Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

357 results about "Iron oxyhydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

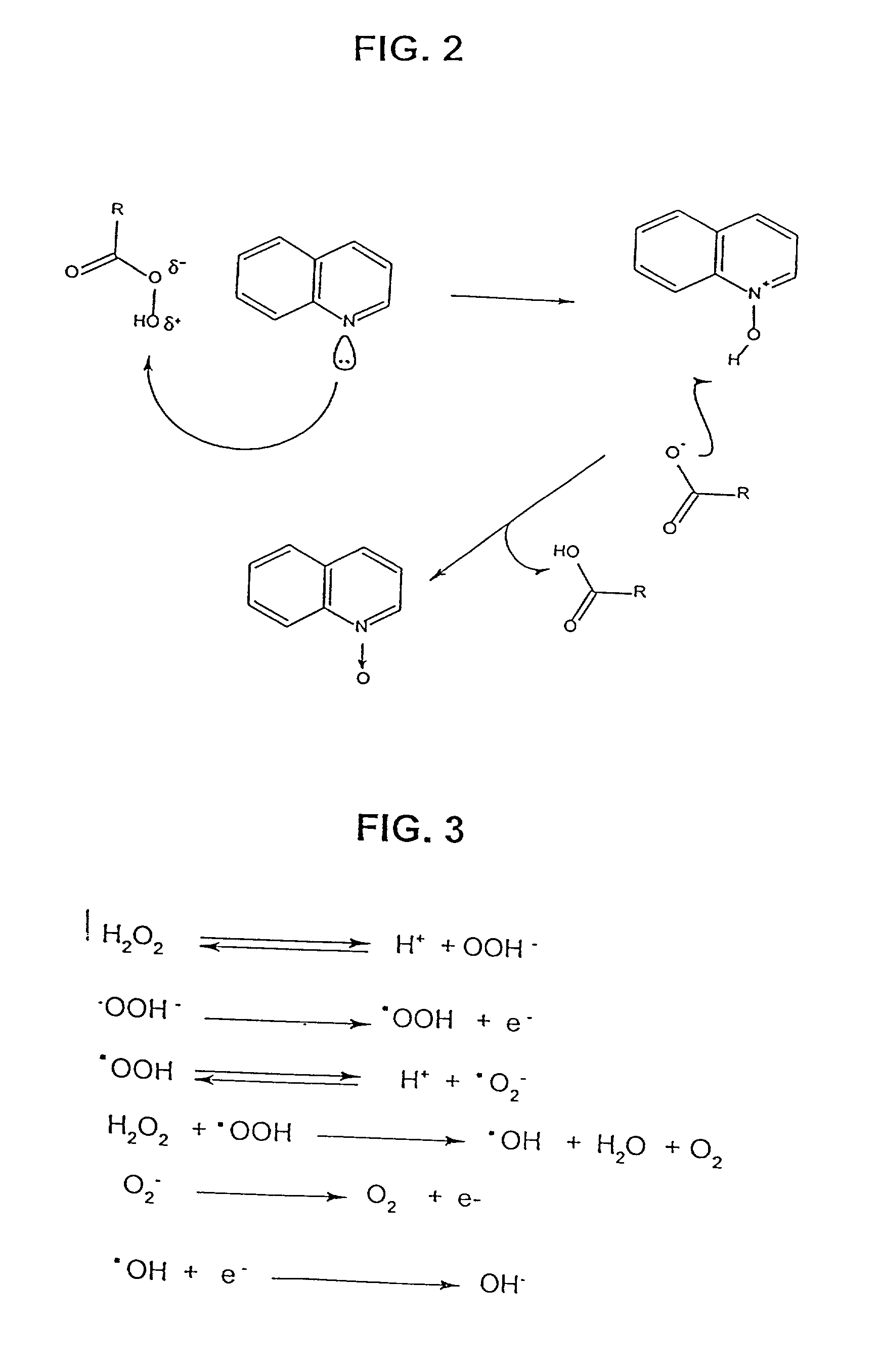

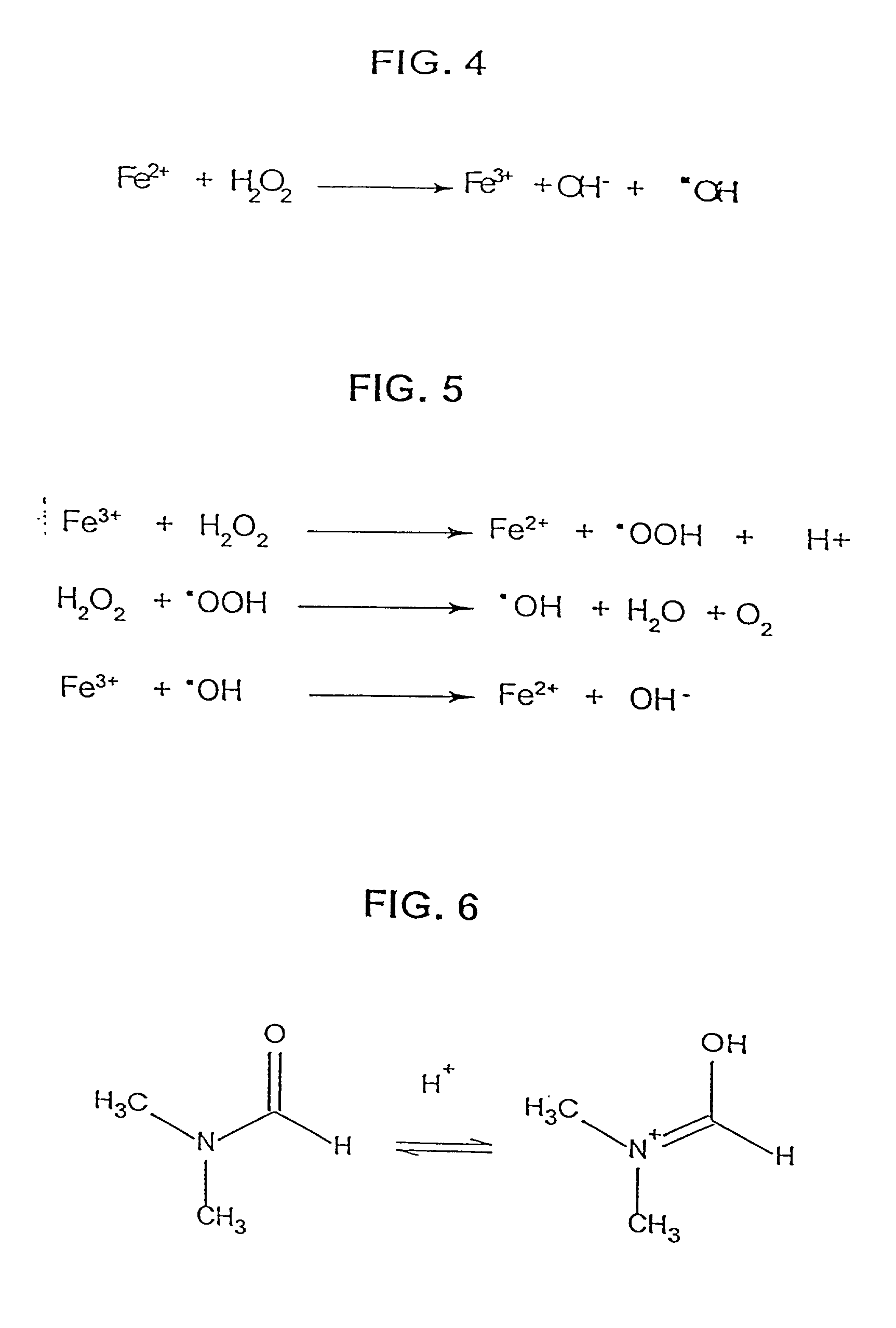

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Iron-dextran compound for use as a component in a therapeutical composition for prophylaxis or treatment of iron-deficiency

An iron-dextran compound for parenteral treatment of iron-deficiency anemia comprises hydrogenated dextran having a weight average molecular weight (Mw) between 700 and 1,400 Daltons, preferably approximately 1,000 Daltons, a number average molecular weight (Mn) of 400 to 1,400 Daltons and wherein 90% by weight of the dextran has molecular weights less than 2,700 Daltons and the Mw of the 10% by weight fraction of the dextran having the highest molecular weights is below 3,200 Daltons, said hydrogenated dextran having been subjected to purification by membrane processes having a cut-off value between 340 and 800 Daltons, in stable association with ferric oxyhydroxide. The compound is produced by using membrane processes to eliminate dextrans of higher molecular weights than approximately 2,700 Daltons and membrane processes to remove saccharides of molecular weights below approximately 340 Daltons from hydrogenated dextran before precipitating ferric hydroxide in the presence of said dextran followed by heat treatment and purification.

