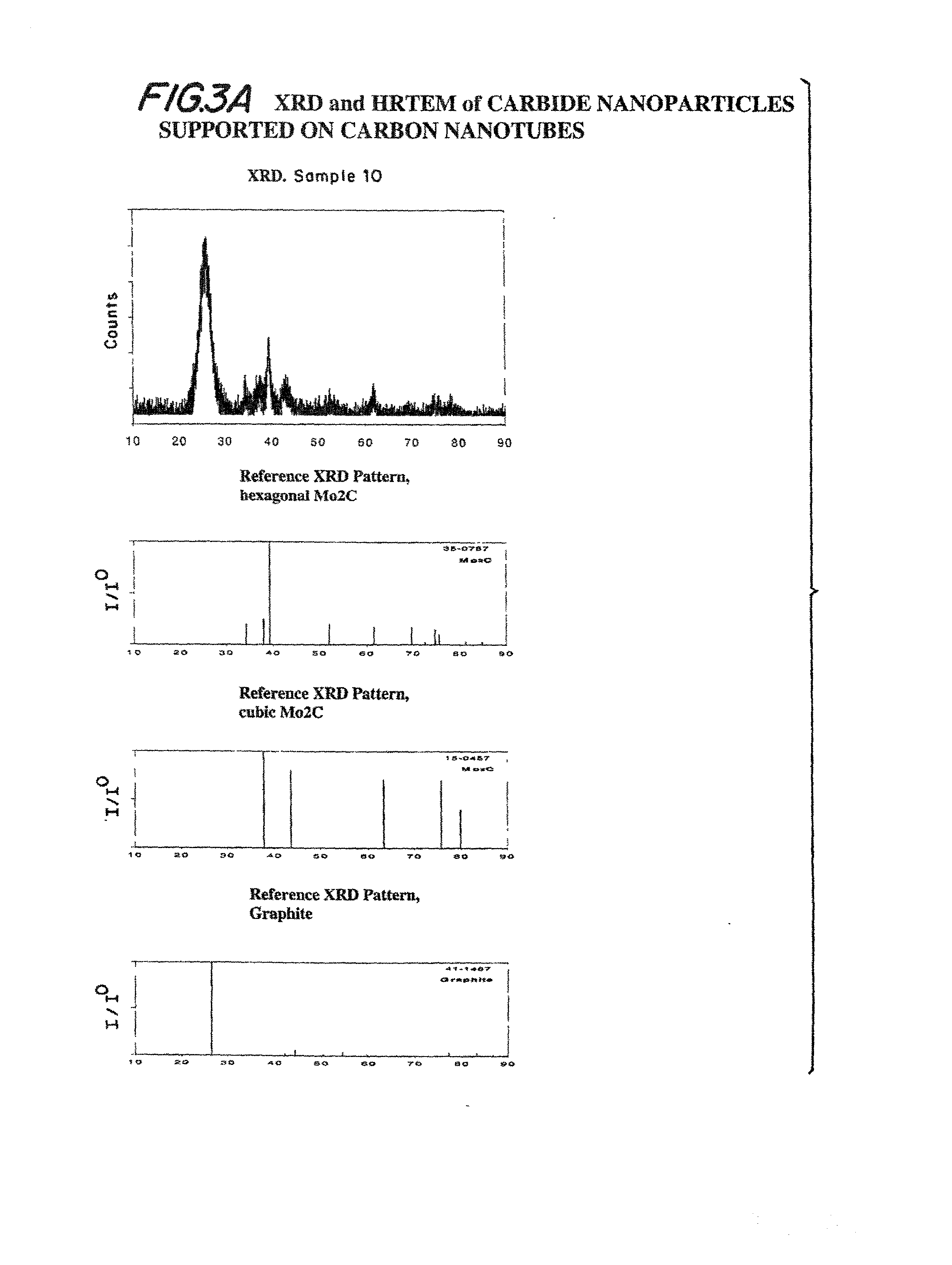

Method of using carbide and/or oxycarbide containing compositions

InactiveUS20020121460A1Facilitated DiffusionHigh porosityMaterial nanotechnologyHydrocarbon by isomerisationFluid phaseChemical reaction

Compositions including carbide-containing nanorods and / or oxycarbide-containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are provided. Rigid porous structures including oxycarbide-containing nanorods and / or carbide containing nanorods and / or carbon nanotubes bearing carbides and oxycarbides and methods of making the same are also provided. The compositions and rigid porous structures of the invention can be used either as catalyst and / or catalyst supports in fluid phase catalytic chemical reactions. Processes for making supported catalyst for selected fluid phase catalytic reactions are also provided.

Owner:HYPERION CATALYSIS INT

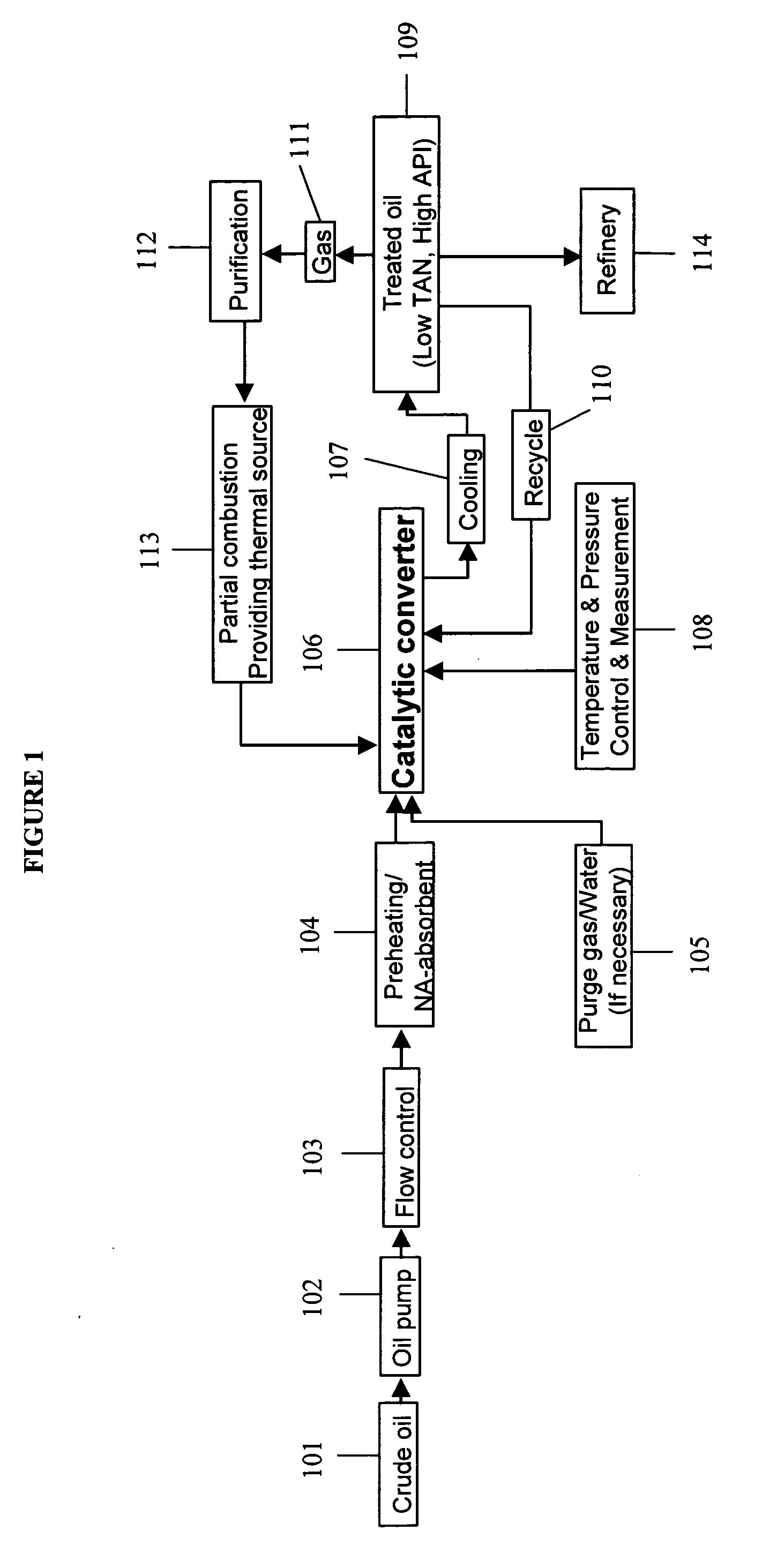

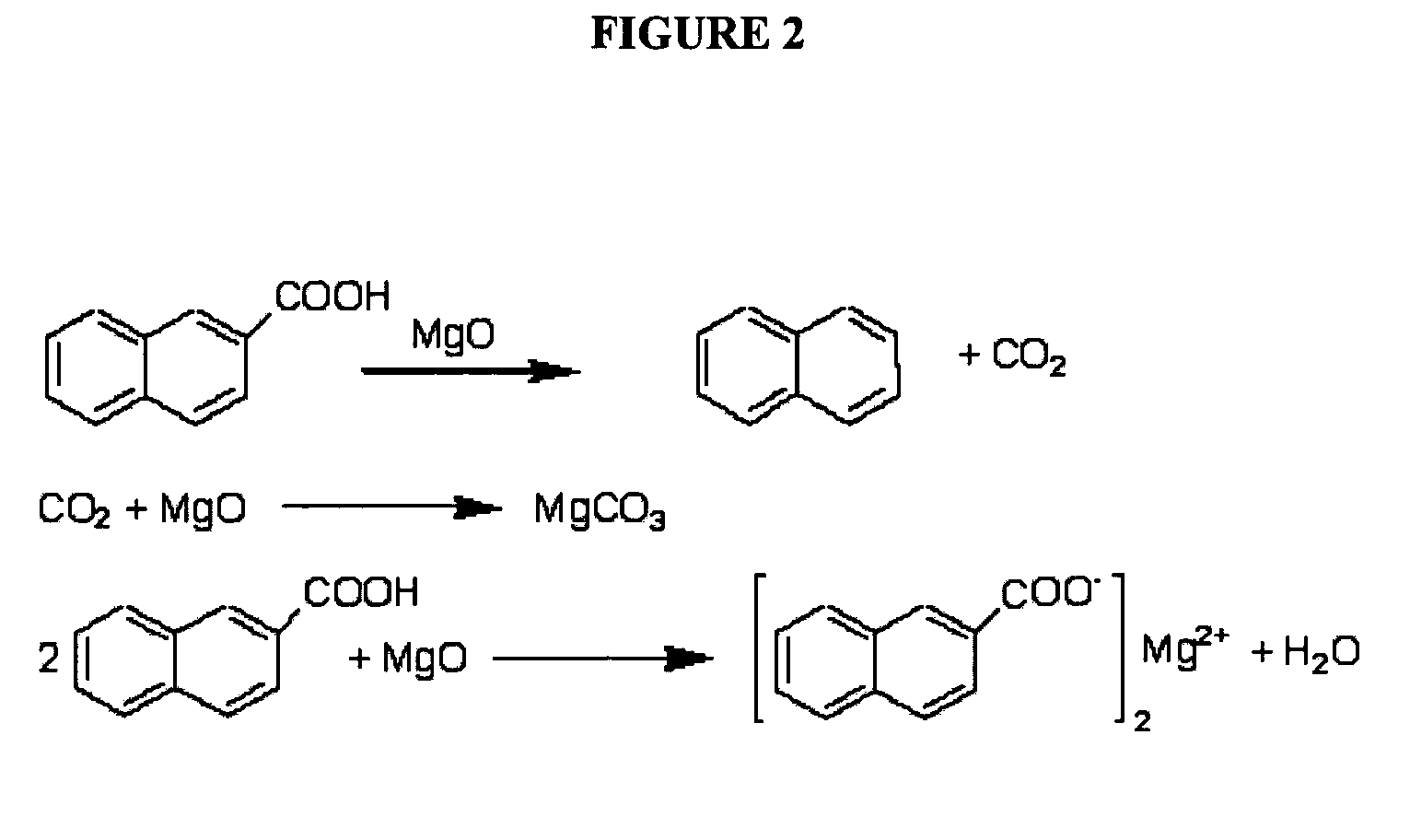

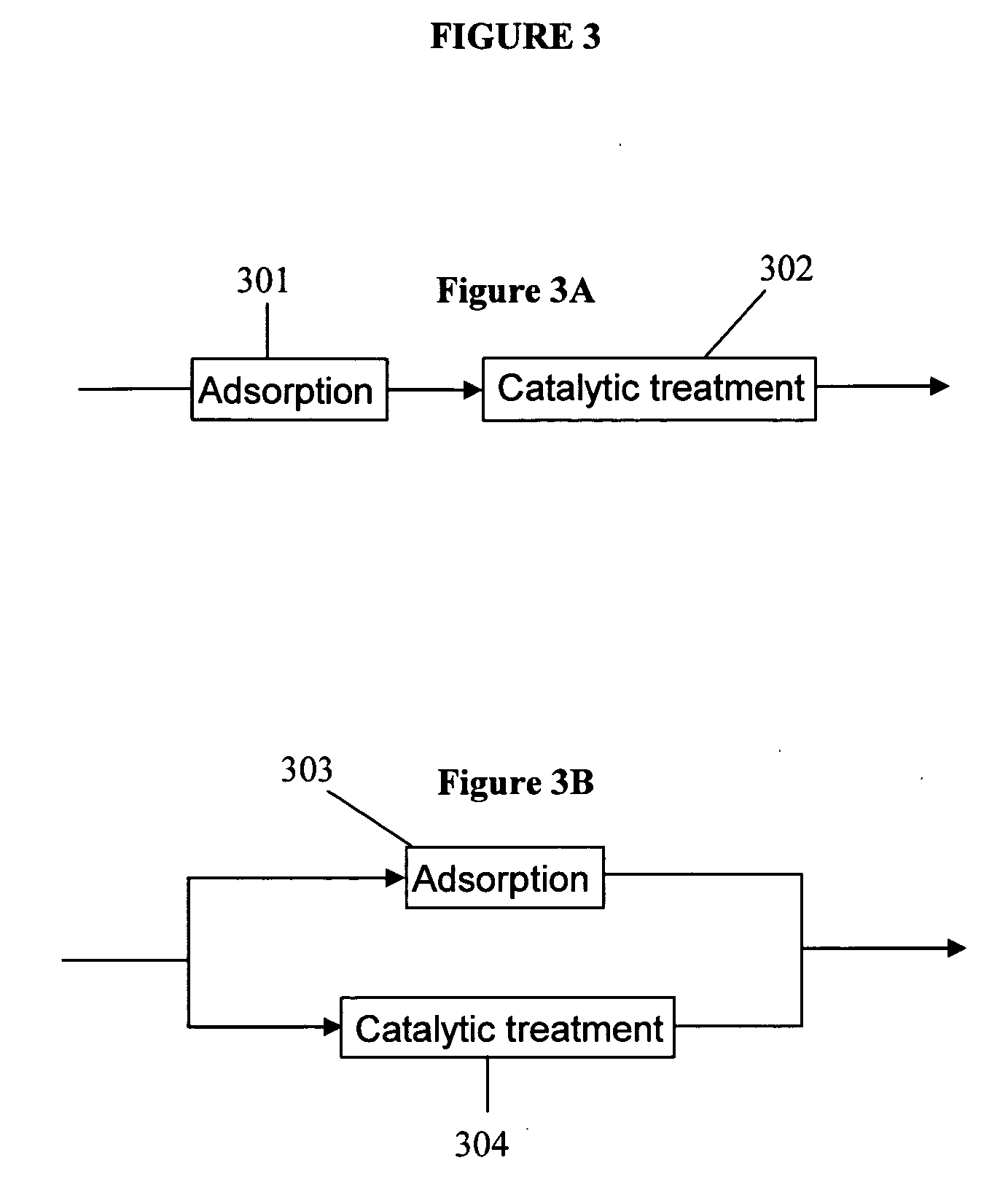

Process to upgrade oil using metal oxides

InactiveUS20060016723A1Reduce acidityReduce the numberRefining with metalsLiquid organic insulatorsHydrocotyle bowlesioidesCarboxylic acid

Described herein are compositions and methods for using metal oxides to upgrade oil. Metal oxides may be used as catalysts to reduce the TAN of the oil by converting carboxylic acids such as naphthenic acids into non-corrosive products. In some cases, the conversion occurs by a decarboxylation of the carboxylic acid to produce CO2. A second process promoted by metal oxides is hydrocarbon cracking. Cracking decreases the viscosity and increases the API, and produces lower molecular-weight hydrocarbons that are useful for many fuels and lubricants. Reductions in TAN and the increases in API improve the quality of increase the value of oil.

Owner:CALIFORNIA INST OF TECH

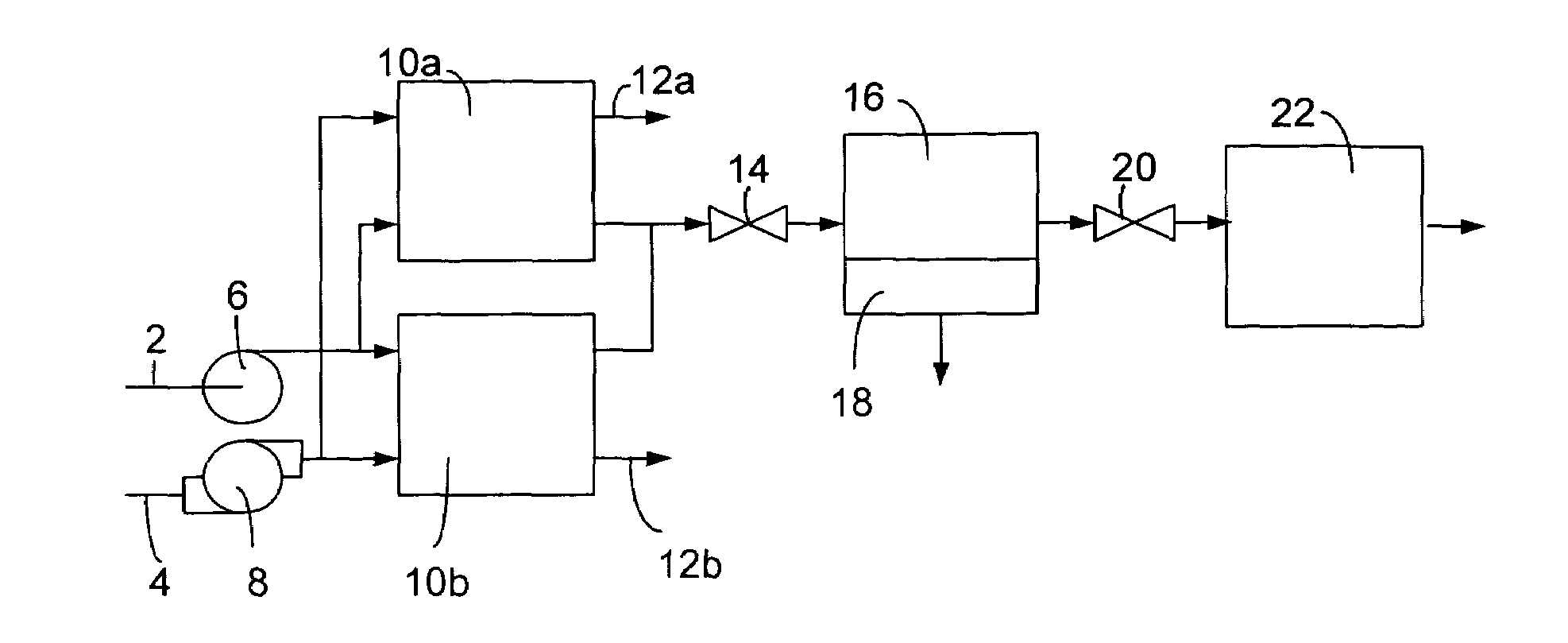

Method for desulfurizing a fuel for use in a fuel cell power plant

A fuel processing system is operable to remove substantially all of the sulfur present in an undiluted hydrocarbon fuel stock supply used to power a fuel cell power plant in a mobile environment, such as an automobile, bus, truck, boat, or the like, or in a stationary environment. The power plant hydrogen fuel source can be gasoline, diesel fuel, naphtha, light hydrocarbon fuels such as butane, propane, natural gas, or other like fuels which contain relatively high levels of organic sulfur compounds such as mercaptans, sulfides, disulfides, and the like. The undiluted hydrocarbon fuel supply is passed through a nickel desulfurizer bed wherein essentially all of the sulfur in the organic sulfur compounds react with the nickel reactant, and are converted to nickel sulfide while the desulfurized organic remnants continue through the remainder of the fuel processing system. The system does not require the addition of steam or a hydrogen source to the fuel stream prior to the desulfurizing step. The system operates at relatively low temperatures and can be used to desulfurize either a liquid or a gaseous fuel stream.

