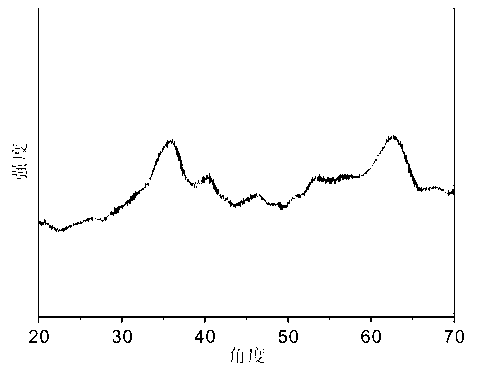

Preparation method of iron oxyhydroxide/graphene oxide composite material

An iron oxyhydroxide and composite material technology, applied in the directions of iron oxide/iron hydroxide, iron oxide, graphene, etc., can solve problems such as affecting the excellent properties of nanomaterials, and achieve low production cost, simple operation process, and low equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

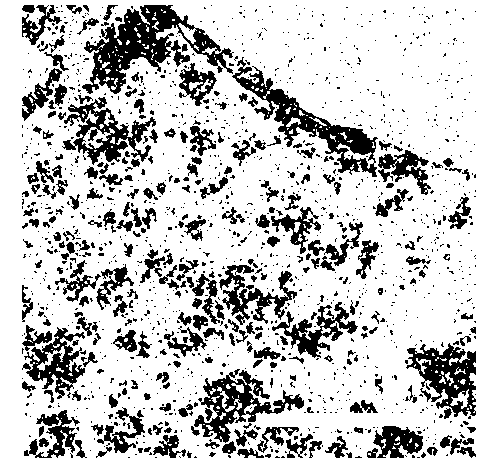

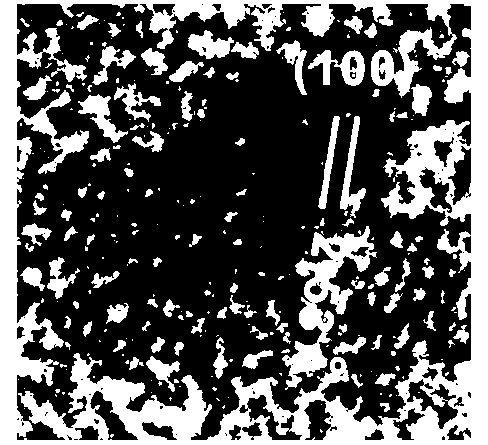

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of iron oxyhydroxide / graphene oxide composite material, comprising the following steps:

[0035] (1) Add 1g of graphite powder with flake structure and 1g of sodium nitrate into 80g of concentrated sulfuric acid with a mass fraction of 98%, and stir for 0.5h at 5°C;

[0036] (2) Add 8g of potassium permanganate to the solution, heat up to 35°C and stir for 2h;

[0037] (3) Slowly add 80ml of deionized water to the solution, heat up to 90°C and stir for 1 hour;

[0038] (4) Add 200ml deionized water again, and add 30% hydrogen peroxide dropwise until the color of the solution changes from dark brown to bright yellow;

[0039] (5) The product was washed three times with hydrochloric acid and deionized water with a mass fraction of 5%, and vacuum-dried after centrifugation to obtain graphene oxide powder;

[0040] (6) Prepare a graphene oxide aqueous solution with a concentration of 1 g / L;

[0041] (7) Add 100ml of saturated ferrous chloride aqueous...

Embodiment 2

[0047] A preparation method of iron oxyhydroxide / graphene oxide composite material, comprising the following steps:

[0048] (1) Add 1g of graphite powder with flake structure and 0.5g of sodium nitrate to 75g of concentrated sulfuric acid with a mass fraction of 98%, and stir at 1°C for 1h;

[0049] (2) Add 5g of potassium permanganate to the solution, heat up to 35°C and stir for 3h;

[0050] (3) Slowly add 90ml of deionized water to the solution, raise the temperature to 90°C and stir for 1 hour;

[0051] (4) Add 210ml of deionized water again, and add 30% hydrogen peroxide dropwise until the color of the solution changes from dark brown to bright yellow;

[0052] (5) The product was washed three times with hydrochloric acid and deionized water with a mass fraction of 5%, and vacuum-dried after centrifugation to obtain graphene oxide powder;

[0053] (6) Prepare a graphene oxide aqueous solution with a concentration of 0.1 g / L;

[0054] (7) Add 100ml of saturated ferrous...

Embodiment 3

[0059] A preparation method of iron oxyhydroxide / graphene oxide composite material, comprising the following steps:

[0060] (1) Add 1g of graphite powder with flake structure and 2g of sodium nitrate into 100g of concentrated sulfuric acid with a mass fraction of 98%, and stir at 4°C for 0.5h;

[0061] (2) Add 10g of potassium permanganate to the solution, heat up to 35°C and stir for 1.5h;

[0062] (3) Slowly add 75ml of deionized water to the solution, raise the temperature to 90°C and stir for 2 hours;

[0063] (4) Add 200ml deionized water again, and add 30% hydrogen peroxide dropwise until the color of the solution changes from dark brown to bright yellow;

[0064] (5) The product was washed three times with hydrochloric acid and deionized water with a mass fraction of 5%, and vacuum-dried after centrifugation to obtain graphene oxide powder;

[0065] (6) Prepare a graphene oxide aqueous solution with a concentration of 0.3g / L;

[0066] (7) Add 100ml of saturated ferric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com