Owner:PHARMACOSMOS HLDG

Method for hydrogenation of coal tar via fluidized bed

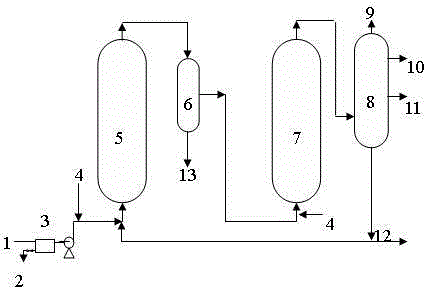

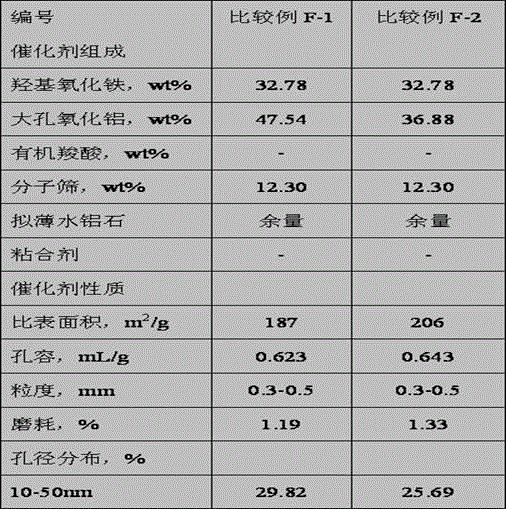

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

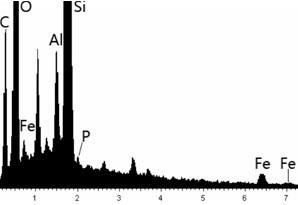

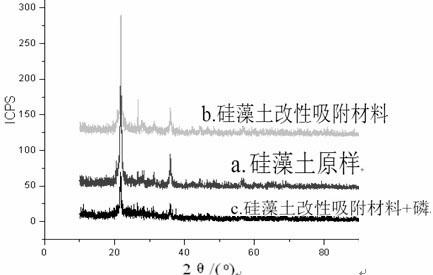

Kieselguhr modified adsorption material and preparation method and application thereof

InactiveCN102091591ASimple preparation processLow costOther chemical processesWater/sewage treatment by sorptionSolubilityFerric hydroxide

The invention discloses a kieselguhr modified adsorption material and a preparation method and application thereof. The kieselguhr modified adsorption material is formed by directly loading ferric hydroxide solution on the acid-washed pretreated raw kieselguhr and drying the kieselguhr. Through the kieselguhr modified adsorption material, the modified kieselguhr micropores and the surface roughness are obviously changed, the specific surface area is enlarged by 10 times, H<+> of ferric hydroxide loaded on the kieselguhr has extremely strong affinity with O<2-> in the structure in the solution of low pH value range, and Fe<3+> is released to the solution, so that the solubility of the adsorption material is increased, the adsorption capacity is enhanced, and the adsorption material is suitable for decontamination research of meta-acid water and has potential application value in the treatment of eutrophic water of Pearl River valley. The preparation method for the kieselguhr modified adsorption material is convenient for operation, simple in process and low in cost. The kieselguhr modified adsorption material is convenient and practical in application.

Owner:GUANGDONG UNIV OF TECH

Ferromagnetic particles and process for producing the same, and anisotropic magnet, bonded magnet and compacted magnet

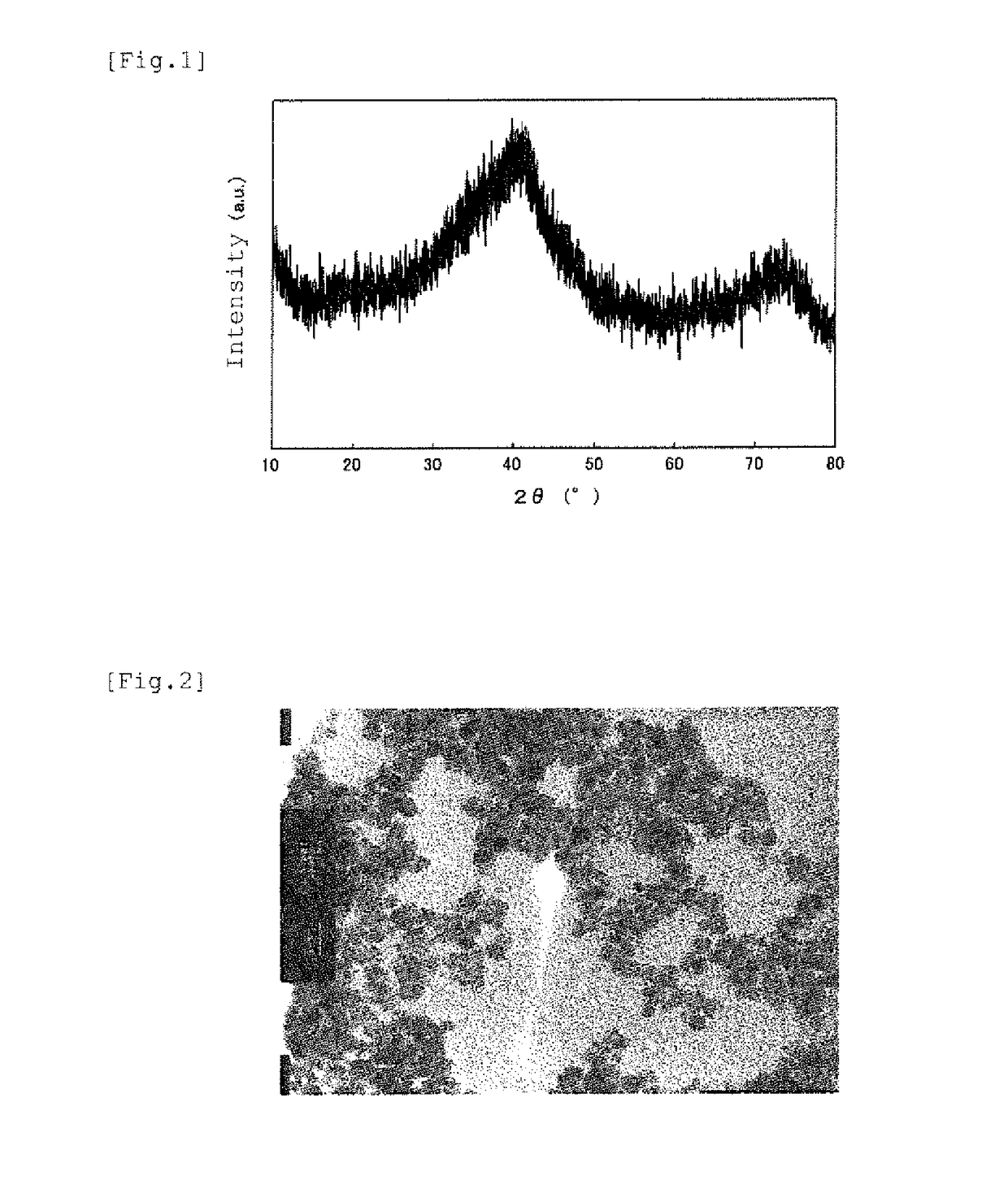

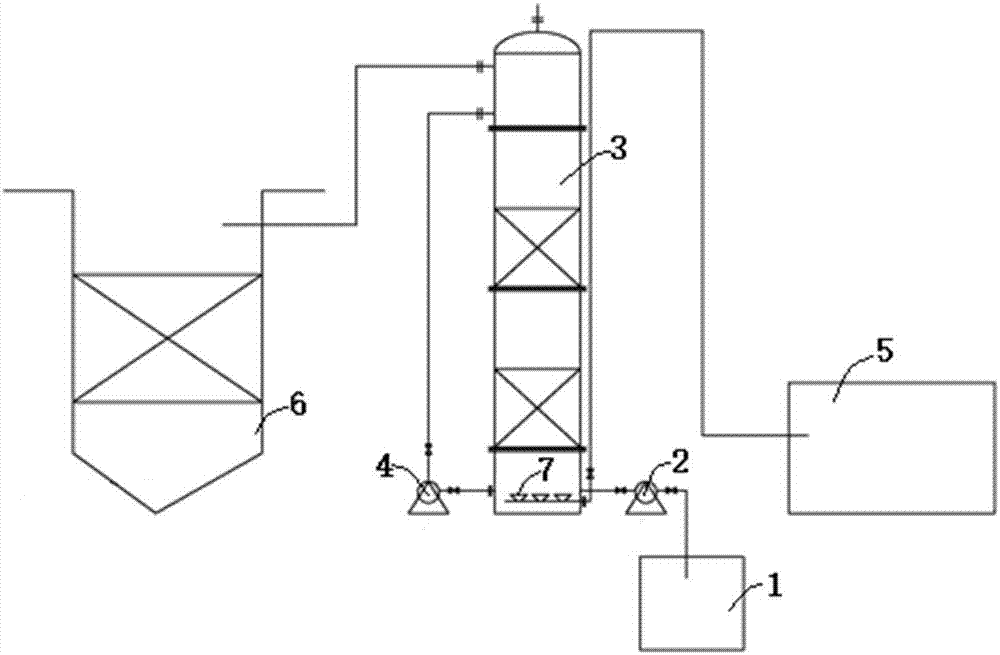

ActiveUS20140001398A1High purityReadily produce stable FeNitrogen-metal/silicon/boron binary compoundsInorganic material magnetismViewpointsIron oxyhydroxide

The present invention relates to ferromagnetic particles capable of exhibiting a high purity and excellent magnetic properties from the industrial viewpoints and a process for producing the ferromagnetic particles, and also provides an anisotropic magnet, a bonded magnet and a compacted magnet which are obtained by using the ferromagnetic particles. The ferromagnetic particles comprising an Fe16N2 compound phase in an amount of not less than 80% as measured by Mössbauer spectrum and each having an outer shell in which FeO is present in the form of a film having a thickness of not more than 5 nm according to the present invention can be produced by subjecting iron oxide or iron oxyhydroxide having an average major axis diameter of 40 to 5000 nm and an aspect ratio (major axis diameter / minor axis diameter) of 1 to 200 as a starting material to dispersing treatment to prepare aggregated particles; subjecting the iron compound particles passed through a mesh to hydrogen reducing treatment at a temperature of 160 to 420° C.; and then subjecting the resulting particles to nitridation treatment at a temperature of 130 to 170° C.