Owner:UNITED TECH CORP

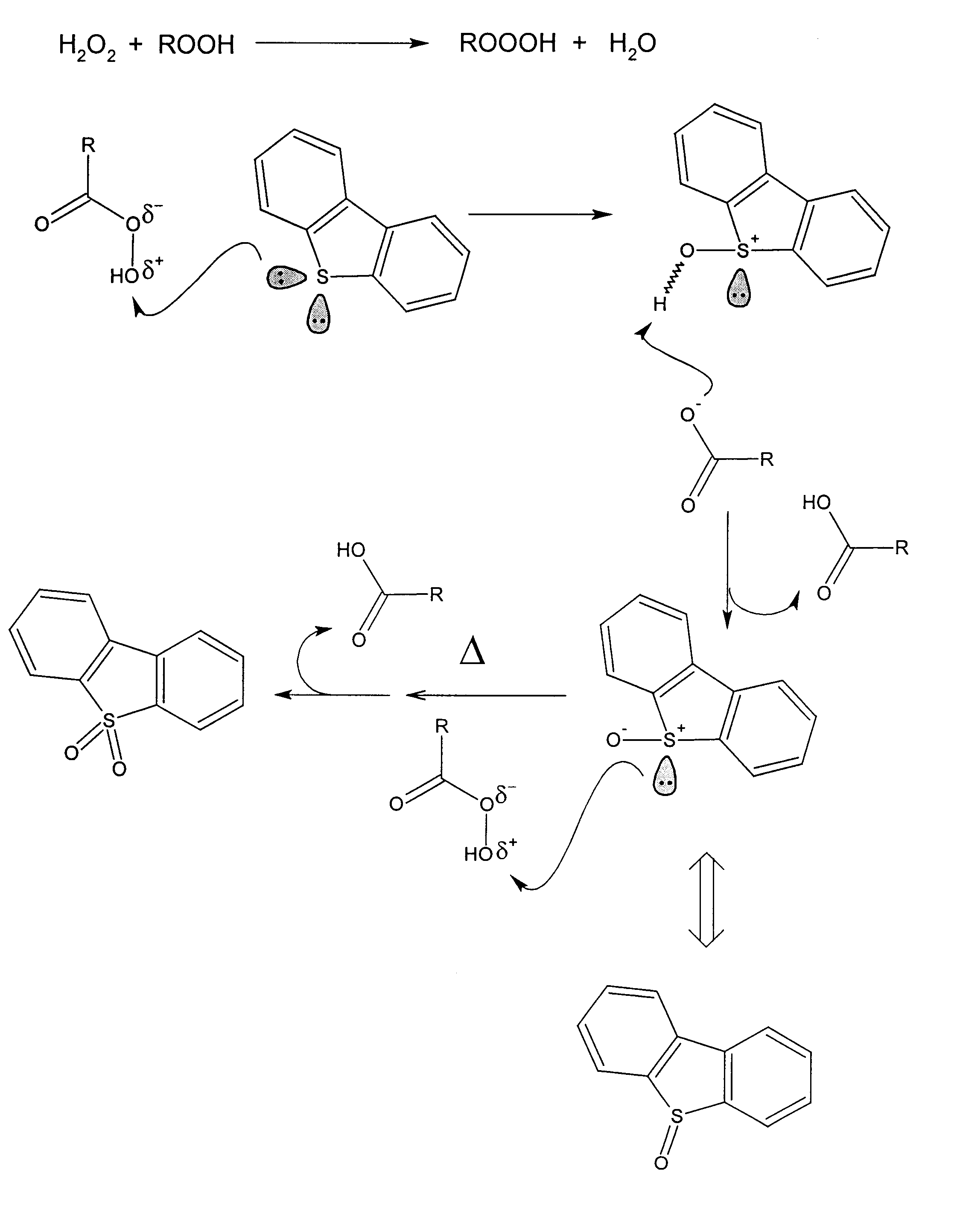

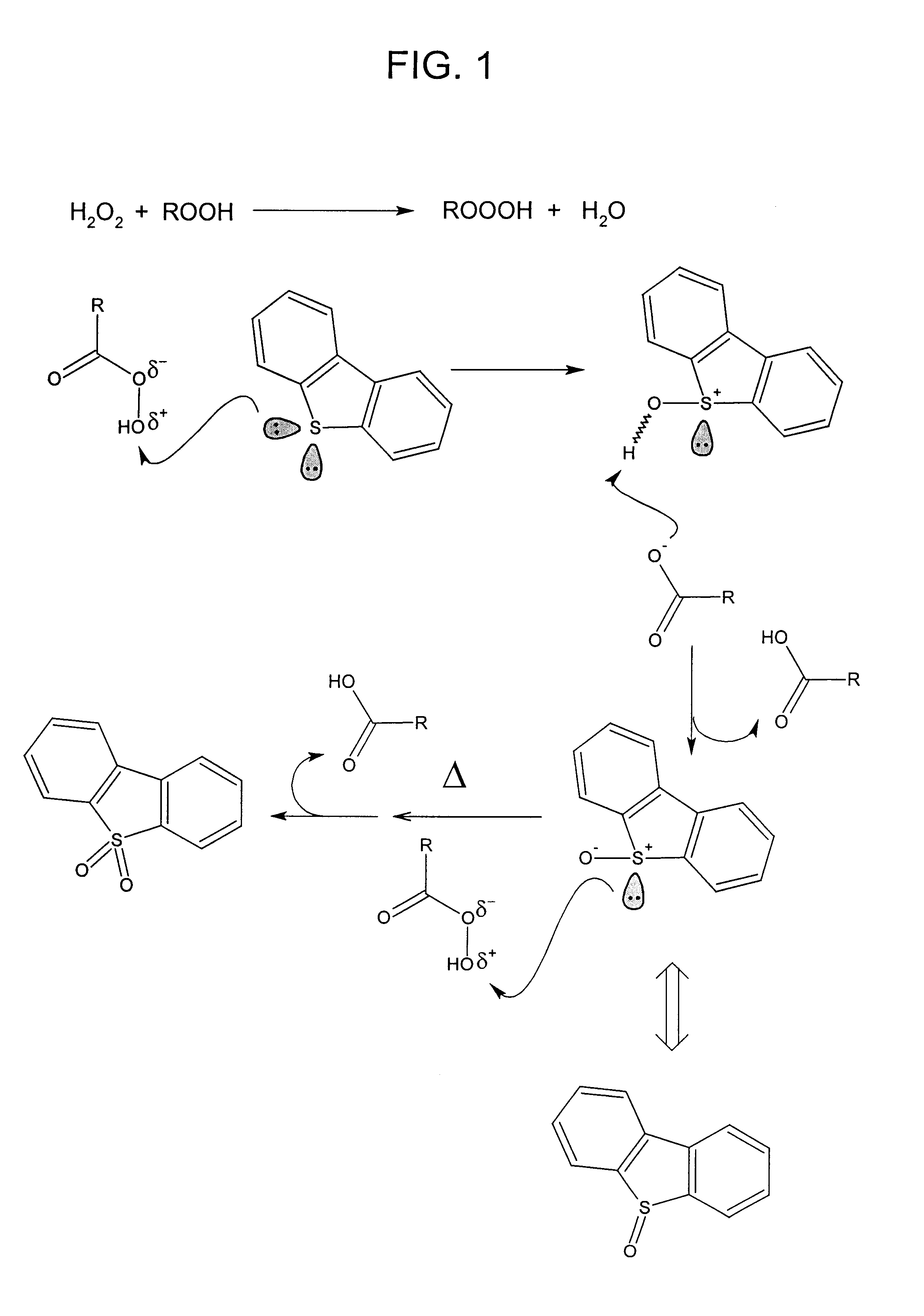

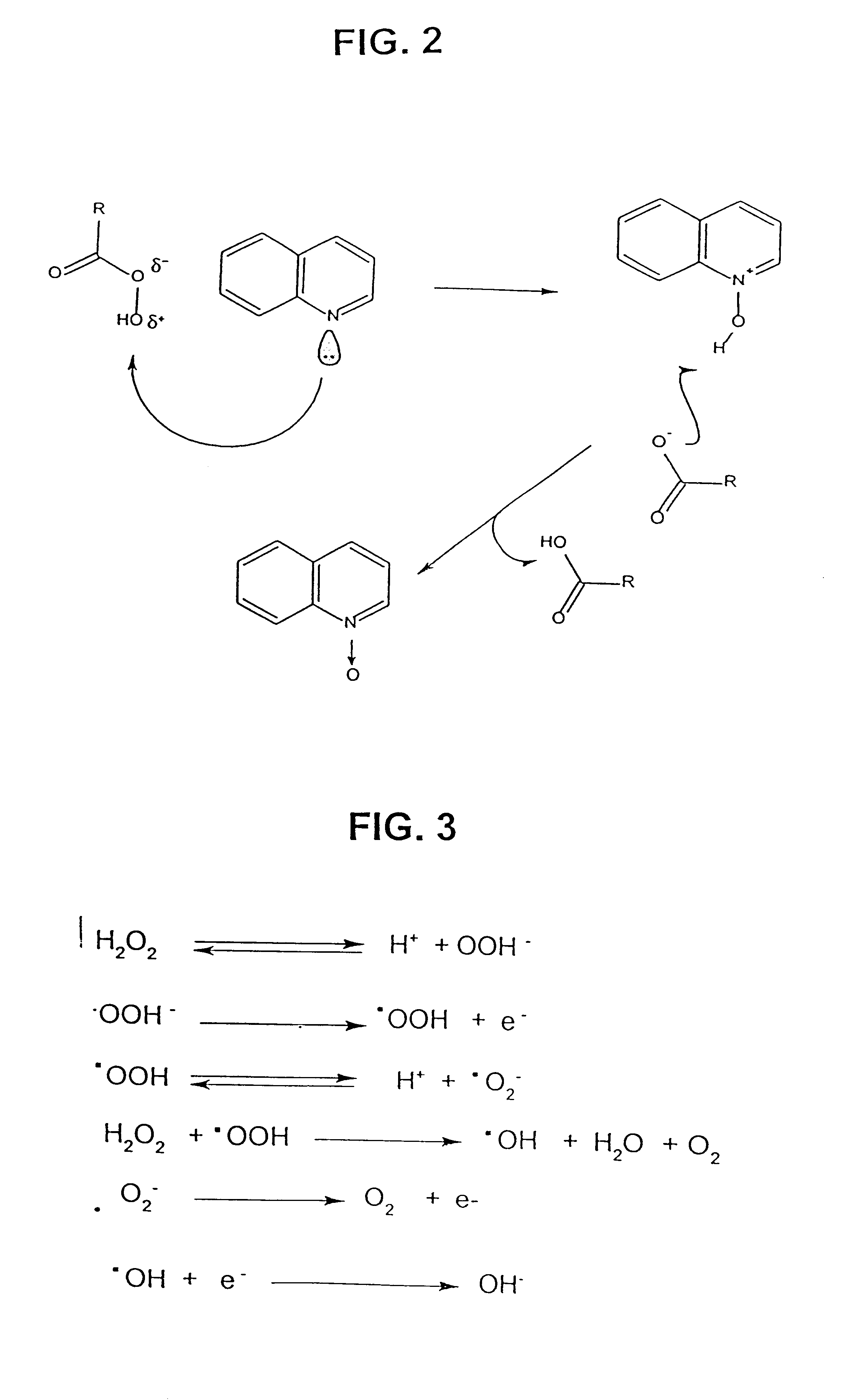

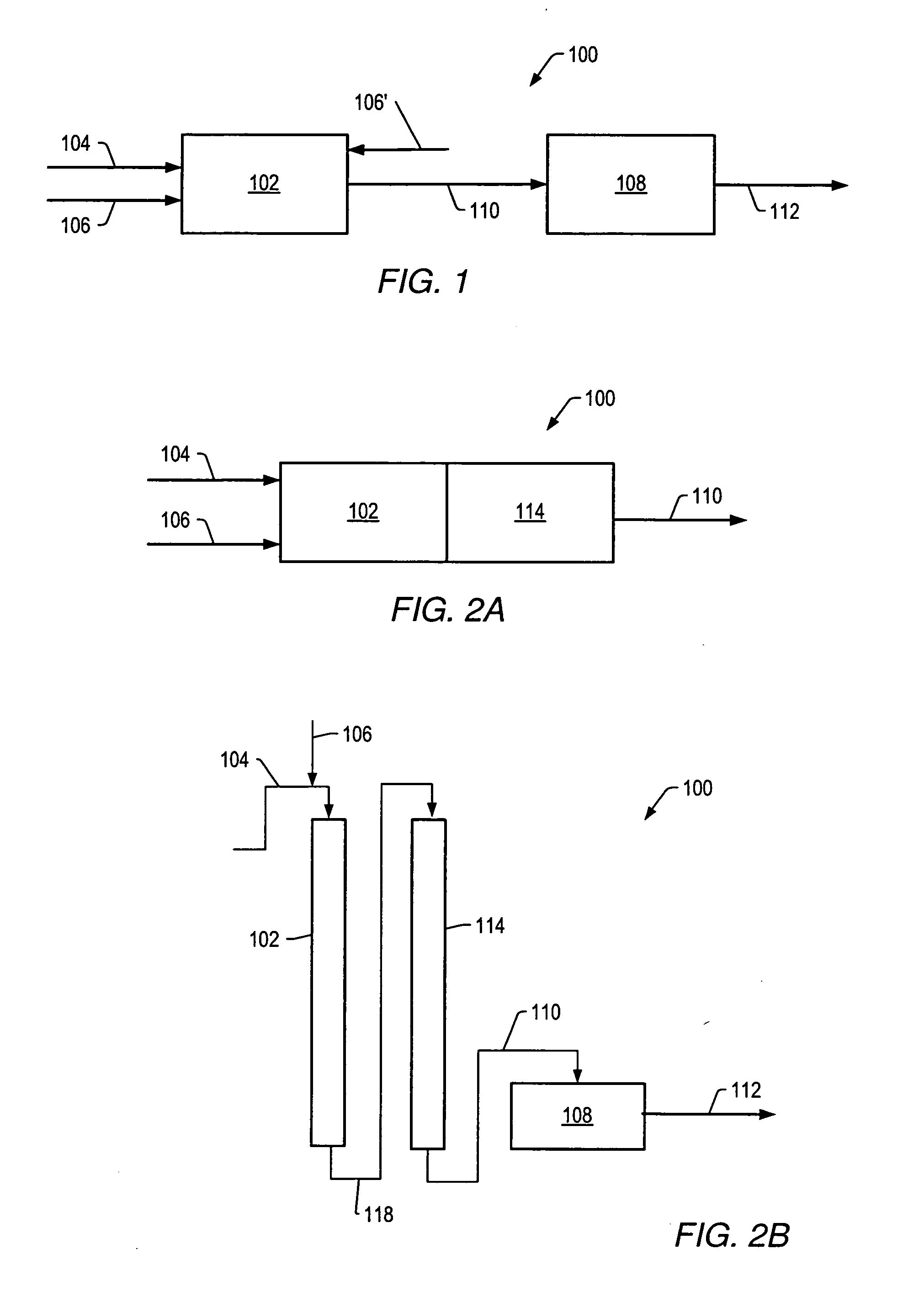

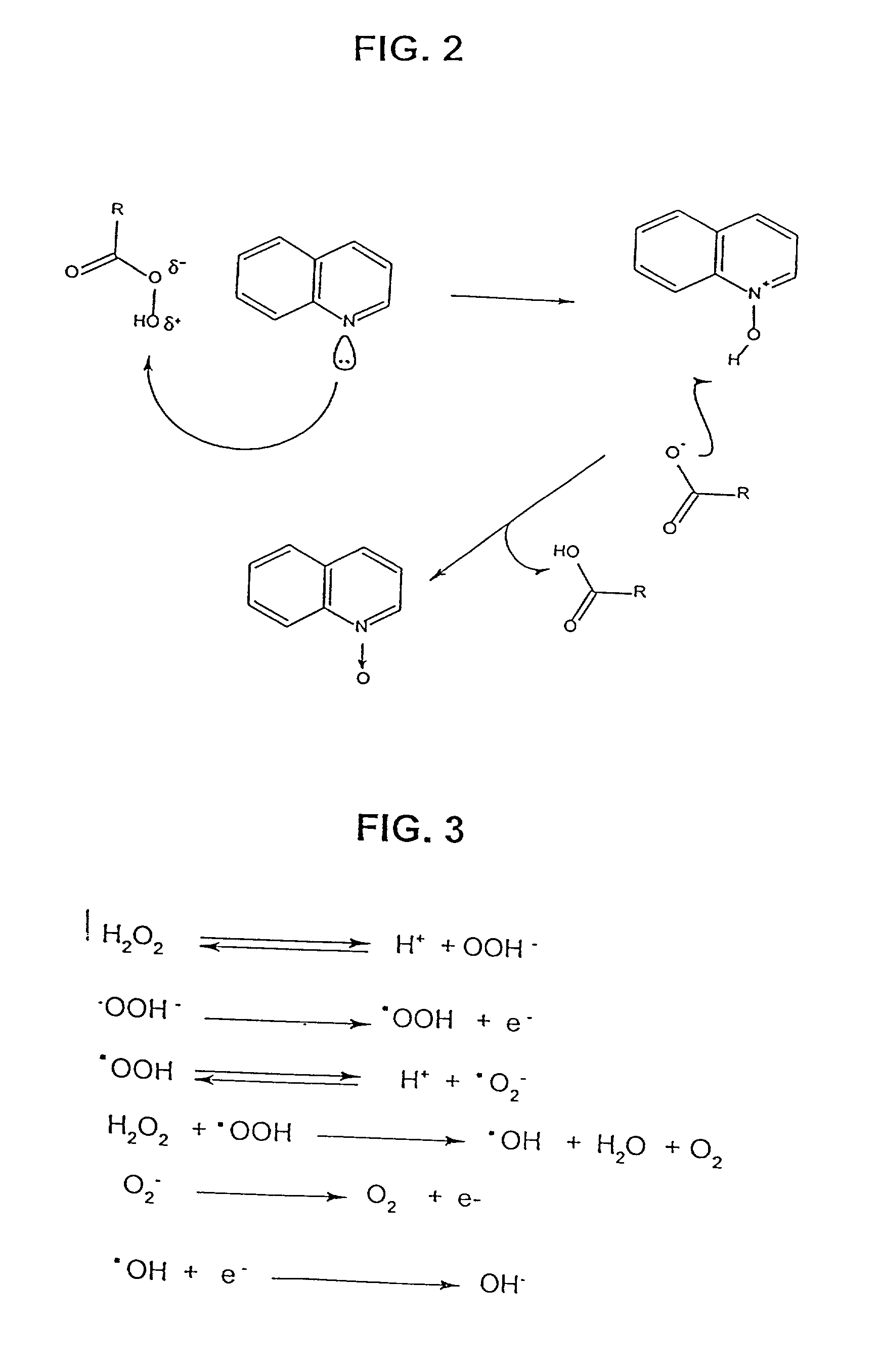

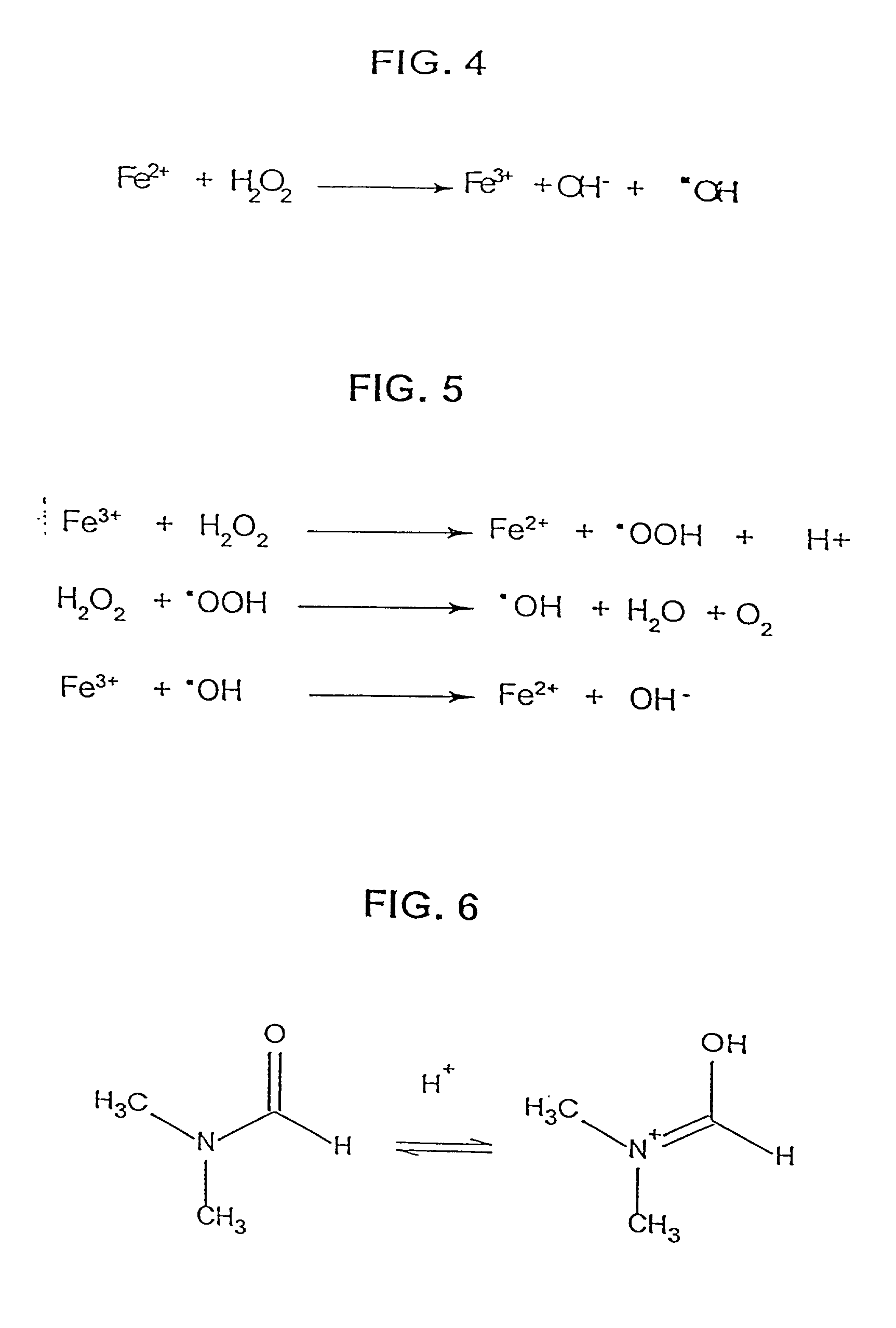

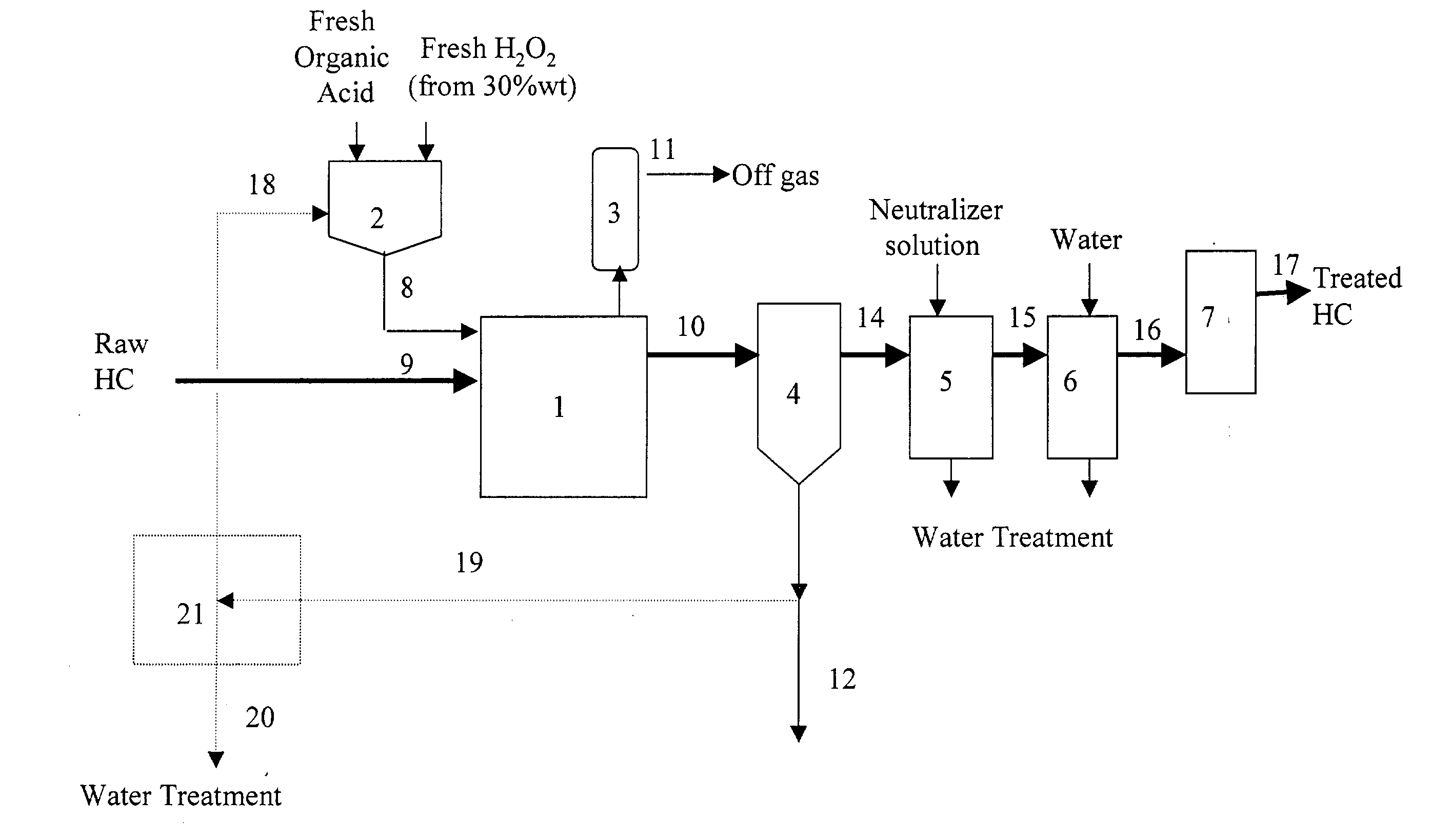

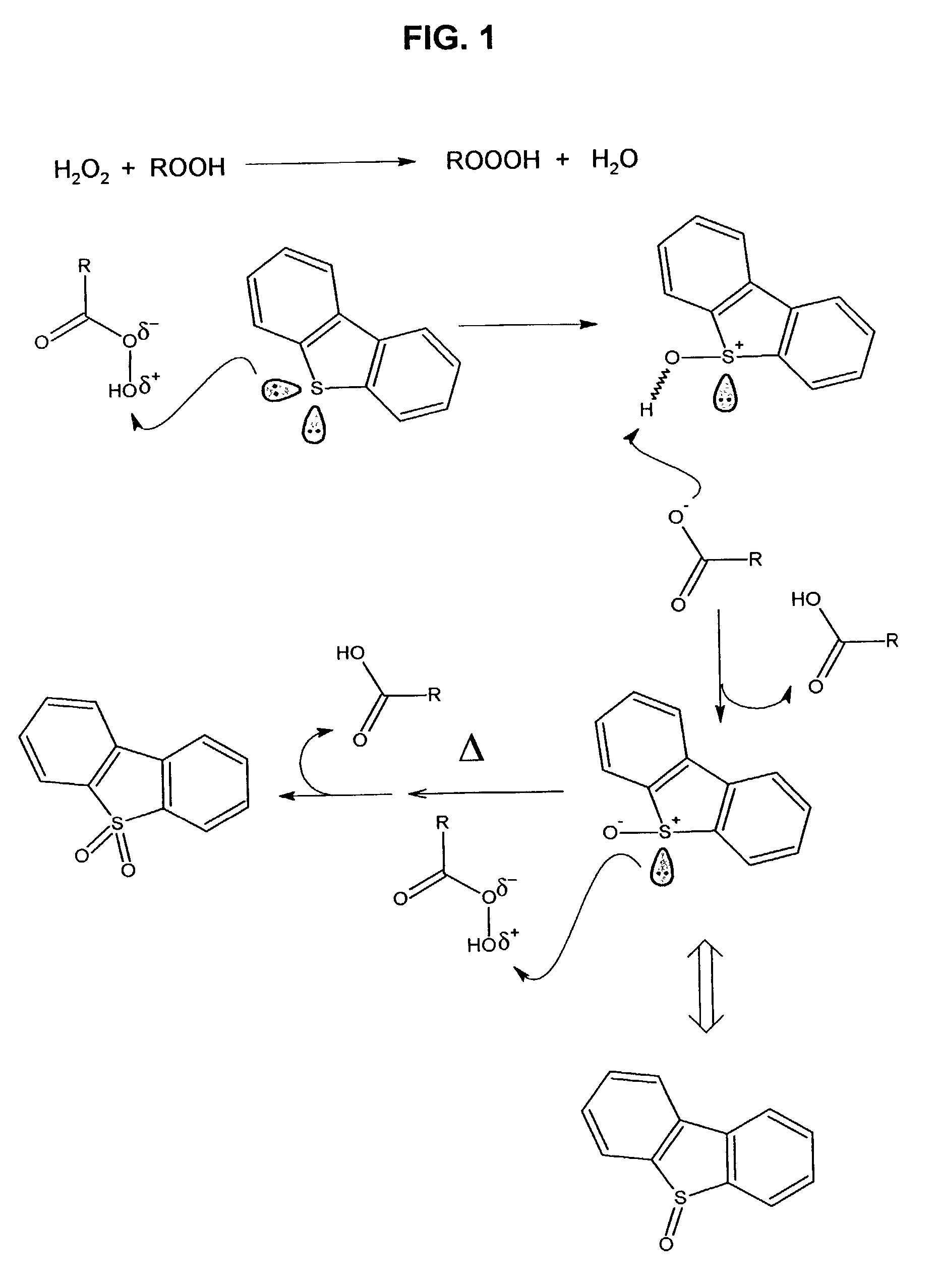

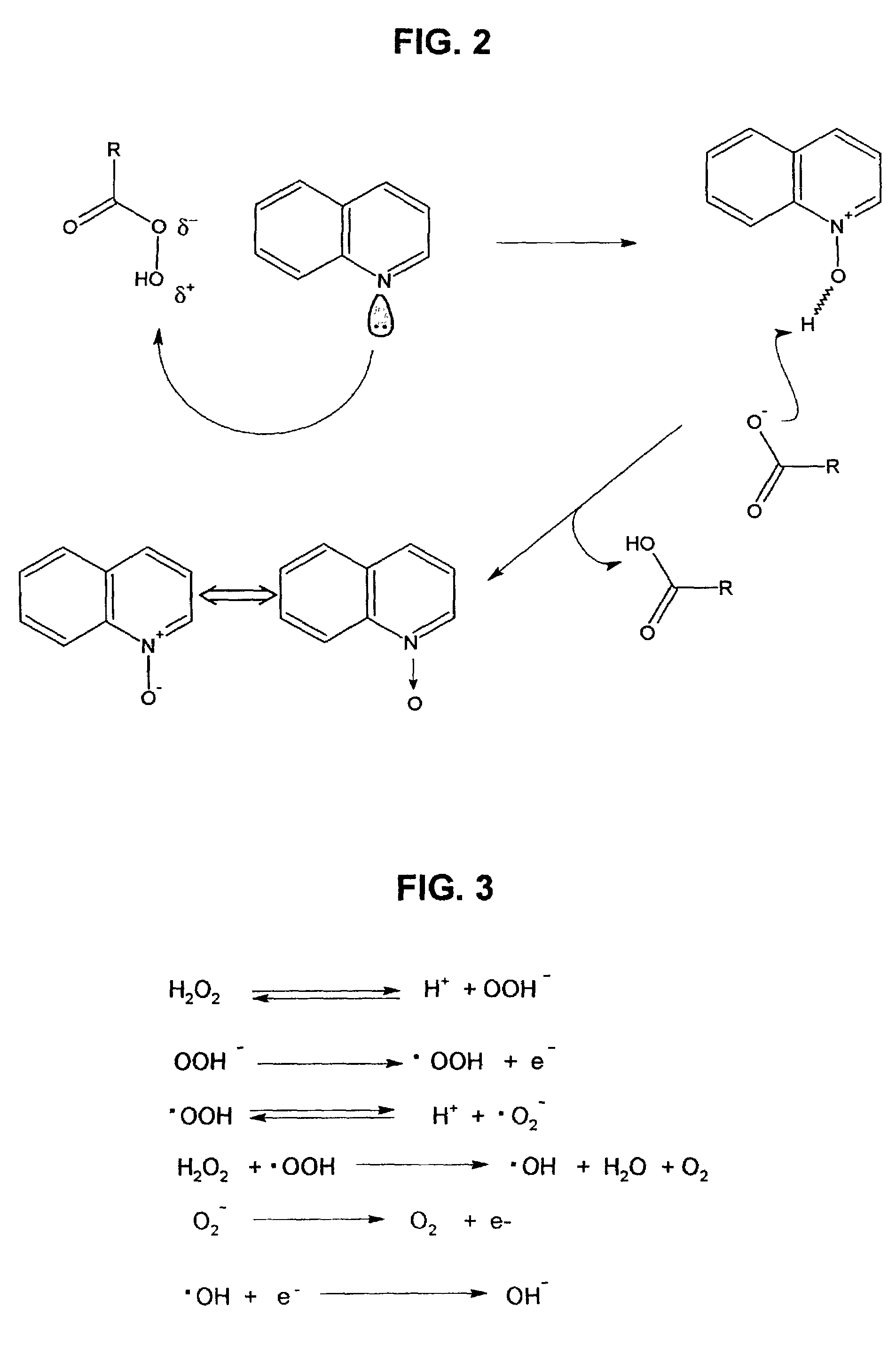

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxyacid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Systems, methods, and catalysts for producing a crude product

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed may include at least 0.1 grams of vacuum gas oil per gram of crude feed. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product may have a vacuum gas oil content of about 30% to about 70% of the vacuum gas oil content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Systems, methods, and catalysts for producing a crude product

Methods and systems for contacting of a crude feed with one or more catalysts produces a total product that includes a crude product are described. At least one of the catalysts is an uncalcined catalyst. The crude product is a liquid mixture at 25° C. and 0.101 MPa. The crude product has a nitrogen content of at most 90% of the nitrogen content of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

Catalytic filtering of a Fischer-Tropsch derived hydrocarbon stream

InactiveUS7150823B2Avoid cloggingRefining with metalsPhysical/chemical process catalystsParticulatesUltra fine

Novel methods of treating a Fischer-Tropsch derived hydrocarbon stream with an active filtering catalyst are disclosed. Such methods are capable of removing soluble (and ultra-fine particulate) contamination, fouling agents, and / or plugging precursors from the Fischer-Tropsch derived hydrocarbon stream such that plugging of the catalyst beds of a subsequent hydroprocessing process is substantially avoided.