Owner:TOHOKU UNIV

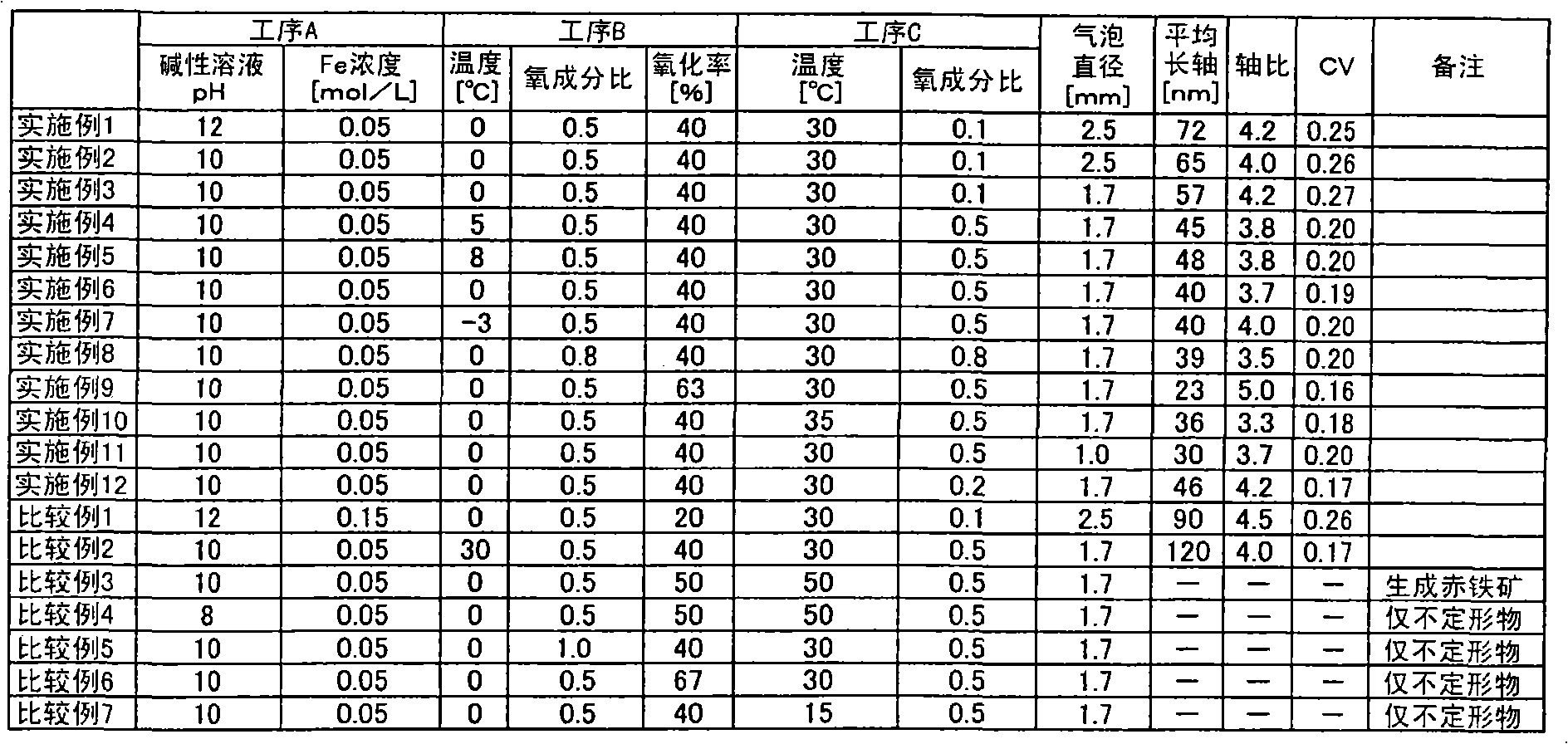

Method for producing iron oxyhydroxide particle

Owner:TDK CORPARATION

Method for preparing amorphous FeOOH and FeOOH desulfurizer prepared thereby

ActiveCN101585556AAvoid generatingTroubleshoot follow-up issuesIron oxides/hydroxidesFerrous saltsPhysical chemistry

The invention relates to a method for preparing amorphous FeOOH, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); and (e) naturally drying or baking a solid obtained in step (d). On the basis, the invention further discloses an amorphous FeOOH desulfurizer prepared by the preparation method, and the desulfurizer has high sulfur capacity and high desulfurization efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

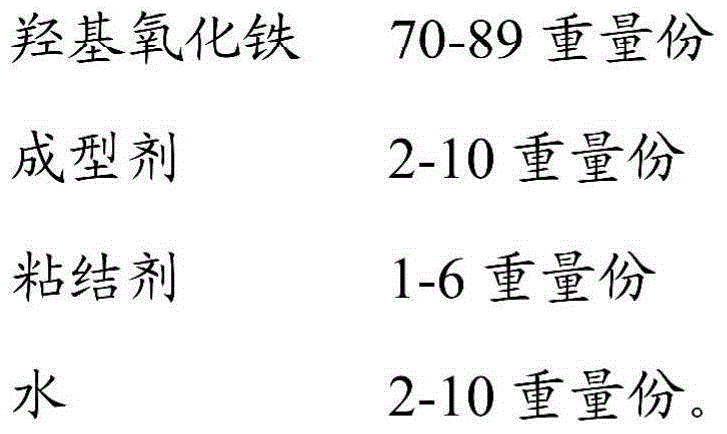

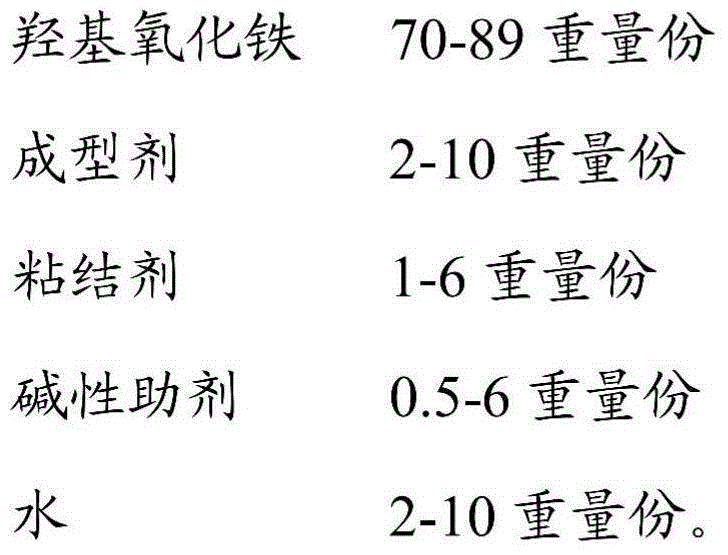

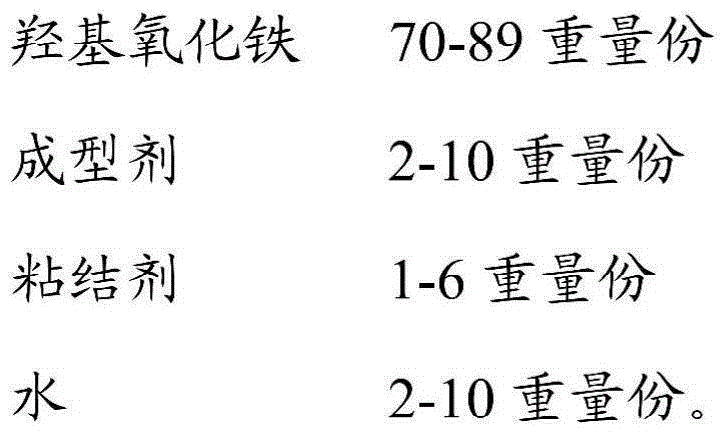

Preparation method of FeOOH low-temperature desulfurizer and desulfurizer prepared through same

ActiveCN105056719APromote generationIncrease oxidation rateDispersed particle separationIndustrial gasAdhesive

The invention provides a preparation method of a FeOOH low-temperature desulfurizer and a desulfurized prepared through the same. The preparation method comprises the following steps: sequentially adding a water soluble ligand, a precipitating agent, and a surfactant into a ferrous salt solution under continuous stirring, performing aging and centrifugation, adding a forming agent and an adhesive, mixing, kneading, and moulding so as to obtain the desulfurizer. For the first time, the directional orientation effect, template effect and dispersing effect of the surfactant have been utilized so as to form abundant point defects and surface hydroxy groups on the surface of FeOOH, thus the specific surface area and active crystal face of the desulfurizer are enlarged, the desulfurizing activity is strengthened and the sulfur capacity is increased. The preparation conditions are middle, the production cost is low, and the preparation method is very suitable for industrial massive production. Furthermore, the provided desulfurizer has a very good low-temperature desulfurizing performance, the low-temperature sulfur capacity can reach 70% at a temperature of 0 to 120 DEG C, the desulfurization precision can reach 2 ppm, and the provided desulfurizer can be used to remove hydrogen sulfide in industrial gas with a high CO2 content and is widely used.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD

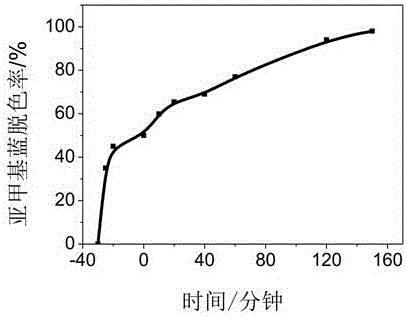

Preparation method and application of beta-FeOOH-loaded graphene oxide catalyst

InactiveCN105921151AEasy to operateGood removal effectWater/sewage treatment by irradiationWater contaminantsWater bathsWater quality

The invention discloses a preparation method and application of a beta-FeOOH-loaded graphene oxide catalyst. The preparation method comprises the following steps: dispersing graphene oxide in water, carrying out ultrasonic treatment so as to obtain uniform dispersion liquid of graphene oxide, then adding ferric trichloride into the dispersion liquid of graphene oxide, carrying out heating in a constant-temperature water-bath so as to load beta-FeOOH onto the surface of graphene oxide and subjecting the obtained product to centrifugation, washing and drying so as to obtain the nanometer beta-FeOOH-loaded graphene oxide catalyst. The catalyst and hydrogen peroxide are added into a dye water body with a certain concentration; and under illumination of visible light, dye chroma is removed, biotoxicity is reduce, and the water body is purified. The catalyst is free of secondary pollution, and an intermediate produced in the reaction has obvious reduced biotoxicity; reaction conditions are mild, and the reaction can be carried out under the condition of visible light; process flow is simple in operation; raw materials used for preparation of the catalyst are easily available; the reacted solid phase catalyst is easy to separate; so the catalyst has good application prospects in the field of water pollution treatment.