Owner:CHEVROU USA INC

Oxidative Desulfurization Process

InactiveUS20080308463A1Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurNitrogen

Disclosed is a process which reduces the sulfur and / or nitrogen content of a distillate feedstock to produce a refinery transportation fuel or blending components for refinery transportation fuel, by contacting the feedstock with an oxygen-containing gas in an 5 oxidation / adsorption zone at oxidation conditions in the presence of an oxidation catalyst comprising a titanium-containing composition whereby the sulfur species are converted to sulfones and / or sulfoxides which are adsorbed onto the titanium-containing composition.

Owner:BP CORP NORTH AMERICA INC

Process for preparing bitumen compositions with reduced hydrogen sulfide emission

InactiveUS20050145137A1Reduce evolutionEmission reductionRefining with metalsRefining with metal saltsScavengerCadmium Cation

In methods of preparing asphalt including asphalt / elastomeric polymer compositions, it has been discovered that the emission or evolution of H2S can be reduced by adding certain H2S scavengers to the asphalt mixture, but that not every known H2S scavenger can be effective in this method. Particularly helpful H2S scavengers include inorganic metal salts. Suitable inorganic or organic metal salt H2S scavengers include, but are not necessarily limited to those where the metal of the salt is zinc, cadmium, mercury, copper, silver, nickel, platinum, iron, or magnesium, and mixtures of these salts.

Owner:FINA TECH

Thermal treatment of triglycerides

A triglyceride or a triglyceride / hydrocarbon combination can be heated to produce thermally treated feeds. The thermally treated feeds can then be contacted with a hydrotreating catalyst in a reaction zone.