Owner:EAST CHINA NORMAL UNIV

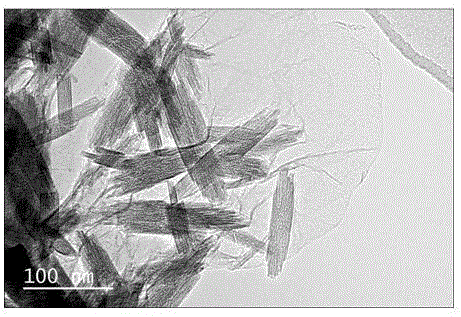

Preparation method of iron oxyhydroxide/graphene oxide composite material

InactiveCN103224255ASmall sizeLarge specific surface areaMaterial nanotechnologyGrapheneActive agentNanoparticle

The invention relates to a preparation method of iron oxyhydroxide / graphene oxide composites. The method uses an improved Hummers method to regulate a proportion of a saturated ferric salt aqueous solution for preparing a precursor sol with boiling water, and a concentration of a graphene oxide aqueous solution, thereby preparing the iron oxyhydroxide / graphene oxide composite material with monodisperse nanoparticles and a size of less than 10 nanometer, and without a surfactant. The iron oxyhydroxide / graphene oxide composite material prepared by the method has characteristics of small particle size of the iron oxyhydroxide, monodispersed iron oxyhydroxide on surfaces of the graphene oxide, and large specific surface area; and the method is low in equipment investment, few in synthesis steps, simple in operation technology, low in production cost, easy to realize industrial production and wide in application prospect.

Owner:ANHUI UNIVERSITY

Recyclable desulfurizer and preparation method thereof and regeneration method

ActiveCN101898108AHigh sulfur capacityLoose structureOther chemical processesIron oxides/hydroxidesCarboxymethyl celluloseSulfur

The invention relates to a recyclable dry desulfurizer with high sulfur capacity. The desulfurizer contains not less than 88% of substances containing FeOOH and not less than 7% of organic binders, wherein the organic binder is one or more of sodium carboxymethyl cellulose, sesbania and cellulose powder. The invention further discloses a preparation method of the desulfurizer and a regeneration method of waste agents generated after the desulfurizer is used. The invention solves the following problems in the prior art: the dry-formed desulfurizer has low sulfur capacity, and after the dry-formed desulfurizer is used once, the waste agents can not be regenerated or the regeneration cost is high, so that great amount of waste agents are only buried, thus not only wasting the effective resources in the original desulfurizer but also leading to new environmental pollution problems.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for controllably preparing hydroxyl oxidize iron, iron sesquioxide and ferroferric oxide

ActiveCN102153146AIncrease concentrationSimple control of pHFerroso-ferric oxidesNanotechnologyAlcoholSesquioxide

The invention discloses a method for controllably preparing hydroxyl oxidize iron, iron sesquioxide and ferroferric oxide. The method comprises the following steps of: dissolving ferrous salt into water to obtain aqueous solution of ferrous salt; then adding alcohol into the aqueous solution of ferrous salt and uniformly mixing the mixture to perform a reaction; after the reaction is completed, drying to obtain the hydroxyl oxidize iron; sintering the obtained hydroxyl oxidize iron in a muffle furnace to obtain the iron sesquioxide; and under the condition of a pH value of 8 to 14, performing a reaction of the hydroxyl oxidize iron and ferrous salt and obtaining Fe3O4 after the reaction is completed. The method is green and environmental-friendly, is simple to operate and is easy for industrial production. Meanwhile, the prepared materials have large specific surface areas and stable structures, can be used as excellent water treatment materials and can also be used as a catalyst for an excellent catalytic reaction.

Owner:INST OF CHEM CHINESE ACAD OF SCI

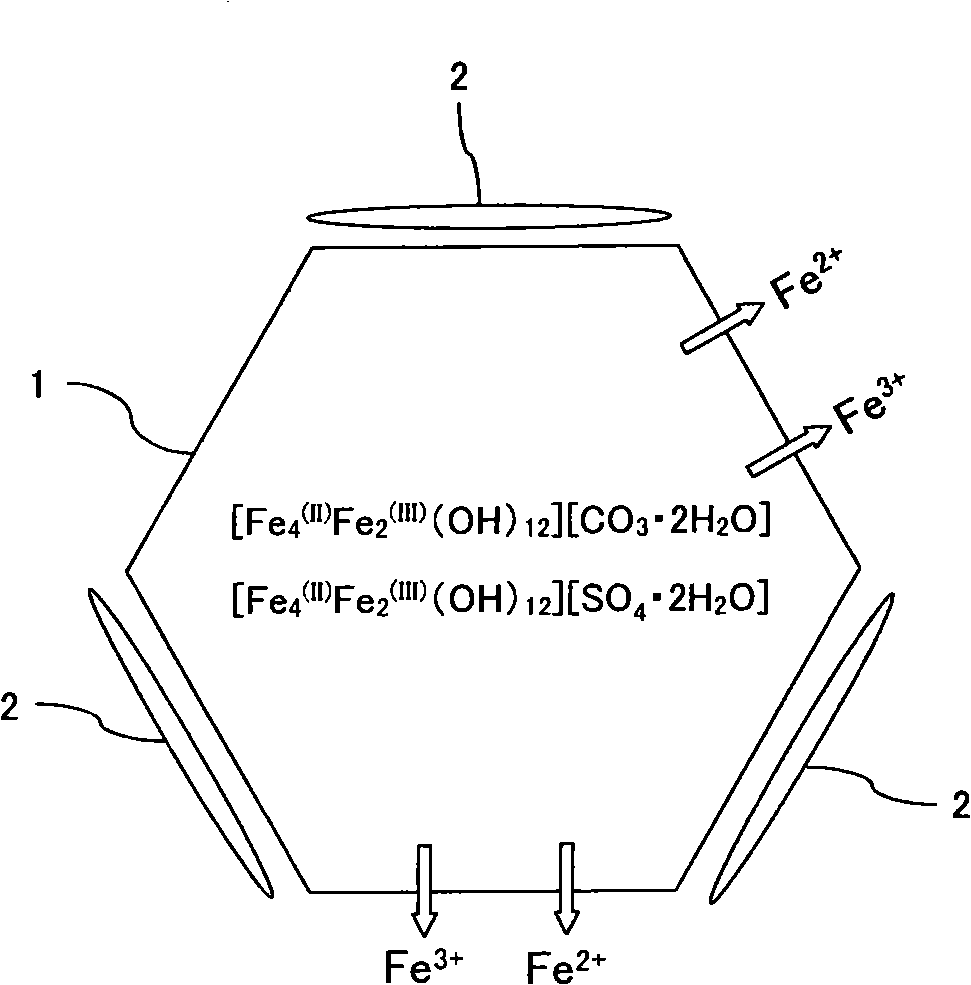

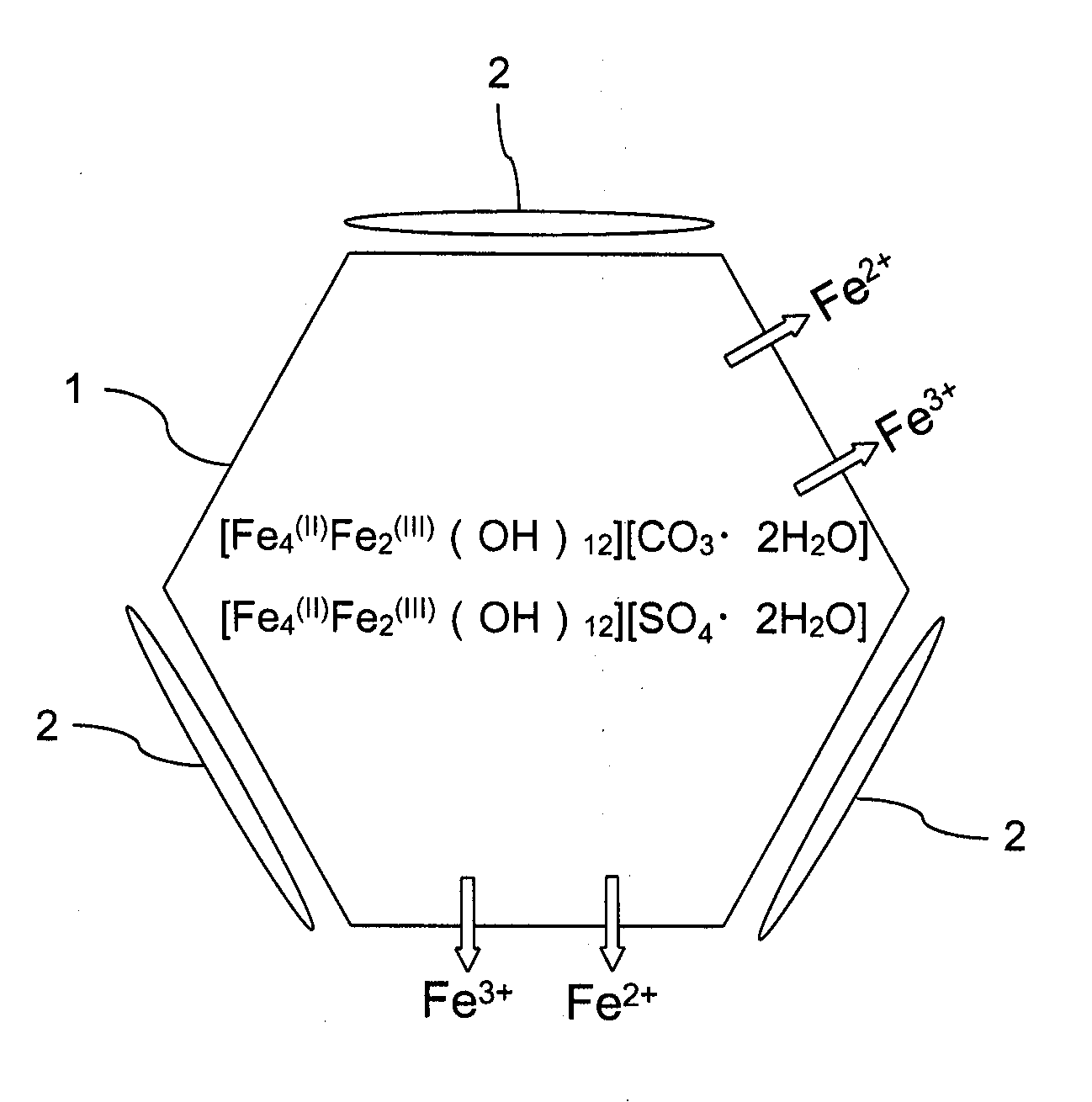

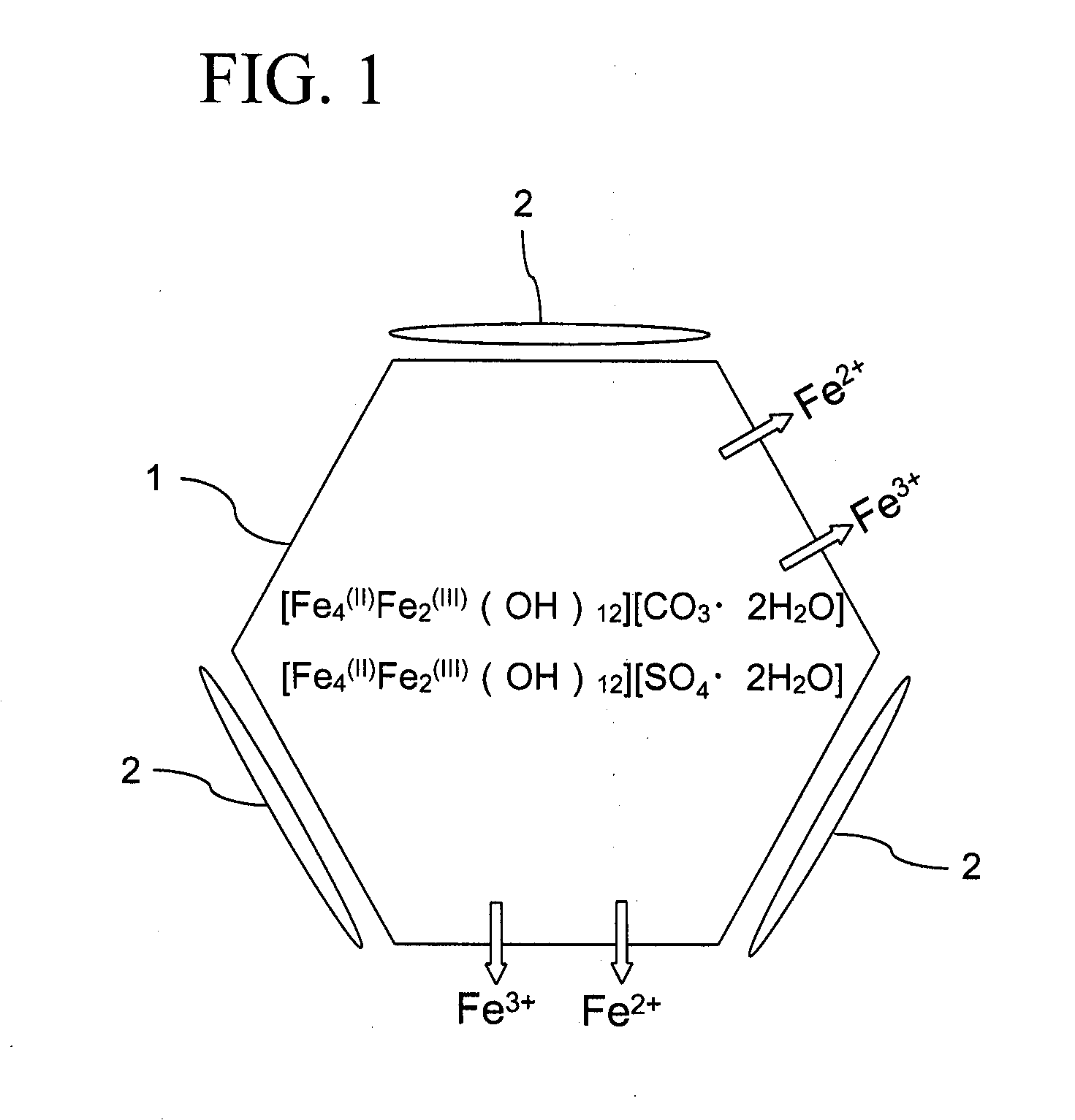

Method for producing iron oxyhydroxide particle

InactiveUS20080241055A1Yield can be ensuredReduce mixMaterial nanotechnologyNitrogen compoundsFerrous saltsIron oxyhydroxide

First, a ferrous iron-containing suspension solution is obtained by mixing an aqueous ferrous salt solution and an aqueous alkali solution containing one or two of an alkali carbonate and an alkali hydroxide. Then, an iron oxyhydroxide particle precursor is obtained by blowing an oxygen-containing gas having an oxygen component proportion of 0.5 to 0.8 into the suspension solution thus obtained to oxidize the ferrous iron in the suspension solution at an oxidation rate of 30 to 65% while the suspension solution is being controlled to fall in a temperature range of −5° C. or higher and lower than 10° C. Thereafter, the iron oxyhydroxide particles 2 are produced from the iron oxyhydroxide particle precursor by blowing an oxygen-containing gas into the suspension solution containing the iron oxyhydroxide particle precursor while the suspension solution is being controlled to fall in a temperature range of 20° C. or higher and lower than 45° C.