Owner:PHILLIPS 66 CO

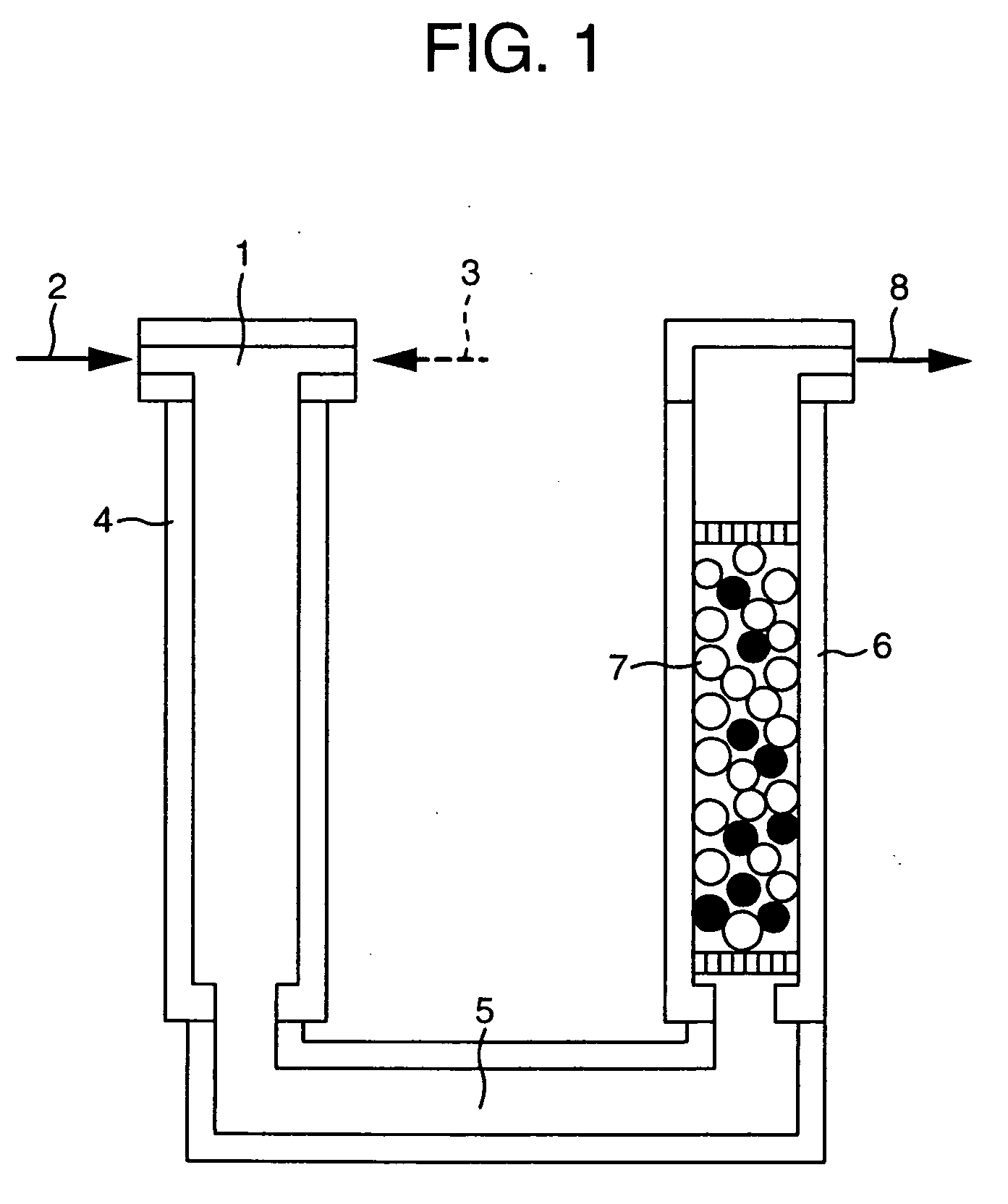

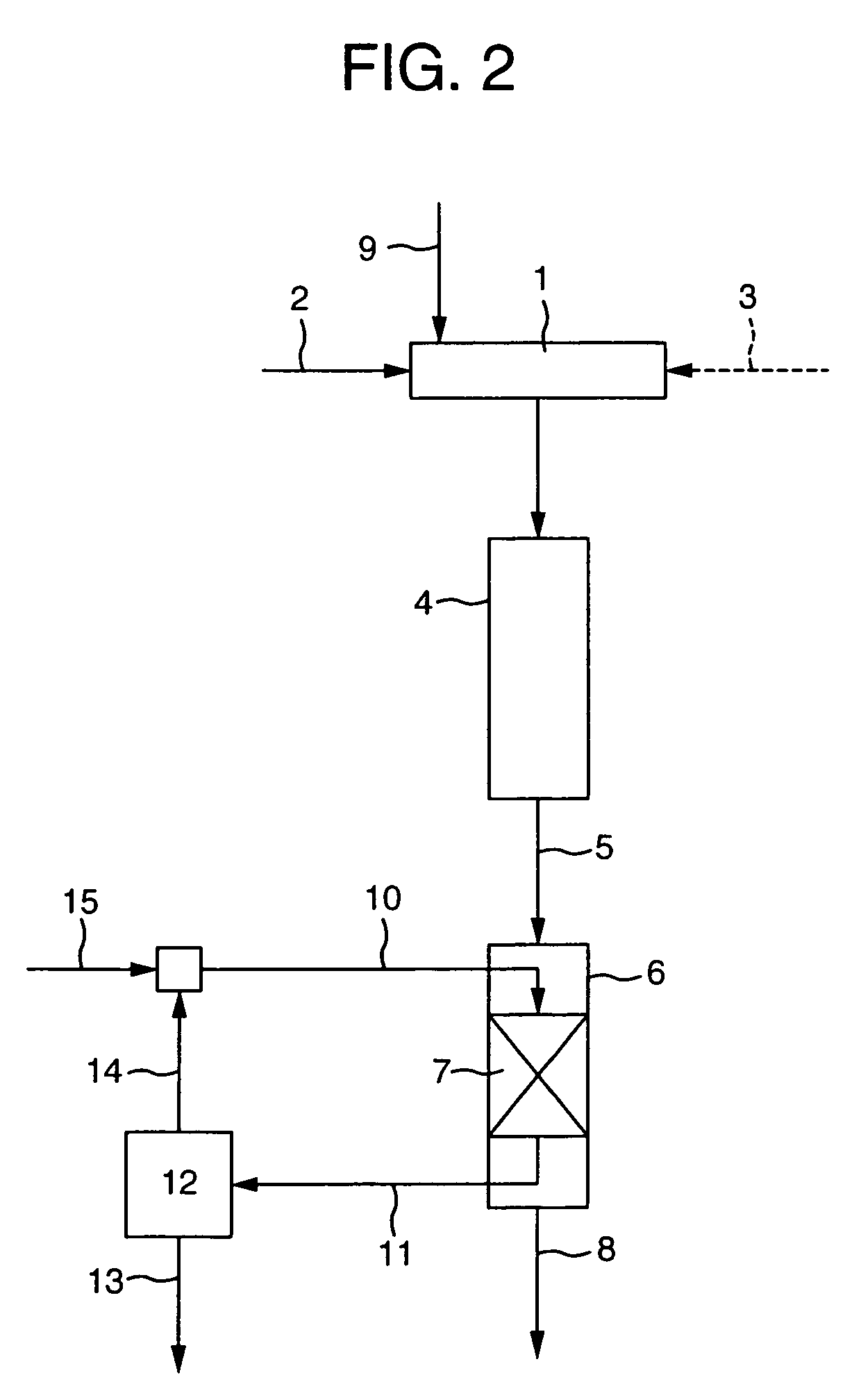

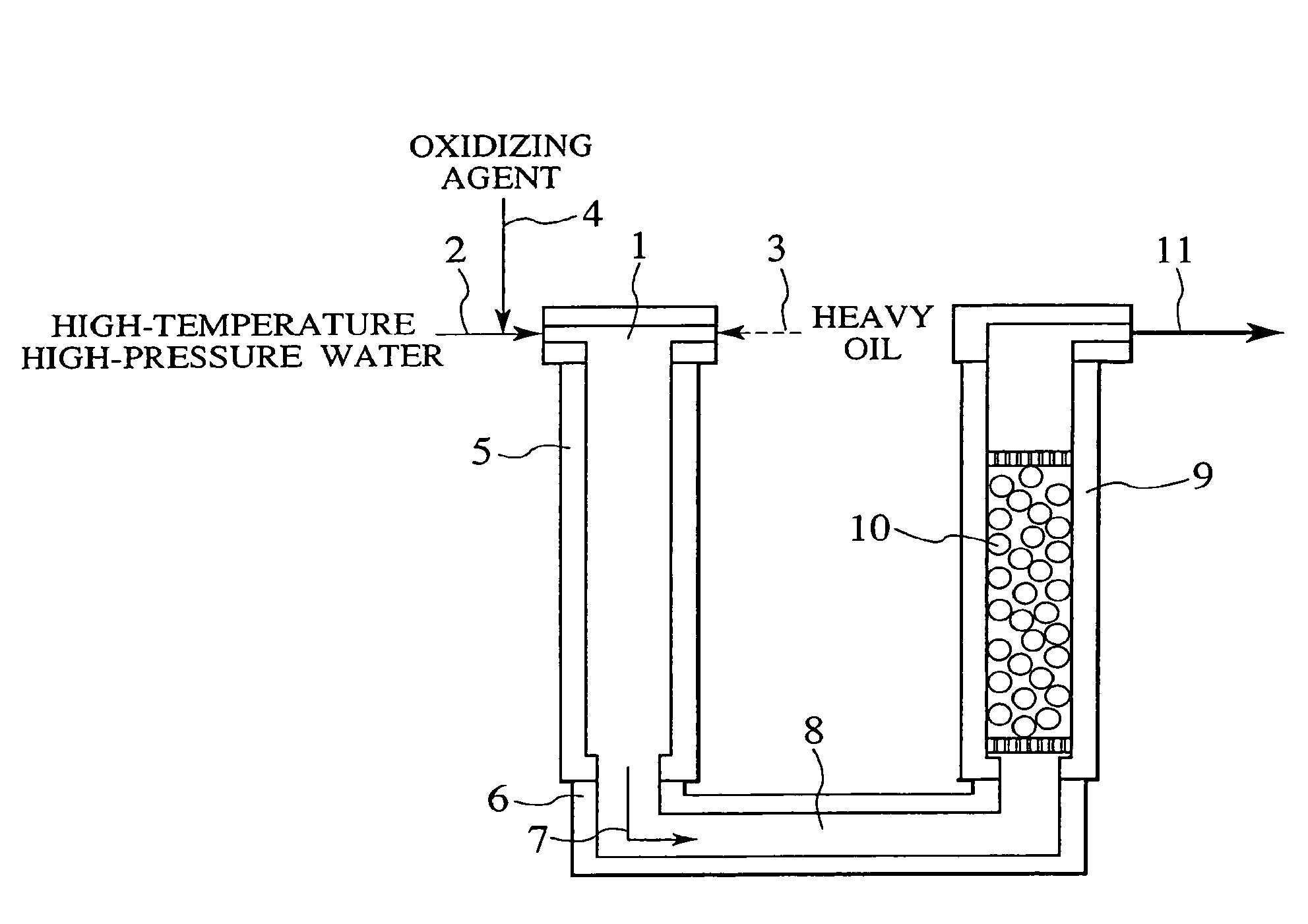

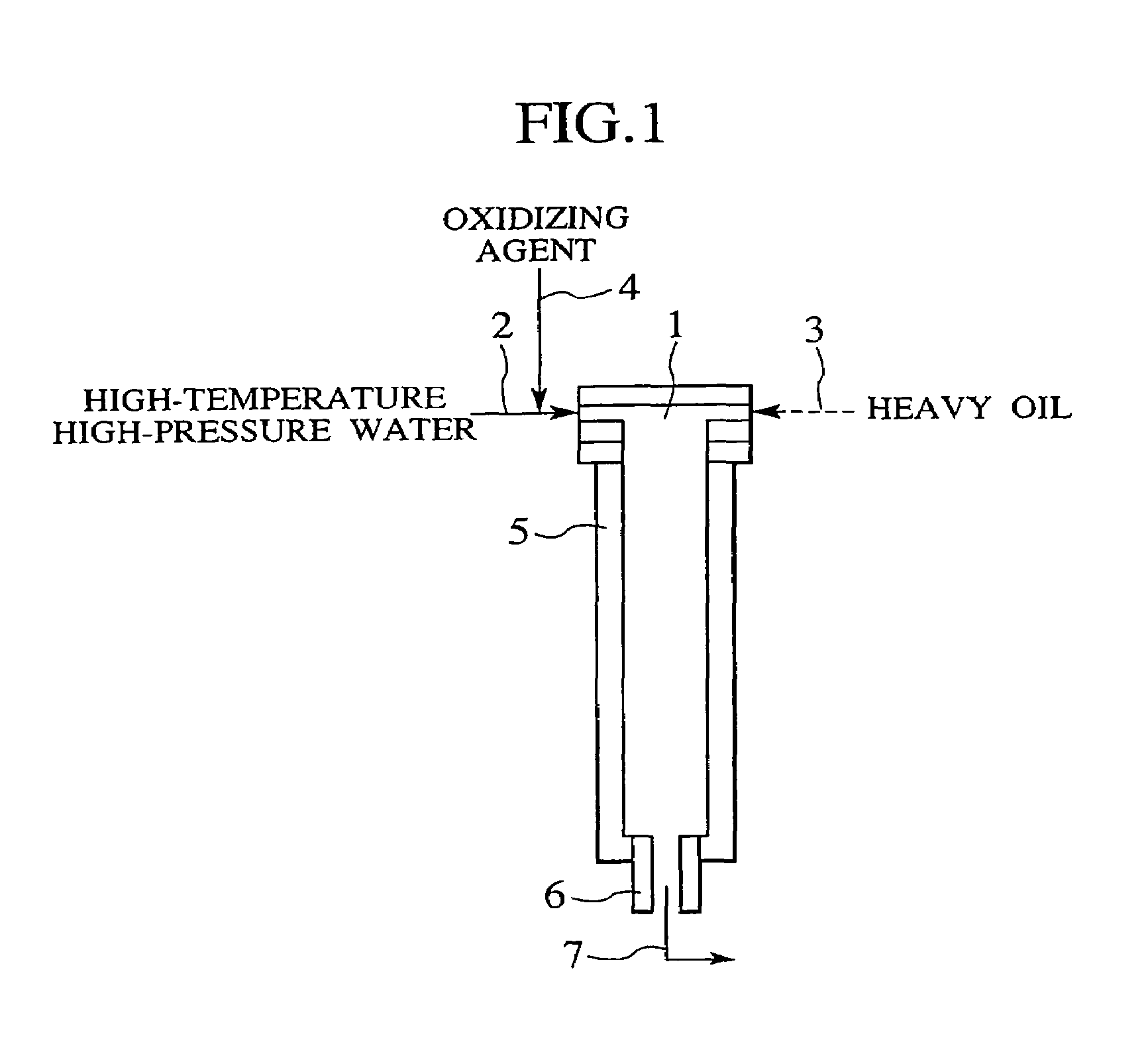

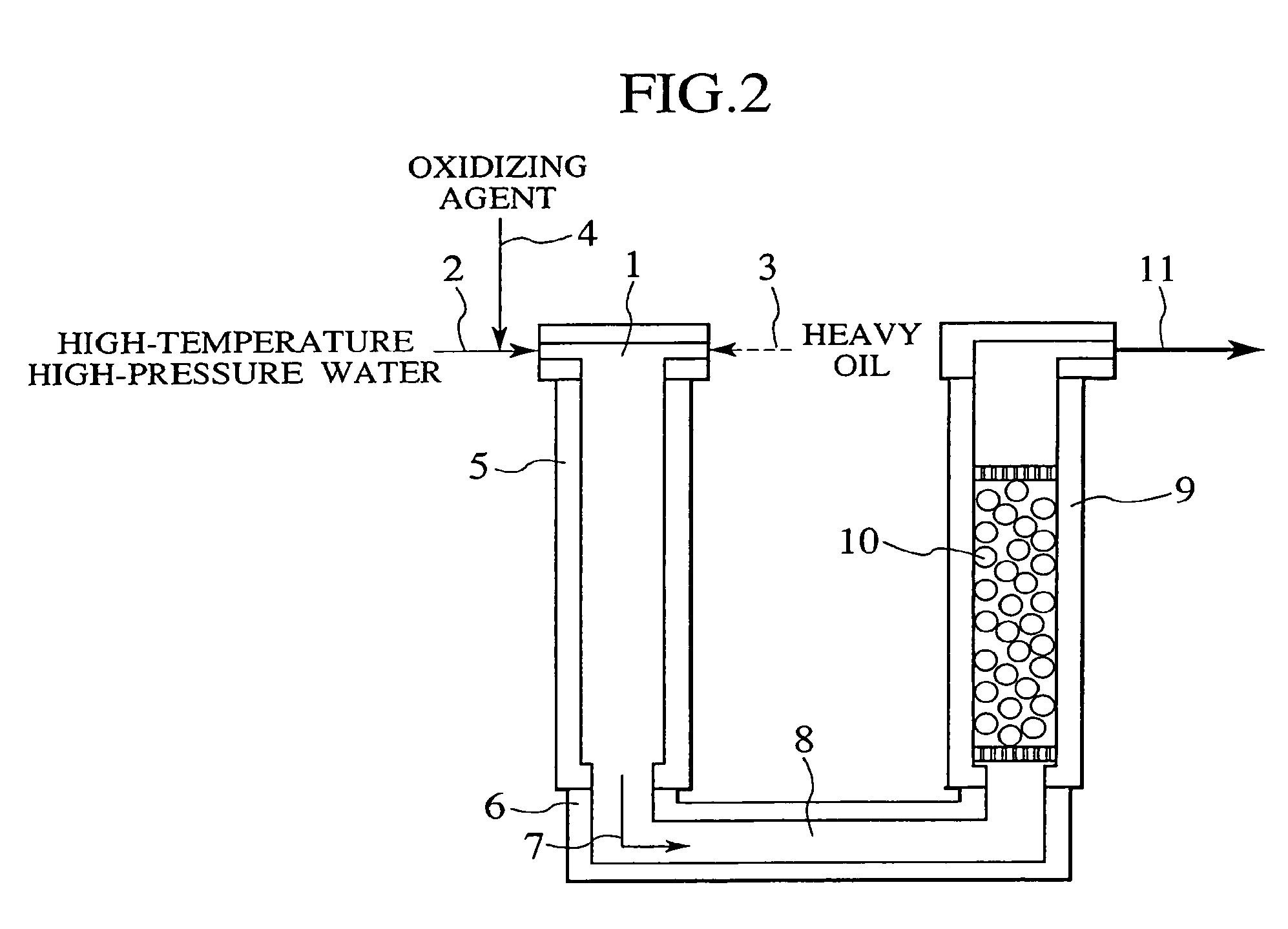

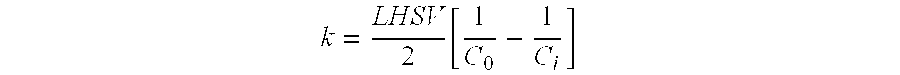

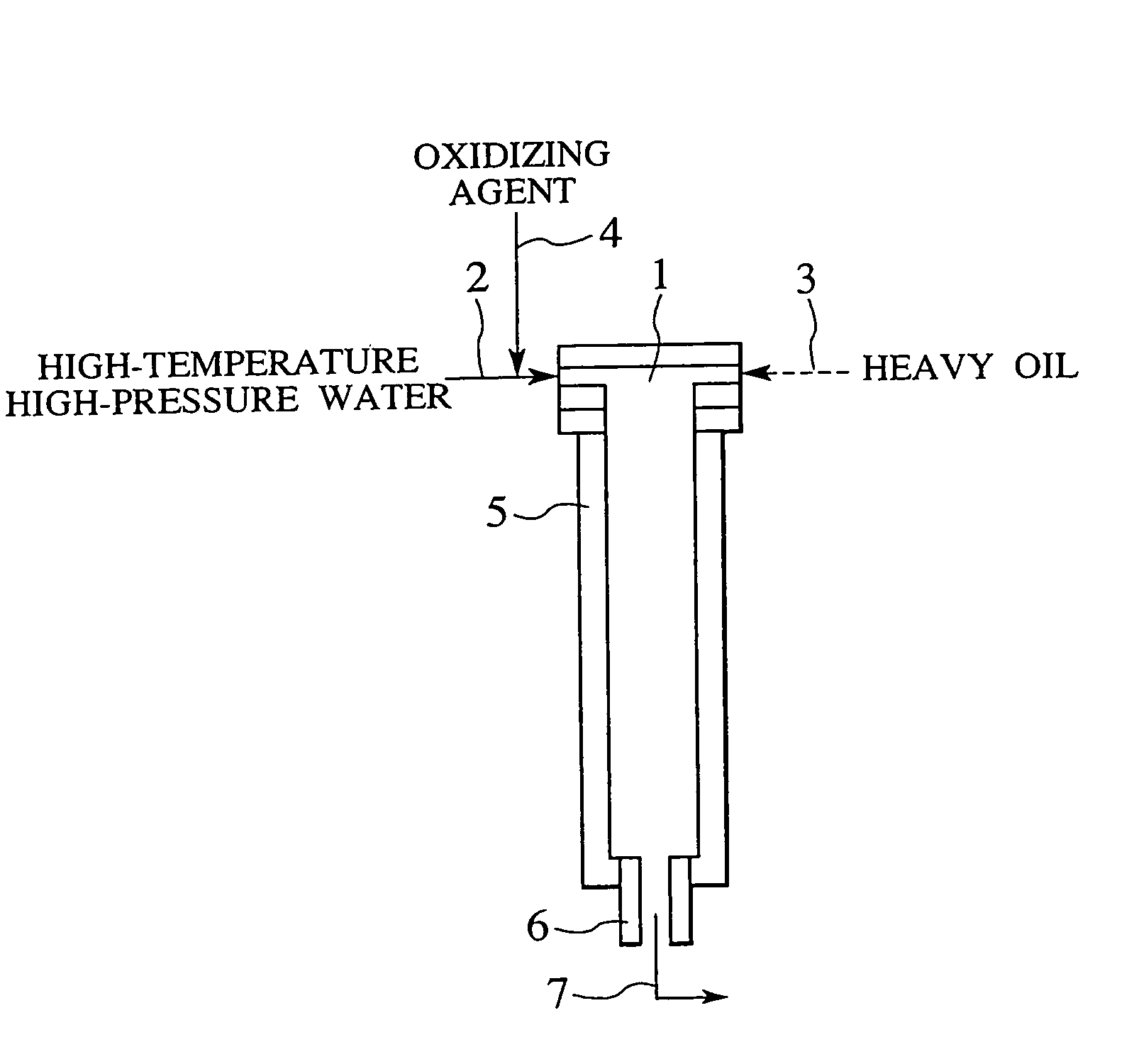

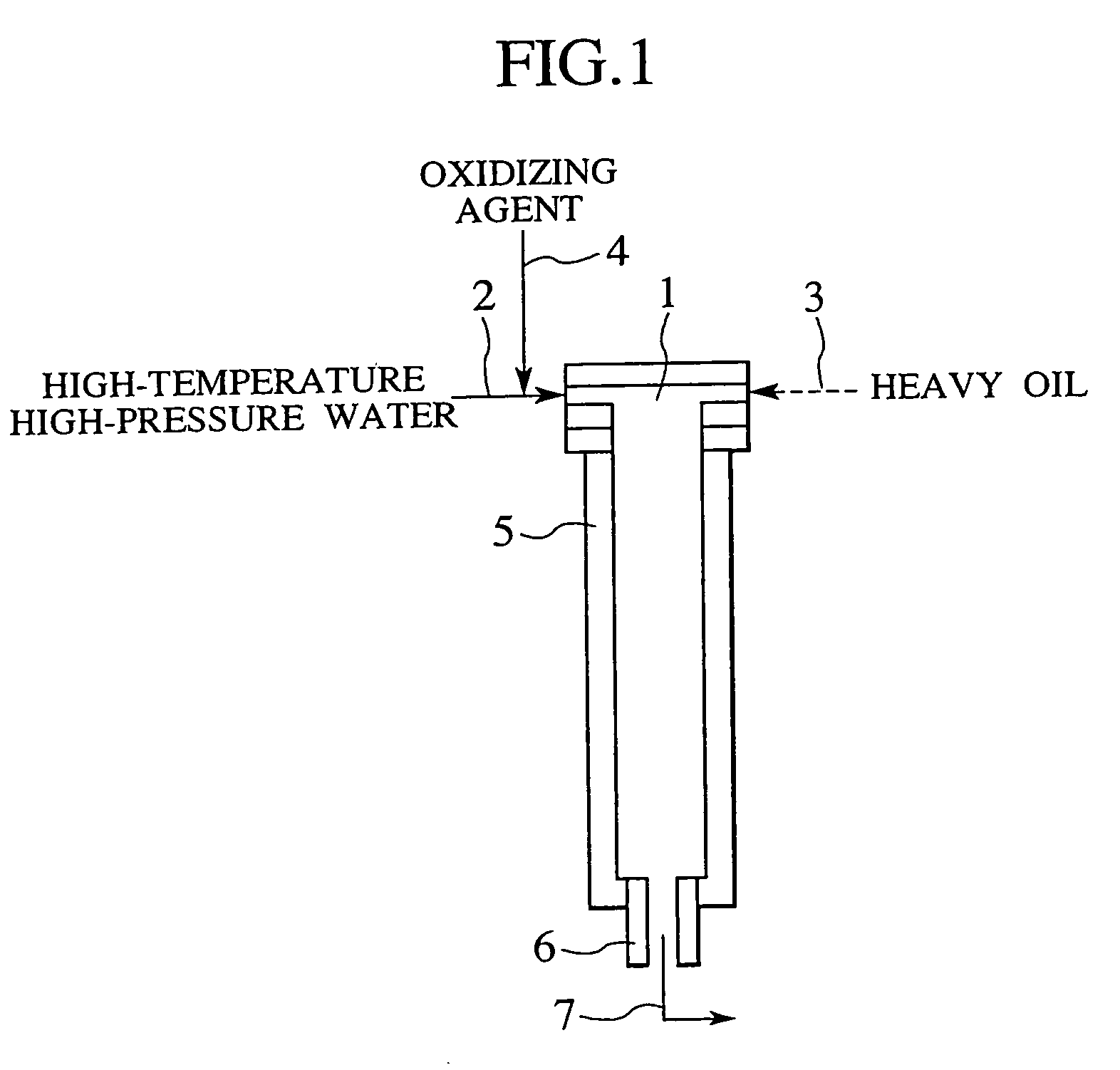

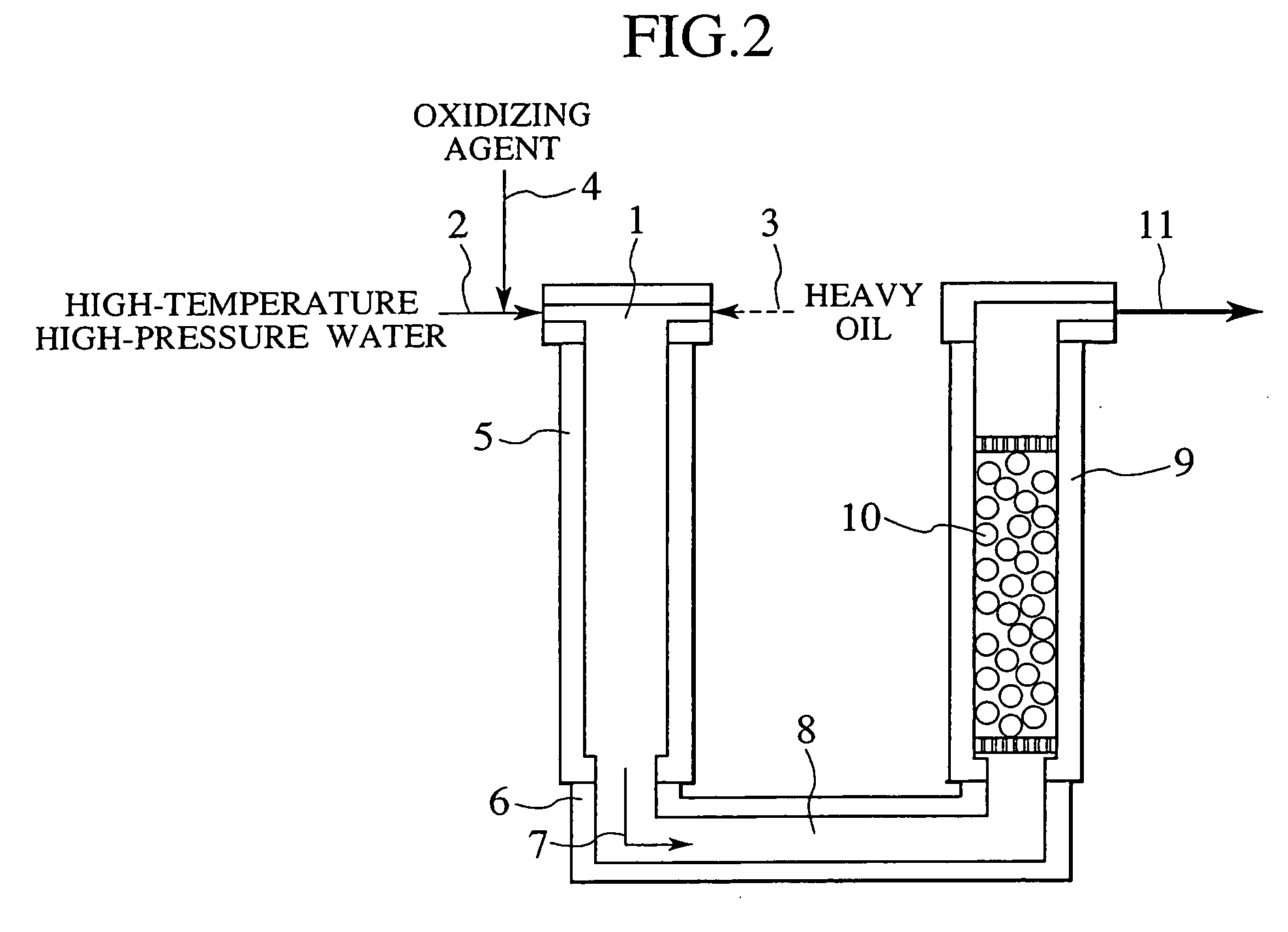

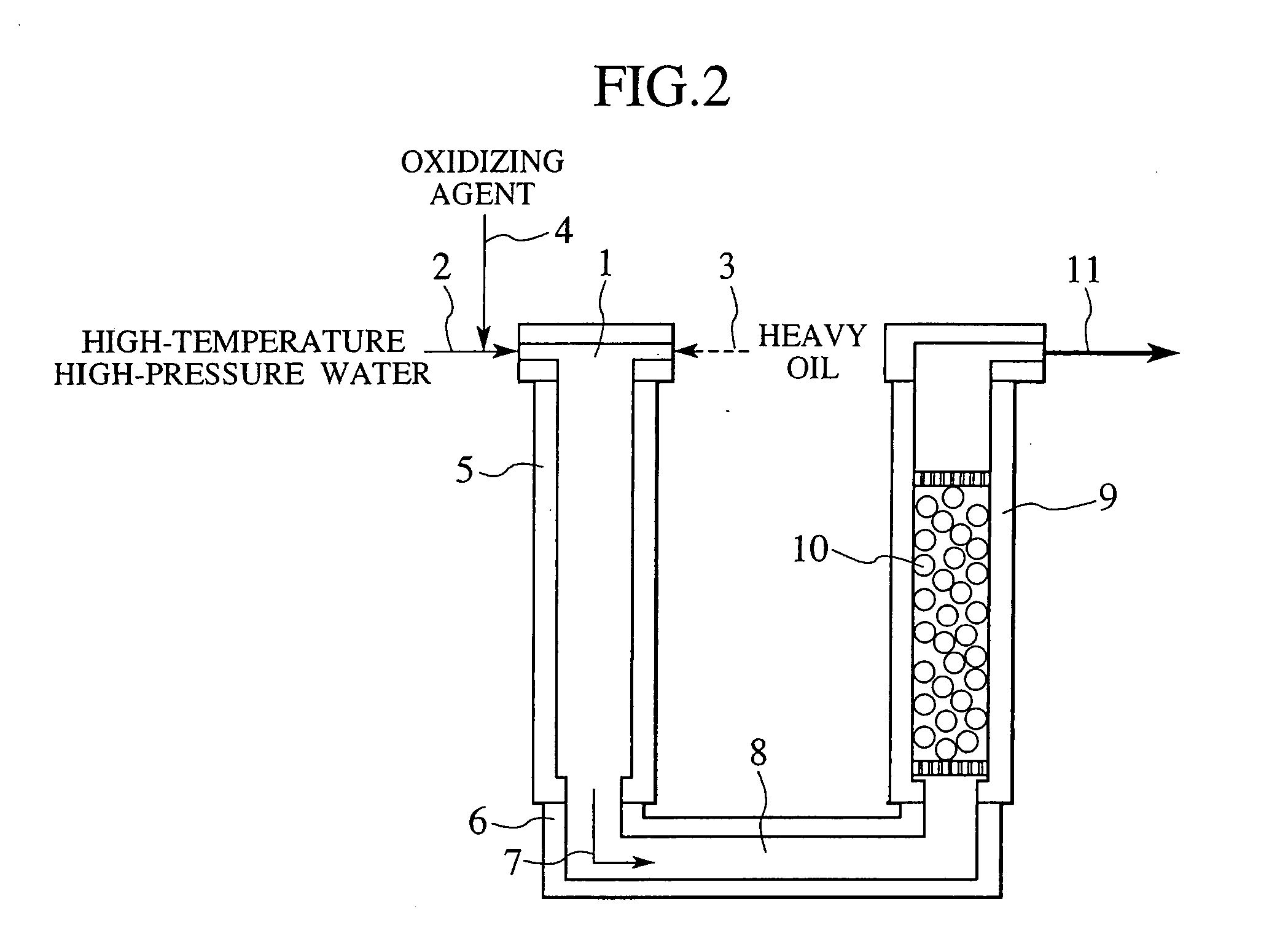

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS7264710B2Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercriticai water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

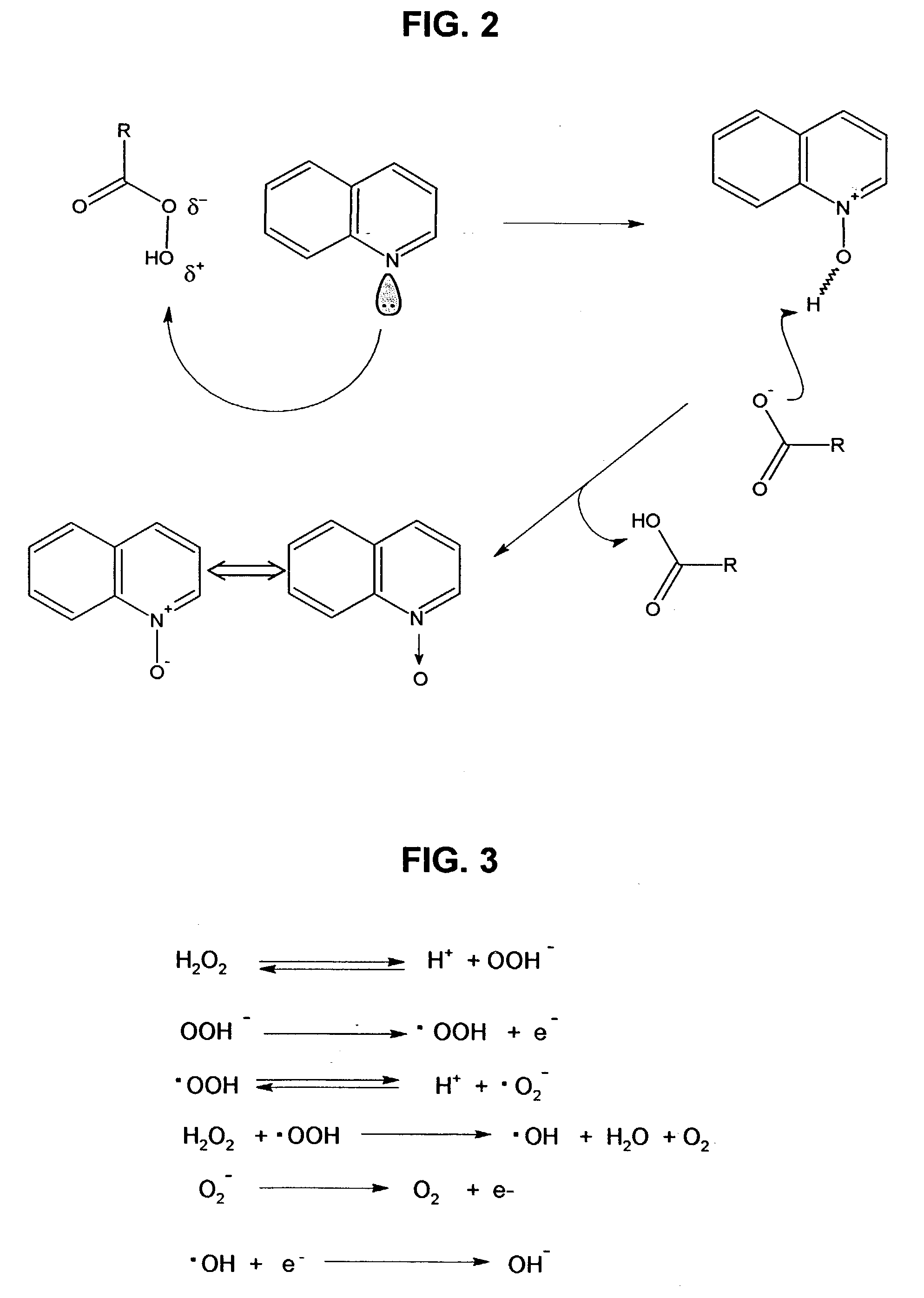

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

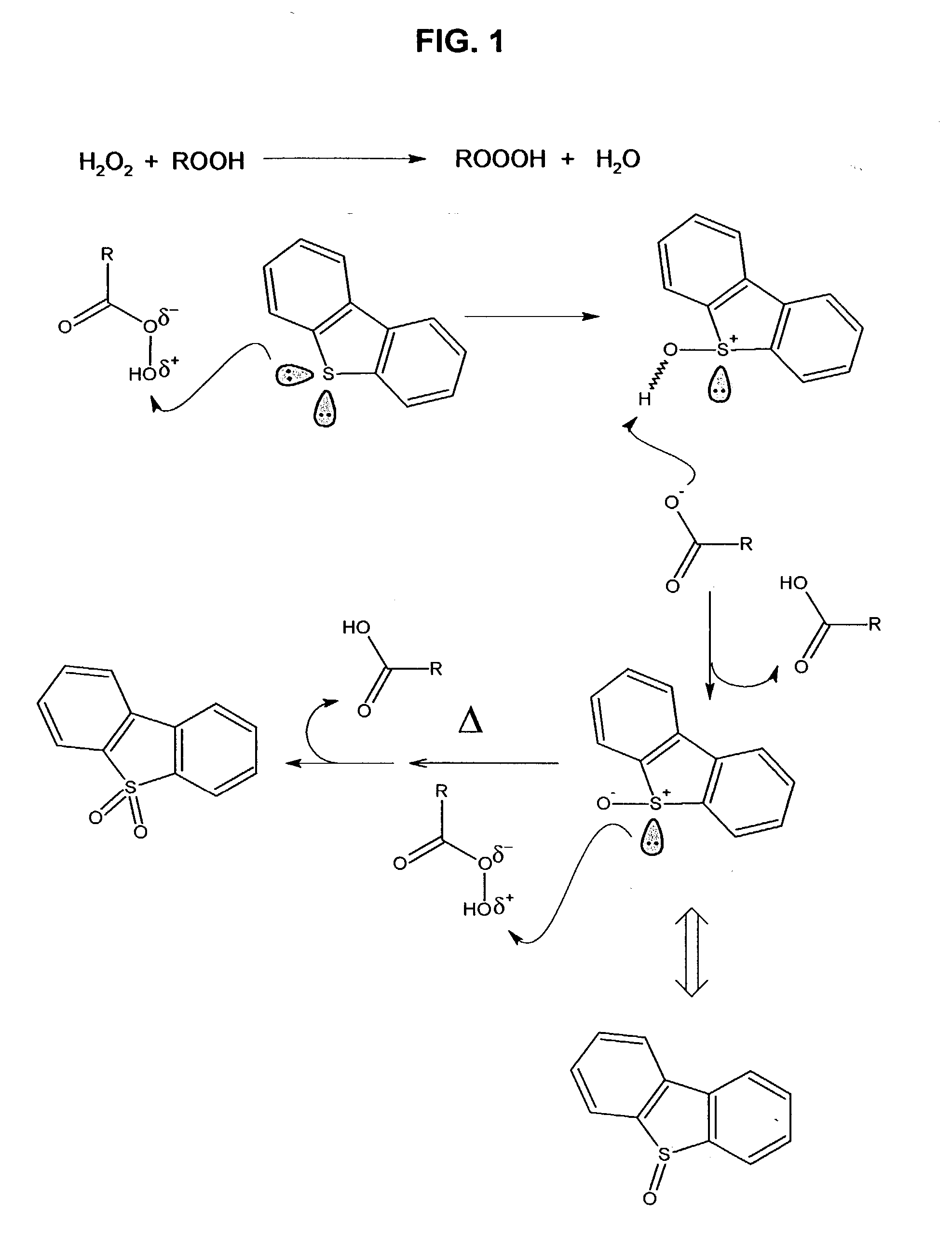

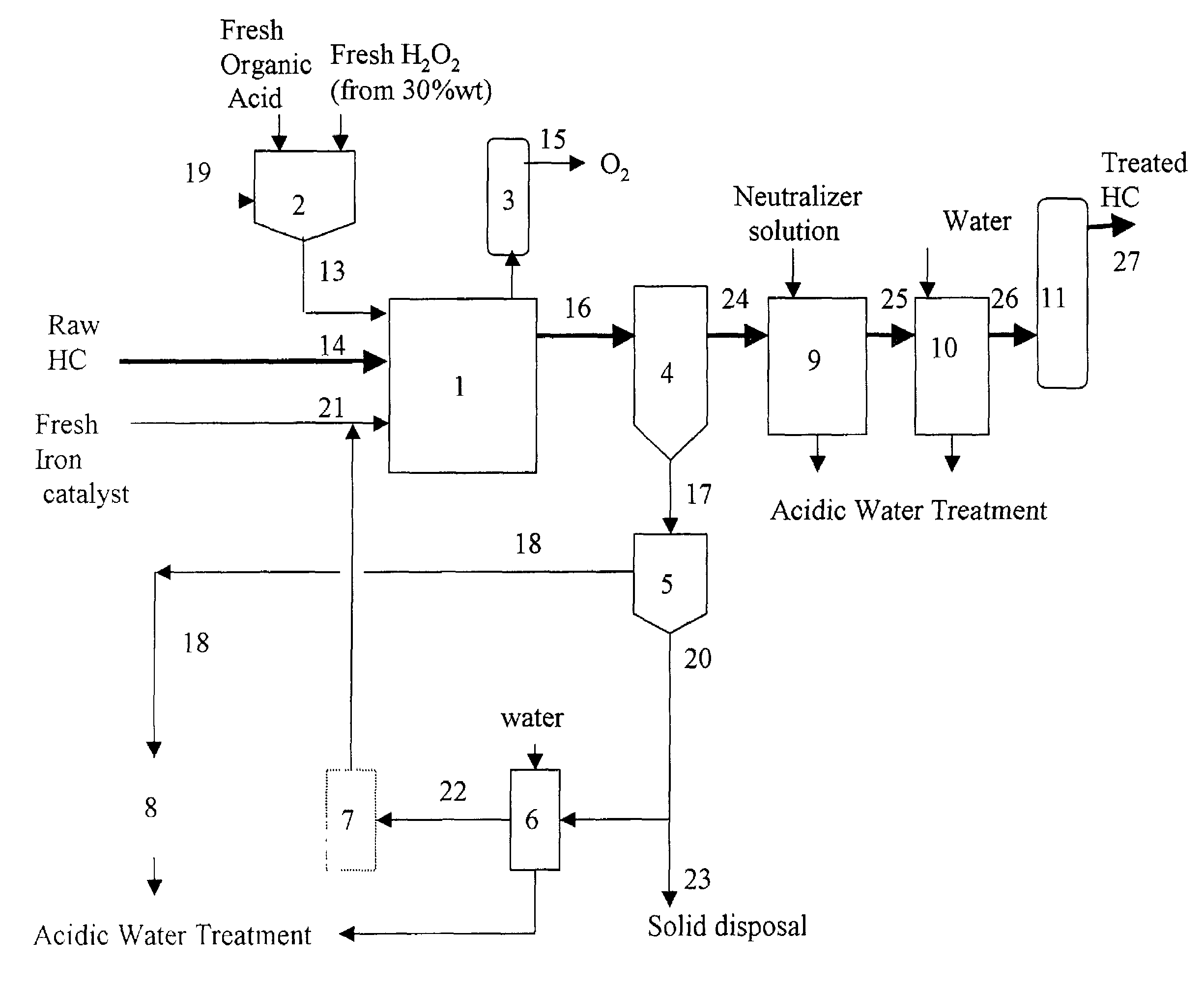

Process for the extractive oxidation of contaminants from raw hydrocarbon streams

A process for the extractive oxidation of contaminants from raw hydrocarbon streams rich in heteroatomic polar compounds is described, the said process involving the extractive oxidation of sulfur and nitrogen compounds from said streams, the said process comprising treating said streams with a peroxide solution / organic acid couple, the weight percent of the peroxide solution and organic acid based on raw hydrocarbon being at least 3 for both the peroxide and organic acid solution, under an acidic pH, atmospheric or higher pressure and ambient or higher temperature. As a result of the reaction, the oxidized heteroatomic compounds, having strong affinity for the aqueous phase, are extracted into said aqueous phase, while the oxidized hydrocarbon is neutralized, water washed and dried, the resulting end product being a hydrocarbon stream from which have been removed 88.1 wt % or more of total nitrogen compounds and basic nitrogen up to 99.1 wt %, both calculated as mass contents, total Sulfur 23.3% removal, and removal of total olefins is limited to 6.5 weight %. The treated product is further directed to any refining process.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method for removal of mercury from hydrocarbon feedstocks

The invention provides a method for removing mercury from a liquid or gas hydrocarbon stream, mixtures thereof, including mixtures of liquid streams with a solid carbonaceous substance, by contacting the hydrocarbon stream with a composition comprising silver and a support material, wherein the composition as measured by ammonia chemisorption has a surface acidity in the range of 0.1-10.0 μmole of irreversible NH3 / g of the composition.

Owner:THE DOW CHEM CO

Arsenic removal catalyst and method for making same

InactiveUS6919018B2Improve stabilityRemoving arsenicRefining with metalsCatalyst activation/preparationPetroleumMetal

A catalyst for removing arsenic from petroleum feedstocks comprising a porous refractory support impregnated with at least 8 wt. % of a Group VIB metal and an amount of Group VIII metal such that the atomic ratio of Group VIII metal to Group VIB metal is between about 1.5 and 2.5. A method of making such catalyst and a process for removing arsenic metals from a petroleum fraction using said catalyst.

Owner:SHELL OIL CO

Catalysts having selected pore size distributions, method of making such catalysts, methods of producing a crude product, products obtained from such methods, and uses of products obtained

ActiveUS20090255850A1Long useful lifeMinimal hydrogen consumptionRefining with non-metalsRefining with metalsPore diameterPeriodic table

A catalyst and a method of preparation of said catalyst is described herein. The catalyst includes one or more metals from Columns 6-10 of the Periodic Table and / or one or more compounds of one or more metals from Columns 6-10 of the Periodic Table, a pore size distribution with a median pore diameter ranging from 105 Å to 150 Å, with 60% of the total number of pores in the pore size distribution having a pore diameter within 60 Å of the median pore diameter, with at least 50% of its pore volume in pores having a pore diameter of at most 600 Å, and between 5% and 25% of its pore volume in pores having a pore diameter between 1000 Å and 5000 Å. Methods of producing said catalyst are described herein. Crude products and products made from said crude products are described herein.