Owner:TDK CORPARATION

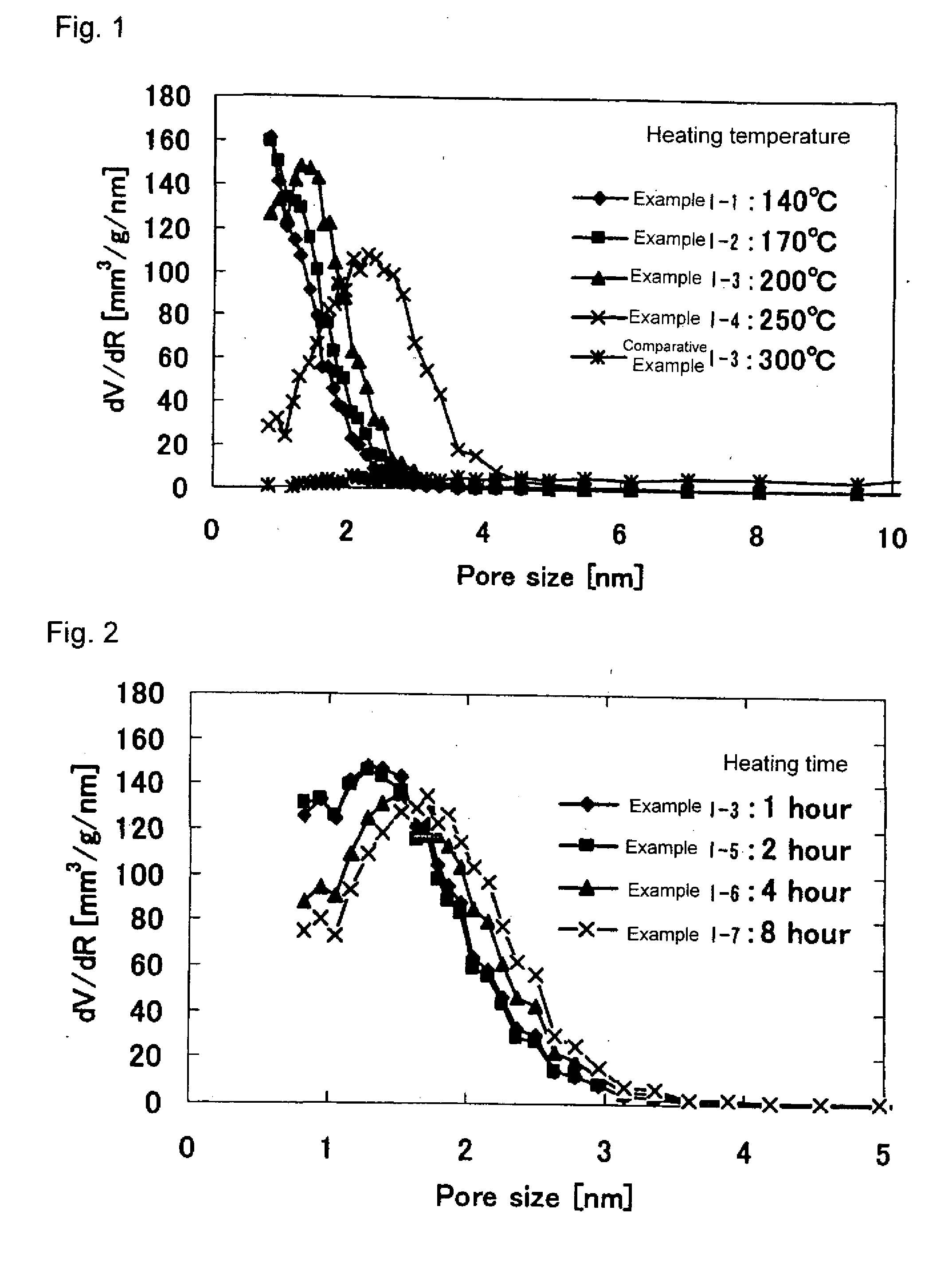

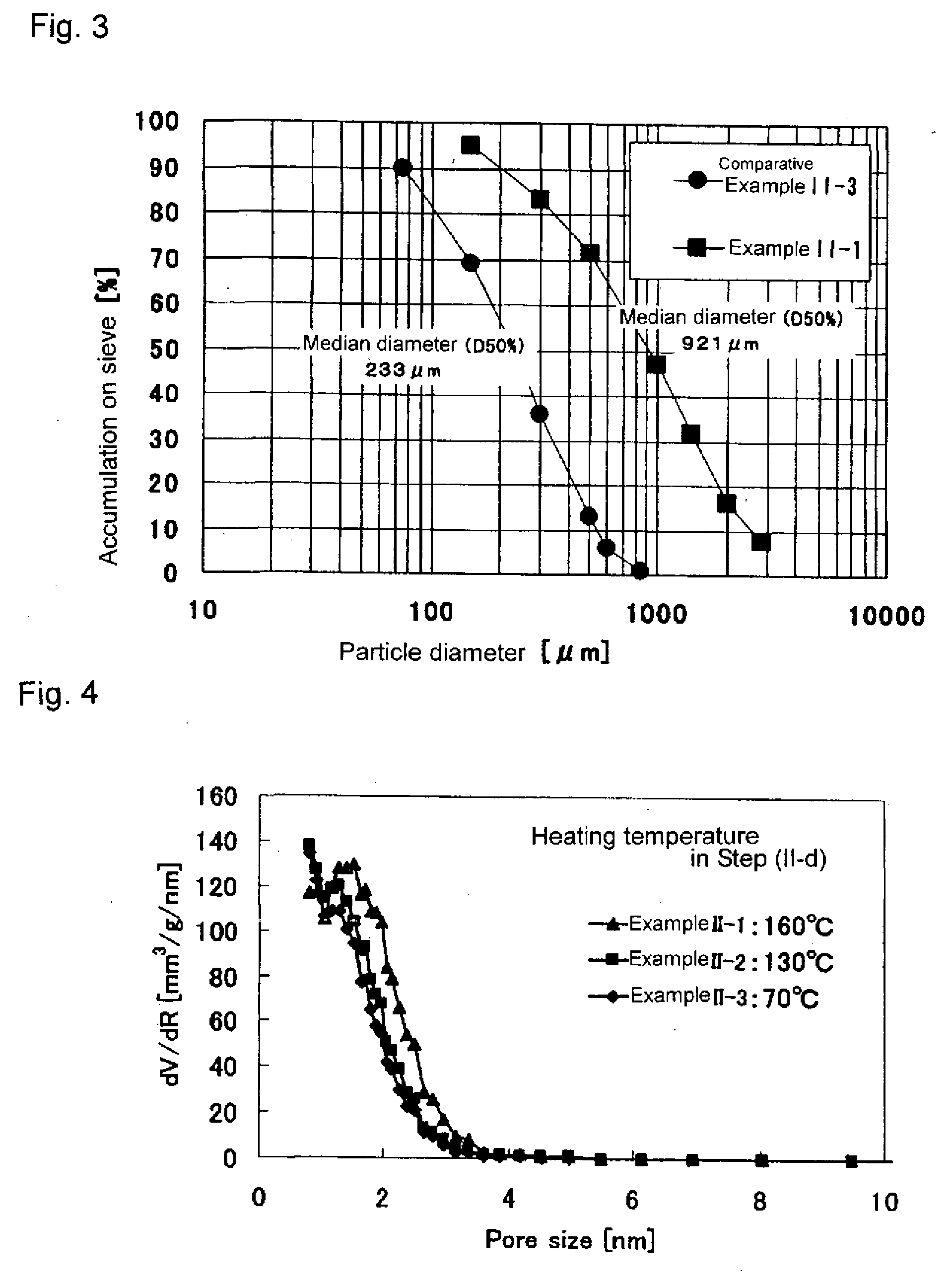

Method for producing iron oxyhydroxide and adsorbing material comprising iron oxyhydroxide

InactiveUS20090028770A1Improve adsorption capacityEfficient productionPhosphorus oxidesNitrogen compoundsIndustrial effluentHazardous substance

The present invention provides a method for advantageously producing an iron oxyhydroxide exhibiting excellent capability of adsorbing harmful substances, such as a phosphrous components and endocrine disrupting chemicals, which are contained in industrial wastewater, exhaust gases, etc., and an adsorbent material comprising the iron oxyhydroxide produced by the method as a main component. Specifically, the present invention provides an adsorbent material produced by a method comprising the steps of:(a) adding a base to an aqueous iron ion-containing solution, adjusting the pH of the resultant mixture to 9 or less, to form a precipitate that contains an iron oxyhydroxide;(b) drying the precipitate at a temperature of 100° C. or lower to obtain an iron oxyhydroxide;(c) contacting the resultant iron oxyhydroxide with water; and(d) subjecting the resultant iron oxyhydroxide to a heat treatment under a gas atmosphere having an inert gas concentration of 80% or greater at a temperature of 100 to 280° C.

Owner:JAPAN SCI & TECH CORP +2

Iron oxyhydroxide modified active carbon desulfurizer as well as preparation method thereof

InactiveCN103521195AEasy to handleEfficient desulfurizationOther chemical processesActivated carbonLignin sulfate

The invention relates to an iron oxyhydroxide modified active carbon desulfurizer which is prepared from the following raw materials in parts by weight: 120-130 parts of active carbon, 12-14 parts of iron oxyhydroxide, 4-5 parts of lignin sulfate, 4-5 parts of polyvinyl alcohol, 8-10 parts of modified attapulgite and an appropriate amount of water. According to the iron oxyhydroxide modified active carbon desulfurizer disclosed by the invention, the iron oxyhydroxide is used to efficiently desulfurate and dechlorinate, and the desulfuration effect is long in lasting time. The lignin sulfate is further used, so that raw materials such as active carbon can be uniformly dispersed in water. Therefore, the desulfurizer has a better water treatment effect, free from toxic substances and low in production cost, and can be repeatedly and recycled, thereby not only saving the industrial cost, but also laying a foundation for industrial application.

Owner:BENGBU PIONEER FILTER

Contact and adsorbent granules

InactiveUS20080271600A1Material nanotechnologySolid sorbent liquid separationSorbentIron oxyhydroxide

The present invention relates to pellets or granules based on iron oxides and / or iron oxyhydroxides and iron(III) hydroxide, a unit suitable for the through-flow of a fluid medium at least partially filled with an adsorbent / catalyst in pellet form consisting essentially of iron oxide and / or iron oxyhydroxide embedded in an iron hydroxide matrix, processes for their production comprising filtering, drying and shaping steps and their processes of their use.