Owner:SHELL OIL CO

Process for sulfur adsorption using copper-containing catalyst

The present invention is a method for the adsorption of sulfur-containing compounds from a hydrocarbon feedstream, and in particular, an olefin feedstream. The method comprises contacting the sulfur-containing compound with a copper oxide / zinc oxide / aluminum oxide catalyst optionally promoted with a metal.

Owner:CLARIANT INT LTD

Heavy oil reforming method, an apparatus therefor, and gas turbine power generation system

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercritical water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

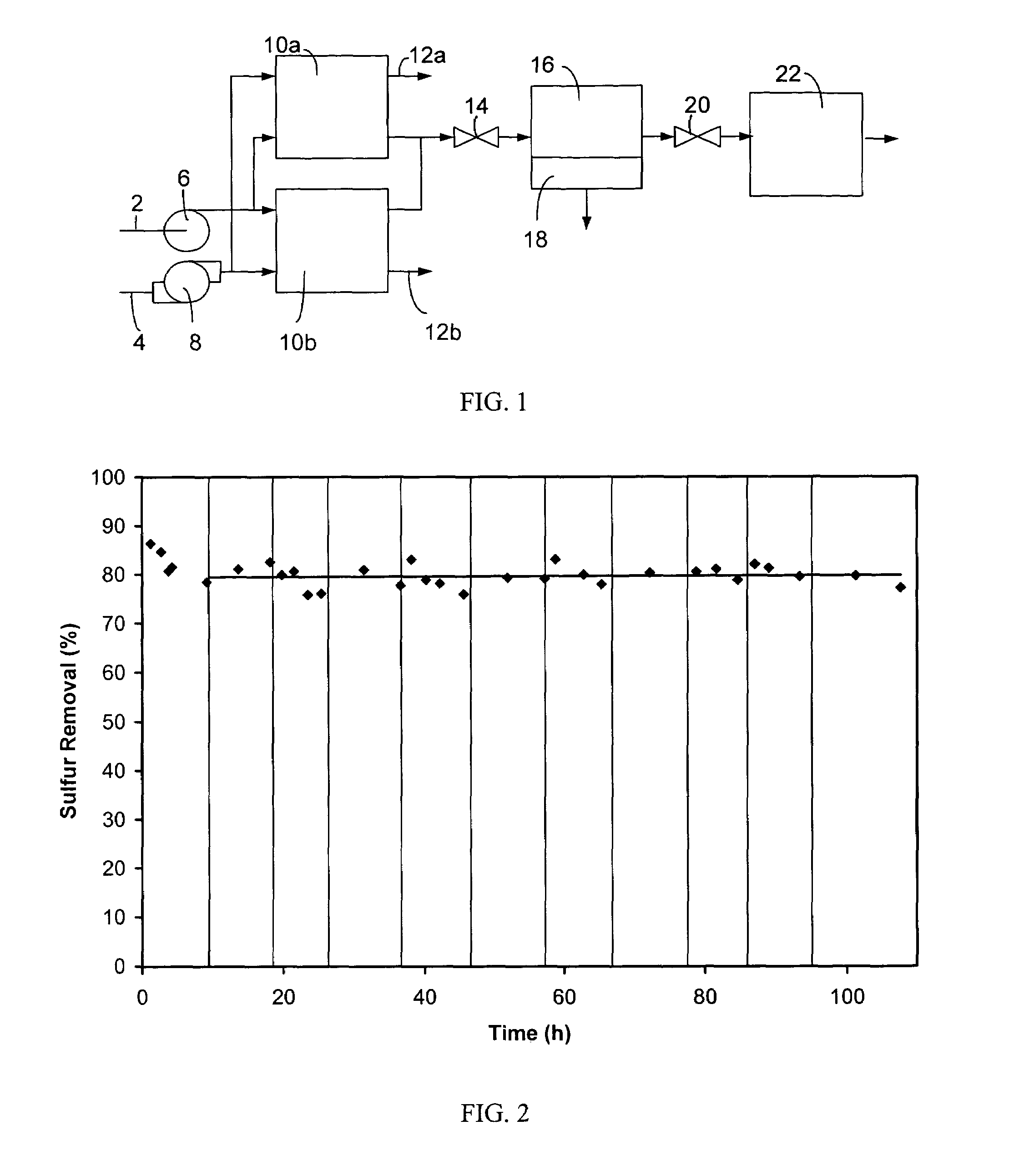

Methods and compositions for desulfurization of hydrocarbon fuels

ActiveUS7309416B2Efficient removalHigh activityTreatment with plural serial cracking stages onlyGas treatmentBoiling pointSulfur

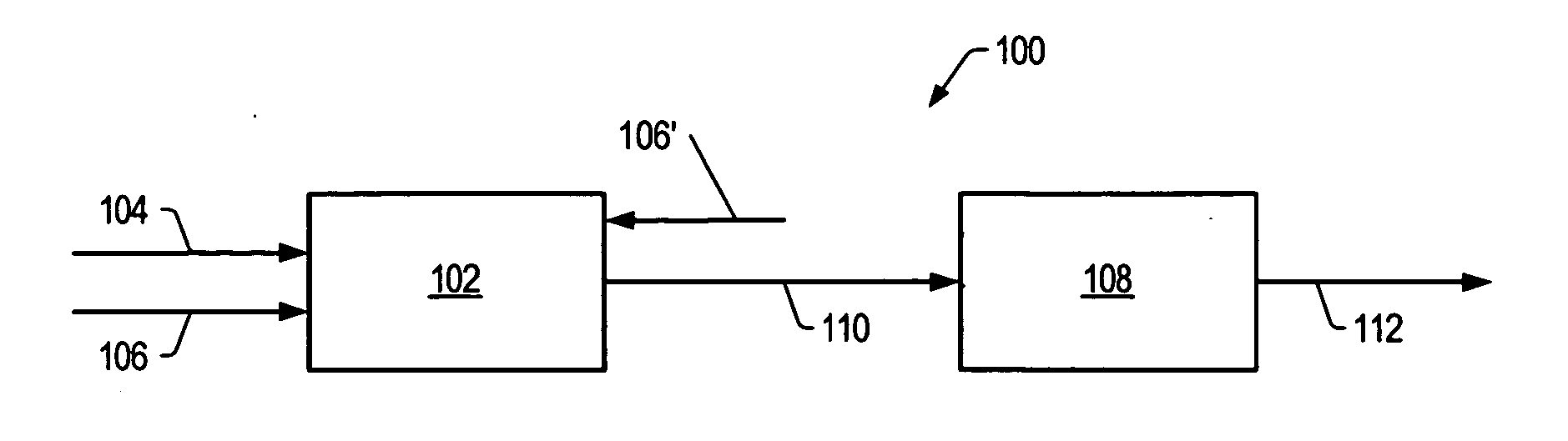

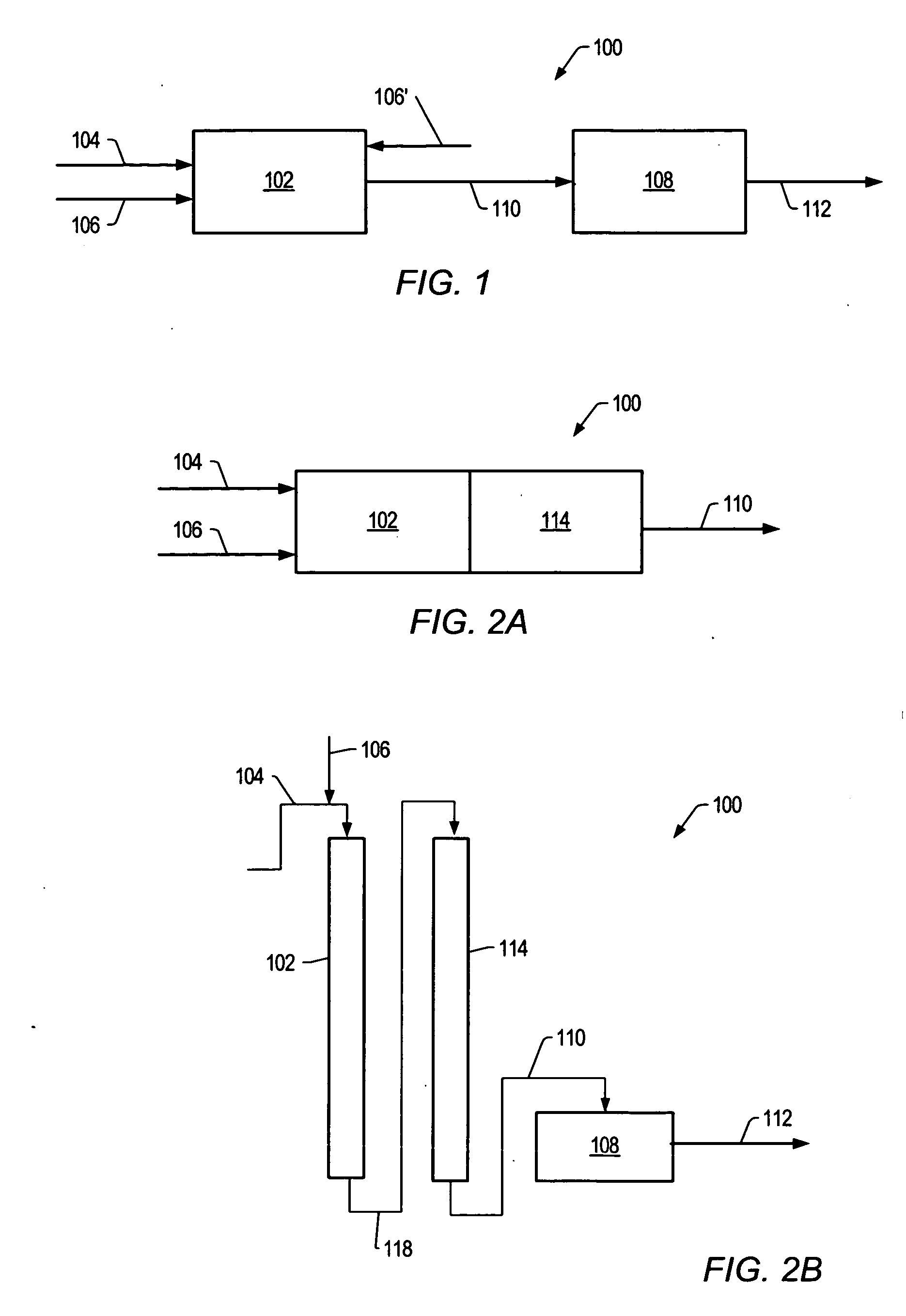

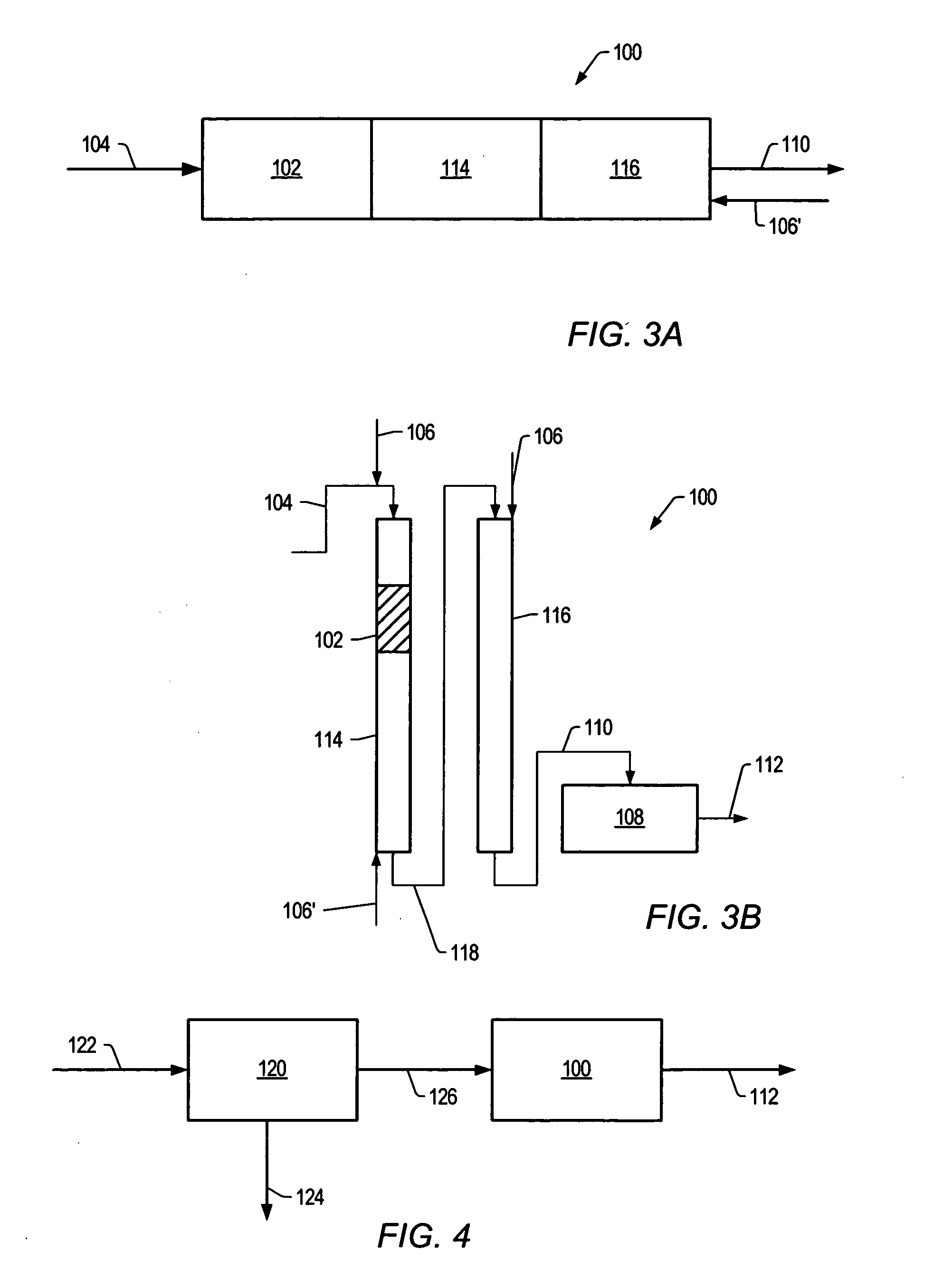

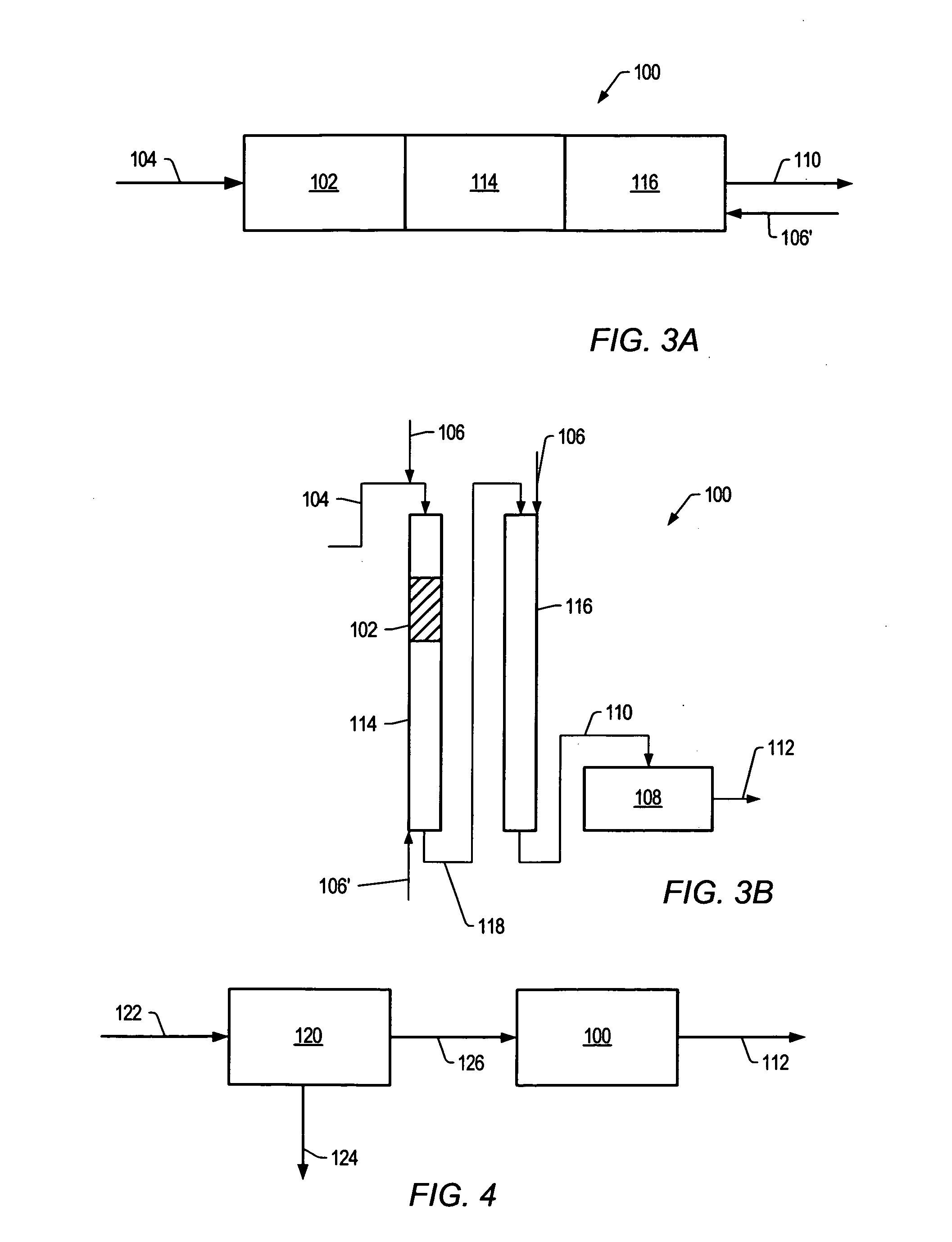

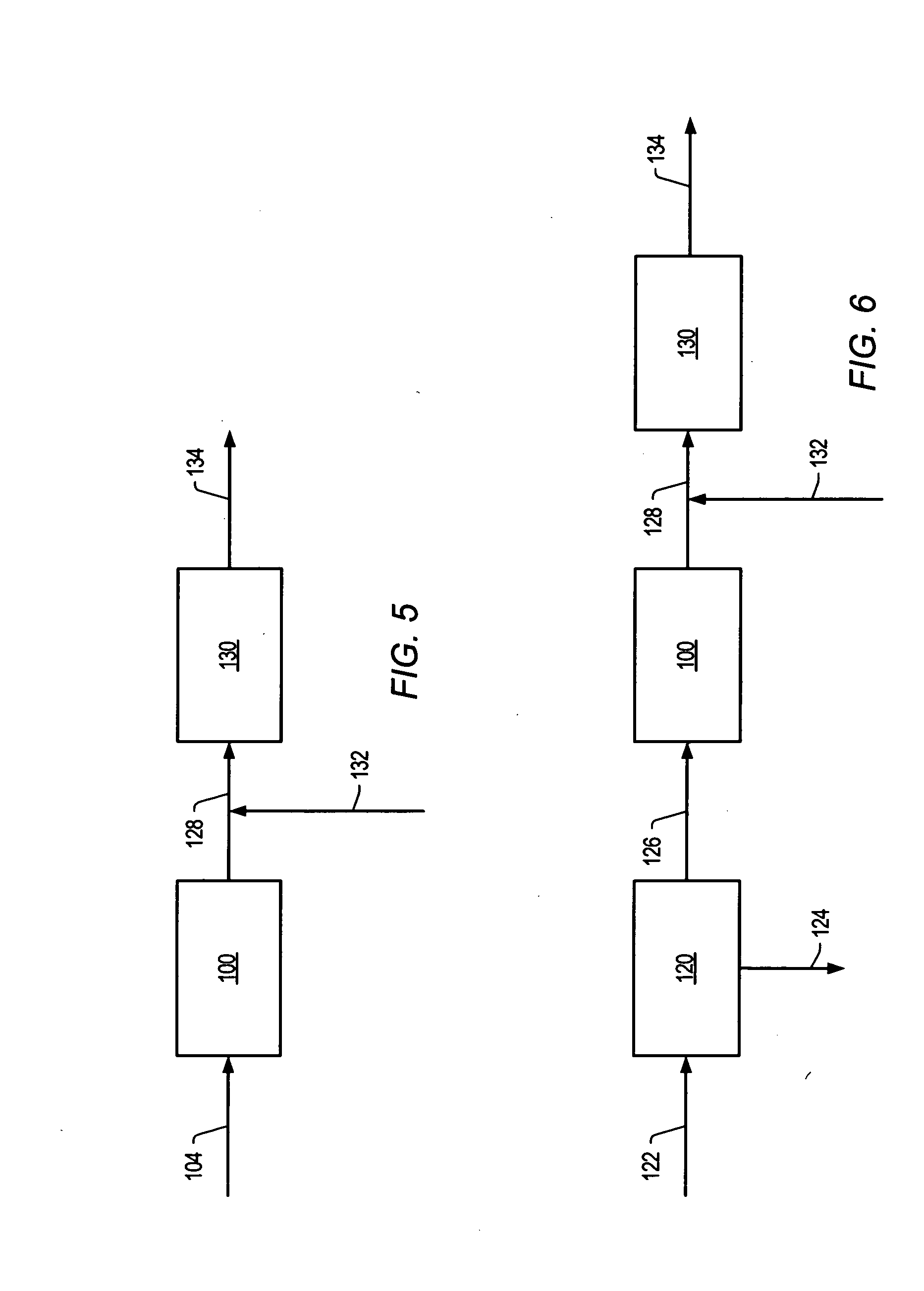

Sulfur is removed from a hydrocarbon fuel via contact with a desulfurization agent; the desulfurization agent is then regenerated (wherein sulfur is released) by exposing it to oxygen. The sulfur removal and regeneration processes each can be carried out at relatively moderate temperatures, e.g., from 300 to 600° C., and pressure, e.g., about 0.79 to about 3.5 MPa; and the desulfurization agent can include a transition metal oxide, such as molybdenum oxide. The process can also include the additional steps of cracking the hydrocarbon, separating high-boiling and low-boiling fractions from the reaction product and contacting the lower-boiling fraction with a secondary desulfurization agent.