Owner:LANXESS DEUTDCHLAND GMBH

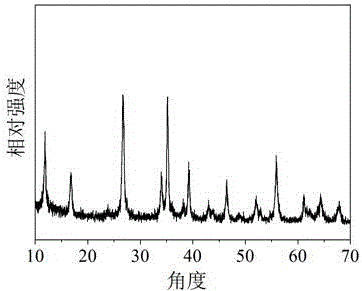

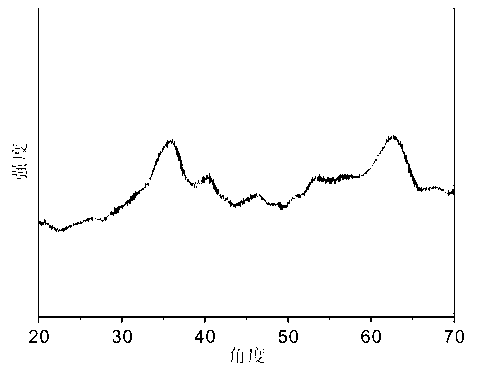

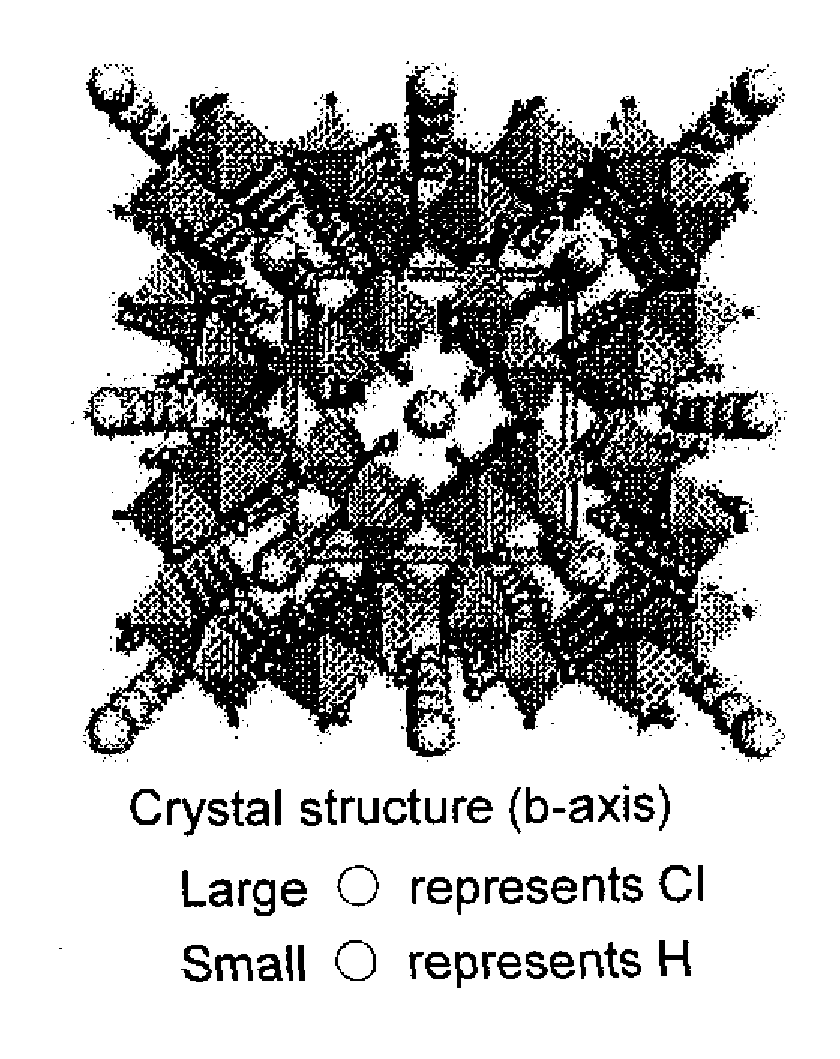

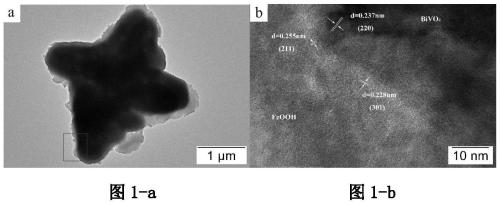

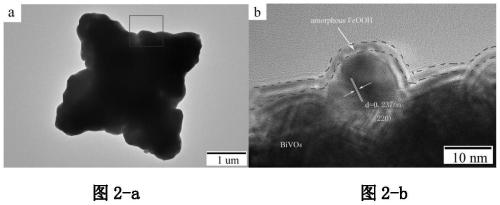

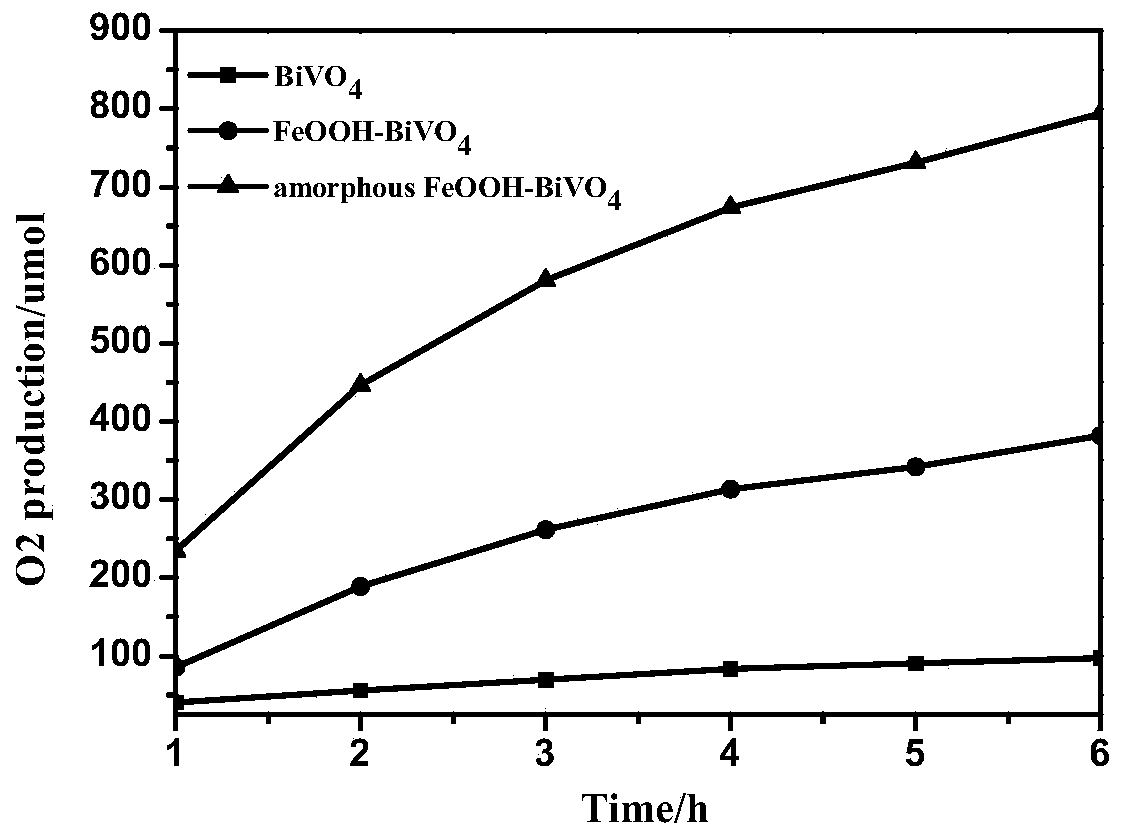

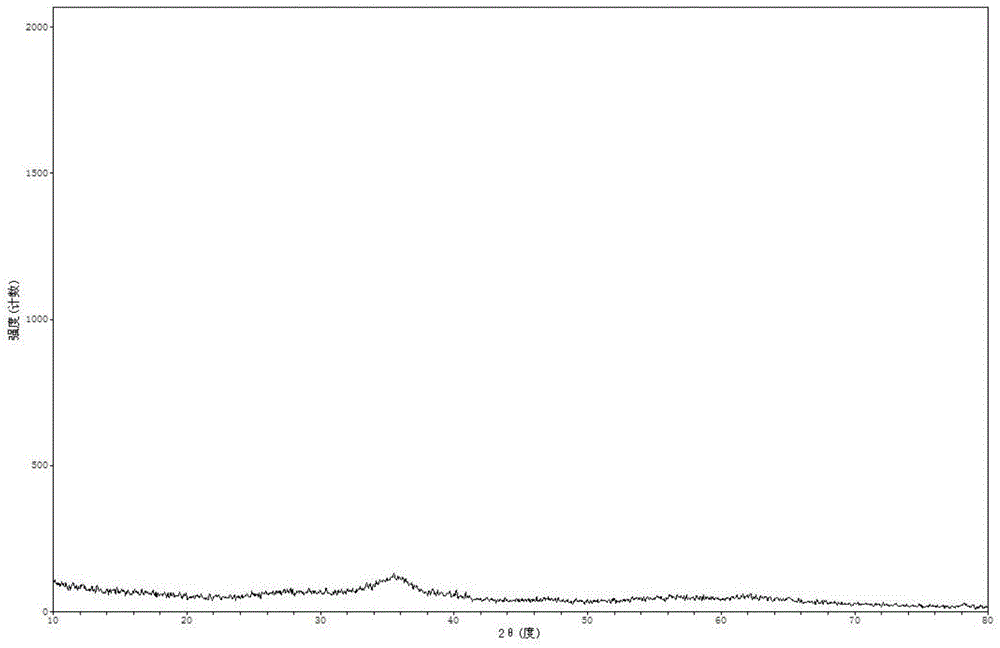

Preparation method of amorphous iron oxyhydroxide/bismuth vanadate composite photocatalytic material

ActiveCN109772355ANarrow band gapEasy transferCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIron(III) chlorideBismuth vanadate

The invention belongs to the field of photocatalyst preparation and particularly relates to a preparation method of an amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material. The preparation method of the amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material comprises the following process steps of synthesizing bismuth vanadate through a hydrothermal method, adopting synthesized bismuth vanadate as a substrate, putting the bismuth vanadate into a mixed solution of ferric chloride and ammonium bicarbonate for stirring, and drying the mixture after centrifuging to obtain a finished product, namely the amorphous iron oxyhydroxide / bismuth vanadate composite photocatalytic material. According to the preparation method, an amorphous material is used as a cocatalyst, and due to the special structure of the amorphous material, the amorphous material lacks ordered atomic arrangement and thus has narrower forbidden bands. These characteristics lead to more defects on the surface of a catalyst, more active sites are provided, the light absorption range is enlarged, and the photocatalytic performance is further improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Amorphous FeOOH and method for regenerating desulfurizing agent taking amorphous FeOOH as active ingredient

ActiveCN101767776ARealize separation and purificationReduce pollutionSulfur preparation/purificationCombustible gas purificationIron sulfideSlurry

The invention relates to a method for regenerating a desulfurizing agent taking amorphous FeOOH as an active ingredient, which comprises the following steps: grinding the waste agent after the amorphous FeOOH is used as the desulfurizing agent into granules to obtain waste agent powder; preparing the waste agent powder into suspension, introducing oxygen-containing gas into the suspension for oxidation, making iron sulfide in the suspension converted into the amorphous FeOOH and elemental sulfur so as to form slurry containing the amorphous FeOOH and simple substance sulfur; and putting the slurry in a container, introducing air into the container to make the elemental sulfur floating upwards, wherein the sediment on the lower part of the container is the regenerated amorphous FeOOH. The regeneration method solves the problems that a large amount of waste agents can only be buried, not only effective resources in the original desulfurizing agent are wasted, but also the environment is seriously polluted because the other desulfurizing agents used in the prior art cannot be regenerated after being used once or the regeneration cost is high.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Ferromagnetic particles and process for producing the same, anisotropic magnet and bonded magnet

InactiveUS20120244356A1Sufficient magnetic propertyMaterial nanotechnologyPretreated surfacesIron oxyhydroxideIron oxide

The present invention relates to Fe16N2 particles in the form of a single phase which are obtained by subjecting iron oxide or iron oxyhydroxide whose surface may be coated with at least alumina or silica, if required, as a starting material, to reducing treatment and nitridation treatment, a process for producing the Fe16N2 particles in the form of a single phase for a heat treatment time of not more than 36 hr, and further relates to an anisotropic magnet or a bonded magnet which is obtained by magnetically orienting the Fe16N2 particles in the form of a single phase. The Fe16N2 particles according to the present invention can be produced in an industrial scale and have a large BHmax value.

Owner:TODA IND +1

Compound type desulfurization grout and preparation method thereof

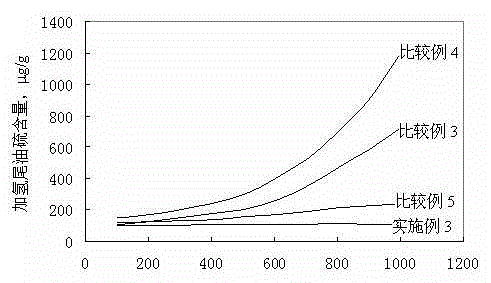

ActiveCN103752163AHigh sulfur capacityImprove desulfurization efficiencyDispersed particle separationSulfurFerric oxyhydroxide

The invention relates to compound type desulfurization grout. According to the compound type desulfurization grout, ferric oxyhydroxide is added into a complex iron desulfurization solution, so that the desulfurization is carried out by virtue of a synergistic effect of the ferric oxyhydroxide and the complex iron desulfurization solution; compared with the prior art, the problem that the desulfurization cost is relatively high because the large amount of complexing solution is circularly used when a ferric complex singly taken as a desulfurization agent with the relatively low saturated sulfur capacity is used for removing H2S by virtue of a wet method is solved; the complex iron desulfurization solution is effectively mixed with the ferric oxyhydroxide, so that the characteristics of high desulfurization speed and desulfurization efficiency of the complex iron desulfurization solution are combined with the high-sulfur-capacity characteristic of the ferric oxyhydroxide, so that the relatively high desulphurization efficiency and the relatively high sulfur capacity are maintained, and the high-speed, high-efficiency and high-precision desulphurization is realized.