Owner:ASPEN PRODS GROUP

Systems, methods, and catalysts for producing a crude product

Contact of a crude feed with one or more catalysts produces a total product that includes a crude product. The crude feed has a total content of alkali metal, and alkaline-earth metal, in metal salts of organic acids of at least 0.00001 grams per gram of crude feed. The one or more catalysts may include a first and a second catalyst. The crude product is a liquid mixture at 25° C. and 0.101 MPa and has a total content of alkali metal, and alkaline-earth metal, in metal salts of organic acids of at most 90% of the total content of alkali metal, and alkaline-earth metal, in metal salts of organic acids of the crude feed. One or more other properties of the crude product may be changed by at least 10% relative to the respective properties of the crude feed.

Owner:SHELL OIL CO

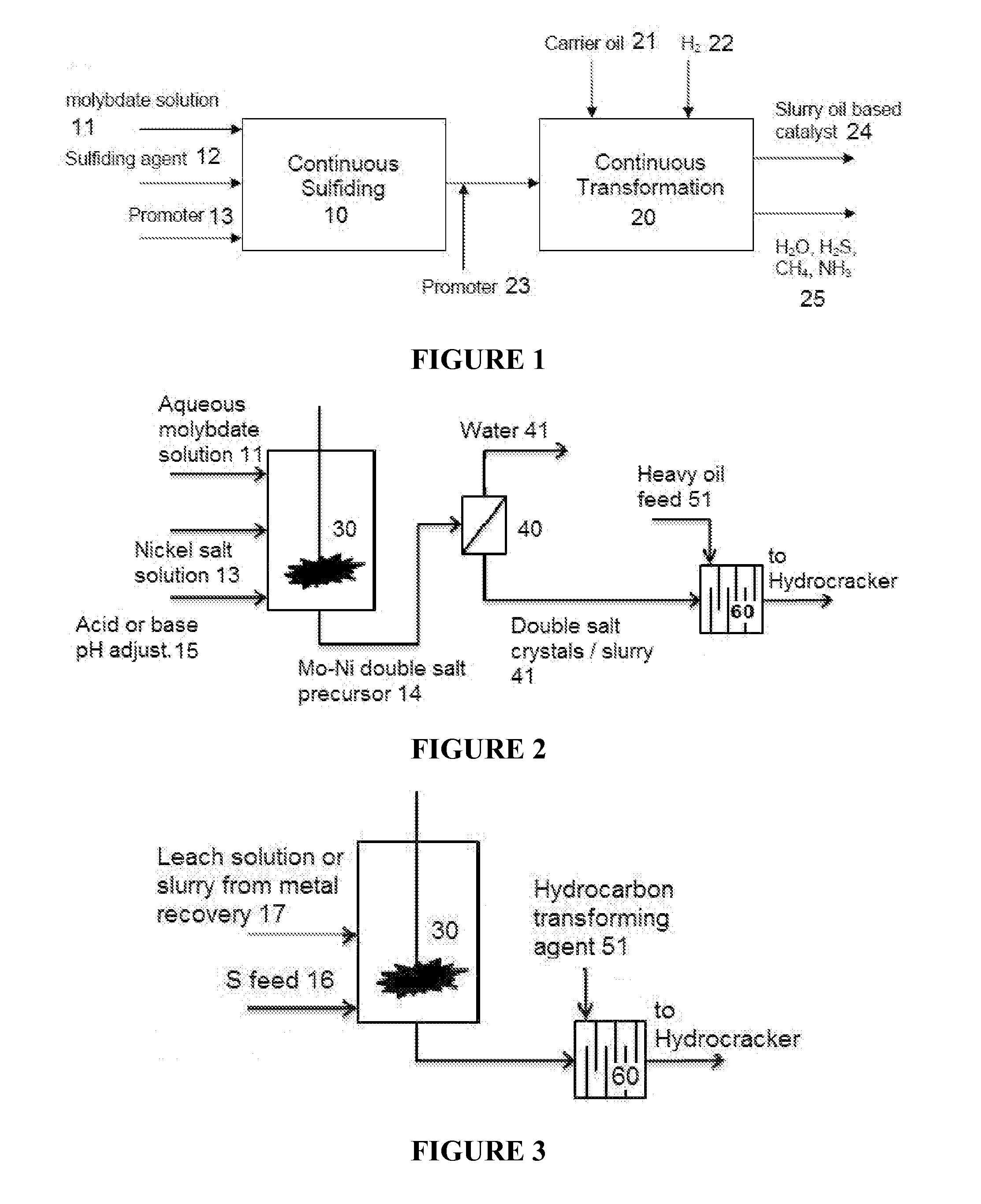

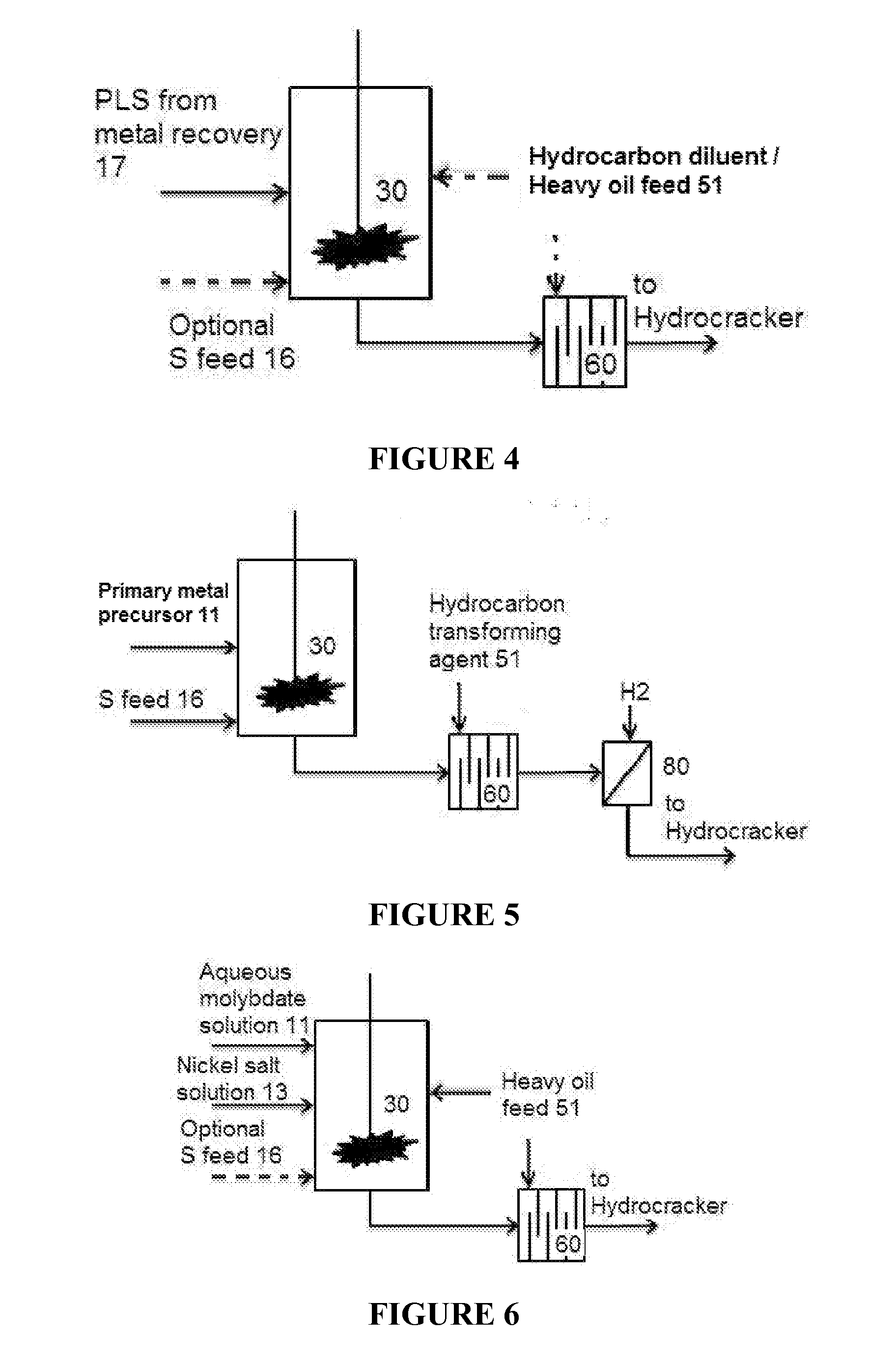

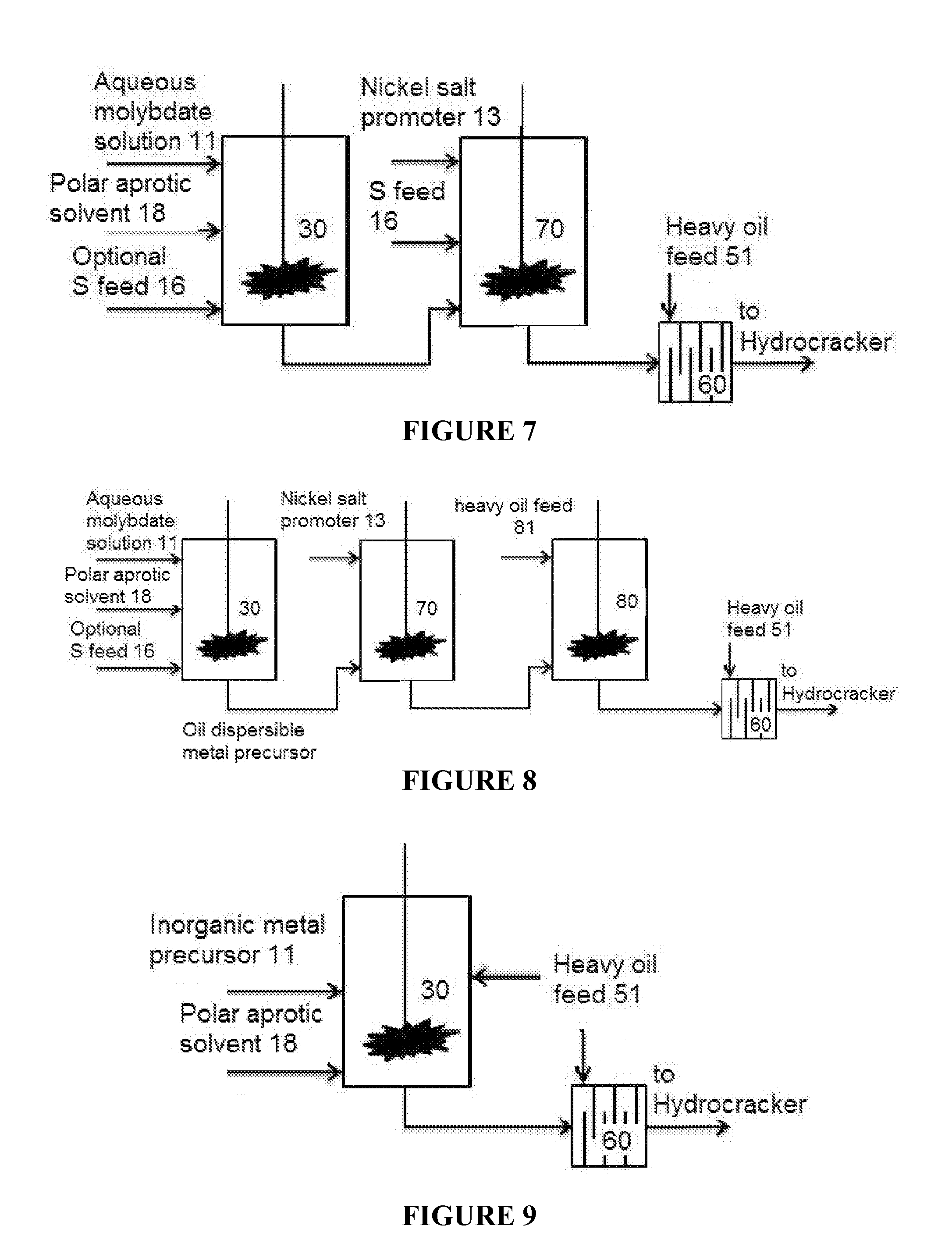

Hydroprocessing catalysts and methods for making thereof

ActiveUS20120168350A1Speed up the processRefining with metalsOrganic-compounds/hydrides/coordination-complexes catalystsSlurryFuel oil

An improved process for preparing a slurry catalyst for the upgrade of heavy oil feedstock is provided. The process employs a polar aprotic solvent to mix with the inorganic metal precursor feed to form an oil-dispersible inorganic metal precursor, at a weight ratio of solvent to inorganic metal precursor of 1:1 to 10:1; the oil-dispersible inorganic metal precursor is subsequently sulfided forming the slurry catalyst. In one embodiment, the sulfiding is in-situ upon mixing the oil-dispersible inorganic metal precursor with a hydrocarbon diluent containing a heavy oil feedstock under in-situ sulfiding conditions.

Owner:CHEVROU USA INC

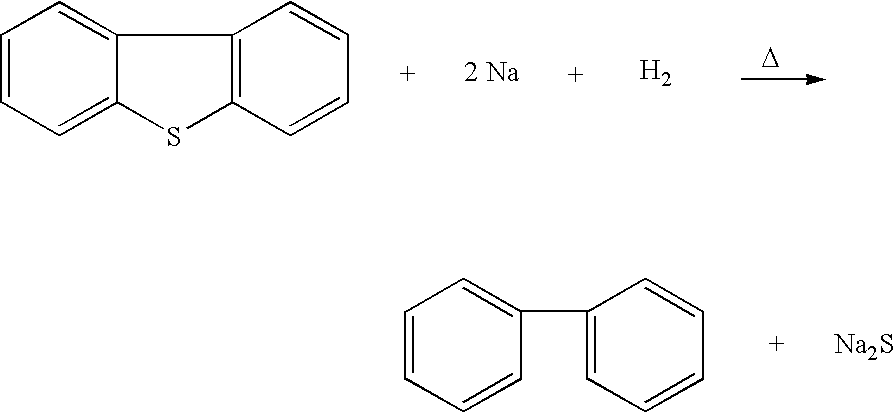

Desulfurization of petroleum streams using metallic sodium

The invention is a method of removing sulfur from a hydrocarbon feed using the steps of dissolving metallic sodium in a solvent and combining the sodium / solvent solution with a liquid hydrocarbon feed containing an organosulfur species. The pressure of combination is above the vapor pressure of the solvent. The combined hydrocarbon feed and solvent solution are placed in a low pressure environment to vaporize the solvent. The resulting stream is combined with hydrogen gas and this stream is heated and pressurized to form a liquid hydrocarbon product containing sodium sulfide. This product is then cooled, and the sodium sulfide is extracted.