Owner:福建三聚福大化肥催化剂国家工程研究中心有限公司 +1

Preparation method for amorphous FeOOH water-purifying agent

InactiveCN105800762AHigh arsenic removal efficiencyEfficient removalWater/sewage treatmentAluminum IonHydrolysis

The invention provides a preparation method for an amorphous FeOOH water-purifying agent. The preparation method comprises the following steps: preparing a ferrous sulfate solution from industrial ferrous sulfate heptahydrate; adding a proper amount of sulfuric acid into the ferrous sulfate solution so as to provide an acidic environment; adding hydrogen peroxide into the solution and allowing ferrous sulfate to be oxidized into ferric sulfate under the condition of hydrolysis promotion by sulfuric acid; subjecting an industrial alkali source and the ferric sulfate solution to a precipitation reaction so as to produce iron hydroxide colloid; and dehydrating the iron hydroxide colloid under proper conditions so as to prepare the amorphous FeOOH water-purifying agent. The amorphous FeOOH water-purifying agent can effectively arsenic in water, has arsenic removal efficiency of 98% or above, does not contain aluminum ions or pose secondary pollution to a water body; after arsenic removal with the water-purifying agent, scorodite stably existing in the nature is produced, so pollution is not posed to the environment; moreover, raw materials used in the invention are of an industrial grade, and the preparation method is low in production cost and simple to operate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Conditioning of ion exchangers for adsorption of oxoanions

The present invention relates to the use of inorganic salts for increasing the adsorption of oxoanions and / or thioanalogues thereof to metal-doped ion exchangers, preferably to iron oxide / iron oxyhydroxide-containing ion exchangers, preferably from water or aqueous solutions, and also the conditioning of these metal-doped ion exchangers having increased adsorption behaviour toward oxoanions and / or thioanalogues thereof by using inorganic salts with the exception of amphoteric ion exchangers which have both acidic and basic groups as functional groups.

Owner:LANXESS DEUTDCHLAND GMBH

Amphoteric ion exchangers for the adsorption of oxo anions

InactiveUS20070241056A1Simple preparation processImproved arsenic adsorptionIon-exchanger regenerationSpecific water treatment objectivesIon exchangeIron oxyhydroxide

The present invention relates to the use of amphoteric ion exchangers for adsorbing oxo anions, preferably to the use of iron oxide / iron oxyhydroxide-containing amphoteric ion exchangers for removing oxo anions from water and aqueous solutions, and to the preparation of these amphoteric iron oxide / iron oxyhydroxide-containing ion exchangers.

Owner:LANXESS DEUTDCHLAND GMBH

Meerschaum-hydroxyl oxidize iron-active carbon composite adsorbent preparation method and application thereof

ActiveCN107262037AMeet the requirements of industrial developmentEasy to operateOther chemical processesSpecific water treatment objectivesFiberSorbent

The invention discloses a meerschaum-hydroxyl oxidize iron-active carbon composite adsorbent preparation method and an application thereof. According to the invention, meerschaum, sodium alginate and water are taken as raw materials, the raw materials are subjected to a hydro-thermal carbonization reaction to prepare a meerschaum gel fibrous raw material; powder particles, meerschaum gel fiber and the ferrous sulphate mixed liquor are subjected to hot melting and a charing reaction to obtain a meerschaum-hydroxyl oxidize iron-active carbon composite adsorbent, the meerschaum-hydroxyl oxidize iron-active carbon composite adsorbent is used for processing Sb(V) and As(III) ions in water environment, and the good experiment result is achieved. The adsorbent prepared by the invention has the advantages of high adsorption capacity, renewable utilization, and wide application scope, and can be widely used for processing the composite heavy metal waste water containing antimony and arsenic.

Owner:HUNAN UNIV OF SCI & TECH

Pharmaceutical compositions

ActiveUS20100247609A1Disintegrates quicklyIncrease loadPowder deliveryHeavy metal active ingredientsOral medicationBuccal administration

Pharmaceutical compositions for oral administration, in particular administration as an oral delivery system to be swallowed directly or capable of disintegration in the oral cavity, comprising iron oxy-hydroxide in high loading.

Owner:VIFOR FRESENIUS MEDICAL CARE RENAL PHARMA LTD

Preparation method for doped iron oxide nanorod catalyst

InactiveCN105498773AImprove stabilityEasy to operateMetal/metal-oxides/metal-hydroxide catalystsElectrochemistryIron oxyhydroxide

The invention especially relates to a preparation method for a metallic element-doped iron oxide nanorod catalyst with photoelectrocatalytic performance, which belongs to the technical field of catalysis. The preparation method comprises the following steps: preparing iron oxyhydroxide with a nanorod structure by using a solution thermosynthesis method; and calcining a sample in a certain atmosphere so as to obtain a metallic element-doped iron oxide nanorod with a same structure. An iron oxide doped nanostructure prepared by using a hydrothermal method has uniform morphology, shows absorption characteristics in a visible light zone and catalyzes photoelectrocatalysis of water under radiation of UV visible light. The solution thermosynthesis method enables the doping degree, morphology and size of a prepared sample to be controllable. The method is simple and easily practicable; and the prepared metallic element-doped iron oxide nanorod catalyst has good application potential in fields like photoelectrocatalysis and electrochemical catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Iron phosphide film hydrogen evolution catalyst and preparation method thereof

InactiveCN107999101ALow costThe preparation of raw materials is safe and environmentally friendlyCatalyst activation/preparationIron saltsIron oxyhydroxide

The invention provides a preparation method of an iron phosphide film hydrogen evolution catalyst and belongs to the field of catalysis. The preparation method comprises a step of preparing an iron oxyhydroxide precursor, namely weighing an iron salt, dissolving the iron salt into a glycerin / water mixed solution, then, mixing the iron salt with the glycerin / water mixed solution, transferring the mixture into a reactor, raising the temperature to 100-140 DEG C to carry out a reaction, cleaning the product by using water and ethanol, and drying the product to obtain a film-like iron oxyhydroxideprecursor. The preparation method further comprises a step of preparing an iron phosphide film, namely placing the film-like iron oxyhydroxide precursor at the downstream of a tube furnace, placing sodium dihydrogen phosphate at the upstream of the tube furnace, and carrying out temperature-controlled phosphorization in an inert atmosphere to obtain an iron phosphide film catalyst. The preparation method has the characteristics of controllable synthesis of the film-like iron oxyhydroxide precursor and low-temperature controllable shape-preserving phosphorization and has the advantages such assafe and environment-friendly preparation raw materials, low price, simple preparation process and easiness in operation. The catalyst shows efficient hydrogen evolution activity and circulation stability in acidic, alkaline and neutral water solutions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Iron-based oxide magnetic particle powder and method for producing iron-based oxide magnetic particle powder

ActiveUS20170287516A1Enhancing magnetic recording characteristicNarrow coercive force distributionMaterial nanotechnologyNanomagnetismCarboxylic acidMicroparticle

An e-type iron-based oxide magnetic particle powder has narrow particle size distribution and has a low content of fine particles which do not contribute to magnetic recording characteristics. As a result, a narrow coercive force distribution is achieved and the powder is suitable for increasing recording density of a magnetic recording medium. The powder containing substituting metal elements can be obtained by: adding an alkali to an aqueous solution containing trivalent iron ions and ions of the metals for partially substituting Fe sites to neutralize the aqueous solution to a pH of 1.5 to 2.5; then adding a hydroxycarboxylic acid; further adding the alkali to neutralize the aqueous solution to a pH of 8.0 to 9.0; washing with water a precipitation of an iron oxyhydroxide containing the substituting metal elements produced; and coating the iron oxyhydroxide containing the substituting metal elements with a silicon oxide and heating the resultant.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

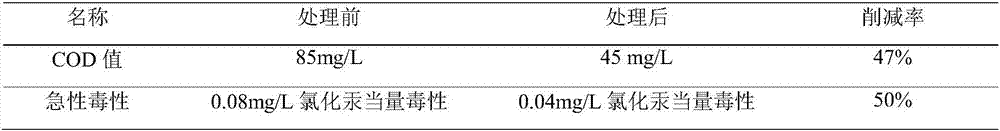

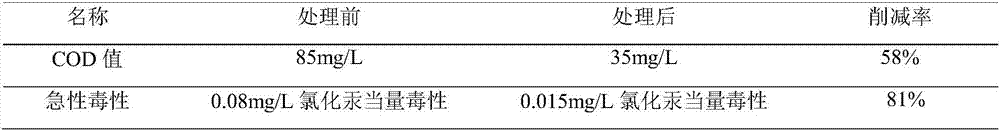

Method for removing toxicity of tail water of fine chemical biochemical treatment

InactiveCN107459170AImprove water quality indicatorsStrong targetingWater treatment parameter controlWater contaminantsAbsorption filterWater quality

The invention discloses a method for removing the toxicity of tail water of fine chemical biochemical treatment, belonging to the field of sewage treatment methods. The method comprises the following treatment steps: (a) carrying out catalytic ozonation, specifically, treating sewage in a catalytic ozonation tower which is internally filled with an iron-aluminum catalyst, wherein the iron-aluminum catalyst is prepared from the following effective components: beta-iron oxyhydroxide and aluminum oxide; (b) absorbing, specifically, carrying out further treatment on wastewater, subjected to treatment in the step (a), by using an absorption filter filled with ceramsites and magnetic resin, wherein the mass ratio of the beta-iron oxyhydroxide to the aluminum oxide in the iron-aluminum catalyst is equal to (15-20) to (80-85), and the volume ratio of the ceramsites to the magnetic resin is equal to (2-3) to (3-5). The method provided by the invention is simple to operate and low in cost, and not only can realize the non-toxic emission of the tail water, but also can improve the comprehensive index of water quality.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com