Owner:TRANS IONICS CORP

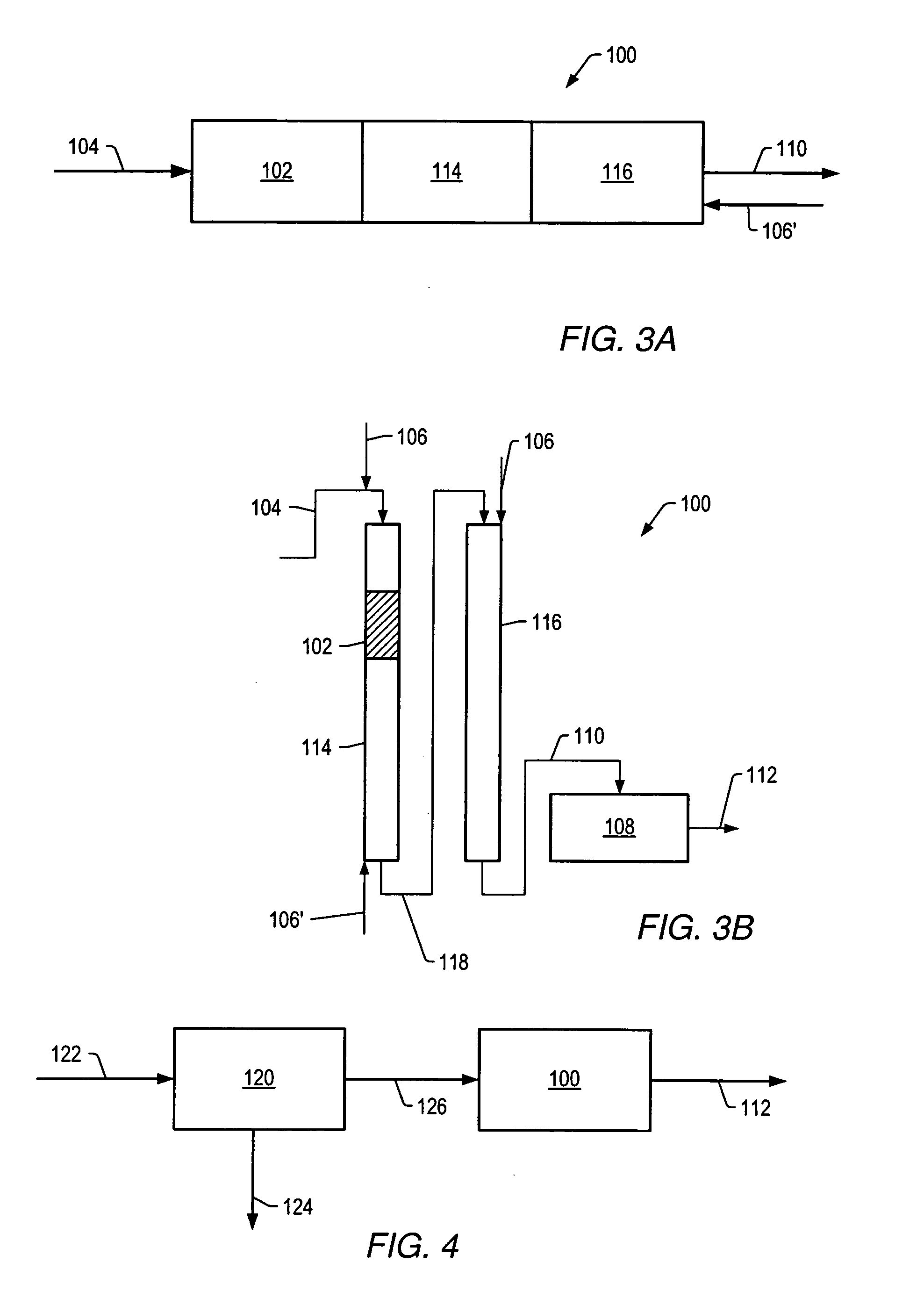

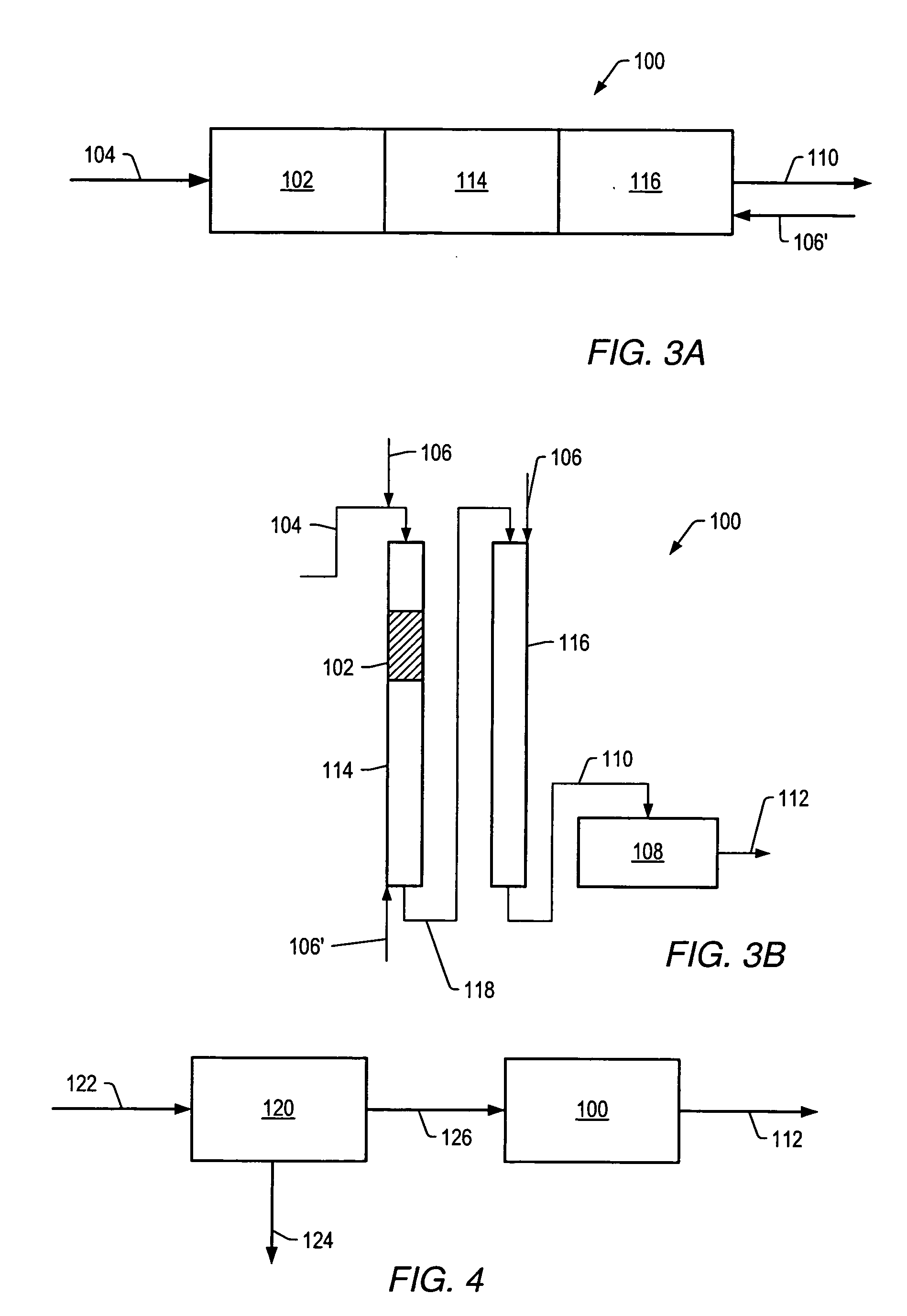

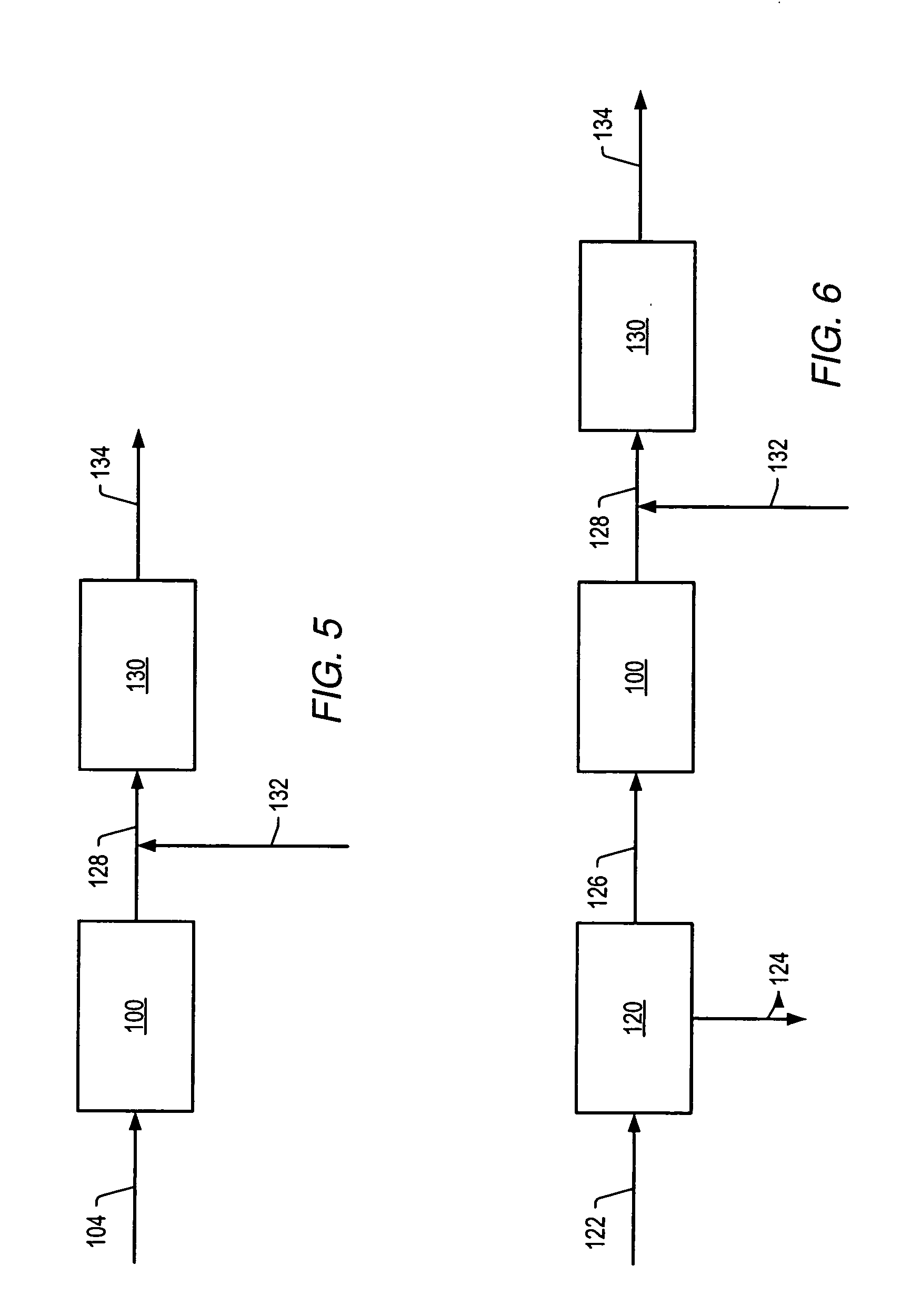

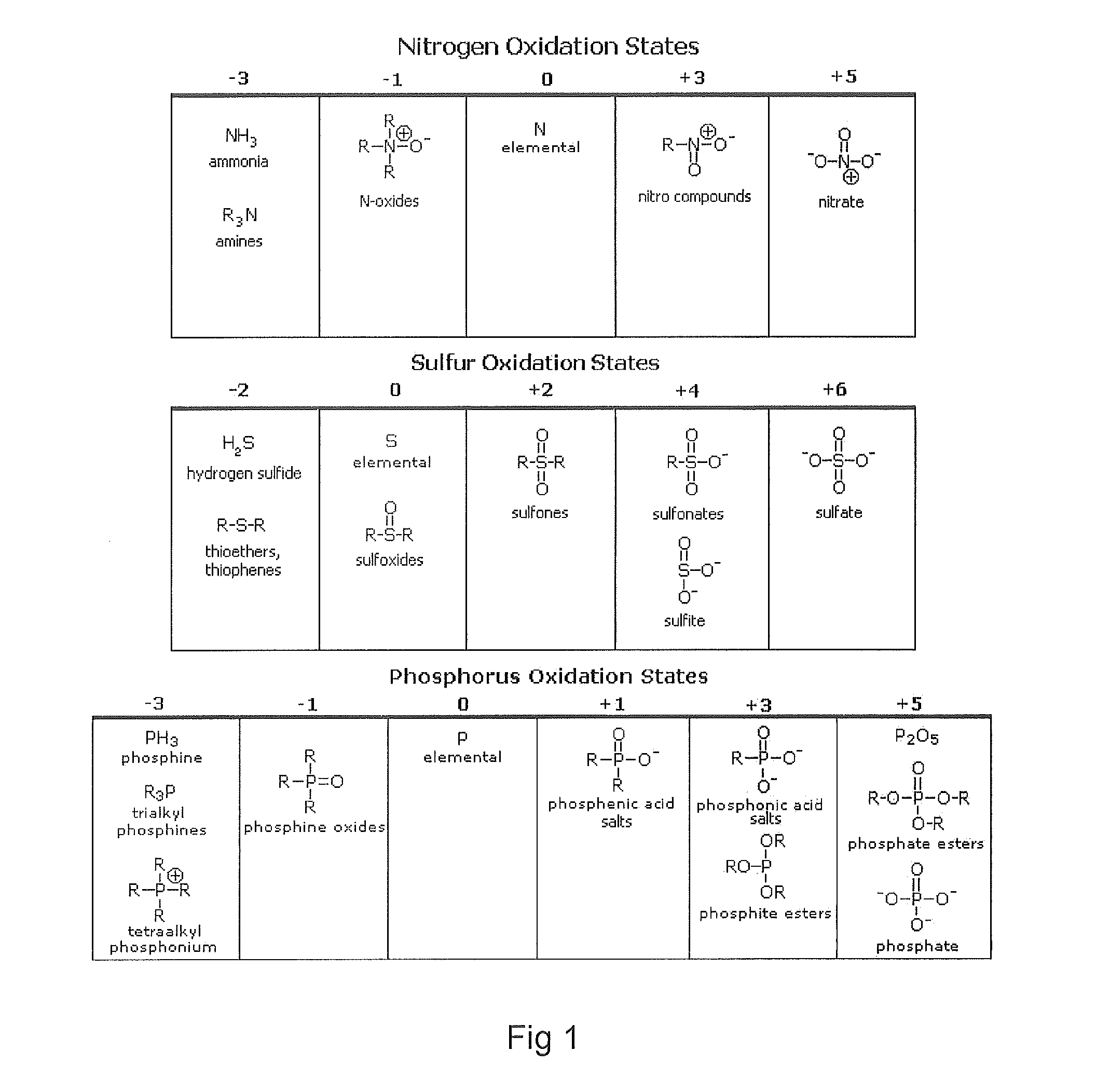

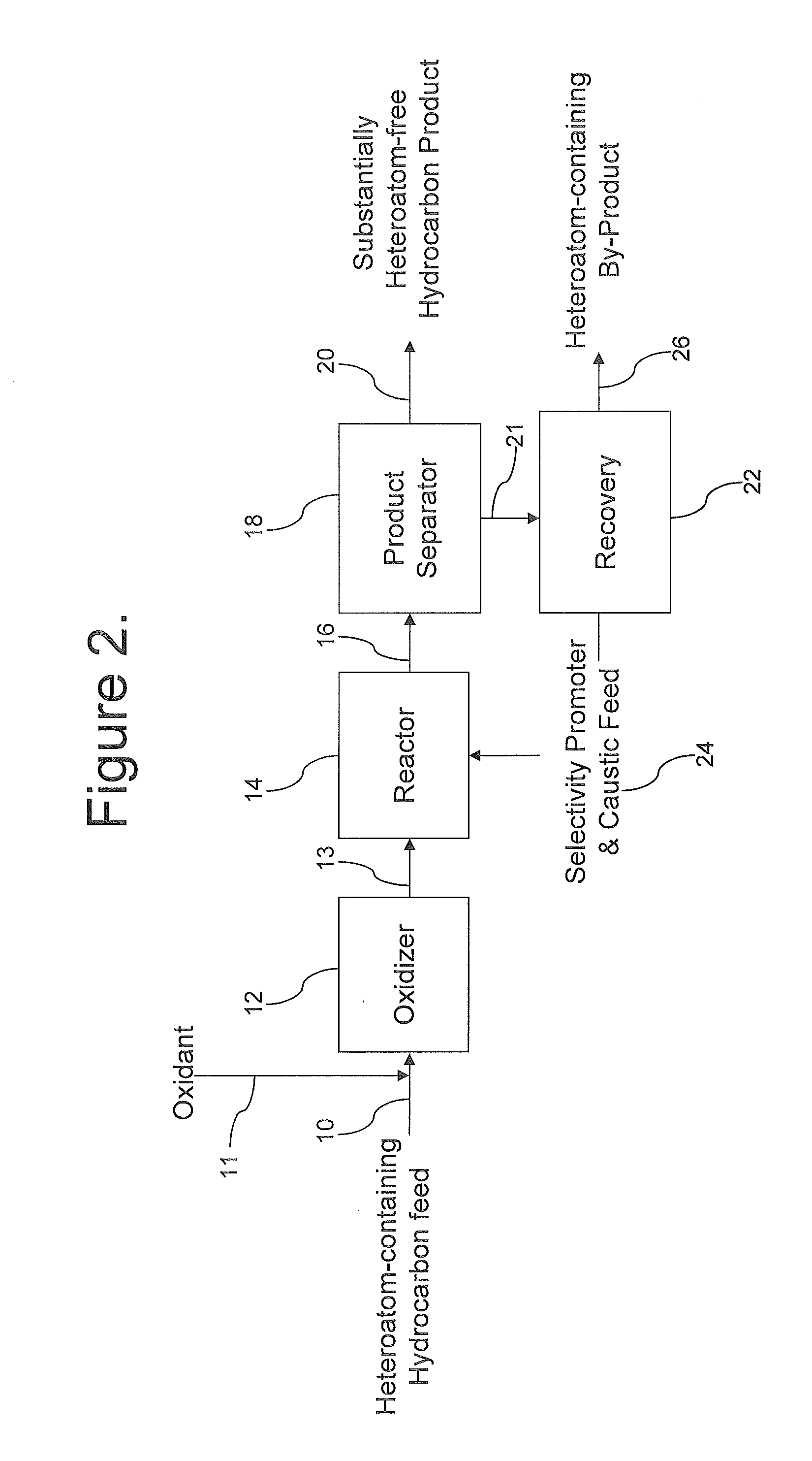

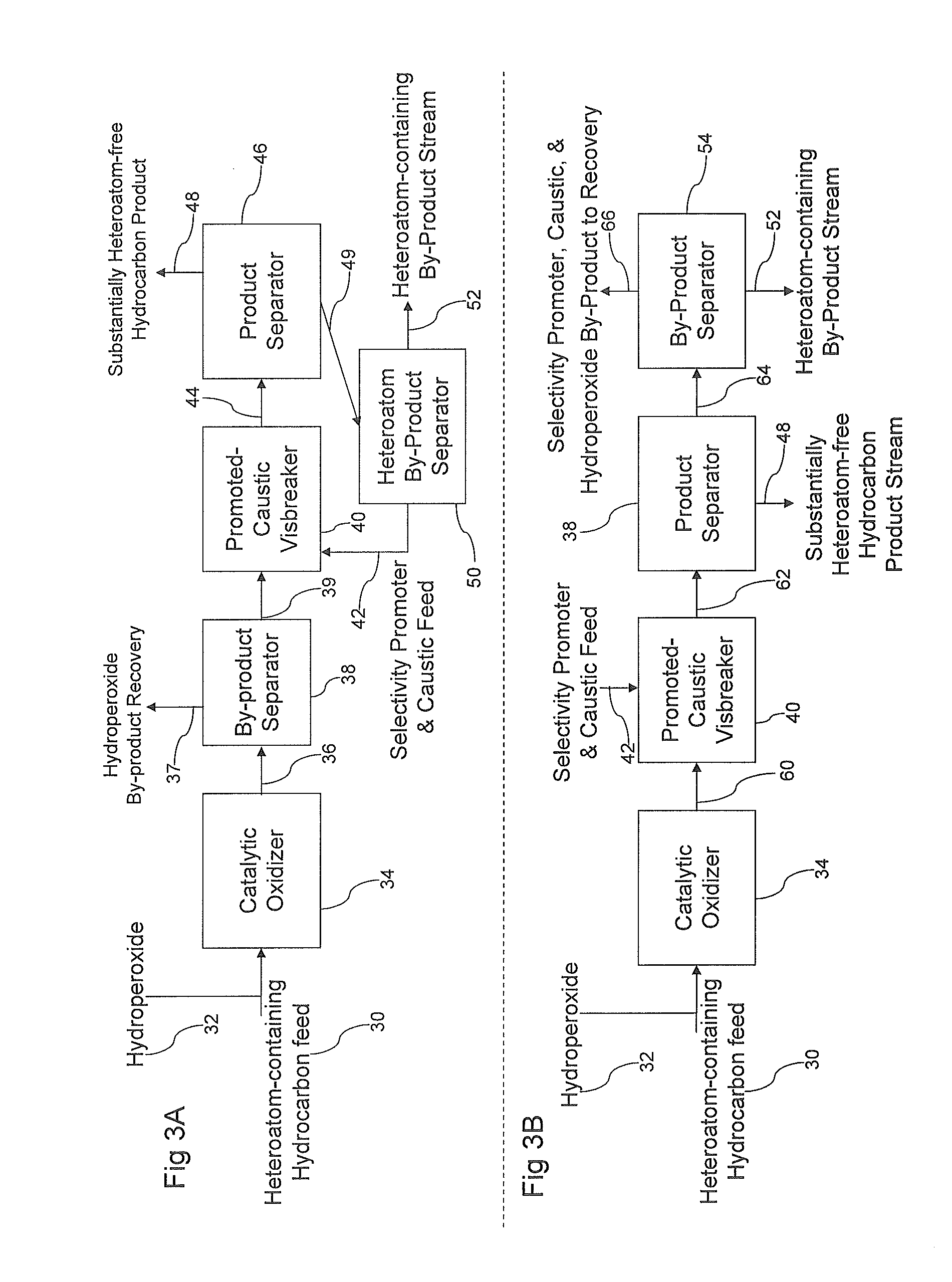

Methods for upgrading of contaminated hydrocarbon streams

A method of upgrading a heteroatom-containing hydrocarbon feed by removing heteroatom contaminants is disclosed. The method includes contacting the heteroatom-containing hydrocarbon feed with an oxidant to oxidize the heteroatoms, contacting the oxidized-heteroatom-containing hydrocarbon feed with caustic and a selectivity promoter, and removing the heteroatom contaminants from the heteroatom-containing hydrocarbon feed. The oxidant may be used in the presence of a catalyst.

Owner:AUTERRA INC

Process for the upgrading of raw hydrocarbon streams

InactiveUS7153414B2Increase polarityPromote oxidationRefining with metalsRefining with oxygen compoundsTotal nitrogenSlurry

A process for the upgrading of raw hydrocarbon streams rich in heteroatomic polar compounds and / or unsaturated moieties involving the extractive oxidation of sulfur, nitrogen, conjugated dienes and other unsaturated compounds from said streams, the said process comprising treating said streams with a peroxide solution / organic acid couple and an iron oxide catalyst which is a limonite ore, under an acidic pH, atmospheric pressure and ambient or higher temperature. As a result of the reaction, the oxidized heteroatomic compounds, having strong affinity for the aqueous slurry phase, are extracted into said aqueous phase, while the oxidized hydrocarbon is separated from catalyst by decanting, neutralizing, water washing and drying, the resulting end product being a hydrocarbon stream from which have been removed 90% or more of total nitrogen compounds and basic nitrogen up to 99.7%, both calculated as mass contents.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Process and apparatus for treating heavy oil with supercritical water and power generation system equipped with heavy oil treating apparatus

InactiveUS20070144941A1Thermal non-catalytic crackingPressurized chemical processScavengerAfter treatment

The reforming of heavy oil with supercritical water or subcritical water is accomplished by mixing together supercritical water, heavy oil, and oxidizing agent, thereby oxidizing vanadium in heavy oil with the oxidizing agent at the time of treatment with supercritical water and separate vanadium oxide. The separated vanadium oxide is removed by the scavenger after treatment with supercritical water. In this way it is possible to solve the long-standing problem with corrosion of turbine blades by vanadium which arises when heavy oil is used as gas turbine fuel.

Owner:HITACHI LTD

Desulfurization and novel sorbents for same

InactiveCN1384770AOctane dropReduce hydrocarbon contentRefining with metalsOther chemical processesAluminateCalcium silicate

Particulate sorbent compositions which are suitable for the removal of sulfur from streams of cracked-gasoline or diesel fuel are provided which have increased porosity, improved resistance to deactivation through the addition of a calcium compound selected from the group consisting of calcium sulfate, calcium silicate, calcium phosphate or calcium aluminate to the support system comprised of zinc oxide, silica and alumina having thereon a promotor wherein the promotor is metal, metal oxide or metal oxide precursor with the metal being selected from the group consisting of cobalt, nickel, iron, manganese, copper, molybdenum, tungsten, silver, tin and vanadium or mixtures thereof and wherein the valence of such promotor has been substantially reduced to 2 or less. Process for the preparation such sorbent systems as well as the use of same for the desulfurization of cracked-gasolines and diesel fuels are also provided.

Owner:CHINA PETROLEUM & CHEM CORP

Popular searches

Dispersed particle separation Solid sorbent liquid separation Catalyst regeneration/reactivation Silicon compounds Metal/metal-oxides/metal-hydroxide catalysts Hydrocarbon oils treatment products Hydrocarbon oil cracking Treatment with hydrotreatment processes Refining to eliminate hetero atoms Coking carbonaceous materials

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com